Page 1

Instruction Manual

Manual de Instrucciones

Manuel d’Instructions

For Occasional Use Only

R

ENGLISH ESPAÑOL

25 HHT

WARNING:

Read and follow all Safety Rules and Operating Instructions before

using this product. Failure to do so can result in serious injury.

ADVERTENCIA:

Lea el manual de instrucciones y siga todas las advertencias e

instrucciones de seguridad. El no hacerlo puede resultar en lesiones graves.

AVERTISSEMENT:

Lirelemanueld’instructionsetbienrespectertouslesavertissements et toutes les instructions de sécurité. Tout défaut de le

faire pourrait entraîner des blessures graves.

Electrolux Home Products, Inc.

250 Bobby Jones Expressway

Augusta, GA 30907

CopyrightE2003 Electrolux Home Products, Inc.

530163900

FRANÇAIS

12/1/03

Page 2

SAFETY RULES

WARNING:

Safety Rules and Precautions can result in

serious injury.

DANGER:

BEDANGEROUS!

injur y includin g ampu tation or blindness to the

operator and others. The warnings and safety

instr uctions in this manual must be followedto

provide reasonable safety and efficiency in using this unit. The operator is responsible for following the warnings and instructions in this

manual and on the unit. Never allow children to

use this tool.

KNOW YOUR UNIT

Readyour instruction manual carefully until

S

you completely understand and can follow

all warningsandsafety rules beforeoperating the unit.

Restrict unit to users who understand and

D

will follow all warnings and safety rules in

this manual and on the unit.

PLAN AHEAD

WARNING:

ing unit. Remove all debris and hard objects

such as rocks, glass, wire, etc. tha t can ricochet, be thrown, or otherwise cause injury or

damage during operation.

Always wear eye protection when operating,

D

servicing, or performing maintenance on unit.

Wearing eye protection will help to prevent

brush ordebris frombeingthrownor ricocheting into eyes and face which can result in

blindness and/or serious injury. Eye protection should be marked Z87.

Wear hearing protection when using this

D

unit.

Secure hair aboveshoulderlength.Secureor

D

remove jewelry, loose clothing, or clothing

with loosely hanging straps, ties, tassels, etc.

They can be caught in moving parts.

Stay alert. Do not operate unit when you are

D

tired ,ill, upse t,orif youareundertheinfluence

of alcohol, drugs, or medication.

Keep children, bystanders, and animals

D

away from work area a minimum of 30 feet

(10meters)whenstartingor operatingunit.

HANDLE FUEL WITH CAUTION

Eliminate all sources of sparks or flame(in-

D

cluding smoking, open flames, or work that

cancause sparks)intheareas wherefuel is

mixed, poured, or stored.

Mix andpour fuel in an outdoor area; store

D

fuel inacool,dry,well ventilatedplace;use

an approved, marked container for all fuel

purposes.

Do not smoke while handling fuel or while

D

operating the unit.

Do not fill fuel tank while engine is running.

D

Make sure the unit is properly assembled

D

and in good operating condition.

Avoidspillingfueloroil. Wipe upfuelspills

D

before starting the engine.

Failure to follow all

THIS POWER TOOL CAN

This unit can cause serious

Inspect area before start-

Moveatleast 10feet(3 meters)awayfrom

D

fuel and fueling site before starting engine.

Always store gasoline in a container ap-

D

proved for flammable liquids.

OPERATE YOUR UNIT SAFELY

DANGER:

HANDS AWAY FROM BLADE

moves momentarily after the trigger is released. Do not attempt to clear away cut material when the blade is in motion. Make sure

the switch is in the OFF position, the spark

plug wire is disconnected, and the blade has

stopped moving before removing jammed

materialfromthe cuttingblade.Do notgrab or

hold the unit by the cutting blade.

Inspect unit before each use for worn,

D

loose, missing, or damaged parts. Do not

use until unit is in proper working order.

