Sears 259.162170 Assembly Manual

1

Customer Service

Toll Free 1-800-396-3838

WARNING

!

Failure to follow all manufacturer’s

instructions could result

in serious personal injury and/or

property damage.

Read and follow all Safety Statements,

Assembly instructions, and Use

and Care Manual Directions before

attempting to assemble and cook.

CAUTION

!

Some parts may contain sharp edges,

wear protective gloves if necessary.

CAUTION

!

THIS GRILL IS FOR OUTDOOR

USE ONLY

Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A www.sears.com

Assembly and Operation

To Installer/Assembler: Leave these

instructions

with consumer.

To Consumer: Keep this manual for future

reference.

Liquid Propane Gas Grill

®

Model No.

SP5290B-37

259.162170

Table of Contents

Limited Warranty

Warranty.........................................................2

Safety..............................................................2

Caring for your equipment..............................3

Hardware........................................................6

Assembly...................................................7-22

Operation.................................................23-24

Cleaning and Maintenance......................25-26

Parts..............................................................27

Exploded view...............................................28

Troubleshooting.............................................29

Product Record

IMPOR

information

Model

TANT: Fill out the product record

below.

Number_____________________________

One Year Full Warranty on Kenmore Grill

If this grill is defective in material or worksmanship within one

year from the date of purchase, contact Sears at

1-800-4-MY-HOME® to have it repaired free of charge.

Additional Full Warranty on Specific Grill Parts

For the time periods listed below, Sears will replace the following

specific grill parts free of charge if they are defective in material

of workmanship:

Lifetime on Cast Aluminum Lids and Bottoms

Five years from purchase date on Stainless Burners

All warranty coverage excludes ignitor batteries and any grill part

paint loss or rusting which are either expendable parts that can

wear out from normal use in less than a year, or are conditions

that can be the result of normal use, accident or improper

maintenance.

All warranty coverage is void if this grill is used for commercial or

rental purposes.

This warranty gives you specific legal rights, and you may also

have other rights which vary from state to state.

Sears, Roebuck and Co., Dept. 817WA, Hoffman Estates, IL 60179

(on carton) Label Lot # GG______________

UPC

Number_____________________________

Serial

Purchased____________________________

Date

WARNING

!

WARNING

Combustion byproducts produced when

using this product contain chemicals

known to the State of California to cause

cancer, birth defects, or other reproductive

harm.

IF YOU SMELL GAS:

1. Shut off gas supply to the

appliance.

2. Extinguish any open flame.

3. Open lid.

!

4. If odor continues, immediately

call your gas supplier or your

department.

fire

WARNING

• Do not store or use gasoline or

other flammable vapors and liquids

in the vicinity of this or any other

appliance.

• An LP cylinder not connected

!

for

the

appliance.

use shall not be stored in

vicinity of this or any other

2

3/8"

VENTURI

TUBE

AIR SLEEVE

VALVE OUTLETS

CASTING

Fig. 1

CAUTION

!

For residential use only. Do not use for

commercial cooking.

WARNING

!

Failure to ensure correct venturi tube

assembly

or explosion causing serious bodily injury

and/or property damage.

may result in a hazardous fire

WARNING

CARBON MONOXIDE HAZARD

Combustion byproducts include carbon

monoxide

!

cause

inside

which has no odor and can

serious injury or death. Never use

homes, vehicles or tents.

Call Grill Service Center For Help And Parts

If you have questions or need assistance during

assembly, please call 1-800-396-3838. You will be

speaking to a representative of the grill manufacturer

and not a Sears employee. To order new parts call

Sears at 1-800-4-MY-HOME®.

WARNING

!

• Your grill is properly assembled.

• There are no leaks in the gas supply system

(see ‘Leak Testing’ section).

• The burner is properly assembled with the venturi tubes

seated over the valve outlets (Figure 1 below) and there

are no blockages present in the venturi tubes

(see ‘Cleaning Venturi Tubes’ section).

• Electrical supply cords and/or gas supply hoses are kept

away from any heated surfaces.

• Your grill is positioned in a safe location

(see ‘Installation’ section).

Figure 1.

• Ensure valve outlets (orifices) are assembled 3/8” (1 cm)

into the venturi tubes.

• Check to see that the valve outlets and venturi tubes are

parallel to the bottom of the base casting of your appliance.

Do not use your grill until you

have read and

information in this manual.

extremely important to be sure that:

understood all the

It is

INSTALLATION

THE INSTALLATION OF THIS APPLIANCE MUST

CONFORM WITH LOCAL CODES OR, IN THE

ABSENCE OF LOCAL CODES:

• In Canada: must conform to CAN/CGA - B149.2 Propane

Installation Code or CAN/CGA B149.1 Natural Gas

Installation.

• In the U.S.A.: must conform to National Fuel Gas Code

ANSI Z223.1.

