Page 1

Mess- und Ortungstechnik

Measuring and Locating Technologies

Leitungsortung

Line Locating

Rohrleitungsnetze

Water Networks

Kommunikationsnetze

Communication Networks

Elektrizitätsnetze

Power Networks

Issue: 1 (09/2008)

5 V

Alarm IN

Operating Instructions

Data Logger

Sebalog D

Page 2

Page 3

1-3

Consultation with SebaKMT

The present system manual has been designed as an operating guide and for reference. It is meant to answer your

questions and solve your problems in as fast and easy a way as possible. Please start with referring to this manual

should any trouble occur.

In doing so, make use of the table of contents and read the relevant paragraph with great attention. Furthermore,

check all terminals and connections of the instruments involved.

Should any question remain unanswered, please contact:

Seba Dynatronic

Mess- und Ortungstechnik GmbH

Hagenuk KMT

Kabelmesstechnik GmbH

Dr.-Herbert-Iann-Str. 6

D - 96148 Baunach

Phone: +49 / 9544 / 68 – 0

Fax: +49 / 9544 / 22 73

Röderaue 41

D - 01471 Radeburg / Dresden

Phone: +49 / 35208 / 84 – 0

Fax: +49 / 35208 / 84 249

E-Mail: sales@sebakmt.com

http://www.sebakmt.com

SebaKMT

All rights reserved. No part of this handbook may be copied by photographic or other means unless SebaKMT have before-hand

declared their consent in writing. The content of this handbook is subject to change without notice. SebaKMT cannot be made

liable for technical or printing errors or shortcomings of this handbook. SebaKMT also disclaim all responsibility

for damage resulting directly or indirectly from the delivery, supply, or use of this matter.

Page 4

1-4

Terms of Warranty

SebaKMT accept responsibility for a claim under warranty brought forward by a customer for a product sold by

SebaKMT under the terms stated below.

SebaKMT warrant that at the time of delivery SebaKMT products are free from manufacturing or material defects

which might considerably reduce their value or usability. This warranty does not apply to faults in the software

supplied. During the period of warranty, SebaKMT agree to repair faulty parts or replace them with new parts or

parts as new (with the same usability and life as new parts) according to their choice.

SebaKMT reject all further claims under warranty, in particular those from consequential damage. Each component

and product replaced in accordance with this warranty becomes the property of SebaKMT.

All warranty claims versus SebaKMT are hereby limited to a period of 12 months from the date of delivery. Each

component supplied by SebaKMT within the context of warranty will also be covered by this warranty for the

remaining period of time but for 90 days at least.

Each measure to remedy a claim under warranty shall exclusively be carried out by SebaKMT or an authorized

service station.

To register a claim under the provisions of this warranty, the customer has to complain about the defect, in case of

an immediately detectable fault within 10 days from the date of delivery.

This warranty does not apply to any fault or damage caused by exposing a product to conditions not in accordance

with its specification, by storing, transporting, or using it improperly, or having it serviced or installed by a workshop

not authorized by SebaKMT. All responsibility is disclaimed for damage due to wear, will of God, or connection to

foreign components.

For damage resulting from a violation of their duty to repair or re-supply items, SebaKMT can be made liable only

in case of severe negligence or intention. Any liability for slight negligence is disclaimed.

Page 5

1-5

Contents

1 Safety Advices..................................................................................................................1-7

2 Technical Description......................................................................................................2-8

2.1 Technical Data ..................................................................................................................... 2-8

2.2 Scope of Delivery ................................................................................................................. 2-9

2.3 Available Configurations....................................................................................................... 2-9

2.4 Design ................................................................................................................................ 2-11

2.5 Accessories........................................................................................................................ 2-13

3 Commissioning the Logger...........................................................................................3-14

3.1 Configuring the Logger....................................................................................................... 3-14

3.2 Preparing the Logger for GSM Connectivity....................................................................... 3-14

3.3 Connecting the Logger....................................................................................................... 3-16

3.3.1 Connecting Sensors and Alarm Devices.................................................................... 3-16

3.3.1.1 Basics .................................................................................................................................3-16

3.3.1.2 Connection Equipment for Single-channel Loggers........................................................... 3-18

3.3.1.3 Connection Equipment for Multi-channel Loggers ............................................................. 3-19

3.3.1.4 Wiring Diagram Examples.................................................................................................. 3-21

3.3.2 Connecting a Tube to an Internal Pressure Sensor................................................... 3-25

3.4 Commissioning the Logger................................................................................................. 3-26

3.4.1 Positioning the Logger ............................................................................................... 3-26

3.5 Positioning the GSM Antenna ............................................................................................ 3-26

3.6 Switching the Logger On/Off .............................................................................................. 3-27

4 Setting Up the Software.................................................................................................4-28

4.1 System Requirements........................................................................................................ 4-28

4.2 Installing the Software........................................................................................................ 4-28

4.3 Connecting the Logger to the PC....................................................................................... 4-29

4.3.1 Radio Communication via E-Box ............................................................................... 4-29

4.3.2 Connecting the Logger via Direct Connection............................................................ 4-30

4.4 Starting the Software.......................................................................................................... 4-31

4.5 Registering a Logger.......................................................................................................... 4-32

4.5.1 Adding / Deleting a Logger......................................................................................... 4-32

4.5.2 Adding / Deleting a Group.......................................................................................... 4-33

5 Configuring the Logger.................................................................................................5-35

5.1 Selecting the Logging Interval............................................................................................ 5-36

5.2 Sensor Configuration.......................................................................................................... 5-36

5.2.1 Sensor Type............................................................................................................... 5-37

Page 6

1-6

5.2.1.1 Configuring a „Customer Specific“ Sensor .........................................................................5-37

5.2.1.2 Input Type Examples..........................................................................................................5-38

5.2.2 Configuring Alarm Conditions (Threshold Monitoring)................................................ 5-40

5.2.3 Finishing the Configuration.........................................................................................5-41

5.3 Configuring the Switching Inputs (Alarm Inputs)................................................................. 5-42

5.4 Configuring the Radio Communication............................................................................... 5-44

5.4.1 SIM Card Configuration..............................................................................................5-46

5.4.2 Configuring the Internet Access Point of the Network Operator................................. 5-46

5.4.3 Email Configuration....................................................................................................5-46

5.4.4 FTP Settings...............................................................................................................5-47

5.4.5 SMS Destinations.......................................................................................................5-47

5.4.6 Summary Messages...................................................................................................5-47

5.4.7 Testing the GSM Settings ..........................................................................................5-48

5.4.7.1 Testing SMS / Email Transmission.....................................................................................5-48

5.4.7.2 Testing FTP Data Transfer .................................................................................................5-50

5.4.8 Finishing the Communication Setup...........................................................................5-50

5.5 Start Time........................................................................................................................... 5-50

5.6 Memory Mode..................................................................................................................... 5-51

5.7 State ...................................................................................................................................5-51

5.8 Finishing the Configuration................................................................................................. 5-51

6 Retrieving and Evaluating Data.....................................................................................6-52

6.1 Retrieving Data from the Logger......................................................................................... 6-52

6.2 Collecting Data from the FTP Server.................................................................................. 6-53

6.3 Evaluating Measured Data ................................................................................................. 6-54

7 Miscellaneous Functions...............................................................................................7-56

7.1 Identifying Loggers ............................................................................................................. 7-56

7.2 Real-Time Measurement.................................................................................................... 7-56

7.3 Setting the Clock................................................................................................................. 7-57

7.4 CSV Export......................................................................................................................... 7-57

7.5 Deleting Logged Data......................................................................................................... 7-57

7.6 Firmware............................................................................................................................. 7-58

8 Replacing the Batteries..................................................................................................8-59

Page 7

1-7

1 Safety Advices

Safety precautions This manual contains basic advice for the installation and operation of the Sebalog D.

It is essential to make this manual accessible to the authorized and skilled operator.

He needs to read this manual closely. The manufacturer is not liable for damage to

material or humans due to non-observance of the instructions and safety advices

provided by this manual.

Locally applying regulations must be observed.

Special transportation

requirements

The lithium batteries of the Sebalog D are dangerous goods. The transport of the

batteries itself and of devices which contain such batteries is subject to regulations

based on the UN Model Regulations “Transport of Dangerous Goods”

(ST/SG/AC.10-1).

Please inform yourself about the transportation requirements and follow them when

shipping the device.

General Cautions

•

The limits described under technical data may not be exceeded.

•

Do not drop the device or subject it to strong impacts or mechanical shocks!

•

Do not operate the device with a voltage unequal to the specified operating voltage!

•

Original accessories ensure safe operation of the equipment. It is not allowed and

the warranty is lost if other accessories than the original ones are used with the

equipment.

•

Cover the sockets on the top of the device always with the provided protection caps

,

if no cable is connected to the terminal. Otherwise, penetrating dirt and water may

damage the device.

CAUTION

!

Page 8

2-8

2 Technical Description

Intended application The Sebalog D is a compact, robust and extremely versatile data logger. The device

can record the readings of various sensor types in user-defined intervals. The

collected data can be periodically transmitted to a FTP server or read out with a PC or

special equipment.

Depending on the configuration of the logger, up to 4 freely programmable channels

can be connected to sensors for data recording.

Furthermore, the logger can be used to trigger user-defined alarm signals (e.g. signal

lights, SMS or email), if a threshold is exceeded or special alarm equipment is

triggered.

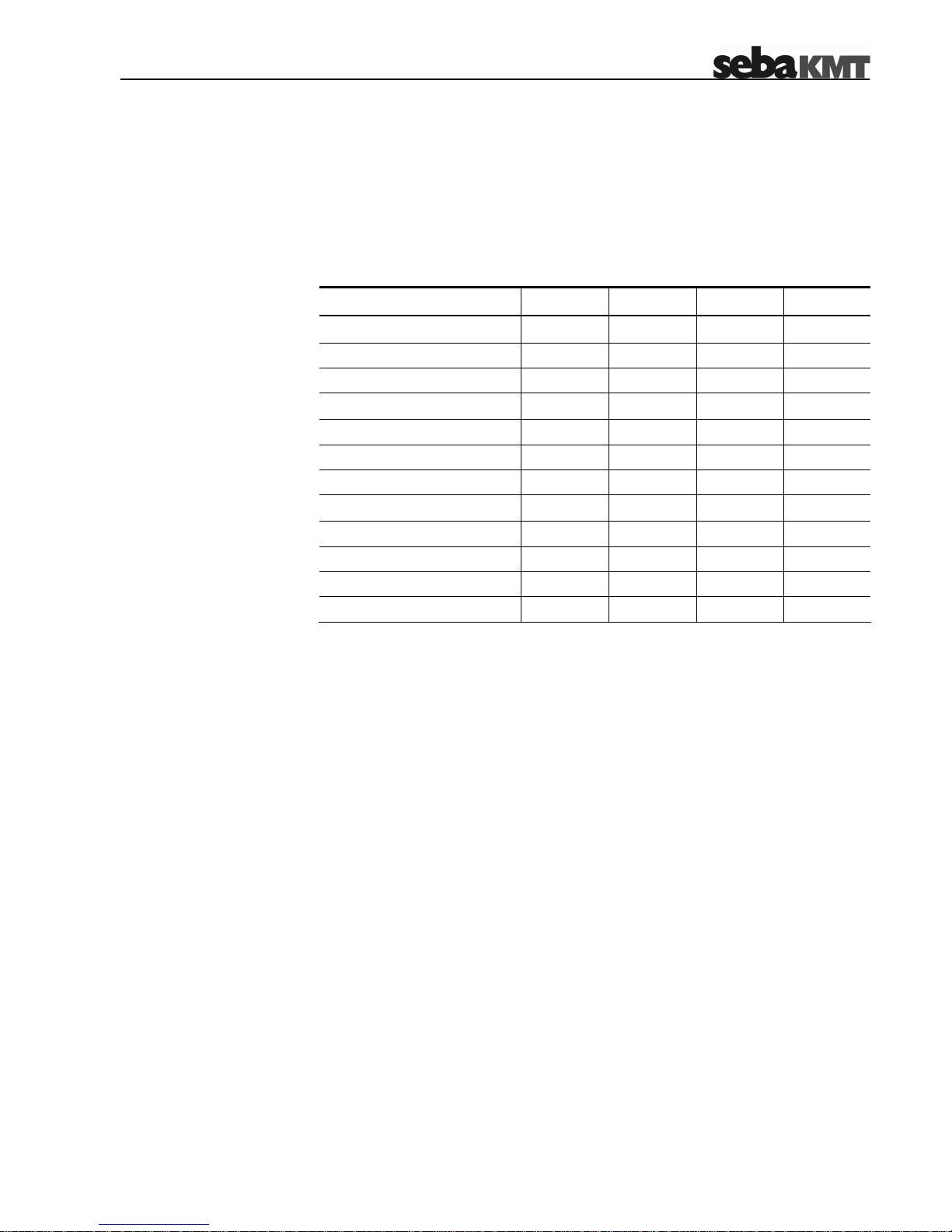

2.1 Technical Data

Depending on the configuration, the Sebalog D is specified by the following

parameters:

Parameter Value

Communication USB interface

Wireless, 868/915 MHz

GSM/GPRS modem, 850/900/1800/1900 MHz

Inputs / outputs

1, 2 or 4 freely programmable channels, analog or digital

(0…5 V / 0…20 mA / pulse / frequency)

up to 2 switching inputs (alarm trigger)

up to 2 switching outputs (alarm installation)

up to 2 connectors for internal pressure sensors

Internal pressure

sensors

up to 2 sensors (optional)

(10 bar / 16 bar / 25 bar / 40 bar)

Accuracy +/- 0,1%

Interval 1 s … 31 days (programmable)

Memory

2 MByte internal memory (expandable via SD)

Block or roll memory

Alarm - switching input(s) and threshold monitoring

- triggering of switching output(s) and SMS / email

notifocation

Operating voltage 12 V DC

Accumulator Internal lithium battery

Operating

temperature

-10°C … +50°C

Dimensions

(L x W x H)

115 x 115 x 180 mm

Weight 0,8 kg

Protection class IP 68

Page 9

2-9

2.2 Scope of Delivery

Besides of the logger unit and a magnet, the Sebalog D package contains a CD with

the following content:

• SebaDataView configuration and readout software

• Driver

• Sebalog D information materials

Depending on the configuration of the logger, the scope of delivery may contain even

more accessories which can also be ordered from SebaKMT (see section 2.5).

