OWNERS MANUAL

MODEL NO. 315.10951

CAUTION: Read Rules for Safe Operation and Instructions Carefully

SAVE THIS MANUAL FOR FUTURE REFERENCE

CRAFTSMAN

71/4 INCH CIRCULAR SAW DOUBLE INSULATED

Introduction Operation Maintenance Repair Parts

Designed exclusively for and sold only by SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

FULL ONE YEAR WARRANTY ON CRAFTSMAN CIRCULAR SAW

If this Craftsman Circular Saw fails to give complete satisfaction within one year from the date of purchase, RETURN IT TO THE NEAREST SEARS STORE THROUGHOUT THE UNITED STATES and Sears will repair it, free of charge.

If this circular saw is used for commercial or rental purposes this warranty applies for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

SEARS, ROEBUCK AND CO. DEPT. 698/731A SEARS TOWER CHICAGO, IL 60684

INTRODUCTION

DOUBLE INSULATION is a concept in safety, in electric power tools, which eliminates the need for the usual three wire grounded power cord and grounded supply system. Wherever there is electric current in the tool there are two complete sets of insulation to protect the user. All exposed metal parts are isolated from the internal metal motor components with protecting insulation.

Features include easily operated bevel cut and depth of cut adjustment mechanisms; directed air flow for keeping line of cut clear.

IMPORTANT — Servicing of a tool with double insulation requires extreme care and knowledge of the system and should be performed only by a qualified service technician. For service we suggest you return the tool to your nearest Sears Store for repair. Always use original factory replacement parts when servicing.

Your saw is equipped with a "lock-off" switch which reduces the possibility of accidental starting. You must depress the button on the side of the handle in order to be able to pull the trigger switch. The lock resets each time the trigger is released.

RULES FOR SAFE OPERATION

WARNING — DO NOT ATTEMPT TO OPERATE UNTIL YOU HAVE READ THOROUGHLY AND UNDERSTAN COMPLETELY ALL INSTRUCTIONS, RULES, ETC. CONTAINED IN THIS MANUAL. FAILURE TO COMPLY CA RESULT IN ACCIDENTS INVOLVING FIRE, ELECTRIC SHOCK, OR SERIOUS PERSONAL INJURY. MAINTAI OWNERS MANUAL AND REVIEW FREQUENTLY FOR CONTINUING SAFE OPERATION, AND INSTRUCTIN POSSIBLE THIRD-PARTY USER.

READ ALL INSTRUCTIONS

- 1. KNOW YOUR POWER TOOL Read owner's manual carefully. Learn its applications and limitations as well as the specific potential hazards peculiar to this tool.

- 2. GUARD AGAINST ELECTRICAL SHOCK BY PREVENTING BODY CONTACT WITH GROUNDED SURFACES. For example: Pipes, radiators, ranges, refrigerator enclosures.

- 3. KEEP GUARDS IN PLACE and in working order. Never wedge or tie lower guard open. Check operation of lower guard before each use. Do not use if lower guard does not close briskly over saw blade. WARNING: IF SAW IS DROPPED, LOWER GUARD MAY BE BENT, RESTRICTING FULL RETURN.

- 4. KEEP WORK AREA CLEAN. Cluttered areas and benches invite accidents.

- 5. AVOID DANGEROUS ENVIRONMENT. Don't use power tool in damp or wet locations or expose to rain. Keep work area well lit.

- 6. KEEP CHILDREN AWAY. All visitors should be kept safe distance from work area. Do not let visitors contact tool or extension cord.

- 7. STORE IDLE TOOLS. When not in use, tools should be stored in dry, high or locked-up place out of reach of children.

- 8. DON'T FORCE TOOL. It will do the job better and safer at the rate for which it was designed.

- USE RIGHT TOOL. Don't force small tool or attachment to do the job of a heavy duty tool. Don't use tool for purpose not intended — for example — Don't use a circular saw for cutting tree limbs or logs.

- 10. WEAR PROPER APPAREL. No loose clothing or jewelry to get caught in moving parts. Rubber gloves and footwear are recommended when working outdoors. Also, wear protective hair covering to contain long hair.

- 11. USE SAFETY GLASSES with all tools. Also face or dust mask if cutting operation is dusty.

