Page 1

Double Impulse Foot Sealers

Model: W-300T, W-450T, W-600T

Distributed By:

Version 1.1_2014

Page 2

General Information

Thank you for purchasing our W-Series Double Impulse Foot Sealers.

This owner’s manual contains information relating to your sealer. The manual will provide you

with basic information concerning both operation and maintenance of your new machine. Please

read it carefully as failure to do so may result in bodily injury and/or damage to the equipment.

Please fill in the information below. You will find the information on the machine identification

plate. You will need this information when ordering replacement parts or making technical

inquiries.

No part of this manual may be duplicated, reproduced, stored in a retrieval system, translated,

transcribed, or transmitted in any form without the express prior written permission of Sealer Sales.

W H D F E Q U I P M E N T I N F O R M A T I O N

Model #

Serial #

Purchase Date:

Reference # (found on packing slip)

Owner:

Page 3

W H D F I N S T R U C T I O N M A N

Safety Instructions

WARNING!

understood priortosettinguporoperating yourequipment.R ead and fullyunderstand all instructionsand

warningspriortousing thisunit.Yoursafetyismostimportant!Failure tocompl

resultinseriousinjuryorpropertydamage.R emember:

responsibility.

Unsafe practices or unauthorized modifications could result in accidents or property damage. Failure to

and take necessary precautions can result in serious injury as well as damage to

Never operate or service your sealer until you have read this manual completely and understand it

Plug the sealer into a standard 120 Volt, 60Hz wall outlet

Do not use the sealer if the power cord, plug or any other parts are damaged. Be sure not to allow

the power cord to drape into your work area. Check that all parts are operating properly and

perform the intended functions.

other conditions that may affect the operation.

Reduce risk of unintentional starting. Make sure the power switch is in the "OFF" position before

to the power source.

sealer from power source before servicing, changing accessories or cleaning the

To provide protection against the risk of electrical shock, the power connection must be properly

Do not leave the sealer unattended when in use.

before leaving the work area.

is used solely for sealing thermoplastic materials. Using the machine for any other purpose

can cause damage to the machine and operator.

While operating machinery, wear cl

external items from getting caught in the machine. Do not wear jewelry when operating the sealer.

B eloware generalsafetyprecautionsand warningsthatshould be

ywithproceduresmay

Your personal safety is your

or surge protector.

r any worn parts before starting operation.

Disconnect the sealer from the power source

fitting clothing and tie back long hair to prevent any

follow these safety rules

equipment.

fully.

U A L

connecting

Always disconnect

unit.

grounded at all times.

Sealer

Check fo

ose-

Check for all

2

Page 4

W H D F I N S T R U C T I O N M A N U A L

Never touch the heating element(s) with bare hand while the sealer is plugged into a power source,

in operation or just finished operation. Touching heated areas may cause fire and/or severe burns.

While machine is in operation, do not place fingers, tools, or other foreign objects on or into the

machine. Do not place hands or fingers near pinch points. Do not touch machine while it is in

operation. Perform all procedures carefully and watch where hands and fingers are at all times.

The sealer is not water resistant or water proof. Spraying down the machine will damage machine

or cause electrical shock. Do not submerge the sealer into water or liquid.

Do not operate sealer in a corrosive or humid environment.

Always keep the machine clean, lubricated and in good working condition. Follow any

maintenance and lubrication procedures outlined in this manual. Make sure unit is disconnected

from power source before cleaning.

NEVER use any accessories or parts from other manufacturers. Machine should not be altered or

modified using parts that are not genuine authorized parts. Doing so will VOID YOUR

WARRANTY.

When replacing the heating elements, always replace the PTFE adhesive under the

heating element. A worn PTFE adhesive can cause the heating element to break.

The

PTFE adhesive works as a barrier between the body of the sealer and the element. Never allow

the element to come in direct contact with the sealer body as that will damage the timer.

Never leave the sealer unattended. Be safe, disconnect the sealer from power source before

leaving work area.

