Sears 172.10855 User Manual

Operator's Manual

71/4-in. Circular Saw

Model No.

172.10855

12 Amp

®

12

Amp

s

1

7

®

C

US

L

D

I

E

S

T

DOUBLE INSULATED

Read, understand and follow

CAUTION

!

all Safety Rules and Operating Instructions

in this Manual before using this product.

Sears, Roebuck and Co.,

Hoffman Estates, IL 60179 U.S.A.

Visit our Craftsman website: www.craftsman.com

• WARRANTY

• SAFETY

• UNPACKING

• ASSEMBLY

• DESCRIPTION

• OPERATION

• MAINTENANCE

REV 10855

2-12-08

TABLE OF CONTENTS

SAFETY SYMBOLS

Warranty………………………………

………….........

...................Page 2

Safety Symbols…………………………….……............................Page 3

Safety Instructions………………………………............................Pages 4 - 10

Glossary of Terms……………

Unpacking …………………………

…………………................

…………..............

..................Pages 11 - 12

............Pages 10 - 11

Assembly.. ……………………………………................................Pages 12 - 13

Description ……………………………

………….........

..................Pages 14 - 16

Operation ………………………………………..............................Pages 16 - 28

Maintenance................................................................................Pages 28 - 29

Troubleshooting...........................................................................Page 29

Accessories.................................................................................Page 29

Sears Repair Parts Phone Numbers...........................................Back Cover

ONE YEAR FULL WARRANTY ON CRAFTSMAN® TOOL

If this Craftsman tool fails due to a defect in material or workmanship within one year from

the date of purchase, RETURN IT TO ANY SEARS STORE OR OTHER CRAFTSMAN

OUTLET IN THE UNITED STATES FOR FREE REPLACEMENT.

This warranty does not include expendable parts such as lamps, batteries, bits or blades.

If this Craftsman product is used for commercial or rental purposes, this warranty applies

for only 90 days from the date of purchase.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

The purpose of safety symbols is to attract your attention to possible dangers.

The safety symbols, and the explanations with them, deserve your careful

attention and understanding. The symbol warnings DO NOT by themselves

eliminate any danger. The instructions and warnings they give are no substitutes

for proper accident prevention measures.

!

WARNING:

this manual, including all safety alert symbols such as “DANGER”, “WARNING”

and “CAUTION”, BEFORE using this drill /driver. Failure to follow all instructions

listed below may result in electric shock, fire and/or serious personal injury.

BE SURE to read and understand all safety instructions in

SYMBOL MEANING

SAFETY ALERT SYMBOL: Indicates DANGER, WARNING, OR

!

CAUTION. May be used in conjunction with other symbols or pictographs.

!

DANGER

!

WARNING

CAUTION

!

Failure to obey this safety warning WILL result in death or

serious injury to yourself or to others. Always follow the

safety precautions to reduce the risk of fire, electric shock

and personal injury.

Failure to obey this safety warning CAN result in death or

serious injury to yourself or to others. Always follow the

safety precautions to reduce the risk of fire, electric shock

and personal injury.

Failure to obey this safety warning MAY result in personal

injury to yourself or others or property damage. Always

follow the safety precautions to reduce the risk of fire,

electric shock and personal injury.

SAVE THESE INSTRUCTIONS!

READ ALL INSTRUCTIONS!

!

Some dust created by using power tools contains chemicals known to

WARNING:

the State of California to cause cancer and birth defects or other reproductive harm.

2

DAMAGE PREVENTION AND INFORMATION MESSAGES

These inform user of important information and/or instructions that could lead to

equipment or other property damage if not followed. Each message is preceded by the

word “NOTE:” as in the example below:

NOTE: Equipment and/or property damage may result if these instructions

are not followed.

!

WARNING:

The operation of any power tool can

result in foreign objects being thrown into your eyes,

which can result in severe eye damage. Before beginning

power tool operation, ALWAYS wear safety goggles or

safety glasses with side shield and a full-face shield

when needed. We recommend a Wide Vision Safety

Mask for use over eyeglasses or standard safety glasses

with side shield, available at Sears Stores or other

Craftsman Outlets.

3

REV 10855

2-12-08

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS cont.

!

WARNING: BE SURE to read and understand all instructions in this manual

before using this circular saw. Failure to follow all instructions may result in

hazardous radiation exposure, electric shock, fire and/or serious personal injury.

