Page 1

SEARS

OWNERS

MANUAL

CRAFTSMAN

MODEL NO.

919.176210

919,176311

919.176320

919.176330

IMPORTANT

Read the Safety Guidelines

and All Instructions

Carefully Before Operating

AIR COMPRESSOR

ASSEMBLY ----

OPERATION

MAINTENANCE

REPAIR PARTS

Record In the spaces provided.

(1) The model number which can be

found on the label on the front Of the

air tank saddle.

(2) The code number which can be

found on the ,'oil label on the aide of

the air tank.

(3) The Manufacturers Number (ASME

Code Compressors only) Is located

on the metal data plate which is

welded onto the side of the air tank,

(This data plate is painted the same

color as the tank.)

(4) The Motor Manufacturers name

which is located on the motor iabet.

(5) The Motor Mfg. number - also

!ocawd on the motor label.

Retain these numbers for future

reference.

Model No ..............

Code NO, =

MfO. No.

BI-30-og.1-D 5/85

Motor Mfg. Name ,

Motor Mfg. No,

Seers, Roebuck and Co., Chicago, IL 60684 U.S.A.

Page 2

TABLE OF CONTENTS

Page

WARRANTY ......................................................... 3

SAFETY GUIDELINES ................................................ 3

SPECIFICATION CHART .............................................. 5

GENERAL INFORMATION ............................................. 6

GENERAL DESCRIPTION OF OPERATION .............................. 6

ASSEMBLY INSTRUCTIONS ........................................... 6

Tools Needed for Assembly ......................................... 6

Attaching Wheels, Handle, Etc....................................... 6

Grounding Instructions .............................................

Start-Up Procedures ............................................... 7

OPERATION ......................................................... 7

Control Console ................................................... 7

Pressure Switch................................................... 8

Safety Valve...................................................... 8

Motor ............................................. : .............. 8

Pressure Release Valve ............................................ 8

MAINTENANCE ...................................................... 8

Replacing Air Intake Filter .......................................... 8

Checking Safety Valve ............................................. 8

Checking and Changing Oil......................................... 9

Location of Air Compressor ......................................... 9

Draining Water From Air Tank ....................................... 9

Replacing Belt .................................................... 9

Storage .......................................................... 9

AIR COMPRESSOR DIAGRAM ......................................... 10

PARTS LIST, ......................................................... 11

ACCESSORIES ...................................................... 13

TROUBLESHOOTING GUIDE .......................................... 13

HOW TO ORDER REPAIR PARTS ...................................... 16

Page 3

FULL ONE YEAR WARRANTY

AIR COMPRESSOR

If this air compressor fails due to a defect in material or workmanship within one year from the date

of purchase, return it to the nearest Sears Service Center/Department throughout the United States

and Sears will repair it, free of charge.

If this air compressor is used for commercial or rental purposes, the warranty will apply for ninety

days from date of purchase,

This warranty gives you specific legal rights and you may also have other rights which vary from

state to state.

Sears, ROebuck and Co,, Sears Tower, Dept. 698/731A, Chicago, IL 60684

SAFETY GUIDELINES

This manual contains information that is important for you to know and understand.

This information relates to YOUR SAFETY and PREVENTING EQUIPMENT PROBLEMS.

To help you recognize this information, we use the following symbols. Please read the manual and

pay attention to those s_ctions.

IMPORTANT INFORMATION FOR PREVENTING INJURY OR LO$._ O.= LIT--.

_ __ ........ _ -

AREA

Indicates where a hazard

can oCCur.

_ m, • ,=

Moving Pa_s

Information for preventing damage to equipment

Note

Information that you should pay special attention to.

WARNING

rl I '1III

PLEASE READ THE FOLLOWING CHART.

_-- .... • ,, _........ _ ..............

HAZARD

Indicates what can happen if pre-

cautions are not observed.

,, _ ,............ __ .......

Loose items, or parts of the bOdy

may get caught and cause sad-

SAFEGUARDS

Indicates how to avoid the hazard and what

special protective clothing, equipment, and

precautions will be used.

Never operate the compressor with the con-

sole removed.

DUe injury or damage,

Keep small children, your hands, and all

items away from the flywheel and belt.

Unit cycles automatically when

power is ON. During service or

repair activities, this automatic

cycling may cause a hazard.

_ _ ,, ,

Always unplug the unit before attempting re-

pairor maintenance ofthecompressor. Also,

make sure the pressure is released from the

compressor and air tank.

, ,,, ,, ,,,,,,,,,,

Page 4

AREA

Hot Parts

HAZARD

i ii

Air compressors get hOt when

running. Serious burns may re-

sult if touched.

SAFEGUARDS

,,,i ..................... ii ,i

Never touch the compressor, tubing, or

motor during or immediately after operation

ofthe compressor.

Air Tank

Electrical ,Shock

Air pressure or mechanical loads

that are higher than design loads

may cause the tank to rupture.

Changes to the air tank structure

will cause the tank to weaken

Tank rupture or explosion may

occur.

iiiii IHIIII I

This unit is powered by 120 or

240 volts.

DO not adjust, remove, or defeat the safety

valve. Check the valve from time to time by

pulling the ring on the valve. If the valve is

stuck or does not operate smoothly, it must

be replaced.

Do not adjust, remove, or defeat the pres-

sure switch.

Never use a motor with higher horsepower

rating than the one supplied.

The compressor was not designed to De

powered bya gasoline engine. Do not substi-

tute a gas engine.

Never drill into, weld, or change the tank in

any way.

,,,,,,,,,,,,,,i

Always unplug unit prior to doing any main-

tenance or repair.

