Page 1

5.5 HP 2 Stage

Snow Thrower

SKU #270-3250

Owner's Manual

DO NOT RETURN TO STORE

Questions? Problems?

Please call our customer help line:

(888) 315-3080 M-F 84 CT

IMPORTANT: PLEASE READ THIS ENTIRE MANUAL BEFORE USING

THIS SNOW THROWER.

Thank you for purchasing a Yardworks ® snow thrower. This manual provides information

regarding the setup, operation, and maintenance of this product. We have made every effort to

ensure the accuracy of the information in this manual. The manufacturer reserves the right to

change this product at any time without prior notice.

Please keep this manual available to all users during the entire life of the snow thrower.

Copyright 2005 Yardworks(R). Do not reprint without written authorization.

Page 2

TABLE OF CONTENTS

GENERAL SAFETY PROCEDURES ........................................................................ 3

PACKAGE CONTENTS ....................................................................................... 6

SNOW THROWER COMPONENTS ......................................................................... 7

ENGINE COMPONENTS ...................................................................................... 8

ASSEMBLY ..................................................................................................... 9

Chute Assembly ........................................................................................ 9

Handle Assembly ....................................................................................... 9

Attaching Drive Speed Control Lever ............................................................... 10

Chute Rotation Handle ................................................................................. 11

Drive Control and Auger Control Cable Assembly ................................................ 11

PREPARING THE SNOW THROWER FOR USE ........................................................ 13

Visually Inspect the Snow Thrower ................................................................... 13

Check Tire Inflation .................................................................................... 13

Add/Check Oil .......................................................................................... 13

Add/Check Gasoline ................................................................................... 14

Adjust Skid Shoes ...................................................................................... 15

OPERATION ..................................................................................................... 16

Starting the Snow Thrower ............................................................................ 16

Using the Snow Thrower .............................................................................. 17

STOPPING THE SNOW THROWER ....................................................................... 19

STORAGE/TRANSPORT PROCEDURES ................................................................ 19

MAINTENANCE / CARE ..................................................................................... 20

Cleaning the Snow Thrower ........................................................................... 20

Clearing Auger or hnpeller Jams .................................................................... 21

Checking Tire Pressure ................................................................................ 21

Checking/Adding Oil .................................................................................. 21

Replacing The Oil ....................................................................................... 22

Air Filter Maintenance ................................................................................. 23

Spark Plug Maintenance ............................................................................... 24

Emptying the Gas Tank ................................................................................ 24

Adjusting Drive and Auger Cables ................................................................... 25

Replacing Shear Pins ................................................................................... 26

SPECIFICATIONS .............................................................................................. 27

TROUBLESHOOTING ......................................................................................... 27

SNOW THROWER EXPLODED VIEW .................................................................... 29

SNOW THROWER PARTS LIST ............................................................................. 30

ENGINE EXPLODED VIEW ................................................................................. 31

ENGINE PARTS LIST .......................................................................................... 32

WARRANTY ..................................................................................................... 33

Page 3

GENERAL SAFETY PROCEDURES

Please familiarize yourself with the following safety symbols and words:

The safety alert symbol A is used with one of the safety words (DANGER, CAUTION,

or WARNING) to alert you to hazards. Please pay attention to these hazard notices both

in this manual and on the snow thrower.

DANGER: Indicates a hazard that will result in serious injury or death if instructions are

not followed.

WARNING: Indicates a strong possibility of causing serious injury or death if

instructions are not followed.

CAUTION: Indicates a possibility of personal injury or equipment damage if

instructions are not followed.

O If you have any questions regarding the hazard and safety notices listed in this

manual or on the product, please call (888) 315-3080 M-F 8-5CT before using the

snow thrower.

A DANGER: This snow thrower produces poisonous carbon monoxide gas when

running. This gas is both odorless and colorless. Even if you do not see or smell

gas, carbon monoxide may still be present. Breathing this poison can lead to

headaches, dizziness, drowsiness, and eventually death.

• Use outdoors ONLY in non-confined areas.

A WARNING: The exhaust from this product contains chemicals known to cause

cancer, birth defects, or other reproductive harm.

WARNING: This snow thrower may emit highly flammable and explosive

gasoline vapors, which can cause severe burns or even death. A nearby open flame

can lead to explosion even if not directly in contact with gas.

• Do not operate near open flame.

• Do not smoke near snow thrower.

• Always turn snow thrower off before refueling. Allow snow thrower to cool for

at least 2 minutes before removing fuel cap. Loosen cap slowly to relieve

pressure in tank.

• Do not overfill gas tank. Gas may expand during operation. Do not fill to the top

of the tank.

• Always check for spilled gas before operating.

• Empty gasoline tank before storing or transporting the snow thrower.

• Before transporting, turn fuel valve to off and disconnect spark plug.

Page 4

A WARNING: Foreign objects entering the auger or impeller can create clogs,

jams, projectiles, and other dangerous conditions.

• Do not use in the path of wires, doormats, snow toys, or other foreign objects.

• If the snow thrower intakes a foreign object, stop the engine, wait for the auger

and impeller to stop rotating, and inspect the snow thrower for damage.

• Turn off the engine and make sure that all moving parts have stopped before

clearing any clogs or jams.

• If the snow thrower makes any abnormal sounds or vibrations, stop the engine

and inspect the snow thrower.

• Use extreme caution when operating on or near dirt or gravel roads.

A WARNING: The auger and impeller rotate at fast speeds that can cause

damage or even amputation of body parts. Even if you do not see the auger or

impeller rotating, they may start at any time if the engine is running.

• Always turn off the engine before attempting to clear any clogs or jams.

• Keep hands and feet away from rotating parts while the engine is running.

• Do not wear loose fitting clothing that can become entangled in rotating parts.

A WARNING: This snow thrower is intended for use in conditions that are cold,

slippery, and otherwise naturally hazardous. Take precautions when operating

machinery in these conditions.

• Always wear warm clothing and shoes intended for slippery surfaces.

• Always operate in daylight with good visibility.

• Never run with snow thrower and be alert to all surrounding people and traffic.

• Do not operate the snow thrower on steep inclines.

• Disengage the drive mechanism to neutral before starting the engine.

• Always hold on to the handles while operating. Never leave the snow thrower

while the engine is running.

A WARNING: This snow thrower produces heat when running. Temperatures

near exhaust can exceed 150°F (65 ° C).

• Do not touch hot surfaces. Pay attention to warning labels on the snow thrower

denoting hot parts of the machine.

• Even in cold conditions, allow the snow thrower to cool several minutes after use

before touching engine or areas that heat during use.

CAUTION: Misuse of this snow thrower can damage it or shorten its life.

• Use the snow thrower only for its intended purposes.

• After starting the engine, allow it to adjust to outdoor temperatures before

clearing snow.

• Do not attempt to clear snow at too fast a rate, as this may overload the snow

thrower.

• Use only Yardworks :_: approved attachments or replacement parts with this snow

thrower.

• Never make adjustments to the snow thrower while the engine is running.

Page 5

A WARNING: In addition to the above warnings please note the following

precautions that should be followed when operating this or ANY machine.

• Read all manuals and warning labels before using a machine.

• Never operate a machine with any guard or cover removed.

• Remove all adjusting keys and wrenches before use.

• Do not allow children or uninstructed persons to operate.

• Use the right tool. Do not force the tool or attachment to do a job for which it was

not designed.

• Do not wear loose clothing, neckties, or jewelry that can get caught in moving

parts. Wear a protective hair covering to contain long hair. Do not wear open-

toed shoes.

• Do not overreach. Keep proper footing and balance at all times.

• Always wear safety glasses when operating.

• Always store machines in a clean dry area free from grease and oil. Never use

petroleum based products or any solvents to clean a tool.

• Allow motor to come up to full speed before operating.

In addition to the above safety notices, please familiarize yourself with the safety and

hazard markings on the snow thrower.