Keep outside surfaces free from oil and fuel.

D

Never start or run engine inside a closed

D

room or building. Breathing exhaust fumes

can kill.

Avoiddangerousenvironments.Donotuse

D

in unventilated areas or where explosive

vapors or carbon monoxide build up could

be present.

Do notoverreachorusefrom unstable sur-

D

faces such as ladders,trees,steepslopes,

rooftops,etc. Keepfirm footingandbalance

at all times.

Do notraise unit aboveyourshoulders;the

D

cutting blade can come dangerously close

to your body.

Always keepunitin frontofyourbody.Keep

D

all parts of yourbodyawayfromthecutting

blade.

Keep the cutting blade and air vents free

D

from debris.

Use only for jobs explained in this manual.

D

MAINTAIN YOUR UNIT PROPERLY

Have all maintenance other than the rec-

D

ommendedproceduresdescribed in theinstruction manual performed by an authorized service dealer.

Disconnect spark plug before performing

D

maintenance except for carburetor adjustments.

Do not use a cutting blade that is bent,

D

warped, cracked, broken, or damaged in

any other way. Have worn or damaged

parts replaced by an authorized service

dealer.

UseonlyrecommendedPoulanPRO!cut-

D

ting blades and replacement parts; use of

anyotherpartsmayvoidyourwarrantyand

cause damage to your unit.

Empty fuel tank before storing the unit. Use

D

upfuel left in carburetorbystarting engineand

lettin git run unt ilit stops.

Handcarrytheunit withtheengine stopped

D

andthe mufflerand cuttingblade awayfrom

your body, preferably with the blade cover

installed.

