Page 1

HomeServices

1-800-4-MY-HOME

Operator: Save these ins uctions re use!--

FAILURE TO READ AND FOLLOW ALL INSTRUCTIONS CAREFULLY

BEFORE INSTALLING OR OPERATING THIS CONTROL COULD CAUSE

PERSONAL INJURY AND/OR PROPERTY DAMAGE.

Your new 5-Day/I-Day/I-Day Digital Thermostat uses the tech-

nology of a solid-state microcomputer to provide precise time/

temperature control. This thermostat offers you the flexibility to

design heating and cooling programs that fit your needs.

Features:

• Separate 5-day (weekday), 1-day (Sat) and 1-day (Sun) pro-

gramming with four separate time/temperature periods per day

• Simultaneous heat and cool program storage

• Preprogrammed temperature control

• Backlit display

• LCD continuously displays setpoint, and alternately dis-

plays time and room temperature

1F80-382

Programmable Electronic Digital Thermostat

iNSTALLATION AND

OPERATION iNSTRUCTiONS

DESCRIPTION

• Temperature override until next program period

• Manual program override (HOLD temperature)

• Temporary HOLD

• °F/°C convertibility

• Temperature range 45° to 90°F

• RC, RH, C, W, Y, G, O and Bterminals

• Optional C terminal (Dual Power option)

• B and O terminals for single stage heat pumps (no auxiliary

heat) or damper operation

• Program storage in case of power loss

• 2 "AA" alkaline batteries included

This thermostat is intended for use with alow voltage system; do

not use this thermostat with a line voltage system. If in doubt

about whether your wiring is millivolt, line, or low voltage, have

it inspected by a qualified heating and air conditioning contractor

or electrician.

Do not exceed the specification ratings.

All wiring must conform to local and national electrical codes and

ordinances.

This control is a precision instrument, and should be handled

carefully. Rough handling or distorting components could cause

the control to malfunction.

To prevent electrical shock and/or equipment damage,

disconnect electric power to system at main fuse or

circuit breaker box until installation is complete.

ELECTRICAL DATA APPLICATIONS

Electrical Rating:

8 to 30 VAC 50/60 Hz. or D.C.

0.05 to 1.0 Amps (Load per terminal)

1.5 Amps Maximum Total Load (All terminals combined)

THERMAL DATA

Setpoint Temperature Range:

45°F to 90°F (7°C to 32°C)

Operating Ambient Temperature Range:

32°F to 105°F

Operating Humidity Range:

0 to 90% RH (non-condensing)

Shipping Temperature Range:

-4°F to 149°F

Do not use on circuits exceeding specified voltage.

Higher voltage will damage control and could cause

shock or fire hazard.

Do not short out terminals on gas valve or primary

control to test. Short or incorrect wiring will damage

thermostat and could cause personal injury and/or

property damage.

Thermostat installation and all components of the sys-

tem shall conform to Class II circuits per the NEC code.

For use with:

• Standard heat/cool or heat only systems

• Electric heat systems

• Gas or oil fired systems

• Gas systems with intermittent ignition devices (M.D.)

and/or vent dampers

• Hydronic (hot water or steam) systems

• Single-stage heat pump systems (no auxiliary heat)

• Millivolt systems

DO NOT USE WITH:

• Multi-stage systems

• Systems exceeding 30 VAC and 1.5 amps

• 3-wire zoned hydronic heating systems

PRECAUTIONS

SPECIFICATIONS

PART NO. 37=6924A

0811

Page 2

INSTALLATION

REMOVE OLD THERMOSTAT

1. Shut off electricity at the main fuse box until installation is

complete. Ensure that electrical power is disconnected.

2. Remove the front cover of the old thermostat. With wires

still attached, remove wall plate from the wall. If the old

thermostat has a wall mounting plate, remove the thermo-

stat and the wall mounting plate as an assembly.

3. Identify each wire attached to the old thermostat using

the labels enclosed with the new thermostat.

4. Disconnect the wires from old thermostat one at a time. DO

NOT LET WIRES FALL BACK INTO THE WALL.

5. Install new thermostat using the following procedures.

ATTENTION!

This product does not contain mercury. However, this product

may replace a unit which contains mercury.

Do not open mercury cells. If a cell becomes damaged, do not

touch any spilled mercury. Wearing nonabsorbent gloves, take

up the spilled mercury with sand or other absorbent material and

place into a container which can be sealed. If a cell becomes

damaged, the unit should be discarded.

Mercury must not be discarded in household trash. When the

unit this product is replacing is to be discarded, place in a

suitable container and return toWhite-Rodgers at 2895 Harrison

Street, Batesville, AR 72501 for proper disposal.