Page 6

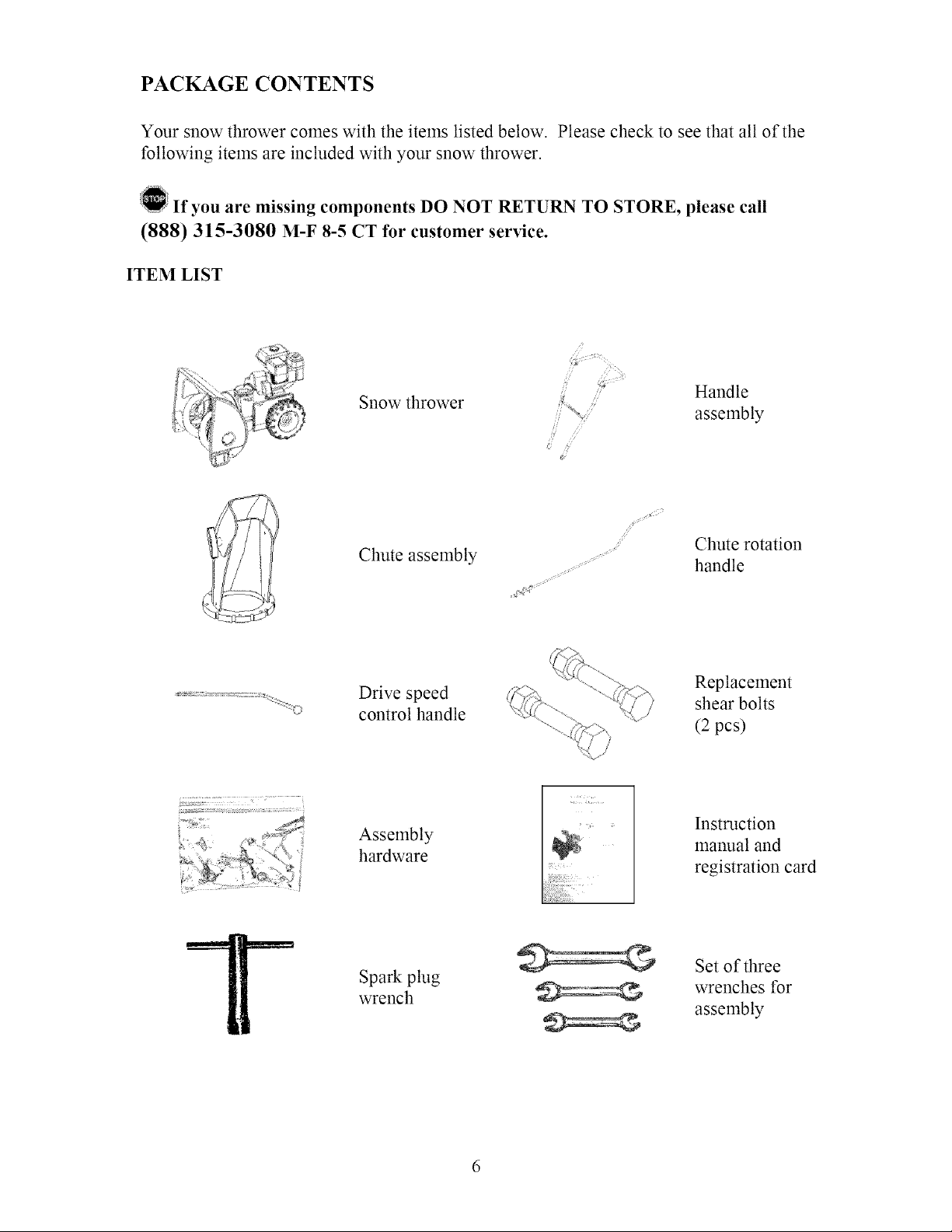

PACKAGE CONTENTS

Your snow thrower comes with the items listed below. Please check to see that all of the

following items are included with your snow thrower.

O If you are missing components DO NOT RETURN TO STORE, please call

(888) 315-3080 M-F 8-5 CT for customer service.

ITEM LIST

Handle

Snow thrower assembly

&

Chute assembly

Drive speed

control handle

Assembly

hardware

Spark plug

wrench

Chute rotation

handle

Replacement

shear bolts

(2 pcs)

Instruction

manual and

registration card

Set of three

wrenches for

assembly

Page 7

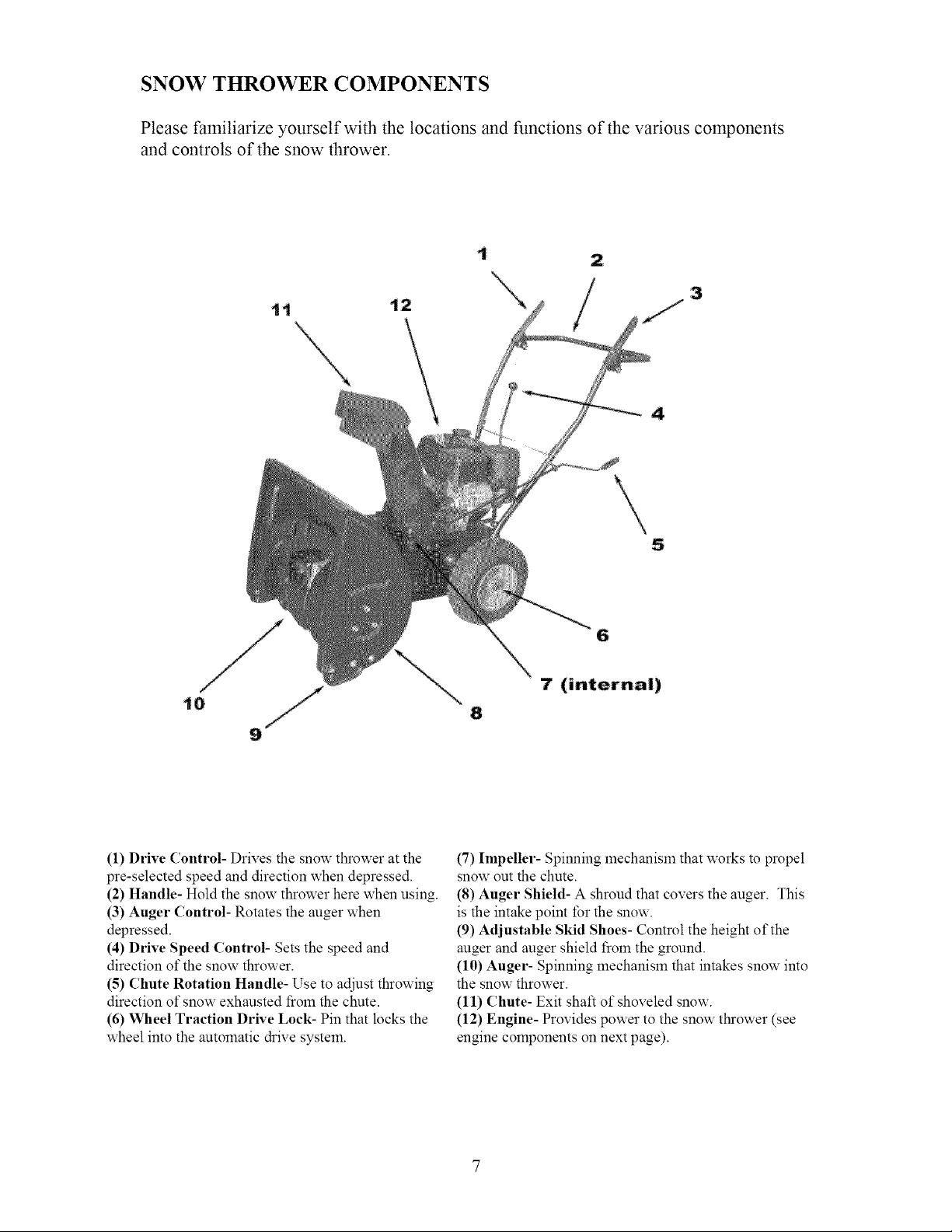

SNOW THROWER COMPONENTS

Please familiarize yourself with the locations and functions of the various components

and controls of the snow thrower.

2

3

4

\

t0

(1) Drive Control- Drives the snow thrower at the

pre-selected speed and direction when depressed.

(2) Handle- Hold the snow thrower here when using.

(3) Auger Control- Rotates the auger when

depressed.

(4) Drive Speed Control- Sets the speed and

direction of the snow thrower.

(5) Chute Rotation Handle- Use to adjust throwing

direction of snow exhausted from the chute.

(6) Wheel Traction Drive Lock- Pin that locks the

wheel into the automatic drive system.

5

\

7 (internal)

(7) Impeller- Spinniug mechanisln that works to propel

snow out the chute.