Use of unsuitable solvents

Flammable vapors

The solvents 1,1,1-Tdchloroeth-

ane and Methylene Chlo_de can

chemically react with aluminum

used in paint spray guns, paint

pumps, etc. and cause an explo-

sion. These solvents can also

react with galvanized compo-

nents and cause corrosion and

weakening of parts.

iiiiiiiiiiiiiiii iiii

A spark from the motor or pres-

sure switch electrical contacts

can ignite flammable vapors

from gasoline or sOlvents, and

cause an explosion or fire.

Never use the unit outdoors when it is rain-

ing.

Always plug the cord into an electrical outlet

with the specified voltage and adequate fuse

protection.

This hazard does not affect your compres-

sor outfit - but it may affect the equipment

used wilh the outfit. Read the label or data

sheet for the material you intend to spray.

Equipment containing aluminum or gal-

vanized parts that will come in contact with

these solvents, and that can contain pres-

sure, must not be used with these solvents.

You must either change the material, or use

only stainless steel spray equipment.

ii III

The compressor and any other electrical

tool must only be used in well ventilated

areas, free of gasoline or solvent vapors.

Page 5

AREA

Toxic Vapors

HAZARD

i i • , ......

Compressed air from this unit

may cenlain poisonous carbon

monoxide.

SAFEGUARDS

illl,

Never directly inhale the compressed air

produced by this unit.

Certain sprayed materials Such

as paints, weed killer, sand, in-

secticides, etc., may be harmful if

used in a closed area or ifinhaled.

Be certain to read labels when spraying

paints or poisons.

Use a mask or respirator whenever there is a

chance that you might inhale anything that

you are spraying. Read all instructions so

that you know that your mask will protect you

from what you are spraying.

Compressed Air

J_JUULII II I,II,,, IIIIII . • ..........................................

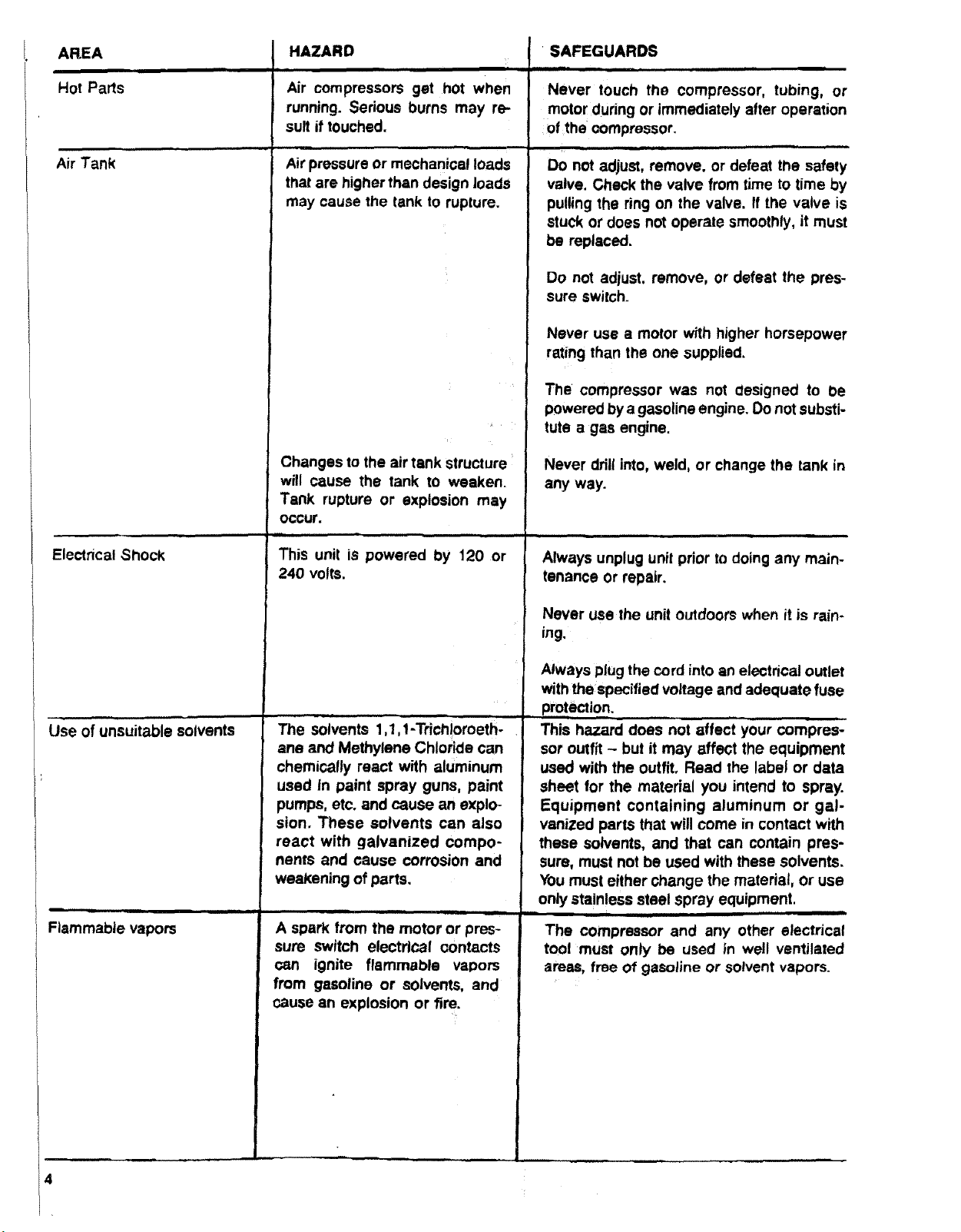

Model No. 919.176210 919,176311

HP

Displacement CFM

Bore

Stroke

Voltage-Single Phase

Branch Circuit Min, Requirements

"Fuse Type "Fusetron" Type T "Fusetron" Type T

Amperage at Max Pressure 19.5 15.5

Air Tank Capacity 12 gel 12 gal ASME

Approximam Cut-in Pressure -'80" psig B0 psig

Approximate Cut-out Pressure 100 psig 100 psig

SCFM at 125 psig _ -

100 psig f 5.6 5.6

90 psig 6.0 6.0

II,ILUU_ ............ i I II IIIIIIIII ii

"Models 919.176210 &919.176311, 1 HP motor is dual voltage, 110-!20 and 220-240 volt, Itis wired for 110-120 voltbut can be converted to