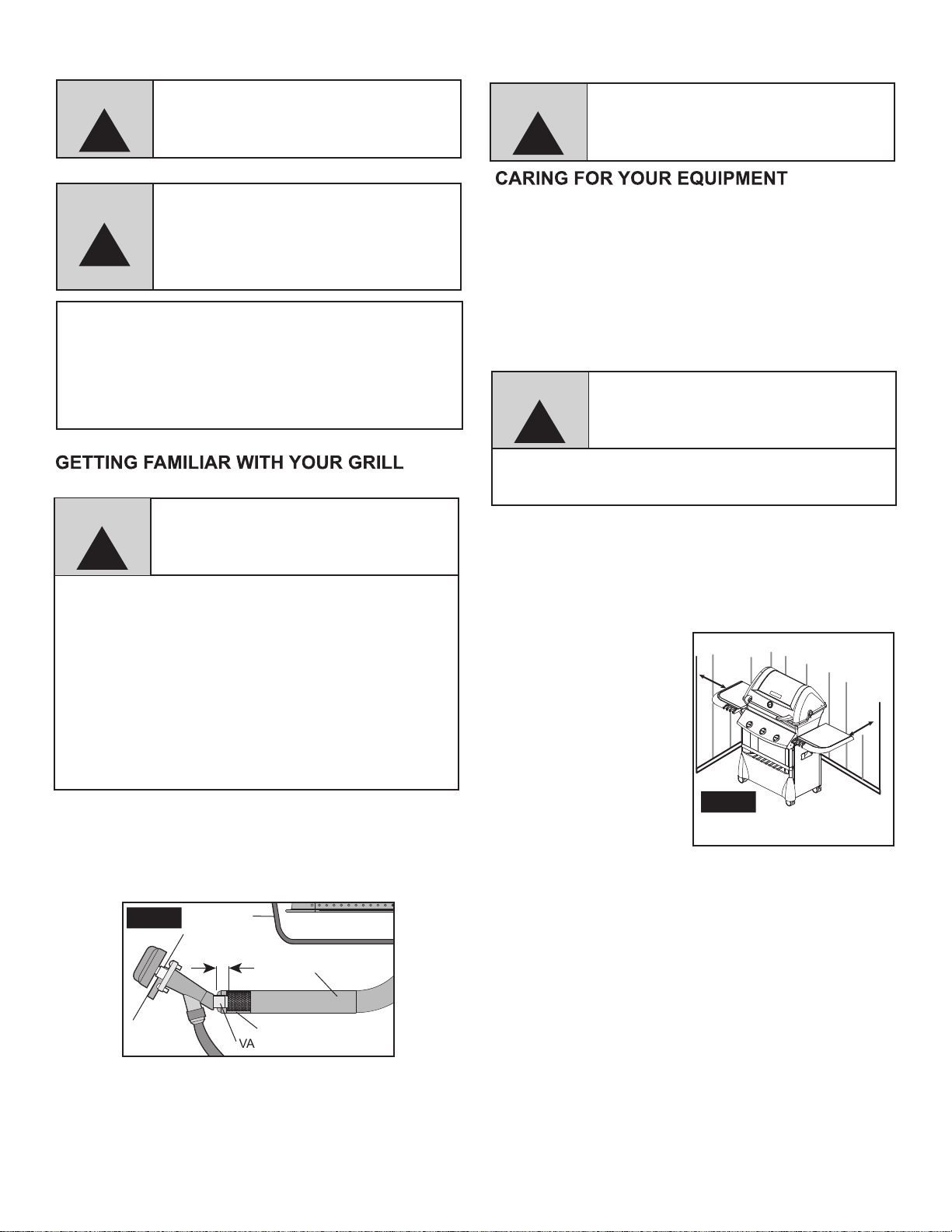

WARNING

!

• 24 inches (61 cm) from side of unit (See Figure 2)

• 18 inches (46 cm) from back of unit (See Figure 2)

FOR YOUR OWN SAFETY:

• Only use your grill OUTDOORS in a well ventilated area

-- preferably 10 feet (3m) from your residence or any

outbuildings.

• Always keep the area around your grill clear of any

combustible materials, gasoline, or other flammable liquids.

• DO NOT operate this grill under overhead or unprotected

construction.

• DO NOT obstruct the

flow of combustion and

ventilation air to the grill.

• DO NOT use in garages,

sheds, breezeways, or

other enclosed areas.

• DO NOT store a spare L.P.

(propane) cylinder under or

near your grill.

• DO NOT leave your

grill unattended while in

operation.

• DO NOT allow children to

operate or play near your

grill.

• DO NOT use while under the influence of alcohol or drugs.

• DO NOT install/use in or on recreational vehicles and/or

boats

When deciding where to place your

appliance, follow these minimum

clearance distances to adjacent

combustivle materials:

24"

(61cm)

(46cm)

Fig. 2

MODEL MAY NOT BE EXACTLY AS SHOWN.

18"

ELECTRICAL CAUTION

• If any accessory installed on this grill requires an external

electrical power source, it must be electrically grounded in

accordance with local laws or in the absence of local laws,

with the Canadian Electrical Code CSA C22.1 or in the U.S.,

with the National Electrical Code ANSI-NFPA 70.

• The three-prong plug provides protection against shock

hazard and should be plugged directly into a properly

grounded three-prong receptacle. Do not cut or remove the

grounding prong from this plug.

• Ensure all electrical supply cords and fuel supply hoses are

kept well away from any heated surfaces.

