Page 1

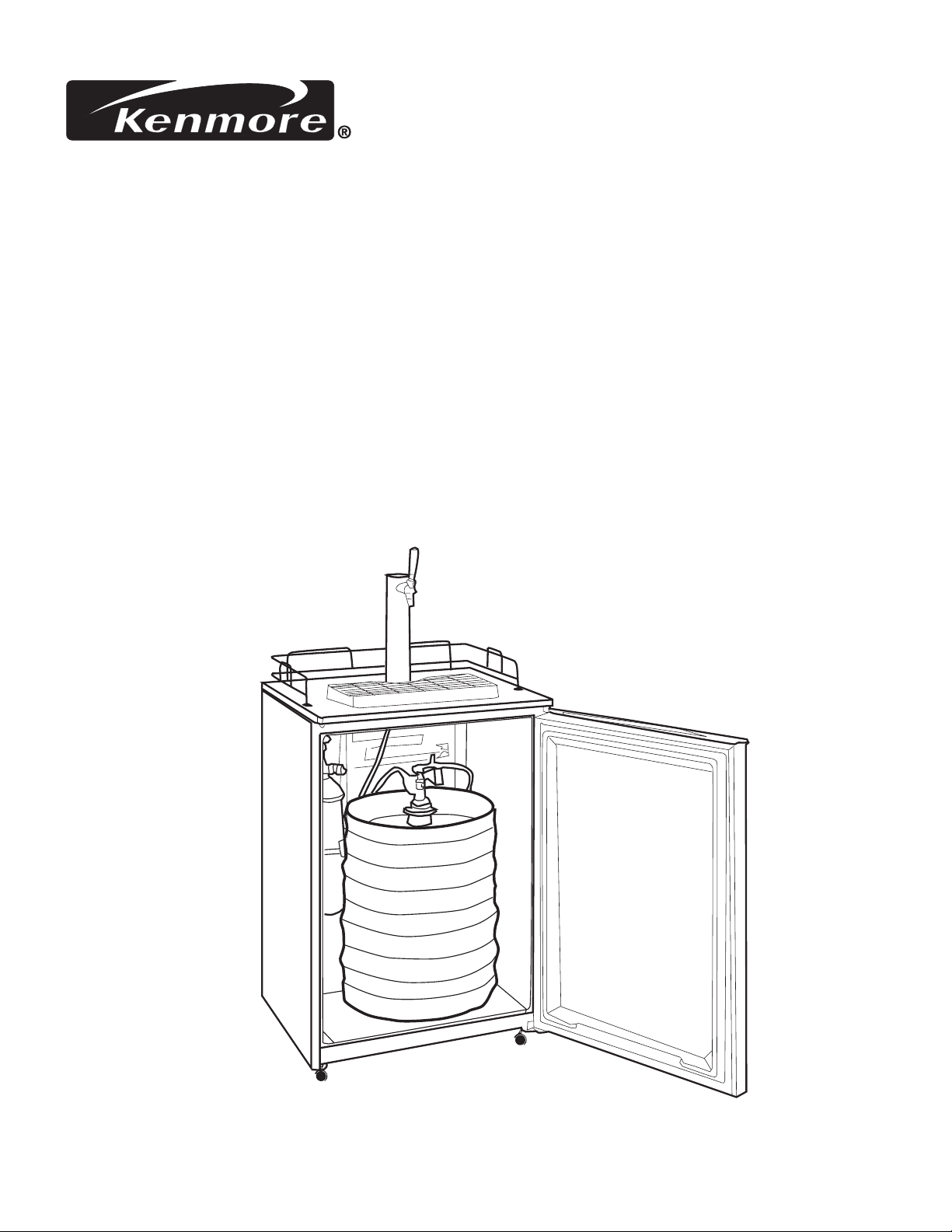

BEER DISPENSER

Holds 1/2, 1/4 & Mini Barrel Kegs

Use & Care Guide

Model 183.91579

DISTRIBUTEUR DE BIÉRE

Volume: 1⁄2, 1⁄4 Tonnelet

Guide d’utilisation

Modéle 183.91579

SURTIDOR DE CERVEZA

Los asideros 1/2, 1/4 los Barriles Minis de Barril

El uso la Guía del Cuidado

Modélo 183.91579

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Page 2

TABLE OF CONTENTS

WARNING

WARNING

WARNING

IMPORTANT SAFETY INSTRUCTIONS

Record Serial/Model Numbers ...................................... 1

Safety .......................................................................1-2

Warranty ..................................................................... 3

First Steps .................................................................3-7

Energy Saving Tips ....................................................... 7

Operating your Beer Dispenser .................................7-8

Care and Cleaning ................................................... 8-9

Power Failure / Beer Dispenser Failure ........................ 10

Troubleshooting Guide .......................................... 11-15

Master Protection Agreements .................................... 16

Sears Service ............................................................. 17

SERIAL / MODEL NUMBERS

READ AND SAVE THESE INSTRUCTIONS

This Use and Care Guide provides specific operating

instructions for your model. Use your beer dispenser only

as instructed in this guide. These instructions are not meant

to cover every possible condition and situation that may

occur. Common sense and caution must be practiced when

installing, operating, and maintaining any appliance.

READ ALL INSTRUCTIONS BEFORE USING THIS BEER

DISPENSER.

FOR YOUR SAFETY

Do not store or use gasoline, or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Read product labels for flammability and other warnings.

CHILD SAFETY

• Destroy carton, plastic bags, and any exterior

wrapping material immediately after the beer dispenser is

unpacked. Children should never use these items to play.

Cartons covered with rugs, bedspreads, plastic sheets

or stretch wrap may become airtight chambers, and can

quickly cause suffocation.

• Remove all staples from the carton. Staples can cause

severe cuts, and destroy finishes if they come in contact

with other appliances or furniture.

• An empty, discarded ice box, refrigerator, or freezer is a

very dangerous attraction to children.

• Remove and discard any spacers used to secure the

shelves during shipping. Small objects are a choke

hazard to children.

Record Your Model and Serial Numbers

Record the model and serial numbers in the spaces

provided below. The serial plate is located on the rear

exterior wall.

Model Number:

Serial Number:

Purchase Date:

183.91579

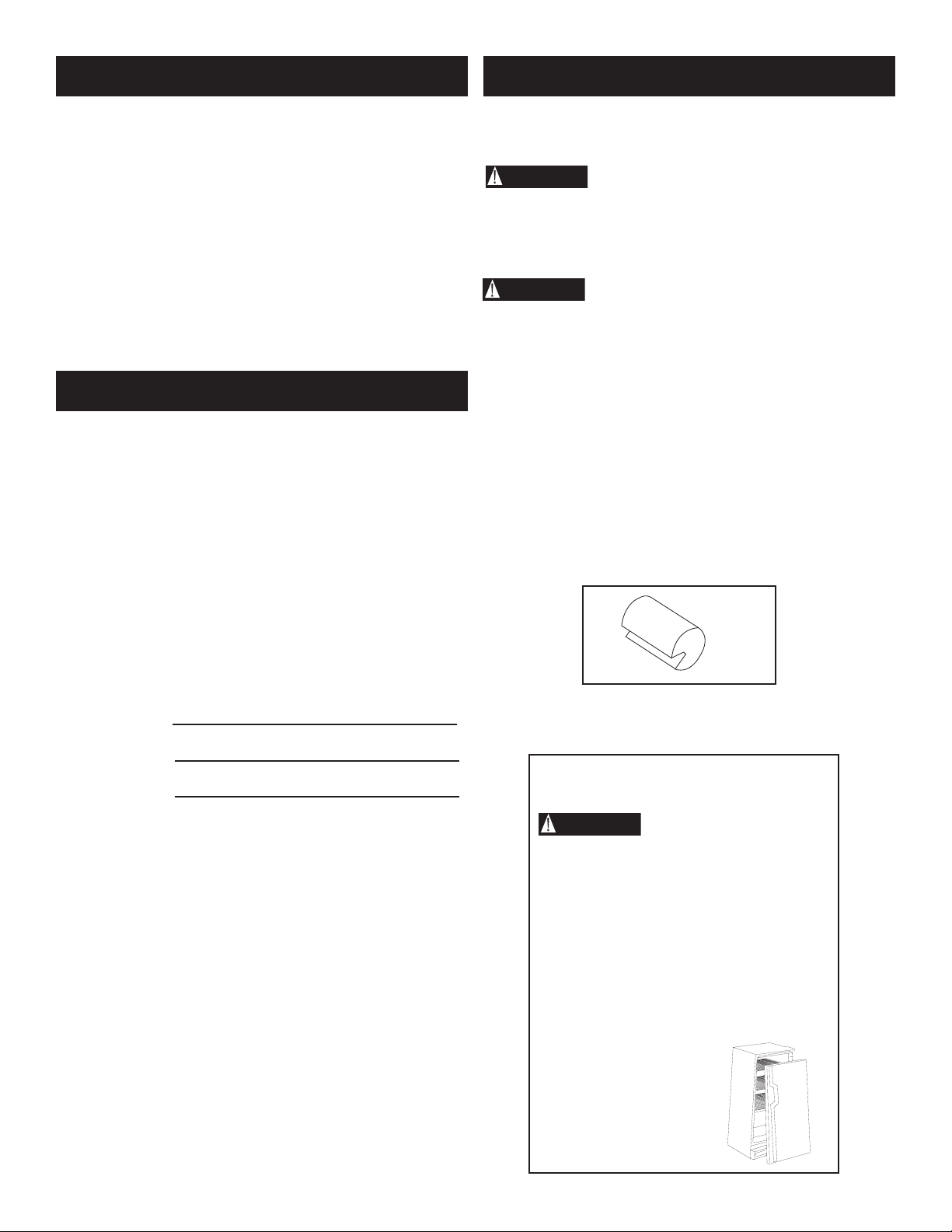

Spacer

Remove the door(s) of any appliance that is not in

use, even if it is being discarded.

Proper Disposal of Your

Beer Dispenser

Risk of child entrapment.

Child entrapment and suffocation are not

problems of the past. Junked or

abandoned beer dispensers are still

dangerous, even if they will sit for “just a

few days.” If you are getting rid of your old

beer dispenser, please follow the instructions below to help prevent accidents.

BEFORE YOU THROW AWAY YOUR OLD

BEER DISPENSER:

• Remove doors.

© Sears, Roebuck and Co.

• Leave shelves in

place so children may

not easily climb inside.

1

Page 3

ELECTRICAL

WARNING

WARNING

Do not, under any

circumstances,

cut, remove,

or bypass the

grounding prong.

INFORMATION

IMPORTANT SAFETY PRECAUTIONS OF CO2

(CARBON DIOXIDE) GAS

These guidelines must be followed to ensure that

safety mechanisms in the design of this beer

dispenser will operate properly.

• Refer to the serial plate for correct electrical

rating. The power cord of the appliance is equipped

with a three-prong grounding plug for your protection

against shock hazards. It must be plugged directly into a

properly grounded three-prong receptacle, protected with

a 15 amp time delay fuse or circuit breaker. The

receptacle must be installed in accordance with local

codes and ordinances. Consult a qualified electrician.

Receptacles protected by Ground Fault Circuit Interrupters

(GFCI) are NOT RECOMMENDED. Do not use an

extension cord or adapter plug.

• If voltage varies by 10% or more, beer dispenser

performance may be affected. Operating a beer

dispenser with insufficient power can damage the motor.

Such damage is not covered under the warranty. If you

suspect your household voltage is high or low, consult

your power company for testing.

• To prevent the beer dispenser from being turned off

accidentally, do not plug unit into an outlet controlled by

a wall switch or pull cord.

• Do not pinch, knot, or bend the cord in any manner.

OTHER PRECAUTIONS

• Never unplug the beer dispenser by pulling on the cord.

Always grip the plug firmly, and pull straight out from the

receptacle.

1. CO2 gas can be dangerous! CO2 cylinders contain

high-pressure compressed gas, which can be

hazardous if not handled properly. Make sure you read

and understand all the procedures for the CO2

cylinders before installation.

2. Always connect the CO2 cylinder to a regulator!

Failure to do so may cause an explosion resulting in

possible death or injury when the cylinder valve is

opened.

3. Never connect the CO2 cylinder directly to the product

container.

4. Always follow the correct procedures when changing

cylinders. (see page 10)

5. Never drop or throw a CO2 cylinder.

6. Always keep CO2 cylinders away from heat. Store extra

cylinders in a cool place (preferably 70˚ F). Securely

fasten with a chain in an upright position when storing.

7. Always ventilate and leave the area immediately if CO2

leakage has occurred!

8. Always check the D.O.T. (Department of Transport) test

date on the cylinder neck before installation. If it has

been over 5 years, do not use. Return the

cylinder to your gas supplier.

9. Never connect a product container unless there are at

least two safety devices in the pressure system; one on

the CO2 regulator and the other on the product

container or in the pressure gas line.

Avoid fire hazard or

electric shock. Do not use an extension

cord or an adapter plug. Do not remove

any prong from the power cord.

Grounding type

wall receptacle

Power supply

cord with 3-prong

grounding plug

2

Page 4

BEER DISPENSER WARRANTY

FIRST STEPS

KENMORE ONE YEAR LIMITED WARRANTY

When installed, operated and maintained according to all

instructions supplied with the product, if this appliance fails

due to a defect in material and workmanship within one

year from the date of purchase, return it to any Sears store,

Sears Parts & Repair Service Center, or other Kenmore

outlet for free repair.

If this appliance is ever used for other than private family

purposes, this warranty applies for only 90 days from the

date of purchase.

This warranty covers only defects in material and

workmanship. Sears will NOT pay for:

1. Expendable items that can wear out from normal use,

including but not limited to filters, belts, light bulbs, and

bags.

2. A service technician to instruct the user in correct product

installation, operation or maintenance.

3. A service technician to clean or maintain this product.

4. Damage to or failure of this product if it is not installed,

operated or maintained according to the all instructions

supplied with the product.

5. Damage to or failure of this product resulting from

accident, abuse, misuse or use for other than its

intended purpose.

6. Damage to or failure of this product caused by the use

of detergents, cleaners, chemicals or utensils other than

those recommended in all instructions supplied with the

product.

7. Damage to or failure of parts or systems resulting from

unauthorized modifications made to this product.

Disclaimer of implied warranties; limitation of

remedies

Customer’s sole and exclusive remedy under this

limited warranty shall be product repair as provided herein.

Implied warranties, including warranties of merchantability

or fitness for a particular purpose, are limited to one year

or the shortest period allowed by law. Sears shall not be

liable for incidental or consequential damages. Some states

and provinces do not allow the exclusion or limitation of

incidental or consequential damages, or limitation on the

duration of implied warranties of merchantability or fitness,

so these exclusions or limitations may not apply to you.