Always keep out of reach of children and pets.

Close supervision is necessary when any appliance is near persons with reduced physical, sensory

or mental capabilities or lack of experience and knowledge . This sealer is NOT to be used by

children or by persons with reduced physical, sensory or mental capabilities or lack of experience

and knowledge.

DO NOT use the sealer outdoors.

DO NOT use the sealer while under the influence of drugs, medications or alcohol.

SAVE THESE INSTRUCTIONS - REFER TO THEM OFTEN AND USE THEM TO INSTRUCT

OTHERS.

3

Page 5

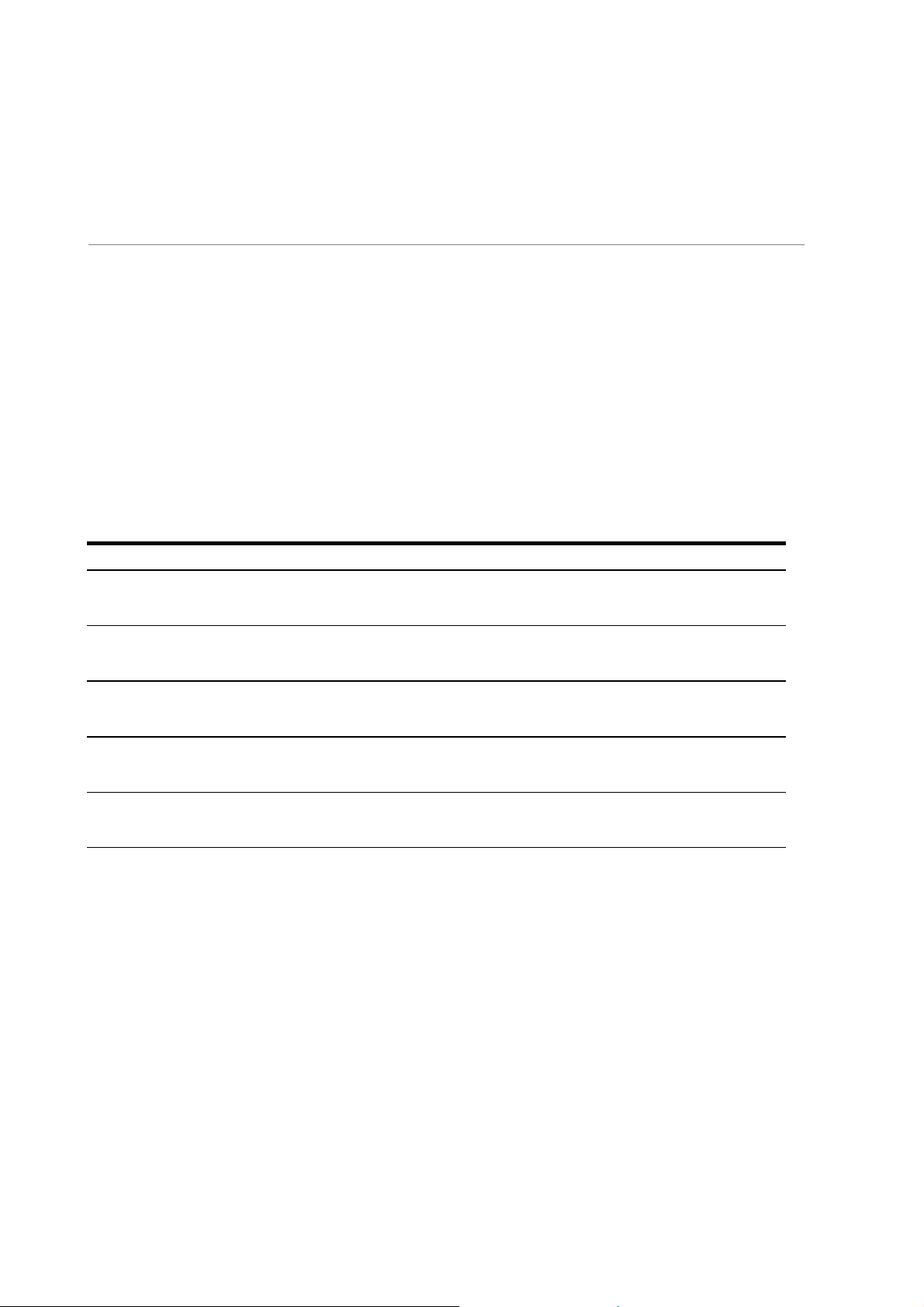

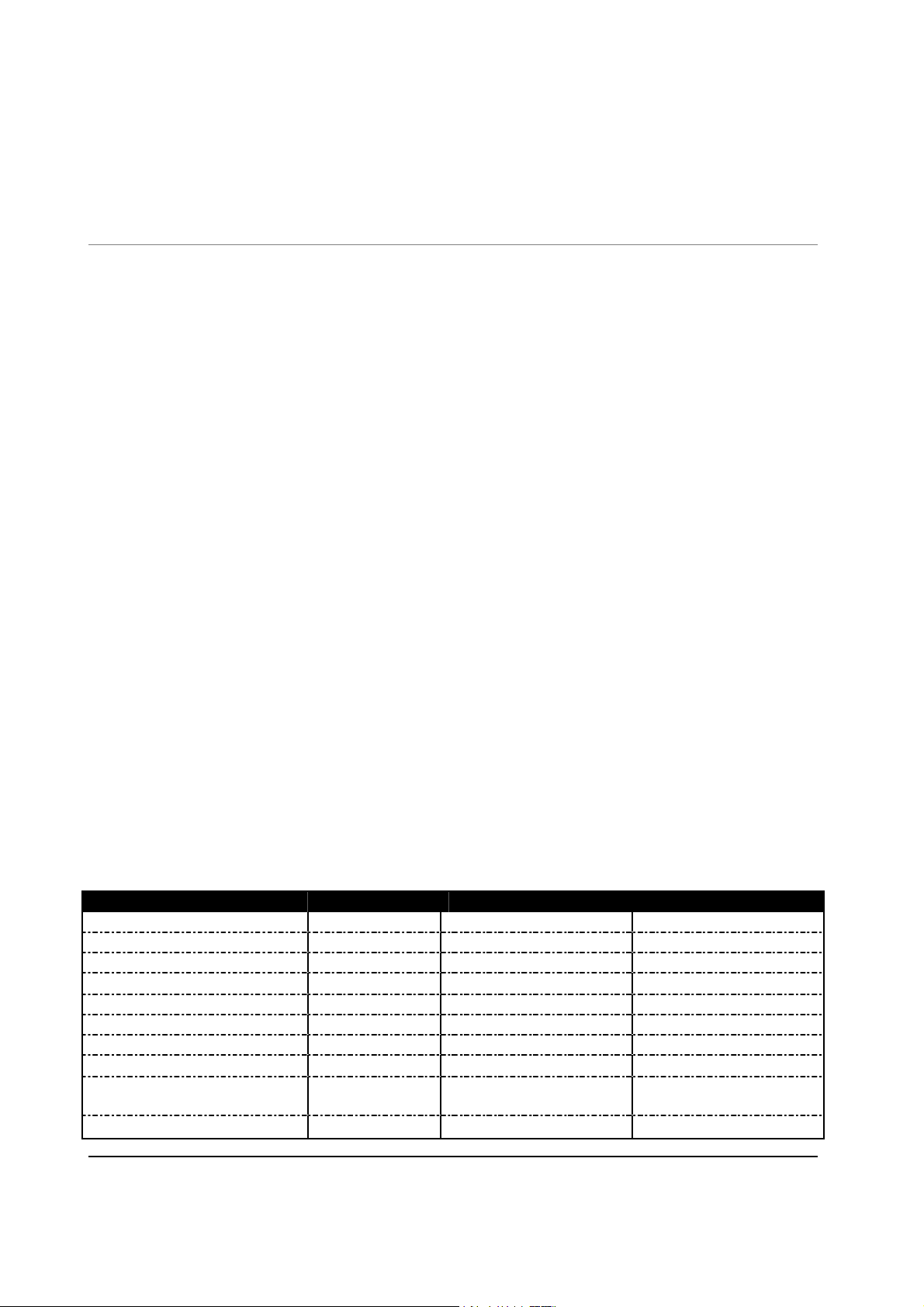

W H D F I N S T R U C T I O N M A N U A L

4

W-300T

W-450T

W-600T

Power

110V/60Hz

110V/60Hz

110V/60Hz

Watts

1000W

1900W

2800W

Sealing Length

/ Width

11.8"

/ 5mm

17.6"

/ 5mm

23.4"

/ 5mm

Standing Height

33 1/2"

33 1/2"

33 1/2"

Working Table Dimensions

12" x 6"

12" x 6"

12" x 6"

Tray Adjustment Height

Up to 6.5"

Up to 6.5"

Up to 6.5"

Throat Depth

1 1/2"