3

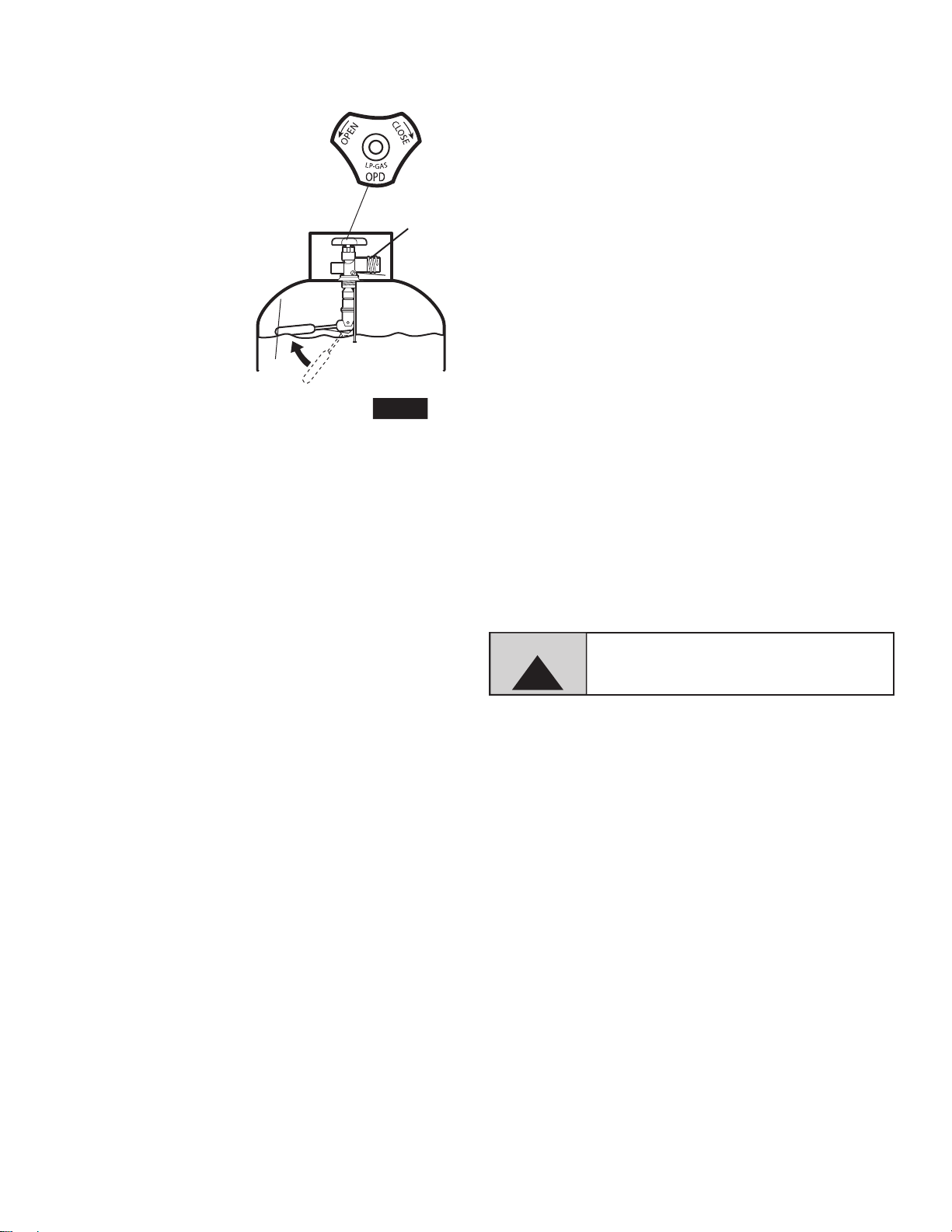

L.P. GAS CYLINDER

Gas cylinders manufactured today have

mechanisms to provide worry free

grilling year round:

Q.C.C.1 or Type 1-Quick Connect

Coupling Valve, ensure fast tank

hook-ups requiring only hand

tightening. The redundant

valve system inhibits the flow

of gas to the burner if the

connection is not correct.

O.P.D. or Overfill Protection

Device prevents accidental

gas leaks caused by cylinder

‘over-pressurization’, the

leading cause of cylinder gas

leaks. The float in the tank

will automatically stop filling at

80% capacity, leaving a

20% area for the expansion

of liquid. Without this safety

feature, the relief valve may

open and discharge propane,

creating a potential safety hazard. An O.P.D. cylinder is easily

distinguished by its triangular hand wheel valve. (Figure 3)

FILLING STOPS AT 80%

NEW OPD

HANDWHEEL

External threads

on Coupling Valve.

O.P.D.

FLOAT

Fig. 3

1. SPECIFICATIONS

Self-contained

used

only with a

a

Type 1 cylinder valve and incorporating an overfill protection

device (O.P.D).THE CYLINDER SHOULD NOT EXCEED 18

(472 MM) IN HEIGHT AND 12 1/2" (317 MM) IN DIAMETER.

1/2"

grill cannot be connected to a #510 P.O.L

This

(ones with left-hand threads).

The cylinder

in accordance

propane

gas grill systems

20

lb (9.1 kg) propane cylinde

are designed to

r

, equipped with

type valve

be

for your gas grill must be constructed and marked

with the specifications

of

L.P. gas cylinders:

THE CYLINDER MUST

a.

A shut-of

specified in current standards:

• Canada: CAN/CGA - 1.6a - M98 - Outdoor

Amend. 1.

• U.S.: ANSI Z 21.58a-1998 OUTDOOR COOKING

APPLIANCES.

b. A

listed

c.

A safety relief valve

vapor space

d.

A collar to

e. An arrangement for vapor

f. A bottom

SAFET

• Always turn of

not in

• Handle

• Never connect an unregulated L.P.

• Never store a

use.

•

Never subject any cylinder

sunlight.

• Always keep your in-use cylinder securely fastened

upright position.

• Do not insert any

may damage the back-check. A damaged back-check

be the source

explosion, fire, severe personal injury or death.

• DO NOT fill the cylinder beyond 80% full.

f valve

overfilling protection

protect the tank shut off valve.

ring for mounting.

Y:

use.

tank valves with care.

WARNING

!

ALSO BE EQUIPPED WITH:

terminating in a proper cylinder valve

Gas

Grills -

device (O.P.D.).

having

direct communication with

of

the cylinder.

withdrawal.

f the cylinder valve tightly when your grill is

spare cylinder under or near

to

excessive heat or direct

foreign objects into the valve outlet.

of

a leak. Leaking propane

If the above instructions are not followed

exactl

y

,

a

fire causing death or serious injury

may

occur.

gas

cylinder to your

your

may result in

grill when

in

outlet

the

grill.

an

You

can

in

In

Canada: The National

Cylinders, Spheres

Dangerous Goods; and Commission.

In

the

U.S.: U.S. Department

DO

NOT CONNECT T

EXCEEDING

AN

Y OTHER TYPE OF

The

Type 1 valve is recognizable by the large external thread on

the

outlet

these

exterior threads. Any attempt to connect

other

than

i) Mating Type 1 connector (recognized by the large black

coupling

or

ii) Standard #510 P.O.L. fitting, by use of adapters or any other

means.

Could result in damage, fire or injury and may negate

the important safety features designed into the Type 1 system.

The connection of a #510 P.O.L. fitting will not provide the flow

control or temperature shut-off features built into the complete

Type 1 System.

THIS CAPACITY

part of

the valve.

the:

nut)

Standards of

of

O

A PRO

, OR USE A CYLINDER WITH

VALVE CONNECTION DEVICE.

Non Type 1

Canada CAN/CSA-B339,

and Tubes for Transportation of

Transportation (D.O.T.)

PANE GAS CYLINDER

valves do

not have

a regulator, with

4

2. TRANSPORTATION AND STORAGE:

WARNING: Although it is safe when used properly, careless

handling of the propane gas cylinder could result in fire,

explosion, and/or serious injury.

PRO

PANE GAS IS HEAVIER THAN AIR, AND WILL COLLECT IN

AREAS, INCREASING THE ABOVE RISKS THEREFORE:

LOW

• ALWAYS use the cylinder

cap provided with your

cylinder whenever the

cylinder is not connected

to your grill. (Figure 4)

• DO NOT store in a

building, garage or any

other enclosed area.