This Owner’s Guide provides specific operating

instructions for your model. Use the beer dispenser only

as instructed in this Owner’s Guide. Before starting the

beer dispenser, follow these important first steps.

INSTALLATION

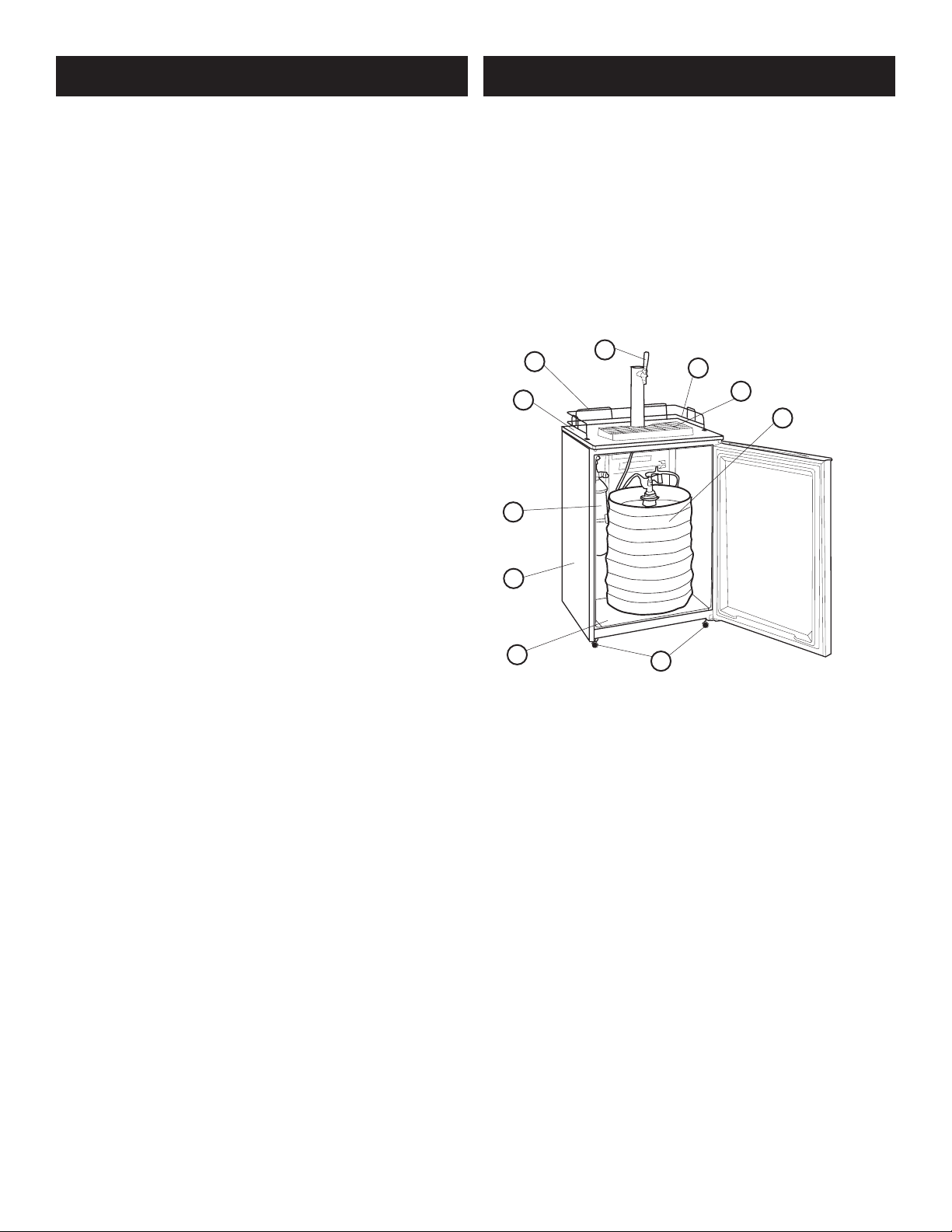

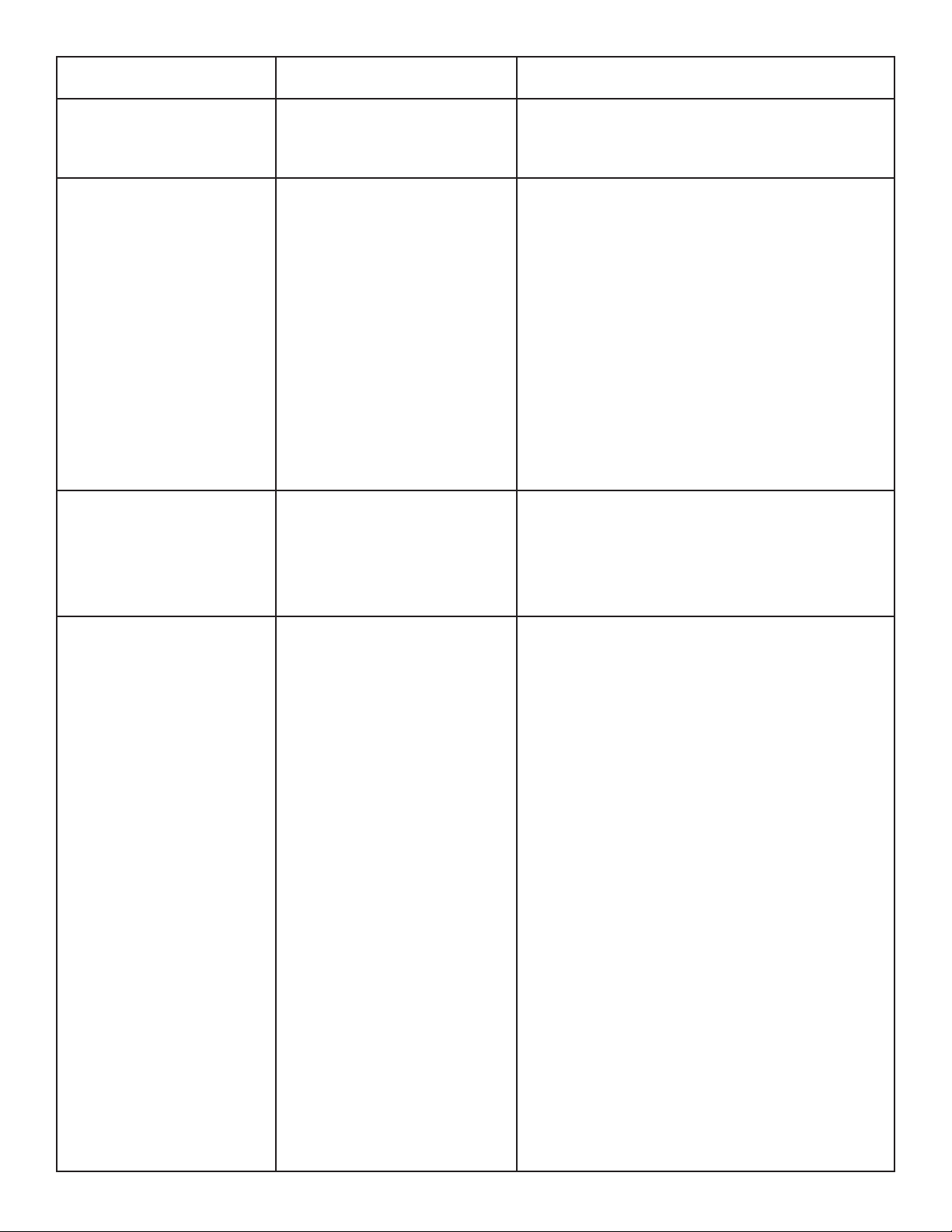

Parts and Features

1. Remove all packing materials. This includes the foam

base and all adhesive tape holding the accessories both

inside and outside.

6

5

4

3

2

1. Casters (Total 4)

2. Interior Keg Support

3. Cabinet

4. CO2 Tank

5. Work Top

6. Chrome Guardrail

7. Beer Tap

Unpacking your Beer Dispenser

1. Remove all packing materials. This includes the foam

base and all adhesive tape holding the accessories both

inside and outside.

7

8

9

10

1

8. Adjustable

Thermostat (Located

in rear)

9. Drip Tray

10. 1/2 Barrel Keg (Not

included. Shown for

illustration purpose

only

This warranty applies only while this appliance is used in

the United States or Canada.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Sears Canada Inc., Toronto, Ontario, Canada M5B

2B8

2. Inspect and remove any remaining packaging, tape or

printed materials before turning on the beer dispenser.

Note: To ensure that the compressor will function properly,

allow the beer dispenser to stand in an upright

position for 8 hours before plugging it in.

3

Page 5

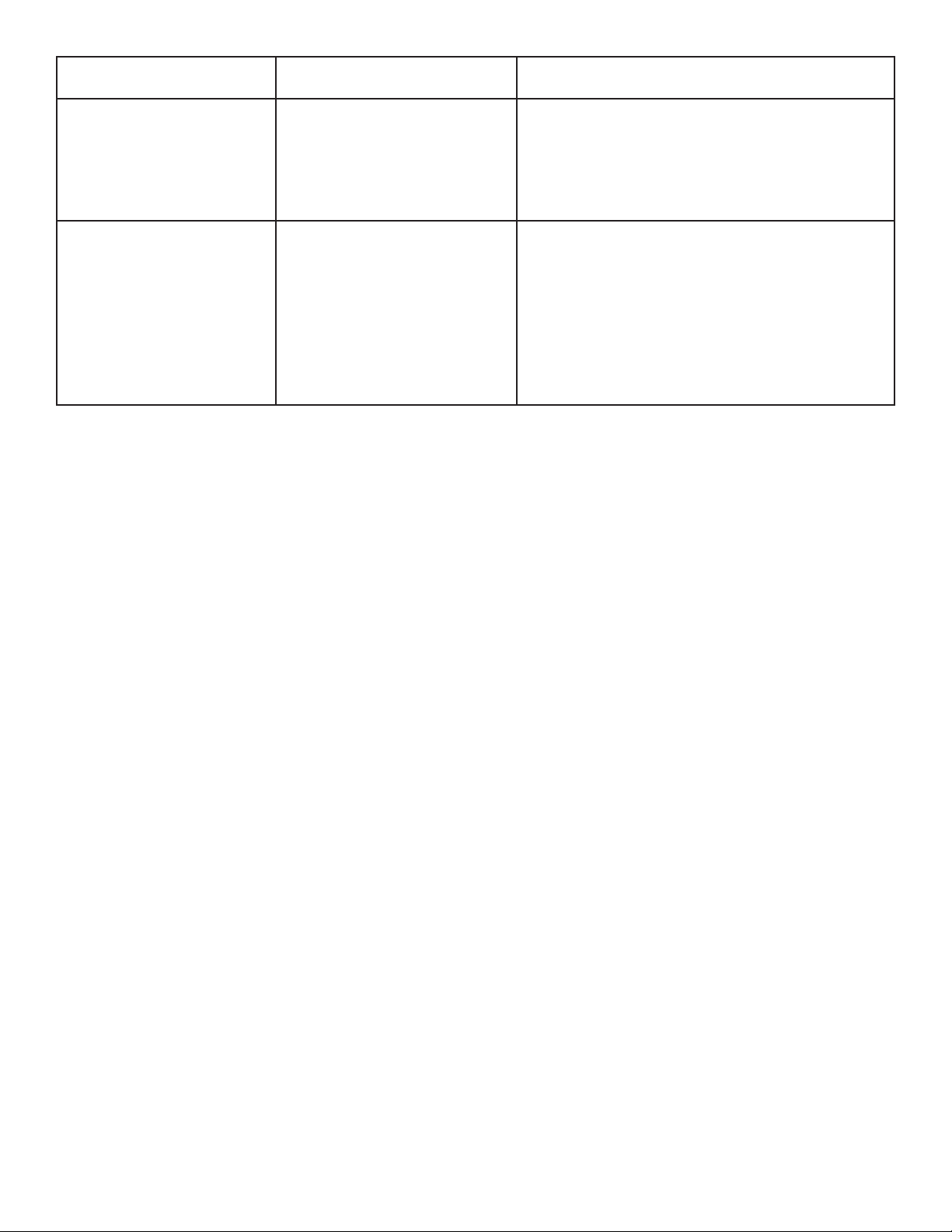

Check all supplied accessories in the carton to be sure that

Caster

Wrench

Nut

Large Philip Head

Small Phillips Head

Beer Tap Assembly

Gasket

Beer line

Guard Rail

nut

Faucet Handle

pilot holes

all pieces are present and in good condition. A checklist of

accessories is shown below for your reference:

1 Beer Tap Assembly Including:

1 Black Faucet Handle

1 Gasket for Beer Tap

1 Beer Line (transparent tube) attached to Beer Tap

1 Black Rubber Washer for Connection of

Beer Line to Keg Tap

1 CO2 Regulator

1 CO2 Cylinder

1 Keg Tap (American Sankey Type)

1 Cleaning Kit

1 CO2 Gas Line (Red Tube)

2 Hose Clamps

1 CO2 Cylinder Retainer (with bolt and nut)

1 Guardrail

1 Drip Tray

4 Casters

1 Wrench (for casters)

4 Large Phillips-Head Screws

8 Small Phillips-Head Screws

2 Retainer Mounting Screws

2 Wire Shelves

4 Support Pins

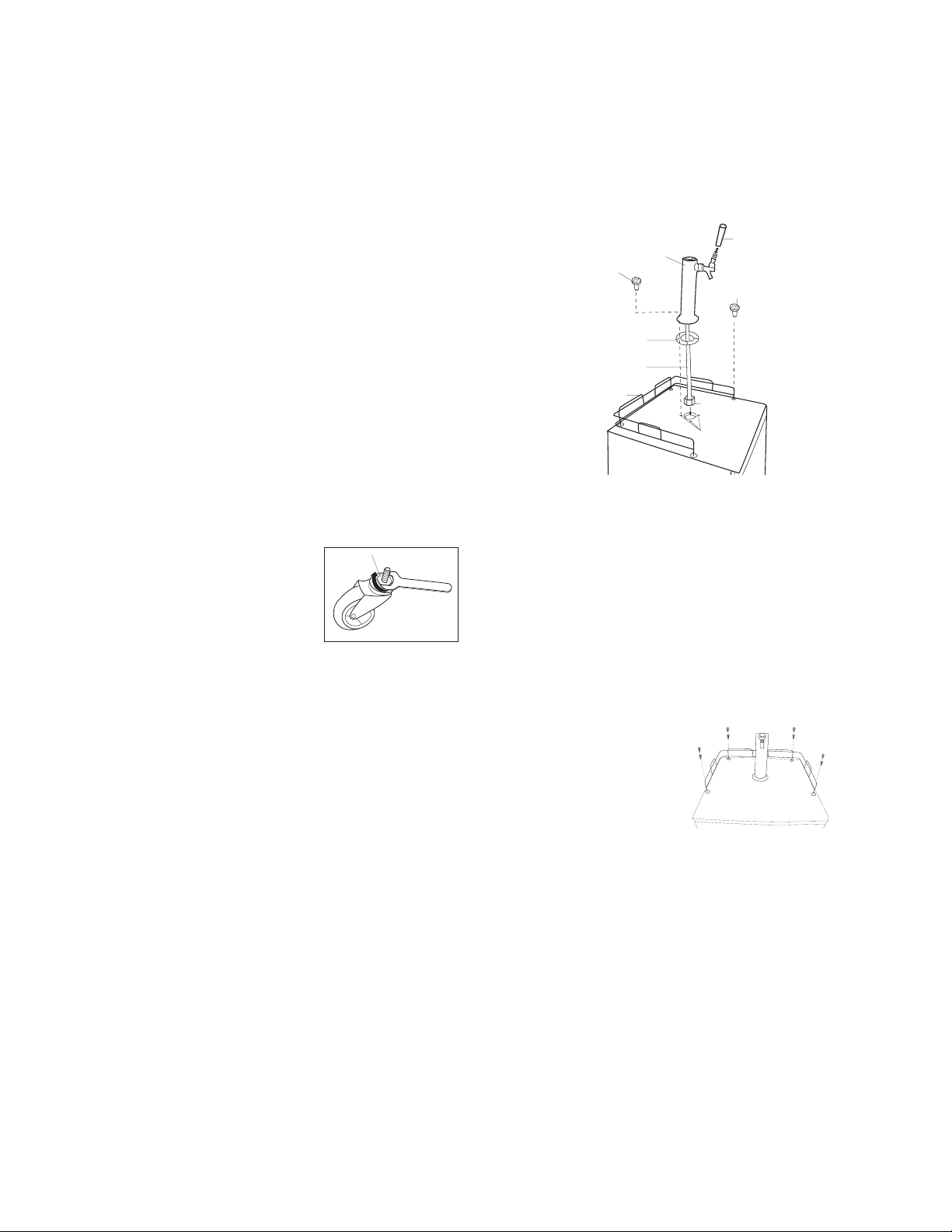

2. Place the gasket over the hole opening on the

worktop and line up 4 holes with pilot holes.