(8) Auger Shield- A shroud that covers the auger. This

is the intake point for the snow.

(9) Adjustable Skid Shoes- Control the height of the

auger and auger shield from the ground.

(10) Auger- Spinning mechanism that intakes snow into

the snow thrower.

(11) Chute- Exit shaft of shoveled snow.

(12) Engine- Provides power to the snow thrower (see

engine components on next page).

Page 8

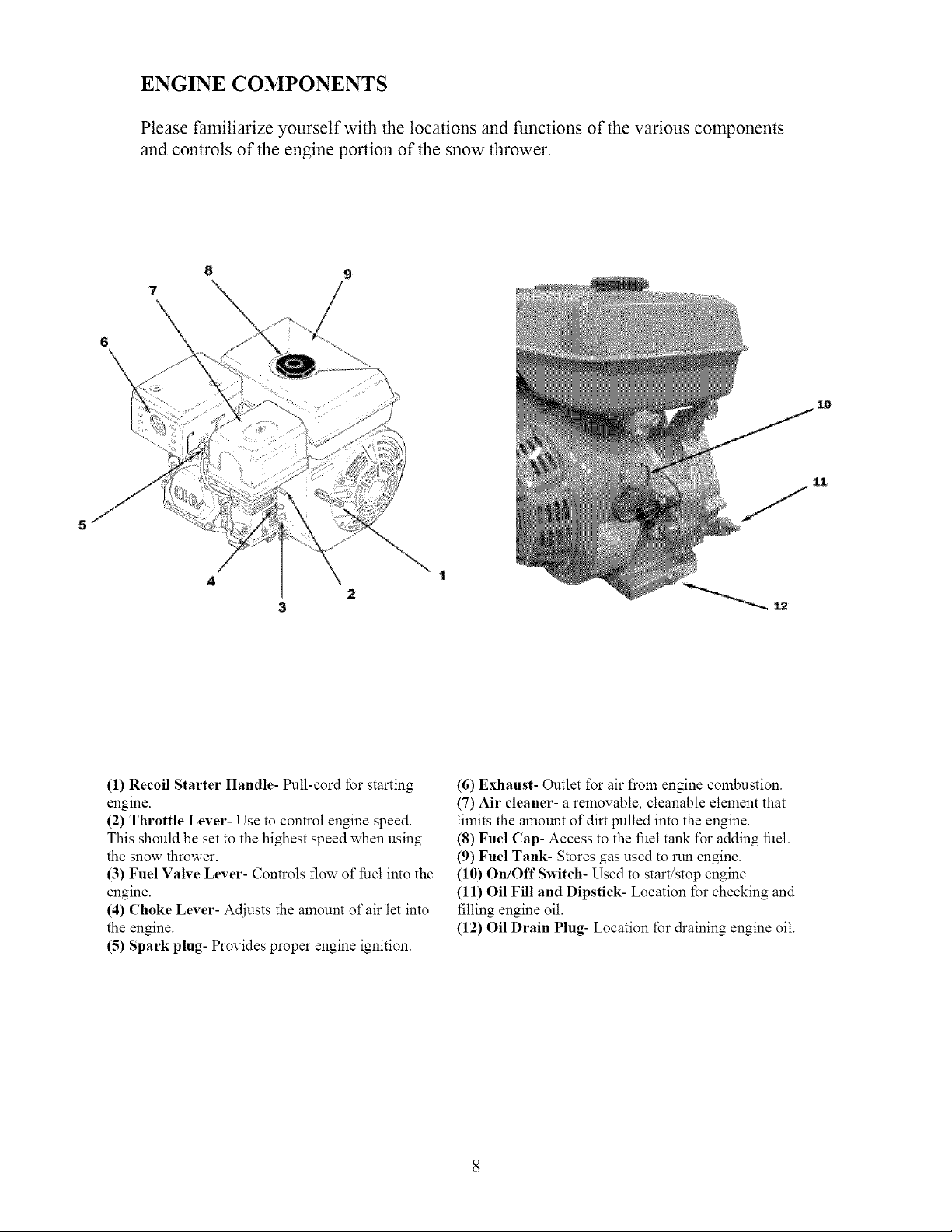

ENGINE COMPONENTS

Please familiarize yourself with the locations and functions of the various components

and controls of the engine portion of the snow thrower.

9

10

(1) Recoil Starter Handle- Pull-cord for starting

engine.

(2) Throttle Lever- Use to control engine speed.

This should be set to the highest speed when using

the snow thrower.

(3) Fuel Valve Lever- Controls flow of fuel into the

engine.

(4) Choke Lever- Adjusts the amount of air let into

the engine.

(5) Spark plug- Provides proper engine ignition.

(6) Exhaust- Outlet for air from engine combustion.

(7) Air cleaner- a removable, cleanable element that

limits the amount of dirt pulled into the engfue.

(8) Fuel Cap- Access to the fuel tank for addfug fuel.

(9) Fuel Tank- Stores gas used to run engine.

(10) On/Off Switch- Used to start/stop engine.

(11) Oil Fill and Dipstick- Location for checking and

filling engine oil.

(12) Oil Drain Plug- Location for draining engine oil.

Page 9

ASSEMBLY

In order to best protect the snow thrower while in the package, this product comes with

some components disassembled. Please complete the following assembly steps before

proceeding to use the snow thrower. For ease of assembly, we recommend attaching the

components in the order listed in this manual.

If after reading this section, you are unsure about how to perform any of the steps

please call (888) 315-3080 M-F 8-5 CT for customer service

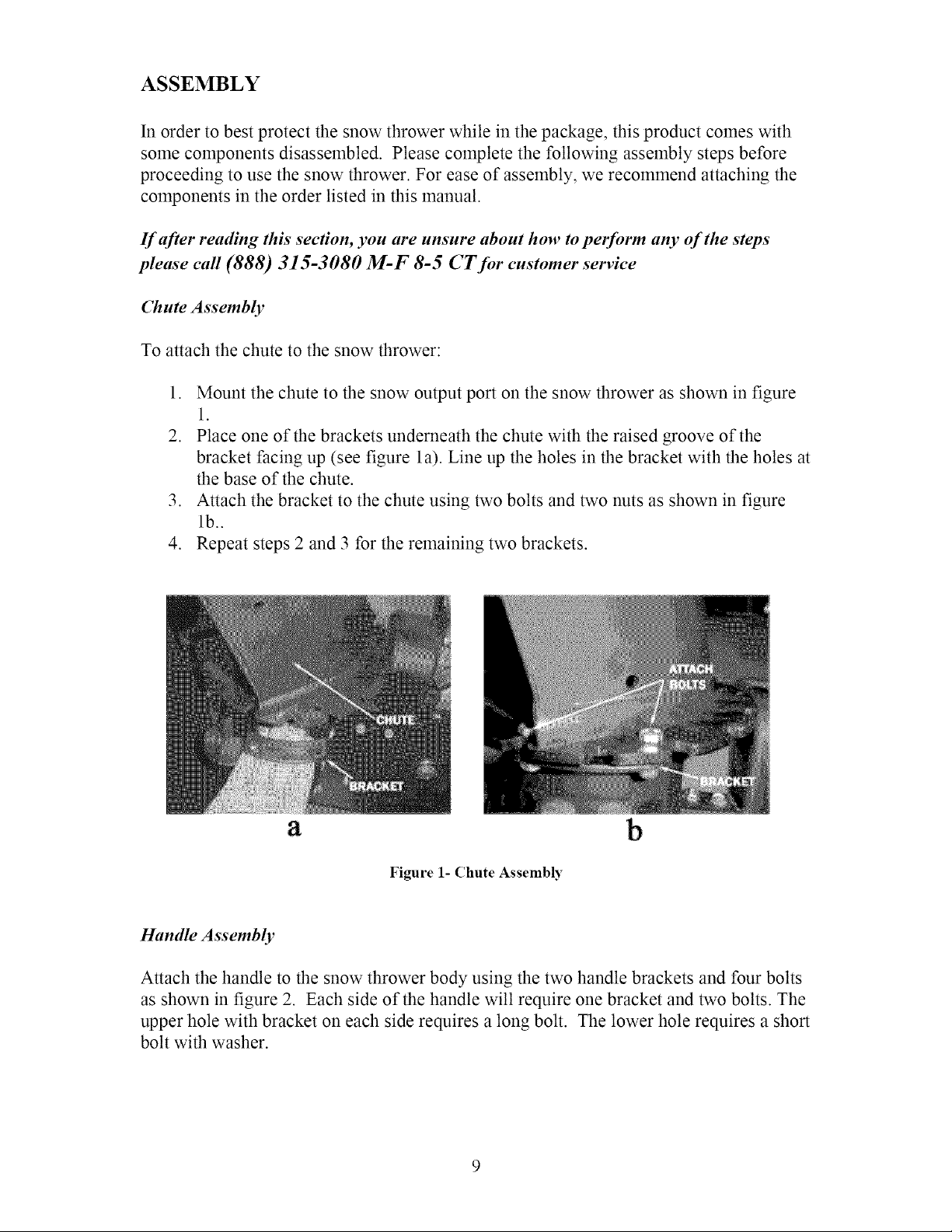

Chute Assembly

To attach the chute to the snow thrower:

1. Mount the chute to the snow output port on the snow thrower as shown in figure

1.

