Page 1

Specifications:

13

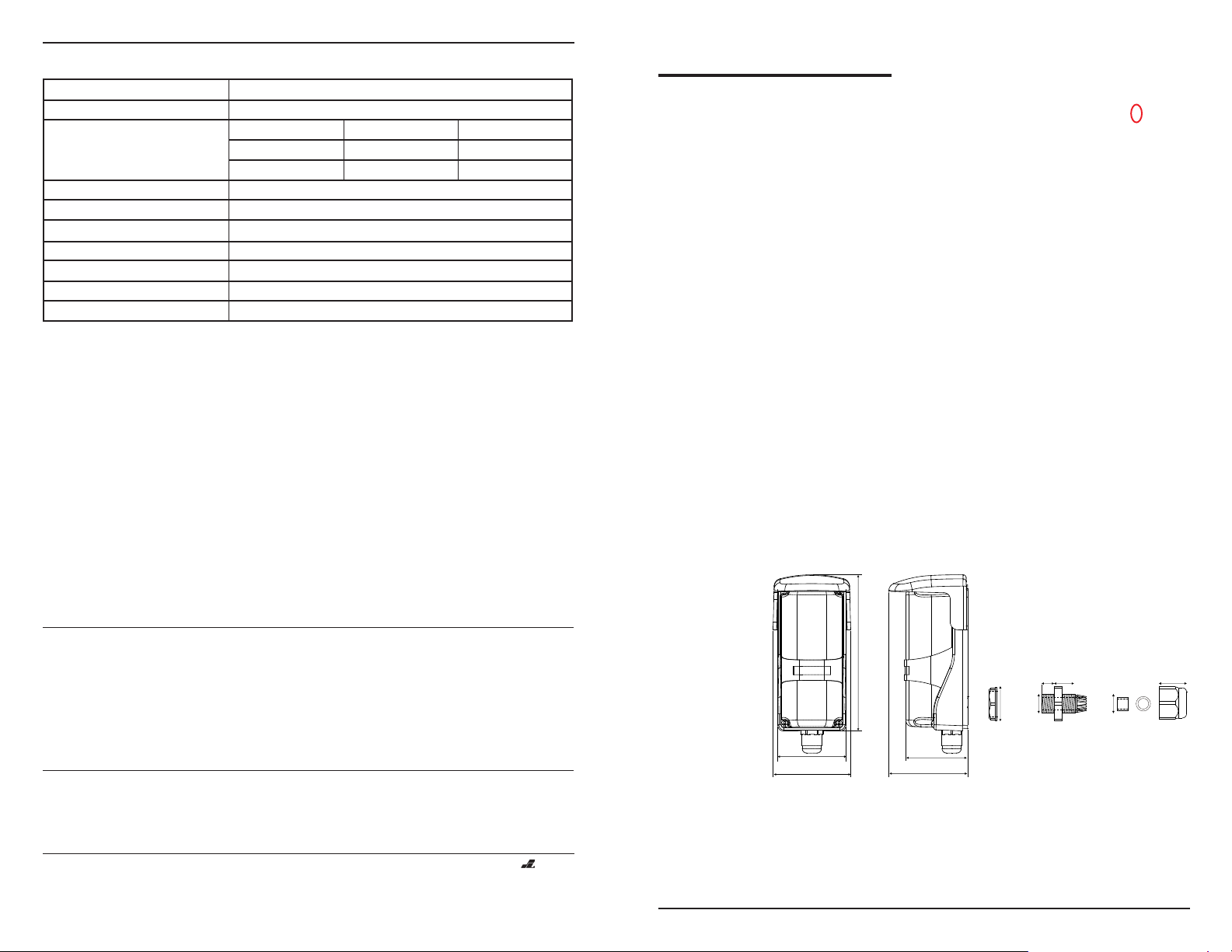

4/" (122mm)

16

3

2 /" (53mm)

32

13

2/" (61mm)

32

7

2 /" (62mm)

16

15

2/" (49mm)

16

5/8(16mm)

5/16”

(8mm)

9/16”

(14mm)

5/16”

(8mm)

1/4”

(6mm)

17/32”

(13 4mm)

Sensing range

Voltage supply

Current drain (max.)