3. Pass beer line with the nut at the end through the hole

in the worktop until the beer tap is resting on top of the

cabinet.

4. Align the holes of the beer tap flauge with the gasket

and pilot holes on the worktop of cabinet. Make sure

faucet faces the front.

5. Secure the beer tap to the cabinet with four large

Phillips-Head screws.

Installing the Casters

Follow the steps below to install the

casters.

1. Empty the inside of the cabinet

completely and lay the beer dispenser down sideways. We recommend that you place a piece of cardboard or cloth

underneath the cabinet to prevent dents or scratches to

the cabinet.

2. Insert the casters into the holes on the bottom corners

of the cabinet. Tighten each caster by turning the nut

clockwise with the wrench provided.

3. Once all four casters have been tightened evenly, stand

the cabinet in an upright position.

Leveling your Beer Dispenser

If you do not install the casters, you will have to level your

beer dispenser.

• Your beer dispenser has 4 leveling legs which are located

in the front and rear corners. After properly placing your

beer dispenser in its final position, you can level it.

• Leveling legs can be adjusted by turning them clockwise

to raise or counterclockwise to lower your beer dispenser.

The beer dispenser door will close easier when the leveling legs are extended.

Installing the Beer Tap

Follow the steps below to install the beer tap.

1. First, remove the cabinet plug located on the worktop.

Firmly grasp the cabinet plug, twist and pull upward.

Note: Store this plug in a safe place as it will be

required when converting the beer dispenser

into a beverage cooler.

Installing the Guardrail

Follow the steps below to install the guardrail on the

worktop.

1. Place the guardrail on top of the cabinet.

2. Align all holes of the guardrail with the holes of the

cabinet.

3. Secure the guardrail to the cabinet with eight small

Phillips-Head screws.

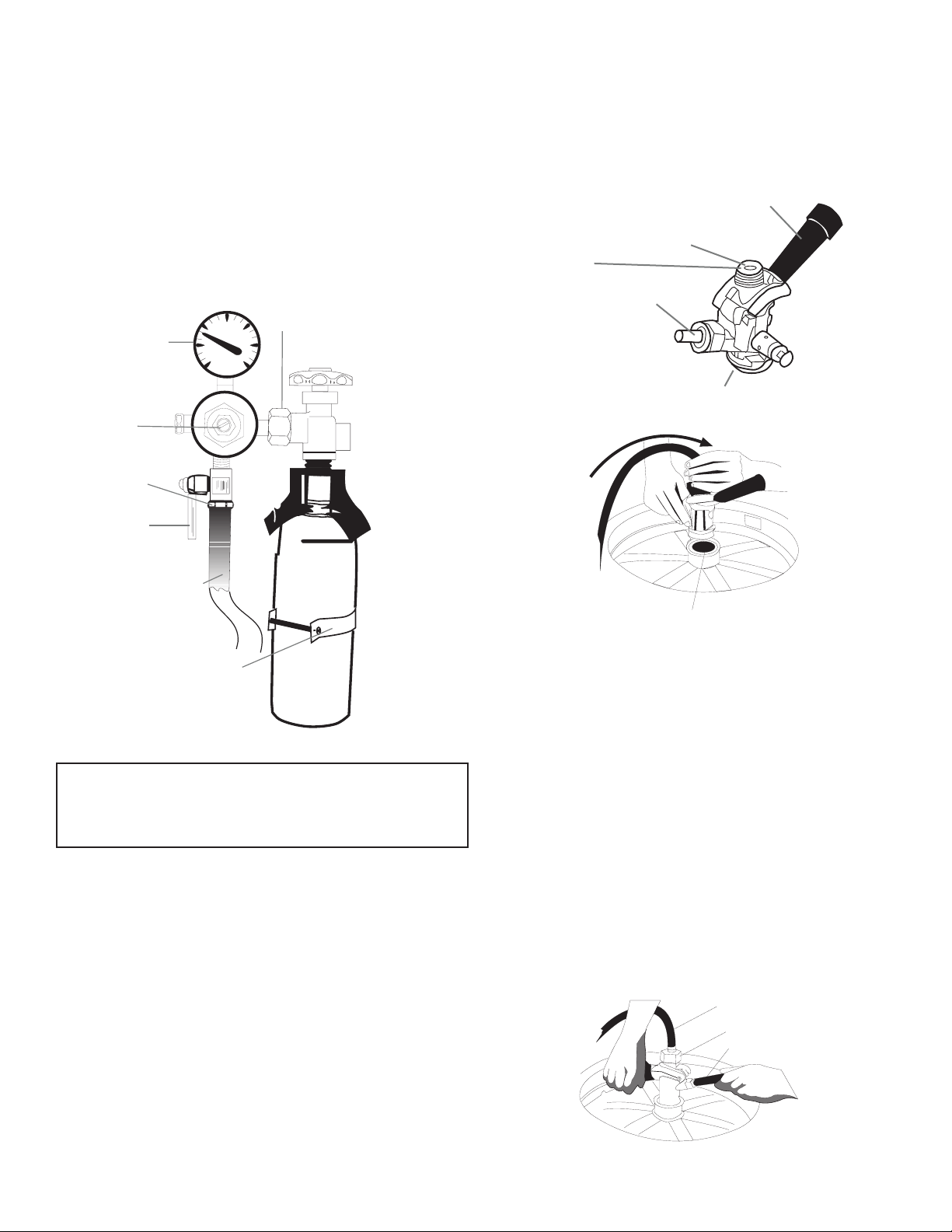

Installing the CO2 Regulator and CO2 Cylinder

Follow the steps below to safely install the CO2 regulator

and CO2 cylinder. You must read and understand the

following procedures for CO2 cylinders before

installation.

Note: Your CO2 cylinder is shipped empty to avoid any

possible accidents during transportation. When you

purchase the first keg of beer, have your beer

distributor fill the CO2 cylinder.

1. Install the CO2 gas line tube to the regulator by

attaching one end of the red tube to the hose barb

connection on the CO2 regulator. Secure the tube by

using one of the two self-locking plastic snap-on clamps.

Use pliers to snap the clamp on tightly to ensure that

there are no leaks.

4

Page 6

2. Attach the CO2 regulator to the CO2 cylinder by

Keg Coupler

Pull handle (upward)

Coupling Head

Connect to the CO

2

Gas Line Tube Barb

Plastic Insert

T

U

R

N

C

L

O

C

K

W

I

S

E

Beer Keg Neck

Beer Line

Coupling Nut

Red Tube (gas line)

CO2 Cylinder

CO2

GAS

CO 2

Regulator

Gauge

Connect to the

Keg Tap (coupler)

Clamp

Shut-Off Valve

Retainer

Connect to the CO2Cylinder

Pressure

Adjustment

Screw

screwing the regulator nut onto the cylinder valve and

tightening with an adjustable wrench.

3. Remove the bolt with the nut from the cylinder retainer.

Using two screws attach it inside the unit on the left side

of the back wall. (Holes are pre-drilled and screws are

included)

4. Slide the cylinder through the retainer and secure it with

the bolt and the nut. Position the cylinder so that you will

be able to read the numbers on the gauge and

easily access the shut-off valve and pressure adjustment

screw.

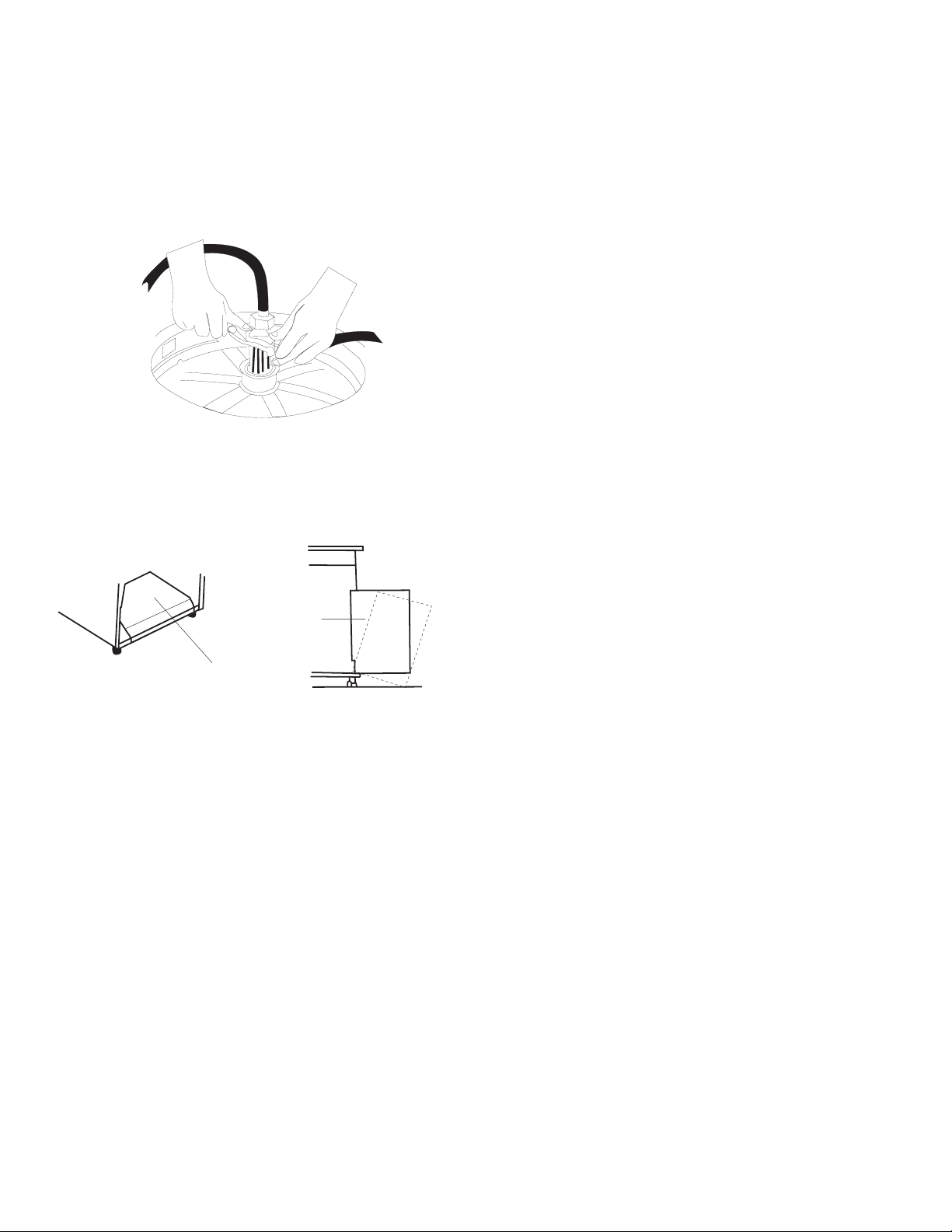

Follow the steps below to tap the keg of beer.

1. Make sure the pull handle of the Sankey Tap is in the

closed (up) position before installing it on the beer keg.

(see fig.1) Insert the keg coupler into the locking neck of

the beer keg and turn clockwise 1/4-turn to lock it into

position. (see fig. 2)

fig. 1

fig. 2

Tapping the Beer Keg – Installing Keg Tap

(Single-Valve Type Barrel)

Your beer dispenser comes with American Sankey Tap. This

type is the most widely used in the United States. Before

purchasing a keg, check with your beer distributor to make

sure that supplied Sankey Tap can be used.

Note: For European draft beer, European Sankey Tap is

WARNING!

CO2 can be dangerous! CO2 cylinders contain high-pressured gas,

which can be hazardous if handled improperly.

required. Please contact Draught Technologies by

visiting www.draughttech.com or call

(860) 677-7312.

They must be handled with care.

2. IMPORTANT: You must insert the black rubber washer

into the beer line coupling nut before screwing the nut

onto the keg tap coupling head. First remove the black

protective shipping cap from the coupling head. Do not

remove the plastic insert from the coupling head. Insert

the black washer inside of the coupling nut. Firmly

hand-tighten the coupling nut onto the coupling head.

(see fig. 3)

3. Attach the open end of the red tube to the hose barb

connection on the Sankey Tap. Next, secure the tube by

using the remaining self-locking plastic snap-on clamp

to ensure that there are no leaks. Secure the clamp

tightly with pliers. (see fig. 3)

fig. 3

5

Page 7

4. Make sure the beer tap faucet is in the closed (faucet

Keg Support

Beer Keg

Lift Upright

handle pointing straight back) position before

connecting the Keg Tap to the beer keg. Pull the pull

handle out and push down until it locks into position.