2. Place one of the brackets underneath the chute with the raised groove of the

bracket facing up (see figure la). Line up the holes in the bracket with the holes at

the base of the chute.

3. Attach the bracket to the chute using two bolts and two nuts as shown in figure

lb..

4. Repeat steps 2 and 3 for the remaining two brackets.

a b

Figure 1- Chute Assembly

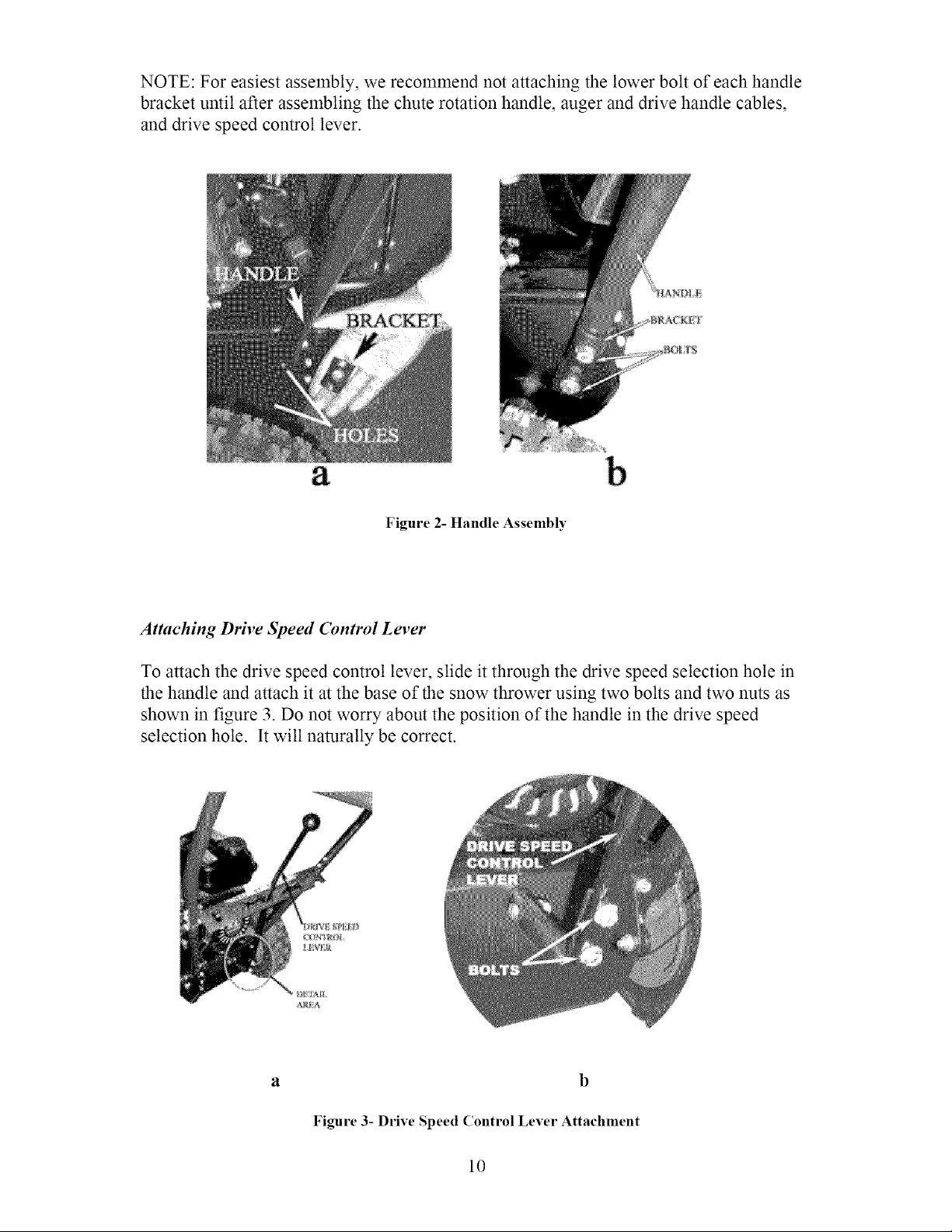

Handle Assembly

Attach the handle to the snow thrower body using the two handle brackets and four bolts

as shown in figure 2. Each side of the handle will require one bracket and two bolts. The

upper hole with bracket on each side requires a long bolt. The lower hole requires a short

bolt with washer.

Page 10

NOTE: For easiest assembly, we recommend not attaching the lower bolt of each handle

bracket until after assembling the chute rotation handle, auger and drive handle cables,

and drive speed control lever.

Figure 2- Handle Assembly

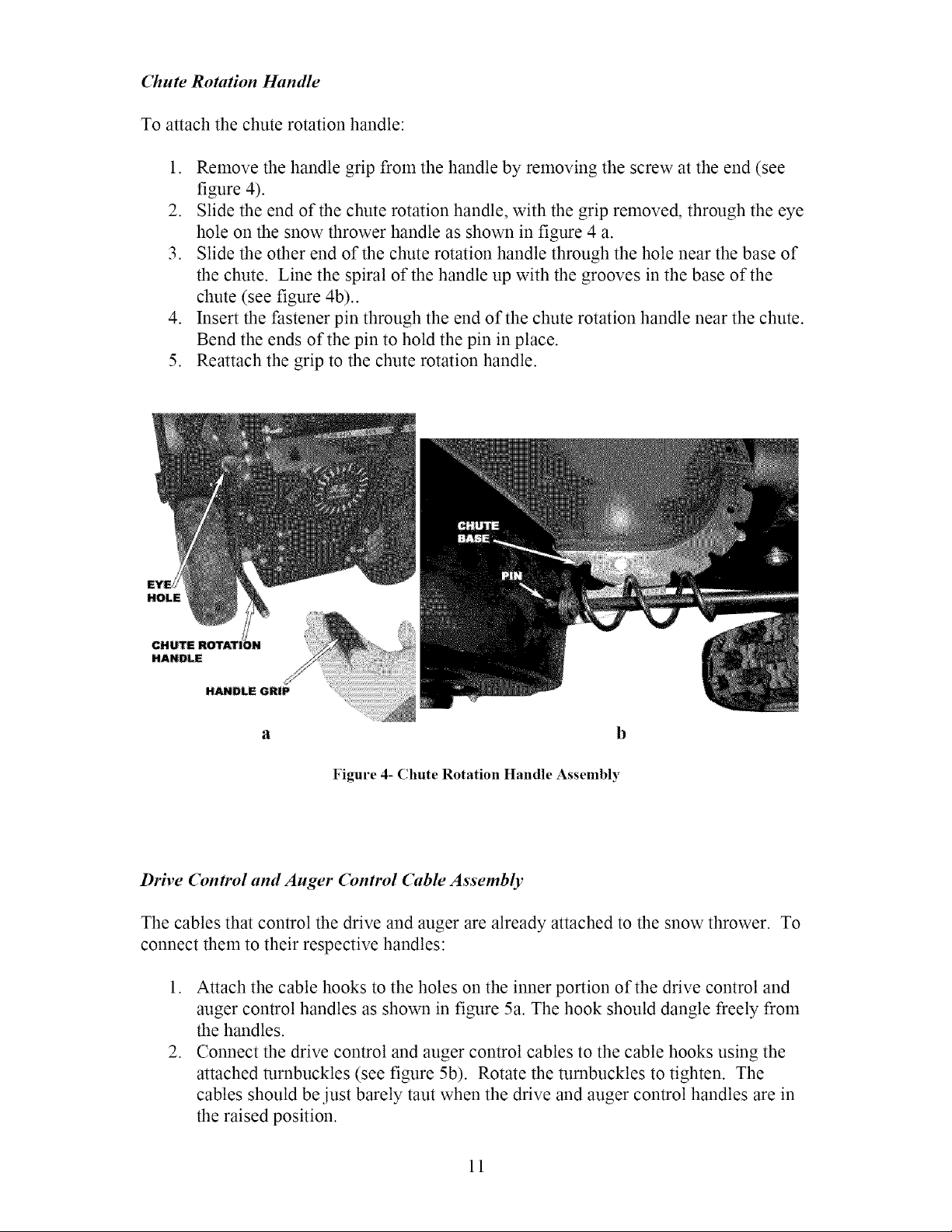

Attaching Drive Speed Control Lever

To attach the drive speed control lever, slide it through the drive speed selection hole in

