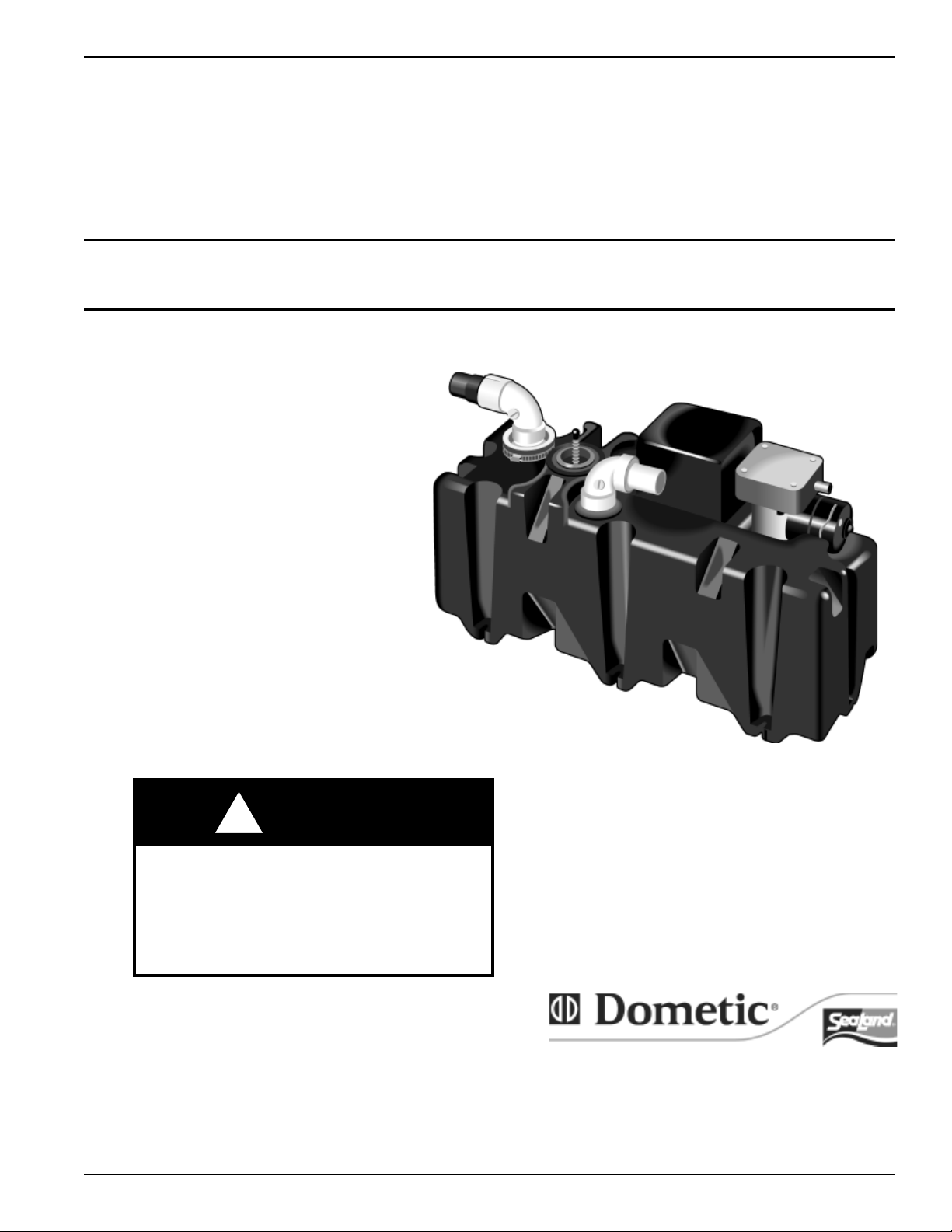

SeaLand VACUUM HOLDING TANK User Manual

VACUUM

HOLDING TANK

OWNER’S MANUAL

WARNING

!

This manual must be read and understood before installation, adjustment,

service, or maintenance is performed. Modification of this product

can result in property damage.

Dometic Corporation • Sanitation Systems

13128 State Rt 226, PO Box 38

Big Prairie, OH 44611

SeaLand Product Customer Service: 1-800-321-9886

(8:00 a.m. - 5:00 p.m. ET)

1

TABLE OF CONTENTS

Product Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Major Components . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Principles of Operation . . . . . . . . . . . . . . . . . . . . . . . 3

System Layout . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Component Locating Procedure . . . . . . . . . . . . . . . . 4

Key Installation Points . . . . . . . . . . . . . . . . . . . . . . . . 4

Installation of Components . . . . . . . . . . . . . . . . . . . . 5

Winterizing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . 6 - 7

Dimensional Specifications . . . . . . . . . . . . . . . . . . . . 7

Manufacturer’s One-Year Limited Warranty . . . . . . . 8

PRODUCT FEATURES

The Vacuum Holding Tank (VHT) brings the

technology, comfort and efficiency of Dometic’s

renowned VacuFlush® vacuum sanitation systems to

smaller boats in an easy-to-use, and easy-to-maintain

package.