ELECTRIC HEAT OR SINGLE-STAGE

HEAT PUMP SYSTEMS

This thermostat is configured from the factory to operate a heat/

cool, fossil fuel (gas, oil, etc.), forced air system. It is configured

correctly for any system that DOES NOT require the thermostat

to energize the fan on a call for heat. Ifyour system is an electric

heat or heat-pump system that REQUIRES the thermostat to

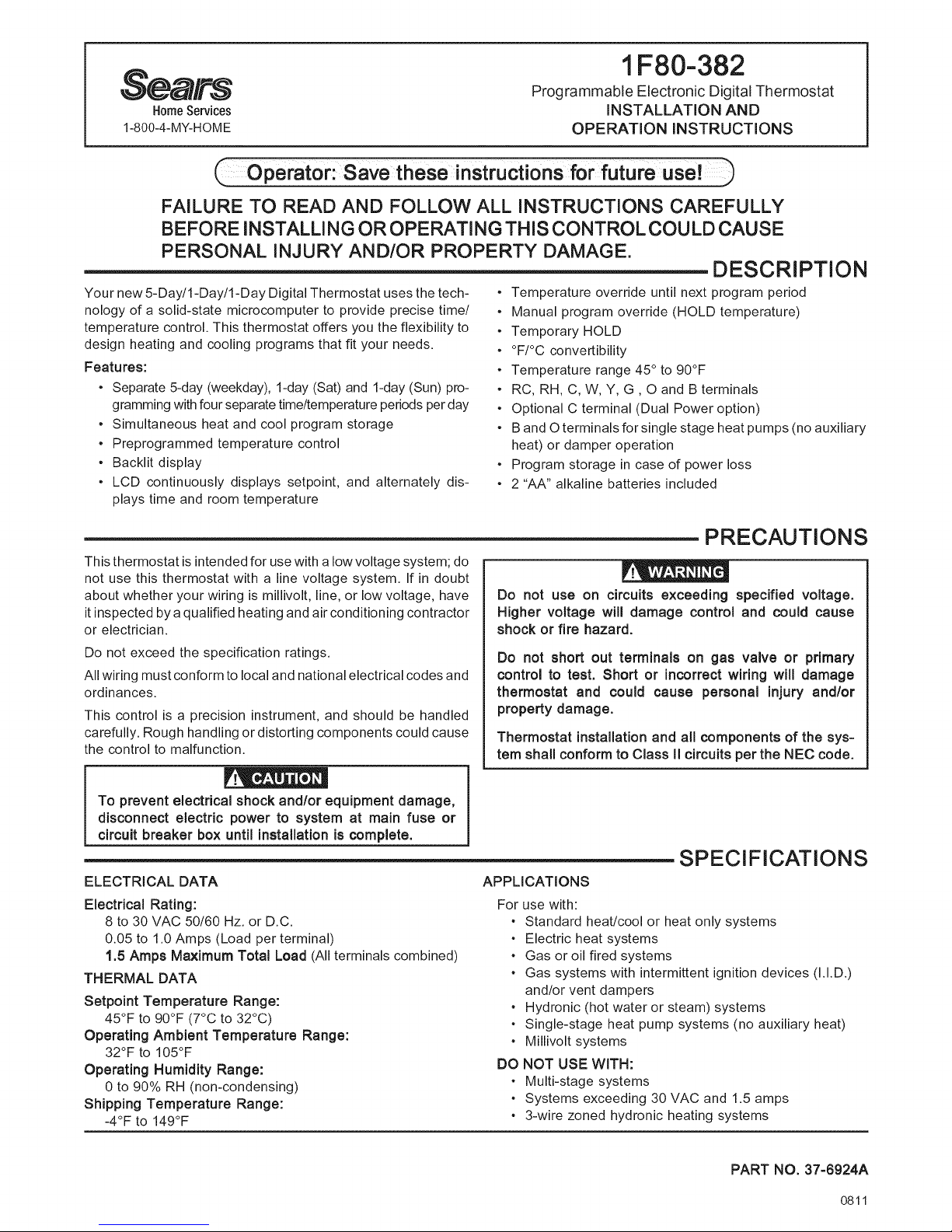

turn on the fan on a call for heat, locate the ELECTRIC/GAS

switch on the back of the thermostat (see fig. 1) and switch itto

the ELECTRIC position. This will allow the thermostat to

energize the fan immediately on a call for heat. Ifyou are unsure

if the heating/cooling system requires the thermostat to control

the fan, contact a qualified heating and air conditioning service

person.

ATTACH THERMOSTAT BASE TO WALL

1. Remove the packing material from the thermostat. Gently

pull the cover straight off the base. Forcing or prying on the

thermostat will cause damage to the unit. If necessary, move

the electric heat switch (see ELECTRIC HEAT SYSTEMS,

above).

