Page 1

Operating instruction

Hydrolux® Leak locator

HLE 500

Produktbild wie in den Prospekten ohne Rahmen

Ansprechpartner Frau Badziura

HLE 5000

Version 1.0

Mess- und Ortungstechnik

Measuring and Locating Technologies

Elektrizitätsnetze

Power Networks

Kommunikationsnetze

Communication Networks

Rohrleitungsnetze

Water Networks

Leitungsortung

Line Locating

Edition: 02 (2005/02)

Page 2

Operating instructions HLE 500/5000

II

MAN_HLE500_HLE5000_eng_02

Page 3

Operating instructions HLE 500/5000

III

Quality certificate

The quality control system used by Seba Dynatronic® and

sebatel® meet the highest requirements of the

international quality standard DIN ISO 9001 and the

European standard EN 29001. This quality system was

approved by the German Association for the Certification

of Quality Systems with the numbers EN 19677 and DQS

19677-01.

How do you contact us?

SebaKMT

Mess- und Ortungstechnik GmbH

Dr.-Herbert-Iann-Str. 6

96148 Baunach, Germany

Telephone: +49 (0) 9544 680

Fax: +49 (0) 9544 2273

Email: sales@sebakmt.com

MAN_HLE500_HLE5000_eng_02

Internet: www.sebakmt.com

Page 4

Operating instructions HLE 500/5000

IV

MAN_HLE500_HLE5000_eng_02

Page 5

Operating instructions HLE 500/5000

V

Table of contents

1 Description 1

1.1 General 1

1.2 Construction 2

1.3 Technical data 2

1.4 Delivery includes 3

1.4.1 5000/500 equipment 3

1.4.2 Selectable microphone sets 3

1.4.3 Optional accessories 4

2 Getting to know the HLE 5000/500 5

2.1 HLE 5000/500 controls 5

2.2 Connections at the side 5

2.3 Battery chamber 6

2.4 Automatic battery monitoring 7

2.5 Illumination of the LCD display 7

2.6 Microphones 7

2.6.1 PAM W-1 8

2.6.2 PAM U 9

2.7 Headphones 10

3 Practical work 11

3.1 Headphones and microphone connection 11

3.2 Switching on

3.3 Volume and amplification 12

3.3.1 Setting the volume 12

3.3.2 Setting the gain 13

3.4 The amplification display 13

3.5 Filter setting (only HLE5000) 14

3.5.1 Adjusting the cut-off frequencies 14

3.6 Filter selection in practice 15

3.6.1 Filter selection A (Ground microphone PAM W-1, PAM U with 3-point

foot) 16

3.6.2 Filter selection B: Sensor rod (Pam U with spike) 16

3.7 Mute button

3.8 The histogram 16

3.9 Long-term measurement (HLE 5000 only) 18

3.10 Location of pipes using the RSP-3 or PWG (HLE 5000 only) 19

3.11 Switching off

11

X

16

19

4 Faults 20

4.1 Can't switch on 20

4.2 Battery monitor does not react 20

4.3 No sound can be heard 20

4.4 Scratching sounds in the headphones 20

MAN_HLE500_HLE5000_eng_02

Page 6

Operating instructions HLE 500/5000

VI

List of illustrations

Fig 1 : HLE 5000/500 control panel...................................................5

Fig 2 : Side view left and right with connections................................6

Fig 3 : Base plate with locking screws...............................................7

Fig 4 : PAM U with sensor rod...........................................................9

Fig 5 : PAM U with magnet................................................................9

Fig 6 : PAM U with 3-point foot........................................................10

Fig 7 : Start image with version number..........................................11

Fig 8 : Opening menu after switch-on..............................................12

Fig 9 : Setting the volume................................................................12

Fig 10 : Setting the gain.....................................................................13

Fig 11 : Current and minimum value .................................................14

Fig 12 : Filter settings........................................................................14

Fig 13 : Adjusting the lower filter cut-off frequency............................15

