Page 1

INFORMATION

MANUAL

SU

Page 2

TABLE OF CONTENTS

Sub-Zero Undercounter Features

• Models 245, 249R & 249RP ....... 3

• Models 249FF & 801RFD ......... 4

Product Operation

• Temperature Controls

A. Adjustment ............... 5

B. Location ................. 5

• Door Closing .................. 5

• Fan Operation ................. 5

• Automatic Defrost Info ........... 5

• Sounds ...................... 5

• Icemaker Operation ............. 6

Product Care

• Maintenance & Cleaning ......... 6

• Light Bulb Replacement .......... 6

• Vacation Time ................. 6

• Vacant Homes ................. 6

WARRANTY

Food Storage Suggestions ........ 7

Product Loading Information ....... 7

Service Information .............. 7

RECORD YOUR MODEL

AND SERIAL NUMBER

On undercounter models 245, 249R,

249RP and 249FF, the serial number is

found on the inside cabinet liner at the

top; open the door to read.

On the model 801RFD, the serial num-

ber is located at the top freezer hinge.

Have this information ready when calling

for service:

Model Number

Serial Number

alii

aut_

Installahon Date

Factory Authorized Service Agent

(Phone Number)

Page 3

Irl

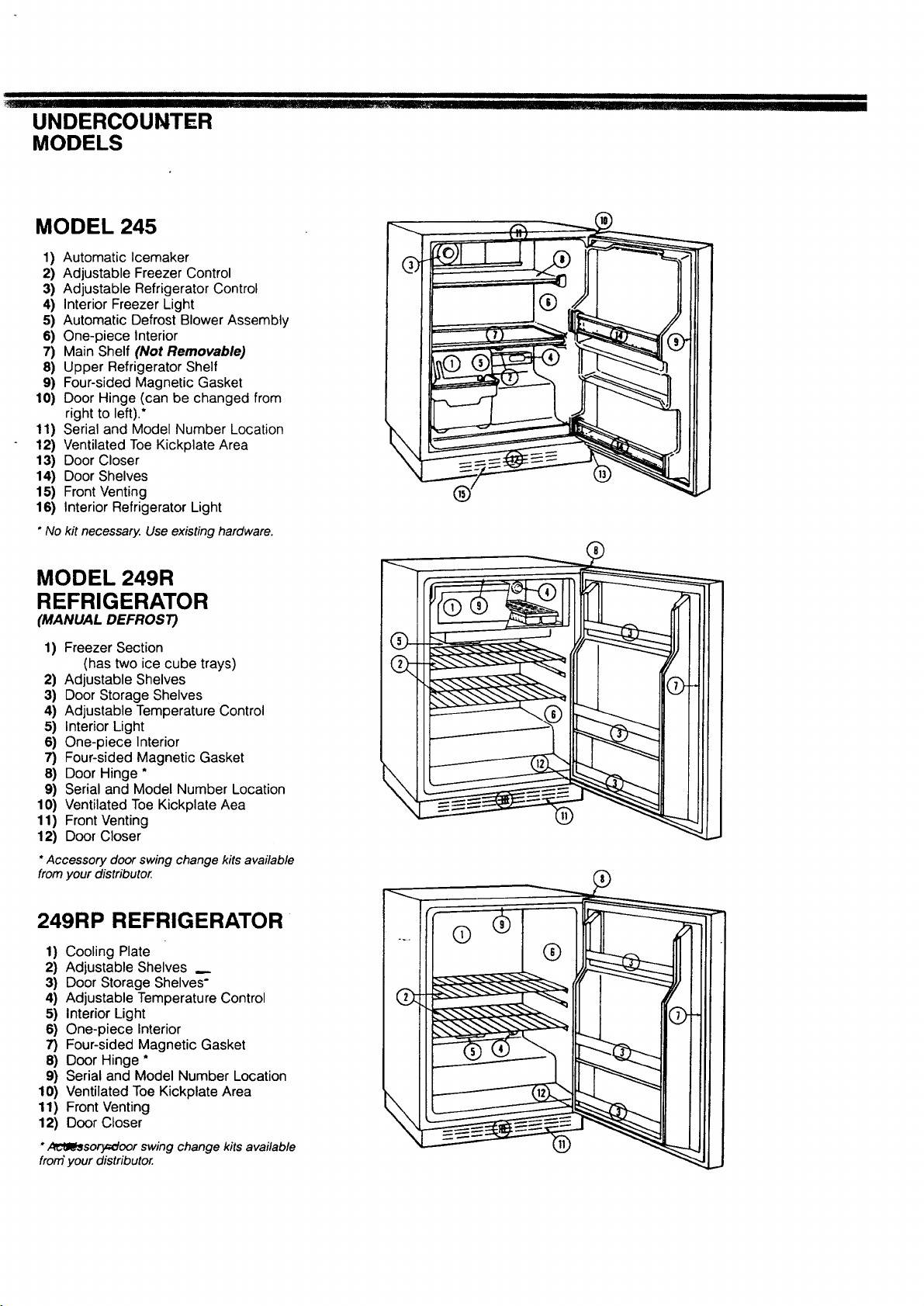

UNDERCOUNTER

MODELS

MODEL 245

1) Automatic Icemaker

2) Adjustable Freezer Control

3) Adjustable Refrigerator Control

4) Interior Freezer Light

5) Automatic Defrost Blower Assembly

6) One-piece Interior

7) Main Shelf (Not Removable)

8) Upper Refrigerator Shelf

9) Four-sided Magnetic Gasket

10) Door Hinge (can be changed from

right to left).*

11) Serial and Model Number Location

12) Ventilated Toe Kickplate Area

13) Door Closer

14) Door Shelves

15) Front Venting

16) Interior Refrigerator Light

* No kit necessary. Use existing hardware.

I

i

J

MODEL 249R

REFRIGERATOR

(MANUAL DEFROST)

1) Freezer Section

(has two ice cube trays)

2) Adjustable Shelves

3) Door Storage Shelves

4) Adjustable Temperature Control

5) Interior Light

6) One-piece Interior

7) Four-sided Magnetic Gasket

8) Door Hinge *

9) Serial and Model Number Location

10) Ventilated Toe Kickplate Aea

11) Front Venting

12) Door Closer

*Accessory door swing change kits available

from your distributor.