2.3 Available Configurations

Introduction The Sebalog D is available in a wide variety of configurations. It ranges from a basic

version with 1 channel to a full equipped version with 4 channels, integrated pressure

sensors and an internal GSM modem.

The feature options can be combined in almost any possible way which leads to the

many configurations listed in the table below. By means of the item number (PN) on

the bottom of the logger you can identify the type of your device:

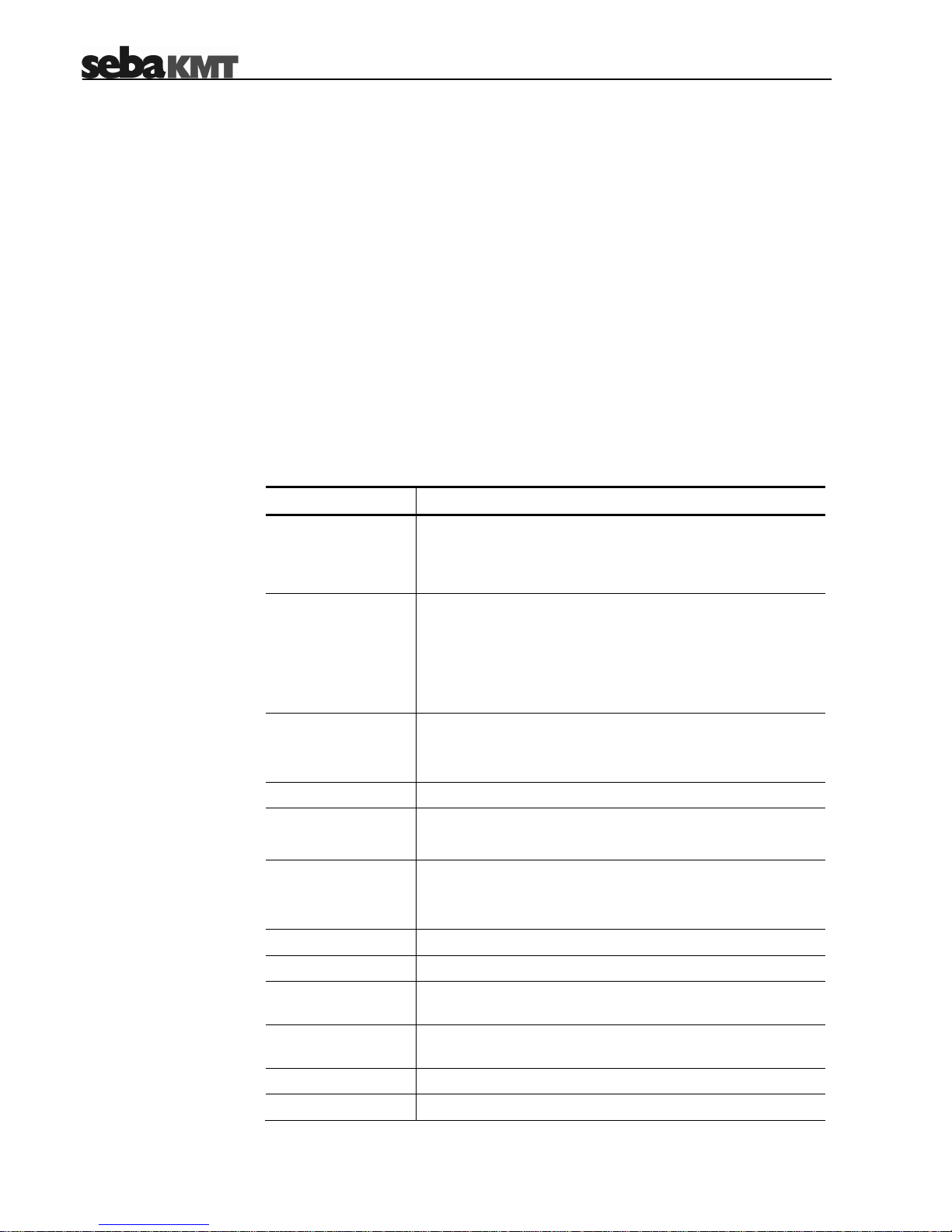

Single-channel versions

Item number Type Item number Type

820013543 LOG D1-B 820013549 LOG D1-GSM-P1-16

820013544 LOG D1-P1-16 820013550 LOG D1-GSM-P1-25

820013545 LOG D1-P1-25 820013551 LOG D1-GSM-P1-40

820013546 LOG D1-P1-40 820013552 LOG D1-I-B

820013547 LOG D1-GSM 820013559 LOG D1-I-GSM

2-channel versions

Item number Type Item number Type

820013506 LOG D2-B 820013522 LOG D2-GSM-P2-16

820013507 LOG D2-P1-16 820013523 LOG D2-GSM-P2-25

820013508 LOG D2-P1-25 820013525 LOG D2-GSM-P2-40

820013510 LOG D2-P1-40 820013527 LOG D2-I-B

820013512 LOG D2-P2-16 820013530 LOG D2-I-P1-16

820013515 LOG D2-P2-25 820013531 LOG D2-I-P1-25

820013516 LOG D2-P2-40 820013532 LOG D2-I-P1-40

820013518 LOG D2-GSM 820013536 LOG D2-I-GSM

820013519 LOG D2-GSM-P1-16 820013537 LOG D2-I-GSM-P1-16

820013520 LOG D2-GSM-P1-25 820013538 LOG D2-I-GSM-P1-25

820013521 LOG D2-GSM-P1-40 820013539 LOG D2-I-GSM-P1-40

Page 10

2-10

4-channel versions

Item number Type Item number Type

820012348 LOG D4-B 820012354 LOG D4-I-B

820012349 LOG D4-P1-16 820012355 LOG D4-I-P1-16

820013478 LOG D4-P1-25 820013487 LOG D4-I-P1-25

820013479 LOG D4-P1-40 820013488 LOG D4-I-P1-40

820012350 LOG D4-P2-16 820012356 LOG D4-I-P2-16

820013480 LOG D4-P2-25 820013489 LOG D4-I-P2-25

820013481 LOG D4-P2-40 820013490 LOG D4-I-P2-40

820012351 LOG D4-GSM 820012357 LOG D4-I-GSM

820012352 LOG D4-GSM-P1-16 820012358 LOG D4-I-GSM-P1-16

820013482 LOG D4-GSM-P1-25 820013491 LOG D4-I-GSM-P1-25

820013483 LOG D4-GSM-P1-40 820013492 LOG D4-I-GSM-P1-40

820012353 LOG D4-GSM-P2-16 820012359 LOG D4-I-GSM-P2-16

820013485 LOG D4-GSM-P2-25 820013474 LOG D4-I-GSM-P2-25

820013486 LOG D4-GSM-P2-40 820013493 LOG D4-I-GSM-P2-40

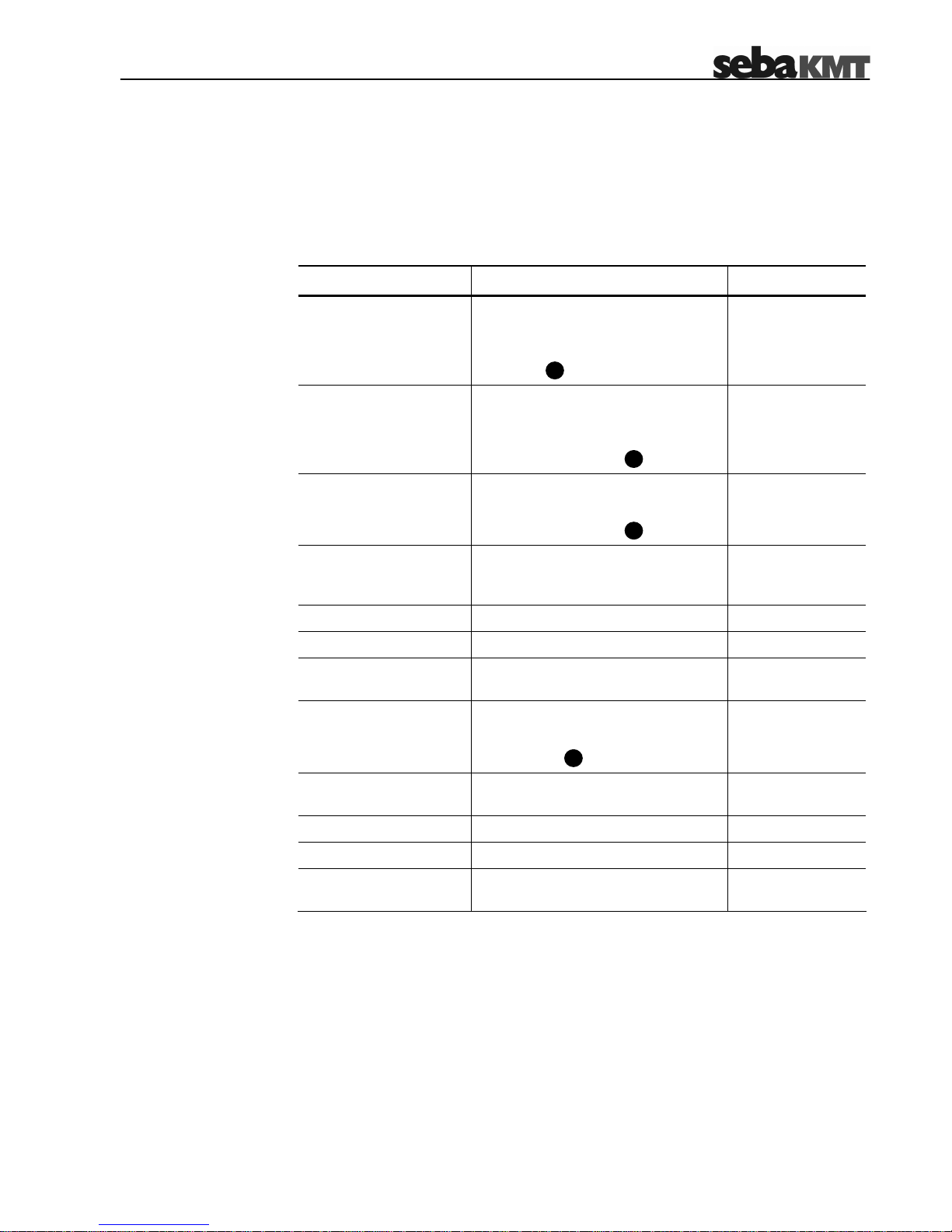

Type number The type number consists of the following segments:

Due to the large amount of possible configurations, this manual cannot state

explicitly whether or not a described function applies to your device. Please use

the information provided within this section to identify the specific capabilities of

your logger.