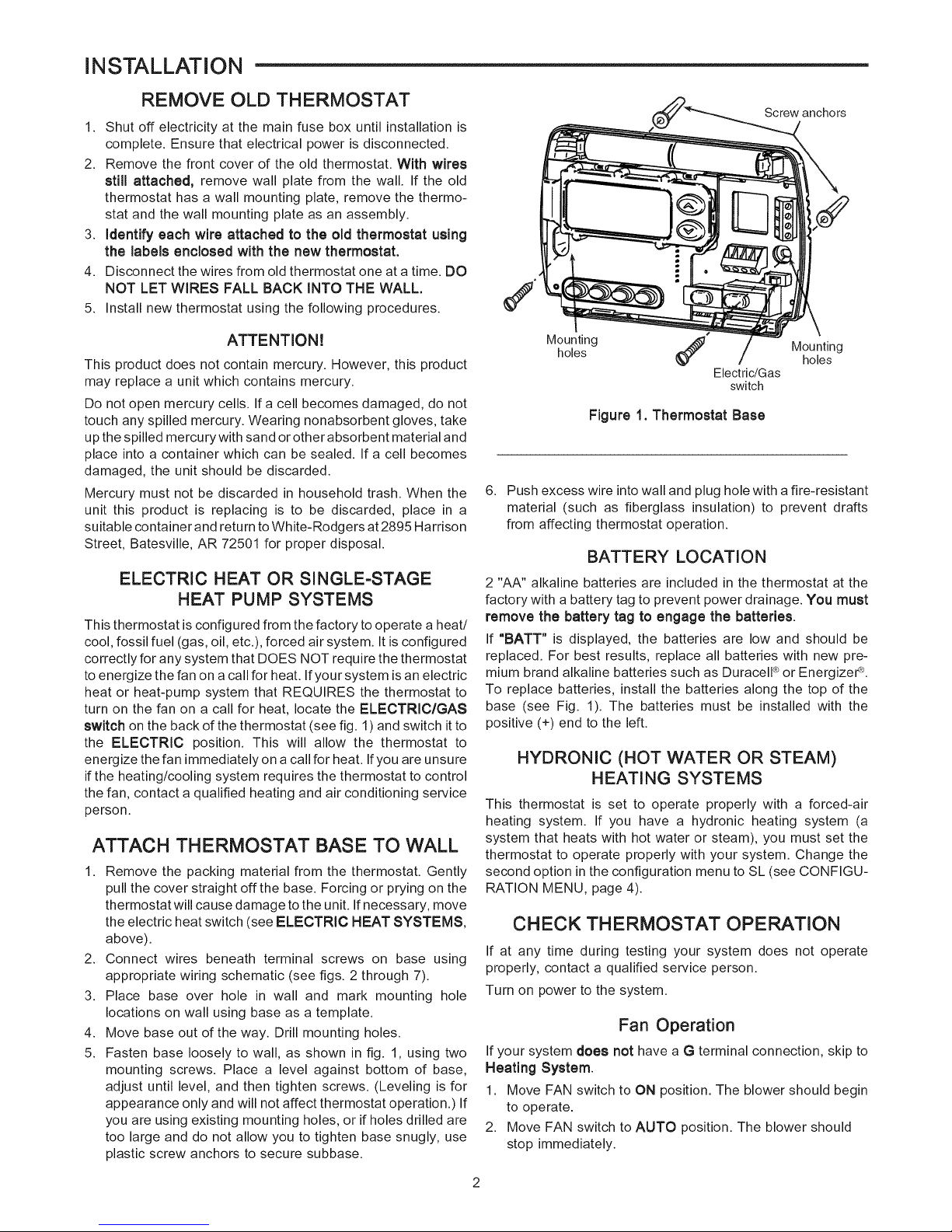

2. Connect wires beneath terminal screws on base using

appropriate wiring schematic (see figs. 2 through 7).

3. Place base over hole in wall and mark mounting hole

locations on wall using base as a template.

4. Move base out of the way. Drill mounting holes.

5. Fasten base loosely to wall, as shown in fig. 1, using two

mounting screws. Place a level against bottom of base,

adjust until level, and then tighten screws. (Leveling is for

appearance only and will not affect thermostat operation.) If

you are using existing mounting holes, or if holes drilled are

too large and do not allow you to tighten base snugly, use

plastic screw anchors to secure subbase.

Screw anchors

Mounting

holes

Electric/Gas

switch

Mounting

holes

Figure 1. Thermostat Base

6. Push excess wire into wall and plug hole with afire-resistant

material (such as fiberglass insulation) to prevent drafts

from affecting thermostat operation.

BATTERY LOCATION

2 "AA" alkaline batteries are included in the thermostat at the

factory with a battery tag to prevent power drainage. You must

remove the battery tag to engage the batteries.

If "BATT" is displayed, the batteries are low and should be

replaced. For best results, replace all batteries with new pre-

mium brand alkaline batteries such as Duracell ®or Energizer _e.

To replace batteries, install the batteries along the top of the

base (see Fig. 1). The batteries must be installed with the

positive (+) end to the left.

HYDRONIC (HOT WATER OR STEAM)

HEATING SYSTEMS

This thermostat is set to operate properly with a forced-air

heating system. If you have a hydronic heating system (a

system that heats with hot water or steam), you must set the

thermostat to operate properly with your system. Change the

second option in the configuration menu to SL (see CONFIGU-

RATION MENU, page 4).

CHECK THERMOSTAT OPERATION

If at any time during testing your system does not operate

properly, contact a qualified service person.

Turn on power to the system.