WORK AREA SAFETY

1. Keep your work area clean and well lit. Cluttered workbenches and dark areas

invite accidents.

2. DO NOT operate power tools in explosive atmospheres, such as in the presence

of flammable liquids, gases, or dust. Power tools create sparks which may ignite

the dust or fumes.

3. Keep bystanders, children and visitors away while operating a power tool.

Distractions can cause you to lose control.

4. Make your workshop childproof with padlocks and master switches. Lock

tools away when not in use.

5. MAKE SURE the work area has ample lighting so you can see the work and that

there are no obstructions that will interfere with safe operation BEFORE using your saw.

PERSONAL SAFETY

1. KNOW your power tool. Read the operator's manual carefully. Learn the saw's

applications and limitations, as well as the specific potential hazards related to this tool.

2. STAY ALERT, watch what you are doing and use common sense when operating

a power tool.

3. DO NOT use tool while tired or under the influence of drugs, alcohol or medication.

A moment of inattention while operating power tools may result in serious personal injury.

4. DRESS properly. DO NOT wear loose clothing or jewelry. Pull back long hair. Keep

your hair, clothing, and gloves away from moving parts. Air vents often cover moving

parts and should also be avoided. Loose clothing, jewelry or long hair can be caught

in moving parts.

5. AVOID accidental starting. Be sure switch is in “OFF” position before

plugging in. DO NOT carry tools with your finger on the switch. Carrying tools

with your finger on the switch or plugging in tools that have the switch in the

“ON” position invites accidents.

6. REMOVE adjusting keys or wrenches before turning the tool “ON”. A wrench

that is left attached to a rotating part of the tool may result in personal injury.

PERSONAL SAFETY cont.

7. Do not overreach. Keep proper footing and balance at all times. Proper footing and

balance enables better control of the tool in unexpected situations.

8. ALWAYS SECURE YOUR WORK. Use clamps or a vise to hold work when practical.

It is safer than using your hand and frees both hands to operate tool.

9. USE SAFETY EQUIPMENT. Always wear eye protection. Dust mask, non-skid

shoes, hard hat, or hearing protection must be used for appropriate conditions.

10. DO NOT USE ON A LADDER or unstable support. Stable footing on a solid surface

enables better control of the tool in unexpected situations.

safety

TOOL USE AND CARE SAFETY

!

WARNING: BE SURE to read and understand all instructions before

operating this saw. Failure to follow all instructions listed below may result in

electric shock, fire and/or serious personal injury.

1. ALWAYS use clamps or other practical ways to secure and support the workpiece

to a stable platform. Holding the work by hand or against your body is unstable and

may lead to loss of control.

2. DO NOT force the tool. Use the correct tool and blade for your application. The

correct tool and blade will do the job better and safer at the rate for which it is designed.

3. DO NOT use the tool if switch does not turn it “On” or “Off”. Any tool that cannot be

controlled with the switch is dangerous and must be repaired.

4. DISCONNECT the plug from the power source before making any adjustments,

changing accessories or storing the tool. Such preventive safety measures reduce

the risk of starting the tool accidentally.

5. NEVER leave the tool running. ALWAYS turn it off. DO NOT leave the tool until it

comes to a complete stop.

6. STORE idle tools out of the reach of children and other untrained persons.

Tools are dangerous in the hands of untrained users.

7. MAINTAIN tools with care. Keep cutting tools sharp and clean. Properly maintained

tools with sharp cutting edges are less likely to bind and are easier to control.

8. CHECK for misalignment or binding of moving parts, breakage of parts, and any

other condition that may affect the tool's operation. If damaged, have the tool serviced

before using. Many accidents are caused by poorly maintained tools.

9. USE ONLY accessories that are recommended for this tool. Accessories that may

be suitable for one tool may become hazardous when used on another tool.