10 … The internal pressure sensors have a measuring

range of 10 bar

16 … The internal pressure sensors have a measuring

range of 16 bar

25 … The internal pressure sensors have a measuring

range of 25 bar

40 … The internal pressure sensors have a measuring

range of 40 bar

LOG D4

-I-

GSM

-

P2

-

16

D1 … the logger has 1 logging channel

D2 … the logger has 2 logging channels

D4 … the logger has 4 logging channels

The logger can be connected to a sensor via current loop

the logger contains an internal GSM modem

P1 …the logger contains one internal pressure sensor

P2 …the logger contains two internal pressure sensors

Page 11

2-11

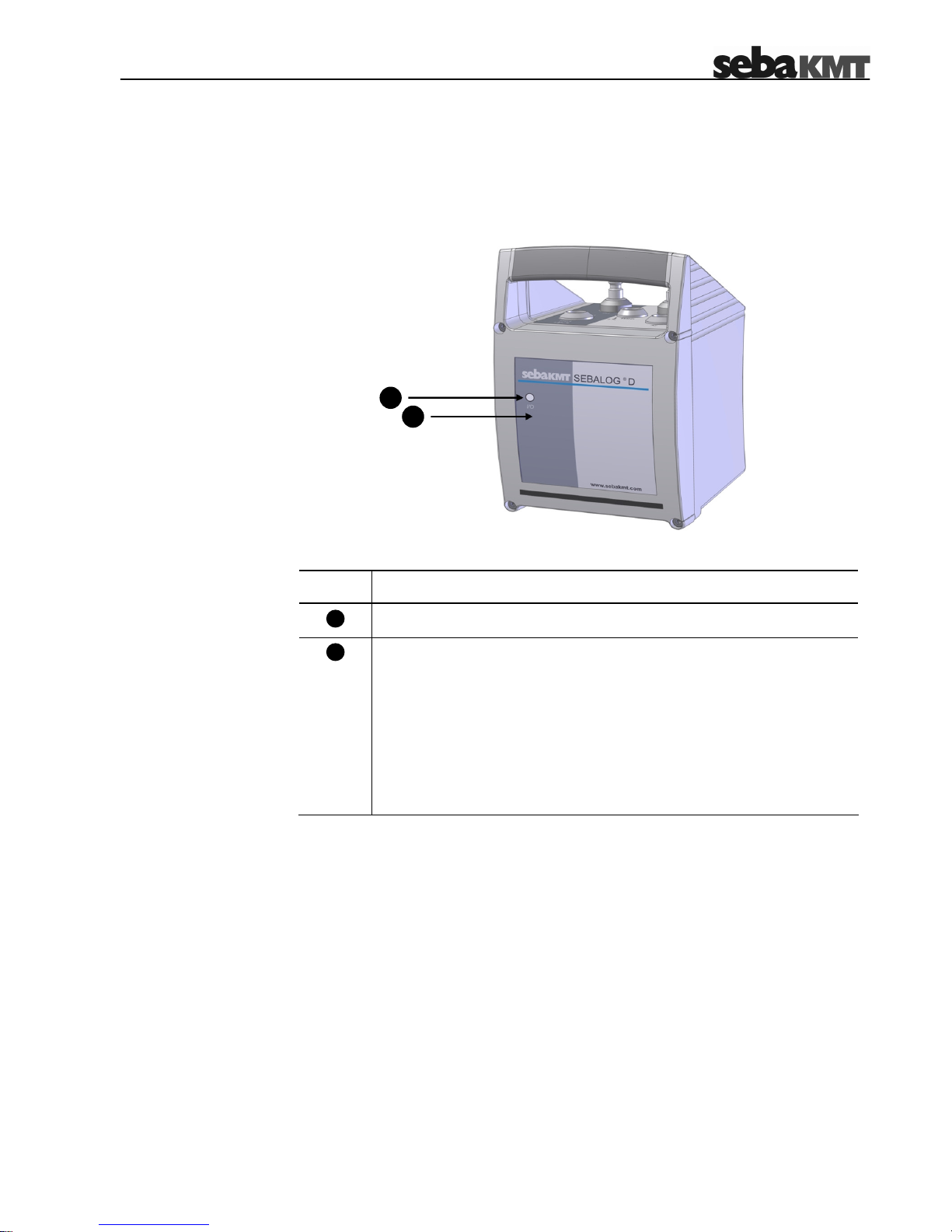

2.4 Design

Controls and indicators The following figure shows all the front panel operating controls and indicators. The unit

is in protection class IP 68:

The Sebalog D consists of the following operating controls and indicators:

Item Description

On/off contact area

I/O control lamp

not lit: Logger is switched off

green (flashing): Logger is switched on and in energy saving mode

green (permanent): Logger is switched on and a radio link to a

PC (E-Box) is established

orange (permanent): Data transfer takes place

red (for a moment): Logger is switching off

1

2

1

2

Page 12

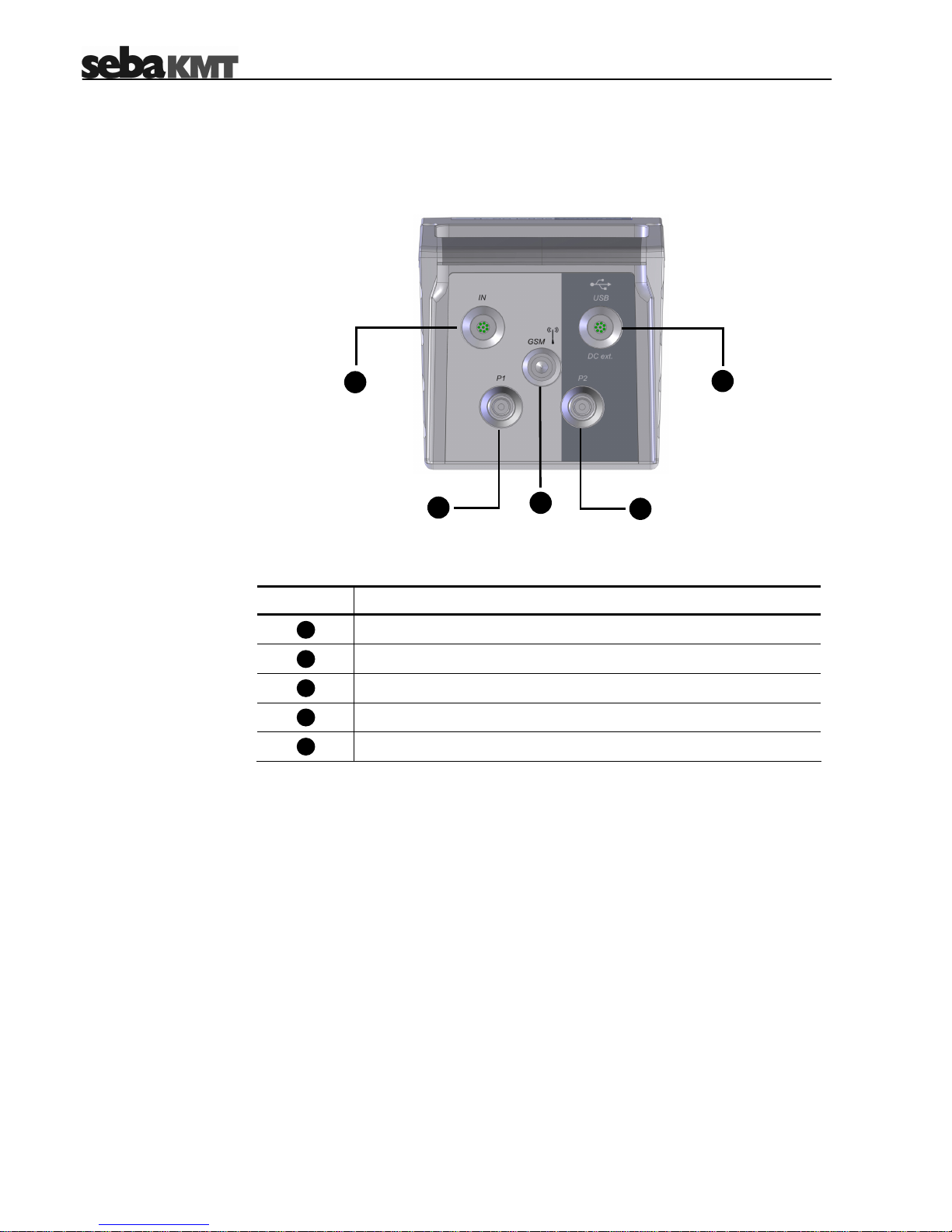

2-12

Connectors The following figure shows the connectors of the Sebalog D which are placed on top of

the device. While the USB socket is always part of the assembly, it depends on the

configuration of the logger whether the other connectors are existent:

The Sebalog D offers the following connectors:

Item Description

IN socket

USB / DC ext. socket

internal pressure sensor P1

internal pressure sensor P2

GSM antenna socket

4

7

6

5

3

5

3 4

6

7

Page 13

2-13

2.5 Accessories

In addition to the standard scope of delivery, there is a large amount of optional

accessory parts which can be ordered from SebaKMT.

The following table describes all available accessory parts:

Accessory part Description Item number

Connection cable

VK 75, green

- for connecting the logger to up to 4

sensors

- must be connected to the

IN socket

820012449

Connection cable

VK 76, red

- for connecting a sensor and up to 2

switching inputs / outputs (alarming)

- must be connected to the

USB / DC ext. socket

820012450

Connection cable

VK 77 USB, red

- for connecting the logger to a PC

- must be connected to the

USB / DC ext. socket

820012451

E-Box USB

Allows wireless data transfer between

the logger and a PC within a range of

about 100 m.

820009270

USB cable (1 m) For connecting the E-Box to the PC 820008969

Antenna for E-Box Spare part 122010014

Reader Box For wireless on-site data readout

without PC

on request

GSM antenna with

connection cable (3 m)

- only for logger with GSM modem

- must be connected to the

GSM socket

820012452 (cable)

Coupler

(1/4” male thread)

For connecting a tube with ¼” female

thread to an internal pressure sensor

820014883

AD-21

External pressure sensor Different measuring ranges available on request

External accumulator External power supply for the logger on request

Charger For charging the external

accumulator (see above)

on request

7

3

4

4

Page 14

3-14

3 Commissioning the Logger

3.1 Configuring the Logger

Prior to its on-site installation, the logger must be properly configured using the

supplied SebaDataView software. In doing so, the logger has to be provided with the

channel allocation, the alarm conditions and the wireless connection parameters

among other things.

(For a detailed description of the logger configuration, please refer to chapter 5).

3.2 Preparing the Logger for GSM Connectivity

If the data collected by the logger should be periodically transferred to a FTP server

or if an alarm notification via email / SMS is required, the following steps must be

performed in order to prepare a logger (with built-in GSM modem) for GSM

connectivity:

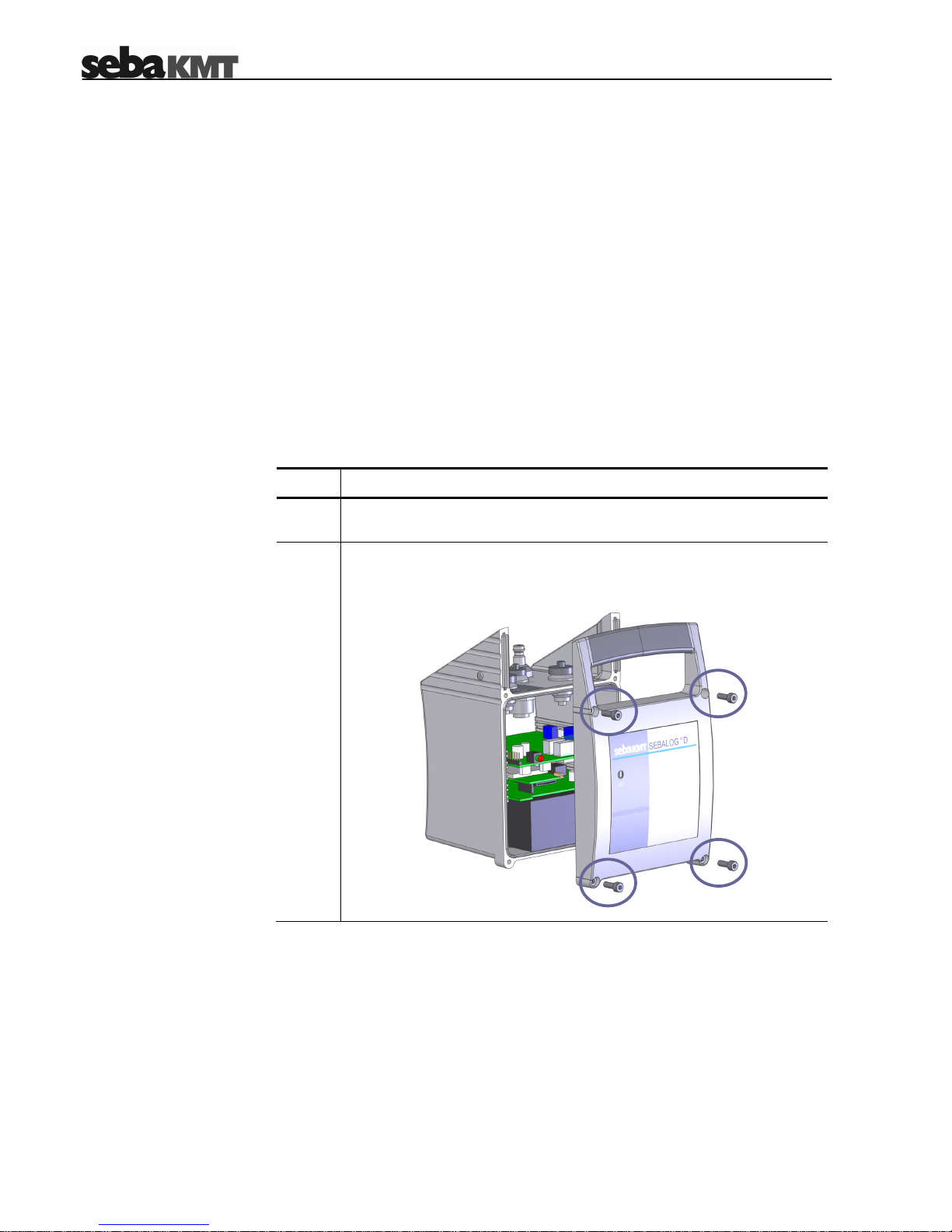

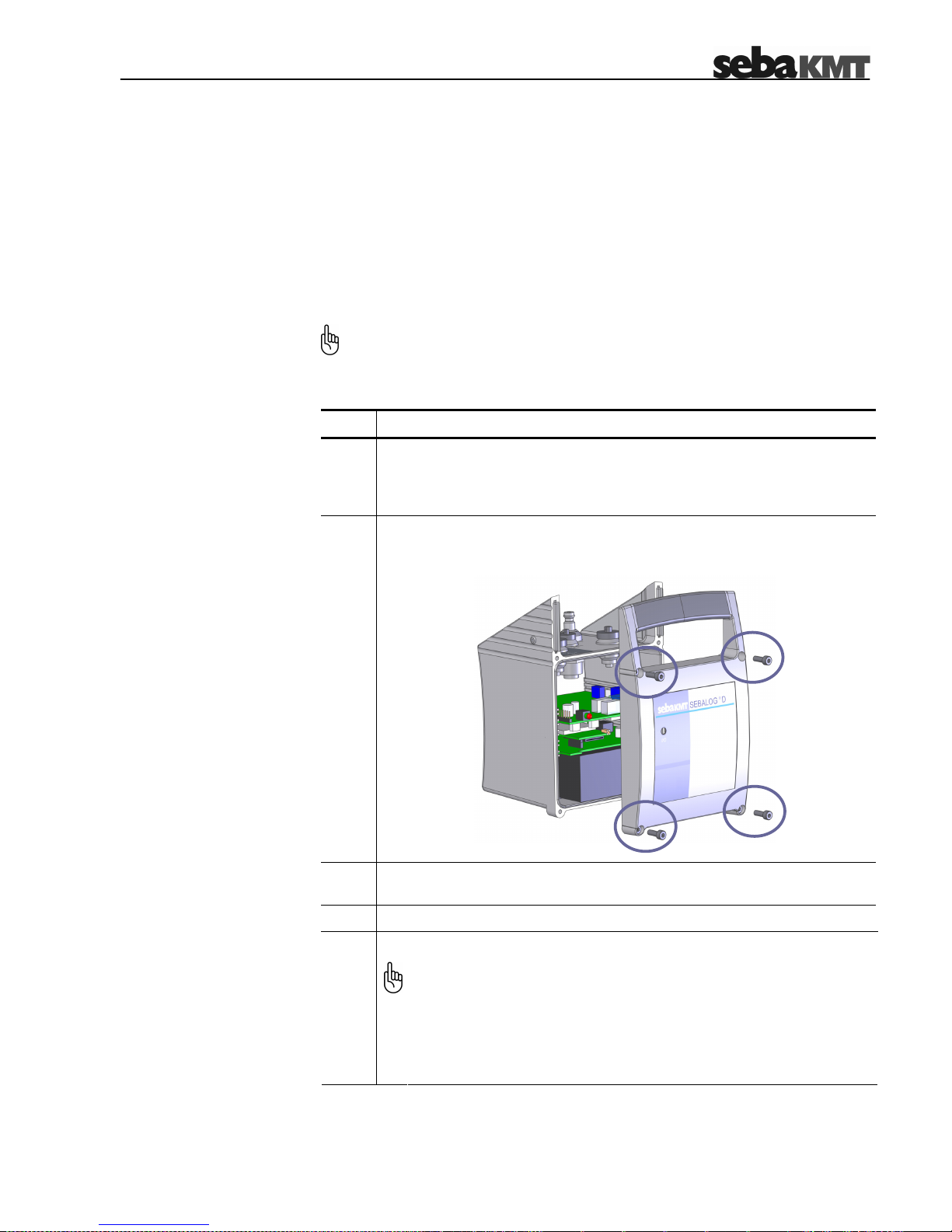

Step Action

1

In order to get a SIM card enabled for data transfer via GPRS, you have

to close a suitable contract with a mobile phone service provider.

2

Loosen the four marked screws with a M3 allen key or with a crosstip

screwdriver respectively (depending on the logger type) and remove

the front panel.

Page 15

3-15

(Continuation from previous page:)

Step Action

Insert the SIM card into the slot as shown in the figure below. The card

has to snap into the spring mechanism.

If you need to release the card, gently press its protruding edge.

3

Please be careful not to damage any electrical parts within the

logger.

Attach the front panel to the housing again.

4

In order to ensure the total protection against water and dust

ingress compliant with IP 68, the following instructions must be

observed:

• If the logger is older then six months and if the front panel has

not been changed during the last six months, a new front panel

including a new rubber seal must be installed. A new front

panel can be ordered from SebaKMT.

• The rubber seal and the contact surfaces of the housing must

be free of dirt.

• Be careful not to jam the housing parts against each other.

• Tighten the screws with a torque of 1 Nm.

5

Connect the supplied GSM antenna with the GSM socket . Make

sure that the guide on the plug fits in the groove in the socket and that

you feel the plug latch in.

6

Make sure that the GSM settings have been properly configured (see

section 5.4).

7

(cut edge to the left)

Page 16

3-16

3.3 Connecting the Logger

Depending on its configuration, the following peripheral and measring devices can be

connected to a logger:

• up to 4 sensors can be attached and the data can be logged (e.g. pressure,

flow velocity)

• up to 2 alarm-triggering devices (e.g. a light barrier) can be connected to the

switching inputs

• up to 2 devices (e.g. signal lamp, pump) can be connected to the switching

outputs and can be triggered in the case of an alarm

• up to two tubes can be directly connected to the internal pressure sensors

Depending on the type of sensors / alarm devices connected to the Sebalog D, the

appropriate parameter values have to be provided to the logger using the

SebaDataView software. For a detailed description of the necessary configuration

steps, please refer to section 5.2.

3.3.1 Connecting Sensors and Alarm Devices

3.3.1.1 Basics

Introduction One end of the VK 75 / VK 76 connection cables used for connecting equipment to

the logger is uncoated and ten colour-coded wires stick out of it. According to its

colour, each of these wires represents a specific input / output of the logger and can

be directly connected to the respective terminal of a peripheral device (e.g. a sensor).

If no adequate terminals are existent, a luster terminal or other accessories can be

used. A proper electrical insulation must be ensured.

For the basic logger version with only one channel, all connections are established

via the VK 76 connection cable attached to the USB / DC ext. socket .

For loggers with 2 or even 4 channels only the switching inputs/outputs and the

external power supply are connected via the VK 76 connection cable. Any

connections to sensors are established via the VK 75 connection cable attached to

the IN socket .

The channels are assigned in numeric order which means that for a 2-channel

logger, the channels 1 and 2 have to be used for the connection setup.

3

4

Page 17

3-17

Fixed channel allocations Due to the internal wiring of the logger, current loops can only be connected to the

channels 2 and 4.

The internal pressure sensors P1 and P2 are always linked to channel 1 and 3. If the

logger is equipped with one or two internal pressure sensors, the respective channels

are in use and must not be connected to external sensors.

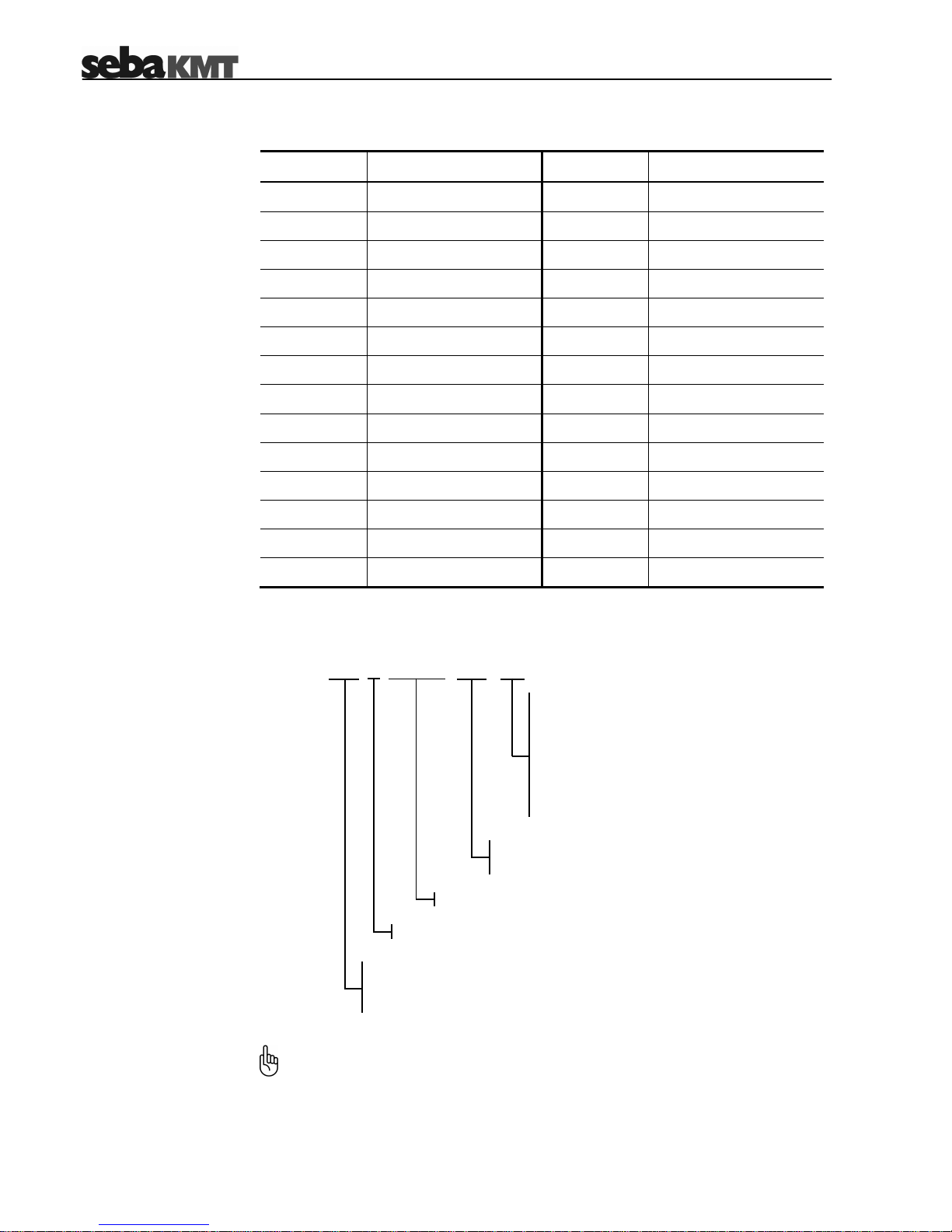

Corresponding to these conventions, the following channel allocations apply:

Channel 1 Channel 2 Channel 3 Channel 4

Single-channel Logger

Int. pressure sensor

X

Current loop

X

2-channel Logger

Int. pressure sensor P1

X

Int. pressure sensor P2

X

Current loop

X

4-channel Logger

Int. pressure sensor P1

X

Int. pressure sensor P2

X

First current loop

X

Second current loop

X

Page 18

3-18

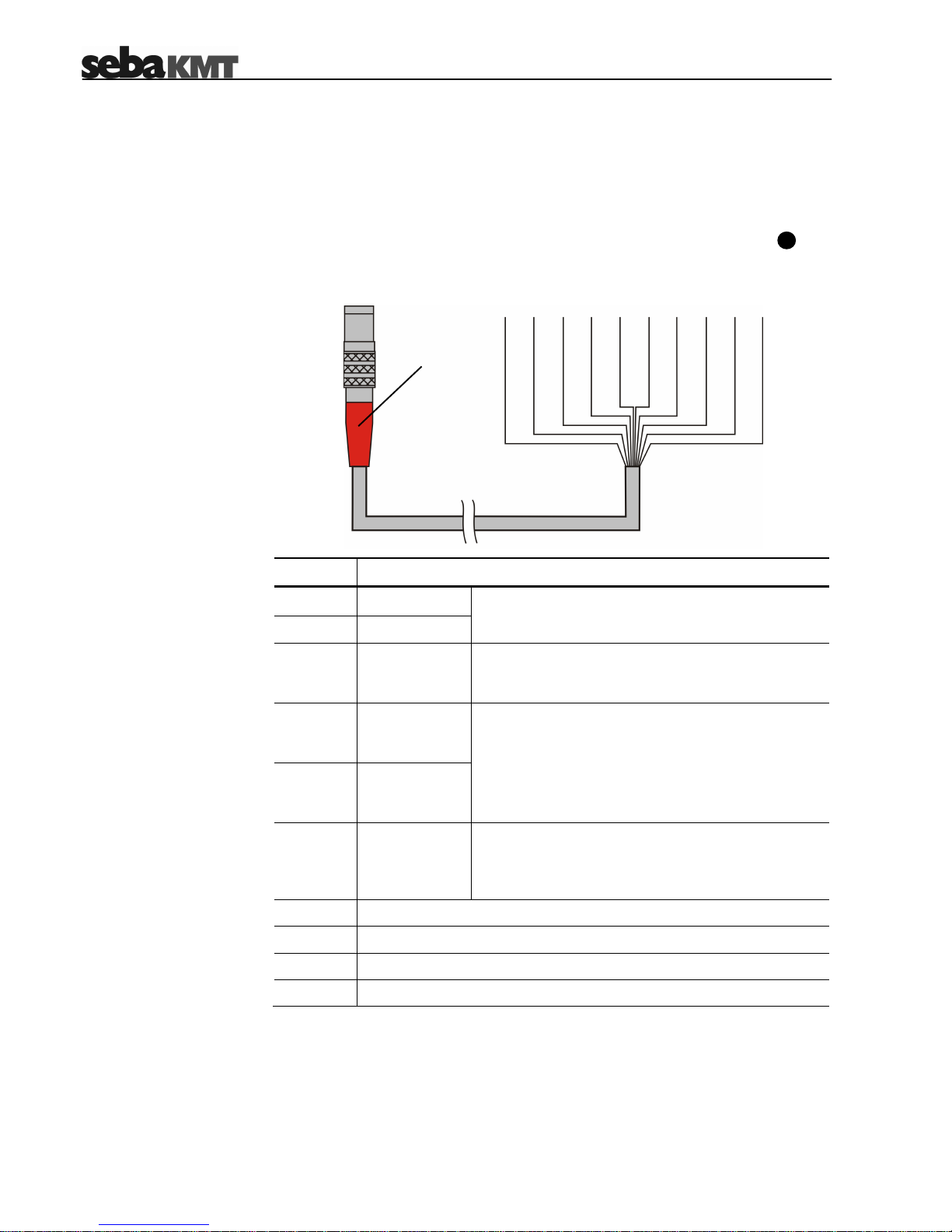

3.3.1.2 Connection Equipment for Single-channel Loggers

Introduction Loggers with only one channel (LOG D-1) can be connected to one sensor, a

switching input and a switching output. All of these connections can be established

with only one connection cable (VK 76) attached to the USB / DC ext. socket .