Fig 14 : Adjusting the upper filter cut-off frequency...........................15

Fig 15 : Dual segment analysis (DSA)...............................................17

Fig 16 : Histogram measurement ......................................................17

Fig 17 : Long-term measurement ......................................................18

MAN_HLE500_HLE5000_eng_02

Page 7

Operating instructions HLE 500/5000

1 Description

1.1 General

The new HLE 5000/500 leak locator comprehensively deals

with finding leaks in pipe networks for the supply of drinking

water. The equipment can of course be used on other pipe

systems, provided that the liquid comes out of the pipe under

pressure and that the resulting noise carries to the surface of

the ground. With the HLE 5000/500 it is possible to both prelocate and to pinpoint the location of the fault. With a special

Dual Segment Analysis (DSA) display, both the minimum

value of the constant noise as well as the leak noise can be

recognised. With the “Mute” option, used when moving the

ground microphone, a new minimum display results. A

comparison of the measured values is thus always possible.

In the “HISTOGRAM” function, each measurement location is

stored, one by one.

This equipment is the first instance where computer

supported reduction of extraneous noise is used, where

impulse type disturbances are acoustically suppressed.

Preferably, only constant noise (as produced by a leaking

pipe) is displayed as a minimum value.

When locating plastic pipes with the assistance of an RSP3

“pipe pecker”, picking up impulses is then desirable and

improves the results. For this reason, the HLE 5000 has a

special pipe location mode that is activated, after switching

on, by pressing the symbol button.

Another important function of the HLE 5000 is the noise level

recording with which the course of the development of the

noise is shown on the LCD display as a graph over time.

1

MAN_HLE500_HLE5000_eng_02

Page 8

Operating instructions HLE 500/5000

1.2 Construction

The leak location equipment is in a splash-proof housing

made of robust plastic. The few control buttons are so

arranged that they can also be operated wearing gloves. The

display is equipped with backlighting. That means that work is

also possible under poor lighting conditions, or at night.

The batteries required to supply the power are housed in the

base of the equipment behind a cover which is easy to open

to quickly exchange the batteries. The connections for the

microphone and headphones are on the two sides of the

equipment and can be quickly plugged in or removed.

2

1.3 Technical data

Analysis bandwidth: 0 Hz – 4000 Hz

Filter cut-off frequencies: 0 - 70 Hz, 106 Hz, 160 Hz,

Histogram recordings: 9 dual displays

Storage of noise levels: 3 – 10 – 30 min

Display 130 x 36 mm: LCD display

LCD illumination: available

Power supply 1:

Power supply 2 (option):

Operating time: > 35 h (battery),

Storage: 9 measurements

Mute button: available

Operating temperature: -10 to +50 °C

Storage temperature: -10 to +70 °C

Protection class when in

operation:

Dimensions (L x W x D): 215 x 95 x 110 mm

Weight: HLE 5000

Weight: PAM W-1

Weight: PAM U

240 Hz, 360 Hz, 540 Hz,

800 Hz, 1200 Hz, 1800 –

4000 Hz

10 x AA batteries, (1.5 Volt)

12 x rechargeable batteries

(1.2 Volt)

> 15 h (rechargeable battery)

IP 54

1200 g (with batteries)

3.5 kg (with carrying pole)

500 g

MAN_HLE500_HLE5000_eng_02

Page 9

Operating instructions HLE 500/5000

1.4 Delivery includes

1.4.1 5000/500 equipment

Leak location equipment with batteries HLE 5000 or HLE 500

Headphones

(extraneous noises filtered)

Carrying strap

Case HLK

Operating instructions BED HLE 5000

1.4.2 Selectable microphone sets

Professional set consisting of:

Piezo ground microphone

(with wind shield)

Connection cable to PAM W-1 VK65

3-point foot adapter PAM W-1D

Carrying pole for PAM W-1

Universal PAM U microphone PAM U

Magnetic adapter

Sensor rod

3-point foot for PAM U PAM U-D

Extension rod VST T-1

Ground microphone (with wind shield) consisting of:

Piezo ground microphone

(with wind shield)

Connection cable to PAM W-1 VK65

3-point foot adapter PAM W-1D

Carrying pole for PAM W-1

Ground microphone

Piezo ground microphone PAM B-1

Connection cable to PAM W-1 VK65

Carrying pole for PAM B-1

Universal microphone

Universal microphone PAM U

Magnetic adapter

Sensor rod

3-point foot adapter for PAM U PAM U-D

KR 2

PAM W-1

PAM W-1

3

MAN_HLE500_HLE5000_eng_02

Page 10

Operating instructions HLE 500/5000

1.4.3 Optional accessories

4

Radio module for wireless

transmission between microphone

and amplifier

Sensor rod extension VST T-1

Special headphones

(highly insulated from extraneous

noise)

Sliding adapter 42 mm AD S-42

Sliding adapter 20 mm AD S-20

Magnetic adapter

PAM 868

KM2

MAN_HLE500_HLE5000_eng_02

Page 11

Operating instructions HLE 500/5000

I/O

HYDROLUX

®

with backlight

2 Getting to know the HLE 5000/500

Before putting the equipment into operation, you should get

to know all of the controls, the devices which can be

connected and the power supply.

2.1 HLE 5000/500 controls

5

ON/OFF/

backlight

button

Mute button

2.2 Connections at the side

LCD display

X

Fig 1 : HLE 5000/500 control panel

Volume

control

Soft keys

The sockets for the microphone and the headphones are on

the two sides of the equipment. The connections are shown

in fig 2.

MAN_HLE500_HLE5000_eng_02

Page 12

Operating instructions HLE 500/5000

connection

6

Headphones

connection

2.3 Battery chamber

Microphone

Fig 2 : Side view left and right with connections

The sockets are only suitable for headphones and

microphones from SebaKMT. Connecting other headphones

or microphones can lead to equipment failure or damage to

the HLE 5000/500.

After opening the base flap (fig. 3) the battery chamber is

accessible. When fitting the batteries make sure that the

polarity is correct.

MAN_HLE500_HLE5000_eng_02

Page 13

Operating instructions HLE 500/5000

Locking screws

Fig 3 : Base plate with locking screws

2.4 Automatic battery monitoring

7

When working with the leak detection equipment, the state of

the batteries is monitored continuously. Should the battery

voltage drop too far, this will be indicated by a flashing

battery symbol in the top right of the display.

From that point, there is about 4 hours of battery life

remaining.

When you have to change the batteries, change all

10 batteries at one time!

2.5 Illumination of the LCD display

By briefly pushing the on/off button

equipment is turned on, the illumination for the display will be

activated / deactivated.

2.6 Microphones

The microphones are connected to the leak location

equipment via a cable. The socket for this connection is on

the right hand side of the equipment (see fig. 2). To record

the sound of leaks there are various sensors/ground

microphones available. A sensor rod microphone is used to

listen to sounds from directly accessible pipe parts, such as

hydrants or valves. Each sensor is used as follows:

when the

MAN_HLE500_HLE5000_eng_02

Page 14

Operating instructions HLE 500/5000

2.6.1 PAM W-1

The PAM W-1 is an active piezo ground

microphone for roads and hard ground

coverings. The microphone is particularly well

shielded from the wind, using a bell-shaped

guard. The carrying pole can be removed with

a quarter turn to the left. This is particularly

useful in reducing extraneous noise to a

minimum when there is a strong wind.

For this ground microphone a VK 65

connection cable is required.

Important note: Piezo-electric microphones should not

be subject to shocks so place them gently in position!

8

MAN_HLE500_HLE5000_eng_02

Page 15

Operating instructions HLE 500/5000

2.6.2 PAM U

PAM U was developed primarily as a sensor rod or contact

microphone, but can be used universally by exchanging the

contact point for various adapters.