RISK OF CUT; KEEP

-- 2 --

--Blade

Page 3

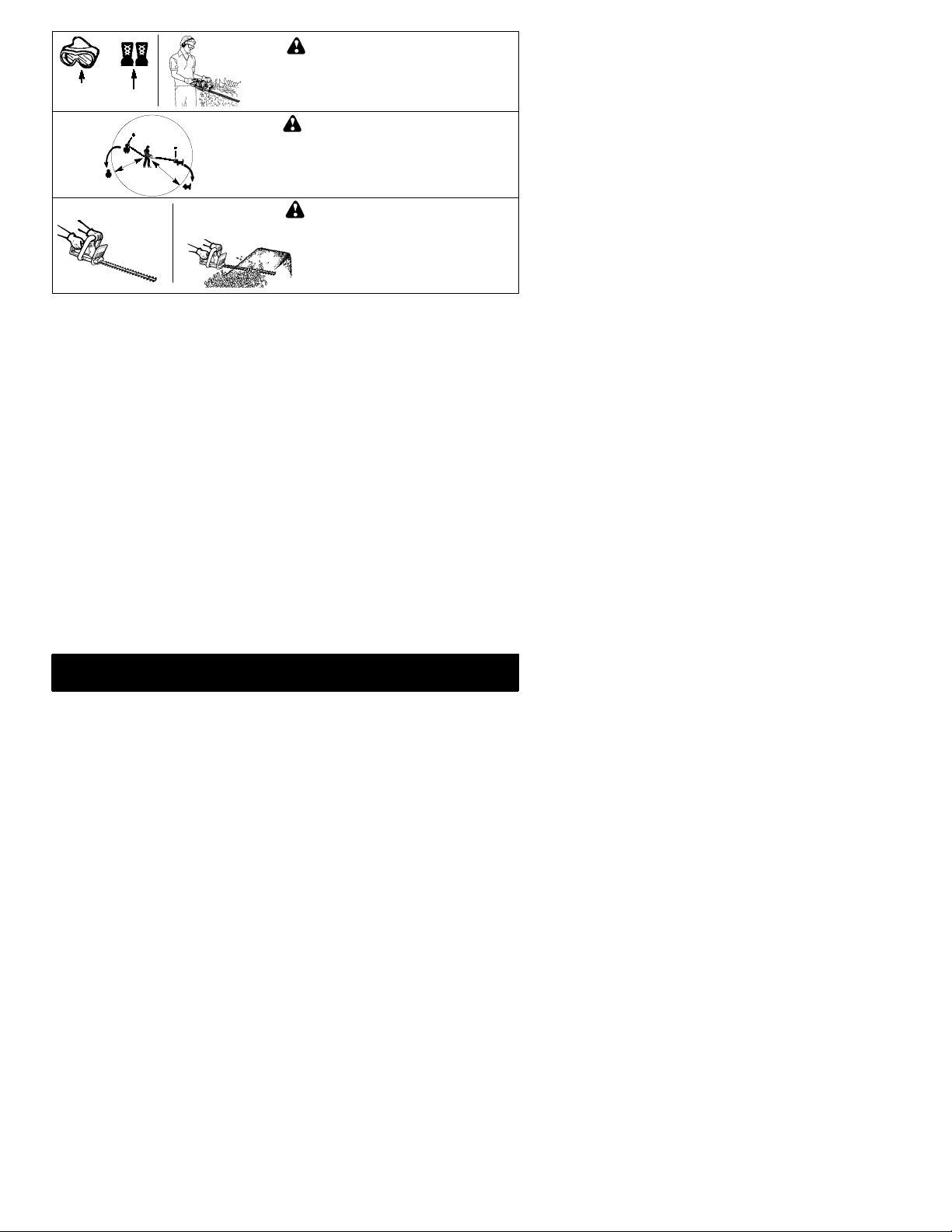

Safety

Glasses

Allow engine to cool, empty the fuel tank,

D

and secure the unit before storing or transporting it in a vehicle.

Donotstoretheunitorfuel in a closed area

D

where fuel vapors can reach sparks or an

openflamefrom hotwaterheaters,electric

motors or switches, furnaces, etc.

Store unit so the cutting blade cannot acci-

D

dentally cause injury.

Store unit with the blade cover installed.

D

Store in a dry area out of reach of children.

D

SAFETYNOTICE:

through prolonged use of gasoline powered

handtools could causebloodvessel ornerve

damage in the fingers, hands, and joints of

people prone to circulation disorders or abnormal swelling. Prolonged use in cold

weatherhasbeenlinked toblood vesseldamagein otherwise healthypeople. If symptoms

occur such as numbness, pain, loss of

strength, change in skin color or texture, or

loss of feeling in the fingers, hands, or joints,

discontinue the use of this tool and seek

medical attention. An anti vibration system

does not guarantee the avoidance of these

problems. Users who operatepowertoolson

a continual and regular basis must monitor

closely their physical condition andthe condition of this tool.

Boots

30 ft.

(10 m)

Blades move

momentarily

after the

trigger is

released.

Allow blades to stop

before removing

them from the cut.

Exposure to vibrations

WARNING:

Blades can throw objects violently.

Y oucan be blinded or injured.

D

Wear safety glasses.

D

WARNING:

Hazard zone for thrown objects

Blades can throw objects violently.

D

Others can be blinded or injured.

D

Keep people and animals 30 feet

D

(10 meters) away.

WARNING:

Blades move momentarily after the

trigger is released.

The blades can seriously cut you or

D

others.

Allow blades to stop before

D

removing them from the cut.

SPECIAL NOTICE:

with a temperature limiting muffler and spark

arresting screen which meets the requirementsofCaliforniaCodes4442 and4443. All

U.S. forest land and the states of California,

Idaho, Maine, Minnesota, New Jersey, Oregon, and Washington require by law that

many internal combustion engines be

equippedwithasparkarrestingscreen. Ifyou

operateina localewheresuchregulationsexist, youare legally responsible formaintaining

theoperatingcondition ofthese parts. Failure

to do so is a violation of the law. For normal

homeowneruse, themufflerandsparkarresting screen will not require any service. After

50 hours of use, we recommend that your

muffler be serviced or replaced by an authorized service dealer.