VK 76 pin assignment in

combination with

single-channel loggers

In combination with a single-channel logger, the VK 76 connection cable has the

following pin assignment:

Wire Description

white

Channel +

brown

Channel –

Channel a sensor can be connected to.

green

Switching

input 2

An alarm-triggering device with a voltage output of

0 … 5 V can be connected between this wire and

the purple wire (GND).

yellow

Switching

output

(relay 2) OUT

pink

Switching

output

(relay 2) IN

An electric circuit with an external DC power supply

up to 12 V / 1 A can be connected between these

two wires. If the internal relay is triggered by an

alarm event, the circuit is closed and the connected

load is activated / triggered.

red

External

power supply

An external power supply with 12 V DC can be

connected between this wire and the purple wire

(GND). The internal battery cannot be charged by an

external power supply.

purple

GND

grey

not used

blue

not used

black

not used

4

red

(to be connected to

USB / DC ext.)

Page 19

3-19

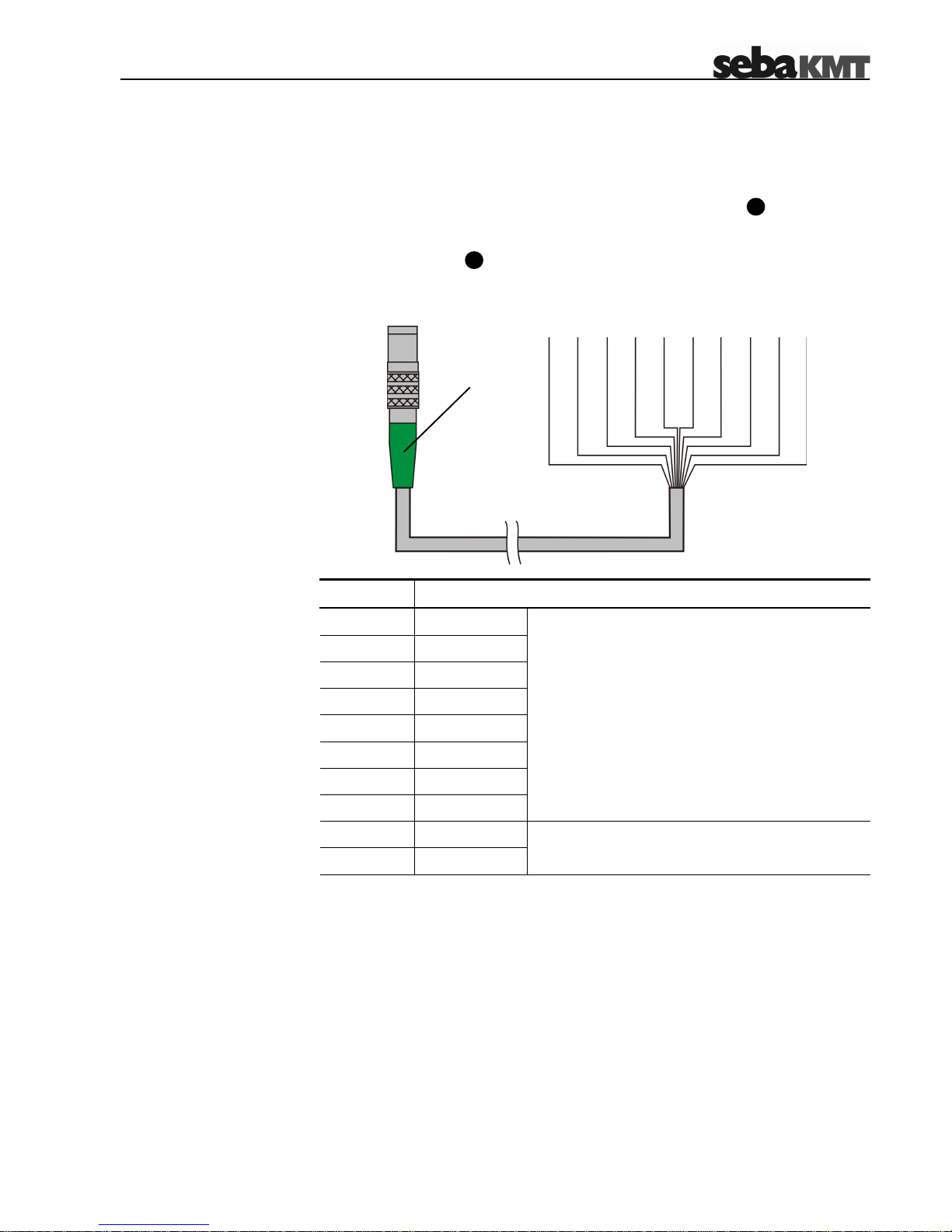

3.3.1.3 Connection Equipment for Multi-channel Loggers

Introduction

Multi-channel loggers are equipped with the additional IN socket up to 4 external

sensors can be connected to (via the VK 75 connection cable). The switching

inputs/outputs and the external power supply have to be connected to the

USB / DC ext. socket (via the VK 76 connection cable).

VK 75 pin assignment In combination with a multi-channel logger, the VK 75 connection cable has the

following pin assignment:

Wire Description

white

Channel 1 +

brown

Channel 1 –

green

Channel 2 +

yellow

Channel 2 –

grey

Channel 3 +

pink

Channel 3 –

blue

Channel 4 +

red

Channel 4 –

Channels up to 4 sensors can be connected to.

black

5 V OUT

purple

GND

DC power supply for sensors or other loads

(U = 5 V / I

max

= 20 mA)

4

3

green

(to be connected to IN)

Page 20

3-20

VK 76 pin assignment in

combination with multi-

channel loggers

In combination with a multi-channel logger, the VK 76 connection cable has the

following pin assignment:

Wire Description

white

Switching

Input 1

green

Switching

Input 2

An alarm-triggering device with a voltage output of

0 … 5 V can be connected between a switching

input and the purple wire (GND).

brown

Switching

output

(relay 1) OUT

yellow

Switching

output

(relay 2) OUT

pink

Switching

outputs IN

An electric circuit with an external DC power

supply up to 12 V / 1 A can be connected to each

switching output. If an internal relay is triggered by

an alarm event, the respective circuit is closed and

the connected load is activated / triggered.

red

External

power supply

An external power supply with 12 V DC can be

connected between this wire and the purple wire

(GND). The internal battery cannot be charged by

an external power supply.

purple

GND

grey

not used

blue

not used

black

not used

red

(to be connected to

USB / DC ext.)

Page 21

3-21

3.3.1.4 Wiring Diagram Examples

Introduction The examples described in the following pages can be realized with any type of

logger even with the basic version with only one channel. For multi-channel loggers,

these examples can be combined in many ways depending on the logger

configuration. A 4-channel logger, for example, can be connected to up to four

different types of sensors and can be included in up to two alarm loops.

Depending on the sensor, the actual wiring diagram and the terminal designation

may differ. For some sensor types, it is necessary to integrate a resistance into the

connection setup in order to dampen or amplify the output signal. Please refer to the

respective sensor manual for detailed information.

Connecting a sensor with

the output signal type

voltage

The following example describes how to connect a sensor with a 0 … 5 V voltage

output:

Connecting a sensor with

the output signal type

current

The following example describes how to connect a sensor to a 0 … 20 mA or

4 … 20 mA current loop:

Current loops can only be connected to loggers which are capable of analyzing

this type of signal. Please check the configuration of your device (see

section 2.3).

A current loop can only be connected to channel 2 or 4.

5 V OUT

Channel +

GND

Channel –

Logger

I +

I –

Sensor

Sensor

Logger

5 V IN

Signal

GND

5 V OUT

Channel +

GND

Channel –

Page 22

3-22

Connecting a sensor with

the output signal type

frequency

The following examples describe how to connect a sensor with a 0 Hz … 1000 Hz

frequency output.

Example 1: the logger does not supply the operating voltage for the sensor:

Example 2: the logger supplies the operating voltage for the sensor:

Sensor

Logger

5 V OUT

Channel +

GND

Channel –

5 V IN

GND

Signal

Sensor

Logger

5 V OUT

Channel +

GND

Channel –

GND

Signal

10 k

10 k

Page 23

3-23

Connecting a sensor with

the output signal type

pulse (reed contact)

The following examples describe how to connect a sensor with pulse output. These

types of sensors transmit a pulse to the logger whenever the value of the

measurement crosses a certain threshold.

Example 1: the logger does not supply the operating voltage for the sensor:

Example 2: the logger supplies the operating voltage for the sensor:

Sensor

Logger

5 V IN

Signal

GND

5 V OUT

Channel +

Channel –

GND

1k

Sensor

Logger

Signal

GND

5 V OUT

Channel +

Channel –

GND

1k

Page 24

3-24

Example of an alarm loop The following example shows an electrical circuit with DC power source connected to

the switching input of the loggers. If an alarm is raised by the alarm device (e.g. light

barrier) is activated, the circuit is closed and the switching input is triggered.

Depending on the alarm configuration, one or two of the internal relays are switched

in order to activate / trigger the load connected to the respective switching output (in

this case a signal lamp) and a SMS and / or email can be sent to predefined

receivers.

Alarms can also be triggered when the value of a monitored measurment crosses a

predefined threshold. Please refer to section 5.2 for detailed information on how to

configure the threshold monitoring.

configured

alarm trigger

Alarm device

GND

Alarm IN

Relay IN

Relay OUT

GSM

SMS

email

Logger

Page 25

3-25

3.3.2 Connecting a Tube to an Internal Pressure Sensor

A Sebalog D logger can be equipped with up to two internal pressure sensors

(optional 10 bar, 16 bar, 25 bar or 40 bar) where tubes can be connected to.

The sensors are capable of measuring the pressure of both liquid and gaseous

media. When connecting a tube to a sensor, the following instructions must be

observed:

• Pressure sensors are sensitive to overpressure. Do not exceed the

measuring range in order to avoid irreparable damage to the sensor.

• Make sure no dirt or rust can ingress inside the sensors. In case of doubt,

use a filter.

• There must not be any water inside the sensor. Otherwise, frost can

damage the sensor.

• After a sensor has been in use or in storage for a longer period, it must be

cleaned with compressed air.

In order to connect a tube to the nipple ( or ) of an internal pressure sensor, the

tube has to be equipped with a coupler compatible to Rectus 21 (5 mm nominal

diameter).

A coupler for tubes with ¼“ female thread can be ordered from SebaKMT.

6 5

Page 26

3-26

3.4 Commissioning the Logger

3.4.1 Positioning the Logger

Thanks to its IP68 protection class, the logger housing is protected against the

ingress of dust and water and, thus, especially qualified for the operation in pipeline

shafts where it can be installed next to the measuring point.

The logger can be installed in vertical and horizontal position and can also be hung

up using, e.g., a cable tie.

During field installation, the following instructions must be observed in order to

ensure proper operation of the logger:

• Make sure that all connections to sensors of other peripheral devices are

established in a professional manner and that the connection points are

properly insulated.

• When you plug a connection cable (VK 75, VK 76 or VK 78) in the

respective socket, make sure you feel the plug latch in. Only proper and

positive locking connections provide protection against ingress of water and

ensure error-free data transfer.

• Care shall be taken to ensure that cables and their connections are not

subjected to tensile load.

• Do not hang the logger on its connection cables.

• Do not bend the connection cables.

• Make sure the logger is switched on before you leave the site.

3.5 Positioning the GSM Antenna

If your logger is equipped with a GSM modem and if you want to make use of the

GSM functionality, you have to observe the following instructions when positioning

the GSM antenna:

• The GSM antenna must be properly connected to the logger (see

section 3.2).