- 12. DON'T ABUSE CORD. Never carry tool by cord or yank it to disconnect from receptacle. Keep cord from heat, oil and sharp edges.

RULES FOR SAFE OPERATION (Continued)

- 13. SECURE WORK. Use clamps or a vise to hold work. It's safer than using your hand and it frees both hands to operate tool.

- 14. DON'T OVERREACH. Keep proper footing and balance at all times.

- MAINTAIN TOOLS WITH CARE. Keep tools sharp at all times, and clean for best and safest performance. Follow instructions for lubricating and changing accessories.

- 16. DISCONNECT TOOLS. When not in use, before servicing, or when changing attachments, blades, bits, cutters, etc., all tools should be disconnected.

- 17. REMOVE ADJUSTING KEYS AND WRENCHES. Form habit of checking to see that keys and adjusting wrenches are removed from tool before turning it on.

- 18. AVOID ACCIDENTAL STARTING. Don't carry plugged-in tools with finger on switch. Be sure switch is off when plugging in.

- 19. OUTDOOR USE EXTENSION CORDS. When tool is used outdoors, use only extension cords suitable for use outdoors. Outdoor approved cords are marked with the suffix W-A, for example SJTW-A or SJOW-A.

- 20. KEEP BLADES CLEAN AND SHARP. Sharp blades minimize stalling and kickback.

- 21. DANGER: KEEP HANDS AWAY FROM CUTTING AREA. Keep hands away from blades. Do not reach underneath work while blade is rotating. Do not attempt to remove cut material when blade is moving.

- 22. NEVER USE IN AN EXPLOSIVE ATMOSPHERE. Normal sparking of the motor could ignite fumes.

- 23. INSPECT TOOL CORDS PERIODICALLY and if damaged, have repaired at your nearest Sears Repair Center.

- 24. INSPECT EXTENSION CORDS PERIODICALLY and replace if damaged.

- 25. KEEP HANDLES DRY, CLEAN, AND FREE FROM OIL AND GREASE. Always use a clean cloth when cleaning. Never use brake fluid, gasoline, or any strong solvents to clean your tool.

- 26. STAY ALERT. Watch what you are doing and use common sense. Do not operate tool when you are tired.

- 27. CHECKED DAMAGED PARTS. Before further use of the tool, a guard or other part that is damaged should be carefully checked to determine that it will operate properly and perform its intended function. Check for alignment of moving parts, binding of moving parts, breakage of parts, mounting, and any other conditions that may affect its operation. A guard or other part that is damaged should be properly repaired or replaced by an authorized service center unless indicated elsewhere in this instruction manual.

- 28. DO NOT USE TOOL IF SWITCH DOES NOT TURN IT ON AND OFF. Have defective switches replaced by authorized service center.

- 29. ALWAYS USE A FENCE OR STRAIGHT EDGE GUIDE WHEN RIPPING.

- 30. TO MINIMIZE THE RISK OF BLADE PINCHING AND KICKBACK, SUPPORT LARGE PANELS AS SHOWN IN FIGURE 5, PAGE 5. When cutting operation requies the resting of the saw on the workpiece, the saw should be rested on the larger portion and the smaller piece cut off.

- 31. WARNING: ALWAYS RAISE THE LOWER BLADE GUARD WITH THE HANDLE TO AVOID SERIOUS INJURY. See Figure 14, Page 8.

- 32. GUARD AGAINST KICKBACK. See Page 5.

- 33. BEFORE MAKING A CUT, BE SURE THE DEPTH AND BEVEL ADJUSTMENTS ARE TIGHT.

- 34. DO NOT USE BLADES WITH INCORRECT SIZE HOLES. Never use blade washers or bolts that are defective or incorrect.

- 35. Inspect for and remove all nails from lumber before cutting.

- 36. DRUGS, ALCOHOL, MEDICATION. Do not operate tool while under the influence of drugs, alcohol, or any medication.

- 37. SAVE THESE INSTRUCTIONS.

The operation of any Circular Saw can result in foreign objects being thrown into the eyes, which can result in severe eye damage. Always wear safety glasses or eye shields before commencing power tool operation. We recommend Wide Vision Safety Mask for use over spectacles or standard safety glasses, available at Sears Catalog Order or Retail Stores.