220.240 volt operation. Instructions for connecting the motor for operation at 220-240 volt can be found printed on the inside of the

motor cover or on the nameplate of motor.

"A c/muir breaker is also acceptable.

40 psig 7.3 73

Compressed air may propel dirt,

metal shavings, etc. and result in

possible injury.

iiiiii Jlll,lllllll

SPEC RCATIO.C, RT

1 1

9.2 9.2

2_/=" 2_/,,,

2" 2"

"110-220 "110-220

20 amp 15 amp

Never point any nozzle or sprayer toward a

person or any part of the body.

Always wear safety goggles or glasses when

spraying.

IIIII _ iiiii

................ i,ii1,1iii

919.176320 " 919,176330

2 3

11.7 14.0

23/,=- 27/e-

2" 2"

220-24.0 220-240

15 amp 15 amp

"Fusetron" Type T "Fusetron" Type T

12.4 14.4

20 gel ASME 30 gal ASME

100 psig 100 psig

125 psig 125 psig

6,4 75

m

7.5 8.5

9.0 10.3

Jill lUll

MODEL #919.178311 (1 HP) air compressor can be oper-

ated on a 15amp circuit provided the following conditions

exist:

t) Voltage supply to circuit Is normal,

2) Circuit Is not used to supply any Other electrical needs

(appliances, lights, etc,)

3) Extension cords comply with specifications in manual.

4) Circuit Is equipped with 15 amp circuit breaker or 15

amp "'Fusetron" Type T time delay fuse.

If any of the above conditions cannot be met or If the

operation of the compressor repeatedly cause interrup-

tion of the power J!may be necessary to operate It from a

20 amp circuit.

When converting 1 HP models to 220-240 volt operation,

the attached three-prong 110-120 volt plug must be

replaced with a three-prong 220-240 volt plug (purchase

loCally) or order line ©ord Part No. SUDL-404-1.

SCFM (Standard Cubic Feet per Minute):

Unit of measure of air delivery

PSIG (Pounds per Square inch Gauge):

Unit of measure of pressure

Page 6

THIS MANUAL IS DESIGNED

TO MAKE IT AS EASY AS POSSIBLE

FOR YOU TO SET UP, OPERATE AND MAINTAIN

YOUR NEW CRAFTSMAN AIR COMPRESSOR

GENERAL INFORMATION

You have purchased an air compressor outfit consisting

ofa 2 cylinder single stage air compressor pumpwithair

tank, an air hose assembly, wheels, a foot extension

bracket and handle. You will also find an air chuck and a

helpful"Power Painting With Sprayers" booklet. This air

compressor can be either portable or permanently

mounted in one place.

These units can be used for operating caulking guns,

grease guns, air brushes, sandblasters, air tools, etc., or

inflating tires and plastic toys, spraying weed killer, in-

secticides, etc.

'GENERAL DESCRIPTION OF OPERATION

To compress air, the pistons move up and down in the

Cylinder. On the downstroke, air is drawn in through the

air intake valve. The exhaust valve remains closed. On

the upstroke of the piston,air iscompressed. The intake

valves close and compressed air is forced out through

the exhaust valve, through the check valve and into the

air tanK. Working air is not available untilthe compressor

has raised the air tank pressure above that required at

Ithe air outlet. Since Ihe air tank pressure is usually

!greater than what isneeded, the tank air is fed to the air

!outlet through a regulator. The air intake opening at the

=endof the console must be kept clear of obstructions

iwhich could reduce air detivery of the compressor.

ASSEMBLYINSTRUCTIONS

Tools Needed For Assembly

TOolsneeded are: (1) a 9/16"socket or open end wrench

for attaching the wheels; and (2) a 7/16"socket or open

end wrench for attaching the foot extension bracket.

Attaching Wheels, Handle, Etc.

i!

PROVID_ AD:OUAT =. CL:_.ARAN3-. STA-

BILJT_,"OR SUPPORT FOR o,,'u_:.,,,_'"'_ TH---

UNIT UP OR DOWN STAIR_ ANi_ F,T_=PS.

THE UNIT MUST B_ LIFTED OR PUSH--D UP

A RAMP.

See diagram on page 10 for attaching wheels (40 or

40A), foot extension bracket (45) and handle (48). The

nuts and bolts can be found in a plastic bag which is

enclosed with the Owner's manuals, air hOSe,etc. Refer

to the illustration Page 10, Key No's. 28, 41, 42, 44, 46

and 47.

NR SWITCH

INTAKE

FILTER"_

AIRCOMPRESSOR

PUMP

OIL

PLUG

PLUG

ON-AUTO/OFF

/

AIR OUll.E'T FOOTEXTENSION DRAIN

CONNECTION BRACKET COCK VALVE

Figure 1

Page 7

It may be necessary to brace or support one

end of the outfit when attaching the wheels

and the foot extension bracket because the

outfit will have a tendency to tip over before

wheels are attached.