249RP REFRIGERATOR

1) Cooling Plate

2) Adjustable Shelves p

3) Door Storage Shelves"

4) Adjustable Temperature Control

5) Interior Light

6) One-piece Interior

7) Four-sided Magnetic Gasket

8) Door Hinge *

9) Serial and Model Number Location

10) Ventilated Toe Kickplate Area

11) Front Venting

12) Door Closer

*AC'tB_soryadoor swing change kits available

frorri your distributor.

!

Page 4

..............._ .......... IIIII

®

UNDERCOUNTER

MODELS

249FF FREEZER

1) Adjustable Shelves

2) Adjustable Temperature Control

3) Interior Light

4) Automatic Defrost Blower Assembly

5) One-piece Interior

6) Four-sided Magnetic Gasket

7) Door Hinge *

8) Serial and Model Number Location

9) Ventilated Toe Kickplate Area

10) Front Venting

11) Door Closer

* Accessory door swing change kits available

from your distributor.

Automatic icemaker available as an option

but must installed at the factooz.

...j

801 REFRIGERATOR/

FREEZER

1) Automatic Icemaker

2) Adjustable Freezer Control

3) Adjustable Refrigerator Control

4) Interior Refrigerator Light

5) Shelves

6) Automatic Defrost Blower Assembly

7) One-piece Interiors

8) Four-sided Magnetic Gasket

9) Serial and Model Number Location

10) Solid Toe Kickplate Area

11) Front Venting

12) Door Closer

13) Door Hinge

4

Page 5

_ IIIIII11 II({I I 'IH I I I

_o - ,,,,H,H,,H, III" .... ' .............. l'll I

PRODUCT OPERATION

The importance of the Installation of

your Sub-Zero CANNOT be

overemphasized. The proper

installation of your unit is the

responsibility of the selling dealer or

installer. Any questions or problems

pertaining to the installation should be

directed to the selling dealer.

TEMPERATURE

CONTROL LOCATION

AND ADJUSTMENTS

- Your new refrigerator and/or freezer was

thoroughly inspected and tested before it

was shipped from the Sub-Zero factory.

During these procedures, the temperatures

were preset to maintain approximately 38

degrees in the refrigerator section and

approximately 0 degrees inthe freezer

section (except 249R). If you wish to make

temperature adjustments, simply turn the

temperature control dial. The higher the

number the colder the temperature (#1 is

the warmest and #7 is the coldest setting).