1 1/2"

1 1/2"

Dimensions

13" x 14" x 34"

21" x 14" x 34"

26 1/4" x 14" x

34"

Shipping Dimensions

21" x 20" x 12"

26" x 20" x 12"

33" x 20" x 12"

Gross Weight

34lbs / 29lbs

45lbs / 29lbs

49lbs / 29lbs

Basic

Introduction

W-Series double impulse foot sealers are ideal for high volume poly bag and other thermoplastic sealing.

Equipped with top and bottom heating elements, our double impulse sealers can seal thicker

thermoplastic materials up to 20mil in total thickness. Single/double sealing switch selector provides the

sealer with the flexibility to seal different types of materials. The sealer allows you to keep both hands

free for quicker and more accurate sealing.

Features of the W-Series Double Impulse Foot Sealers

Y ourfootsealerisequipped witha wide range ofstandard featuresand capab ilities.

Impulse sealing - no warm up time needed

Plug-in electronic timer for variable control

Single or double sealing switch selector

Heavy duty all metal construction

Sits on rectangular stand for stability

Adjustable work table height

Optional: Taller stand and tension rod available adding 10" height

Manufacturer spare parts kit includes: 2 heating elements

How Do W-Series Double Impulse Foot Sealers Work?

Our W-Series double impulse foot sealers fire a short burst of electricity through a

Principles

Place material on lower

jaw and activate

footboard

specially designed heating wire to weld thermoplastic materials together. The

length of the seal time will depend on the sealing characteristics of the bag being

sealed. The sealing process is simple: The operator places the bag between the

sealing jaws and presses the footboard to activate the unit. The operator retrieves the sealed bag and

repeats the process. Our W-Series double impulse sealers utilize twin heating element wires, one on the

upper sealing jaw and one on the bottom sealing jaw providing greater heat penetration for sealing

through thicker materials (up to 20mil total thickness).

Specifications

38" x 19" x 10"

38" x 19" x 10"

38" x 19" x 10"