Listen for the "click" of the pull handle when it shifts into

the final downward position. (see fig. 4) This will open

the beer and CO2 gas valves. Open shut-off valve on

regulator. Turn pressure adjustment screw clockwise until

pressure gauge reads 8 psi. The keg is now tapped.

fig. 4

5. Carefully tilt the beer keg and rest the edge on the

stainless steel keg floor support on the bottom of the

interior cabinet. Slide the beer keg in slowly,

ensuring that it is properly located. (see fig. 5) Close the

door.

• For proper keg cooling, DO NOT put anything in the

refrigerator cabinet other than the keg. Placing ice bags,

beverage cans or food in the open spaces around the

keg will interfere with air circulation inside the cabinet

and reduce cooling effectiveness.

Electrical Requirement

• Make sure there is a suitable power Outlet (115 volts, 60

hz) with proper grounding to power the beer dispenser.

• Avoid the use of 3-Prong adapter plugs or cutting off the

grounding prong in order to accommodate a 2-prong

outlet.

Use of Extension Cord

• Avoid the use of an extension cord because of potential

safety hazards under certain conditions. If it is necessary

to use an extension cord, use only a 3-wire extension

cord that has a 3-blade grounding plug and a 3-slot

outlet that will accept the plug. The marked rating of the

extension cord must be equal to or greater than the electrical rating of the appliance.

Installation Limitations

fig. 5

Important Safety Message for Draft Beer

Dispensing

When CO2 is used for draft beer dispensing, the system

must be adequately protected against excessive pressure

build-up. This is accomplished by the already installed two

safety devices with adequate relief capacity in the system.

Safety devices are installed in the following places:

A. On or immediately downstream from the CO2 regulator.

B. On the keg coupler

Proper Air Circulation

• To assure your beer dispenser works at the maximum

efficiency it was designed for, you should install it in a

location where there is proper air circulation, plumbing

and electrical connections.

• The following are recommended clearances around the

beer dispenser:

Sides 3/4” (19mm)

Back 2” (50mm)

• Do not install your beer dispenser in any location not

properly insulated or heated e.g. garage etc. Your beer

dispenser was not designed to operate in surrounding

temperatures below 55˚ Fahrenheit.

• Select a suitable location for the beer dispenser on a

hard, even surface away from direct sunlight or heat

source e.g. radiators, baseboard heaters, cooking

appliances etc.

• Your beer dispenser is designed for free-standing

installation only. It is not designed for built-in application.

Converting the Beer Dispenser to a Beverage

Cooler Application

For your convenience, this beer dispenser can be converted

to a beverage cooler application. Simply follow the steps

below for a quick and easy conversion.

Note: When using as a beverage cooler, we do not

recommend the use of casters, as stored items may

fall off the shelves when the unit is in motion.

1. Close the main valve on the CO2 cylinder.

2. Close the connection between the beer keg and the keg

tap by pulling and lifting the handle of the keg tap into

an upright position.

3. Disconnect both the beer line and the CO2 gas line

from the keg tap.

4. Remove the beer keg from the cabinet.

5. Disconnect the gas line from the CO2 regulator.

6. Remove the CO2 cylinder from the cabinet.

6

Page 8

7. Remove the beer tower from the worktop unscrewing 4

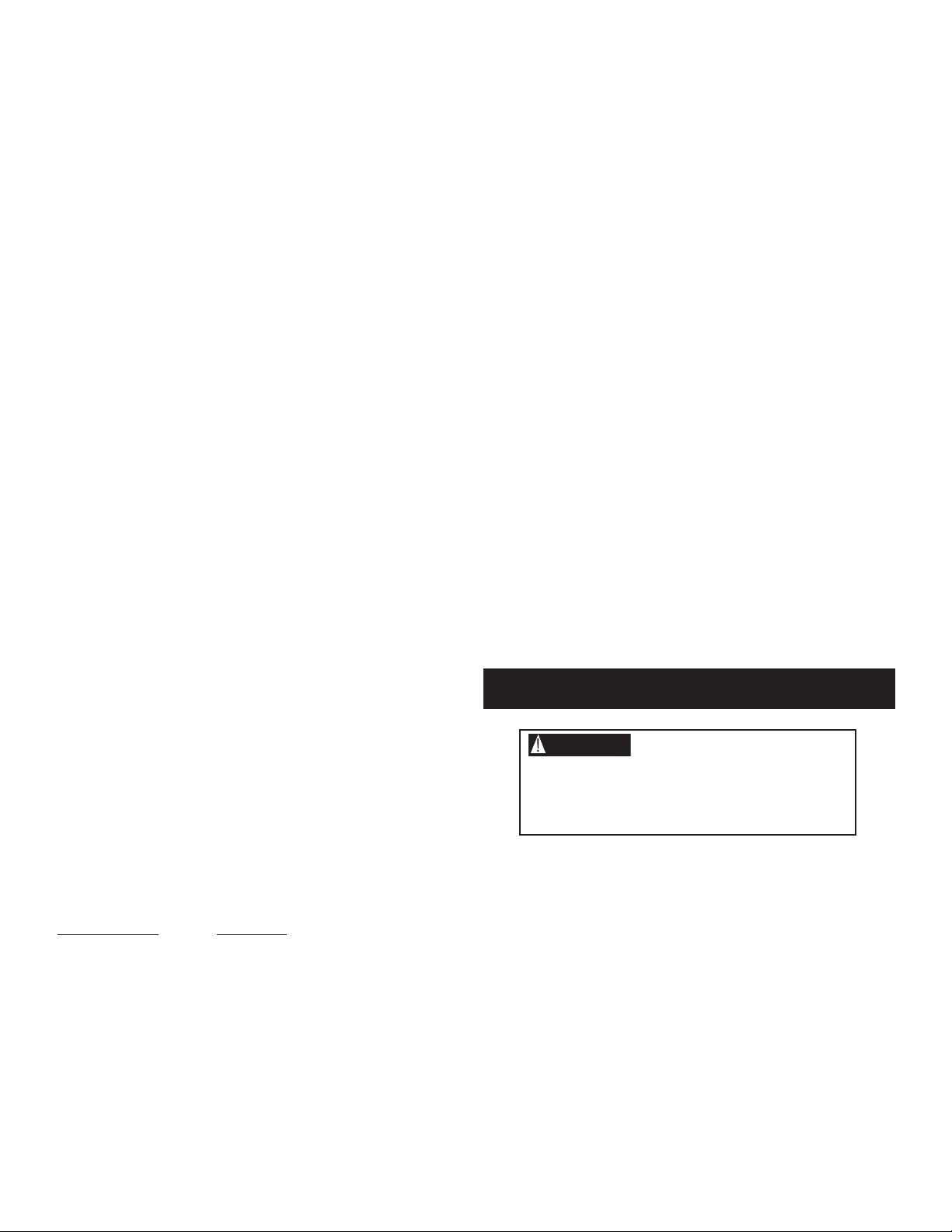

S

A

V

E

M

O

N

E

Y

S

A

V

E

E

N

E

R

G

Y

Bottom hinge spacer

bottom hinge bracket

screws.

8. Pull the beer line through the top of the cabinet.

9. Install the cabinet plug on the worktop.

10. Lay the unit down sideways. We recommend that you

place a piece of cardboard or cloth underneath the

cabinet to avoid dents or scratches to the cabinet.

Remove the casters and install leveling legs and raise

the unit back into upright position.

11. Install the two wire shelves.

• Limit the opening and closing of the door on hot and

humid days. When you open the door, close it quickly to

prevent hot air from entering.

• Check regularly for proper air circulation around the unit

to make sure that the unit receives sufficient airflow.

• Keep the door gasket clean and pliable to ensure a

proper seal. If the door gasket is not sealed properly,

hot air may easily enter into the unit, making the interior

temperature warmer. The compressor must then run

continuously to keep the unit cool, thus making the

energy consumption very high and inefficient.

A. Insert one end of each support pin into the holes on

the right side of the cabinet.

B. Place one end of the wire shelf into the left side of

the cabinet and rest the other end onto the exposed

support pins on the right side.

C. Repeat the same with the second shelf.

12. The conversion process is now complete. Store all the

removed accessories in a safe place for future use.

13. Adjust the temperature of the unit as required for

beverage storage.

Door Alignment

• If needed, loosen the bottom

hinge bracket using a phillips

head screwdriver.

• Adjust the door or place a

spacer in between the hinge

bracket and the cabinet, then

tighten the screws.

ENERGY SAVING TIPS

Note: Replace a damaged door gasket to restore

energy efficiency.

OPERATING YOUR BEER DISPENSER

Dispensing Beer

Follow the steps below to dispense beer.

1. Make sure that the beer dispenser is plugged in properly

to a 120V, 60Hz, 15Amp grounded AC outlet.

2. Place the drip tray under the beer faucet.

3. Open the beer faucet by pulling the tap towards you

quickly and completely to dispense the beer.

Note: If for any reason the beer does not come out of

the tap, refer to the trouble-shooting guide on

page 11.

4. If the beer runs too slowly, increase CO2 pressure by

using a flat blade screwdriver to turn the pressure adjustment screw clockwise. At the correct pressure and temperature, a 10oz. glass should be filled in 4 seconds.

5. Hold the glass steady at a 45˚ angle. When it is 2/3 full,

start straightening the glass. Proper foam should be a

tight creamy head and the collar on an average glass

should be 3/4" to 1" high.

Note: It is normal to see condensation forming on the

faucet. It is caused by the difference in temperature

between the cold beer and the inner surfaces of the

faucet when beer is flowing through the line.

• The beer dispenser should be located in the coolest area

of the room, away from heat producing appliances or

heating ducts, and out of direct sunlight.

• Beer Dispenser shelves should not be lined with

aluminum foil, wax paper, or paper toweling. Liners

interfere with cold air circulation, making the beer

dispenser less efficient.

Temperature Adjustments

The temperature control is located at the rear of the unit on

the bottom left-hand corner. After turning the unit on, you

must wait 24 hours for the unit to cool properly. You may

then adjust the temperature setting based on your needs

and preferences.

Note: When purchasing a keg from your local dealer,

it comes chilled and ready to serve. Please allow

2-4 hours after installation for your

Kenmore beer dispenser to

re-chill your keg to the perfect

serving temperature.

7

Page 9

Beer Temperature

WARNING

• The recommended temperature for serving chilled beer is

between 34˚ and 38˚F. To maintain this temperature in

average room conditions of 70˚F, set the

thermostat to "Normal."

Note: During the summertime when temperatures are

warmer, we recommend that you adjust the

control to a cooler setting accordingly.

Tips for Cleaning Beer Glasses

For the freshest flavor, it is important to serve beer in clean

glasses. For your convenience, the following tips explain

how to properly clean beer glasses before serving beer.

• Do not wash beer glasses together with glasses that have

contained milk or any other fatty substance.

• An excessive amount of germicide build-up will also leave

a fatty film on the glasses, which may cause flat beer.

• Select and maintain the proper temperature inside the

refrigerator cabinet. This is necessary for maintaining the

flavor freshness of beer.

• The best temperature for storing a keg is approximately

38˚F.

• Excessively cold or warm temperatures inside the

refrigerator cabinet may cause a loss of flavor.

Note: Sour beer is produced as a result of secondary

fermentation above 45˚F.

Normal Operating Sound You May Hear

• Boiling water, gurgling sounds or slight vibrations that

are the result of the refrigerant circulating through

the cooling coils.

• The thermostat control will click when it cycles

on and off.

Beer Serving Guide

Beer Serving Tips

The following tips will help you serve the perfect beer.

To serve beer from the tap the way it left the vat, check for

the following:

• Wash glasses thoroughly with a good detergent to

remove all fatty substances (i.e. lipstick).

• Do not use soap.

• Do not wipe glasses dry. Allow glasses to air-dry by

placing them on a wire rack or on corrugated metal.

• Rinse in fresh cold water just before serving beer. It is best

to serve beer in a wet glass.

Two Simple Tests for Clean Beer Glasses

1. Wash the glasses using your usual method. Immerse the

glass heel first in clean water. Empty the glass. If water

droplets cling to the glass or if spots appear on the glass

while pouring, the glass has not been cleaned properly.

A clean glass should air-dry crystal clear.

2. Again, wash the glass using your usual method. Pour out

the water and then shake salt into the wet glass. If salt

does not cling to the entire inside wall of the glass and

clear unsalted spots remain, the glass is not clean.

CARE AND CLEANING

• Cleanliness • Temperature

• Pressure • Use CO2 gas only

What a Half Barrel (Full Size) Keg of

Beer Gives You

This beer dispenser can hold up to a half barrel (full size)

keg. For your convenience, the following table shows how

many servings a half barrel (full size) keg provides.

No. of Glasses Glass Size

192 12 oz.

236 10 oz.

264 9 oz.

290 8 oz.

353 7 oz.

417 6 oz.

Half Barrel (full size) Keg= 15-1/2 Gallons

= 1984 Fluid Ounces

Half Barrel (full size) Keg= 6-3/4 Cases of 12 ounce Bottles

Damp objects stick to

cold metal surfaces. Do not touch

interior metal surfaces with wet or

damp hands.

CLEANING

• Wash any removable parts, the beer dispenser interior,

and exterior with mild detergent and warm water. Wipe

dry. Do not use harsh cleaners on these surfaces.

• Do not use razor blades or other sharp instruments,

which can scratch the appliance surface when removing

adhesive labels. Any glue left from the tape can be

removed with a mixture of warm water and mild

detergent, or touch the residue with the sticky side of tape

already removed. Do not remove the serial plate.

8

Page 10

Automatic Defrosting

WARNING

It is not necessary to defrost the beer dispenser. Ice that

has deposited on the evaporator is automatically defrosted

when the compressor cycles off. The defrosted water collects

in the water drip tray located on the top of the compressor

in the rear of the unit and evaporates.

7. Fill the jar with cool clean water and repeat the process

until the water runs clear.

8. Rinse the tap in the bucket with cool water.

9. Remove the fitting from the tower and replace the

faucet. Make sure the washer is in the back of the

faucet.