This unit is equipped

ASSEMBLY

Examine parts fordamage. Do not use damaged parts.

If you need assistance or find parts

NOTE:

missing or damaged, call 1-800-554-6723.

It is normal for the fuel filter to rattle in the

empty fuel tank.

Finding fueloroil residue onmuffleris normal

due to carburetor adjustments and testing

done by the manufacturer.

ASSEMBLY

Y ourhedge trimmer isfully assembled;noassembly is required.

-- 3 --

Page 4

OPERATION

KNOW YOUR HEDGE TRIMMER

READ THIS INSTRUCTION MANUAL AND SAFETY RULES BEFORE OPERATING YOUR

UNIT. Comparethe illustrationswith yourunitto familiarize yourselfwith thelocationof thevarious controls and adjustments. Save this manual for future reference.

Throttle

Lock--out

Throttle Lock

Spark Plug

Primer

Bulb

Choke

Lever

ON/OFF

Switch

Throttle Trigger

Blade

Cover

ON/OFF SWITCH

The ON/OFF SWITCH is used to stop the engine. T ostop the engine, move theswitch to the

OFF position.

CHOKE

The CHOKE helps to supply fuel to the engine

to aid in cold starting. Activate the choke by

moving choke lever to the desired position. See

STAR TINGYOUR ENGINE for completestarting information.

WARNING:

andafteruse. Do not touch the muffler or allowcombustiblematerialsuch asdrygrass or

fuel to do so.

Muffler

Muffler is very hotduring

BEFORE STARTING ENGINE

WARNING:

information in the safety rules beforeyoubegin.Ifyoudo not understandthesafetyrules,

do not attempt to fuel your unit. Call

1-800-554-6723.

Be sure to read the fuel

FUELING ENGINE

WARNING:

when refueling.

Remove fuel cap slowly

HELPFUL TIP

Toobtainthecorrect oil mix

ratio, pour 3.2 ounces of

2--cycle synthetic oil into

This engine is certified to operate on unleaded

gasoline. Before operation, gasoline must be

mixedwitha good quality synthetic 2-cycleaircooled engineoil designed tobemixed at aratio

of 40:1. Poulan/Weed Eater brand synthetic oil

is recommended. A 40:1 ratio is obtained by

mixing 3.2 ounces (95 ml) of oil with 1 gallon (4

one gallon of fresh gas.

Hand

Guard

PRIMERBULB

ThePRIMERBULBremoves airfromthe carburetorand fuel lines andfills them with fuel.

This allows youtostart theenginewithfewer

pulls on the starter rope. Activate the primer

bulb by pressing it and allowing it to returnto

its original position.

THROTTLE TRIGGER

The THROTTLE TRIGGER controls engine

speed.Squeezethe trigger for full speedoperation; release it for idle speed.

liters) of unleaded gasoline). DO NOT USE automotive oilorboatoil. Theseoils will caus eengine damage. When mixing fuel, follow instructions printed on oil container. Once oil is added

to gasoline, shake container momentarily toassure that the fuel is thoroughly mixed. Always

read and follow the safety rules listed under

HANDLE FUEL WITH CAUTION.

IMPORTANT

Experience indicates that alcohol blended fuels

(called gasohol or using ethanol or methanol)

can attract moisture which leads to separation

and formation of acids during storage. Acidic

gas can damage the fuel system of an engine

while in storage. T o avoid engin e problems,

empty the fuel system before storage for 30

days or longer.Drain the gas tank, start the engine andlet it run until thefuellines andcarburetor are empty. Use fresh fuel next season.

Neveruseengine or carburetorcleanerproducts in the fuel tank or permanent damage

may occur.

OPERATING INSTRUCTIONS

It is recommended that the engine not be

operatedforlongerthan30 secondsat full

throttle.

the engine to briefly return to idle speed (5 -10 seconds) will be sufficient.