Store in a well-ventilated

area.

• DO NOT store near any

gas burning apparatus or

in any high-heat areas such as a closed car or trunk.

• Transport and store the cylinder in an upright position -- do

not tip on its side.

• Store out of reach of children.

• DO NOT smoke while transporting a cylinder in your vehicle.

FILLING:

FOR SAFETY REASONS, IF AN OPTIONAL L.P. GAS

CYLINDER WAS SUPPLIED WITH YOUR GRILL, IT HAS

BEEN SHIPPED EMPTY. THE CYLINDER MUST BE PURGED

OF AIR AND FILLED PRIOR TO USING ON YOUR GRILL.

WHEN GETTING YOUR CYLINDER FILLED:

• Allow only a qualified L.P. gas dealer to fill or repair your

cylinder.

• DO NOT allow the cylinder to be filled beyond 80% full.

• Make sure the L.P. gas dealer checks the cylinder for leaks

after filling.

WARNING

!

If the above instructions are not followed

exactly, a fire causing death or serious injury

may occur.

Fig. 4

CYLINDER

CAP

LP TANK VALVE

RETAINER

STRAP

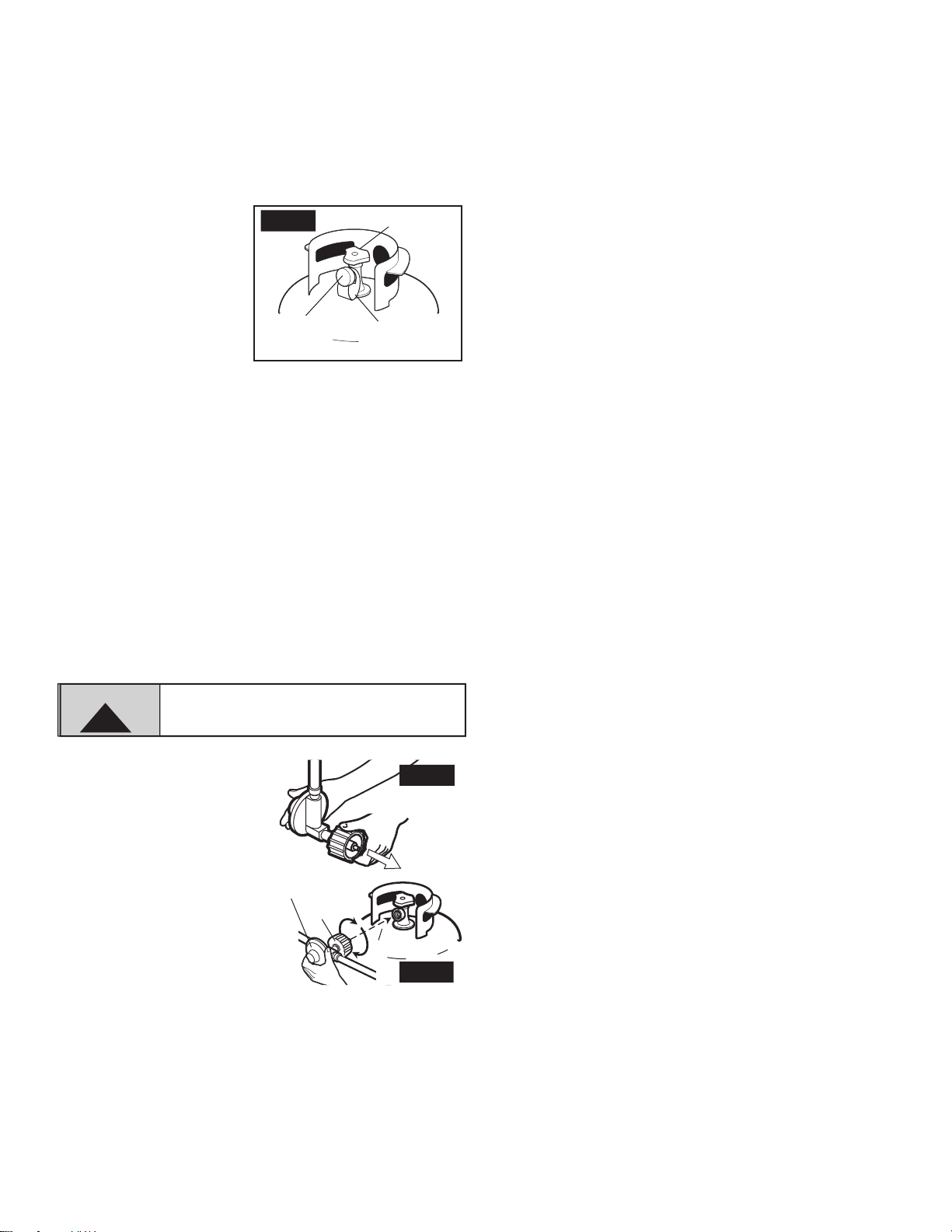

HOSE & REGULATOR

Fig.

5

PROPANE GAS MODELS:

TOR

Your grill is designed to operate

on L.P. (propane) gas at a

pressure regulated at 11" water

column(2.74 kPa). A regulator

preset to this pressure is supplied

with the grill and MUST be used.

This regulator is equipped with

the Q.C.C. Type 1, quick connect

coupling system, which

incorporates the following safety

features: (Figure 5)

• It will not allow gas to flow until a

positive

• It has a thermal element that will shut off the flow of gas

between

• It also has a flow-limiting device which,when activated, will

restrict the flow of gas to 10 cubic feet per hour (0.28 cubic

meters per hour).

seal has been made. (Figure 6)

240 and 300°F (115 and150°C).

Q.C.C.I

REGULATOR

Q.C.C.I

REGUL

A

STRAIGHT

Fig. 6

the hose and regulator

Prior to attaching the

sure

be

cylinder

clockwise

in the

be

make

mating

threaded

until there is

TIGHTEN

Should

exposed to temperatures

and

valve -- thereby

occur, do not attempt

regulator

‘REPLACEMENT

contact

The

corrected before operating your grill again. The regulator probe

also contains a

gas

hour)

that the flow control device has been activated, the cause of the

excessive

your

Please refer to

contact

NOTE:

CAUSE

REDUCED HEAT OUTPUT.