1. Insert the handle into pockets under the tank Saddle;

Put one set screw (28) through holein one side oftank

saddle and tighten down on handle.

2. Remove the protective paper strip from the adhesive

backed rubber foot strip (47). Attach the rubber foot

strip to the bottom of the foot extension bracket (45).

Press firmly into place.

3. Attach foot extension bracket (45) to the air tank

bracket. Use one cap screw (46) one Iockwasber (83)

and one hex nut (44) at each end. Tighten.

4, Use one shoulder bolt (41) and one locking hex nut

(42) for attaching each wheel. Use the lower set of

holes for the 8"wheel (40). Use the upper set ofholes

for the 10"wheel (40A). Tighten securely,

Grounding Instructions

WARNING

f '''' "" m

• IIIIII IIII

I[V;,PROPERGROUNDING CAN RESULT INA

R!SK OF ELECTRICAL SHOCK, IN THE

-VENT OF A SHORT CIRCUIT, GROUNDING

R-:)UCES THE RISK OF SHOCK BY PRO-

VIDING AN 5SCAPE WIRE FOR THE ELEC-

TRIC CURRENT, THIS COMPRESSOR MUST

BE PROPERLY GROUNDED. READ THE

FOLLOWING iNSTRUCTIONS.

1. The compressor is equipped with a cord having a

grounding wire with an appropriate grounding plug.

The plug must be used with an outlet that has been

properly installed and grounded in accordance with

all local codes and ordinances. The outlet must have

the same configuration as theplug, DO NOT USE AN

ADAPTER.

2, If repair or replacement of the cord or plug is ever

necessary, do not connect the grounding wire to

either flat blade terminal. (The grounding wire has

insulationwith an outer surface that isgreen- with or

without yellow stripes.)

3. Do not modify the plug that has been provided, If it

does not fit the available outlet, the correct outlet

should be installed by a qualified electrician.

If these grounding instructions are not completely

understood, or if in doubt as to whether the compressor

ispropedy grounded, have the installation checked by a

qualified electrician or serviceman.

Start-Up Procedures

All units are shipped without oil. Serious

damage may result if the following break-in

instructions are not closely followed. This

operation has to be completed only once

when first putting the unit in service,

PlaCeunit on a level surface. Remove oilfillplug (51) and

slowly add a special compressor oil such as Sears

9H6426 or SAE 20=20W SF motor oil until it is even with

the topof the oil fillhole. When filling the crankcase, the

oilflows into itvery slowly.If theoil isadded too quickly,it

will overflow and appear to be full. (It takes 16 fluid

ounces of oil ot fill the crankcase.) Under winter-type

conditions use SAE 10W oil. Multi-viscosity oil (10W30)

may be used but will result in carbon deposits on critical

components and reduce performance and compressor

life. Replace oil fill plug (51). Plug the compressor into

the correct power source. Start the compressor by

switching the ON-AUTO/OFF switch (19) to the ON-

AUTO position. Turn the regulator knob (23) clockwise

fully to permit air to escape and prevent air pressure

bui!dup in the air tank. RUN THE COMPRESSOR 30

MINUTES IN THIS MANNER TO LUBRICATE PIS-

TONS AND BEARINGS. Shut off air with regulator knob

(turn counterclockwise) and let the unit pump up to cut

off pressure. Turn the switch to "OFF" and check the oil

level; add oil if necessary, Turn switch to _ON" and the

unitis ready for use. Connect the air hose to the air outlet

connection (27) located on the front of the console.

Refer to Figure 1.

OPERATION

Control Console

The control console (33) is located on the front of the

unit. The air pressuro coming from the air tank is con-

trolled bythe regulator knob (23). Turn the regulator knob

clec_ise to increase pressure and countemlockwise to

decrease pressure. To avoid minor readjustment after

making a change in pressure setting, always approach

the desired pressure from a lower pressure. When

reducing from a higher to a lower setting, first reduce to

some pressure less than that desired, then bring up to

the desired pressure. Depending on the air flow require-

ments of each particular accessory, the outlet regulated

air pressure might have tobe adjusted under flow condi-

tions, Alsoon the console is the ON-AUTO/OFF switch,

air outlet, safety valve and two pressure gauges. One

gauge shows the air tank pressure and the other the

outlet regulated pressure. Refer to Figure 2.

Page 8

m

PR,=SSURE LOADS BEYOND DESIGN

LIMITS MAY CAUSE TANK RUPTUR- _ OR

-XFLOSIOi'.:. PRESSURE SWITCH OPERA-

TfON IS RELATED TO MOTOR HP, TANK

F_ATIN3 AF_D SAFETY VALVE SETTING. DO

NOT ATT__,,-IPT TO ADJUST REMOVE, OR

D-FEAT THE PRESSURE SWITCH.. OR

CHANGE At;D t_ODIFY ANY PRESSURE

CONTROL RELATED DEVICE.

The pressure switch (19) starts the motor when the air

tank pressure drops below the factory set cut-in pres-

sure and stOpS the motor when the air tank pressure

reaches the factory set cut-off pressure. (See specifica-

tion chart, page 5.)

Safety Valve

WARNING

OVER-PRESSURIZATION OFTHE AIR TANK

MAY CAUSE TANK RUPTURE OR EXPLO-

SION. THE OUTFIT IS PROTECTED FROM

THE OVER-PRESSURIZATION BY A

SAFETY VALVE. DO NOT ELIMINATE, MAKE

ADJUSTMENTS OR SUBSTITUTIONS TO

THIS DEVICE.