Page 6

W H D F I N S T R U C T I O N M A N U A L

5

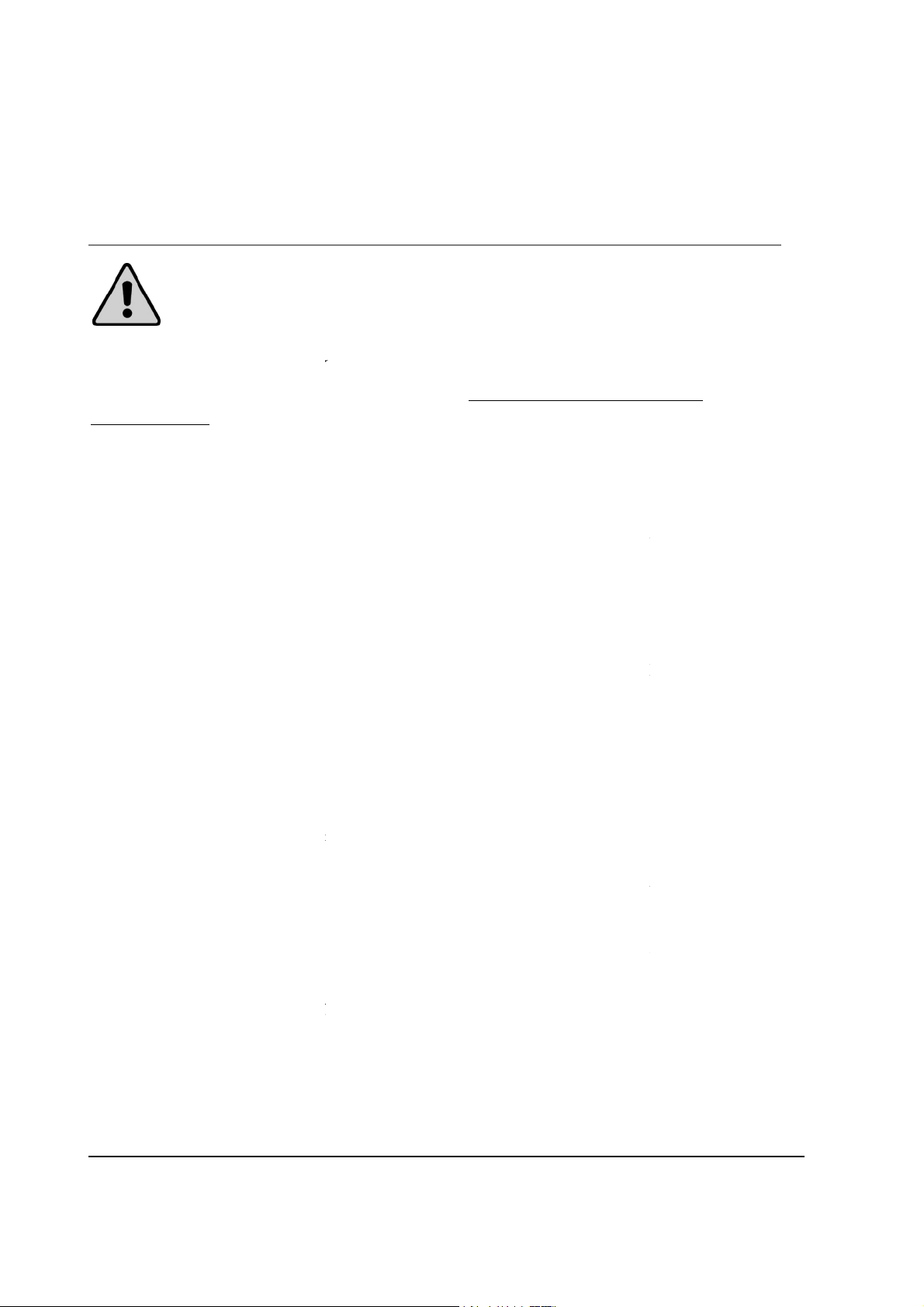

Getting to Know your Foot Sealer

W-Series Double Impulse Foot Sealers are simple and efficient sealing machines.

ControlP anel

P lug-InT im er

Adjustable t imerfor

various materi al

thic knesses

S ealA rea

Place mat eri al to be

sealed be tween up pe r

and lower jaws

P ow erS w itch

Turn offw hen sealer is

S ingle/Double S witch

Adjust work table he ight

not in use

Choose bet ween single

or double i mp ulse

sealing based on

materi al thickness

W orkingT able

as needed

FootBoard

Press down on foot

board to activate sealing

proce ss

Figure 1. W-Series Double Impulse FootSealer Overview

Page 7

W H D F I N S T R U C T I O N M A N U A L

6

Operating your Sealer

Assembly Instructions

Figure 2. Double Foot Assembly Diagram

1. Position the pedestal on the floor standing upright.

2. Mount the complete sealer head to the top of the pedestal and attach with four screws.

3. Bring the upper jaw down and position the small pulling pole/plate set (Figure 8, Item #12A)

through the pressing spring (Figure 8, Item #12B).