the handle and attach it at the base of the snow thrower using two bolts and two nuts as

shown in figure 3. Do not worry about the position of the handle in the drive speed

selection hole. It will naturally be correct.

b

Figure 3- Drive Speed Control Lever Attachment

10

Page 11

Chute Rotation Handle

To attach the chute rotation handle:

1. Remove the handle grip from the handle by removing the screw at the end (see

figure 4).

2. Slide the end of the chute rotation handle, with the grip removed, through the eye

hole on the snow thrower handle as shown in figure 4 a.

3. Slide the other end of the chute rotation handle through the hole near the base of

the chute. Line the spiral of the handle up with the grooves in the base of the

chute (see figure 4b)..

4. Insert the fastener pin through the end of the chute rotation handle near the chute.

Bend the ends of the pin to hold the pin in place.

5. Reattach the grip to the chute rotation handle.

HOLE

HANDLE

_DLE GRIP

b

Figure 4- Chute Rotation Handle Assembly

Drive Control and Auger Control ('able Assembly

The cables that control the drive and auger are already attached to the snow thrower. To

connect them to their respective handles:

1. Attach the cable hooks to the holes on the inner portion of the drive control and

auger control handles as shown in figure 5a. The hook should dangle freely from

the handles.

2. Connect the drive control and auger control cables to the cable hooks using the

attached turnbuckles (see figure 5b). Rotate the turnbuckles to tighten. The

cables should be just barely taut when the drive and auger control handles are in

the raised position.

11

Page 12

NOTE: When attaching the cables, be sure they are properly threaded through the main

handle. The auger control cable should fit through the hole next to the speed selector.

The drive control cable should fit in the handle groove on the other side of the speed

selector.

C TIGHTEN

b

Figure 5- Cable attachment

12

Page 13

PREPARING THE SNOW THROWER FOR USE

_ The following section describes steps you must follow to prepare the snow thrower

for use. If after reading this section, you are unsure about how to perform any of the

steps please call (888) 315-3080 M-F 8-5 CT for customer service. Failure to

perform these steps properly can damage the snow thrower or shorten its life.

Visually Inspect the Snow Thrower

Before using the snow thrower for the first time, be sure that the machine is properly

assembled (see the "Assembly" section of this manual). Check that all parts are properly

attached and free from damage. If you are unsure about the assembly or condition of any

of the snow thrower parts, call the customer help line for service.

Before each use of the snow thrower, check the snow thrower for damaged or missing

components. If parts are damaged or missing, do not attempt to use the machine.

Instead, call our customer help line.

Check Tire Inflation

Before each use of the snow thrower, check the tire pressure. The pressure of the two

tires should be equal and in the range of 20-24 PSI for each tire to ensure the best

performance.

The pressure can be checked using an ordinary tire pressure gauge. Fill the tires using a

portable air compressor or other compressed air source. NOTE: Do not over-inflate the

tires. For more detail about how to check the tire pressure and fill the tires, see the

Maintenance section of this manual.

Add/Check Oil

If this is' your first time using this snow thrower:

The snow thrower requires engine oil to operate properly. The snow thrower, when new

from the package, contains 17o oil in the engine crankcase. To add oil to your snow

thrower for the first time, follow these steps:

1. Make sure the snow thrower is fully assembled and on a level surface.

2. Unscrew the oil filler cap from the engine crankcase as shown in figure 6.

3. Using a funnel, add approximately 21 fluid oz. of motor oil. Use a regular car

motor oil that performs well in cold conditions. The temperature conditions and

recommended oil grade will vary by geographic area.

4. Wipe the dipstick attached to the oil filler cap with a clean dry cloth. Now replace

the cap.

13

Page 14

5. Remove the oil filler cap again and inspect the attached dipstick. Oil should now

be visible on the stick. Ifoil is not visible on the stick, you may need to add more

oil and repeat steps 4 and 5.

6. Replace the oil filler cap and screw tightly.

NOTE: Even if you have previously measured 21 ounces ofoil, some spillage is

common when adding oil to the crankcase. Always ensure that the engine has

sufficient oil by checking the dipstick. See Figure 6 for proper oil level.

,9399U

J::IV3J

Figure 5- Removing oil filler cap

If this is not your first time using the snow thrower."

Before

each use, you should check the oil level in the snow thrower:

1.

Unscrew the oil filler cap and wipe the dipstick with a clean dry cloth. Now

Figure 6- Proper oil level

replace the cap.

.

Remove the oil filler cap again and inspect the attached dipstick. Oil should now

be visible on the stick. Ifoil is not visible on the stick, you may need to add more

oil and repeat these steps to check the proper oil level.

.

Once you have ensured the engine oil level is correct, replace the oil filler cap and

screw tightly.

Add/Check Gasoline

A WARNING: Gasoline and gas fumes are highly flammable.

• Do not fill tank near an open flame.

• Do not overfill. Always check for fuel spills.

To ensure that the snow thrower runs smoothly, use only FRESH, U_NLEADED GAS

WITH AN OCTANE RATING OF 87 OR HIGHER. To add gasoline:

1. Make sure the snow thrower is turned off and situated on a level surface.

2. Unscrew gas cap and set aside (NOTE: the gas cap may be tight and hard to

unscrew).

3. Slowly add unleaded gasoline to the fuel tank. The snow thrower fuel tank when

new from the package is empty. The capacity of the fuel tank is 0.95 Gallons. BE

CAREFUL NOT TO OVERFILL. Do not fill the gas tank to the very top.

4. Replace fuel cap and wipe up any spilled gasoline with a dry cloth.

14

Page 15

IMPORTANT:

• Never use an oil/gasoline mixture.

• Never use old gas.

• Avoid getting dirt or water in the fuel tank.

• Gas can age in the tank and make it hard to start up the snow thrower in the

future. Never store the snow thrower for extended periods of time with fuel in the

tank.

Adjust Skid Shoes

Adjustment of the skid shoes governs the height above the ground at which the auger

shield operates.

For clearing snow from concrete, asphalt, and other smooth surfaces, it is best to set the

auger shield so that the bottom of the shield scrapes the ground.

For clearing snow from gravel, dirt, and other rough surfaces, it is best to set the auger

shield slightly above the ground to avoid dirt and gravel from entering the auger.

The optimal height of the shield will vary depending on the type of surface being cleared.

Surfaces with larger gravel or stones would require a more raised auger shield.

To adjust the skid shoes:

1. Make sure the snow thrower is on a solid, smooth, and level surface.

2. Place a spacer board on the ground underneath the auger shield between the skid

shoes. The thickness of the board should be the same as the height above the

ground you wish to raise the auger shield to. The skid shoes should not touch the

board (see figure 7).

3. Using a wrench, loosen the four nuts located on the skid shoes (2 nuts on each

skid shoe) and allow the skid shoes to slide to the ground.

4. Re-tighten the nuts on the skid shoes and wheel the snow thrower off of the

spacer board

A_UST

SKID SHOf

SPACER

BOARD

Figure 7- Adjusting Skid Shoes

15

Page 16

OPERATION

_ Before starting the snow thrower, make sure you have read and performed the

steps in the "Preparing the Snow Thrower for Use" section of this manual. If you are

unsure about how to perform any of the steps in this manual please call (888) 315-

3080 M-F 8-5 CT for customer service.

Starting the Snow Thrower

To start up the snow thrower, perform the following steps:

1. Turn the engine fuel valve lever to the "on" position (see figure 8).

2. Move the choke lever to the closed position as shown in figure 7 (NOTE: If you

have just been using the snow thrower and the engine is still warm, keep the

choke in the "open" position).