Fan Operation

If your system does not have a G terminal connection, skip to

Heating System.

1. Move FAN switch to ON position. The blower should begin

to operate.

2. Move FAN switch to AUTO position. The blower should

stop immediately.

Page 3

JUMPER

WIRE

_)24_SYSTE:°t

l _ Neutral

a TRANSFORMER

attacln to RH and W J TRANSFORMER

Figure 2.Typical wiring diagram for

heat only, 3-wire, single transformer systems

JUMPER

WiRE

TRANSFORMER

Figure 3. Typical wiring diagram for

cool only, 3-wire, single transformer systems

RED jumper wire (provided with thermostat) must be

_connected between thermostat RR and RC terminals_ JUMPER

_for proper thermostat operation with this system. _ WIRE

T o

TRANSFORMER

Figure 4.Typical wiring diagram for

heat/cool, 4=wire, single transformer systems

v

Figure &Typical wiring diagram for

heat/cool, 5-wire, two-transformer systems

JUMPER JUMPER

WIRE WIRE

I _1 Contactor|U L____

_ ! ! L 24VAC U _C

* Reversing valve is energized when tlne _=J_Neutral

system switch is in the COOL position TRANSFORMER

Figure 6. Typical wiring diagram for heat pump

with reversing valve energized in COOL

JUMPER JUMPER

WIRE WIRE

24vAcLI 14.120wc

'==L_ Neutral

COOLING TRANSFORMER

T

)mpressorll t-an I I

;°ntact°r ! Re[_

* Reversing valve is energized when the

system switch is in the HEAT position

Figure 7.Typical wiring diagram for heat pump

with reversing valve energized in HEAT

1 24wc

TRANSFORMER

* The 24 Volt neutral connection to terminal C on the thermostat is not required ifthe batteries are replaced once a year

with fresh premium brand alkaline batteries.

Heating System

1. Move SYSTEM switch to HEAT position. If the heating

system has a standing pilot, be sure to light it.

2. Press (_ to adjust thermostat setting above room tempera-

ture. The heating system should begin to operate.

3. Press (_ to adjust temperature setting below room tem-

perature. The heating system should stop operating.

Cooling System

To prevent compressor and/or property damage, if the

outdoor temperature is below 50°F, DO NOT operate

the cooling system.

1. Move SYSTEM switch to COOL position.

2. Press (_) to adjust thermostat setting below room tempera-

ture. The blower should come on immediately on high

speed, followed by cold air circulation

3. Press (_ to adjust temperature setting above room tem-

perature. The cooling system should stop operating.