For the location of the control, refer to the

model of your Sub-Zero on the following

pages.

You should be aware it is normal for the

above temperatures to fluctuate slightly,

depending on external influence such as:

open door for extended periods, the

degree of humidity present and room tem-

perature.

.4) ADJUSTMENT

To adjust the freezer and refrigerator

controlson our models 245, 249R, 249RP,

249FF and 801RFD, simply turn the control

knob so the indicator lines up with the

desired number.

B) LOCATION

MODEL 245

The freezer control is located on the back

wall above and right of the ic_emaker

assembly. (See Model 245 Features on

page 3.) The refrigerator control is situated

left of center at the top of the refrigerator

compartment. (See Model 245 Features on

page 3.)

MODEL 249R

(MANUAL DEFROST)

The control issituated on the right hand

side of the back wall in the upper freezer

corn artment. See

pageant.) 1._ Model 249RP Features

on

MODEL 249RP

The control is located on the right side of

the back wall just below the lower shelf

assembly. (See Model 249RP Features on

page 3.)

MODEL 249FF

The control is found at the top of the freezer

on the right side of the defrost blower

assembly. (See Model 249FF Features on

page 4.)

MODEL 801 RFD

The refrigerator control is located on the top

left wall of the refrigerator compartment as

you face the unit. (See Model 801 RFD

Features on page 4.) The freezer control is

situated on the right side of the automatic

defrost blower assembly located at the top

of the freezer compartment. (See Model

801RFD Features on page 4.)

DOOR CLOSING

MODELS 245 and 801RFD

The doors on our models 245 and 801RFD

are equipped with a door closing cam

system to assist in the closing of the door.

As you close the door, the cam will take

over at approximately the 15 degree posi-

tion to assist in the closing of the door.

MODELS 249R, 249RP and 249FF

The refrigerator and freezer doors are both

equipped with a spring-loaded door clo-

sure mechanism. As the doors are closed,

the door closure engages at approximately

the 15 degree position to assist the door in

closing and sealing.

CONDENSER FAN

OPERATION

All undercounter units have one fan located

behind the kickplate at the base of the unit.

On all undercounter models the fan

operates on/ywhen the compressor is run-

ning.

EVAPORATOR FAN

OPERATION

MODELS 245, 249FF and 801RFD

A fan motor islocated in the freezer section

on the models listed above. These fans

operate onlywhen the compressor is

running.

AUTOMATIC DEFROST

INFORMATION

For your convenience, Sub-Zero has

equipped the following models with an

automatic defrost system: 245, 249RP,

249FF and 801RFD. NOTE: Our model

249R is not equipped with automatic

defrost. To manually defrost, turn the a

control knob to the off position.

SOUNDS

Certain noises may be evident with the

normal operation of the unit. Surrounding

acoustics like walls, floors and cabinets

may affect the sound level of your unit.

A gurgling sound or running water sound

may be evident as the refrigerant circulates

through the tubing.

During the icemaker cycle, you may hear

the sound of ice dropping into the bucket

or the solenoid valve while refilling the ice-

maker with water.

During the freezer defrost, you may hear

crackling and/or sizzling as the heat from

the defrost element clears the frost from the

freezer coil and water runs into the defrost

water pan.

While the compressors are in operation, a

slight hum might be evident. During the

startup and shutdown of the compressor,

some vibration may occur lasting only a

few seconds.

ICEMAKER OPERATION

The icemaker in your Sub-Zero is fully auto-

matic and has been factory pretested. To

put into operation, it requires only a con-

nection to the house water supply.

Page 6

IIIII

PRODUCT CARE

i

I [!!]1!!!!i!i1_!.....

I!1111

FOOD STORAGE

SUGGESTIONS

ICE PRODUCTION

The level of ice in the ice container is con-

trolled by an ice level arm. When the con-

tainers are filled with ice, the ice level arm

senses the level and shuts down the ice-

maker. As ice is used, the level drops and

the level arm signals the icemaker to

restore ice production.

These icemakers are designed to produce

a more than adequate supply of ice for

normal family consumption, the length of

time between ice harvest cycles will vary

depending on load conditions, door open-

ings and ambient room temperatures. On

the average, you can expect a harvest of

ice every two hours.