3. Move the engine throttle lever to the last position (see figure 8).

4. Move the engine switch to the "on" position as shown in figure 9.

CHOKE

Figure 8 Engine lever positions

ENGINE SWITCH

ON

Figure 9- Engine switch positions

16

Page 17

5. Pull on the recoil starter handle slowly until a slight resistance is felt (see figure

10) then pull quickly to start the engine. Return cord gently into the machine.

Never allow the cord to snap back.

6. If engine fails to start, repeat step 5. NOTE: After repeated attempts to start the

engine, please consult the troubleshooting guide before attempting again. If

problems persist please call (888) 315-3080 M-F 8-5 CT.

7. Once the engine has started and run for about a minute, move the choke lever

about halfway towards the "open" position. Wait another 30 seconds and then

move the choke lever all the way to the "open" position.

NOTE: Allow the snow thrower to run outdoors for several minutes before attempting to

use the machine.

Figure 10- Pulling the recoil starter handle

Using the Snow Thrower

Once the snow thrower has been running outside for several minutes, it is now ready for

use. To use the snow thrower:

1. Make sure the path in front of the snow thrower is free from people, animals,

objects, and all other obstructions except for snow.

2. Adjust the chute outlet to the desired direction. Turn the chute rotation handle

clockwise or counter-clockwise until the desired position is reached (see figure

11).

IMPORTANT: Never direct the chute outlet toward people or animals. While

snow may seem harmless, it can contain rocks or other debris that can cause

serious injury when projected through the chute.

3. Move the drive speed control lever to the desired speed. There are seven speeds-

five forward speeds and two reverse speeds. 1 is the slowest forward speed and 5

is the fastest forward speed. R1 is the slowest reverse speed and R2 is the fastest

reverse speed (see figure 12). NOTE: There is no neutral drive setting.

4. Press down on the auger control handle. The auger should start spinning.

5. Press down on the drive control handle. The machine should start moving in the

direction and speed selected with the drive speed control lever.

6. When you have finished clearing the ilmnediate snow path, release the auger

control handle and the drive control handle.

17

Page 18

You can adjust the drive speed and direction using the drive speed control lever. Be

sure to release both the auger control handle and the drive control handle before

adjusting the drive speed control lever.

As you use the snow thrower, you may want to adjust the chute outlet direction. Be

sure to release both the auger control handle and the drive control handle before

adjusting the chute outlet direction.

Figure 11- Adjusting Chute Outlet Direction Figure 12- Adjusting Drive Speed and Direction

CHUTE DEFLECTOR

The angle of the chute deflector controls the throwing distance of the snow leaving the

chute. Raising the angle will increase the throwing distance. Lowering the angle will

decrease the throwing distance (see figure 13).

To adjust the chute deflector:

1. Make sure the engine is stopped and the auger and impeller have come to a full

stop.

2. Loosen the knobs on the chute deflector as shown in figure 13 and adjust the

chute deflector to the desired angle.

3. Re-tighten the knobs on the chute deflector. Do not over-tighten.

increase

throwing_

distance _1_

decrease

throwing

distance

ustment

Figure 13- Adjusting the chute deflector

18

Page 19

STOPPING THE SNOW THROWER

When you are finished using the snow thrower, perform the following steps to shut it

down:

1.

Move the snow thrower away from any snow piles.

2.

Run the auger and impeller for 30 seconds to clear any remaining snow inside the

snow thrower.

.

Set the engine switch to the "off' position. This will stop the motor.

4.

Move the fuel valve lever to the "off' position.

5.

Dust snow off of all snow thrower surfaces.

WARNING: Allow the snow thrower to cool for several minutes before touching

areas that become hot during use.

CAUTION: Allowing gas to sit in the snow thrower fuel tank for long periods of

time without use can make it difficult to start the snow thrower in the future. Never

store snow thrower for extended periods of time with fuel in the tank.

STORAGE / TRANSPORT PROCEDURES

A CAUTION: Never place any type of storage cover on the snow thrower while it

is still hot.

When transporting or storing your snow thrower for extended periods of time:

• Empty the gas tank (see "Emptying the Gas Tank" in the "Maintenance"

section).

• Disconnect the spark plug.

• Do not obstruct any ventilation openings.

• Keep the snow thrower in a cool dry area.

19

Page 20

MAINTENANCE/CARE

Proper routine maintenance of the snow thrower will help prolong its life. Please

perform maintenance checks and operations according the schedule in figure 14.

If you have questions about any of the maintenance procedures listed in this manual,

please call (888) 315-3080 M-F 8-5CT.

CAUTION: Never perform maintenance operations while the snow thrower is

running.

Recommended Maintenance Schedule

Mechanism Function Frequency

Auger and

Impeller

Tires

Engine Oil

Air Filter

Spark Plug

Gas Tank

Drive and

Auger Cables

Shear Pins

Clear jams

check pressure

check level

replace

check

clean

check/clean

check gas level

Empty

Adjust tension As necessary

Replace When broken

Every 50 hours or as needed

Every 50 hours or as needed

Before storing for extended time

As necessary

Before each use

Before each use

Every 10 hours

Every 100 hours

Before each use

Figure 14- Recommended maintenance schedule

('leaning the Snow Thrower

TIMELINE: When dirty.

To clean the snow thrower, use a damp cloth and mild detergent on the surfaces only.

Never get soap or water inside the working mechanisms of the snow thrower.

NOTE: Do not clean with water when the snow thrower is cold from being outdoors as it

may cause water to freeze onto the machine and damage it.

20

Page 21

Clearing Auger or Impeller Jams

A WARNING: The auger and impeller rotate at fast speeds that can cause damage

or even amputation to body parts. Even if you do not see the auger or impeller

rotating, they may start at any time if the engine is running.

• Always turn off the engine before attempting to clear any clogs or jams.

• Keep hands and feet away from rotating parts while the engine is running.

• Do not wear loose fitting clothing that can become entangled in rotating parts.

To clear a jam in the auger or impeller:

1. Turn off the snow thrower engine

2. Wait until the auger and compeller have come to a full stop.

3. Clear any visible jams using a long stick or broom handle. DO NOT try to clear

jams with your hands or feet.

4. If the jam is too difficult to clear, do not force it out. Call the customer service

line at (888) 315-3080.

Checking Tire Pressure

TIMELINE: Before each use for best performance.

To get the best performance from your snow thrower, the pressure in the tires should be

equal and in the range of 20 to 24 PSI. To check the tire pressure, unscrew the inflation

nozzle cap and attach an ordinary tire pressure gauge as shown in figure 15. If needed,

inflate using an air compressor or other compressed air source. DO NOT OVER-

1NFLATE.

Figure 15- Checking tire pressure

CheeMng/ Adding Oil

TIMELINE: Before each use, you should check the oil level in the snow thrower:

1. Unscrew the oil filler cap and wipe the dipstick with a clean dry cloth (figure 16).

Now replace the cap.

2. Remove the oil filler cap again and inspect the attached dipstick. Oil should now

be visible on the stick. Ifoil is not visible on the stick, you may need to add more

oil and repeat these steps to check the proper oil level. Use a regular car motor oil

21

Page 22

that performs well in cold conditions. The telnperamre conditions and

recommended oil grade will vary by geographic area.

.

Once you have ensured the engine oil level is correct, replace the oil filler cap and

screw tightly.

Figure 16- Removing oil filler cap Figure 17- Proper oil level

Rephtcing the Oil

TIMELINE: You should drain and replace the oil in the crankcase every 50 hours or

when dirty.

To drain the oil from the crankcase:

1. Place a bucket near the engine to catch oil as it drains.

2. Using a wrench, unscrew the oil drain plug. The oil drain plug is located just

below and to the left of the oil filler cap as shown in figure 18. Allow all the oil

to drain from the crankcase.

3. Replace the oil drain plug and tighten with the hex wrench.

Figure 18- Draining the oil

22

Page 23

After you have drained the dirty oil, refill the crankcase with fresh auto motor oil. To fill

the crankcase, perform the steps listed in the "Checking/Adding Oil" portion of this

MAINTENANCE section.