4 5

REV 10855

2-12-08

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

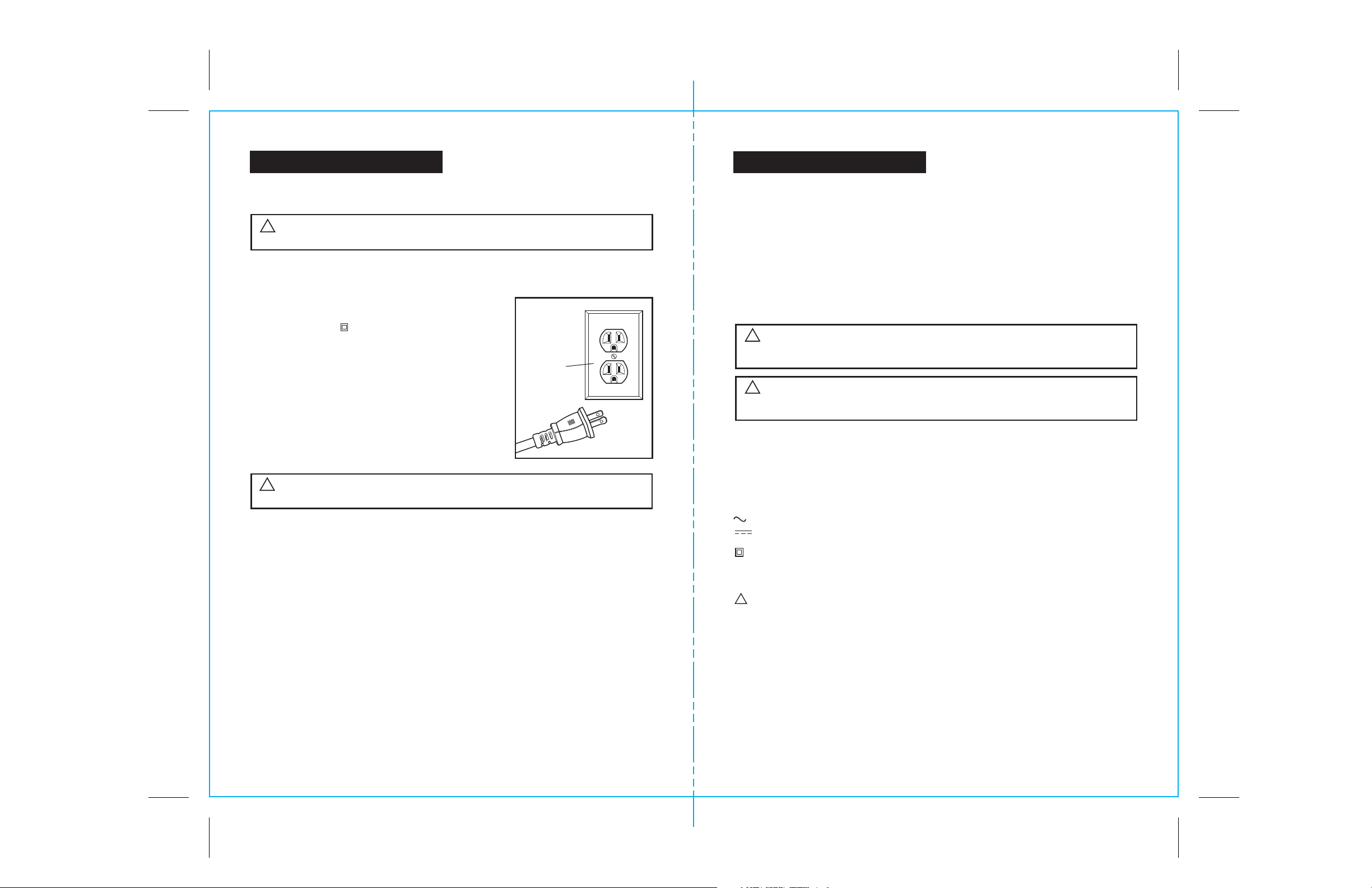

ELECTRICAL SAFETY

!

WARNING: Do not permit fingers to touch the terminals of plug when

installing or removing the plug from the outlet.

1. Double insulated tools are equipped with a polarized plug (one blade is wider than

the other). This plug will fit in a polarized outlet only one way. If the plug does not

fit fully in the outlet, reverse the plug. If it still does not fit, contact a qualified electrician

to install a polarized outlet. Do not change the

plug in any way.

2. Double insulation eliminates the need for the

three-wire grounded power cord and grounded

power supply system. Applicable only to Class II

(double-insulated) tools. This circular saw is

a double insulated tool.

!

WARNING: Double insulation DOES NOT take the place of normal safety

precautions when operating this tool.