4. Gently push the upper jaw to meet the lower jaw. While jaws are compressed, reach under the

unit and hook the pulling pole (Figure 8, Item #5). onto the small pulling pole/plate set.

5. With jaws still compressed, lift up the foot pedal to a 45˚ angle and slide the metal foot pedal rod

onto one of the two pre-molded slots. This will create tension on the foot pedal and cause the

pedal to stand upright at 45˚.

6. Sealer is now ready to operate.

7. To install the optional working plate and table, remove the screws from bottom sealing jaw and

install the working plate and table.

Page 8

W H D F I N S T R U C T I O N M A N

Operation

Before operating, check the heating element, PTFE cover, PTFE adhesive and the

into the correct receptacle (12

Select single or double impulse sealing using the switch selector. Us

when sealing thicker materials.

Set the timer knob to the lowest setting. Always start with a low setting and increase gradually as

Place material to be sealed under the upper jaw and press down on the foot board gently, but

light found on the timer will turn on

, keep pressing the foot board for an additional 2

a high quality seal, seals must cool under pressure. We usually recommend a congeal

setting of at least 2x that of the heat setting but every bag will have variations. Thicker

ll require a longer cool (congealing) time.

Tips for Successful Sealing

If the seal is broken or damaged, decrease the sealing time.

If the seal is not fully welded, increase the sealing time.

If the sealing material sticks to the sealing pad, decrease th

If the width of the seal is not perfect or does not match the size of the element, increase the

Always keep the sealer clean. Remove any residue found on the platform and PTFE cover. Silicone

is purpose.

When replacing the heating elements, always replace the PTFE adhesive under

the heating element. A worn PTFE adhesive can cause the heating element to break.

PTFE adhesive works as a barrier between the body of the sealer and the element

ent to come in direct contact with the sealer body as that will damage the timer.

sionally check the condition of the silicone rubber for wear or burns. A damaged silicone

rubber will affect the quality of the seal.

turn off the power or unplug the unit before replacing any parts.

7

e double impulse sealing

when sealing time is complete.

1.

silicone rubber.

U A L

2. Insert the power cord

3. Turn the power switch on.

4.

5.

needed.

6.

firmly. The UP

7. When UP light turns on

materials wi

1.

2.

3.

4.

congealing time.

0V).

-3 seconds. For

e congealing time.

5.

spray may be used for th

6.

elem

7. Occa

8. Be sure to

The

. Never allow the

Page 9

W H D F I N S T R U C T I O N M A N U A L

8

W-300T

W-450T

W-600T

Maintenance

The following maintenance procedures should be followed to ensure the longevity of your W-Series

double impulse foot sealer.

Inspection and Cleaning

1. Inspect your machine daily.

2. Use a clean cloth to remove any plastic residue remaining on the PTFE cloth.

3. When replacing the elements, always check the condition of the bottom PTFE tape.

4. Check the condition of the silicone rubber for wear and burns. A damaged silicone rubber will

affect the quality of the seal.

Replacement Kit Instructions

Our W-Series double foot impulse sealers will require new heating elements and PTFE from time to time.

Heating elements will break through wear and tear. A good rule of thumb is to replace the PTFE adhesive

every time you change your heating element. The PTFE cover prevents the plastic or other thermoplastic

material you are sealing from sticking to the heating element.

Replacement kits are available from your distributor. Kits include (2) heating elements, (2) PTFE adhesives,

and 2ft long roll of PTFE cover. For replacement kit part #s, refer to your model #.