OPERATION

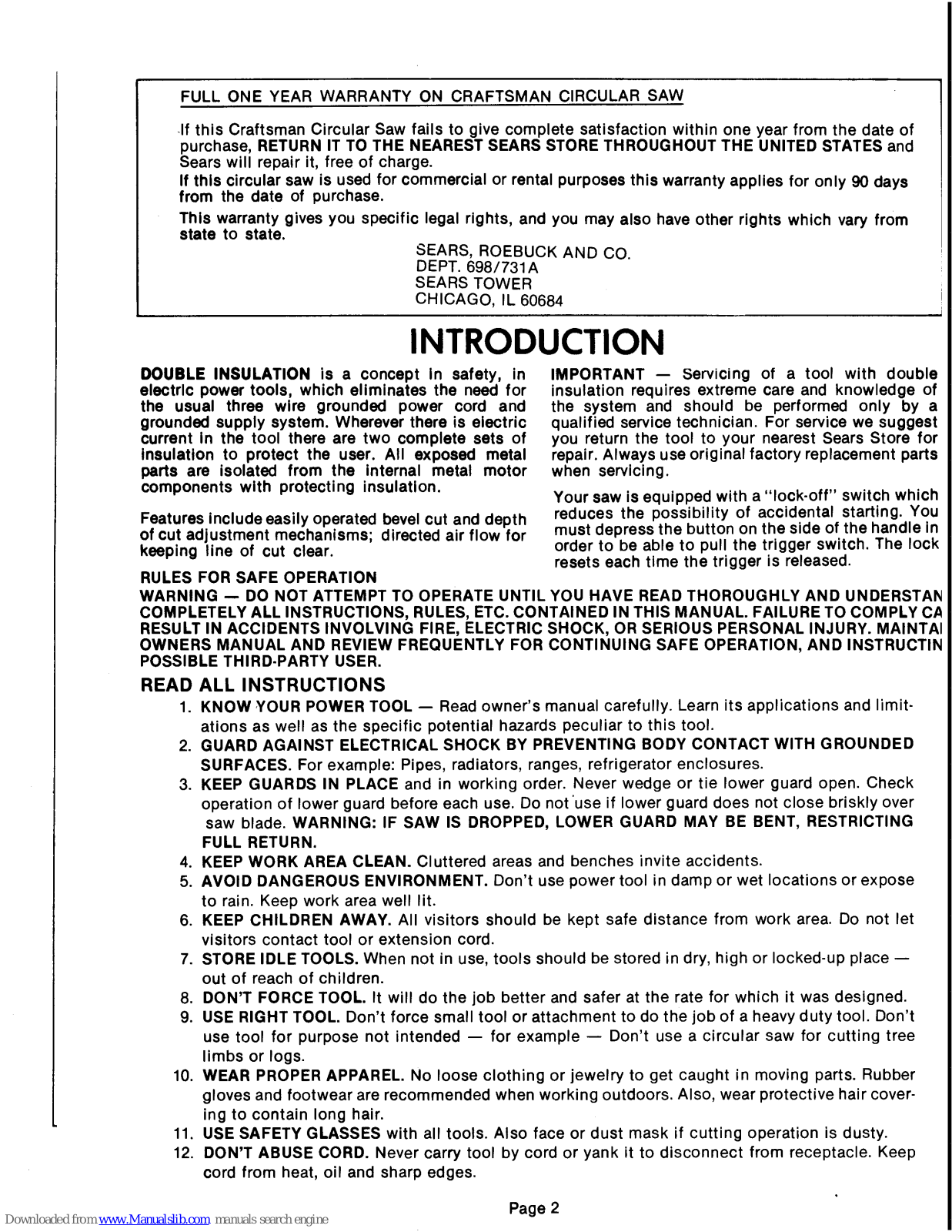

TO ASSEMBLE BLADE

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting causing serious injury.

- Position unit on end of motor housing and remove blade screw, spring washer, and "D" washer. WARNING: If inner blade washer is removed when assembling blade, it must be replaced before placing blade on spindle. See Figure 1.

- 3. Fit the saw blade inside the blade guard and onto the spindle with the saw teeth pointing upward at front of saw.

- 4. Replace the "D" washer and spring washer with "cupped" side of spring washer against outer blade "D" washer. See Fig. 1.