3. BEFORE plugging in the tool, BE SURE that the outlet voltage supplied is within the

voltage marked on the tool's data plate. DO NOT use “AC only” rated tools with a DC

power supply.

4. AVOID body contact with grounded surfaces, such as pipes, radiators, ranges and

refrigerators. There is an increased risk of electric shock if your body is grounded.

5. DO NOT expose power tools to rain or wet conditions or use power tools in wet or

damp locations. Water entering a power tool will increase the risk of electric shock.

6. INSPECT tool cords for damage. Have damaged tool cords repaired at a Sears

Service Center. BE SURE to stay constantly aware of the cord location and keep it well

away from the moving blade.

7. DO NOT abuse the cord. NEVER use the cord to carry the tool by or pull the plug

from the outlet. Keep cord away from heat, oil, sharp edges or moving parts. Replace

damaged cords immediately. Damaged cords increase the risk of electric shock.

Cover of

Grounded

Outlet Box

EXTENSION CORDS

Use a proper extension cord. ONLY use cords listed by Underwriters Laboratories (UL).

Other extension cords can cause a drop in line voltage, resulting in a loss of power and

overheating of tool. For this tool an AWG (American Wire Gauge) size of at least 14-gauge

is recommended for an extension cord of 25-ft. or less in length. Use 12-gauge for an

extension cord of 50-ft. Extension cords 100-ft. or longer are not recommended.

Remember, a smaller wire gauge size has greater capacity than a larger number

(14-gauge wire has more capacity than 16-gauge wire; 12-gauge wire has more capacity

than 14-gauge). When in doubt use the smaller number. When operating a power tool

outdoors, use an outdoor extension cord marked “W-A” or “W”. These cords are rated for

outdoor use and reduce the risk of electric shock.

!

CAUTION: Keep the extension cord clear of the working area. Position the

cord so that it will not get caught on lumber, tools or other obstructions while

you are working with a power tool.

!

WARNING: Check extension cords before each use. If damaged replace

immediately. Never use tool with a damaged cord since touching the damaged

area could cause electrical shock, resulting in serious injury.

SAFETY SYMBOLS FOR YOUR TOOL

The label on your tool may include the following symbols.

V.......................................................................Volts

A......................................................................Amps

Hz....................................................................Hertz

W.....................................................................Watts

....................................................................Alternating current

.................................................................Direct current

no ....................................................................No-load speed

....................................................................Class II construction, Double Insulated

RPM……........................………………… . . .Revolutions per minute

SPM……..........................…………………....Strokes per minute

OPM………........................………………......Orbits per minute

.....................................................................Indicates danger, warning or caution.

!

It means attention! Your safety is involved.

SERVICE SAFETY

1. If any part of this saw is missing or should break, bend, or fail in any way;

or should any electrical component fail to perform properly: SHUT OFF the power

switch and remove the saw plug from the power source and have the missing, damaged

or failed parts replaced BEFORE resuming operation.

2. Tool service must be performed only at a Sears Parts and Repair Center. Service or

maintenance performed by unqualified personnel could result in a risk of injury.

3. When servicing a tool, use only identical replacement parts. Follow instructions in

the maintenance section of this manual. Use of unauthorized parts or failure to follow

maintenance instructions may create a risk of electric shock or injury.

6

7

REV 10855

2-12-08

SAFETY INSTRUCTIONS cont.

SAFETY INSTRUCTIONS cont.

SAFETY RULES FOR CIRCULAR SAWS

!

DANGER:

Keep hands away from cutting area and blade. Keep your

second hand on the auxiliary handle or motor housing. If both hands are holding

the saw, the blade cannot cut them.

!

CAUTION: Blades coast after saw is switched off.

1. KEEP your body positioned to either side of the saw blade and not in direct

line with the saw blade. Kickback could cause the saw to jump backwards. (See

“Kickback…What Causes It and Ways to Prevent It” on pages 18 and 19).

2. DO NOT reach underneath the work. The guard cannot protect you from the blade

beneath the workpiece.

!

DANGER:

When sawing through a workpiece, the lower blade guard DOES

NOT cover the blade on the underside of the workpiece (Pg. 17 Fig. 4). ALWAYS

keep your hands and fingers away from the cutting area.

