SeaLand Vacuum Pump User Manual

M-Series

Vacuum Pump

OWNER’S MANUAL

Dometic Corporation

13128 State Rt 226, P.O. Box 38

Big Prairie, Ohio 44611-0038 USA

SeaLand Product Hotline 1-800-321-9886

(8:00 a.m. - 5:00 p.m. ET)

1

TABLE OF CONTENTS

Safety Instructions ............................................ 2

Models .............................................................. 2

Installation Instructions...................................... 2

Maintenance ..................................................... 3

Troubleshooting ................................................. 7

Wiring Diagrams ............................................... 8

Dimensional Specifications................................ 8

Parts List ................................................... 9 - 11

Manufacturer’s One-Year Limited Warranty: .... 12

SAFETY INSTRUCTIONS

WARNING: When using this product, always exercise basic safety precautions including the following:

• Read all instructions before use or installation.

• Never connect this product to any electrical circuit other than the specified voltage, and never exceed the

amperage draw specified in “Electrical Wiring” on page 3.

• Never install, use or service any component of this device in an atmosphere with potentially flammable or

explosive vapors unless specified for explosion-proof atmospheres.

NOTE: EXPLOSION-PROOF COMPONENTS MUST BE WIRED TO NEC CLASS 1, DIV. 2, GROUP D

REQUIREMENTS.

MODELS

PART NUMBER

501200

502400

503200

511500

VOLTAGE HORSEPOWER

12VDC

24VDC

32VDC

115/230VAC

1/2

1/2

1/2

1/2

Also available with optional 3/4 horsepower, explosion-proof and 50 cycle motors.

INSTALLATION INSTRUCTIONS

Preparation

1. Note: Motor is shipped separately in its own carton. Remove motor from carton.

2. Verify that motor shaft key, mounting bolts, and lock washers are included.

3. Be sure motor shaft is clean and free of dirt. Remove any “burrs” that may be present in the keyway of motor

shaft.

4. Remove pump from shipping carton.

5. Do not clean grease from the inside of the input shaft of the gear reducer.

6. Insert key in motor shaft keyway. Align motor shaft key with keyway in gear reducer input shaft.

7. Insert motor shaft until motor fits against flange on gear reducer. Align four (4) clearance holes in the flange

with the four (4) threaded holes in the motor.

8. Secure the motor to the gear reducer using the four (4) 3/8"-16 x 1" hex head screws and lock washers

supplied with the pump.

Mounting the Pump

1. Remove shipping platform from bottom of pump.

2. Set pump in position with inlet and outlet pointing in direction of flow.

3. Secure pump to mounting surface using 1/4" (6mm) diameter or larger fasteners.

NOTE: Due to the unbalanced weight of the pump, it is important that adequate fastener size be used

to secure the pump.

2

Electrical Wiring

It is imperative that adequate wire size and proper over-current protection (fuse or circuit breaker) sizes are used.

The following chart can be used as a guideline. Refer to chart on page 10 for solenoid/relay information.

PUMP VOLTAGE

12 VDC

24 VDC

32 VDC

115 VAC (1 phase)

230 VAC (1 phase)

PUMP MOTOR WIRE SIZE

1/2 HP

6 to 8 ga.

8 to 10 ga.

10 to 12 ga.

12 to 14 ga.

14 to 16 ga.

3/4 HP

3 to 4 ga.

6 to 8 ga.

8 to 10 ga.

10 to 12 ga.

12 to 14 ga.

BREAKER/FUSE SIZE

1/2 HP

50 amp

25 amp

20 amp

10 amp

5 amp

3/4 HP

75 amp

40 amp

30 amp

15 amp

8 amp

MAINTENANCE

ELECTRICAL CAUTION: DISCONNECT POWER SUPPLY TO PUMP BEFORE SERVICING UNIT. FOLLOW

PROPER LOCK-OUT/TAG-OUT PROCEDURES.