• Be aware that thick walls and other barriers do affect the signal strength

negatively.

• If the logger is installed underground, e.g. in a pipeline shaft, the antenna

should be positioned as near as possible to the ground surface.

Check the GSM connectivity using test functions of the SebaDataView software (see

section 5.4.7) right after the GSM antenna has been positioned. If no connection can

be established, a better position has to be found. If necessary, lead the antenna out

of the shaft and bury it a few centimetres under the ground surface.

Page 27

3-27

3.6 Switching the Logger On/Off

The logger is switched on by moving the supplied magnet in front of the contact

area . After the magnet switch has been activated, the I/O control lamp is lit

green for a moment and starts flashing green after the logger has been started up.

The device is now in energy saving mode.

Whenever a connection to an E-Box is established and whenever a data transfer

takes place, the logger automatically switches to data transfer mode.

After the logger has been switched on, it automatically starts logging as specified in

its configuration. The device keeps logging even if a data transfer takes place or an

alarm is triggered.

In order to switch the logger off, the magnet must be held in front of the contact

area for a few seconds while the I/O control lamp is lit orange. As soon as the

lamp switches to red, the magnet has to be taken away from the contact area.

Afterwards, the logger switches off and the lamp goes out.

Make sure to take the magnet away immediately after the lamp switches to red.

Otherwise, the logger reboots right after it has been switched off. Check that the

lamp does not start flashing green again.

1 2

2 1

Page 28

4-28

4 Setting Up the Software

The Sebalog D does not dispose of a display or any controls. Any communication

(configuration, data readout) with the device is performed using the SebaDataView

software.

4.1 System Requirements

Your machine must meet the following minimum system requirements in order to run

the SebaDataView software:

• PC or notebook with Windows XP® or higher

• min. Pentium compatible CPU

• min. 256 MB memory

• CD ROM drive

• USB interface

4.2 Installing the Software

To install the SebaDataView software insert the provided CD into your CD ROM

drive, execute the SDV-setup.exe and follow the instruction on the screen. The

application is installed to the C:\Program Files\SebaKMT\SebaDataView folder.

A database is created in the …\My Documents\SebaDataView\Data folder.

Do not delete any files from the Data folder.

If you would like to make the data available for other accounts, the complete

…SebaDataView\Data folder has to be transferred to the …\My Documents

folder of the respective account.

During start-up, the current version of the SebaDataView software is indicated.

Please check www.sebakmt.com regularly for updates.

Page 29

4-29

4.3 Connecting the Logger to the PC

If you would like to configure a logger or to retrieve data from a logger, a connection

to the logger has to be established first. This connection can be either established via

the VK 77 USB cable or via radio communication using the E-Box.

4.3.1 Radio Communication via E-Box

Introduction The E-Box, while connected to the PC via USB interface, offers you the possibility to

access all loggers in a range of up to 100 m (depending on the environmental

conditions) via radio link. That way, you are able to initiate a data transfer without

sitting next to the device.

If a logger receives a signal from the E-Box addressed to it, it changes from energy

saving mode to data transfer mode. During data transfer, the I/O control lamp

is lit green.

Design of the E-Box The following figure shows the E-Box:

Item Description

Antenna (replaceable)

USB socket

Control lamp

not lit: E-Box is not connected to a PC

red (flashing): E-Box is connected but not initialized

(e.g. due to missing driver)

green (permanent): E-Box is ready

orange (permanent): a data transfer takes place

red (permanent): E-Box is defective

2

10

9

8

10

8

9

Page 30

4-30

Connecting the E-Box Connect the E-Box to the USB port of your PC using the provided USB cable.

After the E-box has been connected to the PC or disconnected from the PC, it is

automatically switched on or off respectively. A green LED indicates that the E-Box is

supplied with power and ready for operation.

Driver Installation When the E-box is connected to a PC for the first time, the driver must be installed.

Windows operating systems (XP or later) will automatically identify the E-Box as new

hardware after it has been connected.

Follow the instructions on the screen and browse to the location

(C:\ Program Files \SebaKMT\SebaDataView\USBDriver) where the driver has been

automatically stored during software installation.

Windows may report that the driver is not certified and warn for possible danger.

Since the driver is not causing any danger for your system you can continue the

installation.

4.3.2 Connecting the Logger via Direct Connection

Connecting the logger To establish a direct connection to a PC, use the VK 77 USB cable supplied to

connect a USB port on the PC to the USB / DC ext. socket on the device. On the

device, make sure that the guide on the plug fits in the groove in the socket and that

you feel the plug latch in.

Driver Installation When the logger is connected to a PC for the first time, the driver must be installed.

Windows operating systems (XP or later) will automatically identify the logger as new

hardware after it has been connected.

Follow the instructions on the screen and browse to the location

(C:\ Program Files \SebaKMT\SebaDataView\USBDriver) where the driver has been

automatically stored during software installation.

Windows may report that the driver is not certified and warn for possible danger.

Since the driver is not causing any danger for your system you can continue the

installation.

4

Page 31

4-31

4.4 Starting the Software

Start the application by double-clicking on the desktop icon created during the

installation process. Alternatively, the application can be started via the Windows

start menu.

During start-up you are asked to select the language of the user interface. Make your

choice and click on OK.

The user interface of the software consists of the following basic elements:

Menu bar

Offers access to all functions of the software

Toolbar

Offers quick access to frequently used

functions of the software.

Logger tree

All registered loggers are arranged in a

directory structure of groups and sub-groups.

Each logger is indicated by its ID and a

comment.

Display area

This area contains the active dialog window.

Page 32

4-32

4.5 Registering a Logger

In order to configure or read out a logger, the device has to be added to the

database, if this has not been done before. All loggers which have been added to the

database are shown in the logger tree on the left side of the screen.

4.5.1 Adding / Deleting a Logger

Adding a logger Perform the following steps in order to add a logger to the database:

Step Action

1

Select a group in the logger tree, the logger shall be assigned to (see

also section 4.5.2).

Proceed in one of the following ways:

o Select Group -> New logger from the menu bar.

o Select from the toolbar.

o Right-click on the group name in the logger tree and select

New logger from the context menu.

2

Result: The following window appears:

Enter the Identification Number of the logger into the respective field.

The ID can be taken from a label which is located at the bottom of the

device and looks as follows:

3

The logger ID is a six-digit number. Prefixed zeros can be ignored.

So 815 can be entered for a logger with the ID 000815.

4 Enter a Comment into the respective field (e.g. location of the logger).

Save the data by clicking OK. 5

Result: The logger is now visible in the logger tree.

ID: 000815

Page 33

4-33

Deleting a logger Perform the following steps in order to remove a logger from the database:

Step Action

1

Select the logger to be deleted in the logger tree.

2

Proceed in one of the following ways:

o Select Logger -> Delete from the menu bar.

o Right-click on the logger in the logger tree and select Delete from

the context menu.

Confirm the deletion by clicking on OK. 3

Result: The logger is removed from the logger tree.

You can move a logger within the logger tree via drag and drop. This way, a

logger can be assigned to another group.

4.5.2 Adding / Deleting a Group

The registered loggers can be combined in groups. These groups and sub-groups

form the folder structure of the logger tree.

Adding a group Perform the following steps in order to add a group to the logger tree:

Step Action

1

Select the parent folder (existing group or root folder) where you want the

new group to be placed in.

Proceed in one of the following ways:

o Select Group -> New group from the menu bar.

o Select from the toolbar.

o Right-click on the group name in the logger tree and select

New group from the context menu.

2

Result: The following window appears:

3 Enter the name of the group into the Group field.

4 Enter a short description of the group into the Description field.

Save the data by clicking OK. 5

Result: The group is now visible in the logger tree.

Page 34

4-34

Deleting a group Perform the following steps in order to remove a group from the logger tree:

Step Action

1

Select the group to be deleted in the logger tree.

If a group is deleted, all loggers assigned to this group and its subgroups are deleted too and the collected data is lost. Move the logger

to another group first, if you want to keep the data.

2

Proceed in one of the following ways:

o Select Group -> Delete from the menu bar.

o Right-click on the group name in the logger tree and select Delete

from the context menu.

Confirm the deletion by clicking on OK. 3

Result: The group is removed from the logger tree.

You can move a group within the logger tree via drag and drop.

Page 35

5-35

5 Configuring the Logger

Introduction Before a logger can be installed in the field, the device has to be properly configured.

In doing so, you can specify the inputs / outputs, the logging intervals, the alarm

conditions and the radio communication settings, among other things.

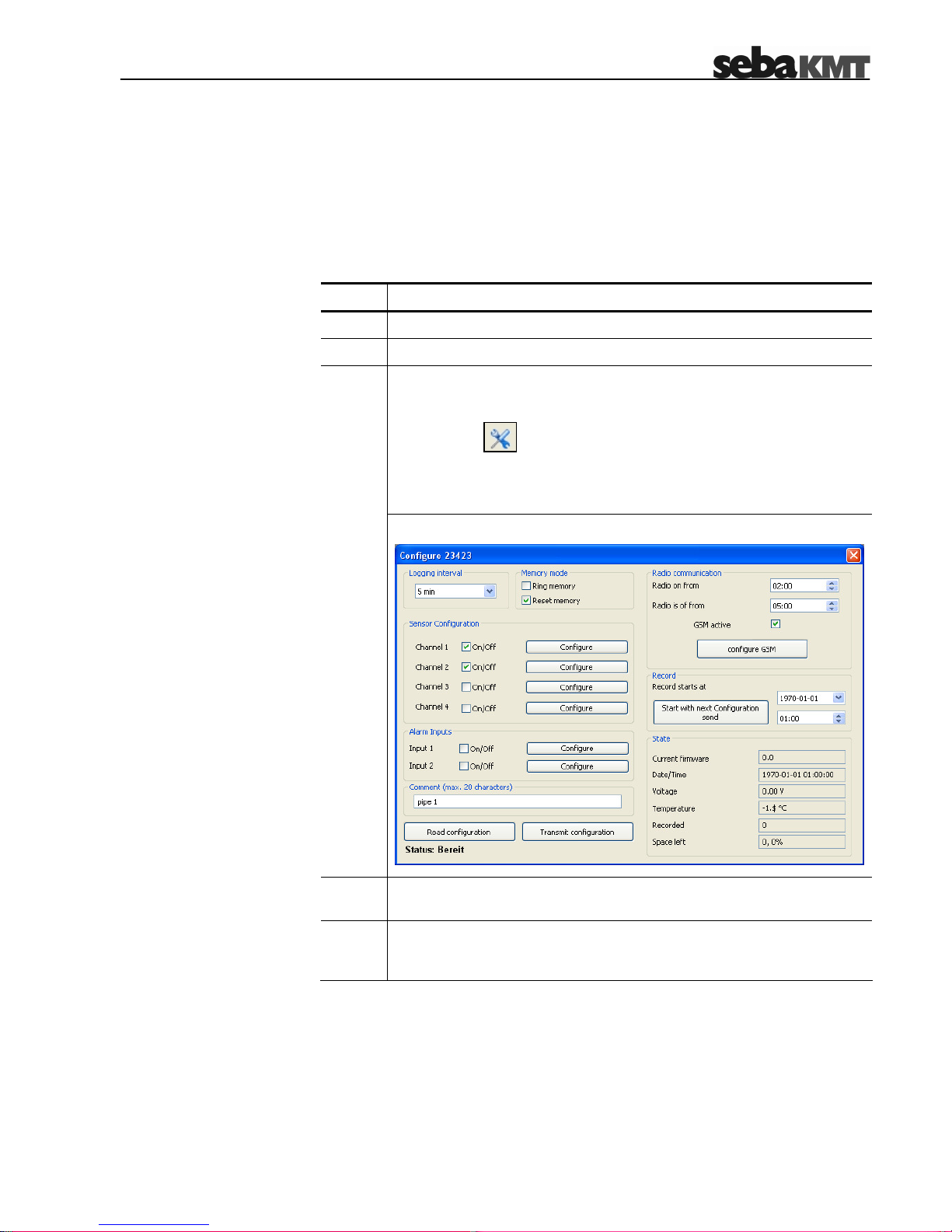

Preparation Proceed as follows to access the configuration of a specific logger:

Step Action

1

Make sure the logger is connected to the PC and switched on.

2

Select the logger you want to configure in the logger tree.

Proceed in one of the following ways:

o Select Logger -> Configuration from the menu bar.

o Select from the toolbar.

o Right-click on the logger in the logger tree and select

Configuration from the context menu.

3

Result: The following window appears:

4

Read out the effective configuration from the logger using the

Read configuration button.

5

Configure the logger as described in the following sections and,

afterwards, transmit the new configuration data to the device as

described in section 5.8.

Page 36

5-36

5.1 Selecting the Logging Interval

You can select the time interval in which the measured values are logged from the

Logging interval drop-down list.

5.2 Sensor Configuration

Depending on its configuration, up to 4 sensors can be connected to a logger. In

order to evaluate the logged data in the right way, the logger needs to know which

type of sensor is connected to which channel.

Introduction

• Make sure that the sensor configuration is consistent with the effective

connection setup. Each channel is linked with specific wires of the

VK 75/76 connection cables. For a detailed description, please refer to

section 3.3.1.