3. CHECK lower guard for proper closing BEFORE each use. DO NOT operate the

saw if the lower guard does not move freely and close instantly. Never clamp or

tie the lower guard in the open position. If the saw is accidentally dropped, the

lower guard may be bent. Raise the lower guard with the retracting lever. The guard is

operating properly when it moves freely, does not touch the blade or any other part in

all angles and depths of cut, and readily returns to the closed position.

4. CHECK the operation and condition of the lower guard spring. If the guard and

the spring are not operating properly, they MUST BE serviced before use. The

lower guard may operate sluggishly, due to damaged parts, gummy deposits, or a

buildup of debris. DO NOT operate your saw until the damage has been repaired or

replaced.

5. The lower guard should be retracted manually ONLY for making special cuts,

such as pocket or compound cuts. ALWAYS raise the lower guard by retracting

its lever. As soon as the blade enters the material, the lower guard MUST be

released. For all other sawing, the lower guard should operate automatically.

6. ALWAYS make sure that the lower guard is covering the blade BEFORE placing

the saw down on a work bench or floor. An unprotected moving blade will cause

the saw to walk backwards, cutting whatever is in its path. Make note of the time it

takes for the blade to stop spinning after the switch is released.

7. NEVER hold the piece being cut in your hands or across your legs. It is important

to support the workpiece properly in order to minimize body exposure, blade binding,

or loss of control.

8. HOLD TOOL by insulated gripping surfaces (handles) when performing an

operation where the cutting tool may contact hidden wiring or its own cord.

Contact with a “live” wire will make the exposed metal parts of the tool “live” and shock

the operator.

9. ALWAYS clamp the workpiece securely so it will not move when making the cut.

10. When ripping, ALWAYS USE a rip fence or straight edge guide. This improves the

accuracy of the cut and reduces the chance of the blade binding.

11. ALWAYS USE blades that have the correct size and shape (diamond vs. round)

arbor holes. Blades that do not match the mounting hardware of the saw will run

erratically and cause loss of control.

8

SAFETY RULES FOR CIRCULAR SAWS cont.

11. ALWAYS USE blades that have the correct size and shape (diamond vs. round)

arbor holes. Blades that do not match the mounting hardware of the saw will run

erratically and cause loss of control.

12. NEVER use damaged or incorrect blade washers or bolts. The blade washers and

bolts were specially designed for your saw, for optimum performance and safety of

operation.

13. NEVER cut more than one piece at a time. DO NOT STACK more than one

workpiece on the worktable at a time.

14. AVOID awkward operations and hand positions where a sudden slip could cause

your hand to move into the blade.

15. NEVER reach into the cutting path of the blade.

!

WARNING:

WARNING: Some dust created by using power tools contains

chemicals known to the State of California to cause cancer and birth defects or

other reproductive harm. Some examples of these chemicals are:

• Lead from lead-based paints.

• Crystalline silica from bricks and cement and other masonry products.

• Arsenic and chromium, from chemically treated lumber.

Your risk from these exposures varies, depending upon how often you do this

type of work. To reduce your exposure to these chemicals:

• Work in a well-ventilated area.

• Work with approved safety equipment, such as those dust masks

that are specially designed to filter out microscopic particles.

Avoid prolonged contact with dust from power sanding, sawing, grinding, drilling

and other construction activities. Wear protective clothing and wash exposed

areas with soap and water. Allowing dust to get into your mouth, eyes, or lay on

the skin may promote absorption of harmful chemicals.

!

WARNING: Use of this tool can generate and/or disburse dust, which may

cause serious and permanent respiratory or other injury. Always use

NIOSH/OSHA approved respiratory protection appropriate for the dust exposure.

Direct particles away from face and body.

ADDITIONAL RULES FOR SAFE OPERATION

!

WARNING: BE SURE to read and understand all instructions. Failure to

follow all instructions listed below may result in electric shock, fire and/or

serious personal injury.

1. Know your power tool. Read operator's manual carefully. Learn the applications

and limitations, as well as the specific potential hazards related to this tool. Following

this rule will reduce the risk of electric shock, fire or serious injury.

2. ALWAYS wear safety glasses or eye shields when using this saw. Everyday

eyeglasses have only impact-resistant lenses; they are NOT safety glasses.

3. PROTECT your lungs. Wear a face mask or dust mask if the operation is dusty.

9

REV 10855

2-12-08

Loading...

Loading...