Maintenance intervals and normal parts replacement vary widely depending on numerous factors such as

frequency of system use and quality of flush water, etc. The chart below is intended strictly as a general

guideline. Owner discretion and consideration of actual usage must be the first basis for determining proper

maintenance levels.

Maintenance Procedure

Change Oil

Inspect Diaphragm

Inspect Rod Bushing

Inspect Eccentric Pin

Duckbill Valve Replacement

Speed Reducer Replacement

Motor Replacement

Procedure

A

B

C

D

E

F

G

Approximate Maintenance Level

See instructions

Every two years

Every two years

Every two years

Every two years

If needed

If needed

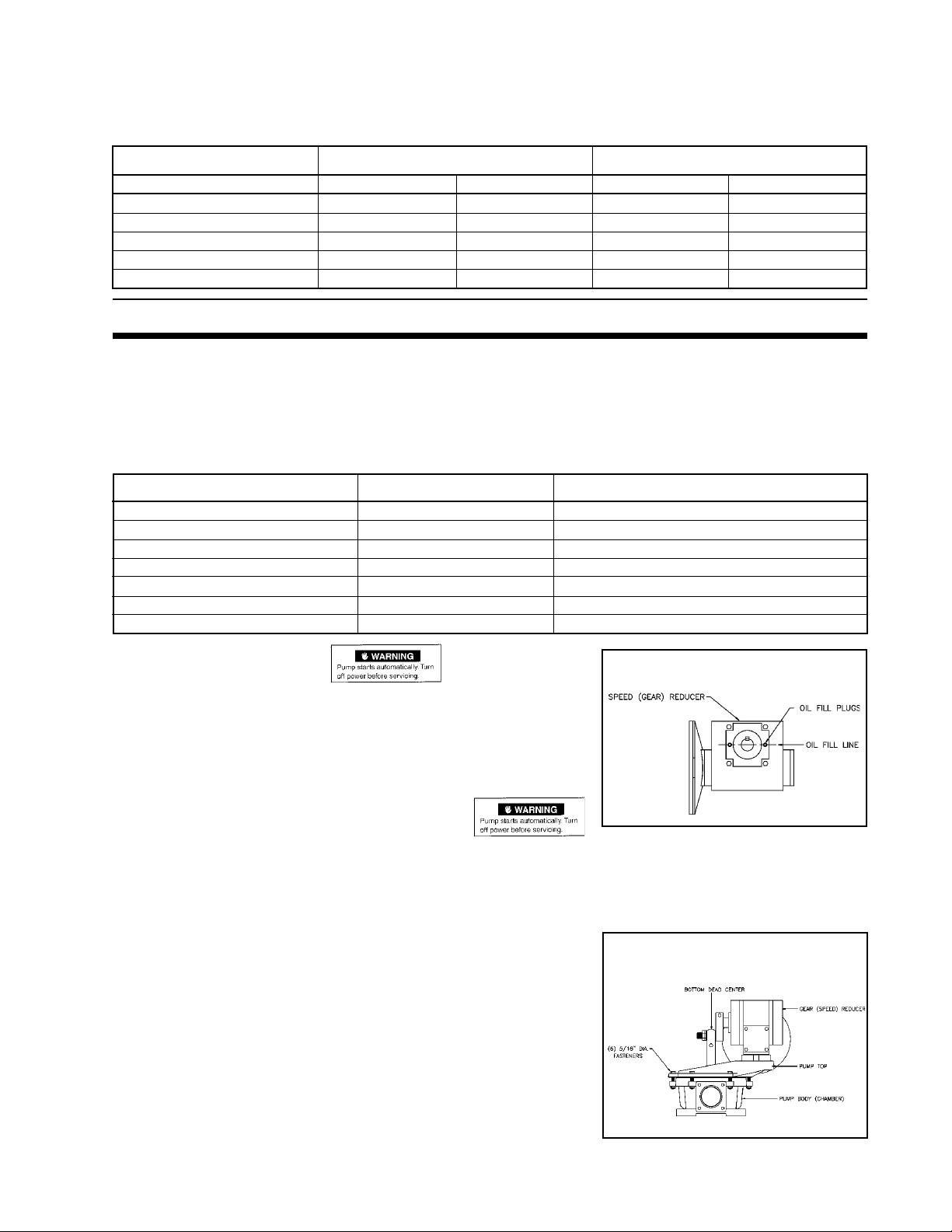

A. CHANGE OIL

The gear reducer oil should be changed after first 50 hours, thereafter

every 200 hours. Drain and fill with 90W oil or equivalent to bottom of

oil level inspection hole (opposite of output shaft). Grease the rod

bushing every 200 hours. (See item 9 on Pump Parts List)

Fig. 1

B. DIAPHRAGM REPLACEMENT

CAUTION: KEEP HANDS AND ALL OTHER EXTREMITIES AWAY FROM ROD AND DIAPHRAGM. FLUSH

THE PUMP WITH CLEAN WATER AND DISINFECTANT BEFORE SERVICING.

When replacing a diaphragm, be sure to follow maintenance instructions B-D.

IMPORTANT: Incorrect alignments and clearances may cause premature diaphragm failure. It is important to insure that proper

alignment is achieved between the eccentric pin and the diaphragm rod. Make sure that clearances are correct between the

diaphragm rod and the eccentric (Fig. 6) and also between the

eccentric and the gear reducer hub (Fig. 7).

To Remove the Diaphragm:

1. Remove pump cover (not used in SaniService applications).

2. Jog motor until rod is at bottom dead center position.

NOTE: See manual rotation method on page 4.

3. Close the maintenance valves (if installed) in the inlet and outlet

piping.