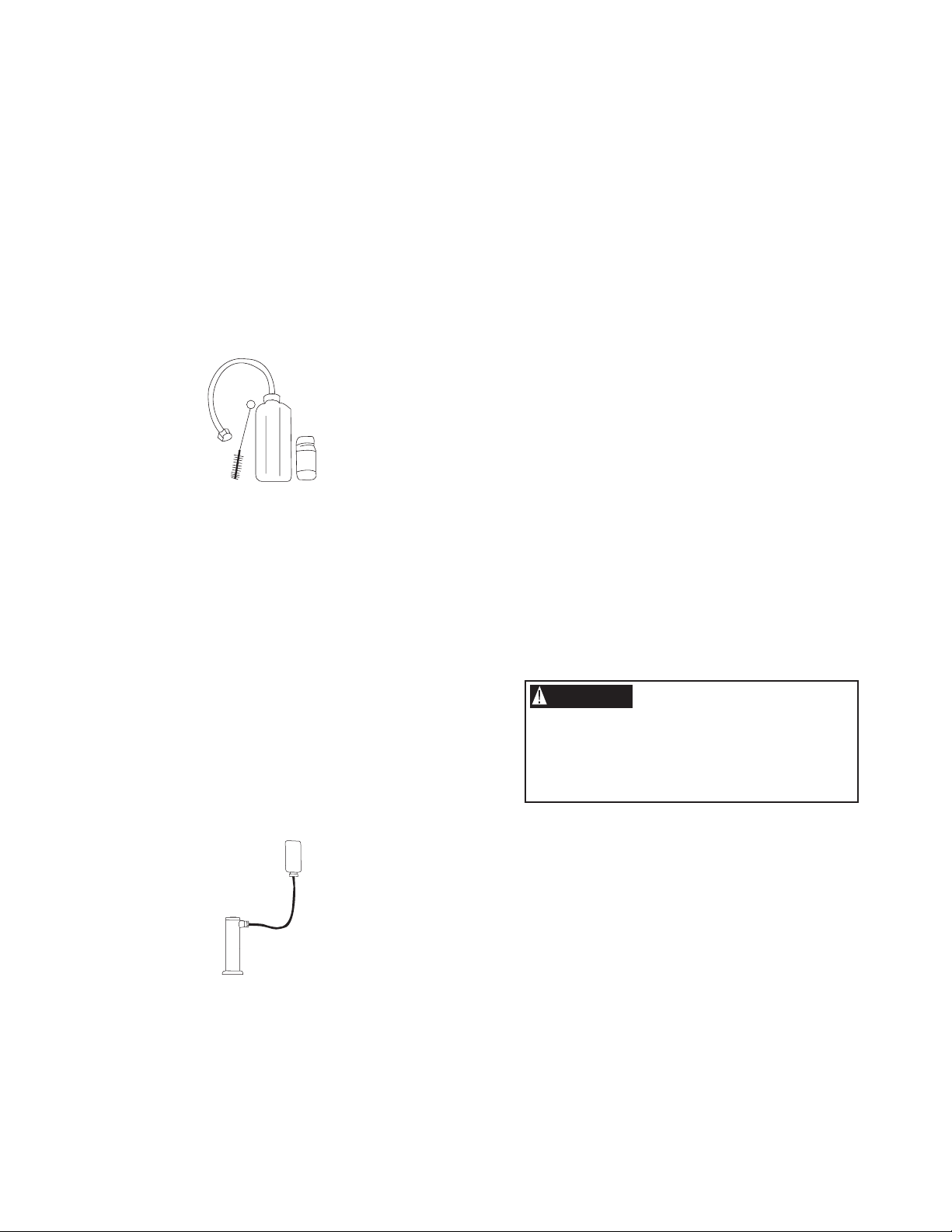

Installing the Cleaning Kit

Read and understand the following instructions before

installing the cleaning kit.

1. Mix one gallon of warm water and one ounce (one

tablespoon) of cleaner in a bucket.

Note: Do not use lye, soap or hot water.

2. Remove the cleaner cap. Fill the jar and replace the

cap. Leave the remaining solution in the bucket.

3. Turn off either the air cock on the regulator or the valve

on the CO2 tank.

4. Disconnect the tap from the barrel. Then disconnect the

beer line from the tap by turning the nut counter-clockwise. Place the tap and the end of the hose in the

bucket.

10. Re-attach the beer hose to the tap and attach the tap to

the barrel.

Note: Beer lines should be flushed after each keg is

emptied.

CLEANING THE INSIDE

Wash inside surfaces of the beer dispenser with a solution

of two tablespoons of baking soda in one quart (0.946

liters) warm water. Rinse and dry. Wring excess water out of

the sponge or cloth when cleaning in the area of the

controls, or any electrical parts.

Wash the removable parts with the baking soda solution

mentioned above, or mild detergent and warm water. Rinse

and dry. Never use metallic scouring pads, brushes,

abrasive, cleaners, or alkaline solutions on any surface. Do

not wash removable parts in a dishwasher.

CLEANING THE OUTSIDE

Wash the cabinet with warm water and mild liquid

detergent. Rinse well and wipe dry with a clean soft cloth.

Replace parts.

5. Remove the faucet from the tower with the wrench and

attach the fitting on the cleaning bottle in its place.

Note: Make sure there is a washer in the back of the

fitting.

6. Hold the cleaning jar upside down until the solution

runs through the system into the bucket as shown.

If leaving the beer

dispenser door open while on vacation,

make certain that children cannot get

into the beer dispenser and become

entrapped.

9

Page 11

VACATION AND MOVING TIPS

Beer Line

Keg Coupler

(Sankey Type)

Regulator

Low Pressure

Gauge

Regulator

Coupling Nut

Drum Valve

Set Screw

Shut off Valve

CO2 Tank

Air Line

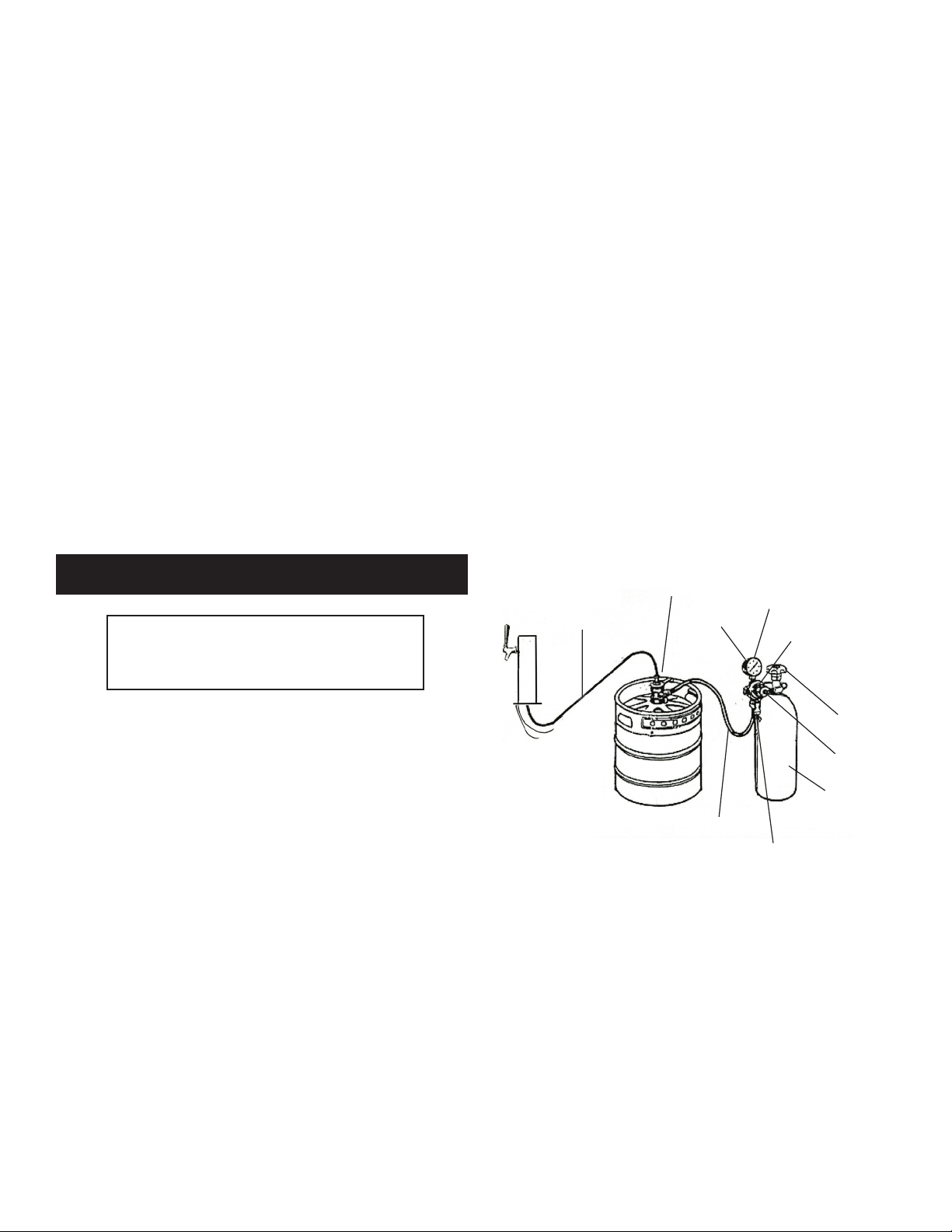

KEG CONNECTIONS – TANK REPLACEMENT

Short Vacations:

Leave the beer dispenser operating during vacations of less

than three weeks.

Long Vacations:

If the beer dispenser will not be used for several months:

• Unplug the power cord.

• Clean and dry the interior thoroughly.

• Leave the beer dispenser door open slightly, blocking it

open if necessary, to prevent odor and mold growth.

Moving:

When moving the beer dispenser, follow these guidelines to

prevent damage.

• Disconnect the power cord plug from the wall outlet.

• Remove keg, and clean the beer dispenser.

• Secure all loose items such as the basket and the shelves

by taping them securely in place to prevent damage.

• In a moving vehicle, secure beer dispenser in an upright

position to prevent movement. Also protect outside of

beer dispenser with a blanket, or similar item.

How do I replace an empty C02 tank?

1. Close tank drum valve by turning clockwise.

2. Unscrew adjustment Set Screw (counter-clockwise) as far

as it will go and close shut off valve.

3. Remove regulator from empty tank.

4. Remove dust cap from the new full tank. Open and

close drum valve quickly to blow of the dust from the

outlet.

5. With drum valve in closed position, reattach regulator to

the tank. Be sure to check the washer, which is

pre-installed on the C02 regulator.

6. Open drum valve all the way. (This is important because

this drum valve seals in two places.)

7. Readjust regulator pressure by turning set screw and

open shut off valve.

Tank Information: Tank must always be fastened in the

upright position. It takes about 1/2 lb.

of C02 to dispense 1/2 barrel keg of

beer. A 5 lb. C02 tank should dispense

between 8-10 1/2 barrel kegs or 18-20

1/4 barrel kegs. Full weight of 5 lb. tank

is appx. 17-1/2 lbs.

POWER FAILURE/BEER DISPENSER FAILURE

NOTE: Do not open beer dispenser

door unnecessarily if beer dispenser

is off for several hours.

If the beer dispenser has stopped operating, see

Beer Dispenser Does Not Run in the Troubleshooting

Guide.

10

Page 12

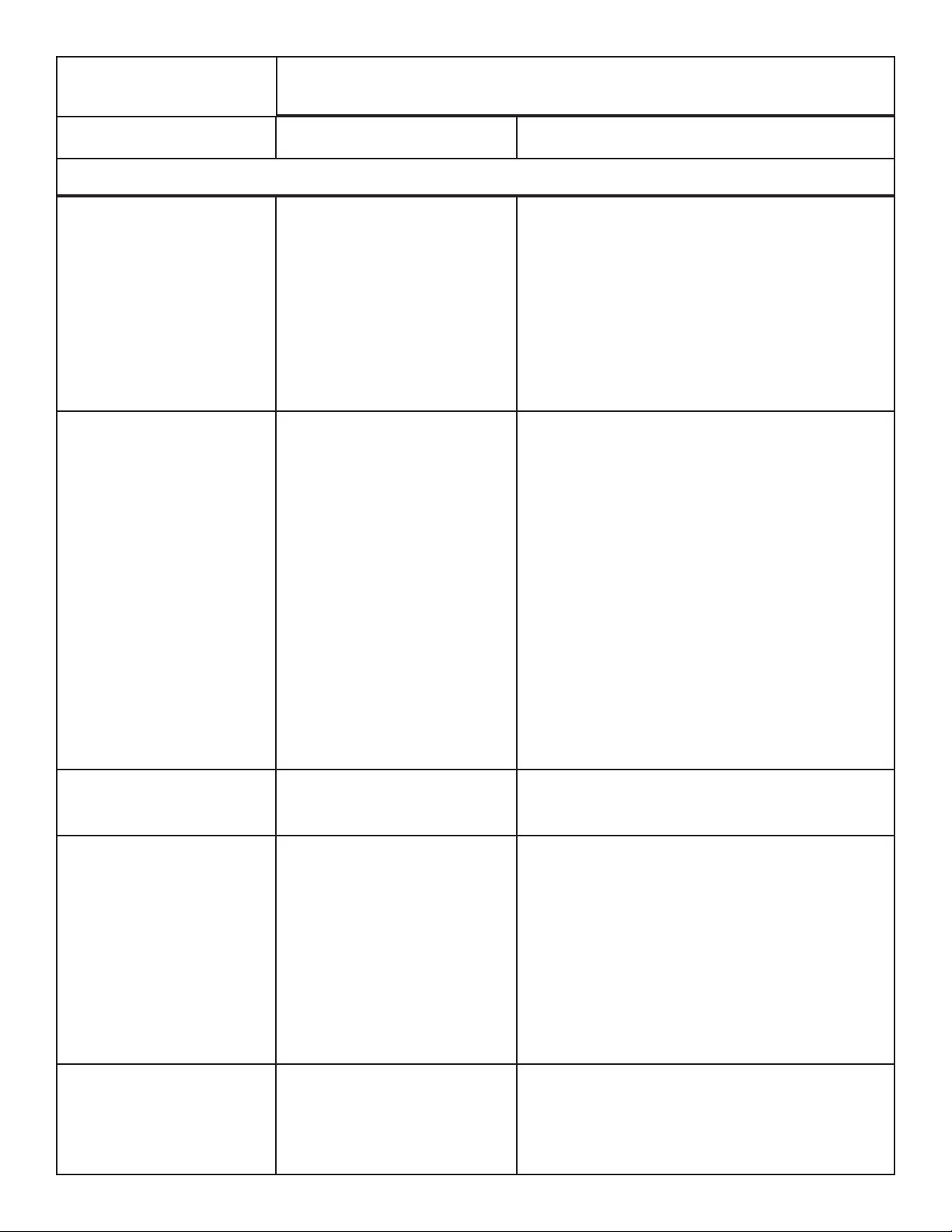

TROUBLESHOOTING

GUIDE

Before calling for service, review this list. It may save you time and expense. This list includes

common occurrences that are not the result of defective workmanship or materials in this

appliance.

PROBLEM CAUSE CORRECTION

BEER DISPENSER DOES NOT RUN

Beer Dispenser does not

run.

Beer Dispenser runs too

much or too long.

• Beer Dispenser is plugged into

a circuit that has a ground

fault interrupt.

• Beer Dispenser may not be

plugged in, or plug may be

loose.

• House fuse blown or tripped

circuit breaker.

• Power outage.

• Room or outside weather is

hot.

• Beer Dispenser has recently

been disconnected for a

period of time.