- 5. Tighten the blade screw until spring washer is flattened.

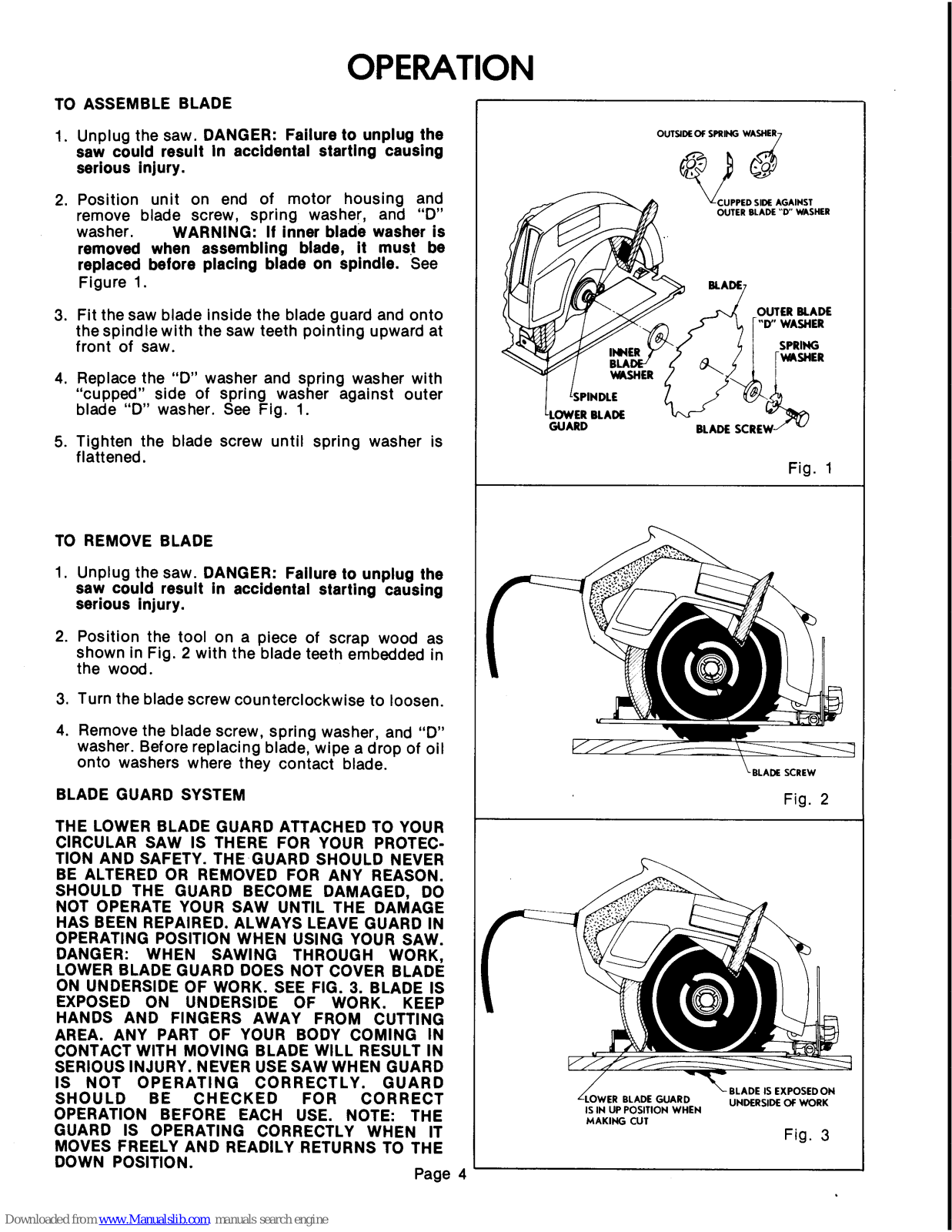

TO REMOVE BLADE

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting causing serious injury.

- 2. Position the tool on a piece of scrap wood as shown in Fig. 2 with the blade teeth embedded in the wood.

- 3. Turn the blade screw counterclockwise to loosen.

- 4. Remove the blade screw, spring washer, and "D" washer. Before replacing blade, wipe a drop of oil onto washers where they contact blade.