Sensor rod variant:

In this variant the PAM U is suitable for listening to

valves, hydrants or even directly on a pipe.

It is particularly good when used as a ground

microphone on soft ground (soil, meadow etc.). Push

the point as deep as possible into the ground to get

optimum acoustic contact to the source of the noise.

When using an extension rod VST 1 the working

posture is more comfortable but, due to the extension,

wind and surrounding sources of noise are more

intrusive.

Take care: When pulling the microphone out, always

pull the body of the microphone and not the cable,

otherwise you may damage the cable.

9

Fig 4 : PAM U with sensor rod

Magnetic variant:

When you hold the microphone, even the smallest

movement creates loud noises that can interfere

with the measurement. It is thus ideal if you can let

go of the microphone during a measurement. The

magnet screwed in at the front is suited to that. Due

to the high holding force of the magnet an excellent

acoustic coupling is achieved. This is however only

possible when in contact with ferromagnetic

materials, not with plastic, some stainless steels,

etc.

Fig 5 : PAM U with magnet

MAN_HLE500_HLE5000_eng_02

Page 16

Operating instructions HLE 500/5000

Take care: When removing the microphone from a valve,

always pull the body of the microphone and not the cable,

otherwise you may damage the cable.

3-point foot variant:

By screwing in a 3-point foot, the PAM U can

also be used as a ground microphone on a hard

surface. Surrounding noise, particularly wind, is

not so well screened off as with the ground

microphone PAM W-1, but nevertheless very

good results can be achieved with this variant.

10

Fig 6 : PAM U with 3-point foot

2.7 Headphones

The KR 2 headphones with ambient sound insulation are

supplied as standard. These electrodynamic headphones

reproduce leak sounds well. Other models of headphone

should be avoided if at all possible, as hearing protection to

VBG 121 can not be guaranteed. According to para. 10 VBG

121 the headphone volume may not exceed 85 dB.

The KR 2 headphones with particularly effective ambient

sound insulation are available as an accessory and can also

be used on the HLE 5000/500.

MAN_HLE500_HLE5000_eng_02

Page 17

Operating instructions HLE 500/5000

3 Practical work

Now that you have got to know the HLE 5000/500 leak

detector, you can start with the practical use.

3.1 Headphones and microphone connection

Before switching on the HLE 5000/500, connect both the

headphones and the microphone. The reverse is true when

switching off: Always switch the equipment off first and then

remove the microphone and headphones.