I Illll ,_' ",eAeEl't' VALVE_

ON-AUTOIOFF ., TANK PRESSURF

SWITCH

Immmm

m

m

Note

Ifthe overload protector shuts the motor off fre-

quently, check for a possible voltage problem.

Low voltage can also be suspected when"

1. The motor does not get up to full power or

speed;

2. Fuses blOwout when starting the motor.

3. Lights dim and remain dim when motor is

started.

' i

.... Note

=

Avoid using long extension cords. They can

cause a power loss to the motor, Add extra air

hose instead of extension cords.

If an extension cord must be used:

- use only a 3-wire extension cord that has a 3-blade

groundingplug, and a 3-slot receptacle thatwill accept

the plug on the product.

- make sure the cord isin good condition.

- the cord should bend longer than 50 feet.

- theminimum wire size is 12 gauge (AWG). (Wire size

increases as gauge number decreases. 10AWG and

8 AWG mayatso be used, 0o not use 14 AWG or 16

AWG,)

Pressure Release Valve

The pressure release valve located on the side of the

pressure switch is designed to unload air from the com-

pressor head automaUcally al unitshut off. This protects

the motorfrom starting against air pressure remaining in

the compressor head and tubing. When the motor stops

running, air will be heard escaping from the valve for a

few seconds. When the motor is running, no air should

be leaking from the pressure release valve.

MAINTENANCE

AIR OUTLET

Figure 2

The pressure switch (19) is pre-set toshut off the motor

automatically at the maximum operating pressure. If the

)ressure switch does not shut off the outfit at its cul-off

_ressure seffJng, the safety valve will protect against

Jigh pressure by popping at its pre-set pressure.

Motor

I:he motorhas a thermal ovedoad prOtector.Ifthe motor

_verheats for any reason, the overload protector will

;hut off the motor. The motor must be allowed to cool

_efore restarting. Turnthe ON-AUTO/OFF switch to the

)FF position. Depress the reset button Iocaled on the

_nd of the motor. To restart, turn the ON-AUTO/OFF

_itch to the ON position. Refer to Figure 1.

Replacing Air intake Filter

A dirty air intake filter will not allow the compressor to

operate at full capacity. When the intake filter becomes

dirty, oily,or covered with paint overspray, replace it. Do

not Operate the compressor with the air intake filter

removed. To replace the filter, use needle nosed pliers

and pull or pry the old filterout. Replace with new. Refer

to Figure 1.

Checking Safety Valve

WARNING l_

OVER-PRESSURIZATL.qN CAUSING "I_ANK

RUPTURE OR EXPLOSION MAY OCCUR 1=

THE SAFETY' VALVE DO=S NOT WORK

PROPERLy. OCCASIONALLY PULL THE

RING ON THE SAF__TY VALVE TO MAKE

SURE THAT THE VALVE OPERATES

FRE£LY. IF THE VALVE IS STUCK OR DO_S

NOT OPERATE SMOOTHLY, IT MUST BE

REPLACED.

Page 9

Chan_.;,=, v..

Overfilling with oil will cause premature

compressor failure. Do not overfill,

Check oil level in the crankcase before each use. The oil

level should be even with the top of the fill holeand must

not be allowed to be lower than _/8"from the top (6

threads down from the top) at any time. It is recom-

mended that the oil in the base (52) be changed after

every 100hours ofoperation. Todrain the oil,remove the

oil drain plug (51) and collect the oil in a Suitable con-

tainer. Be sure to replace the plug securely before

adding new oil. Use a special compressor oil, such as

Sears 9-16426 or SAE 20-20W SF motor oil (crankcase

oil capacity is 16 fluid ounces). Under extreme winter

conditions use SAE 10W oil,

Location of Air Compressor

Locate the unit in a dry, clean, cool and well ventilated

area. The compressor crankcase and head are

designed with fins which allow for proper cooling: Clean

or blow off fins and any other parts of the compressor

that collect dust Ordirt. A clean compressor runscooler

and provides longer service. Do not place rags, contain_

ers or other material on or against the console which

would obstruct ventilation openings necessary for prop:

er compressor operating temperature. If humidity is

high, a Sears Air Filter can be installed on the air outlet

adapter to remove excess moisture. Follow the instruc-

lions packaged with the air filter for proper installation.

Draining Water From Air Tank

WARNING _

IIIII

WATER WILL CONDENSE IN THE AIR TANK.

IF NOT DRAINED, THE WATER WILL COR-

RODE AND WEAKEN THE TANK. DRAIN

THE TANK AS INSTRUCTED BELOW.

Water should bedrained from the air tank after eacJi use.

Todrain the wamr that has gathered in the air tank, open

drain cock valve (43, page 10) and a)low to drain. _en

empty, close the valve tightly before operating the

compressor.

Note

If drain cock is clogged, release air pressure in

the air tank and then remove. Clean and rein-

stall the valve.

Replacing Belt

i _n," J_ • '- I

SSRIOUS !,',,JUR. OF :'-.,,,,_,',-=_- I_,_."."

OCCUR IF PARTS 0."-T:,-:Z-:.:,:". ,3F. :-.C','-'SE

IT---_r;3 GET " '....... .,,.,A

,,'_,TT": _ ! _--=_NEV_=R OPERATF TH- ....... W_TI-'. ....

COX','SOLE REMOV=--_ T._E " '-

.,3 I,_ :. _Z

SH_, LD S-" R=,F._:OV--':O!'_,L_° WH_i; : ._:

;POWER CORD IS D!£_,_NN--CT-D.

i ;

The motor is mounted on an adjustable motor base. By

loosening the wing nut (31), the motor can be tilted in to

allow for easy tightening or removal of the belt (74).