NOTE: Never dispose of used motor oil in the trash or down a drain. Please call

your local recycling center or auto garage to arrange oil disposal.

Air Filter Maintenance

TIMELINE: Clean the air filter every 50 hours or more often in dirty environments.

To clean the air filter:

1. Unscrew the wing nut from the top of the air filter and remove the plastic case

(see figure 19).

2. Unscrew the wing nut that holds the metal air filter bracket to the machine.

Remove the metal bracket with sponge attached.

3. Slide the sponge element off of the metal bracket. Wash the sponge element in

household detergent and warm water. Allow to dry.

4. Soak the dry element in engine oil. Squeeze out any excess oil.

5. Tap the metal bracket, with paper air filter inside, against a hard surface to knock

out any dirt.

6. Slide the sponge element back onto the metal bracket.

7. Replace the metal bracket and secure with the inner wing nut. Then replace the

plastic cover and secure with the outer wing nut.

@

Figure 19- Removing the air filter

23

Page 24

Spark Plug Maintenance

TIMELINE: Every 100 hours or as needed.

The spark plug is important for proper engine operation. A good spark plug should be

intact, free of deposits, and properly gapped. To inspect your spark plug:

1. Pull on the spark plug cap to remove it.

2. Unscrew the spark plug from the engine using the spark plug wrench included

with this product (see figure 20).

3. Visually inspect the spark plug. If it is cracked or chipped, discard and replace

with a new spark plug. Measure the plug gap with a gauge (see figure 21). The

gap should be 0.7-0.8ram (0.028-0.03 lin).

4. If you are re-using the spark plug, use a wire brush to clean any dirt from around

the spark plug base and then re-gap the spark plug.

5. Screw the spark plug back into its place on the engine using the spark plug

wrench. Replace the spark plug cap.

Figure 20- Removing the spark plug Figure 21- Measuring the spark plug gap

Emptying the Gas Tank

TIMELINE: Before storing the snow thrower for extended periods of time.

To drain the snow thrower engine of gas:

1. Make sure the engine is turned off.

2. Place a gas safe container under the carburetor (see the "Snow Thrower Parts

Diagram" to reference this part).

3. Move the fuel valve lever to the "on" position.

4. Unscrew the outward facing bolt from the bottom of the carburetor (see figure

22). Gas should start to empty from this point.

5. Catch the emptying gas in the gas safe container until all the gas has drained.

6. Turn the fuel valve to the "off' position.

24

Page 25

7. Replace the bolt on the carburetor.

8. Store the emptied gasoline in a suitable place.

_k CAUTION: Do not store fuel from one season to another.

A[k CAUTION: Never pour gasoline down a drain or in a gutter. Call your local

authorities to dispose of gas properly.

Figure 22- Draining gas from the carburetor

Adjusdng Drh,e and Auger Cables

TIMELINE: As needed.

Over time, the tension in the cables that lead to the drive control and auger control

handles may loosen. Ideally, the cables should be just barely taught when the handles

are in the released position. To tighten the handle cables, use a wrench or pliers and

gently rotate the metal turnbuckle at the top of the cable until the desired tension is

achieved (see figure 23).

/_ T|GHTEH

Figure 23- Adjusting drive and auger cable tension

25

Page 26

Replacing Shear Pins

A WARNING: The auger and impeller rotate at fast speeds that can cause

damage or even amputation to body parts. Even if you do not see the auger or

impeller rotating, they may start at any time if the engine is running.

• Always turn off the engine before attempting to clear any clogs or jams.

• Keep hands and feet away from rotating parts while the engine is running.

Do not wear loose fitting clothing that can become entangled in rotating

parts.

TIMELINE: When Broken

The snow thrower contains two shear pins, one on each end of the auger shaft as

shown in figure 24. A clog or jam in the auger may cause one or both of the shear

pins to break. This is a safety mechanism to protect the rest of the snow thrower from

overload and damage. The snow thrower comes with two replacement shear pins. To

order more shear pins, please call our customer service line.

To replace a shear pin:

1. Turn off the engine and wait for all moving parts to come to a complete stop.

2. Remove any remnants of the broken shear pin. You may need to unscrew the nut

from the broken shear pin.

3. Place a new shear pin through the hole in the auger shaft and tighten using the

shear pin nut.

Figure 24- Replacing the shear pin

26

Page 27

SPECIFICATIONS

Snow Thrower

Clearing Width

Throwing Distance

Chute Rotation

Wheel

Drive Speeds

Dimensions

Dry Mass

Engine

Engine Type

Ignition System

Fuel Tank Capacity

Crankcase oil capacity

22 Inches

Max. 50 feet

180 degrees

Pneumatic, tubeless, size 4.10-6 N.H.S.

Forward: 0.9, 1.2, 1.5, 1.8, 2.5 MPH

Reverse: 0.9, 1.2 MPH

L = 35.5" W = 24.5" H = 31.5"

158 Lbs

4-Stroke OHV Single Cylinder

Non-Contact Transistor

0.95 Gallons

21.1 Fluid Ounces

TROUBLESHOOTING

IMPORTANT: If trouble persists please call our customer help line at (888) 315-3080

M-F 8-5.

Problem

Engine will not

start or runs poorly

Cause

Engine switch is set

Lo "off".

Fuel valve lever is

set to "closed".

Shoke is open.

Engine is filled with

sontaminated or old

gas Change the gas in the engine.

Spark plug is dirty. Clean spark plug.

Spark plug is

3roken. Replace spark plug.

Snow thrower is not Move snow thrower to a level surface to prevent low oil

3n level surface, shutdown from triggering.

Oil is low Add or replace oil.

Solution

Set engine switch to "on".

Move the fuel valve lever to "open" position.

Close the choke.

Add gas. Engine is out of gas.

27

Page 28

Auger or impeller

does not rotate

Snow is not thrown

or not thrown very

far

Snow thrower will

not drive or drives

poorly

_,uger drive handle

s not depressed

_,uger drive handle

sable is loose

Foreign substance

slogging auger or

mpeller

Shear pin broken

Belt broken or loose

Impeller or chute is

slogged

Shute deflector is

set too low

Drive handle is not

depressed

Drive handle cable is

oose

Speed is not

3roperly engaged

Tire inflation is poor

Tire pins are not

engaged

Depress auger drive handle

Adjust tension in cable

Turn off machine and unclog auger or impeller

Replace shear pin.

Call customer service

Turn off engine and unclog.

Adjust chute deflector angle.

Depress drive handle

Adjust cable tension

Engage the speed selector handle to one of the seven

speeds.

Inflate tires.

Check the pins that hold the wheels to the drive axle.