If ice is not used regularly, it will tend to

fuse together. To avoid this, empty the ice

container periodically.

NOTE: To shut off icemaker, lift up

icemaker stop arm to the up or off position

(see Figure 1 below).

MAINTENANCE

AND CLEANING

I&CAUTION I

We recommend for maintenance and

cleaning, that the circuit breaker to the

refrigerator be shut off and protective

gloves be worn.

For general cleaning of the refrigerator and

freezer interior surfaces and removable

parts, wash with a mild solution of soap

and water to which a sma'r_amount of bak-

ing soda has been added. Rinse and dry

thoroughly. Avoid getting water on lights

and/or control dial.

To insure proper performance, the clean-

ing o; your unit's condenser is required.

IMPORTANT!! This should be performed

every 3 to 6 months under normal use

and living conditions.

To expose the condenser, remove the

kickplate at the base of the unit. To do this

simply remove the screws located at each

corner of the kickplate.

Once the condenser is exposed, use a

"soft" bristle brush and vacuum hose to

remove the accumulation of dust and lint par-

ticles on the condenser (see Figure 2 below).

IMPORTANT!! Failure to properly clean

this area could result in temperature

lost and/or possible mechanical failure

of the refrigerator and/or freezer.

Figure 2

LIGHT BULB

REPLACEMENT

,_k,WARNING I

For your safety, the circuit breaker to

the refrigerator should be shut off

before replacing bulbs. Protective

gloves should be worn when handling

light bulbs.

MODEL 245

To replace the refrigerator light bulb (25

watt), remove upper shelf and pull control

knob off. Grip refrigerator control diffuser

firmly on top and bottom and snap out of

position. Thelight bulb is now accessible.

To replace the freezer light bulb (25 watt),

pull control knob off. Grip freezer control

diffuser firmly on top and bottom and snap

out of position. The bulb is now accessible.

To reinstall, reverse procedure.

MODEL 249R

The light bulb (25 watt) is located beneath

the freezer evaporator and is accessed by

reaching up underneath behind the right

hand side of the freezer section. Unscrew

and replace.

MODEL 249RP

The light bulb (25 watt) is accessible by

removing three screws which anchor the

light bracket. Remove bracket and reach

behind the light diffuser and unscrew bulb.

Toreinstall, reverse procedure.

MODEL 249FF

The light bulb (25 watt) is mounted behind

the left side of the blower fan assembly at

the top of the back wall of the freezer.

Unscrew and replace.

MODEL 801RFD

The refrigerator light bulb (25 watt) is

situated on the upper left side of the

refrigerator compartment in front of the

refrigerator control panel. Unscrew and

replace.

VACATION TIME

For short vacations: Remove all

perishable items. Shut off the icemaker

(see Icemaker Operation on page 5). Do

not change the settings of your controls.

For extended vacations: The control(s) to

your refrigeratoror freezer should be shut

off. Empty all contents in the refrigerator/

freezer and wash, rinse and dry interiorof

unit.

Vacant homes: If for any reason this unit

is put into service on a temporary basis

and later shut off, the control(s)to the

refrigerator or freezer should be shut off.

For extended vacations or vacant homes,

you should block door(s) open slightly.

About one inch, so fresh air can circulate

and keep interiordry. You should also turn

off power to the unit or loosen light bulb(s).

[&CAU'nON 1 .

The moisture developed during even the

shortest amount of running time could

attack the metal parts if the doors are

left closed after shutting down. Be sure

the doors are blocked open after any

operation.

Page 7

i I

I Illl I I I ill

SERVICE INFORMATION

FOOD STORAGE

SUGGESTIONS

New techniques are constantly being

developed. Consult the College or

County Extension Service or your local

Utility Company for the latest

information on freezing and storing

food. *U.S. Department of Agriculture

Fresh Food Storage

Shelf life of fresh foods may vary,

depending on the freshness at time of

purchase. To keep your foods fresher

longer, follow the recommended storage

procedures.

Vegetables

Wash in cool water and drain. Store in

air-tight container or plastic wrap. Most

vegetables should be stored in higher

humidity.

Fruits

Wash and dry. Store in crisper compart-

ment. More aromatic fruits should be

stored in plastic bags. Most fruits should

be stored in lower humidity.