To replace belt:

1. Unplug unit from power source before repairing.

2. Remove screws (I) from the front and rear of the

console. Remove console (2).

3. Loosen wing nut (31) and tilt motor in.

4. Remove belt and replace with new.

Note

The belt should be centered over the grooves

on the flywheel and motor pulley.

5_PUsh the motor back intoregular position and tighten

wing nut securely. Proper tensionis approximately V="

belt deflection measured midway between the pulley

and flywheel when a 3 pound weight or equivalent

finger pressure is applied at thispoint. A loose belt will

squeal at unit start-up.

6. Replace console (2) and screws (1).

Storage

When you have finished using the compressor, do the

following before storage:

1. Set the On-Auto!Off switch to OFF and unplug the

cord.

2. Relieve all pressure from the air tank.

3. Drain the water from the air tank, then close the drain

valve.

4. Protect the electrical cord and air hose from damage

caused by being stepped on or run over. Roll them

loosely around the OUtfithandle.

9

Page 10

Air Compressor

76

79

31

33 27

81

29

|SA

40 or 40A

_0

43

Page 11

KEY

NO. PART NUMBER DESCRIP_ON

PARTS LIST

J

1 SSF-953-ZN

2 CAC-21

3 CAC-44

3A LA-1666

LA-1687

4 SSF-6627

5 CAC-111

6 SSF-8113-ZN

7 266-18

8 SSF-935

" 9 9-16279

10 SS-8553

11 STD575025

STD575026

12 CAC-16

13 SSF-955

14 SSP-9401

15 STD575050

$TD575051

16 CAC-137

17 CAC-437-1!,

16 SUDL-403-1

SUDL-404-1

"19 CAC-a,P'/'#,,_ -1

20 SUDL-402-2

T21

22 CAC-61

23 CAC-201

23A CAC-202

24 CAC-107

SS-2110

CAC-228

26 TIA-4325

TIA-4125

TIA-4150

26

27 H-2099

28 SS-391

29 C-PU-2833

C-PU-2835

C-PU-2866

30 STD580104

31 STDSa1631..

32 -M_

MO-6039,'P

MO-6221-P

MO*6322-P

33 CAC-20

34 SSF-8086

35 SUDL-59

35A -

Self tapping screw (9 used)

Console

Belt guard closure

Labet (Models 919.176210& 919.176311)

Label (Models 919.176320 & 919.176330)

Stud

Bracket

Lock nut

Filter retainer

Screw #8-32 x 3/a"(2 used)

Kit of two intake filters(1 used)

Connector body

i/,,, Nut (2 used)

1/4"Ferrule (2 used)

Pressure release tube

Thread forming screw 3/,,"-16× 11/2"(5 used)

Connector body

1/2"Nut (2 used)

1/2"Ferrule (2 used)

Outlet tube

Check valve

Cord assembly (Models 9!9.176210 & 919;176311)

Cord assembly (Models 9!9.176320 & 919.176330)

Pressure switch(Models 919.176210 & 919.176311)

Pressure switch (Models 9:19.176320& 919376330)

Cord assembly (motor to pressure switch) , _, . i_----J-_, _._

Panel nut _ _[/_ _'_0_/-)r"/u ,_

Regulator knob

,,- Regulating spring (not shown)

Nipple (Models 919176210 & 919.176311)

Nipple (Model 919.176320)

Nipple (Model 919.176330)

Safety valve (Model 919.176210)

Safety valve ASME (Model ' 919.176311)

Safety valve ASME (Models 919.176320 & 919.176330)

Adapter

aauge(2used)

Set screw

Motor Pulley (Models 919,176210& 919.i76311)

MOtOrPulley (Model 919:176320)

Motor Pulley (Model 919.176330)

Key 3/_,,x _e" x liA"

Wing nut

Motor (Model 919.176210)/_"I'_€::>-_ Lc,'_._r.#-

Motor (Model 9!9.176311

Motor (Model 919.176320)

Motor (Model 919.176330)

Subpanel

Speed nut

Hold down screw

U.L Label (not available)

•See page13 forpartsorderingInformalion.

f-Seepage 13forpartsorderinginformat_'_

11

Page 12

KEY

NO. PARTNUMBER

PARTS LIST (Continued)

DESCRIPTION

36 SUDL-54

37 TA-4001

TA-4003

TA-4007

TA-4043 -

38 LA-1693

LA-1694

LA-1695

39 LA-1689

LA-1690

LA-1691

LA-1692

40 CAC-410

40A CAC-435

41 CAC-60

42 STD541437

43 SS-2707

44 STD541025

45 CAC-104

46 STD522507

47 SUDL-6-1

48 SUDL-43

49 SSF-925

50 SSF-926

5t SSP-1413

52 265-3

"53 265-16

54 265-41

55 265-4-1

CAC-51

56 SSF-92"/

57 265-410

58 CAC-207

59 265-15

CAC-55

"60 265-192-1

"60A CAC-57

"61 265-191-1

"61A CAC-58

"62 265-195-1

"62A CAC-56

63 265-145-2

"64 265-196

65 265-29

"66 SSF-9821

"67 265-26-1

"68 265-25

6g 265-24-!