• A warm keg has been installed

recently.

• Doors are opened too

frequently or too long.

• Beer Dispenser door may be

slightly open.

• Temperature Control is set too

low.

• Beer Dispenser gasket is dirty,

worn, cracked, or poorly fitted.

• Use another circuit. If you are unsure about the

outlet, have it checked by a certified technician.

• Ensure plug is tightly pushed into outlet.

• Check/replace fuse with a 15 amp time delay fuse.

Reset circuit breaker.

• Check house lights. Call local Electric Company.

• It’s normal for the beer dispenser to work harder

under these conditions.

• It takes a few hours for the beer dispenser to cool

down completely.

• A warm keg will cause beer dispenser to run more

until the desired temperature is reached.

• Warm air entering the beer dispenser causes it to

run more. Open doors less often.

• See “DOOR PROBLEMS” Section of the Trouble

Shooting Guide.

• Adjust control to a warmer setting. Allow several

hours for the temperature to stabilize.

• Clean or change gasket. Leaks in the door seal

will cause beer dispenser to run longer in order to

maintain desired temperature.

Interior Beer Dispenser

temperature is too cold.

Interior Beer Dispenser

temperature is too warm.

Beer does not come out

of tap.

• Temperature Control is set too

low.

• Temperature Control is set too

warm.

• Door is kept open too long or

is opened too frequently.

• Door may not be seating

properly.

• A warm keg has been installed

recently.

• Beer Dispenser has recently

been disconnected for a period of time.

• CO2 tank may be empty or

not installed properly.

• CO2 Regulator & CO2

Cylinder may not be installed

properly.

11

• Turn the control to a warmer setting. Allow several

hours for the temperature to stabilize.

• Turn control to a colder setting. Allow several hours

for the temperature to stabilize.

• Warm air enters the beer dispenser every time the

door is opened. Open the door less often.

• See “Door Alignment Section on page 7”

Section.

• Wait until the beer dispenser has had a chance to

reach its selected temperature.

• Beer Dispenser requires a few hours to cool down

completely.

• See "Keg Connections – Tank Replacement"

on page 10.

• See "Installing the CO2 Regulator and CO2

Cylinder" on page 4-5.

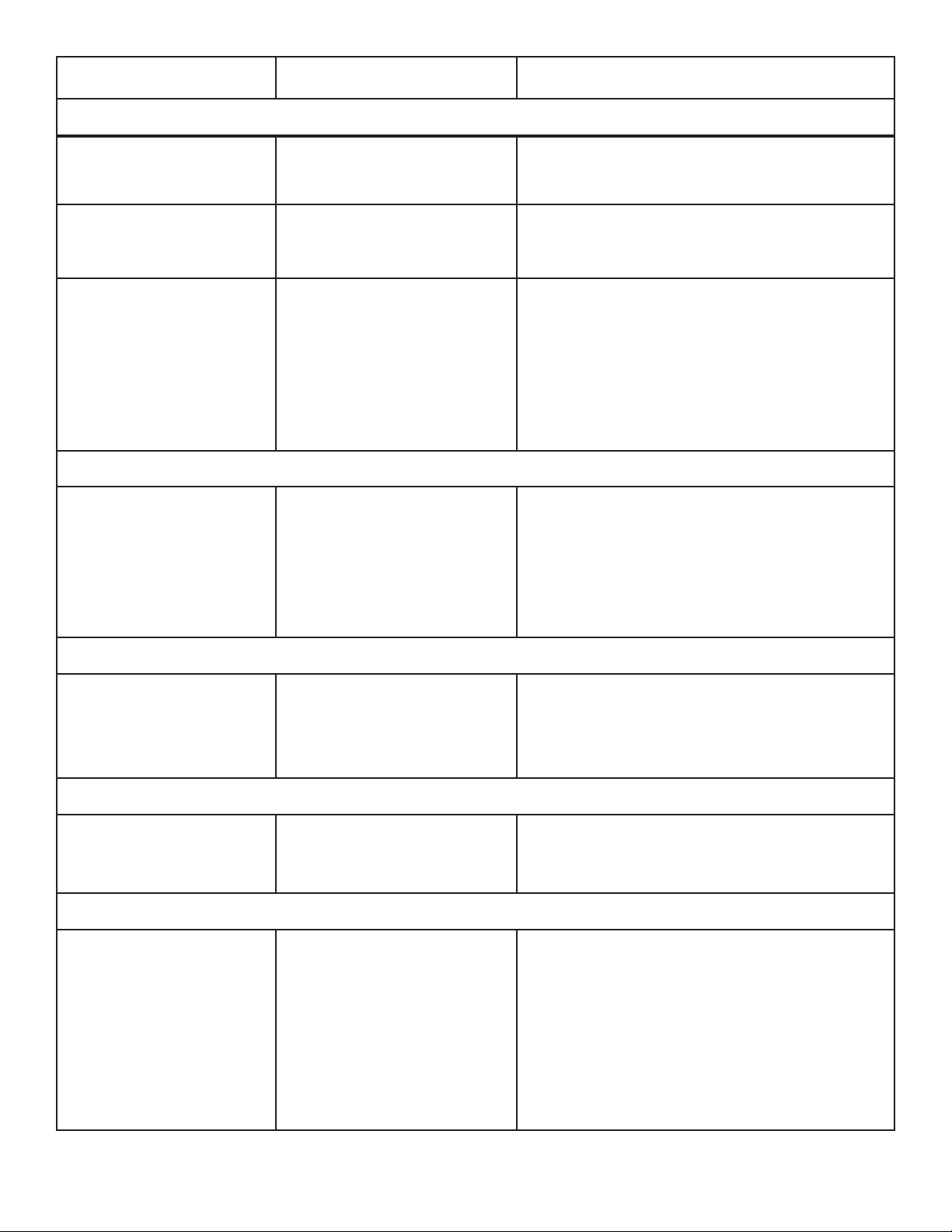

Page 13

PROBLEM CAUSE CORRECTION

SOUND AND NOISE

Popping or cracking

sound when compressor

comes on.

Bubbling or gurgling

sound, like boiling

water.

Vibrating or rattling

noise.

• Metal parts undergo

expansion and contraction,

as in hot water pipes.

• Refrigerant (used to cool

beer dispenser) is circulating

throughout the system.

• Floor is uneven or weak.

Wine cellar rocks on floor

when it is moved slightly.

• Beer Dispenser is touching the

wall.

WATER/MOISTURE/INSIDE BEER DISPENSER

Moisture forms on inside

beer dispenser walls.

• Weather is hot and humid,

which increases internal rate of

frost build-up.

• Door may not be seating

properly.

• Door is kept open too long, or

is opened too frequently.

• This is normal. Sound will level off or disappear as

beer dispenser continues to run.

• This is normal.

• Ensure floor is level and can adequately support

beer dispenser. Level the beer dispenser.

• Re-level the beer dispenser or move beer dispenser

slightly.

• This is normal.

• See “DOOR ALIGNMENT” Section on page 7.

• Open the door less often.

WATER/MOISTURE/OUTSIDE BEER DISPENSER

Moisture forms on

outside of beer

dispenser.

• Door may not be seating

properly, causing the cold air

from inside the beer dispenser

to meet warm moist air from

outside.

ODOR IN BEER DISPENSER

Odor in beer dispenser.

• Interior needs to be cleaned.

DOOR PROBLEMS

Door will not close.

• Beer Dispenser is not level. It

rocks on the floor when it is

moved slightly.

• Door may not be seating

properly.

• Floor is uneven or weak. Beer

Dispenser rocks on floor when

it is moved slightly.

• Check for blockage

• See “DOOR ALIGNMENT” Section on page 7.

• Clean interior with sponge, warm water,

and baking soda.

• This condition can force the cabinet out of square

and misalign the door. Refer to "LEVELING" on

page 4.

• See “DOOR ALIGNMENT” Section on page 7.

• Level the beer dispenser by using the adjustable

leveling legs underneath it or move it to a different

location.

• Adjust keg.

12

Page 14

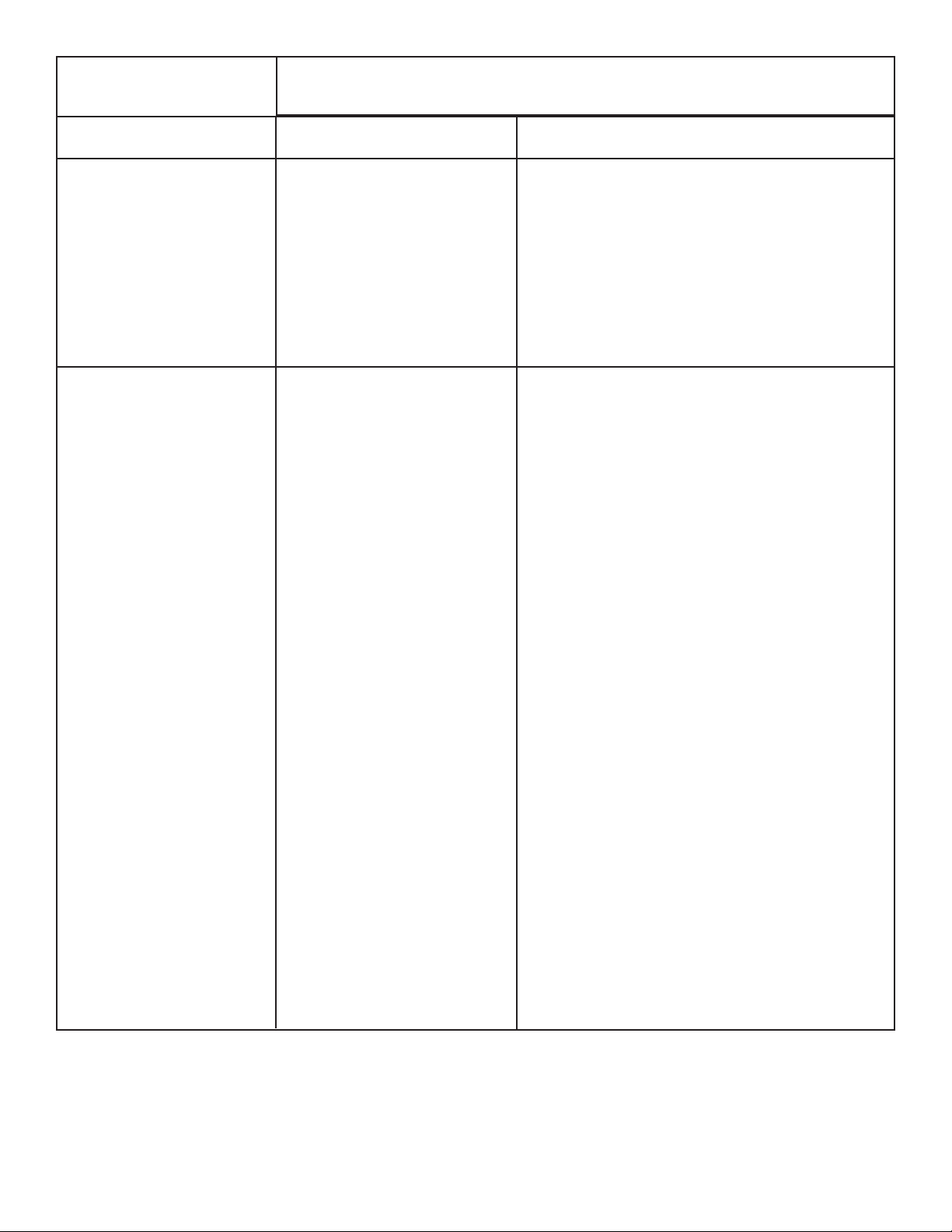

When dispensing beer into the glass, if you find that the beer is Cloudy, Flat, Bubbly, Off-Taste,

POOR QUALITY BEER

Sour, Wild or Tail-End Beer, refer to some of the following hints.

PROBLEM CAUSE CORRECTION

Cloudy Beer.

The beer in the glass

appears hazy, and not clear.

Flat Beer.

Beer lacks its usual breweryfresh flavor. The foamy head

disappears quickly.

• Excessively low temperatures

may cause hazy or cloudy

beer, particularly when the

beer lies in the cold coil for

long periods of time.

• The beer faucet was only

opened partially.

• The glass is greasy.

• Improper drawing of beer into

the glass.

• Not enough pressure.

• Make certain that the lines are thoroughly cleaned

and then raise the temperature slightly.

• Open the faucet quickly and completely.

• Replace any worn washers and parts in the

faucet when necessary to allow the faucet to be

fully opened.

• Do not wash beer glasses together with glasses that

have contained milk or any other fatty substance.

An excessive amount of germicide build-up may

also leave a fatty film, which will cause beer to go

flat.

• It is preferable to steam and sterilize glasses where

health laws permit.

• Wash glasses thoroughly with a good detergent to

remove all fatty substances (i.e. lipstick).

• Do not use soap.

• Do not wipe the glasses dry. Permit glasses to airdry by placing them on a wire rack or on corrugated metal.

• Rinse the glasses in fresh cold water just before

serving beer. It is best to serve beer in a wet glass.

• Open the faucet quickly and completely.

• Proper foam should be a tight creamy head. The

collar on the average glass should be 3/4" to 1"

high. Beer drawn without head has the appearance

of being flat.

• Increase the pressure if beer runs too slowly. The

correct flow should fill a 10oz. glass in 4 seconds.

(Approx. 8oz. of liquid)

• Check the pressure source to determine whether

there are obstructions in the air line.

• Replace a sluggish air source or the CO2 regulator

and gauge.

• The tank pressure must always be higher than the

pressure used on the keg.

• Always apply pressure to the keg before drawing

beer.

13

Page 15

PROBLEM CAUSE CORRECTION

Loose Foam.

Large soap-like bubbles that

settle quickly.

Off-Taste Beer.

Often bitter and bitey;

sometimes completely lacking in flavor and zest. May

also have an oily or foul

odor, which carries an

unpleasant taste.

Sour Beer.

Beer tastes and smells

extremely yeasty or moldy.

• This is generally the same as

the Flat Beer condition.

• Improper cleaning of the tap.

• Contaminated air line.

• Improper type of beer tube

• Improper transporting of beer

kegs. Beer that is delivered

on an open truck during high

summer temperatures may

start a secondary fermentation

process.

• See the Flat Beer causes above.

• Brush and clean the tap properly. It should be

scoured using a detergent, then rinsed clean.

• Beer tube should be examined. If contaminated, it

should be replaced.

• A rubber hose will absorb and retain odors. Try

using a plastic tube instead.

*General Recommendations for Off-Taste Beer:

Beer lines should be flushed after each keg is

emptied. Maintain fresh, clean, sanitary conditions

around the dispenser. Smoke, cooking odors and

disinfectants will harm the taste and flavor of beer.

These conditions, as described, may come from an

air source or from actual contact with the glass when

drawing beer.