12 VDC

24 VDC

Response time

Tx LED element

LEDs

Trigger output

SPDT relay output, 1 A @ 125 VAC, 2 A @ 30 VDC

Tamper switch

Enclosure

Ambient temperature

Also available from SECO-LARM:

Quad and Twin

Photobeam Detectors

Up to 660' (200 m)

Flush-Mount

Photobeam Sensors

Up to 33' (10 m)

E-932-D33TBQ

0.5' to 33' (0.1 - 10 m)

12~250 VAC/DC

Stand by

20 mA

10 mA

Active

40 mA

20 mA

10 ms (max.)

Infrared - 740 nm

Green LED (Alignment), Red LED (trigger)

N.C., 500 mA @ 30 VAC

IP 66 weatherproof

-40~1310 F (-200~550 C)

Entry Alert System

Photobeam Sensors

Up to 22' (7 m)

ENFORCER

Sensor

Polarized Retro-Reflective

Photoelectric Sensor

E-931-S33PRQ

Range: 33 ft. (10 m)

INSTALLATION MANUAL

Features:

•

• Polarized sensor is immune to shiny

objects: Triggers only when correctly

reflected light is detected.

• Weatherproof (IP 66) design with

cable gasket for indoor/outdoor use.

• Anti-condensation case.

•

• Dark ON operation.

• Round reflector, Dia.: 80 mm.

• Input volt.: 12-250 VDC/VAC.

• Form "C" relay, 2A @ 30 VDC.

• LED alignment system.

• Tamper switch: N.C. 500 mA @ 30 VDC.

Typical Applications:

• Safety sensor for garage doors,

outdoor gates, or sliding doors.

• Overhead door security sensor.

• Industrial automation

Detect small objects on a

manufacturing line.

• Assist in measuring parking distance.

• Alarm sensor for windows, terraces,

parking lot, etc.

ЮЮЮЮЮЮ

ЮЮЮЮЮЮ

Includes:

• Reflector

• Sensor

• Sensor mounting plate

•

--

• Weather-resistant gasket

•

• Sensor hood

•

E-931CS22RRCQ

E-964-Q660Q

(Shown)

WARRANTY

service for a period of one (1) year from the date of sale to the original consumer customer. SECO-LARM’s obligation is

limited to the repair or replacement of any defective part if the unit is returned, transportation prepaid, to SECO-LARM.

This Warranty is void if damage is caused by or attributed to acts of God, physical or electrical misuse or abuse, neglect,

repair, or alteration, improper or abnormal usage, or faulty installation, or if for any other reason SECO-LARM determines

that such equipment is not operating properly as a result of causes other than defects in material and workmanship.

The sole obligation of SECO-LARM, and the purchaser’s exclusive remedy, shall be limited to replacement or repair only, at

SECO-LARM’s option. In no event shall SECO-LARM be liable for any special, collateral, incidental, or consequential

personal or property damages of any kind to the purchaser or anyone else.

NOTICE:

SECO-LARM policy is one of continual development and improvement. For this reason, SECO-LARM reserves the right

to change specifications without notice. SECO-LARM is also not responsible for misprints or typographical errors.

Copyright © 2010 SECO-LARM U.S.A., Inc. All rights reserved. This material may not be reproduced or copied, in whole

or in part, without the written permission of SECO-LARM.

SECO-LARM® U.S.A., Inc.

16842 Millikan Avenue, Irvine, CA 92606

Tel: 800-662-0800 / 949-261-2999 Fax: 949-261-7326

This SECO-LARM product is warranted against defects in material and workmanship while used in normal

The information and specifications printed in this manual are current at the time of publication. However, the

E-932-S16RRQ

Website: www.seco-larm.com

E-mail: info@seco-larm.com

MiE931-S33PROQ_1012.PMD

®

PITSW3

Dimensions:

Caution:

• This sensor was not designed to prevent bodily injury

or loss of life.