"70 265-28-1

"70A CAC-54

71 265-19

"72 265-6

Pin

Air tank (Model 919,1762!0)

Air tank ASME (Model 919.176311)

Air tank ASME (Model 919.!763_20)

Air tank ASME (Model 919.176330)

Label (Models 919.176210& 919.176311)

Label (Model 919.176320)

Label (Model 919,176330)

Label (Model 919.176210)

Label (Model 919.176311)

Label (Model 919,176320)

Label (Model 919.176330)

8"Wheel (2 used) (Models 919.176210, 919,176311& 919.176320)

10"Wheel (2 used) (Model 919.176330)

Shoulder bolt (2 used)

Locking hex nut (2 used)

Drain cock valve (1/=-NPT)

Hex nut 1,_"-20(2 used)

Foot extension bracket

Cap screw 1/,"-20 x %" (2 used)

Rubber foot strip

Handle

Thread forming screw 1/4"-20x 7/8"(12 used)

Thread forming screw _"-18 x %" (4 used)

Oil fill/drain plug (2 used) (1/=, NPT)

Base

Base gasket

Needle bearing

Crankcase and Cylinder (MOdels 919.1762!0, 919.176311& 919.176320)

Crankcase and Cylinder (Model 919.176.330)

Screw 1/4%20× 11/e"(4 used)

Connecting md assembly (includes (2) SSF-927 screws) (2 used)

Pistonpin plug (4 used)

Piston (2 used) (Models 919.176210,919.176311 & 919.176320)

Piston (2 used) (Model 919.176330)

Oil ring expander (2 used) (Models 919.176210, 919.176311 & 919.176320)

Oil ring expander (2 used) (Model 9!9.176330)

Oil ring (4 used) (Models 919,176210, 919.176311 & 919.176320)

Oil ring (4 used) (Model 919_176330)

Compression ring (2 used) (Models 919.176210, 919.176311& 919.176320)(Install in top piston

Compression ring (4 used) (Model 919.176330) groove on/y)

Valve plate , _ "..... --......

Exhaust flapper valve with corner bevels (2 used on valve plate)

Restdcter plate (2 used)

Screw (8 used)

Head gasket

Intake flapper valve (2 used on head) _

Head

Valve plate gasket (Models 919.176210, 919.176311, 9!9.176320)

Valve plate gasket (Model 919.176330)

Piston pin (2 used)

Vent filter

"See page 13 for parrs ordering information.

T See Dage 13for partS ordedr_ )nformatJon,

Page 13

PARTS LIST (Continued)

KEY

NO. PART NUMBER

"73 265-1tl

74 C-BT-215

75 STD523107

76 SSN-1014-ZN

77 265 -2

78 265-9

79 265-23

"80 265-13

81 _.265:.L

82 SSW-7367

83 21181-506

SSH-8

9-16163

SI-30-09-1-D

630-01

•Parts Ordering Information

Key No 9, 53, 67, 70, 72, 73,

919.17631.1& 919.176320).

Key No. 9, 53, 67, 70A, 72, 73, 80 available as individual parts and as part of KK-4312 (Model 919.176330)

Key No, 60, 61, 62 only available as part of rtng kit KK-4209 (Models 919.176210,919.17631,1& 919.176320).

Key No. 60A, 61A, 62A only available as part of ring kit KK-4313 (Model 919.176330),

Key No. 19 pressure release valve and nut available as part of KK-4315.

Key No. 64, 66, 68 only available as part of valve kit KK-4275.

1"Internal parts can be purchased as regulator repair kit KK-4294.

DESCRJPTION

Oil seal

Poly-V-beit

Cap screw 5A="-18× %"

Belleviile washer

Flywhee]

End plate i

Needle bearing

End plate gasket

Crankshaft

Strain relief (2 used)

Lockwasher (2 used)

NOT ILLUSTRATED

Air Chuck

Air Hose Assembly (%" x i5')

Owners Manual

"Power Painting With Sprayer" booklet

80 available as individual parts and as part of kit KK-4268 (Models 919.176210.

ACCESSORIES FOR USE WITH SEARS CRAFTSMAN COMPRESSORS AVAILABLE THROt

THE CURRENT GENERAL SEARS CATALOG OR AT FULL LINE SEARS STORES.

1. Spray Guns 9. Inflator Kits

2. Sandblasters 10. Quick Connector Sets: various sizes

3. P_int Tanks

4, Blow Guns

5. Air Brushes

6. Air Tanks

7. Air Tools: sanders, drills, impact wrenches,

hammers

8. Air Hose: 1/4",5/1_"or =/a"inside diameter, 15', 25', "

11. VJscosimeter

12. Air Line Filters

13. Oil Fog Lubricators

14, Tire Air Chucks

15. Air Caulking Gun

15. Air Powered Washer Gun

50' lengths TROUBLESHOOTING GUIDE

P-RFORMING TROUBLESHOOTING OR REPAIRS MAY EXPOSE VOLTAG_ £CJRC=g, MOVING PART_. _.

COMPRESSED AIR SOURCES, PERSONAL INJURY MAY OCCUR IF EXPC'5-7-. ¢._;OP, TO ATT_.MPTING Ai

TROUBLESHOOT|NG OR REPAIRS, THE COMPRESSOR MUST BE DISCONN,CTED FROM THE POWER SOURC

NEVER OPERATE THE OUTFIT WITH THE CONSOLE REMOVED, THE CONSOLE SHOULD B__ REMOVED ON.

WH_,N THE POWER CORD IS DISCONNECTED.

PROBLEM

Motor Will Not Run

....... ,,,,,,,

Motorov,rJ0adprof..on

has tripped.

Tank pressure exceeds pressure

switch cut-in pressure:

CAUSE

CORRECTION

Let motor cool off and reset switch by pres-

sing the red reset button located on the enc

of motor. See motor section on page 6.

Motor will start automatically when tanl

pressure drops below cut-in pressure o

pressure switch.