11

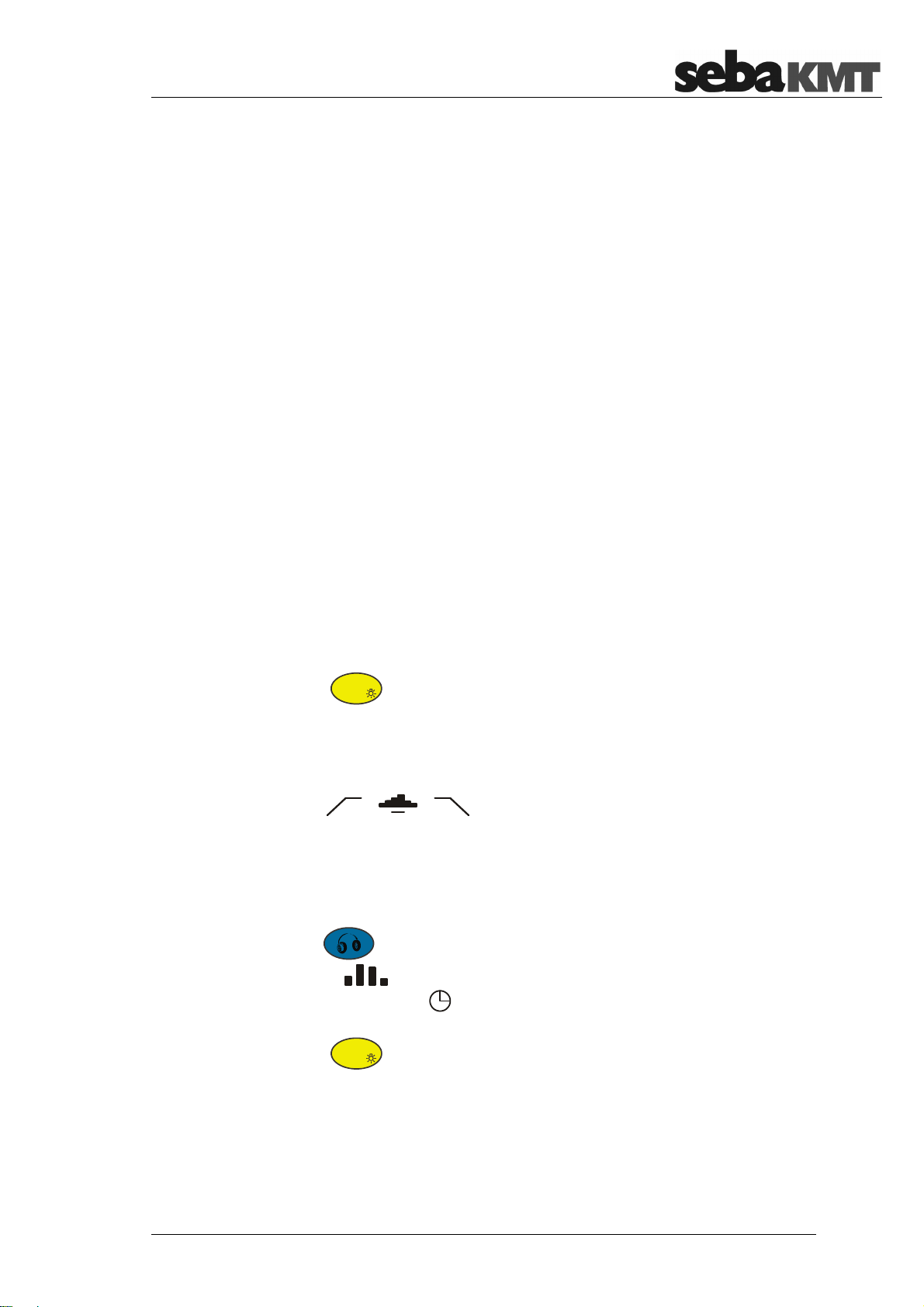

3.2 Switching on

By pushing the on/off button

turned on. The start image then appears, together with the

current version number and the battery status.

Fig 7 : Start image with version number

After a few seconds, the opening menu appears with the last

equipment settings.

the equipment will be

Battery status

MAN_HLE500_HLE5000_eng_02

Page 18

Operating instructions HLE 500/5000

0

headphone volume

setting

100 200

150

50

Setting the

0 – 4000 Hz

12

Fig 8 : Opening menu after switch-on

3.3 Volume and amplification

The HLE 5000/500 is equipped with separate controls for

volume and amplification. Thus, every user can make the

best settings for their personal characteristics.

3.3.1 Setting the volume

Using the two buttons on the right (see fig. 9) the headphone

volume can be set. To start a measurement, medium volume

- 3 scale units - should be selected.

Amplification

Fig 9 : Setting the volume

MAN_HLE500_HLE5000_eng_02

Page 19

Operating instructions HLE 500/5000

3.3.2 Setting the gain

The amplification of the microphone signal, the gain, is set

via the two soft keys, bottom right (see fig. 10). The gain is

shown via a horizontal bar. On top of this bar the gain values

of 1 to 8 can be seen.

13

Fig 10 : Setting the gain

To start a measurement, medium gain e.g. 3-4 should be

selected.

Changing the gain affects the level bar and the volume in the

headphones.

3.4 The amplification display

The bar display (fig. 11) shows both the current value of the

sound picked up and the amplified sound.