BLADE GUARD SYSTEM

THE LOWER BLADE GUARD ATTACHED TO YOUR CIRCULAR SAW IS THERE FOR YOUR PROTEC-TION AND SAFETY. THE GUARD SHOULD NEVER BE ALTERED OR REMOVED FOR ANY REASON SHOULD THE GUARD BECOME DAMAGED. DO NOT OPERATE YOUR SAW UNTIL THE DAMAGE HAS BEEN REPAIRED. ALWAYS LEAVE GUARD IN OPERATING POSITION WHEN USING YOUR SAW. DANGER: WHEN SAWING THROUGH WORK LOWER BLADE GUARD DOES NOT COVER BLADE ON UNDERSIDE OF WORK. SEE FIG. 3. BLADE IS EXPOSED ON UNDERSIDE OF WORK. KEEF HANDS AND FINGERS AWAY FROM CUTTING AREA. ANY PART OF YOUR BODY COMING IN CONTACT WITH MOVING BLADE WILL RESULT IN SERIOUS INJURY. NEVER USE SAW WHEN GUARD IS NOT OPERATING CORRECTLY. GUARD SHOULD BE CHECKED FOR CORRECT OPERATION BEFORE EACH USE. NOTE: THE GUARD IS OPERATING CORRECTLY WHEN IT MOVES FREELY AND READILY RETURNS TO THE DOWN POSITION.

Page 4

AVOID DANGEROUS PRACTICES GUARD AGAINST KICKBACK.

Kickback occurs when the blade stalls rapidly and the saw is driven back towards you. DANGER: RELEASE SWITCH IMMEDIATELY IF BLADE BINDS OR SAW STALLS. See Fig. 4. Kickback could cause you to lose control of your saw. Loss of control can lead to serious injury. Kickback is caused by:

- 1. Incorrect blade depth setting. See Fig. 4.

- 2. Sawing into knots or nails in work.

- 3. Twisting blade while making cut.

- 4. Making cut with dull blade.

- 5. Incorrectly supporting work. See Fig. 5.

- 6. Forcing a cut.

TO LESSEN THE CHANCE OF KICKBACK:

- Always keep correct blade depth setting the correct blade depth setting for all cuts has one whole tooth projecting below the material to be cut. (For carbide-tipped blades, only one-half of a tooth.)

- 2. Inspect the work for knots or nails before beginning a cut. Never saw into a knot or nail.

- 3. Make straight cuts. Always use a straight edge guide when rip cutting. This helps prevent twisting the blade in the cut.

- 4. Always use sharp blades Never make cuts with dull blades. Sharp blades lessen the chance of kickback.

- 5. Support the work properly before beginning a cut to avoid pinching the blade. The right and wrong ways to support large pieces of work are shown in fig. 5.

- 6. When making a cut use steady, even pressure. Never force cuts.

WHEN USING YOUR SAW ALWAYS STAY ALERT AND EXERCISE CONTROL. DO NOT REMOVE THE SAW FROM WORK DURING A CUT WHILE THE BLADE IS MOVING.

DEPTH OF CUT ADJUSTMENT

Always keep correct blade depth setting. The correct blade depth setting for all cuts has one whole tooth projecting below the material to be cut. (For carbidetipped blades, only one-half of a tooth). More blade depth will increase the chance of kickback and cause the cut to be rough.

TO ADJUST BLADE DEPTH:

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting causing serious injury.

- 2. Loosen Locking Lever. See Fig. 6.

- 3. Hold base flat against the work and raise saw until the required depth is reached.

- 4. Tighten Locking Lever.

RIGHT

Fig. 5

STARTING A CUT

KNOW THE RIGHT WAY TO USE YOUR SAW. SEE FIG. 7. NEVER USE YOUR SAW AS SHOWN IN FIG. 8.

ALWAYS keep control of your saw. It makes sawing easier and safer. To help keep control, always support the work near the cut. Support the work so the cut will be on your right. Clamp your work so it will not move during the cut. The work moving during a cut could result in the loss of control of your saw possibly causing serious injury.

Place the work with its good side down. NOTE: The good side is the side on which appearance is important. Before beginning a cut, draw a guide line along the desired line of cut. Then place the front edge of the base on that part of the work that is solidly supported. See Fig. 7. NEVER place the saw on that part of the work that will fall off when the cut is made. See Fig. 9.