Releasing the trigger and allowing

-- 4 --

Fuel Mix

Fill Cap

Page 5

IMPORTANT POINTS

Use theminimum throttle speednecessary

S

to effectively cut hedges for optimal hedge

trimmer performance.

Never attempt to use this hedge trimmer to

S

cut hedges that have any branches with a

diameter larger than5/8"(1.5cm).

OPERA TINGPOSITION

Hearing

Protection

STOPPINGYOUR ENGINE

To stop the engine, move the ON/OFF

D

switch to the OFF position.

If engine does not stop, move choke lever

S

to the FULLCHOKE position.

ST ARTING YOUR ENGINE

Fuel engine. Move at least 10 feet (3 me-

D

ters) away from the fuelingsite.

Remove the blade cover from the blade

D

before starting the unit.

Hold the unit on the ground in the starting

D

position as shown. Support unit so the

blade is off of the ground and away from

trees, bushes, onlookers, etc.

Eye

Protection

ON/OFF

Switch

Throttle

Trigger

1. Move the ON/OFF switch to the ON position.

2. Engage the throttle lock as follows:

press the throttle lock--out;

D

squeeze and hold throttle trigger;

D

press and hold throttle lock, then

D

release the throttle trigger

D

NOTE:

the engine starts.

3. Slowly press the primer bulb 6 times.

4. Move thechokelever tothe FULLCHOKE

position.

Primer Bulb

Throttle Lock

Throttle Lock-out

Keepthe throttle lock engageduntil

Choke

Lever

HELPFUL TIP

If your engine still does not

start after following these

instructions, please call

1--800--554--6723.

STARTING A COLDENGINE(or a

warm engine after running out of

fuel)

WARNING:

moving once the throttle lock has been set

and the engine is started. Wear your protectiveequipmentandobserveall safetyinstructions.

The cuttingblade will be

5. Pull starter rope handle sharply until engine sounds as if it is trying to run, but do

not pull rope more than 6 times.

6. Move the choke lever to the HALF

CHOKE position.

7. Pull starter rope sharply until the engine

runs, but no more than 6 pulls.

If the engine doesn’t start after 6 pulls

NOTE:

(at the HALF CHOKE position), check to

make sure the ON/OFF switch is in the ON

position. Move the choke lever to the FULL

CHOKE position and press the primer bulb 6

times; pull the starter rope 2 more times.

Movethechoke lever to theHAL FCHOKE

position and pull thestarter rope until the engine runs, but no more than6 more pulls. If

the engine still doesn’t start, it is probably

flooded. Proceed to STARTING A

FLOODED ENGINE.

8. Once the engine starts, allow the engine to

run 10 seconds, then move the choke lever

totheOFFCHOKEpositio n.Allowthe unitto

runfor 30moreseconds attheOFFCHOKE

position before squeezing and releasing the

throttle trigger to release the throttle lock.

If enginedieswith thechoke lever in

NOTE:

the OFF CHOKE position, move the

choke lever to the HALF CHOKE position

and pull the ropeuntil theengineruns, but

no more than 6 pulls.

-- 5 --

Page 6

STARTING A WARM ENGINE

1. Move the ON/OFF switch to the ON position.

2. Slowly press the primer bulb 6 times.

3. Move the choke lever to the HALF

CHOKE position.

4. Engage the throttle lock as directed in

STARTING A COLD ENGINE.

Keepthe throttle lock engageduntil

NOTE:

the engine starts.

5. Pull starter rope sharply until engine runs,

but no more than5 pulls.

6. Allow the engine to run 10 seconds, then

move the choke lever to the OFF CHOKE

position.

7. Releasethethrottlelock bysqueezingand

releasing the trigger .

SERVICE

WARNING:

is in the OFF position and disconnect the

spark plug before performing maintenance

except for carburetor adjustments.