Page 4

OPERATION

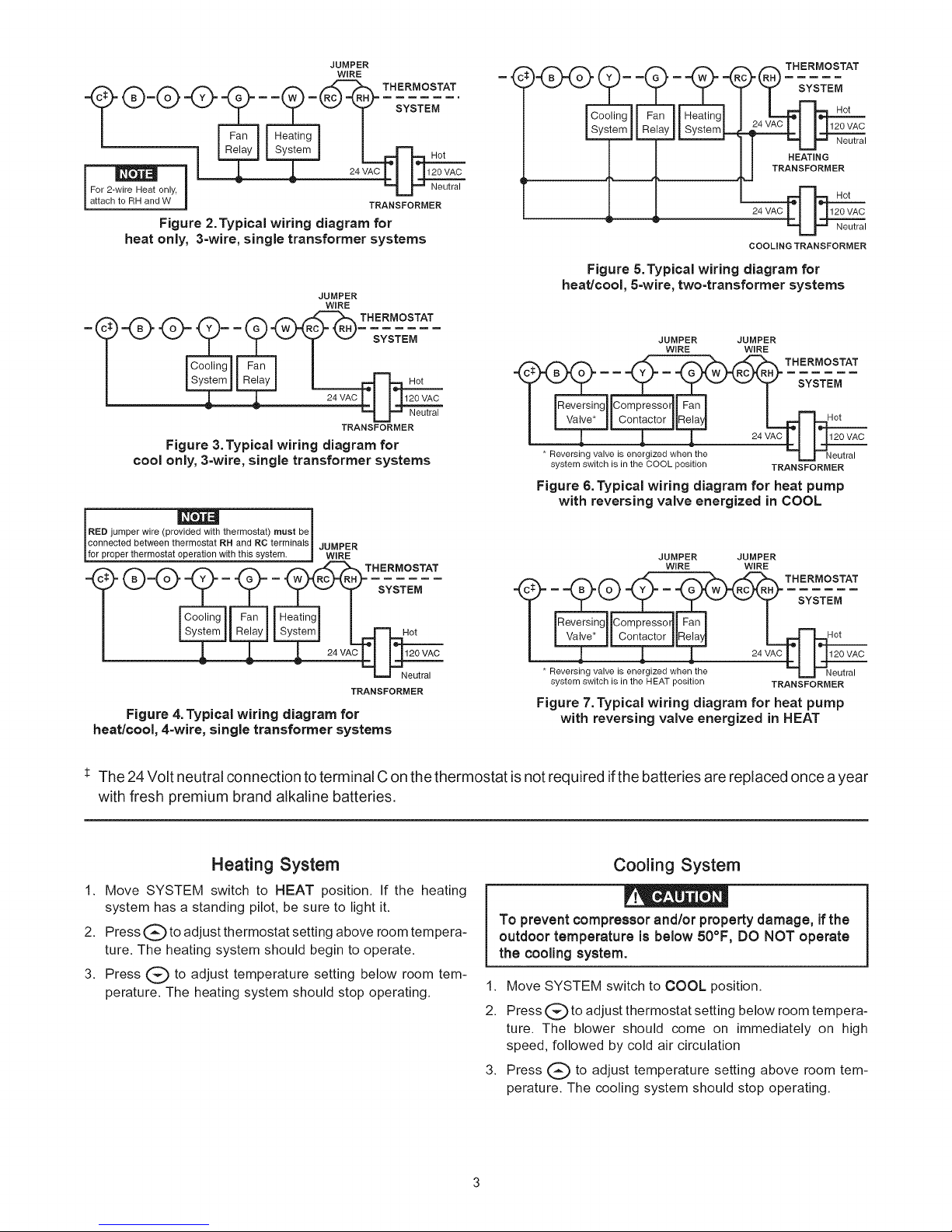

Before you begin programming your thermostat, you should be

familiar with its features and with the display and the location

and operation of the thermostat buttons. Your thermostat con-

sists of two parts: the thermostat cover and the base. To

remove the cover, pull it straight out from the base. To replace

the cover, line up the cover with the base and press until the

cover snaps onto the base.

The Thermostat Buttons and Switches

Q Raises temperature setting.

Q Lowers temperature setting.

Q TIME button.

Q PRGM (program) button.

Q RUN (run program) button.

Q HOLD temperature button.

Q FAN switch (ON, AUTO).

Q SYSTEM switch (COOL, OFF, HEAT).

The Display

Q Indicates day of the week.

Q Flame icon (_) is displayed when the SYSTEM switch is in

the HEAT position. Snowflake icon (_)is displayed (non-

flashing) when the SYSTEM switch isin the COOL position.

Snowflake is displayed (flashing) if the thermostat is in

lockout mode to prevent the compressor from cycling too

quickly.

run

are

pro-

Q Displays "BATT" when the 2 "AA" batteries low and

should be replaced. Only "BATT" and "LO" in the minutes

field are displayed when batteries are low with no system

power.

Q Alternately displays current time and temperature. Dis-

plays "LO" in the minutes field when batteries are low.

Q The word "HOLD" is when the thermostat is in

the HOLD mode. "HOLD" is displayed flashing when the

thermostat is in a temporary HOLD Mode.

Q Displays currently programmed temperature (this

blank when SYSTEM switch is in the OFF position).

Q Displays "FLTR" when the has for the

grammed filter time period as a reminder to change or clean

your air filter.

displayed

set is

system

CONFIGURATION MENU

The configuration menu allows you to set certain thermostat

operating characteristics to your system or personal require-

ments.

Press RUN to make sure the thermostat is in the run program

mode, then press PRGM and RUN atthe same time to enter the

configuration menu. The display will show the first item in the

configuration menu.

The configuration menu table summarizes the configuration

options. An explanation of each option follows.

Figure 8. Thermostat display, buttons, and switches

Press HOLD to change to the next menu item or press TIME to

go backwards to the previous item in the menu. To exit the menu

and return to the program operation, press RUN. If no keys are

pressed within fifteen minutes, the thermostat will revert to

normal operation.

1) Select Temporary Hold Time - The thermostat can hold

any temperature you set it to for the amount of time you

select on this option. Your choices are 0:00 to 8:00 hours in

15 minute increments. 0:00 disables the function

Example:

1. You have selected 3:00 hours for the Temporary Hold

time period.

2. With the thermostat set to Heat or Cool, press HOLD for

approximately five seconds until HOLD time (3:00

indicating 3 hours) appears as a setting reminder.

3. After releasing the button, "HOLD" on the display will

blink.

4. Use (_ or (_ to set the temperature to your prefer-

ence. The thermostat will maintain this temperature

setting for 3 hours with "HOLD" blinking to remind you it

is in Temporary Hold. After 3 hours the thermostat will go

back to the program temperature and "HOLD" will no

longer blink or display.

2) Select FA or SL (Fast or Slow) Heating Cycle Rate - The

FAsetting is frequently used for gas, oil or electric heat. The

SL setting produces a longer heating cycle which is nor-

mally for hot water or steam (hydronic) systems. Both

settings produce very accurate temperature control and

can be set to your personal preference. FA cycles the

system just under I°F and the SL setting cycles at approxi-

mately 1.5°F.

3) Select backlit display- The display backlight improves

display contrast in low lighting conditions. Selecting back-

light ON will keep the light on for a short period of time after

any key is pressed. Selecting OFF will keep the light off.