• This sensor was not designed for use in

environments where there is the possibility of

explosive gasses present.

• Use of this sensor in certain security applications

may be regulated by local laws or codes.

SECO-LARM is not responsible for compliance with

such laws or codes.

Page 2

1

2

3

4

5

6

7

AC/D

2~ 50

NC O COM T1 T 2

(N n poai y)

1

2

3

4

5

6

7

AC/DC

1

2~250V

NC NO COM TP1 TP2

(Non polarity)

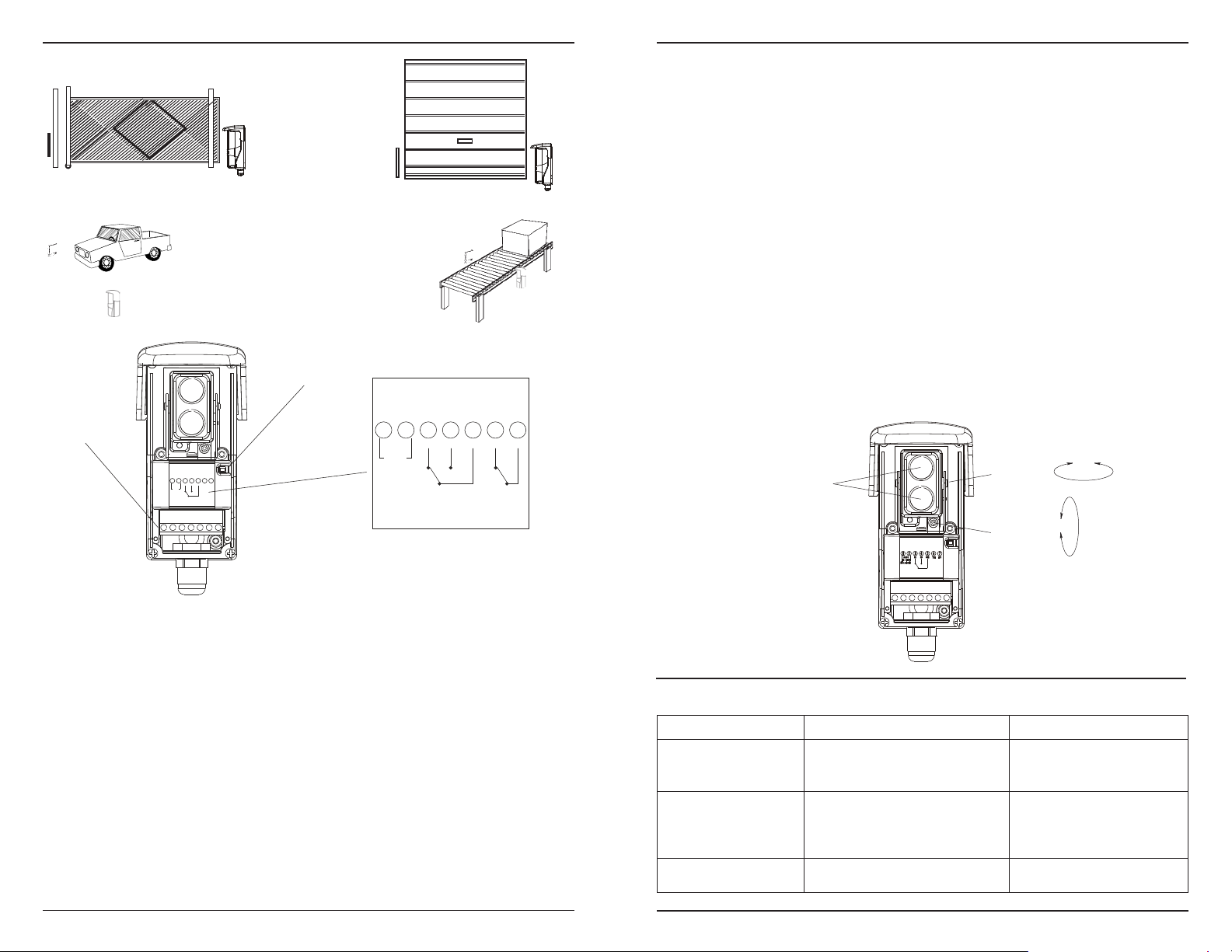

Sample Installations:

Gate

ЮЮЮЮЮЮЮЮЮЮЮ

Vehicle detection

ЮЮЮЮЮЮ

ЮЮЮЮЮЮ

Wiring:

Removeable

Terminal

Blocks

ЮЮЮЮЮЮЮЮЮЮЮ

N.C.

Tamper

Switch

Garage

door

ЮЮЮЮЮЮЮЮЮ

Factory assembly line

ЮЮЮЮЮЮ

ЮЮЮЮЮЮ

Installation and Adjustment:

Dual-Color LED Functions:

• Red LED - - When ON, it indicates the sensor is

ЮЮЮЮЮЮЮЮЮ

• Green LED - - When ON, it indicates that the sensor is

• LED alternately flashes red and green - - Sensor beam

Installation:

1. Mount the reflector and the sensor so they face each

2. Connect power to the sensor. Typically the red LED

3. To find the correct alignment, slowly turn the lens

triggered.

properly aligned with the reflector, and the sensor is

not triggered.

signal is weak (not triggered).

other.

will turn ON indicating that the sensor and reflector

are not yet properly aligned. If the Green LED is ON

(red LED OFF), it indicates that the sensor and

reflector are aligned (although it still may be

necessary to slightly adjust the alignment).

Lens

Assembly

assembly left and right, and use the vertical

adjustment screw to tilt the sensor up and down.

NOTE 1: Correct alignment is reached when the red

LED turns OFF and the Green LED turns ON.

NOTE 2: If the LED alternately flashes green and

red, the sensor is at the edge of sensing the signal,

and may not work properly.

4. Put the object to be detected between the sensor

and reflector (in about the place where the object

would normally be detected by the sensor). The

green LED should turn OFF and the red LED will turn

ON).

Testing:

1. Power up the sensor. The green LED should be ON;

the red LED should be OFF.

2. Pass the object to be detected between the sensor

and reflector. The red LED should turn ON and the

green LED

should turn OFF. This indicates that the object

has been detected.

Horizontal

±90°

Adjustment

Mounting the Sensor:

Additional function:

TP1/TP2 - Tamper Switch:

N.C. 500 mA @ 30 VDC

1. Unscrew the 4 screws and remove the cover.

2. Loosen the captive screw to free the sensor from

the mounting plate.

3. Using the included screws, mount the mounting

plate to the wall.

4. If the wires come from inside the wall, use the

breakout and rubber gasket on the back of the

sensor to run the wires. If not, use the breakout

and cable gland at the bottom of the sensor to run

the wires.

5. Remove the terminal block using long-nose pliers

and wire the unit according to the wiring diagram

above.

6. Hang the sensor back on to the plate, and use the

captive screw to secure it in place.

7. Re-attach the cover, and use the included small

screws to secure it.

8. Attach the hood to the top of the sensor.

2

Troubleshooting:

Trouble Remedy(s)Possible Origin(s)

Sensor does not detect the

object.

Green LED does not

turn on.

Red LED lights when object

is detected, but no output.

1) Sensor sensitivity is not properly set.

2) Object may have a reflective surface

which confuses sensor.

1) Dirty sensor and/or reflector.

2) Reflector and/or sensor is

misaligned.

No continuity between sensor and

alarm device.

Vertical

Adjustment

±5°

Change the angle of the sensor or

readjust the sensitivity setting.

1) Clean the sensor and reflector

with a damp (not wet) cloth.

2) Adjust the reflector and/or

sensor for proper alignment.

Check cable from sensor to alarm

device. Test sensor.

3

Loading...

Loading...