The lower, thicker bar shows the minimum value of the

measurement. When considering the nature of a leak sound,

which is a continuous noise, the display of this value provides

a much better result and is much less susceptible to pulses of

interference. This minimum value is recalculated after the

mute button has been pushed.

MAN_HLE500_HLE5000_eng_02

Page 20

Operating instructions HLE 500/5000

0

1800

–

4000

0 –

70

Curre

nt value

Minimum value

cut-off

cut-off

14

100 200

150

50

Fig 11 : Current and minimum value

0 – 4000 Hz

3.5 Filter setting (only HLE5000)

Filter settings on the HLE 5000 are very easy.

Use the soft key button in the main menu, to

get in to the filter settings.

As you can see in fig. 12, in the centre of the display, there

are 9 vertical level bars. Underneath, there is a horizontal

bar, which identifies the selected filter range.

The lower and upper cut-off is shown to the left and right of

the bars respectively.

Lower

0 - 70Hz

106Hz

240Hz

160Hz

540Hz

360Hz

1200Hz

800Hz

1800 4000Hz

Upper

Fig 12 : Filter settings

The following 9 cut-off frequencies can be set:

0 - 70, 106, 160, 240, 360, 540, 800, 1200, 1800 -4000 Hz

3.5.1 Adjusting the cut-off frequencies

To adjust the lower cut-off frequency, use the two soft key

buttons underneath , as you can see in fig. 13.

MAN_HLE500_HLE5000_eng_02

Filter range

Page 21

Operating instructions HLE 500/5000

1800

–

HYDROLUX

0 –

®

HYDROLUX

Fig 13 : Adjusting the lower filter cut-off frequency

The upper cut-off frequency is adjusted in a similar way,

using the two soft key buttons to the right, underneath

(see fig. 14).

4000 Hz

®

15

Hz

70

Fig 14 : Adjusting the upper filter cut-off frequency

For the two cut-off frequencies, you can set the 9 frequencies

specified above and can thus easily set the special filter

range for every measurement.

After the filter range has been correctly set, use the soft key

button “ESC” to return to the main menu.

3.6 Filter selection in practice

The decision about the filter settings has to be made by the

user. In general, one can say that, for measurements with

ground microphones, lower frequency ranges should be

chosen. For measurements directly on the pipe or valve

using the sensor rod, higher frequency ranges should be

MAN_HLE500_HLE5000_eng_02

Page 22

Operating instructions HLE 500/5000

chosen. Should a measurement not be successful, then a

broadband setting is to be recommended, to ensure that

none of the leak sound is filtered away.

3.6.1 Filter selection A (Ground microphone PAM W-1, PAM U with

3-point foot)

As a standard setting, a filter from 240 Hz - 540 Hz should be

used. Particularly with plastic pipes and pipes at low

operating pressures, lower frequencies can occur.

3.6.2 Filter selection B: Sensor rod (Pam U with spike)

For measurements directly on the pipe with the sensor rod,

the frequency range should be set to 540 Hz - 1200 Hz.

16

X

3.7 Mute button

To move the ground microphone, you should first of all push

the mute button

the headphones to be interrupted and the current level will be

“frozen”. This means that your hearing is protected as the

loud contact noises are suppressed. After you have chosen a

new location for the ground microphone, the mute button

X

should be pushed again. This switches the headphones

back on, the level display is updated and the minimum is

recalculated.

3.8 The histogram

The “Histogram” function is used to be able to compare a series

of sequentially recorded measurements. This can be used when

pre-locating a burst pipe with a sensor rod microphone as well

as when pinpointing the actual leak. For the HLE 5000/500 a

maximum of 9 measurements are displayed.

X

(see fig. 1). This causes the sound in

After pressing the soft key button (see fig. 1) the LCD

display switches to the histogram view and the first histogram

is activated.