• Please pay regard to the fixed channel allocations when configuring

internal pressure sensors or sensors with current output (see section

3.3.1.1).

• Make sure you enter the values in the same format as shown in the figures.

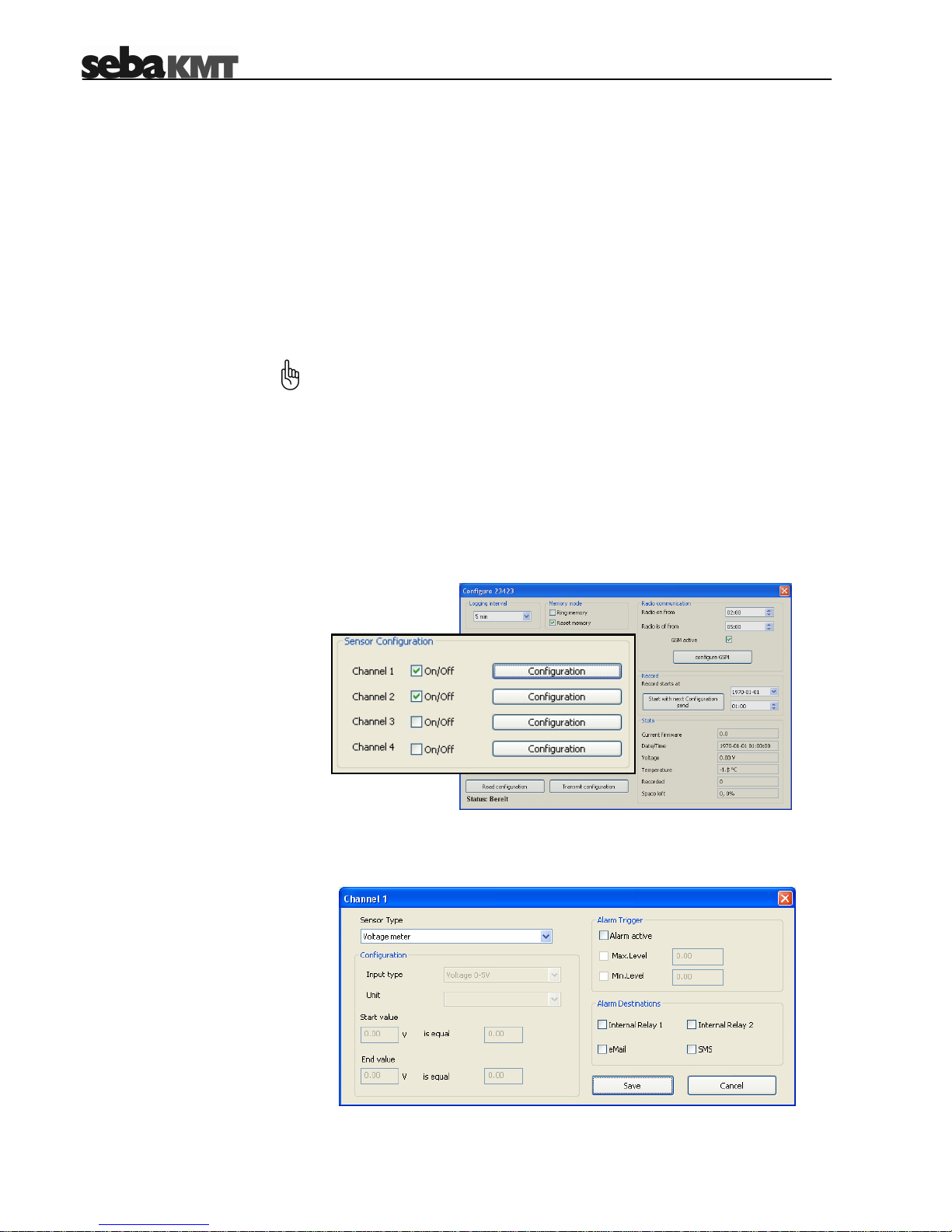

Activating channels First of all, you have to specify which channels are in use (connected to a sensor)

during the upcoming operation period. A channel can be activated by marking the

respective On/Off checkbox exemplified by the following figure:

Configuring a channel After a channel has been activated, it has to be specified which type of sensor is

connected to the channel. Click the respective Configuration button. The following

window appears:

Page 37

5-37

5.2.1 Sensor Type

Selecting the sensor type Select the sensor connected to the channel from the drop-down list. The sensors

contained in this list are parameterized and no further configuration is required. The

internal pressure sensors (Seba Standard Pressure) of the Sebalog D are also part

of this list. The measuring range of the internal pressure senor can be obtained from

the type number of the logger (see section 2.3). If the sensor type is not contained in

the drop-down list, the customer specific entry has to be selected.

5.2.1.1 Configuring a „Customer Specific“ Sensor

Introduction The physical value measured by the sensor is transformed into an electrical signal

(e.g. voltage, pulses, frequency) which is used to transmit the data to the logger. In

order to transform this carrier signal back into the original physical values, the logger

needs to know how the ranges are correlated to each other.

If a predefined sensor from the drop-down list has been selected, these parameters

have been automatically populated.

However, in the case of a customer-specific sensor, the input type (carrier) and the

unit of the physical value have to be specified manually. Furthermore, the upper and

lower thresholds of the input signal and the correlating measurement values have to

be specified.

Configuring the input type Perform the following steps to configure the input type of a customer-specific sensor:

Step Action

1

Select the type of signal, the sensor uses to pass the measured data to

the logger from the Input type drop-down list.

2

Select the unit of the physical value measured by the sensor from the

Unit drop-down list.

Depending on the selected input type and value, some additional fields

may need to be populated with the upper and lower thresholds of the

input signal and the correlating measurement values.

3

For detailed information about the input type and the ranges, please

refer to the manual of the connected sensor.

Correlating measured values

Input signal thresholds

Page 38

5-38

5.2.1.2 Input Type Examples

Input type Voltage

A 10 bar pressure sensor with voltage output is connected to a channel of the

logger.

Input type: Voltage 0-5V

Unit: bar

The lower limit of the measuring range (0 bar) is indicated by a voltage value of 0 V

while the upper limit (10 bar) correlates with 5 V. As a result, the fields must be

populated as follows:

The maximum permissable input voltage is 5 V. Higher input voltages may

damage the device.

Input type Frequency

A level meter with frequency output is installed in a 430 l tank.

Input type: Frequency

Unit: l

The maximum level of 430 l is indicated by a frequency of 1000 Hz. As a result, the

fields must be populated as follows:

The maximum permissable frequency is 1000 Hz. If the connected sensor

transmits higher frequencies, a frequency divider must be interconnected.

Page 39

5-39

Input type Pulse

A flowmeter with a di

gital pulse output is connected to a channel of the logger. The

flowmeter transmits one pulse per 16 litre.

input type: Pulse

Unit: l

The flow can be measured per hour or per second. If per hour is selected, the

logging interval must be higher than 15 minutes. Otherwise, an error message

appears.

Determining the leading

sign for another channel

A flowmeter is connected to channel 2. In addition to the flow rate itself, the flow

direction shall be determined. For this purpose, a sensor which indicates the flow

direction by means of voltage values is connected to another channel of the logger.

Input type: Sign slave for other channel

First of all, it has to be specified which direction is indicated by the 5 V value. A

voltage value of 0 V automatically indicates the opposite direction. Furthermore, the

channel (flow), the determined flow direction applies to, has to be selected (in this

case Channel 2).

Page 40

5-40

5.2.2 Configuring Alarm Conditions (Threshold Monitoring)

Introduction The Sebalog D can trigger an alarm whenever a specified minimum or maximum

threshold is crossed.

That way, up to two connected devices (e.g. a pump or a valve) can be triggered by

the internal relays.

Furthermore, alarm messages can be sent via SMS or email, if GSM connectivity

has been established and properly configured (see sections 3.2 and 5.4).

The alarm thresholds must be individually specified for each channel.

Configuring alarms Perform the following steps to configure the alarm thresholds and the alarm

destinations:

Steps Action

1 Activate the Alarm active checkbox in order to enable alarming for this

channel.

2

Specify whether there is a minimum and / or a maximum threshold to be

monitored by activating the respective checkbox(es).

3

Enter the minimum and / or the maximum threshold into the respective

field(s).

Specify under Alarm Destinations which of the relays shall switch in the

case of an alarm and which type of alarm message shall be sent.

4

The internal relay of single-channel loggers (LOG D-1) is always

Relay 2!

Page 41

5-41

When a maximum threshold is exceeded, the device connected to the internal relay

is switched on. The device is switched off as soon as the measured value falls below

the threshold again. This applies for the lower threshold the other way around.

A relay cannot be assigned to more than one alarm. If a relay is already

included in an existing channel configuration, it cannot be used in combination

with any other channel or switching input (see section 5.3).

5.2.3 Finishing the Configuration

Confirm and save the configuration of a channel by clicking the Save button.

Perform the configuration for the remaining channels.

Page 42

5-42

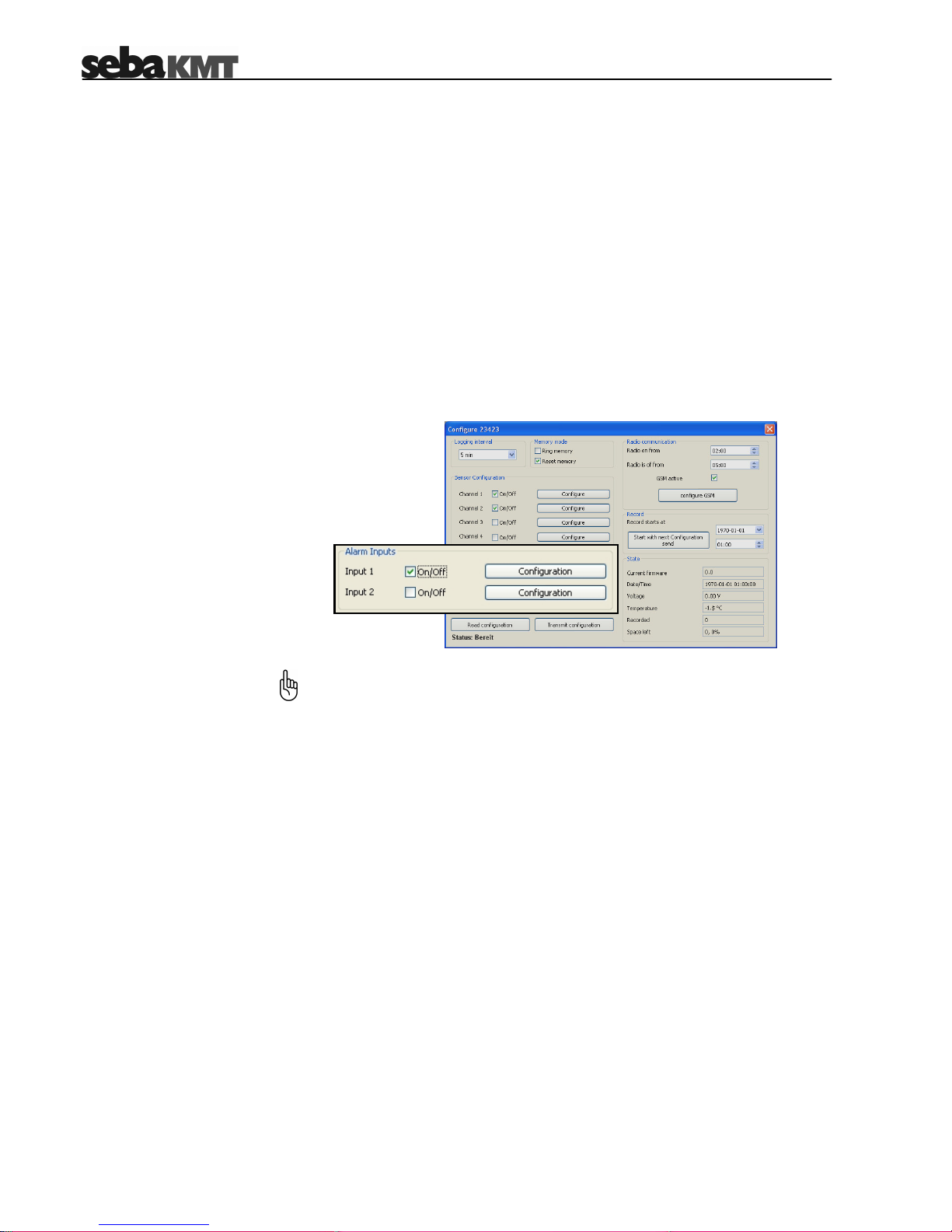

5.3 Configuring the Switching Inputs (Alarm Inputs)

Introduction Depending on its configuration a logger can be equipped with up to two switching

inputs (alarm inputs) which can be connected to active circuits. For each of these

inputs, it can be specified which input voltage value causes an alarm. An example of

such an alarm loop is shown in section 3.3.1.4.

As known from the channel configuration, an alarm can trigger up to two internal

relays.

Furthermore, alarm messages can be sent via SMS or email, if GSM connectivity

has been established and properly configured (see sections 3.2 and 5.4).

First of all, you have to activate the Alarm inputs which are going to be part of an

alarm input during the upcoming operation period by marking the respective On/Off

checkbox:

Activating an

alarm input

The switching input of single-channel loggers (LOG D-1) is always Input 2!