• If possible, have beer kegs delivered in a closed,

refrigerated truck. If an open truck is used, cover

beer kegs with tarpaulin for protection against

summer heat and warm air.

Wild Beer.

Beer that is either all foam,

or too much foam and not

enough liquid.

• Improper drawing of beer into

the glass.

• Yeast growth or other obstructions in the faucet, which is

usually caused by a non-refrigerated faucet. Worn faucet

parts and worn faucet washers.

• The beer was stored in an area

that is not cold enough and

has thus become warm.

• Too much air pressure.

• Excessive amounts of CO2.

• Open the faucet quickly and completely.

• Proper foam should be a tight, creamy head, and

the collar on the average glass should be 3/4" to 1"

high.

• Check for, and replace any kinked, dented, or

twisted lines from the barrel to the faucet.

• Examine for frayed coupling washers behind the

faucet that may cause an obstruction.

• Keep kegs of beer refrigerated at all times at

38˚F-40°F all year round!

• First, check the source of pressure to make sure it is

working. Then adjust the pressure to suit a properly

balanced system. The correct beer flow should fill a

10oz. glass in 4 seconds at the proper temperature.

• Adjust the CO2 pressure to as low as possible.

However, the applied pressure must remain slightly

higher than the internal pressure of the beer. No

more than 18 lbs. should be applied. The proper

amount should be between 10-12psi/lbs.

• The colder the beer and the higher the applied

CO2 pressure, the more rapid the absorption of

CO2 by the beer. This over-carbonates the beer,

causing Wild Beer.

• Check the pressure regulators periodically to ensure

that the operating pressures remain constant.

14

Page 16

PROBLEM CAUSE CORRECTION

Wild Beer. (continued)

Beer that is either all foam,

or too much foam and not

enough liquid.

Tail-End Beer

Beer draws well at the

beginning of the keg.

Towards the bottom, it

becomes flat. This is more

likely to occur when beer

turnover is slow.

• Not enough pressure or no

pressure at all.

• An old keg of beer which has

not been stored in cool

temperatures has been used.

• Where air is used as a

pressure source, air replaces

the CO2 in beer, causing flat

beer. This problem is not

evident when beer is being

drawn rapidly.

• Check for defective air vents.

• Always turn the pressure on before drawing beer.

• If beer has been allowed to stand in warm temperatures beyond 45°F for an excessive length of time,

it may begin a secondary fermentation. Store beer

at 38˚F-40°F all year round.

• Whenever possible, use CO2 Gas as a pressure

source.

15

Page 17

Master Protection Agreements

Congratulations on making a smart purchase. Your new Kenmore®

product is designed and manufactured for years of dependable

operation. But like all products, it may require preventive maintenance or repair from time to time. That’s when having a Master

Protection Agreement can save you money and aggravation.

The Master Protection Agreement also helps extend the life of your

new product. Here’s what the Agreement* includes:

Parts and labor needed to help keep products operating

properly under normal use, not just defects. Our coverage

goes well beyond the product warranty. No deductibles, no

functional failure excluded from coverage— real protection.

Expert service by a force of more than 10,000 authorized

Sears service technicians, which means someone you can

trust will be working on your product.

Unlimited service calls and nationwide service, as often

as you want us, whenever you want us.

“No-lemon” guarantee – replacement of your covered prod-

uct if four or more product failures occur within twelve months.

Product replacement if your covered product can’t be fixed.

Annual Preventive Maintenance Check at your request

– no extra charge.

Fast help by phone – we call it Rapid Resolution – phone

support from a Sears representative on all products. Think of us

as a “talking owner’s manual.”

Power surge protection against electrical damage due to

power fluctuations.

$250 Food Loss Protection annually for any food spoilage

that is the result of mechanical failure of any covered refrigerator

or freezer.

Rental reimbursement if repair of your covered product takes

longer than promised.

10% discount off the regular price of any non-covered repair

service and related installed parts.

Once you purchase the Agreement, a simple phone call is all that it

takes for you to schedule service. You can call anytime day or night,

or schedule a service appointment online.

The Master Protection Agreement is a risk free purchase. If you can

cel for any reason during the product warranty period, we will

provide a full refund. Or, a prorated refund anytime after the product

warranty period expires. Purchase your Master Protection Agreement

today!

Some limitations and exclusions apply. For prices and

additional information in the U.S.A. call 1-800-827-6655.

* Coverage in Canada varies on some items. For full details

call Sears Canada at 1-800-361-6665.

Sears Installation Service

For Sears professional installation of home appliances, garage door

openers, water heaters, and other major home items, in the U.S.A. or

Canada call 1-800-4-MY-HOME®.

16

Page 18

TABLE DES MATIERES

AVERTISSEMENT

AVERTISSEMENT

AVERTISSEMENT

CONSIGNES DE SÉCURITÉ IMPORTANTES

Numéros de série et de modèle.................................... 1

Consignes de sécurité .............................................. 1-2

Garantie ..................................................................3-6

Étapes de l’installation ................................................. 3

Conseils d’économie d’énergie..................................... 7

Caractéristiques du distributeur de bière ....................7-8

Nettoyage et Entretien ............................................... 8-9

Panne de courant/Panne du distributeur de bière ........ 10

Problèmes et Solutions ..........................................11-15

Liste des pièces .......................................................... 16

NUMÉROS DE SÉRIE ET DE MODÈLE

LISEZ ET CONSERVEZ CES INSTRUCTIONS

Ce guide d’utilisation et d’entretien indique comment

utiliser ce modèle. Utilisez uniquement votre distributeur de

bière pour les fonctions prévues et décrites dans ce guide.

Ces instructions n’ont pas pour but de couvrir toutes les

conditions et situations possibles. Il convient de faire preuve

de bon sens et de prudence lorsque vous installez, utilisez

et réparez un appareil quel qu’il soit.

Notez le numéro de modèle et le numéro de série

LISEZ TOUTES LES INSTRUCTIONS AVANT

D’UTILISER CE DISTRIBUTEUR DE BIÈRE.

POUR VOTRE SÉCURITÉ

Do not store or use gasoline, or other flammable vapors

and liquids in the vicinity of this or any other appliance.

Read product labels for flammability and other warnings.

SÉCURITÉ ENFANT

• Après avoir déballé le distributeur de bière détruisez tous

les matériaux d’emballages, sacs en plastique, etc. Les

enfants ne devraient jamais jouer avec ces emballages.

Les cartons recouverts d’un tapis, de couvertures ou de

sacs en plastique peuvent devenir des chambres à air et

peuvent rapidement entraîner la suffocation.

• Retirez toutes les agrafes du carton. Elles peuvent causer

des coupures graves et abîmer les finitions si elles entrent

en contact avec d’autres appareils ou meubles.

• Un bac à glaçons vide, un distributeur de bière, un

congélateur vide et mis au rebut attirent beaucoup les

enfants et cela est très dangereux.

• Retirez et jetez les espaceurs utilisés pour maintenir en

place les clayettes durant le transport. Les objets de petite

taille sont dangereux pour les enfants car ils peuvent

s’étouffer en les avalant.

N’oubliez pas de noter les numéros de modèle et de série

de votre appareil. Ils se trouvent sur une étiquette au dos

de l’appareil.

Numéro du modèle:

183.91579

Numéro de série:

Date d’achat:

Espaceur

Retirez la (les) porte(s) de tout appareil qui n’est

pas utilisé même si vous allez vous en débarrasser.

Comment vous débarrassez de votre

distributeur de bière en toute sécurité.

Le risque de confinement et de suffocation des enfants n’est pas un problème du passé. Les

distributeur de bières qui ne sont plus utilisés ou abandonnés sont encore dangereux même s’ils ne sont mis de

côté que pendant quelques jours. Afin d’éviter tout risque

de suffocation et de confinement des enfants (le fait qu’ils

puissent se retrouver enfermés à l’intérieur de l’appareil)

suivez les consignes suivantes.

AVANT DE JETER VOTRE VIEUX

DISTRIBUTEUR DE BIERE :

• Retirez les portes.

• Laissez les clayettes et bacs en place pour que les

enfants ne puissent grimper facilement à l’intérieur.

© Sears, Roebuck and Co.

1

Page 19

INFORMATION

AVERTISSEMENT

AVERTISSEMENT

Ne coupez, ne retirez

et ne dérivez en

aucun cas la lame

de mise à la terre.

ÉLECTRIQUE

CONSIGNES DE SÉCURÍTE IMPORTANTES

POUR LE CO2 (GAZ CARBONIQUE)

Ces règles doivent être suivies pour s’assurer que

les mécanismes de sécurité propres à ce distributeur de bière fonctionneront correctement.

• Reportez-vous à la plaque signalétique pour con-

naître la tension électrique appropriée. Le cordon

d’alimentation de l’appareil est équipé d’une fiche polarisée à trois lames qui doit être insérée dans une prise

murale à trois trous, protégée avec un fusible à 15 amp

ou un disjoncteur. La prise de courant doit être installée

conformément aux codes et ordonnances locaux. Faites

appel à un électricien agréé. Les prises de courant protégées par Ground Fault Circuit Interrupters (GFCI) NE

SONT PAS RECOMMENDES. N’utilisez pas de ral-

longe ou d’adaptateur.

• Si la tension de la source électrique varie de 10% ou plus

la performance du distributeur de bière risque d’en être

affectée. Faire fonctionner un distributeur de bière sur

une tension insuffisante peut endommager le moteur. Un

tel dommage ne sera pas couvert par la garantie. Si vous

pensez que la tension de votre habitation est élevée ou

faible consultez votre compagnie de courant électrique

pour un test.

• Afin d’éviter que le distributeur de bière soit éteint accidentellement ne branchez pas l’appareil dans une prise

murale contrôlée par un interrupteur mural et ne tirez

pas sur le cordon d’alimentation.

• Ne tordez pas, ne nouez pas et ne faites pas pendre le

cordon d’alimentation.

AUTRES PRÉCAUTIONS

1. Le gaz carbonique ou dioxyde de carbone peut être

dangereux! Les bouteilles de CO2 contiennent du gaz

sous pression qui peut être dangereux si vous ne le

manipulez pas correctement. Veuillez lire et comprendre

toutes les consignes concernant les bouteilles de CO2

avant de procéder à l'installation.

2. Veuillez toujours raccorder la bouteille de CO2 à un

régulateur! Le non-respect de cette consigne risque de

provoquer une explosion et d'entraîner des blessures

graves voire mortelles lorsque vous ouvrez la valve de

la bouteille.

3. Ne raccordez jamais la bouteille de CO2 directement

sur le contenant, tonnelet, baril ou fût de bière.

4. Respectez toujours la marche à suivre lorsque vous

changez de bouteille.

5. Ne jamais lancer ou laisser tomber une bouteille de

CO2.

6. Conservez toujours les bouteilles de CO2 loin des

sources de chaleur. Stockez les bouteilles de rechange

dans un endroit frais (de préférence 70°F ou 21°C).

Fixez solidement la bouteille en place avec une chaîne,

en la plaçant droite.

7. Assurez-vous que l'endroit possède une bonne ventilation et quittez immédiatement cet endroit en cas de fuite

de CO2!

8. Vérifiez toujours la date à laquelle la bouteille a été

testée par le D.O.T (Ministère des transports américain)

figurant sur le col de la bouteille avant l'installation.

Si cette date est antérieure à 5 ans, n'utilisez pas la

bouteille. Ramenez la bouteille à votre fournisseur.

• Ne débranchez jamais votre distributeur de bière en

tirant sur le cordon d’alimentation. Tenez fermement la

fiche et retirez-la de la prise électrique.

Évitez les incendies et décharges

électriques. N’utilisez pas de rallonge ou d’adaptateur.

Ne retirez aucune lame du cordon d’alimentation.

prise murale mise

à la terre

Cordon d’alimentation avec

fiche polarisée à 3 lames

grounding plug

9. Ne raccordez jamais un tonnelet, fût ou autre contenant

de bière à moins qu'il existe au moins deux dispositifs

de sécurité au niveau du circuit de pression.

2

Page 20

ETAPES DE L’INSTALLATION GARANTIE DU DISTRIBUTEUR DE BIÈRE

GARANTIE LIMITÉE D’UN AN KENMORE

Lorsque cet appareil est installé, utilisé et réparé selon les

instructions fournies avec l’appareil si l’appareil ne fonctionne pas correctement du à un défaut de main d’œuvre

ou de pièces pendant une durée d’un an à compter de

la date d’achat, retournez-le à n’importe quel magasin

Sears, un centre de réparation Sears ou un lieu de vente de

produits Kenmore pour une réparation gratuite.

Si cet appareil est utilisé pour un usage autre que domestique cette garantie s’applique seulement pendant 90 jours

à compter de la date d’achat.

Cette garantie couvre uniquement les défauts de

main d’œuvre pièces. Sears NE PAIERA PAS pour:

1. Les articles consomptibles qui peuvent se détériorer suite

à une utilisation normale, dont mais pas limités aux filtres, ceintures, ampoules et sacs.

2. Qu’un technicien indique à l’utilisateur comment installer, utiliser, et réparer le produit correctement.

3. Qu’un technicien nettoie et répare ce produit.

4. Les dommages et pannes de ce produit s’il n’est pas

installé, utilisé ou réparé selon les instructions fournies

avec ce produit.

5. Les dommages et pannes de ce produit résultant d’un

accident, abus, mauvaise utilisation ou utilisation pour

une fin autre que celle prévue.

6. Les dommages et pannes de ce produit causés par

l’utilisation de détergents, nettoyants, produits chimiques

ou ustensiles autres que ceux recommandés dans les

instructions fournies avec ce produit.

7. Les dommages et pannes des pièces ou systèmes résultant de modifications autorisées apportées à ce produit.

Renonciation de garanties implicites; limitation des

voies de recours

Cette garantie limitée est offerte à la place de toute autre

garantie exprimée ou incluant les garanties de qualité

marchande et de comptabilité à une fin particulière. Elle est

limitée à un an ou à la période la plus courte autorisée par

la loi. Le recours offert dans cette garantie est exclusif et est

offert comme seul et unique recours au client. Cette garantie Sears ne couvre pas les dommages secondaires. Dans

certains États et provinces cette mesure d’exclusion n’est

pas autorisée donc la mesure d’exclusion ci-dessus ne vous

concerne peut-être pas.

Cette garantie s’applique uniquement lorsque l’appareil est

utilisé aux États-Unis ou au Canada.

Cette garantie vous donne des droits légaux spécifiques et

il se peut que vous ayez d’autres droits qui varient d’un État

à l’autre.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Sears Canada Inc., Toronto, Ontario, Canada M5B

2B8

Ce guide d’utilisation vous donne des consignes de fonctionnement spécifiques à votre modèle. N’utilisez le distributeur de bière que comme indiqué dans ce guide. Avant

de mettre le distributeur de bière en marche lisez

ces étapes importantes.