Simple Installation

• All system components are “installation ready.”

• No solvent bonding is required.

• Removable hose insert fittings make hose installation

simple.

• Vacuum pump and switch are pre-wired at factory.

• Easy to mount.

Reliability is Built-In

• No impellers or macerators. Motor can run without

burning up.

MAJOR COMPONENTS

The Vacuum Holding Tank (VHT) system consists of a

VacuFlush toilet or EcoVac™ toilet and the Model VHT

Vacuum Holding Tank. The VHT is a unique combination of the vacuum tank, vacuum pump and holding tank

components used in a standard VacuFlush toilet

system.

Each toilet series consists of several models, allowing

for a multitude of installation variations: a rear discharge

standard height unit, a bottom discharge standard height

unit, and a bottom discharge low-profile unit designed to

fit on a platform.

The vacuum toilet must be purchased separately;

it is not included with the VHT.

VACUUM HOLDING TANK (VHT)

The VHT produces and stores vacuum between flushes.

The vacuum holding tank is made of highly durable polyethylene. The pump is integrally connected with

the vacuum tank. The vacuum pump is electric and draws

only 2 to 4 amps of current at 12 VDC.

One vacuum holding tank is required for each toilet.

Two or more toilets cannot be connected to one VHT.

The VHT contains the pre-set pressure differential switch

control that turns the pump on and off when the proper

level of vacuum is created.

A unique component on the VHT is the Vacuum Relief

Valve (VRV). The VRV prevents excessive vacuum from

accumulating in the tank. The VRV is calibrated to open

at 13" of vacuum and close at 11" of vacuum. This feature is beneficial during pump-outs.

The VHT system comes equipped with a full level float

switch. This float switch is wired directly to an automatic

shutdown relay. The relay prohibits the vacuum pump

from generating vacuum once the tank is full. A full level

indicator light should be wired to the full float, by the

installer. If a full level indicator light was not installed,

order part number 318714 from Dometic. The indicator

light is not part of the basic system.

VACUUM HOSE

To complete a VacuFlush installation, OdorSafe® Sanitation Hose or rigid PVC pipe (Schedule 40 or heavier)

must be used. OdorSafe hose is specially formulated to

provide up to 16 times greater resistance to malodors

than other “no-odor” marine hoses.

VACUUM TOILETS

The VacuFlush 500 series features a large householdsize bowl and seat. The VacuFlush 1000 series also

features a deep bowl with an adult-sized seat. The

EcoVac series offers space-saving models with adultsized seats. All come with an attractive, easy-to-use flush

pedal.

2

PRINCIPLES OF OPERATION

VacuFlush systems use a small amount of water (one

pint to one quart) and the vacuum that is generated by

the vacuum pump to flush. Each toilet must be connected to a pressurized water system. Fresh water is

recommended and will result in an odor-free bathroom.

If seawater is used, the water should be filtered.

No complicated user instructions are required. Lifting the

flush lever adds water to the bowl. Pressing the flush

lever (or pulling the flush lever on a 106 toilet) opens a

mechanical seal that allows the vacuum force to pull the

waste from the bowl as clean water rinses the bowl. The

vacuum moves the waste (at approximately 7 feet [2.1

m] per second) through a one-inch opening in the toilet

base. Incoming air fragments the waste as it passes

through the base opening. This process eliminates the

need for macerators or mechanical motors in the toilet

base.

Next, the waste is transferred into the Vacuum Holding

Tank (VHT). System vacuum is monitored by a vacuum

switch that is located on the outside of the VHT. When

the switch senses a drop in vacuum in the system, it

automatically signals the pump to energize and bring

the vacuum back to operating level. This process is normally completed in about one minute.

In a properly operating system, the stored vacuum will

“leak” down between flushes, causing the vacuum pump

to run for a short period. The pump should not run more

than once every three (3) hours after the last flush.

An “On-Off” night switch can be installed to silence the

vacuum pump during sleeping hours. The VacuFlush

Status Panel, an optional accessory, features an integral circuit breaker that provides a convenient night

switch.

IMPORTANT: Before pumping out the VHT, it

is recommended that the power to the system be

turned off. Then, flush the toilet. This releases the

stored vacuum in the tank, thus, allowing the

dockside pump to empty the waste out more easily.

If the dockside pump has low suction capability,

you may need to flush the toilet a second time

during the pump out.