Page 43

5-43

Configuring an

alarm input

After an alarm input has been activated, it must be specified which input voltage

value causes an alarm and which actions are triggered by an alarm. Click the

respective Configuration button. The following window appears:

Proceed as follows to configure an alarm input:

Step Action

1

Specify the input voltage value which does, when present at the

switching input, trigger an alarm.

The input voltage threshold is 2.5 V. Any voltage value below 2.5 V is

interpreted as 0 V while voltages higher than 2.5 V are interpreted as

5 V. In order to ensure a reliable classification, the actual voltage values

should not be too close to 2.5 V.

2 Specify under Alarm Destinations which of the relays shall switch in

the case of an alarm and which type of alarm message shall be sent.

3 Confirm and save the settings by clicking the Save button.

The internal relay of single-channel loggers (LOG D-1) is always Relay 2!

A relay cannot be assigned to more than one alarm. If a relay has been already

assigned to a switching input, it can neither be assigned to the other switching

input nor be used for threshold monitoring (see section 5.2.2).

Page 44

5-44

5.4 Configuring the Radio Communication

Configuring a timeframe

for radio communication

Data transfer between logger and PC can be performed via radio connection using

the E-Box (see section 4.3.1). If radio communication is going to be established

during a specific timeframe only (e.g. during daytime), the range of this timeframe

has to be specified via the Radio on from and Radio is off from fields. Out of this

timeframe, the logger is not accessible via radio interface. That way, energyintensive changes from energy saving mode to data transfer mode can be avoided.

If the same time value is entered in both fields, radio access is not restricted.

Page 45

5-45

If the logger is equipped with a GSM modem, the logger can be used for alarm

messaging via email and SMS. Furthermore, periodical data transfer to a FTP server

can be set up.

For this purpose, a GPRS-enabled SIM card (data contract) is required which can be

obtained from almost any local mobile network operator.

Configuring the

GSM settings

Usually, all the data required to set up mobile data transfer is provided within the

contract. Further information can be obtained from the website or the hotline of

the mobile network operator. If necessary, request guidance for setting up data

communication in particular. SebaKMT cannot provide any specific technical

advice in this case.

Proceed as follows to set up data communication via GPRS:

Step Action

1

Make sure the logger has been properly prepared for GSM connectivity

(see section 3.2).

2 Activate the GSM active checkbox in order to enable the GSM

functionality.

Click the configure GSM button. 3

Result: The following window appears:

4

Configure the interface settings as described in the following sections.

Page 46

5-46

5.4.1 SIM Card Configuration

Enter the phone number and the PIN code of the SIM card into the respective

fields. These numbers are an essential part of the contract data.

5.4.2 Configuring the Internet Access Point of the Network Operator

Populate the fields under Internet configuration with the access point data

provided by your mobile network operator. Normally, this information can be taken

from the contract data. Otherwise, contact your mobile network operator.

If your operator is contained in the Templates drop-down-list, the data is

automatically filled in.

5.4.3 Email Configuration

Perform the following steps, if you want to enable alarm messaging via email:

Step Action

1 Enter the SMTP server address (SMTP), User and Password of the

account used for email transmission into the respective fields.

If the mail server of your company is not capable for this task (e.g. due

to a firewall), a webmail account from an internet service provider

(e.g. Yahoo or Google) can be used instead, if its SMTP settings are

known. Usually, this kind of information can be obtained from the “How

to configure an email client” tutorial on the providers’ website.

Username and password can be specified during the account setup

procedure or can be requested from your system administrator.

SebaKMT does not provide email accounts.

2 Enter a sender email address into the Name field. This address should

clearly indicate the logger, the email has been sent from

(e.g. Logger815@group2.de). This makes it easier to localize where the

alarm has been raised.

3

Enter the recipient address, the alarm message shall be send to, into

the eMail field.

4

Optionally, enter another recipient address, receiving a copy of the

alarm message, into the eMail CC field.

Page 47

5-47

5.4.4 FTP Settings

If you want the logged data to be transferred to a FTP server at regular intervals, you

have to specify the server settings. You can ask your administrator to set up a FTP

server using the server infrastructure of your company or you can rent a server from

an ISP. In the latter case, all required information (server address, port, username

and password) have to be obtained from the service provider.

In order to activate the FTP transfer, please check the activated checkbox under

FTP Settings and populate the fields with the data of your FTP server.

After the server has been activated and configured, a data transfer takes place each

day or after 500 data sets have been collected respectively.

A logd folder must be created on the FTP server. Furthermore, a subfolder

named similar to the logger ID (plus two leading zeros) must be created inside

this folder.

Example: In order to enable FTP data transfer for a logger with the ID 000815,

the …/logd/00000815 folder must be crated on the FTP server.

5.4.5 SMS Destinations

You can specify up to three mobile numbers where alarm messages via SMS shall

be sent to under SMS destination.

5.4.6 Summary Messages

Under Summary you can specify whether or not a summary message containing the

highest and lowest measured values of the day or week shall be sent to all mobile

numbers / email addresses stored in the database. To do so, please proceed as

follows:

Step Action

1

Check the respective checkbox in order to activate a summary message

via SMS and / or email, whereupon new fields are activated.

2 Specify whether a daily or weekly summary message shall be sent by

checking the respective checkbox.

3

Specify the point in time and, if required, the day of the week, the

message shall be sent.

Make sure to enter the values in proper format. Time values are specified in

24-hour format.

Page 48

5-48

5.4.7 Testing the GSM Settings

You can send a test email or a test SMS in order to check whether a GSM

connection can be established with the active settings. Furthermore, the FTP settings

can be tested by creating a file to the respective FTP folder.

The GSM configuration must have been already finished (see previous

sections) and the settings must have been transferred to the logger before a

test can be performed (see section 5.8).

5.4.7.1 Testing SMS / Email Transmission

Perform the following steps to send a test SMS / email:

Step Action

Click on the Test GSM settings button. 1

Result: A new window appears

Click on the Send Test SMS button or the Send Test eMail button in

order to send a test SMS or email respectively. During transmission, the

I/O control lamp is lit orange.

2

Result: If the transmission has been successfully completed, all

addressees should receive a SMS or email of the following layout:

2

LOG D; ID 00815

(comment):

18.03.2008

12:44:27

SignalQ: 13

NetWorkReg: 1

Identification number of the logger

Date and time of the test

Signal quality

Network registration status

Page 49

5-49

(Continuation from previous page:)

Step Action

If no SMS or email has been received, the logger probably failed to

establish a GSM connection.

Click on the Read GSM log button in order to identify possible sources

of the problem. A message of the following layout appears in the display

area:

3

The comment behind the error code can be a good indication of the

source of the problem. In the case of a PIN ERROR, e.g., you should

check the SIM card configuration (see section 5.4.1).

In the case of bad signal quality (SignalQ 0 or 1), it may help to move

the GSM antenna in a better position (see section 3.5).

If the network registration has failed, use a mobile phone to check

whether the SIM card works.

GSM LOG:

12:44:27 18.03.2008

Code 14, PIN Error

SignalQ: 0 Bad

Net: 0 Not registered,

search stopped

Signal quality: 0-1 … bad

2-15 … average

16-30 … good

Error code with comment

Date and time of the test

Network registration status:

0 … „not registered, search stopped“ 4 … “unknown”

1 … „registered, home network” 5 … “registered, roaming”

2 … “not registered, searching…” default … “unknown code”

3 … “registration denied!”

Page 50

5-50

5.4.7.2 Testing FTP Data Transfer

Perform the following steps to check the FTP settings:

Step Action

Click on the Test GSM settings button. 1

Result: A new window appears.

Click on the Send Test FTP data button. Thereupon, the logger tries to

create a test file inside the respective folder on the FTP server. During

the test procedure, the I/O control lamp is lit orange.

2

Result: If a file has been created in the folder, the test was successful.

3

If no file has been created, the logger probably failed to establish a GSM

connection or was not able to establish a connection to the server. Click

on the Read GSM log button in order to identify possible sources of the

problem (see step 3 of previous section). Do also check the FTP

settings.

5.4.8 Finishing the Communication Setup

Close and save the communication settings by clicking on the Save button.

5.5 Start Time

The point in time, the logger starts logging, has to be defined under Record.

You can specify a point in time using the controls. If you click on the Start with next

Configuration send button, logging starts right after the configuration has been

transmitted to the logger.

2

Page 51

5-51

5.6 Memory Mode

The logger has 2 MB internal memory. By default, the device stops logging as soon

as the memory is full.

By checking the Ring memory checkbox, the logger can be set to ‘ring buffer’ mode.

As the memory fills up with data in this mode, the device keeps logging and the

respective oldest value is overwritten.

By checking the Reset memory checkbox, the memory is cleared. Afterwards, you

have to confirm the deletion of the data. The memory is cleared as soon as the

configuration is transmitted to the logger.

5.7 State

Some characteristic data about the logger are listed under State. The data has been

derived during the last data or configuration readout. Amongst others, the remaining

memory in percent and the supply voltage are indicated.

If EXT is displayed instead of an actual voltage value, the logger is connected to an

external power supply.

5.8 Finishing the Configuration

Adding a comment

By adding a comment to the Comment field you can take some notes, e.g., on the

location of the logger.

Transmitting the

configuration data

Click on the Transmit configuration button in order to finalize the configuration

and to store the settings on the logger. Thereupon, the data is transmitted to the

logger.

After the settings have been saved on the device, a confirmation message appears.

If no connection to the logger can be established, an error message appears.

Check the link between logger and PC (see section 4.3) and try to transmit the data

again.

Page 52

6-52

6 Retrieving and Evaluating Data

6.1 Retrieving Data from the Logger

The data can be readout via cable connection (see section 4.3.2) or radio link (see

section 4.3.1). Proceed as follows, to readout the data from the logger:

Step Action

1

Make sure, the logger is connected to your PC (either via USB cable or

via E-Box).

2

Mark the logger, you want to collect the data from, in the logger tree.

Proceed in one of the following ways:

o Select from the toolbar.

o Right-click on the logger in the logger tree and select Read data

from the context menu.

3

Result: A new window appears.

4

If you would like to receive only these data sets which are not already

contained in the local database, check the Read only new data

checkbox. Otherwise, all data stored on the logger is transmitted which

may considerably increase the transmission time, if the logger is

connected via radio link.

5 Click on the Read data using EBox / USB cable button to readout the

data from the logger.

A progress bar indicates the progress of the transmission.

6 After the data transfer has been finished, click on the Open button. A

new window appears and the data is presented in a diagram.

You can evaluate the data and change the way the data is represented

in the diagram using the functions described in section 6.3.

Page 53

6-53

6.2 Collecting Data from the FTP Server

If the logger is equipped with a GSM modem, the logged data can be automatically

transmitted to a FTP server (see section 5.4.4). You can access a FTP server from

any PC with an internet connection.

Proceed as follows to download the data from the FTP server:

Step Action

1 Select Program Settings -> Settings from the menu bar and enter

server address, username and password into the respective fields under

FTP settings. Confirm the settings by clicking the Save button.

2

Mark the logger, you want to collect the data from, in the logger tree.

Proceed in one of the following ways:

o Select from the toolbar.

o Right-click on the logger in the logger tree and select Read data

from the context menu.

3

Result: A new window appears.

4

If you would like to receive only these data sets which are not already

contained in the local database, check the Read only new data

checkbox. Since, in most cases, the data is downloaded via broadband

connection, this option does not affect the transfer time.

5 Click on the Read data from FTP server button to download the data

from the FTP server.

A progress bar indicates the progress of the transmission.

6 After the data transfer has been finished, click on the Open button. A

new window appears and the data is presented in a diagram.

You can evaluate the data and change the way the data is represented

in the diagram using the functions described in section 6.3.

Page 54

6-54

6.3 Evaluating Measured Data

Displaying the

measured data

After the measured data has been retrieved from the logger (see section 6.1), the

progression of the measured values can be illustrated in a diagram and, by this

means, can be easily evaluated.

Proceed as follows to display the data of a specific logger:

Step Action

1

Mark the logger whose data you want to display in the logger tree.

Proceed in one of the following ways:

o Select Logger -> Display data from the menu bar.

o Right-click on the logger in the logger tree and select Display

data from the context menu.

2

Result: The following window appears:

Diagram The curves of the different channels share in one diagram. The X-axis represents the

timeline while the Y-axis represents the measured values.

By clicking on a curve, the channel is selected and the curve is shifted to the

foreground.

By double-clicking the diagram, the diagram properties can be changed.

Info bar If you click on a channel in the blue info bar at the top right of the window, the

respective curve is shifted to the foreground and some characteristics of the channel

are displayed in the info bar.

The values shown in the info bar result only from the visible part of the curve. Any

maximum or minimum values outside of the current visible time range are not

considered.

By selecting a channel / curve, the unit of the Y-axis is adapted to the respective

measurement. However, the scaling does not change.

Page 55

6-55

Navigating through the

measured values

You can use the navigation panel at the lower right of the window to navigate:

Arrow keys Scrolling along the axes

Magnifier Zooming in and out

In addition you can use the mouse wheel for navigation (you have to click on the

diagram first):