INSTALLATION

Pièces et Caractéristiques

1. Tous matériels emballant. Ceci inclut la base de mousse

et toute bande adhésive tenant l'intérieur d'accessoires et

dehors.

6

5

4

3

2

1. Roulettes avant

2. Support intérieur du

3. Habillage/caisson

4. Bouteille de CO2

5. Surface de travail

6. Barre

7

1

sol pour fût de bière

8

9

10

8. Thermostat réglable

(situé à l'arrière)

9. Ramasse-gouttes

10. Fût de bière (non

fourni. Montré ici

à titre d'illustration

uniquement.)

7. Robinet de bière en

chrome

Déballage distributeur de bière

1. Retirez tous les matériaux d'emballage y compris le

socle en mousse et le ruban adhésif retenant les accessoires à l'intérieur et à l'extérieur. Sortez l'équipement en

le glissant et retirez le plastique ou la mousse de protection protégeant le compresseur lors du transport.

2. Inspectez l'équipement et retirez tout matériau

d'emballage restant, ruban adhésif ou documentation

avant de mettre sous tension la fontaine à bière.

Remarque: Pour s'assurer que le compresseur fonction-

nera correctement, permettez au distributeur

de bière de se tenir en position droite pendant

8 heures avant de la brancher.

3

Page 21

Vérifiez tous les accessoires fournis avec le carton et

Roulette

Clé plate

Noix

La grande Vis

de Tête de Philip

Petite Vis à

tête phillips

Esquisser

l'Assemblée de Bras

Joint

Canal de bière

Garder la Barre

voler la noix

Poignée

piloter des

assurez-vous que toutes les pièces sont en bon état.

Reportez-vous à la liste ci-dessous. Si un des accessoires

est en mauvais état ou s'avère manquant, veuillez contacter

notre service à la clientèle:

1 robinet de bière avec:

1 Bouton noir

1 joint pour le robinet de bière

1 rondelle pour raccorde ment manchon fût bière

1 régulateur de CO2

1 cylindre de CO2

1 kit de nettoyage (American Sankey Type)

1 Trousse de Nettoyage

1 CO2 Ligne de Gaz (le Tube Rouge)

2 Serre-joints de Tuyau

1 CO2 Cylindre de retenue (avec le boulon et la noix)

1 barre de protection

1 bac ramasse-gouttes

4 roulettes

1 clé (pour les roulettes)

4 vis cruciforme Phillips

8 petites vis cruciforme Phillips

2 Vis Réparant de retenue

2 étagères métalliques

4 chevilles de support

Montage des Roulettes

Suivez les étapes suivantes pour monter les roues.

1. Videz complètement l'intérieur de la caisse et placez la

fontaine à bière à plat, sur le côté. Nous vous conseillons de placer un morceau de carton ou de chiffon sous

le caisson afin d'éviter de rayer ce dernier.

2. Introduisez les roulettes dans les

trous des coins inférieurs du caisson. Serrez chaque roue en tournant

l'écrou dans le sens des aiguilles

d'une montre avec clé fournie.

3. Après avoir serré les quatre roues,

lacez le caisson debout.

2. Placez le joint

sur l'écrou à

oreilles en bas

du robinet de

bière.

3. Faites passer le

tube de bière

dans le joint

jusqu'au bas du

robinet de bière.

4. Poussez l'écrou

à oreilles et le

conduit de bière

dans le trou de

la surface de travail jusqu'à ce que le robinet repose sur

le dessus du caisson.

5. Fixez le robinet de bière au caisson en introduisant quatre grandes vis cruciformes Pihllips dans les trous puis

serrez.

Montage de la Barre de Sécurité

Suivez les étapes ci-dessous afin d’installer la barre de

sécurité sur la surface de travail.

1. Positionnez la barre sur le dessus du caisson.

2. Alignez tous les trous de la barre sur ceux du dessus du

caisson.

3. Fixez la barre sur le caisson en utilisant huit petites vis

cruciforme Phillips.

Niveler votre Distributeur de Bière

Si vous n'installez pas les roulettes, vous devrez niveler votre

distributeur de bière.

• Le distributeur de bière de Your a 4 jambes de mise à

niveau qui sont plac dans les coins avant et arrière.

Après avoir correctement placé votre distributeur de bière

dans sa position finale, vous pouvez la niveler.

• La mise à niveau des jambes peut être ajustée en les

tournant dans le sens des aiguilles d'une montre à

l'augmenter ou dans le sens contraire des aiguilles d'une

montre abaisser votre distributeur de bière. La porte de

distributeur de bière

Montage du Robinet de Bière

Suivez les étapes ci-dessous pour le robinet de bière.

1. Tout d'abord, retirez le bouchon du caisson situé sur la

surface de travail. Saisissez le bouchon, tournez-le puis

tirez vers le haut.

REMARQUE: Rangez ce bouchon dans un endroit sûr

car vous en aurez besoin afin de convertir la fontaine à bière réfrigérateur.

Installation du régulateur de CO2 et de la bouteille

de CO2

Suivez les étapes ci-dessous afin d’installer le régulateur de

CO2 et la bouteille de CO2 en toute sécurité. Veuillez lire

et comprendre les instructions suivantes

concernant les bouteilles de CO2 avant de procéder à

l’installation.

REMARQUE: Votre bouteille de CO2 est expédiée vide afin

d’éviter tout risque d’accident lors du transport. Lorsque vous achetez le premier fût de

bière, demandez à ce votre revendeur remplisse la bouteille de CO2.

1. Raccordez la conduite d’air du CO2 au régulateur en

branchant un bout de la conduite d’air rouge au manchon de raccordement pour tuyau sur le régulateur de

CO2. Fixez le tuyau à l’aide Utilisez les pinces pour fixer

fermement serre-câble afin qu’il n’y ait pas de fuite.

4

Page 22

2. Retirez l’écrou du boulon de retenue. Utilisez deux vis de

Bouteille de CO2

CO2

GAS

Régulateur

du CO2

Connecter au

Robinet de Fût

(l'attelage)

Collier de serrage

Vanne de fermeture

Étrier de retenue

Raccordez à la bouteille de CO2

Faire pression sur la

vis d'ajustement

Beer Line

Coupling Nut

Red Tube (gas line)

Manchon de raccordement

pour fût de bière

La poignée noire de

traction (ascendant)

Raccordez à la conduite de bière

Raccordez à la

conduite d’air de CO2

T

O

U

R

N

E

R

D

A

N

S

fixation afin de fixer l’étrier de retenue sur les trous au

dos de la bouteille.

raccordement dans le col de verrouillage du fût de bière

et tournez dans le sens des aiguilles d’une montre 1⁄4 de

tour afin de le verrouiller. (voir figure 1)

3. Glissez la bouteille dans l’étrier de retenue et placez

l’ensemble caisson. Ensuite, serrez l’écrou de retenue.

4. Poussez l'écrou à oreilles et le conduit de bière dans le

trou de la surface de travail jusqu'à ce que le robinet

repose sur le dessus du caisson.

fig. 1

2. Branchez l’extrémité ouverte de la conduite d’air rouge

au raccord destiné au tuyau situé sur le manchon de

raccordement. Ensuite, fixez le tuyau autobloquant à

pression afin de vous assurer qu’il ne présente aucune

fuite. Utilisez les pinces pour fixer fermement le serrecâble afin qu’il n’y ait pas de fuite. (voir figure 2)

fig. 2

AVERTISSEMENT!

Le CO2 peut être dangereux ! Les bouteilles de CO2 contiennent un gaz à

manipulé correctement. Ces bouteilles doivent être manipulées précaution.

Mise en perce du fût de bière

(baril à valve unique)

Votre fontaine à bière est fournie avec un robinet American

Sankey Tap fabriqué par Banner Equipment Company.

Cette marque est la plus utilisée aux États-Unis. Avant

d’acheter un fût de bière, vérifiez la fontaine à bière afin de

vous assurer qu’elle peut accueillir un robinet Sankey Tap.

REMARQUE: Pour la bière pression européenne, la pose

d’un robinet Sankey de calibre européen

est obligatoire. Veuillez contacter Draught

Technologies en composant sans frais le

(860) 677-7312 á www.draughttech.com

pour plus d’informations.

Suivez les étapes ci-dessous pour la mise en perce du

fût de bière:

1. Assurez-vous que la poignée noire du manchon de raccordement est fermée (vers le haut) avant de le brancher

sur le dessus du fût de bière. Introduisez le manchon de

3. Il est très important que la rondelle noire en caoutchouc

soit installée à l’intérieur de l’écrou à oreilles avant de

raccorder la conduite de bière au manchon de raccordement. Retirez la capuchon de protection noir en caoutchouc situé sur le dessus du manchon de raccordement

et vissez l’écrou à oreilles avec la rondelle en caoutchouc sur le manchon de raccordement. Serrez fermement à la main. (voir figure 3)

fig. 3

5

Page 23

4. Assurez-vous que le robinet de bière est fermé (la poi-

Support du füt

Füt de Biére

Sou;evez le Füt

gnée du robinet est orientée vers l’arrière) avant de

brancher le manchon de raccordement et le fût de bière.

Pour effectuer le raccordement, tirez sur la poignée du

manchon de raccordement pour la sortir puis appuyez

dessus jusqu’à ce que le manchon se bloque en place.

La poignée devrait émettre un déclic lorsqu’elle se bloque en place. (voir figure 4) Open shut-off valve on regulator. Tourner de la vis dans le sens des aiguilles d'une

montre d'ajustement de pression jusqu'à ce que la jauge

de pression lit 8 livres par pouce carré.

fig. 4

5. En faisant preuve d’une grande precaution, penchez le

fût de bière afin que le bord du fût repose sur le support

en acier inoxydable du fond du caisson. Glissez le fût

lentement en place, en veillant à le correctement. (voir

figure 5)

Circulation de l’air

• Afin que votre appareil fonctionne au maximum de ses

capacités, installez-le dans un lieu où l’air circule bien et

où la plomberie et l’électricité sont bons.

• Laissez les distances recommandées suivantes autour du

distributeur de bière:

Sur les côtés 3/4” (19mm)

À l’arrière 2” (50mm)

• Ne remplissez pas trop votre distributeur de bière afin

que l’air interne puisse bien circuler.

Besoins électriques

• Assurez-vous qu’il y ait une prise électrique (115V, 60Hz)

correctement mise à la terre pour brancher l’appareil.

• Évitez d’utiliser un adaptateur à trois lames ou de couper

la troisième lame pour que cela marche dans une prise

électrique à deux trous.

Utilisation des Rallonges

• Evitez l’usage des rallonges car dans certains cas cela

peut entrainer des risques pour la sante. S’i c’est necessaire d’utiliser une cordon d’extension, utilisez une rallonge a 3 conducteurs disposant d’une fiche a 3 lames et

une sortie a 3 fentes qui accepteront la prise. Le calibre

defini des rallonges doit etre egal ou superieur a celui

de l’equipement.

Restrictions d’installation

fig. 5

Consigne de Sécurité Importante pour le Tirage de

la Bière

Si vous utilisez le CO2 pour tirer la bière pression, le système devra être correctement protégé contre toute accumulation excessive de pression. Ceci peut être effectué en

montant au minimum deux dispositifs de sécurité capables

de gérer toute surpression au sein du circuit.

Ces dispositifs de sécurité doivent être installés dans les

emplacements suivants:

A. Sur le régulateur de CO2 ou immédiatement en aval de

ce dernier.

B. Sur le dispositif de tirage lui-même.

• Ne placez pas votre distributeur de bière dans un lieu

qui n’est pas correctement isolé ou chauffé comme un

garage par exemple. Votre appareil n’est pas fait pour

être utilisé à des températures inférieures à 13ºC (55ºF)

• Choisissez une surface stable et plane loin de toute

source de chaleur ou d’exposition directe à la lumière du

soleil comme radiateurs, chauffages, appareils de cuisson, etc.

• Ce modèle est un modèle pose libre. Il n’est pas encastrable.

Convertir la Fontaine à Bière en Réfrigérateur

Pour faciliter les choses, cette fontaine à bière peut être

transformée en réfrigérateur. Suivez simplement les étapes

ci-dessous pour transformer rapidement et facilement

l’unité.

REMARQUE: Lorsque vous utilisez l’unité en tant que

réfrigérateur, il est déconseillé d’utiliser des

roulettes car les articles à l’intérieur du réfrigérateur risquent de tomber des étagères si

vous déplacez l’unité.

1. Fermez la commande principale de la bouteille de CO2.

6

Page 24

2. Fermez le raccordement entre le fût de bière et le man-

É

C

O

N

O

M

I

S

E

R

D

E

l

’

A

R

G

E

N

T

F

A

I

S

A

N

T

D

E

S

É

C

O

N

O

M

I

E

S

d

’

É

N

E

R

G

I

E

Le gond inférieur plus spatial

abaisser le crochet

chon de raccordement en tirant et en relevant la poignée du manchon de raccordement afin de la mettre

droite.

3. Débranchez la conduite de bière et la conduite d’air du

CO2 du manchon de raccordement.

4. Retirez le fût de bière du caisson.

5. Débranchez la conduite d’air de la bouteille de CO2.

6. Retirez la bouteille de CO2 du caisson.

7. Retirez la colonne de bière du caisson en saisissant le

centre de la colonne. Tournez dans le sens des aiguilles

d’une montre et soulevez.

8. Tirez sur la conduite de bière afin de la faire passer

par le dessus du caisson.

9. Installez le bouchon du caisson sur la surface de tra-

vail.

10. Placez l’unité à terre, sur sa partie latérale. Nous vous

recommandons de placer un morceau de carton ou

de chiffon sous le caisson afin d’éviter de rayer ou

d’endommager ce dernier. Retirez les roulettes et montez les pieds de mise à niveau.

11. Montez les deux étagères:

A. Introduisez une extrémité de chacune des chevilles

de support dans les trous du côté droit du caisson.

• Le distributeur de bière doit être placé dans la partie la

plus froide de la pièce, loin de toute source de chaleur et

d’exposition directe à la lumière du soleil.

• Les clayettes ne doivent pas être recouvertes de papier

aluminium, de papier paraffiné ou de papier Essuie-tout.

Ils interfèrent avec la circulation de l’air froid et rendent

le distributeur de bière moins efficace. N’ouvrez pas la

porte inutilement.

• Ouvrez et fermez la porte le moins possible lors des jours

chauds et humides. Lorsque vous ouvrez la porte, fermez-la rapidement afin d’éviter que l’air chaud pénètre à

l’intérieur.

• Vérifiez régulièrement que le périmètre autour de l’unité

présente une bonne circulation d’air afin que cette

dernière soit bien ventilée.

• Veillez à ce que le joint de porte demeure propre et