Keep the cord away from the cutting area. ALWAYS place the cord to prevent it from hanging up on the work while making a cut. See Fig. 7. DANGER: If the cord hangs up on the work during a cut, release the switch trigger immediately. Unplug the saw and reposition the cord to prevent it from hanging up again. If the cord has been damaged, have it replaced before using your saw again. DANGER: Using your saw with a damaged cord could result in serious injury or death.

Hold the saw firmly with both hands. See Fig. 7. Push in the lock-off button and squeeze the switch trigger. ALWAYS let the blade reach full speed, then guide the saw into the work.

WARNING: The blade coming in contact with the work before it reaches full speed could cause the saw to "kickback" towards you resulting in serious injury.

When making a cut use steady, even pressure. Forcing the saw causes rough cuts, could shorten the life of the saw and could cause the saw to "kickback."

When sawing through work the lower blade guard does not cover the blade. BLADE IS EXPOSED ON UNDERSIDE OF WORK. KEEP YOUR HANDS AND FINGERS AWAY FROM THE CUTTING AREA. ANY PART OF YOUR BODY COMING IN CONTACT WITH THE MOVING BLADE WILL RESULT IN SERIOUS INJURY.

When you complete your cut, release the switch trigger. Allow the blade to come to a complete stop before lifting the saw from the work. WARNING : When lifting the saw from the work the blade is exposed on the underside of the saw until the lower blade guard closes. Never reach under the saw for any reason.

Page 6

TO CROSS CUT OR RIP CUT

When making a cross cut or rip cut line up your cut with the notch in the saw base. See Fig. 10. Make a trial cut in scrap material along a guide line to determine how much, if any, the guide line must be offset to produce an accurate cut. Note: The distance from the line of cut to the guide line is the amount you should offset the guide line. Use a rip guide when rip cutting. This helps prevent twisting the blade in the cut. Twisting the blade in the cut causes kickback. A rip guide will help you in making rip cuts up to five inches. To assemble rip guide to your saw:

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting causing serious injury.

- 2. Place rip guide through holes in saw base as shown in Fig. 11.

- 3. Adjust rip guide to the length needed for the cut.

- 4. Tighten wing nut securely.

When using the rip guide hold the face of the rip guide firmly against the edge of work. This makes for a true cut without pinching the blade. The guiding edge of work must be straight for your cut to be straight. Use caution to prevent the blade from binding in the cut.

TO BEVEL CUT

The angle of cut may be adjusted to any desired setting between zero and 45 degrees. There is a notch in the saw base to help you line up the blade with the line of cut. See Fig. 12. Always make a trial cut in scrap material along a guide line to determine how much you should offset the guide line on the board to be cut.

When making a bevel cut hold the saw firmly with both hands as shown in Fig. 13. Rest the front edge of the base on the work. Push in the lock-off button and squeeze the switch trigger. ALWAYS let the blade reach full speed, then guide the saw into the work. WARNING: The blade coming in contact with the work before it reaches full speed could cause the saw to "kickback" towards you resulting in serious injury. After you complete your cut release the trigger and allow the blade to come to a complete stop. AFTER the blade has stopped, remove it from the work.

To adjust the bevel setting:

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting causing serious injury.

- 2. Loosen knob. See Fig. 12.

- 3. Raise motor housing end of saw until you reach desired angle setting on bevel scale. See Fig. 12.

- 4. Tighten knob securely. DANGER: Attempting bevel cut without knob securely tightened can result in serious injury.

Page 7

TO POCKET CUT

DANGER: Always adjust bevel setting to zero before making a pocket cut. Attempting a pocket cut at any other setting will result in loss of control of your saw possibly causing serious injury.