Page 14

PROBLEM

Motor Will Not Run (Cont'd)

CAUSE

ii, i

Fuse blown, circuitbreaker

pped,

i

iiiii iiii

!) Check fuse box for blown fuse and replace

as necessary or reset circuitbreaker. Do not

use a fuse orcircuit breaker with a rating that

ishigher than what is specified for your par-

ticular branch circuit. (See Specification

Chart, page 5.)

2) Check for proper fuse, only "Fusetron"

Type T fuses are acceptable.

3) Remove check valve and clean or replace

if it is stuckopen or closed.

4) Check for low voltage conditions and/or

proper extension cord.

5) Disconnect the other electrical appliances

from circuitor operate the compressor on its

CORRECTION

Excessive Tank Pressure

(Safety Valve Pops Off)

Wrong gauge wire Or length of

extension cord.

Pressure release valve on pres-

sure switch has not unloaded

head pressure.

Check valve struck.

Loose electrical connections.

Capacitor on the motor.

Faulty motor.

Pressure Switch doesn't shut off

motor.

own branch circuit

Check forproper gauge wire and cord length.

Refer to extension cord recommendation

under motor section on page 8.

Bleed line by pushing lever on pressure

switchto OFF position which opens the pres-

sure release valve. If valve still does not

open, replace it.

A defective check valve results in a constant

air leak at the pressure release valve

attached to the side of the pressure switch

(19)when there is pressure in the air tank and

the compressor is not running. Remove and

clea n or replace check valve (do not

overtighten).

Check wiring connection inside pressure

switch. Pressure switch cover can easily be

removed by lifting cover at rear of switch.

Return to Sears Service Center to check and

replace if necessary.

Unless motor is visibly damaged, remove

motor and have it checked at local Sears

Service Center.

,i,.iiii ,,,,,,,

Move pressure switch lever to the "off"posi-

tion. If outfit doesn't shut off, replace the

switch.

Air Leaks

I'

Pressure switch cut-out too high,

, i,, i

Tube or hose r_tings loose.

Defective check valve.

Return outfit to Sears Service Center to

check and adjust or replace if necessary.

i jiiiiiii i iiiii ii

Tighten fittings with audible leak and check

fittings under pressure with soapy water

solution (do not overtighten).

.A defective check valve results in a constant

air leak at the pressure release valve

attached to the side of the pressure switch

(19) when there is pressure inthe air tank and

the compressor is not running. Remove and

clean or replace check valve (do not

overtighten).

J

Page 15

.... _ ....... wx vv|_l_ q_VUIItl|lb_

PROBLEM

Air Leaks (Cont'd)

Restricted Air Intake

lln i ,,_

Squealing Souncl

ii i i ,, ii

Low Discharge Pressure

iKnocking

CAUSE

ii

Leak at welds.

Air leak in safety valve.

Dirty air filter.

,mini ,..i., pill il II

Belt too loose.

No oil in compressor,

Prolonged excess v,. use of air.

tit it,l _ ilillli

Restricted air intake filter.

Belt too loose.

Hole in hose.

Ill ",1111111111

Loose pulley.

Low oil level.

CORRECTION

DO NOT DRILL IKT_. WELD OF.

OTHERWISE MO,:::)I_=_.' AIR TANI'. OF

TANK WILL BE WEAK=-.NED, TANK

MUST 5-- RF.PLA3_E:.

Operate safety valve manually by pulling on

ring. If valve stillleaks, itshould be replaced.

Clean or replace with new.

,,.,, iiiii iii iiiii __

"lighten wing nut on motor mount.

Add oil to top of fill hole in base.

,i i ii

Decrease amount of air usage, compressor

is not large enough for air requirement. See

specification chart, page 5.

Clean or replace air intake filter.

Tighten wing nut on motor mount.

Check and replace if required.

Tighten pulley sat screw.

Check oil level and maintain at prescribed

level,

Excessive Belt Wear

iiiiiiii

Flywheel loose.

Compressor bolts loose.

Loose belt.

Carbon build up.

Belt too loose.

Belt too tight.

Pulley wobble.

Make sure flywheel is tight by tightening

screw.

Check all belts and tighten as required.

Adjust wing nut on motor mount,

Remove head and valve plate, Clean top of

piston and bottom of valve plate. Reassem-

ble using new gasket and torque screws to

25-30 ft.-tbs,

,,,ll,lllll

Adjust tension using wing nut on motor

mount.

Adjust tension using wing nut on motor

mount.

Check for worn keyway or pulley bore result-

ing from running the compressor with loose

pulleys. Also check for bent motor shaft.

15

Page 16

SEARS

OWNERS

MANUAL

SERVICE

MODEL NO.

919.176210

919.176311

919.176320

919.176330

CRAFTSMAN

AIR COMPRESSOR

Now that you have purchased your Sears Air Compressor, should a

need ever exist for repair parts or service, simply contact any Sears

Service Center and most Seam, Roebuck and Co. stores. Be sure

to provide all pertinent facts when you call or visit.

The model number of your Sears Air Compressor is 919.........................._.

This number can be found on the label which is located on the front

of the sir tank.

HOW TO ORDER

REPAIR PARTS

,

SI-30-09-_-D 5/85

WHEN OROERING REPAIR PARTS, ALWAYS GIVE THE

FOLLOWING INFORMATION:

-PARTNUMBER • PART DESCRIPTION

• MODEL NUMBER

If service or repair parts are required for the motor, supply all motor

nameplate information including manufacturers name.

All parts listed may be ordered from any Sears Service Center and

most Sears stores.

If the parts you need are not stocked locally,your order will be elec-

tronically transmitted to a Sears Repair Parts Distribution Center for

handling.

Sears, Roebuck and Co., Chicago, IL 60684 U.S.A.

.NAMEOFITEM

Printedin U-S,A,

Loading...

Loading...