Page 5

ConfigurationMenu

Step PressButton(s) Displayed(FactoryDefault) Press (_ or (_ to select: COMMENTS

1 PRGM HOLD 0to 8hrs(in SelecttemporaryHoldtime

2 HOLD_' 4) SL Select FAor SL (Fastor Slow) heating cycle rate

3 HOLD_' d-L OFF SelectdisplaybacklightOFForON

4 HOLD_ E OFF SelectEnergyManagementRecoveryOFFor ON

5 HOLD_ Filter 0to 1950hours Selectfilterreplacementruntime

6 HOLD_, LOC ON SelectcompressorlockoutOFForON

7 HOLDs' 0 HI 4 LO to Selecttemperaturedisplayadjustmenthigheror lower

8 HOLD_ (F) C Selecttemperaturedisplayto For C

9 RUN Returnstonormaloperation

* Press HOLD to advance to next item or TIME to movebackwards to previous item

and RUN (0:00) 15minuteincrements)

(FA)

(ON)

(ON)

(000) (in50 hour increments)

(OFF)

(0) 4 HI

4) Select Energy Management Recovery OFF or ON -

Energy Management Recovery (EMR) causes the thermo-

stat to start heating or cooling early to make the building

temperature reach the program setpoint at the time you

specify. Heating will start 5 minutes early for every 1° of

temperature required to reach setpoint.

Example: You select EMR and have your heating pro-

grammed to 65° at night and 70° at 7 AM. If the building

temperature is 65° the difference between 65° and 70° is

5°. Allowing 5 minutes per degree the thermostat setpoint

will change to 70° at 6:35 AM. Cooling allows more time per

degree because it takes longer to reach temperature.

5) Select filter replacement run time - The thermostat will

display "FLTR" after a set time of operation. This is a

reminder to change or clean your air filter. This time can be

set from 0 to 1950 hours in 50 hour increments. A selection

of 000 will cancel this feature. When "FLTR" is displayed,

you can clear it by pressing HOLD and RUN at the same

time. This resets the timer and starts counting the hours

until the next filter change. Changing the time in the menu

also resets the timer.

6) Select Compressor Lockout LOC OFF or ON - Selecting

LOC ON will cause the thermostat to wait 5 minutes before

turning on the compressor if the heating and cooling sys-

tem loses power. It will also wait 5 minutes minimum

between cooling cycles. This is intended to help protect the

compressor from short cycling. Some newer compressors

already have a time delay built in and do not require this

feature. Your compressor manufacturer can tell you if the

feature is already present in their system. When the com-

pressor time delay occurs it will flash the (snowflake icon)

for about five minutes then turn on the compressor.

7) Select Temperature Display Adjustment 4 LO to 4 HI -

Allows you to adjust the room temperature display 4° higher

or lower. Your thermostat was accurately calibrated at the

factory but you have the option to change the display

temperature to match your previous thermostat.

8) Select F° or C° Readout- Changes the display readout to

Centigrade or Fahrenheit as required.

OPERATING FEATURES

Now that you are familiar with the thermostat buttons and

display, read the following information to learn about the many

features of the thermostat.

• SIMULTANEOUS HEATING/COOLING PROGRAM

STORAGE -- When programming, you can enter both

your heating and cooling programs at the same time. There

is no need to reprogram the thermostat at the beginning of

each season.

• TEMPERATURE OVERRIDE -- Press (_) or (_) until

the display shows the temperature you want. The thermo-

stat will override current programming and keep the room

temperature at the selected temperature until the next

program period begins. Then the thermostat will automati-

cally revert to the program.

• HOLD TEMPERATURE-- The thermostat can hold any

temperature within its range for an indefinite period without

reverting to the programmed temperature. Momentarily

press HOLD button. "HOLD"will be displayed. Then choose

the desired temperature by pressing (_ or (_). The

thermostat will hold the room temperature at the selected

setting until you press RUN button to start program opera-

tion again.

• CONFIGURATION MENU -- Allows you to customize

certain thermostat options.

PROGRAMMING YOUR THERMOSTAT

This section will help you plan your thermostat's program to

meet your needs. For maximum comfort and efficiency, keep

the following guidelines in mind when planning your program.

• When heating (cooling) your building, program the

temperatures to be cooler (warmer) when the building is

vacant or during periods of low activity.

• During early morning hours, the need for cooling is

usually minimal.

Page 6

Planning Your Program

Look at the factory preprogrammed times and temperatures

shown in the sample schedule. If this program will suit your

needs, simply press the RUN button to begin running the factory

preset program.

If you want to change the preprogrammed times and tempera-

tures, follow these steps.

Determine the time periods and temperatures for your weekday

and weekend programs. You must program four periods for

both the weekday and weekend program. However, you may

use the same heating and cooling temperatures for consecutive

time periods. You can choose start times, heating tempera-

tures, and cooling temperatures independently for both week-

day and weekend programs (for example, you may select 5:00

AM and 70° as the weekday 1st period heating start time and

temperature, and also choose 7:00 AM and 76° as the weekday

1st period cooling start time and temperature).