MAN_HLE500_HLE5000_eng_02

Page 23

Operating instructions HLE 500/5000

The individual histogram displays consist of a dual segment

analysis (DSA), which show the current value and the

minimum value. This DSA is shown in fig. 15. The narrow

segment stands for the current value and the wide segment

shows the minimum value, which is of particular significance

when looking for burst pipes.

17

Fig 15 : Dual segment analysis (DSA)

X

With the first push of the mute button

measurement is stored and simultaneously displayed. In this

way, nine values can be stored, one after the other. When

more than nine values are measured, the first value will be

deleted and all other values will be shifted one position to the

left. The last nine values are thus always available.

Fig 16 : Histogram measurement

the current

MAN_HLE500_HLE5000_eng_02

Page 24

Operating instructions HLE 500/5000

The histogram measurement as shown in fig. 16 shows very

different current values. On the other hand the 5th DSA

shows a clear maximum for the minimum values. The burst

pipe is thus in the vicinity of the 5th measurement location.

Additionally a small graphical symbol indicates the maximum

measurement for easy recognition. To leave the histogram

measurement, press the “ESC” soft key.

3.9 Long-term measurement (HLE 5000 only)

This function is intended to record sounds over a

programmable period and then display as a graph. With this

method the identity of a water pipe can be established by

recording the flow noise of a valve. To do that, the

microphone is put onto the pipe and the long-term

measurement is started. Then, you close the valve for a

certain time (at least 2 minutes) and then open it again. If the

pipe at the listening location is identical to the shut-off pipe,

then this should be visible on the sound level curve. In fig. 17

a sound level curve like this is shown.

18

Fig 17 : Long-term measurement

To set this function, from fig. 1 the soft key is pushed.

The menu for the long-term measurement will appear as in

fig. 17. To specify the duration press the soft key (time)

repeatedly until the required measurement time is set, as

shown top right in the display. Recording durations of 3 - 10 30 minutes are available. After setting the duration, push the

(start) soft key. The measurement will start and could be

stopped early by pressing the (stop) soft key.

MAN_HLE500_HLE5000_eng_02

Page 25

Operating instructions HLE 500/5000

3.10 Location of pipes using the RSP-3 or PWG

(HLE 5000 only)

To switch the HLE 5000 into this mode, after switching on,

soft key 2 (underneath the impulse symbol ) should be

pressed whilst the welcome image is displayed.

The HLE 5000 is now in pipe location mode, shown by the

impulse symbol at the top edge of the display.

This mode of operation is particularly suited to display

impulse noise, such as the tapping of the pipe pecker or the

PWG. The horizontal level bars respond particularly

sensitively to impulses, the bar is shown much larger and is

delayed more and the filters are set to lower frequencies Of

course, if required, the filter frequencies can be altered as

usual.

The HLE5000 stays in pipe location mode until it is switched

off. After being turned on again, it will be in normal mode.

19

3.11 Switching off

The equipment is switched off by a longer press on the

button. Any measurements stored will be lost. After 35

minutes in operation, the equipment switches off

automatically.

In histogram mode the equipment will also switch off

automatically after 35 minutes, as long as the mute and the

illumination button are not used.

MAN_HLE500_HLE5000_eng_02

Page 26

Operating instructions HLE 500/5000

4 Faults

4.1 Can't switch on

Presumably the headphones are not plugged in or

headphones are being used which do not belong to the

system.

4.2 Battery monitor does not react

One or more batteries are incorrectly fitted. Open base flap

and check the polarity of the batteries. See fig. 3.

If the polarity of all of the batteries is OK, the state of every

single battery must be checked.

20

4.3 No sound can be heard

With working equipment there are two possibilities:

a. Headphones not fitted, or fitted incorrectly

X

b. The mute button

headphones are switched off. Press the mute button

X

again to restore the sound.

4.4 Scratching sounds in the headphones

This is usually caused by a poor contact. Check all contacts.

is active, which means that the

MAN_HLE500_HLE5000_eng_02

Page 27

Loading...

Loading...