SeaLand Dometic VacuFlush Series Installer's Manual

VacuFlush

®

Installer’s Guide

This book belongs to ________________

0

VacuFlush

SeaLand recommends that the

OEM label key sanitation system

components: such as vacuum

generators, wye valves and

directions, seacocks, etc.

®

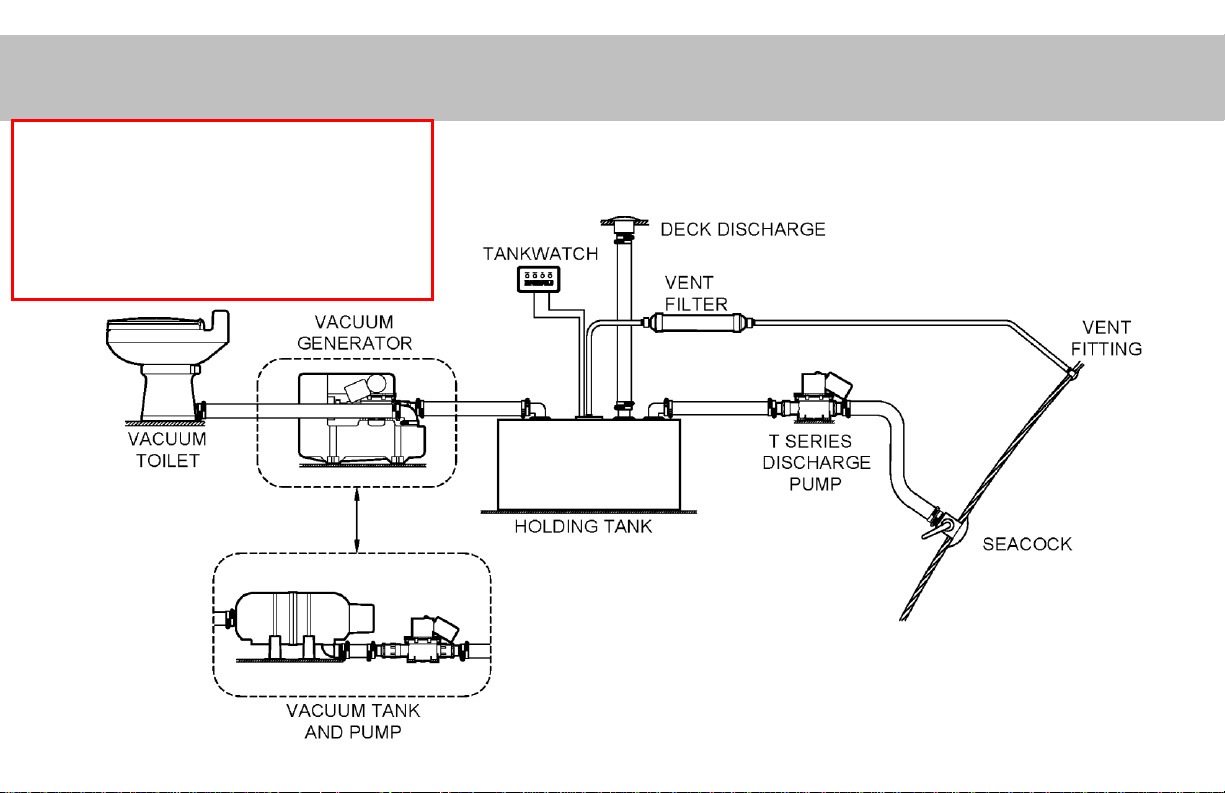

System Components

VacuFlush® toilet systems are not difficult to

install BUT certain steps are CRITICAL and

must be followed as described. These areas

are highlighted throughout this guide in RED.