Use the following table to plan your program time periods and

the temperatures you want during each period. Fill in the

complete table to have a record of your programs.

Entering Your Program

Follow these steps to enter the heating and cooling programs

you have selected.

Set Current Time and Day

1. PressTIME button once. The displaywill showthe houronly.

EXAMPLE: ;2: PM i

2. Press and hold either(_ or(_ until you reach the correct

hour and AM/PM designation (AM begins at midnight; PM

begins at noon).

3. Press TIME once. The displaywindowwill showthe minutes

only.

EXAMPLE: "U

4. Press and hold either(_ or(_ until you reach the correct

minutes.

5. PressTIME once. The display will showthe dayofthe week.

6. Press (_ or(_ until you reach the current day of the week.

7. Press RUN once. The display will show the correct time and

room temperature alternately.

Enter Heating Program

1. Move the SYSTEM switch to HEAT.

2. Press PRGM once. "MO TU WE TH FR" (indicating week-

day program) will appear in the display. Also displayed are

the currently programmed start time for the 1st heating

period and the currently programmed temperature (flash-

ing).

EXAMPLE: [M_---TU-wI_R'AM_jl_,

This display window shows that for the 1st weekday period,

the start time is 6:00 AM, and 68° is the programmed

temperature (this example reflects factory preprogramming).

3. Press (_) or (_ to change the displayed temperature to

your selected temperature for the 1st heating program

period.

4. Press TIME once (the programmed time will flash). Press

(_ or (_ until your selected time appears. The time will

change in 15 minute increments. When your selected time

is displayed, press TIME again to return to the change

temperature mode.

5. Press PRGM once. The currently programmed start time

and setpoint temperature for the 2nd heating program

period will appear.

6. Repeat steps 3 and 4 to select the start time and heating

temperature for the 2nd heating program period.

7. Repeat steps 3 through 5 for the 3rd and 4th heating

program periods. Weekday heating programs are now com-

plete.

8. Press PRGM once. "SA" (indicating Saturday program) will

appear in the display, along with the start time for the 1st

heating period and the currently programmed temperature.

9. Repeat steps 3 through 7 to complete Saturday heating

programming.

10.Press PRGM once. "SU" (indicating Sunday program) will

appear in the display, along with the start time for the 1st

heating period and the currently programmed temperature.

11.Repeat steps 3 through 7 to complete Sunday heating

programming.

12.When you have completed entering your heating program,

press RUN.

I__r"l__lI__l

Heating/Cooling Schedule Plan (Factory Program)

WEEKDAY (5 DAY) SATURDAY (1 DAY) SUNDAY (1 DAY}

Period Time Temperature Time Temperature Time Temperature

! 3RD 5:00 PM 70°F 5:00 PM 70°F 5:00 PM 70°F

O

O 3RD 5:00 PM 78°F 5:00 PM 78°F 5:00 PM 78°F

Start Start Start

1ST 6:00 AM 70°F 6:00 AM 70°F 6:00 AM 70°F

2ND 8:00 AM 62°F 8:00 AM 62°F 8:00 AM 62°F

4TH 10:00 PM 62°F 10:00 PM 62°F 10:00 PM 62°F

1ST 6:00 AM 78°F 6:00 AM 78°F 6:00 AM 78°F

2ND 8:00 AM 85°F 8:00 AM 85°F 8:00 AM 85°F

4TH 10:00 PM 82°F 10:00 PM 82°F 10:00 PM 82°F

SAMPLE

Heating/Cooling Schedule Plan

WEEKDAY (5 DAY) SATURDAY (1 DAY) SUNDAY (1 DAY)

Period Time Temperature Time Temperature Time Temperature

_ 2ND

IJA

! 3RD

_ 2ND

O

O 3RD

Start Start Start

1ST

4TH

1ST

4TH

Page 7

Enter Cooling Program

If the outside temperature is below 50°F, disconnect

power to the cooling system before programming.

Energizing the air conditioner compressor during cold

weather may cause personal injury or property dam-

age.

Move SYSTEM switch to COOL position.

2. Follow the procedure for entering your cooling program,

using your selected cooling times and temperatures.

CHECK YOUR PROGRAMMING

Follow these steps to check your thermostat programming one

final time before beginning thermostat operation.

1. Move SYSTEM switch to HEAT position.

2. Press PRGM to view the 1st weekday heating period time

and temperature. Each time you press PRGM, the next

heating period time and temperature will be displayed in

sequence for weekday, then weekend program periods (you

may change anytime or temperature during this procedure).

3. Press RUN.

4. Move SYSTEM switch to COOL position.

5. Repeat step 2 to check cooling program.

6. Move SYSTEM switch to HEATorCOOLand press RUN to

begin program operation.

YOUR THERMOSTAT IS NOW COMPLETELY PROGRAMMED

AND READY TO PROVIDE MAXmMUM COMFORT AND EFFm-

ClENCY!