Fig. 2

3

4. Disconnect electrical source to motor, following lock-out/tag-out procedure.

5. Remove the six (6) 5/16" fasteners around the circumference of the pump top.

6. Carefully remove the pump top from the pump body.

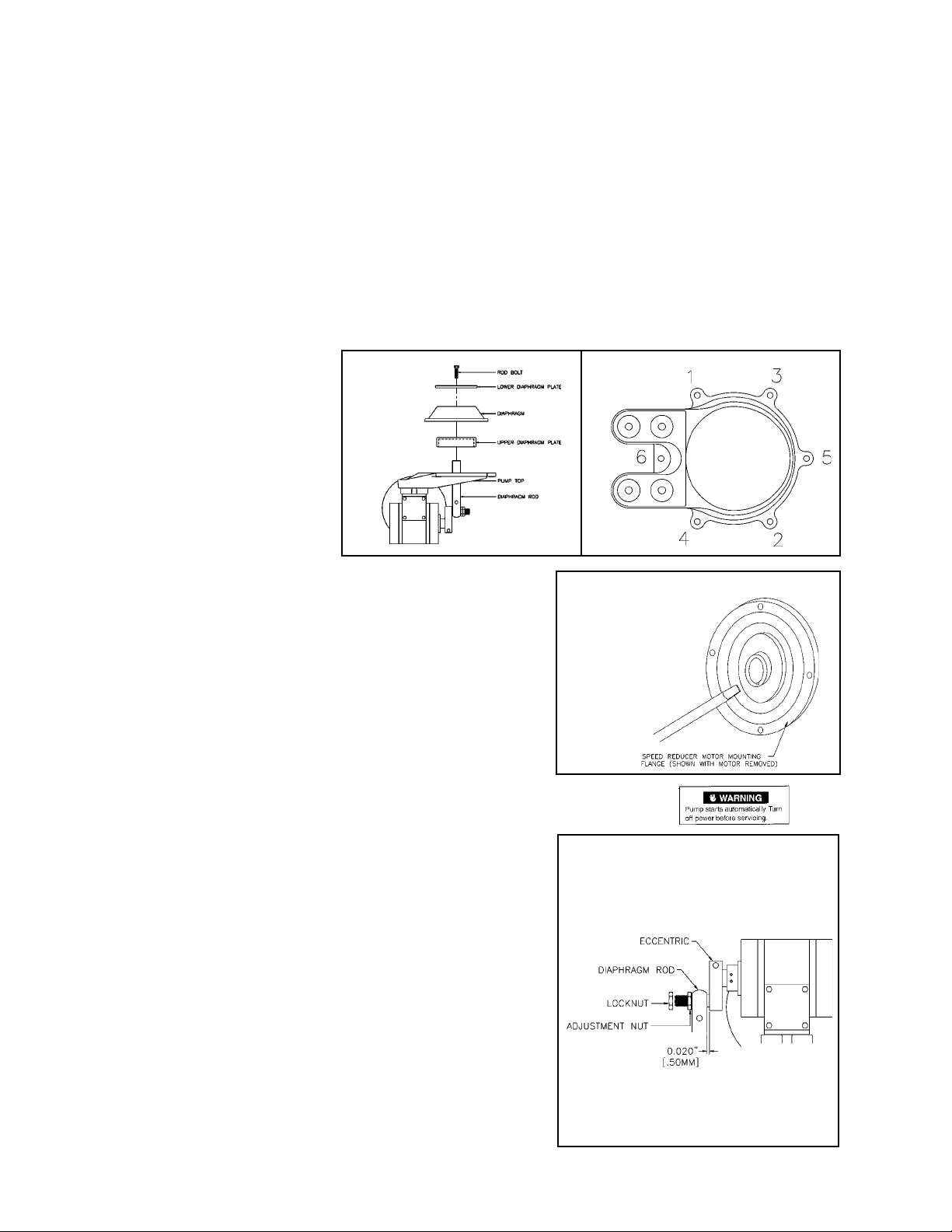

7. Turn the pump top upside down to expose the diaphragm and rod bolt. (See Fig. 3)

8. Remove the rod bolt.

9. Pull the diaphragm away from the rod.

10. Clean the old silicone adhesive from the top and bottom diaphragm plate and bottom of the rod.

11. Clean the old grease (if any) from the diaphragm sealing groove in the pump body.

To Install the Diaphragm:

1. Apply bead of silicone adhesive around the rod bolt hole on both sides of the diaphragm and let cure until the

silicone skins over.

2. Assemble the diaphragm, upper and lower plates to the rod.

3. Apply silicone grease to the

diaphragm sealing groove in the

pump body.

4. Carefully install the pump top and

diaphragm into the pump body.

Make certain the diaphragm is

properly seated in the groove in

the pump body.

5. Tighten the six (6) 5/16"

mounting bolts in a criss-cross

pattern as shown. (See Fig. 4)

Fig. 3

Fig. 4

Manual Rotation Method:

1. Remove motor from speed (gear) reducer.

2. Wedge a large flat-bladed screwdriver or pry bar into hollow input

shaft keyway of speed reducer and rotate until rod is at bottom

dead center. (See Fig. 5)

C. ROD BUSHING INSPECTION AND REPLACEMENT

NOTE: The rod and bearing must be replaced as an assembly

because the bearing is pressed into the rod using special

equipment.

To Inspect:

1. Follow steps 1 through 11 in “To Remove the Diaphragm” on

page 3.

2. Remove the hex nuts from the eccentric pin and slide off the old

rod.

3. Inspect the bushing in the rod for wear by measuring the bushing

diameter. If worn beyond the service limits, replace the rod and

bushing.

New: 0.625" [15.88mm]

Service Limit: 0.630” [16mm]

Fig. 5

Fig. 6

To Install:

1. Lubricate the bushing and eccentric pin with anti-seize compound.

2. Slide rod onto the eccentric pin. (See Fig. 6)

4

Loading...

Loading...