1

VacuFlush

®

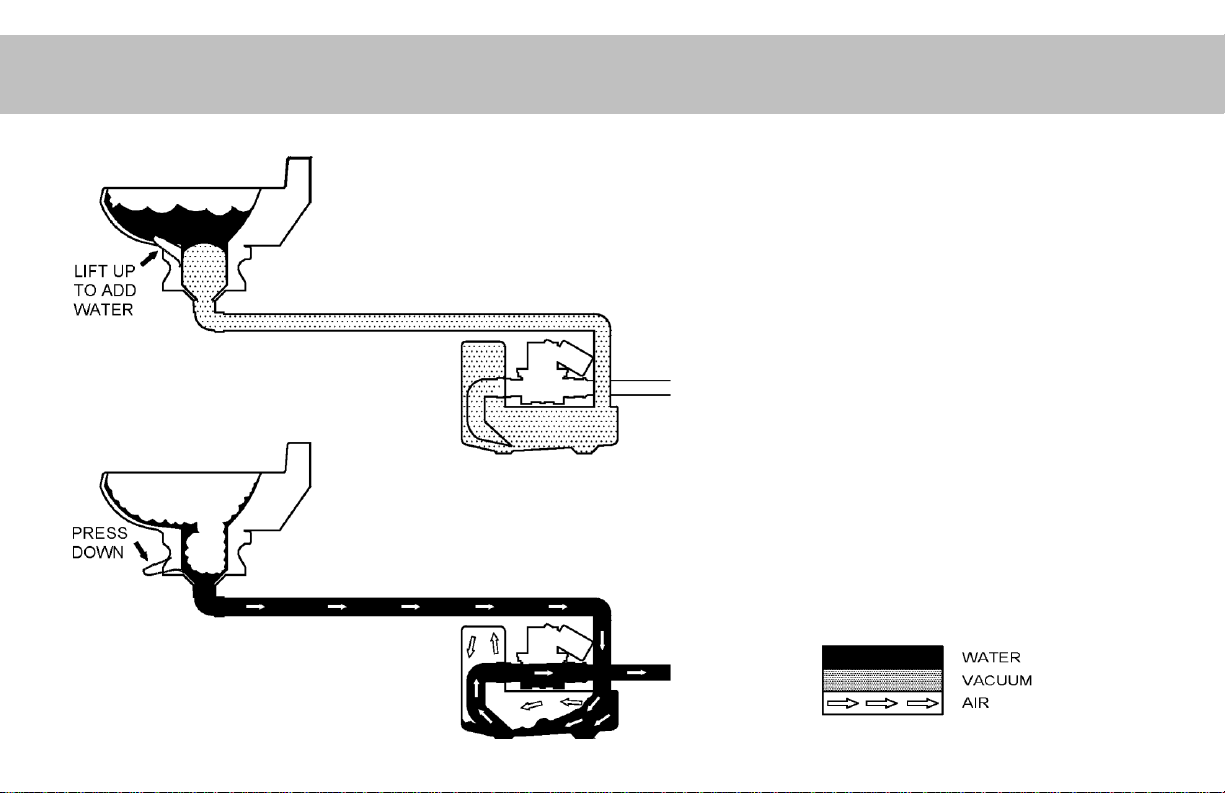

Principles of Operation

• Uses pressure difference between

atmosphere and vacuum in the tank.

• The vacuum pump is activated by the

loss of vacuum in the vacuum tank.

• Vacuum is maintained at all times.

The “leak-down” time period should be

approximately three hours. (The

pump should not come on within a

three hour window of non-use.)

• Recharging vacuum takes less than a

minute.

2

Note: Magnum Opus and VHT Installations are shown in other Installation Guides

VacuFlush® System Components

VacuFlush® Principles of Operation

Table of Contents ………………….

Section I: Toilet Installation …….

• Critical Mounting Clearances ………..

• Standard Discharge Configurations ...

• Toilet Base & Through-floor Funnel

Installation Guidelines ………………

• Solvent Bonding ……………………….

• Incoming Water Supply ………………

• Keep Debris Out of the Toilet ………..

• CRITICAL GUIDELINES …………….

Section II: Vacuum Sources …….

• Vacuum Pump Locations …………….

• Supporting the Vacuum Hose ……….

• S-Series Pump ………………………..

• Sailboat Pump Mounting ……………..

• Vacuum Tank Do’s and Don’ts ………

• Accessibility ……………………………

• CRITICAL GUIDELINES ……………..