Adjust the bevel setting to zero and swing the lower blade guard up using the lower blade guard handle DANGER: ALWAYS raise the lower blade guard with the handle to avoid serious injury. While holding the lower blade guard by the handle, rest the front of the base flat against the workpiece with the rear of the base raised so the blade does not touch the work. See Fig. 14. Push in the lock-off button and squeeze the switch trigger. WARNING: ALWAYS LET THE BLADE REACH FULL SPEED then slowly lower blade into the work until base is flat against work. After you complete your cut release the trigger and allow the blade to come to a complete stop. After the blade has stopped, remove it from the work. Corners may then be cleaned out with a hand saw or sabre saw. DANGER: NEVER TIE THE LOWER BLADE GUARD IN A RAISED POSITION SINCE LEAVING BLADE EXPOSED COULD LEAD TO SERIOUS IN.IURY

MAINTENANCE

WHEN SERVICING USE ONLY IDENTICAL REPLACEMENT PARTS

POWER CORD AND/OR SWITCH REPLACEMENT

- 1. Unplug the saw. DANGER: Failure to unplug the saw could result in accidental starting or shock causing serious injury or death.

- 2. Remove switch cap and screws as shown in Fig. 15.

- 3. Carefully lift handle cover away from tool.

- Note the locations of all wiring inside the handle and how each wiring connection has been made. IMPORTANT: When the new cord or switch is installed, identical connections must be made.

- Remove the wires from the switch by inserting a 1/32" diameter pin or nail into each switch lead receptacle and pull the wires as shown in Fig. 15. This will release the wires. Remove the pin or nail with a twisting motion.

- 6. Push each lead into its proper receptacle in the switch as far as possible.

- 7. Locate the switch in the handle and place all wiring so it cannot be pinched when handle cover is replaced.

- 8. Replace handle cover, screws, and switch cap.

GENERAL

Only the parts shown on parts list page 11 are intended to be repaired or replaced by the customer. All other parts represent an important part of the double insulation system and should be serviced only by a qualified service technician.

Avoid using solvents when cleaning plastic parts Most plastics are susceptible to various types of commercial solvents and may be damaged by their use. Use clean cloths to remove dirt, carbon dust, etc. WARNING: DO NOT AT ANY TIME LET BRAKE FLUIDS, GASOLINE, PENETRATING OILS, ETC. COME IN CONTACT WITH PLASTIC PARTS. THEY CONTAIN CHEMICALS THAT CAN DAMAGE AND/OR DESTROY PLASTICS

When electric tools are used on fiberalass boats sports cars, etc., it has been found that they are subject to accelerated wear and possible premature failure, as the fiberglass chips and grindings are highly abrasive to bearings brushes commutator etc. Consequently it is not recommended that this tool be used for extended work on any fiberalass material. During any use on fiberglass it is extremely important that the tool is cleaned frequently by blowing with an air jet. ALWAYS WEAR SAFETY GLASSES OR EYE SHIELDS BEFORE BEGINNING THIS OPERATION

EXTENSION CORDS

The use of any Extension Cord will cause some loss of power. To keep this to a minimum and to prevent overheating and motor burn-out, use the following table to determine the MINIMUM wire size (A.W.G.) Extension Cord

| Extension Cord Length | Wire Size, A.W.G |

|---|---|

| 25-50 Ft. | 16 |

| 50-100 Ft. | 14 |

Extension Cords suitable for use with your circular saw are available at your nearest Sears Catalog Order or Retail Store. WARNING: CHECK EXTEN-SION CORDS BEFORE EACH USE. IF DAMAGED, REPLACE IMMEDIATELY. NEVER USE TOOL WITH DAMAGED CORD SINCE TOUCHING THE DAMAG ED AREA COULD CAUSE ELECTRICAL SHOCK RESULTING IN SERIOUS INJURY.

SAW BLADES

The best of saw blades will not cut efficiently if they are not kept clean and sharp. Using a dull blade will place a heavy load on your saw and increase the danger of kickback. Keep extra blades on hand, so that sharp blades are always available.

Gum and wood pitch hardened on blade will slow it down. Use hot water or kerosene to remove these accumulations. DO NOT USE GASOLINE.

LUBRICATION — All of the bearings in this tool are lubricated with a sufficient amount of high grade lubricant for the life of the unit under normal operating conditions, therefore, no further lubrication is required.