The Vacuum Relief Valve (VRV) will automatically open

at 13" of vacuum and is spring loaded to close at 11" of

vacuum to prevent leaking during normal operation.

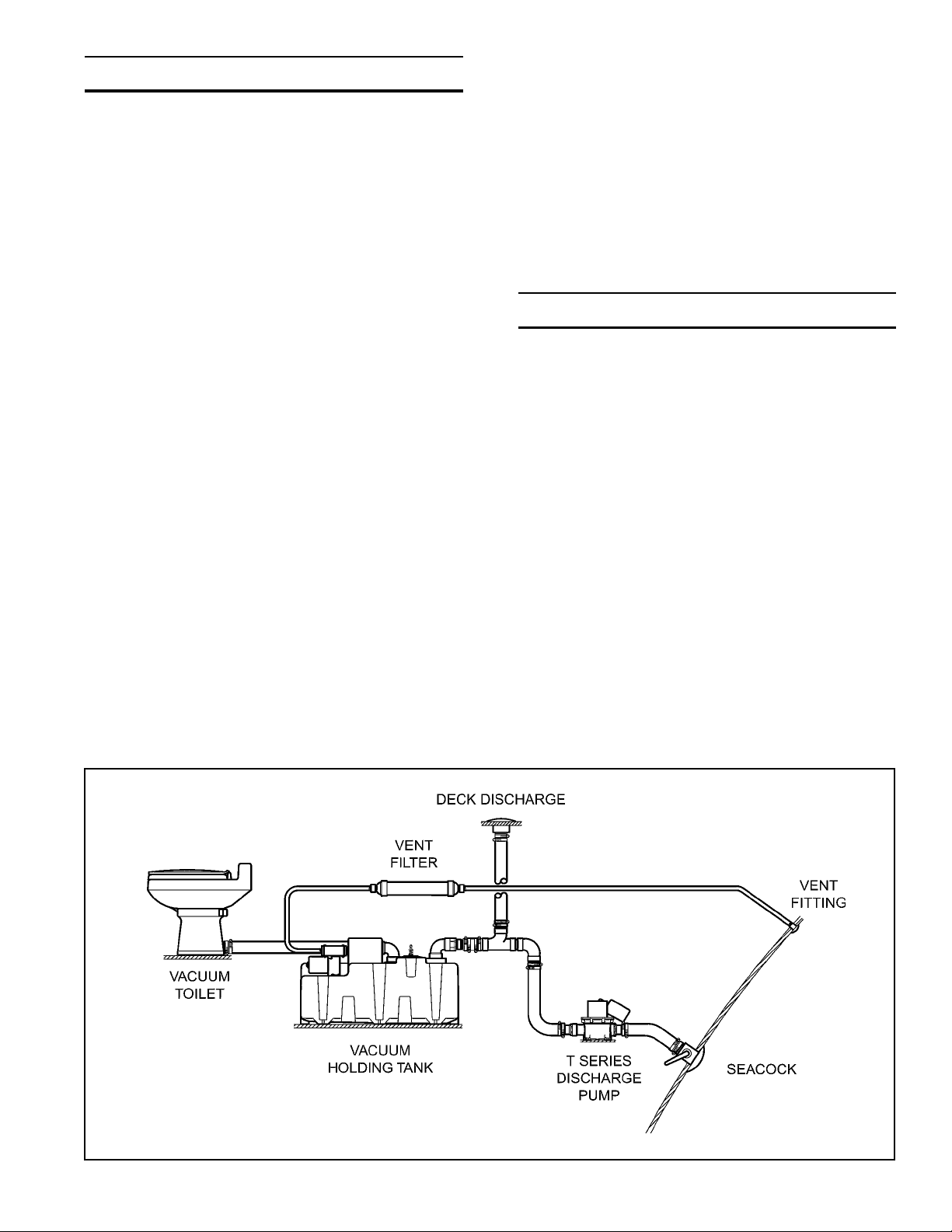

SYSTEM LAYOUT

The Vacuum Holding Tank (VHT) system can be installed

on most boats that presently use a portable, manual or

electric toilet. The following procedure will be helpful:

1. Review the typical system layout to get a general

idea of how the system will operate and what discharge

options will be considered (see Figure 1).

2. Draw or obtain a layout of the boat which allows the

location of head compartments, bulkheads, engine space,

tanks, through-hull fittings, etc. This layout should include

top views and side views and show relative distances

and heights with reasonable accuracy.

3. Use the information in the Component Locating

Procedure section to help select the best locations for

your boat layout.

4. Routing of vacuum hose should be considered when

selecting a location for the toilet and the (VHT). A

maximum of 20 feet (6.1 m) of hose can be used between the toilet and the VHT.

5. Before starting the actual installation, carefully review the Key Installation Points.

Figure 1

3

Loading...

Loading...