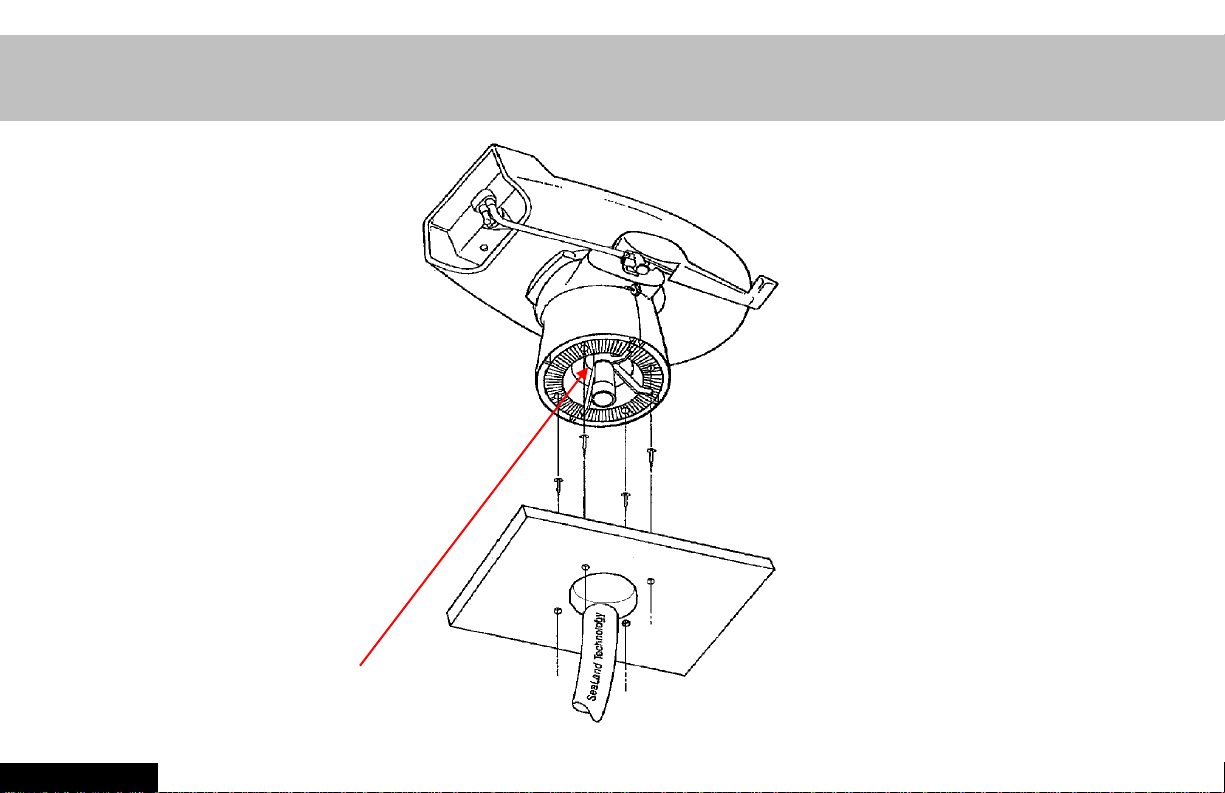

Arrow indicates

extremely

critical items

Table of Contents

Section III:

1

Hose and Piping Layout ………….

2

• Piping Runs to the Vacuum Source ….

3

• Bend Limits …………………………….

4

• Hose Run Simplification ……………….

5

• Avoiding Heat Sources ………………..

6

• Routing Hose and Piping ……………..

• Making Hose Connections …………….

9

11

12

13

14

15

16

17

18

19

20

21

25

–Hose Heaters & Assembly …………………

–Lubrication …………………………………..

–Assembly Tips ………………………………

• Avoiding Malodors ……………………..

• SeaLand Fitting Information …………..

• CRITICAL GUIDELINES ……………..

Section IV: Holding Tanks ……….

• Simplified layout ……………………….

• Holding Tank Locations ……………….

• Diptubes ………………………………..

• Vent Filters ……………………………..

• Discharge Pump ……………………….

• Level Indicators ………………………..

• CRITICAL GUIDELINES ……………..

Section V: Electrical Guidelines …

• CRITICAL GUIDELINES ……………..

26

27

29

30

31

32

34

34

35

36

37

39

42

43

44

46

48

49

50

51

52

53

53

Section VI: System Checkout .

• Power On Check ………………….

• Winterizing the System …………..

• System Leak Rates ……………….