IN

RESE

BURNER

SECONDS, THEN

30

EXTREME

BURNER VAL

• Never connect a propane gas grill to an unregulated

propane gas supply or any other gas.

alter the hose or regulator in any way.

• The connection

from the propane tank. If the fitting is allowed to drag on

the ground,

leak

PRO

• Do not allow any grease (or other hot material) to fall onto

• Visually inspect

• Follow the ‘LEAK TEST’ instructions

cylinder

the

valve is turned

(left to

off position. When attaching

sure that the

Q.C.C. 1

Q.C.C.1

a positive stop

ON

the large black

allow the regulator probe to disengage from the cylinder

assembl

us at

cause of the excessive

to the regulator to

in the event of

flow

grill again.

1-800-396-3838.

us

IMPROPER

THE FLOW CONTROL TO ACTIVATE, RESULTING

THE

T

CONTROLS AND THE CYLINDER VALVE.

Y

L

when connected to the propane tank.

PANE

hose,

the

surfaces

each use

before

excessive

replaced

as

specified in the Parts List should be used.

for the first

grill

if any gas

refilled,

flow-limiting

of storage or non-use or at least once per season.

periods

propane cylinder

valve and

right)

small probe in the nipple

cylinder

black nut

.

LY

shutting

y, and replace it with a new one. (See

PART

1-800-396-3838

flow-sensing

a

should be determined and

troubleshooting

the

LIGHTING PROCEDURES

FLOW CONTROL BY SHUTTING OFF AL

SLOWLY - WAIT 5

VE ON AND LIGHT AS NORMAL.

fitting must be protected when

nicks and scratches could occur resulting

NA

AND

or allow the hose to come in

of the grill.

the entire length of the hose

of the grill. If it is evident there is

abrasion/wear, or the hose is cut, it must be

to using your grill. Only the hose

prior

time, every time a

device has been activated, after prolonged

the

off by rotating

stops and all

until it

valve (see Figure

onto the valve

. DO

thermally

above 240 and 300°

off the flow

reconnect the nut. Remove the entire

to

S’ section

element, which will limit the flow of

manageable amount (10

a

hose or regulator rupture. If it is evident

TURN THE CYLINDER V

TURA

component is changed, if

to

appliance valves are OF

the handwheel (see

appliance valves should

the regulator

6). Turn

in a clockwise motion

NOT USE

sensitive coupling nut be

)

heat should

IF THIS IS SUSPECTED,

SECONDS AND TURN THE

L GAS

gas. Should

of

in assembly instructions or

guide on page 29 or

MODELS:

propane

to the

centered in

is

right hand

the

A WRENCH,

will soften

F, it

this

determined and

be

cubic feet per

corrected before

CAN

ALVE ON

not attempt to

Do

disconnected

contact with any hot

assembly

assembly

before lighting your

cylinder is

the regulator

WAIT

F. The

Figure 3)

cylinde

the

HAND

using

L

in a

,

r,

5

6

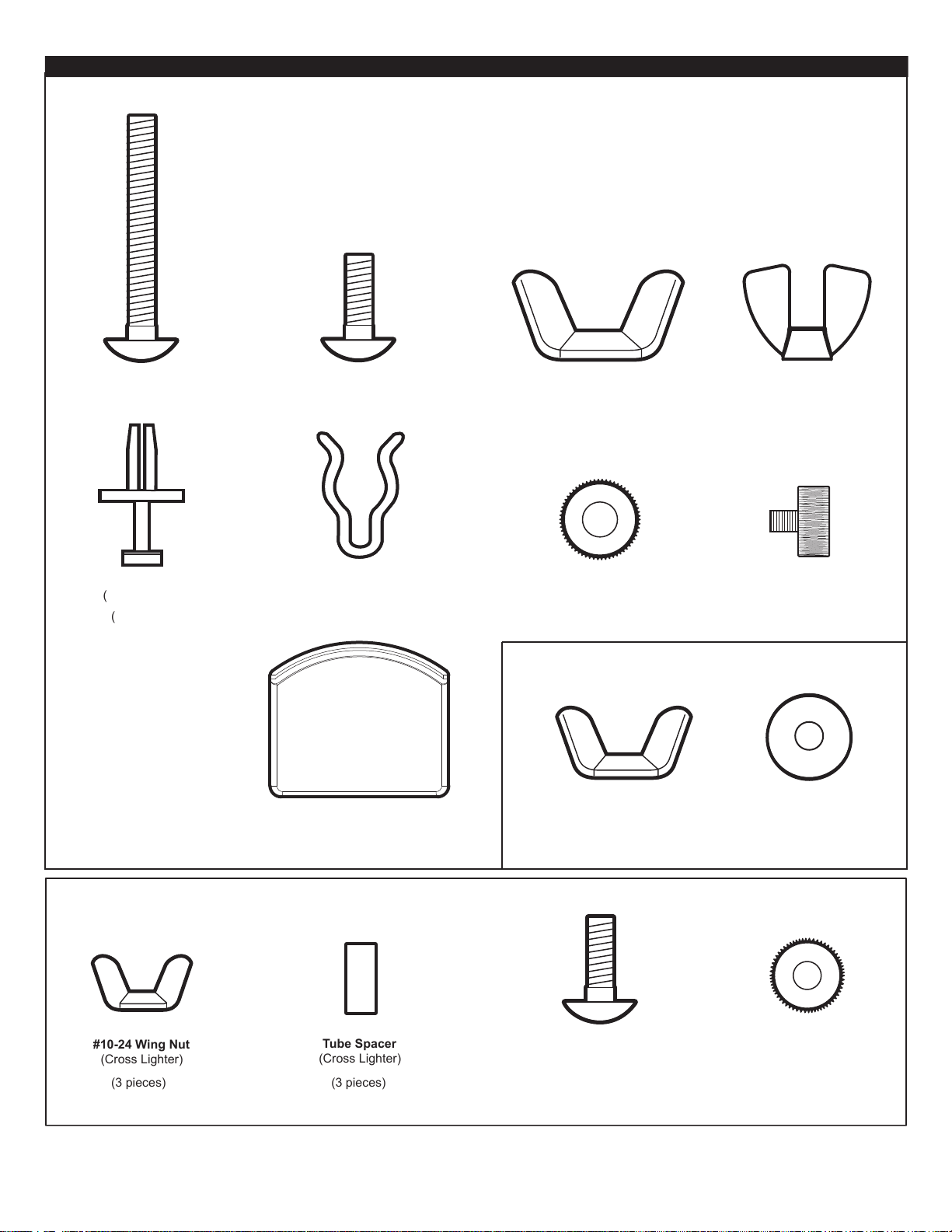

1/4" - 20 X 3/4" Carriage Bolt

#10-24 Wing Nut

(Cross Lighter)