Replacement Kit RK-12FD-W-300T RK-18FD-W-450T RK-24FD-W-600T

Heating Element HE-12-5-W-300T HE-18-5-W-450T HE-24-5-W-600T

PTFE Adhesive TA-12 TA-18 TA-24

PTFE Cloth (1ft. roll) TR-12 TR-18 TR-24

Silicone Rubber

(notincluded inRK)

SR-W-300T SR-W-450T SR-W-600T

Page 10

W H D F I N S T R U C T I O N M A N U A L

9

To install your replacement kit on your sealer, turn off power and unplug sealer.

Removing Worn Parts.

1. Loosen the screws on the PTFE cover plate.

2. Remove the terminal assembly block cover (Figure 8, Item #7a).

Figure 3. Loosenscrewson PTFE plate.

Figure 4. Remove heating element cover.

3. Lift up the PTFE cover to expose the heating element (Figure 8, Item #12).

4. Remove the heating element by unscrewing the element screw (apply pressure to the heating

element with your finger while unscrewing the screw to prevent heating element from twisting.)

5. Peel off the PTFE adhesive under the heating element.

Installing New Replacement Parts.

1. Remove the backing of the liner found on the PTFE adhesive.

2. Apply it to the sealer’s sealing platform. The PTFE adhesive must always extend past the sealing

platform by approximately ¼” to ½” on both ends. Bend down the excess on both ends. (The

PTFE adhesive acts a barrier between the metal body and the heating element. Never allow the

heating element to come in direct contact with the sealer’s body because it will damage the timer.)

3. Place a new element on top of the PTFE adhesive by screwing the element in the heating terminal

assembly block. To attach the element to the other side, lift the latch found on the heating

terminal assembly block to push the block inward and securely screw the element to the block.

Check the element to ensure it is tight and intact.

Page 11

W H D F I N S T R U C T I O N M A N U A L

Figure 5. Screw element in place.

Figure 6. Lift latchon heating block to screw element in place.

4. Cut off any worn out PTFE cover. Ease out enough footage of PTFE cover to cover the heating

element and extend to the front of the PTFE cover plate.

5. Tighten the screws to affix the PTFE cover plate.

6. If a whole roll of PTFE cover needs to be replaced, loosen the multi-star knob (Figure 8, Item

#31) found on the plate for PTFE (Figure 8, Item #30) and remove the PTFE roller (Figure 8,

Item #14). Tape one end of the PTFE cover to the rod and roll up the entire piece. Position the

PTFE cover and rod using the plate for PTFE. Ease out enough footage of PTFE cover to cover

the heating element and extend to the front of the PTFE cover plate.

Figure 7. Loosenmulti-star knobto remove thePTFE roller.

10

Page 12

W H D F I N S T R U C T I O N M A N U A L

Parts Diagram

Figure 8. Spare Parts DiagramOverview

11

Page 13

W H D F I N S T R U C T I O N M A N U A L

Figure 9. Spare Parts Diagram Overview

Item Part # Description Comments

1 Control SetBracket/Skull (18", 24")

2 UpperJaw ( 18", 24")

3 ST-WH Standing Tube

3a STE-WH Standing Tube Extended, 36"

4 WHDF-4 Pedal Base

5 PPS-WH Level Set, Pulling Pole Set

5a PPSE-WH Level Set, 36"

ST+PP-WH Standing Tube + Pulling Pole Set

STE+PPE-WH Standing Tube, Extended, 36" + Pulling Pole Set

6 WHDF-6 Pressing Spring, Small W-00403

6a WHDF-6A Cap Screw and Washer on top of Pressing Spring

6b WHDF-6B UpperBracket including Screws and Washers

7 HTAB-WH Element Spring Hook Unit W-00803

7a WHDF-7a Element Hook Cover

8 Silicone Rubber Holder Plate

8a ExtraStrip for Bottom Silicone Holder - silver

9 SR- Silicone Rubber, 3/8" Flat/no grove

10 HE-specifymodel# Heating Wire5mm

11 TA-specifymodel# PTFE Cover (New Model)

12 W-300T-12 Pressing Spring, Large(W-300T and W-300DAT)

WHDF-12-450/ 600 Pressing Spring, XL (same as WHLF) W-00402

12A WHLF-9A Short Pulling Pole and Plate Set

13 TR-specifymodel# PTFE Cover

14 PTFE Roller, Iron Stick

WHA-18a Iron Stick 300 (WHA / WHDF)