If any dealer other than an authorized

service dealer performs work on the

product, Electrolux Home Products,

Inc., may not pay for repairs underwarranty. Itis yourresponsibility tomaintain

and perform general maintenance.

GENERALRECOMMENDATIONS

Thewarrantyonthisunitdoesnotcover items

that have been subjected to operator abuse

or negligence. To receive full value from the

warranty, the operator must maintain unit as

instructed in this manual. Various adjustments will need to be made periodically to

properly maintain your unit.

CHECK FOR LOOSE

FASTENERSAND PARTS

Spark Plug Boot

S

Air Filter

S

Housing Screws

S

CHECK FOR DAMAGED OR

WORN PARTS

Contact an authorized service dealer for replacement of damaged or worn parts.

ON/OFF Switch -- Ensure ON/OFF switch

S

functions properly by moving the switch to the

OFF position. Make sure engine stops; then

restart engine and continue.

Fuel Ta nk -- Do not use unit if fuel tank shows

S

signs of damage or leaks.

Gearbox -- Do notuse if the gearboxshows

S

signs ofdamageor leaks. After 50 hoursof

use, we recommend that your gearbox be

serviced by an authorized service dealer.

Ensure ON/OFF switch

HELPFUL TIP

IMPORTANT:

repairs other than the recommended maintenance

described in the instruction

manual performed by an

authorized service dealer.

Have all

If engine has not started, pull starter

NOTE:

rope 5 more pulls. If engine still does not

run, it is probably flooded. Proceed to

STARTING A FLOODED ENGINE.

ST ARTING A FLOODED ENGINE

Flooded engines can be started by placing

theON/OFFswitch intheONpositionandthe

choke lever in the OFF CHOKE position and

engaging the throttle lock as directed in the

STAR TINGA COLD ENGINE section; then,

pull the rope to clear the engine of excess

fuel. Starting could req uire pulling the starte r

rope many times depending on how badly the

unit is flooded. If the unit still doesn’t start, refer

to the TROUBLESHOOTING TABLE or call

1-800-554-6723.

INSPECT AND CLEAN UNIT AND

LABELS

Before and after each use, inspect com-

S

plete unitforloose ordamagedparts. After

each use, clean the unit and labels using a

damp cloth with a mild detergent.

Wipe off unit with a clean dry cloth.

S

CLEAN AIR FILTER

Air Filter

Cleaning the air filter:

A dirty air filter decreases engine performance and increases fuel consumption and

harmful emissions. Always clean after every

5 hours of operation.

1. Clean the cover and the area around it to

keepdebrisfrom fallingintothecarburetor

chamber when the cover is removed.

2. Remove parts as illustrated.

Donotcleanfilteringasoline orother

NOTE:

flammable solvent. Doing socancreatea fire

hazardorproduceharmful evaporativeemissions.

3. Wash the filter in soap and water.

4. Allow filter to dry.

5. Add a fewdropsof oil tothefilter;squeeze

filter to distribute oil.

6. Replace parts.

INSPECT MUFFLER AND SPARK

ARRESTINGSCREEN

WARNING:

uct contains chemicals known to the State of

California to cause cancer.

The muffler on this prod-

-- 6 --

Air Filter

Cover

Screw

Page 7

As yourunitisused,carbondeposits build up

on the muffler and spark arresting screen.

For normal homeowner use, however, the

mufflerandspark arrestingscreen will notrequire any service. After 50 hours of use, we

recommend that your muffler be serviced or

replaced by your authorized service dealer.

CARBURETOR ADJUSTMENT

WARNING:

making idle speed adjustments. The blade

will be movingduringmost of this procedure.

Wearyourprotectiveequipmentand observe

all safety precautions. When making adjustments, use a screwdriver short enough to

keep your hands behind the handguard and

away from the blade. After making adjustments,theblademustnotmoveat idlespeed.