Tube Spacer

(Cross Lighter)

1/4"-20 Knurl Nut

(Burners)

Cross Lighter/Burner Bagpack

(Cross Lighter)

1/4" - 20 X 2" Carriage Bolt

1/4"-20 Large Body Wing Nut

1/4" - 20 X 3/4" Carriage Bolt

#10-24 Knurl Screw

Push Pin

(Side Panel)

Hinge Clip

1/4”-20 Tapered Wingnut

3/8"-16 Knurl Nut

(logo, Heat Indicator)

(Console)

(Lid)

Upper Tank Bracket

(Tank)

Master Bagpack

Handle

1/4-3/4 Washer

#10-24 Wing Nut

(Handle)

(6 pieces)

(16 pieces) (2 pieces)

(22 pieces)

(2 pieces)

(1 piece) (2 pieces) (2 pieces)

(1 piece)

(2 pieces) (2 pieces)

(3 pieces) (3 pieces) (3 pieces) (3 pieces)

HARDWARE

ASSEMBLY

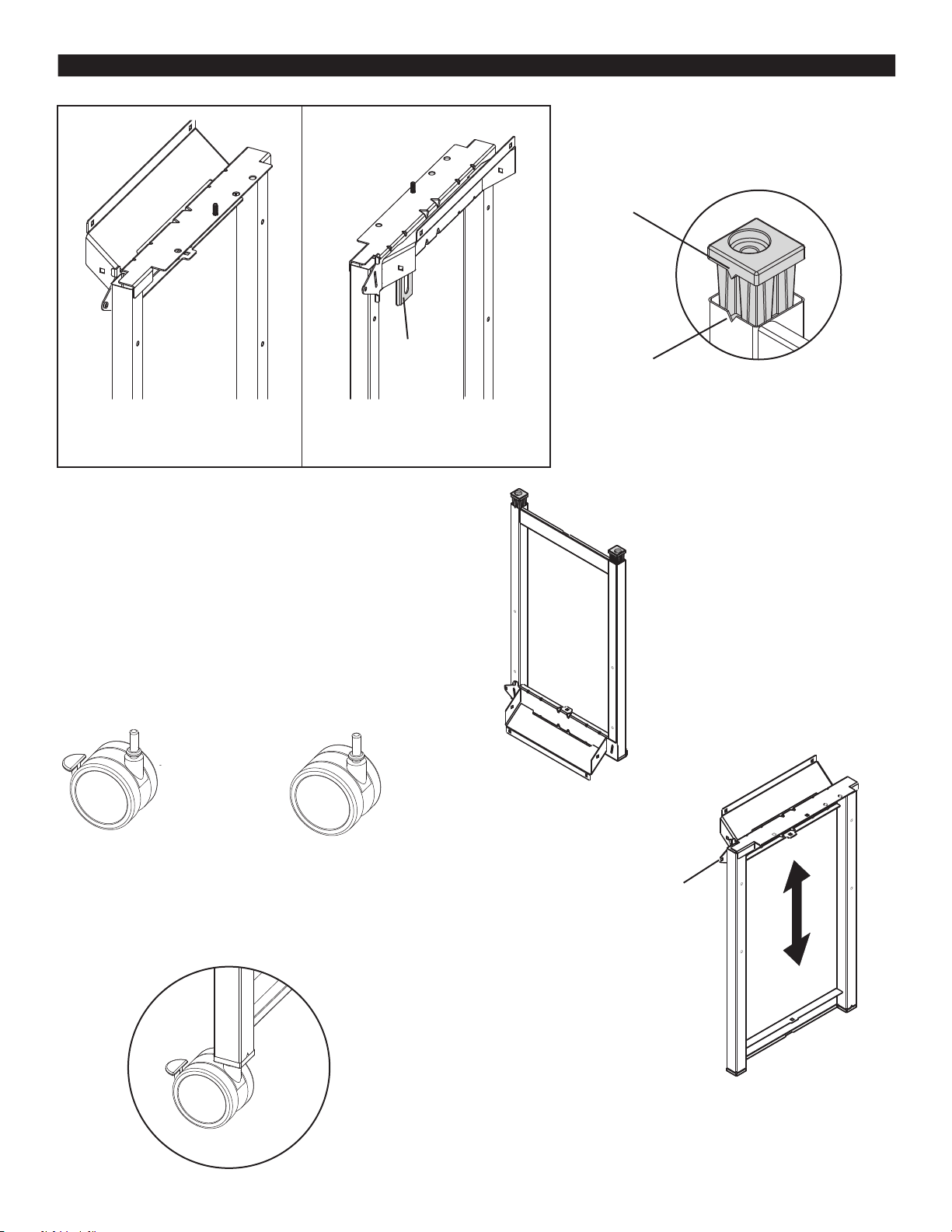

Tab

No Tank

Bracket

Left hand leg assembly

1. Turn leg assembly upside down as

shown and insert caster plug.

Make sure caster plug tab is in line with

notch in leg

2. Turn leg assembly over and tap on a hard surface

until the caster plugs are fully seated.

.

Right hand leg assembly

Tank

Bracket

Notch

Caster Plug

Leg Assembly

(Left Hand shown)

Locking Caster

3. Insert locking casters into the caster plugs on front of leg

assemblies and press in until caster is fully seated as shown

Non-Locking Caster

Console mounting

tabs are on front

side of leg

.