2g

Page 29

9 8

r_

\

79

36

6

/

/

10

100

\

99

÷

\

b_

\

i4

!05

9O

Page 30

SNOW THROWER PARTS LIST

Part #

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

2O

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

4O

41

42

43

44

45

46

47

48

49

5O

51

52

53

54

55

Part Description

_andle assembly

_uger and chive conr_ot handles

_ubber cap

_8x50 He..: scre'_ s

_8 hex imts

Ftmlbuckte

2able

_peed co1_tml frame

_6x35 Hex screw

)rive Speed Control Lex er

_teel bracket

_6x30 He..: scre'_ s

_ye bolt

_lbber ring

,_asher

_ing-pin

_ex screws

2hain Wheel

mite.',' molmting plate-1

_6x10 Hex scre'_ s

xtlley molmting plate-3

_neluna_ic Tire

_ey

_arge Gear

_d cap bushing

hivin_ shaft

?in

i ansmlssion case cover

51ran flax washer

21rote rotation handle grip

"ockei

_oly-ring

_teel Motmtlng Plate

\¢8x20 square neck screws

aasher

mglne

_Theel Cover

_mall tension bracket

?ace1

_pring 5

xl_hing-2

mlall tensioning wheel wi bearing

_pacer

\Cain pulley

_:-Belt

_:-Belt

Fransmission case

\¢10 Hex mlts

10 iron Flat washei

)ear-Wheel Cox er with bearing

)ear-Wheel Washel

albbei ring

)ear-Wheel

Aex Gear-shaft

leep groox e bearing

Quantity

1 set

2 sets

1set

Part # Part Description Quantity

56 8 lmll Flax washer 3

2

2

4

35

2

2

1

5

1

1

1

1

1

2

2

3

3

1

23

1

2

2

1

2

1

1

1

27

1

1

1

1

4

2

1

1

1

1

1

1

2

1

1

1

1

2

1

2

2

1

1

2

57 M8 x 20 Hex screws 1

58 l"_nslmssion piffle 5, 1

59 _tlley motmt1_ plate 1

60 transmission p_llle 5, shaft 1

61 Deep Groove Bearing 2

62 _pa_er bi_hing 1

63 _fltey _a_ket 1 set

64 angle plate 1

65 _hift arm 1 set

66 M8x40 Hex screws 1

67 Spacer 1

68 Large Pulley 1

69 fiat key 1

70 _lmd co_ _r 1

71 _ph_rical bearing 1

72 Hex screws 1

73 Spring 1 1

74 mottntlng plate 1

75 Large tension wheel assy With bearing 1 set

76 Spacer 1

77 Clmte 1

78 Cln_e deflector 1

79 Cln_te deflector knob 1

80 _afety bar assy 1 set

81 _pring-3 1

82 Clmte Mortaring "_,Va sher 3

83 Plastic Cover 1

84 M6 Hex nu_ 26

85 C-shaped plate 1

86 M6x 15 square-necked scre'_ 5

87 Auger Shield 1 set

88 Skid Shoe 2

89 M8x25 square neck scows 10

90 Long blade 1

91 Fan Assen_ly 1 set

92 Washer 1

93 Pm 2

94 l"lmlst Bea_ing 1

95 Deep Groove Bearing 1

96 Drive Worm 1

97 Bearing 1

98 Pdght A_lger 1

99 M6x20 Hex screws 10

100 Upper Worm Case 1

101 Worm Gear 1

102 Lower worm case 1

103 _ltl)_lt shaft bushing 1

104 Drive Shaft Bushing 4

105 _ivmg sh_ 1

106 Left Auger 1

107 Shaft Bushing 1

108 Bearing end cup 2

109 Seal 1

1 t 0 _hear bolts 2 sets

30

Page 31

@ @

Page 32

PART #

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

ENGINE PARTS LIST

PART DESCRIPTION

_LANGE BOLT ( M6'12 )

_EAD COVER COMP

_tEAD COVER PACKING

BREATHER TUBE

_IVOT ADJUSTING NUT

ROCKER AR_M PIVOT

ROCKER AK\I

_IVOT BOLT ( M8 )

VALVE ROTATOR

N VALVE SPRING RETAINER

EX VALVE SPRING RETAINER

VALVE SPRING

gUSH ROD GUIDE PLATE

_LANGE BOLT ( M8'58 )

_'YLFNDER HEAD COMP

EXHAUST PIPE STUD BOLT

SPARK PLUG ( LD NGK )

2ARBURETOR STErD BOLT

2YIFNDER HEAD GASKET

DOWELPIN ( 10"16 )

VALVE

EX VALVE

2AMSHAFT ASSY

3ISTON RING SET

)USH ROD

_'ALVE LIFTER

_ISTON PIN

_ISTON PIN CLIP ( 18rim1 )

_tSTON

_'ON_ECTING ROD ASSY

DRAIN PLUG BOLT

DRAIN PELTLI WASHER ( 10 21ran )

BATL BEARING ( 6205 )

PRANK CASE

GNITIDN COIL ASSY

:LANGE BOLT ( M6'25 )

DIL SEAL ( 25"41 25*6 )

_'LYWHEEL CDMP

SEMICIRCLE KEY

POOLING FAN

STARTER PLIIEY

8HROLX)

:LYWHEEL NUT

:LYWHEEL SIDE PLATE

QTY

PART #

12

1

1

1

2

2

2

2

1

1

1

2

1

4

1

2

1

2

1

2

1

1

1

1

2

2

1

2

1

1

2

2

2

1

1

2

2

1

1

1

1

1

1

1

PART DESCRIPTION

52

_'ARBURETOR PAPER GASKET

_'ARBURETOR

53

54

2HOKE LEVER COMP

55

2ARBURETOR SPACER COMP

a_IR CLEANER ELBOW COMP

56

57

FLANGE NUT ( M6 )

58

FLANGE BOLT ( M6'20 )

59

ELBOW GASKET

SILENCER NOSE

60

61

hIR FILTER ELEMENT

62

adR FILTER GROMMET

hiP. FILTER BRACKET WFNGNUT

63

64

a_IR FILTER COVER

65

hiP. FILTER COVER WINONUT

\,IUFFLER GASKET

66

67

FLANGE NUT ( M8 )

68

\,IUFFLER COMP

69

YAPPING SCREW ( M5'8 )

70

\,IUFFLER OUTER PROTECTOR

71

_'RANKSHAFT COMP

PLAIN KEY

72

73

_'ASE COVER PACKING

74

DOWEL PFN ( 8"i4 )

75

_'IL4NKCASE COVER ASSY

DIL FITLER CAP GASKET

76

77

DIL FILLER CAP

78

FLANGE BOLT ( M8'28 )

SLIDER SHAFT

79

80

PLAIN WASHER

81

3OVERNDR GEAR ASSV

30VEKNOR HOLDER CLIP

82

83

PHRUST WASHER ( 61ran )

84

30VERNOR SLIDER

ROCKER

85

86

LOCK PIN ( 81ran )

87

PUBE CLIP

88

FUEL TU13E

89

FLANGE BOLT ( M6'30 )

FUEL TANK JOINT

90

91

D-RING ( 14nm_ )

92

FUEL TANK COMP

FUEL FILTER

93

94

FUEL FILTER CAP PACKING

95

FUEL CAP

QTY

1

1

1

1

1

5

1

1

1

1

1

1

1

1

1

2

1

4

1

1

1

1

2

1

2

2

6

1

1

1

1

1

1

1

1

2

1

1

1

1

1

1

1

1

32

Page 33

45 _'LANGE BOLT ( M6'16 ) 1

46 :AN COVER COMP 1

47 ENGINE STOP SWITCH ASSY 1

48 _COIL STARTER ASSY 1

49 _'LANGE BOLT ( M6'8 ) 3

50 ._TAKE PIPE GASKET 1

51 2ARBETRETOR INSULATING PLATE 1

96 E'ONTROL ASSY 1

97 £HROTTLE RETURN SPRLNG 1

98 3OVERNOR ROD 1

99 _O\7EI_NOR SPRING ]

100 .)UADRATE BOLT ( M6 ) 1

101 2ONTROL ARM 1

33

Page 34

LIMITED WARRANTY FOR YARDWORKS _'s_ SNOW THROWER

Remember to save your receipt and to accurately fill out and mail your product registration

card. You must provide proof of purchase for all warranty work.

This Yardworks ": snow thrower is warranted to be free from defects in materials and

workmanship for a period of two (2) year from date of original purchase. If this snow thrower

is used for Commercial or Rental purposes, it has a warranty period of 90 days from date of

original purchase. Keep purchase receipt and mail in the product registration card for proof of

purchase.

Yardworks _R: will repair or replace, at its discretion, any part that is proven to be defective in

materials or workmanship under normal use during the two (2) year warranty period.

Warranty repairs or replacements will be made without charge for parts or labor. Parts

replaced during warranty repairs will be considered as part of the original product and will

have the same warranty period as the original product.

To exercise the warranty, DO NOT RETURN TO RETAILER. Instead, call the toll free

Customer Service number: (888) 315-3080 and you will be instructed on where to take the

snow thrower for warranty service. Take the snow thrower and proof of purchase (your

receipt) to the repair facility recommended by the Customer Service Representative.

The warranty does not extend to snow throwers damaged or affected by accidents, neglect,

misuse, unauthorized alterations, use in an application for which the product was not designed

and any other modifications or abuse.

Yardworks :R: is not liable for any indirect, incidental or consequential damages from the sale

or use of this product. Any implied warranties are limited to two (2) year as stated in this

written limited warranty. Some states do not allow the exclusion or limitation of incidental or

consequential damages. Some states do not allow limitation on the length of an implied

warranty. This warranty gives you specific legal rights, and you may have other rights that

vary from state to state.

Yardworks _s_ PO Box 1110. Dundee, IL 60118

34

Loading...

Loading...