Prepackaged Meets

Store in original packaging. After opening,

rewrap tightly in plastic wrap or aluminum

foil.

UnfrozenFish,Meats and Poultry

Removestore wrappings. Thenrewrap in

plastic wrap,foil or waxed paper, and

refrigerateimmediately.

Eggs

Storeunwashed in carton orportable egg

tray.Use within twoweeks.

Milk, Cream, Cottage Cheese

Keep carton closed. Store on refrigerator

shelf and use within five days.

Cheese :

Store in original packaging until ready to

use. After opening, rewrap tft_Jhtlyinplastic

wrap or aluminum foil.

Left Overs

Letcool and cover tightlywith plasticwrap

or foil. Airtightplastic containerswork well

to preventdryingoutandodortransfer.

Freezer Storage

Foods should be wrapped in material

designed for frozen food storage. The wrap

must be sealed so as not to allow air or

moisture through the wrapping.

DO NOT refreeze thawed meats.

Ice Cream

The firmness of the ice cream will depend

on the cream content of the ice cream. The

higher quality ice creams usually have a

higher cream content requiring colder

freezer temperatures to maintain its firm-

ness. Soft ice cream is not always an indi-

cation of a temperature problem.

PRODUCT LOADING

SUGGESTIONS

Items that inhibit proper closing of your

doors and affect the temperatures

should not extend beyond the front of

your shelves or beyond the face of your

door shelf assemblies. DO NOT fill

freezer with large quantities of

unfrozen expecting to "fast freeze"

these items. For best results, space

out new unfrozen items to allow for

air circulation.

SERVICE INFORMATION

Before ceiling service-

Ifyou think that your refrigerator is not

operating properly, check the following

before calling your Sub-Zero Factory

Authorized Service Agency or dealer. This

may save you time and the expense of a

service call.

If Refrigerator/Freezer is not operating:

• Is there electrical power to equipment?

• Is home fuse blown or circuit breaker off?.

• Is refrigerator/freezer control on?

• Is condenser clean?

• Has door been left open? Be sure no

foods are obstructing proper door

closing.

• If still not running, unit may be in defrost;

wait 30 minutes to see if unit will restart.

ff Refrigerator/Freezer Is warmer than

usual:

• Check controlfor proper setting.

• Has door been left open too long?

• Have you recently added a large

quantity of food?

• Is condenser behind grille clean?

(See page 6.)

If Refrigerator/Freezer runs too much:

• Is condenserbehind grille clean?

(See page6)

• On hot daysand warmroomambients,

themotorrunslonger.

• Havedoors been open for extended

timesorlargeamountsoffood added?

If Refrigerator/Freezer is frosted up:

• Have the doors been left open?

• Are doors closing and sealing pr6perly?

ffyou hear unusualnoises:

• These may be normal operating sounds

(See page5 under "Sounds").

If condensation forms inside the unit:

• This is normal during high humidity and

frequent door openings.

• Are doors closing and sealing properly?.

If condensation forms on the outside:

• It is possible during periods of high

humiditythat some condensation could

appear. This condition will subside when

humidity levels drop. If condensation is

excessive, contact your Sub-Zero

Factory Authorized Service Agency.

• Be sure doors are closed and gaskets

are sealing.

If it is too hot around freezer compart-

ment (excluding 249R and 249RP):

• Clean condenser (see page 6).

Ifthere is odorin the unit and ice:

• Completelyclean product (see page 6).

• Cover foods tightly.

If light bulb needs replacing:

• Turn off circuit breaker to refrigerator,

wear gloves to protect against broken

glass (see page 6).

If you hear occasional buzzing:

• Is water supply connected to icemaker

and turned on?

ff you need service --

• Please have model and serial number

available (for location _fer to page 2

along with pictures of each unit on

pages 3 and 4).

• Call your nearest Sub-Zero Authorized

Service Agency. For the name of a local

Sub-Zero Authorized Service Agency,

contact your dealer or: Sub-Zero

Freezer Co., Inc., Service Department,

P.O. Box 44130, Madison, Wl 53744-

4130. Phone (800) 222-7820.

Page 8

SUB-ZERO FREEZER CO., INC.

FORM NO. 3-75-301-2

P.O. BOX 44130, MADISON, WISCONSIN 53744-4130

PRINTED IN U.S.A.

(608) 271-2233

8/94

Loading...

Loading...