4. Insert non-locking casters into the caster plugs

on rear of leg assembiles.

assemblies.

7

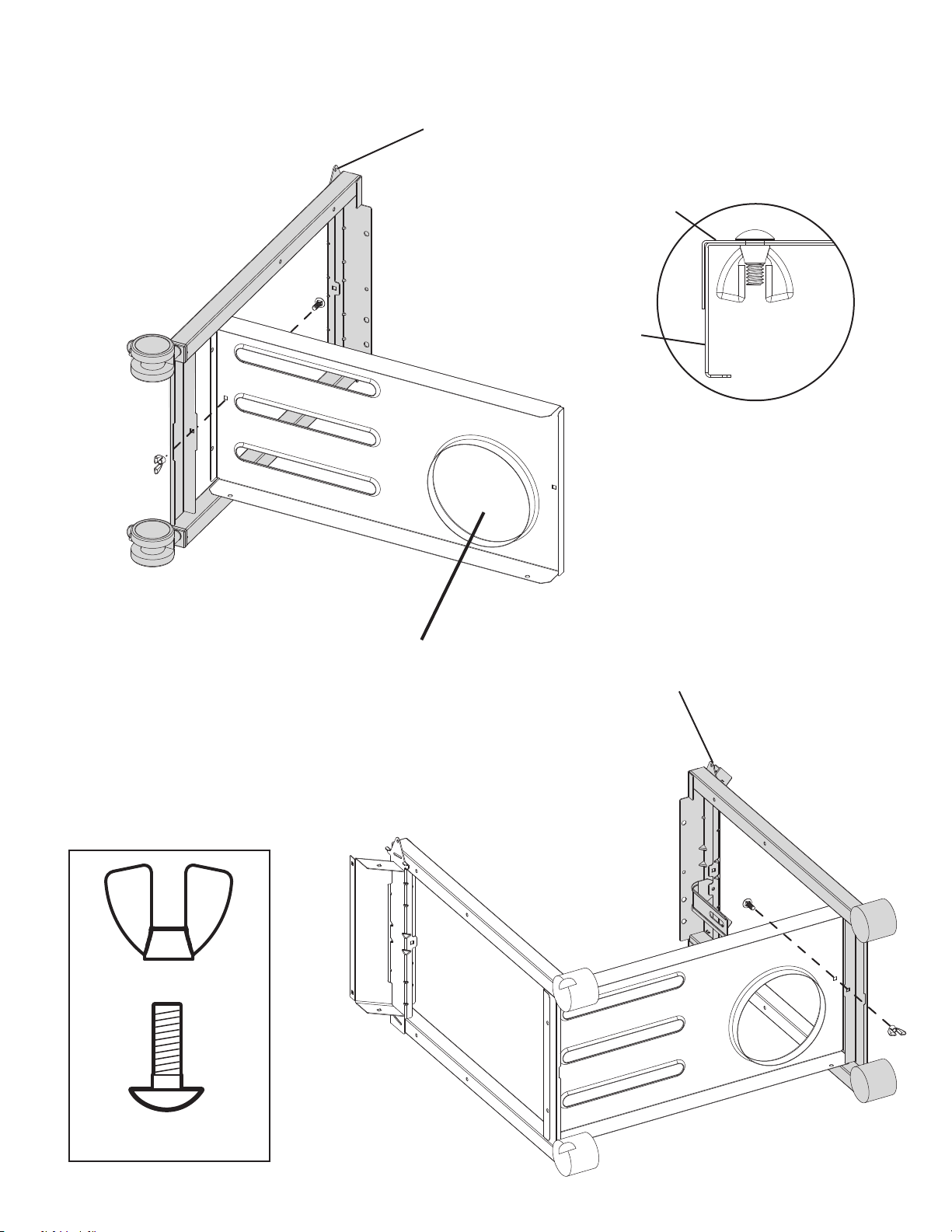

5. Position left hand leg assembly as shown with console mounting tab facing up.

Place non-tank side of bottom pan over bottom support. Attach bottom pan with

1/4”-20 x 3/4” carriage bolt and tapered wing nut.

Console mounting tab facing up.

Bottom Support

Bottom Pan

Tank opening on right side.

6. Position right hand leg assembly as shown, with console mounting tab facing up.

Place tank side of bottom pan over bottom support. Attach bottom pan with

1/4-20 x 3/4” carriage bolt and tapered wing nut.

1/4”-20 Tapered Wingnut

Console mounting tab facing up.