The carburetor has been carefully set at the

factory.Adjustments may benecessary ifyou

notice any of the following conditions:

Engine will not idle when the throttle is re-

S

leased.

The blade moves at idle.

S

Keep others away when making idle speed

adjustments. Make adjustment s with the unit

resting on a level surface free of debris that can

be caught in the hedge trimmer blade. Serious

injury to the operator and others can occur if the

carburetor is not properly adjusted. Keep all

parts of your body away from the blade and

muffler.

Idle Speed Adjustment

Allowengineto idle.Adjustspeeduntil engine

runswithout blademoving (idletoofast)or engine stalling (idle speed too slow).

Turn idle speed screw clockwise to in-

S

creaseenginespeedif enginestallsordies.

Turnidle speedscrew counterclockwise to

S

decrease engine speed if the blademoves

at idle.

Keep others away when

Ifyou requirefurtherassistance orareunsure

about performing this procedure, contact an

authorized service dealer or call

1--800--554--6723.

BLADE ADJUSTMENT

The clearance between the cutting blades

mustbeadjustedperiodicallytomaintain optimal performance and sharp cutting.

Nut

Blade guide

Blades

Flat

Washer

Blade

guide

1. Using a wrench, loosen each nut on the

top side of the blade guide.

Wrench

2. Tighten each bolt from underside of blade

with a wrench.

Bolt

Nut

Cupped

Washer

Nuts

TOP SIDE OF BLADE

WARNING:

after each adjustment. The blade must not

move at idle speed to avoid serious injury to

the operator or others.

Recheck the idle speed

Idle Speed Screw

UNDERSIDEOF BLADE

Bolt

3. Loosen each bolt 1/2 turn.

1/2 turn

Bolt

4. While holding each bolt in place with a

wrench, retighten the nuts.

UNDERSIDEOF BLADE

TOP SIDE

OF BLADE

-- 7 --

Page 8

After adjustment, the washers be-

NOTE:

tween the bolt head and the blade should be

able to be turned by hand, but not loose

enough to move when the unit is tilted from

side to side.

CAUTION:

cutting blades is set toowide, the blades will

notcutcorrectly.Iftheblades areadjustedtoo

tight, overheating may occur.

REPLACE SPARK PLUG

Replace spark plug each year to ensure the

engine starts easier and runs better. Set

spark plug gap at 0.025inch (0.6 mm). Ignition timing is fixed, nonadjustable.

1. Twist, then pull off spark plug boot.

2. Remove spark plug from cylinder and discard.

3. Replace with Champion RCJ-6Y spark

plug and tighten securely with a 3/4 inch

(19 mm) socket wrench.

4. Reinstall thespark plug boot.

If the clearance between the

STORAGE

REPLACE FUEL FILTER

Toreplacefuelfilter,drainunitby runningit dry

of fuel, then remove fuel cap/retainerassembly from tank. Pull filter from tank andremove

itfromthefuelline. Installnewfuelfilteronfuel

line; reinstall parts.

Fuel Line

Fuel

Filter

WARNING:

steps after each use:

Allow engine to cool, and secure the unit

S

before storing or transporting.

Store unit and fuelin a well ventilated area

S

where fuel vapors cannot reach sparks or

open flames from water heaters, electric

motors or switches, furnaces, etc.

Store unit with the blade cover installed.

S

Position unit so that any sharp object cannot accidentally cause injury.

Store unit and fuel well out of the reach of

S

children.

SEASONALSTORAGE

Prepareunit forstorageat end ofseasonorif

it will notbeusedfor30daysor more.

If your unit is to be stored for aperiodoftime:

Clean the entire unit.

S

Store in a clean dry area.

S

Clean all parts and check for damage.

S

Have damaged parts repaired or replaced

by an authorized service dealer.

Keep all nuts, bolts, and screws tight.

S

Lightly oil external metal surfaces, includ-

S

ing the blade.

Install the blade cover.