71/4" Saw Blade (9 32489)

THE FOLLOWING RECOMMENDED ACCESSORIES WERE AVAILABLE AT THE TIME THIS MANUAL WAS PRINTED.

|

Saw Guide (

9

1719)

Cord Lock ( 9 2595) Carrying Case ( 9 1464) |

Mitre-Arm Attachment (Cat. #1715N)

71⁄4'' Saw Blade ( 9 32712) 71⁄4'' Saw Blade ( 9 32423) 71⁄4'' Saw Blade ( 9 32494) |

7

1

/4" Saw Blade (

9

32564)

7 1 /4" Saw Blade ( 9 32664) 7 1 /4" Saw Blade ( 9 32444) 7 1 /4" Saw Blade ( 9 32483) 7 1 /4" Saw Blade ( 9 32464) |

|---|

CAUTION: The use of attachments or accessories not listed above might be hazardous.

Page 10

.....2 ....................................... Masher . sleeve Bearing.....1 ower Blade Guard Support....1 Screw (#8-32 x 3/8 Pan Hd.)**STD510803....4 Extension Spring.....1 ower Blade Guard Assembly.....1 Nen. Retaining Ring .....1 nner Blade Washer....1 ***Saw Blade 7-1/4 For 5/8" Arbor.....1 Outer Blade Washer....1 Spring Washer....1 3olt ..... 1 Rip Guide.....1 Wrench.....1 Spring Washer.....1 Drive Screw.....1 Gear & Spindle Assembly.....1 Screw (#8-32 x 3/4 Pan Hd.)**STD610807. NOTE: "A" — The assembly shown represents an important part of the Double Insulated System. To avoid the possibility of altera-tion or damage to the System, service should be performed by your nearest Sears Repair Center. Contact your nearest Catalog Order or Retail Store. Bumper ..... Dwner's Manual CRAFTSMAN CIRCULAR SAW - MODEL NUMBER 315.10951 The Model Number will be found on a plate attached to the motor housing. Always mention the Model Number in all correspondence regarding your CIRCULAR SAW or when ordering repair parts. ***Complete Assortment Available At Your Nearest Catalog Order Or Retail Store SEE BACK PAGE FOR PARTS ORDERING INSTRUCTIONS 614979-002 306303-002 324023-001 311707-001 31944-801 11688-004 14658-001 000-86068 11711-001 18602-804 15617-003 310565-001 06334-001 23547-002 512999-001 16763-002 11103-002 22347-002 95247-037 12547-079 *Standard Hardware Item - May Be Purchased Locally **Available From Div. 98 -- Source 980.00 PARTS LIST Х° Хо g 24 2 2 33 34 ŝ 37 4 Quan. Carriage Bolt Bend Relief.....1 switch Cap.....1 screw (#8-10 x 5/8 Pan Hd.).....8 Handle Assembly.....1 Data Plate.....1 Screw (1/4-20 x 5/8 Pan Hd.).....2 -ogo Plate.....1 H. P. Logo.....1 Bearing Base Assembly.....1 Sinding Stud.....1 WING NUT **STD541625 Knob.....1 Nasher ..... 1 Roll Pin.....1 Carriage Bolt (1/4-20 x 5/8) **STD532507...1 Locking Lever.....1 Lock Nut..... Cord Switch. Description 611680-002 621347-000 621438-004 612961-001 616467-002 612984-000 617205-002 612998-001 622319-001 931744-059 941401-815 621433-004 611672-001 613651-001 611159-001 611154-001 617966-009 989236-001 612217-001 89237-001 714043-005 Part Number ۇ ۋ 10 F 12 13 14 15 16 17 18 19 20 5 33

Page 11

•

|

Sears

Owners Manual |

CRAF

7¼ IN DOUBLE |

|

|---|---|---|

| SERVICE |

Now that you

should a need simply contac Sears, Roebuc all pertinent fa |

|

|

MODEL NO.

315.10951 |

The model n

found on the |

|

|

HOW TO ORDER

REPAIR PARTS |

|

|

| L |

TSMAN ® CH CIRCULAR SAW

E INSULATED

have purchased your Circular Saw, ever exist for repair parts or service. t any Sears Service Center and most ck and Co. stores. Be sure to provide acts when you call or visit.

umber of your Circular Saw will be plate attached to the motor housing.

RING REPAIR PARTS, ALWAYS GIVE ING INFORMATION

- ABER

- PART DESCRIPTION

- JMBER

- NAME OF ITEM Circular Saw

may be ordered from any Sears Service ost Śears stores.

need are not stocked locally, your order nically transmitted to a Sears Repair ion Center for handling.

SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

Loading...

Loading...