1/4" - 20 X 3/4" Carriage Bolt

8

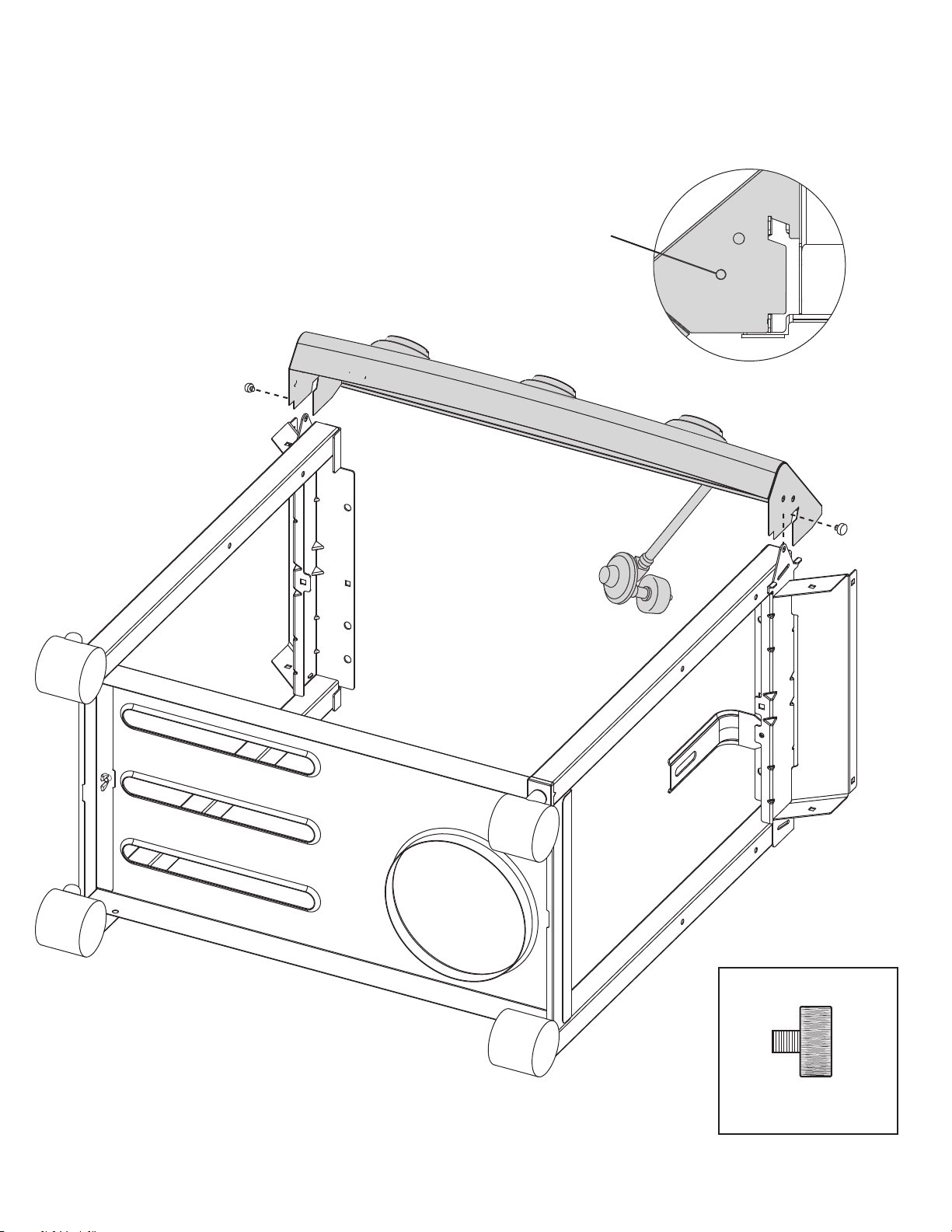

7. Attach console/valve assembly by positioning console over tabs and inserting two #10 knurl screws.

Locate Console on tabs as shown.

(Right side shown)

Mounting Hole

#10-24 Knurl Screw

9

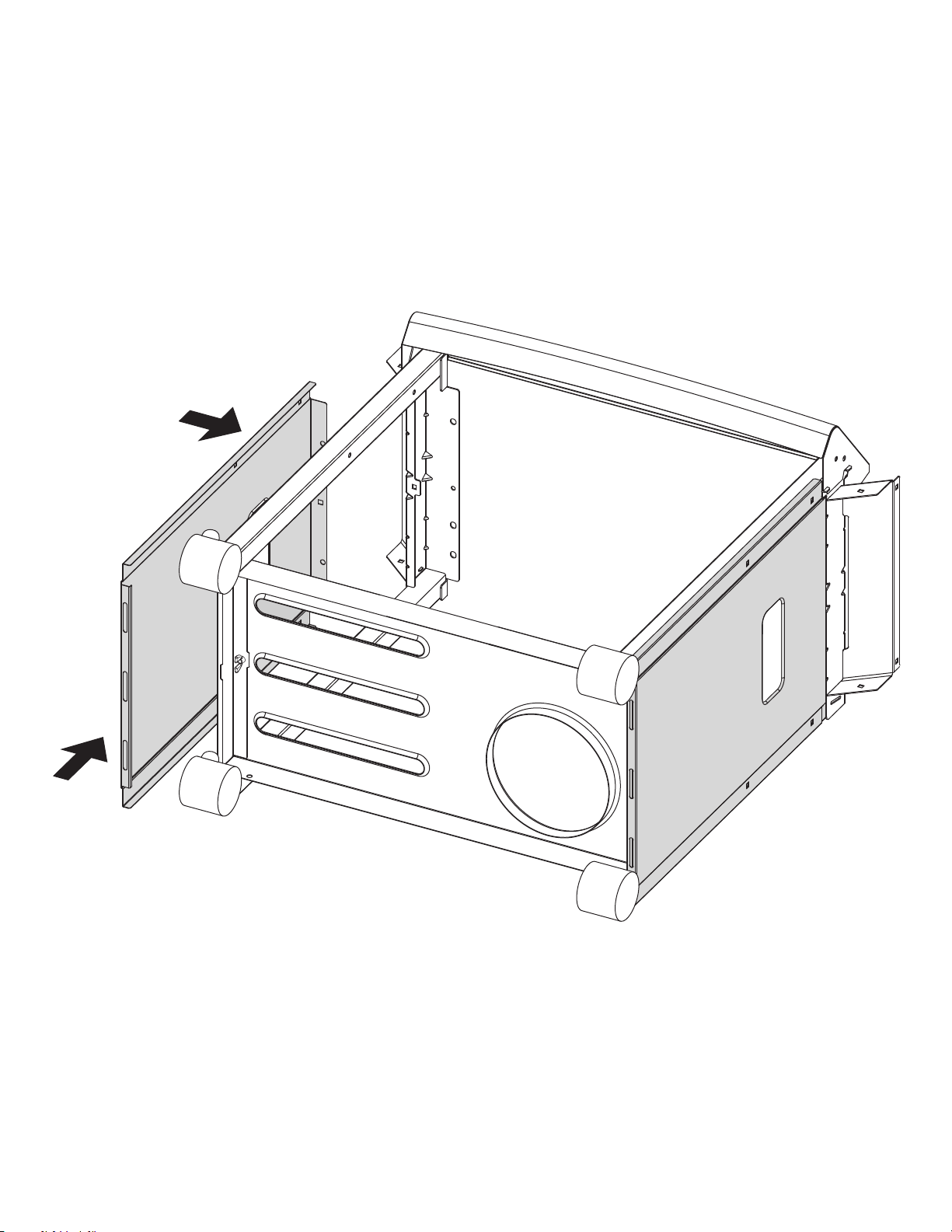

8. Position side panels over legs and slide up into position.

Bottom flange of side panel hooks over bottom support.

Push against

leg assembly

Then slide up

into position

10

Loading...

Loading...