S

Tooil the blade,do the following:

Stoptheengine andallow bladeto cometo

S

a complete stop.

EnsureON/OFFswitch is in theOFF posi-

S

tion.

Disconnect the spark plug wire.

S

Apply a light machine oil along the edgeof

S

the top strap as shown.

Perform the following

OIL

Top Strap

FUEL SYSTEM

Under FUELING ENGINE in the OPERATIONsectionofthis manual,seemessage labeled IMPORTANT regarding the use of gasohol in your engine. Fuel stabilizer is an accept able alternative in minimizing theformatio n

of fuel gum deposits during storage. Add stabilizer to gasoline in fuel tank or fuel storage container. Follow the mix instructions found on stabilizercontainer. Run engine at least 5 minute s

after adding stabilizer.

HELPFUL TIP

During storageof your gas/

oilmixture,theoil will separate from the gas.

We recommend that you

shake the gas can weekly

toinsureproperblending of

the gas and oil.

-- 8 --

Page 9

ENGINE

Remove spark plugand pour1teaspoonof

S

40:1,2-cycle engine oil (air cooled)through

the spark plug opening. Slowly pull the

starter rope 8 to 10 times to distribute oil.

Replacesparkplugwithnewone ofrecom-

S

mended type and heat range (see REPLACE SPARK PLUG section).

Clean air filter.

S

Check entire unit for loose screws, nuts,

S

and bolts. Replace any damaged, broken,

or worn parts.

At the beginning of the next season, use

S

only freshfuel having thepropergasolineto

oil ratio.

OTHER

Do not store gasoline from one season to

S

another.

Replaceyourgasolinecanifitstarts torust.

S

NEED ASSISTANCE?

NEED ASSISTANCE?

Call 1-800-554-6723for assistance.

NEED SERVICE PARTS?

Contact your dealer.

TROUBLESHOOTING TABLE

WARNING:

recommended remedies below except remedies that require operation of the unit.

Alwaysstopunitanddisconnect sparkplugbeforeperformingall ofthe

TROUBLE CAUSE REMEDY

Enginewill not

start.

Enginewill

notidle

properly.

Enginewill not

accelerate,

lacks power,

or dies under

a load.

Engine

smokes

excessively.

Engine runs

hot.

1. ON/OFF switch in the

OFF position.

2. Engine flooded.

3. Fuel tank empty.

4. Spark plug not firing.

5. Fuel not reaching

carburetor.

6. Compressionlow.

1. Carburetor requires

adjustment.

2. Crankshaft seals worn.

3. Compression low.

1. Air filter dirty.

2. Spark plug fouled.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

5. Compressionlow.

1. Choke partially on.

2. Fuel mixture incorrect.

3. Air filter dirty.

4. Carburetor requires

adjustment.

1. Fuel mixture incorrect.

2. Spark plug incorrect.

3. Carburetor requires

adjustment.

4. Carbon build-up on

muffler outlet screen.

1. Move ON/OFF switch to the ON

position.

2. See “Starting a Flooded Engine”

in Operation Section.

3. Fill tank with correct fuel mixture.

4. Install new spark plug.

5. Check for dirty fuel filter; replace.

Check for kinked or split fuel line;

repair or replace.

6. Contact an authorized service dealer.

1. See “Carburetor Adjustment” in

Service and Adjustments Section.

2. Contact an authorized service dealer.

3. Contact an authorized service dealer.

1. Clean or replace air filter.

2. Clean or replace plug

and regap.

3. Contact an authorized service dealer.

4. Contact an authorized service dealer.

5. Contact an authorized service dealer.

1. Adjust choke.

2. Empty fuel tank and refill with

correct fuel mixture.

3. Clean or replace air filter.

4. Contact an authorized service dealer .

1. See “Fueling Engine” in Operation

section.

2. Replace with correct spark plug.

3. Contact an authorized service dealer .

4. Contact an authorized service dealer .

-- 9 --

Loading...

Loading...