WHA-18b Iron Stick 450 (WHA / WHDF)

WHA-18c Iron Stick 600 (WHA / WHDF)

15 WHA-21 FiberPlate W-030A (same as WHA-21)

16 TRNS-specifymodel# Transformer W-00612

17 PC-WH PowerCord

18 MSW-WHF Lim it/Microswitch MSW-WHF W-00701

19 WHDF-19 Working Adjusting Plate - 6 1/4" x 9 1/2" (W x L)

19A WHDF-19A Working Adjusting Plate Screw Set - (Includes: 2-screws, 4-washers, and 2-wing nuts) - WHA, WHDF

20 WHDF-20 Working Plate- 13 1/2" x 7" (W x L)

20A WHDF-20A Working Plate Screw Set - WHA, WHDF

21 WHDF-21 Fuse Holder, 15A, 125Vac E-00205

22 T-W-Double Timer, E-009A T-W-300T/450T/600T, SH2-Y1-2S

23 WHLH-7 Power Switch, 3P, 15A/125V (W-Series)

24 WHDF-24 Lamp for Double Wire, Red

25 WHDF-25 Single/Double Select Switch, 4P E-00102

26 WHDF-26 Lamp for Single Wire, Yellow

26a WHDF-26a Lamp for Single Wire, Orange

27 PTFE Cover Fixed Plate

28 WHDF-28 Foot BoardB racket

28A WHDF-28a Screws for Pedal

29 FB-WH Foot Board

30 WHA-14 Pl atefor PTFE Sheet (Clip) (W-Seri es)

31 WHA-15 Multi Star Knob (W-Series)

32a Fuse-15am p Fuse 12" 15 amp, E01904

32b Fuse-20amp Fuse 18" 20 amp

32c Fu se-25amp Fuse 24" 25 amp

33a W-600T-33A Relay 40A for W-600T

33b W-450T-33B Relay 25A for W-450T

34 WHI-11A Circuit Breaker, 7A

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

specify model # when ordering

12

Page 14

W H D F I N S T R U C T I O N M A N U A L

Troubleshooting

Problem Possible Causes Solution

1. Disconnected power cord

No sealing

Timer lights off

No sealing

Timer lights are on

No sealing

Power light on

Heat indicator off

Burnt PTFE cloth

Broken heating el ement 1. Worn PTFE adhesive 1. Replace PTFE adhesive

Wrinkled seal

Imperfect seal

Burnt seal 1. Seal time is set too high 1. Decrease seal time

2. Power cord is broken

3. Blown fuse

4. Transformer is broken

1. Heating el ement is broken

2. Poor contact at heating terminal

blocks

1. Microswitch malfunction

3. Microswitch out of place

1. Timer malfunction

2. Timer setting too high

1. Seal time is set too high

2. Cooling (congeal) time is too

short

1. Worn PTFE cloth

2. Worn silicone rubber

1. Check or change plug

2. Replace power cord

3. Replace fuse

4. Replace the transformer

1. Replace the heating element

2. Clean, tighten or change the heating terminal

blocks

1. Replace microswitch

3. Adjust microswitch

1. Replace timer

2. Decrease timer setting

1. Decrease

2. Increase congealing time

1. Replace PTFE cloth

2. Replace the silicone rubber

No seal 1. Seal time is set too low 1. Increase seal time

Seal sticking to PTFE cloth

1. Worn or dirty PTFE cloth

2. Worn or dirty silicone rubber

13

1. Replace or clean PTFE cloth

2. Replace or clean silicone rubber

Loading...

Loading...