TROUBLESHOOTING

Reset Operation

If a voltage spike or static discharge blanks out the display or

causes erratic thermostat operation you can reset the thermo-

stat by pressing (_, (_ and TIME at the same time. This also

resets the factory defaults to the configuration menu and

Symptom

No Heat/No Cool/No Fan

(common problems)

No Heat

No Cool

Possible Cause

1. Blown fuse or tripped circuit breaker

2. Furnace power switch to OFE

3. Furnace blower compartment door or

panel loose or not properly installed.

1. Pilot light not lit.

2. SYSTEM Switch not set to H EAT.

3. Loose connection to thermostat or system.

4. Furnace Lock-Out Condition. Heat may also

be intermittent.

5. Heating System requires service or thermostat

thermostat requires replacement.

1. SYSTEM Switch not set to COOL

2. Loose connection to thermostat or system.

3. Cooling System requires service or thermostat

requires replacement.

program. If the thermostat has power, has been reset and still

does not function correctly contact your heating/cooling ser-

vice person or place of purchase.

Batteries

For optimum performance, we recommend replacing batteries

once a year with fresh "AA" alkaline batteries.

Corrective Action

Replace fuse or reset breaker.

Turn switch to ON.

Replace door panel in proper position to engage

safety interlock or door switch.

Re-light pilot.

Set SYSTEM Switch to Heat and raise setpoint

above room temperature.

Verify thermostat and system wires are securely

attached.

Many furnaces have safety devices that shut the

system down when a lock-out condition occurs.

If the heat works intermittently contact the furnace

manufacturer or local service person for assistance.

Diagonistic: Set SYSTEM Switch to HEAT and

raise the setpoint above room temperature. Within

a few seconds the thermostat should make a soft

click sound. This sound usually indicates the

thermostat is operating properly. If the thermostat

does not click, try the reset operation listed above.

If the thermostat does not click after being reset

contact your heating and cooling service person or

place of purchase for a replacement. If the

thermostat clicks, contact the furnace manufacturer

or a service person to verify the heating system is

operating correctly

Set SYSTEM Switch to COOL and lower setpoint

below room temperature.

Verify thermostat and system wires are securely

attached.

Same procedure as diagnostic for No Heat

condition except set the thermostat to COOL and

lower the setpoint below the room temperature.

There may be up to a five minute delay before

the thermostat clicks in Cooling if the compressor

lock-out option is selected in the configuration

menu (Item 6).

Page 8

TROUBLESHOOTING

Symptom

Heat, Cool or Fan Runs Constantly.

Furnace Cycles Too Fast or Too Slow

(narrow or wide temperature swing)

Cooling Cycles Too Fast or Too Slow

(narrow or wide temperature swing)

Thermostat Setting and Thermometer

Disagree

Clock Loses or Gains Time

Heat or Cool Starts Early

ThermostatDoes Not Follow Program

Blank Display and/or Keypad Not

Responding

Possible Cause

1. FAN Switch set to Fan ON.

2. Possible short in wiring.

3. Possible short in thermostat.

4. Possible short in Heat/Cool/Fan system.

1. The location of the thermostat and/or the size

of the Heating System may be influencing the

cycle rate.

1.The location ofthe thermostatand/orthesize

of the CoolingSystemmay be influencingthe

cycle rate.

1.Thermostatthermometersettingrequires

adjustment.

1. Loss of power to thermostat and low batteries.

1. EMRactivated

1.AMor PMset incorrectlyinprogram.

2. AM or PM set incorrectlyonthe clock.

3.Voltage spikeor static discharge.

1. Loss of power and dead batteries.

2. Voltage Spike or Static Discharge.

Corrective Action

Check each wire connection to verify they are

not shorted or touching together. No bare wire

should stick out from under terminal screws.

Try resetting the thermostat. If the condition

_ersists the manufacturer of your system

or service person can instruct you on how

to test the Heat/Cool system for correct

operation. If the system operates correctly,

replace the thermostat.

Item 2 in the Configuration Menu is the adjustment

that controls the cycle rate. If an acceptable cycle

rate is not achieved using the FA (Fast) or SL

(Slow) adjustment contact a local service person

for additional suggestions.

The cycle rate for cooling is fixed and can not be

adjusted. Contact a local service person for

suggestions.

The thermometer can be adjusted +/- 4 degrees as

listed in item 7 of the Configuration Menu. No other

adjustment is possible.

The thermostat will maintain its program in memory

even with no power/no batteries but the clock time

will be incorrect when power is restored. See No

Heat/No Cool/No Fan (common problems) above

for items to check in the system.

See Configuration Menu (Item 4).

Check current clock and program settings including

the AM or PM designations for each time period.

If a voltage spike or static discharge occurs use the

Reset Operation listed above.

Replace batteries and check heat/cool system for

proper operation. If a voltage spike or static discharge

occurs use the Reset Operation listed above.

PROGRAMMING HELP LINE: 1-800-284=2925

White-Rodgers is a division

of Emerson Electric Co.

The Emerson logo is a

trademark and service mark

of Emerson Electric Co.

White

Rodgers,o

St. Louis, Missouri Markham, Ontario

www.white-rod gers.com

EMERSON

Loading...

Loading...