Section VII:

System Troubleshooting ……

1. Water will not stay in the bowl ………

2. Plastic flush ball will not close ………

3. Plastic flush ball will not open ………

4. Water doesn’t shut off in toilet ……..

5. Water does not enter toilet properly .

6. Cannot lift flush lever to add water

to the bowl …………………………….

7. Water is leaking from the water

valve assembly ……………………….

8. Water is leaking from the rear of

toilet……………………………………

9. Water is leaking from the base/bowl

Connection ……………………………

10. Pump is running too often ………….

11. Pump runs continuously …………….

12. Pump will not run …………………….

13. Vacuum pump runs too slowly, very

hot, or blows fuses frequently ……..

14. Toilet will not flush …………………...

15. Pump leaks water ……………………

54

55

56

57

58

58

59

59

60

61

62

62

63

63

64

65

66

67

68

69

3

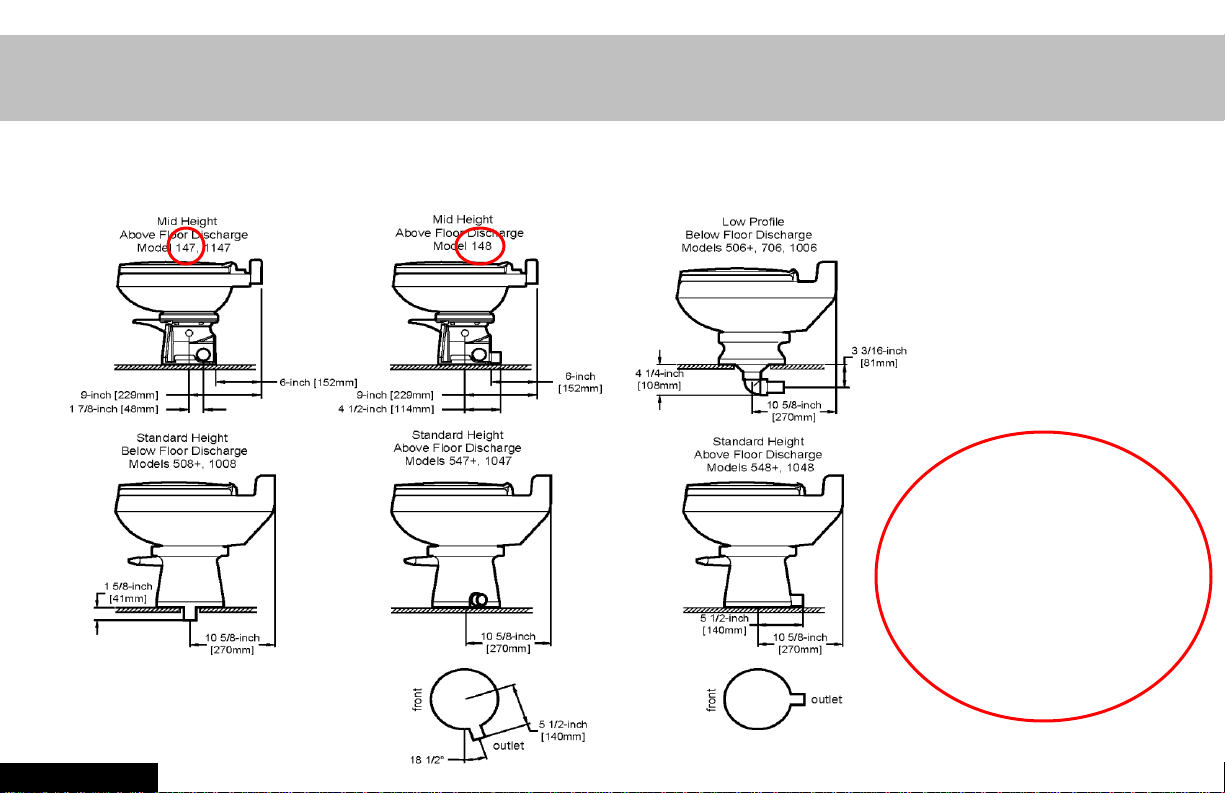

Section I: Toilet Installations

SeaLand toilets are available in many different outlet configurations.

Please review a SeaLand brochure for current model information.

HINT: If the Model

Number has a zero in

the middle, the toilet

discharges through the

floor.

For models

with 147 or 148

the connection

must be a hose

connection, not

a glued joint.

Section I

4

REAR

SIDE

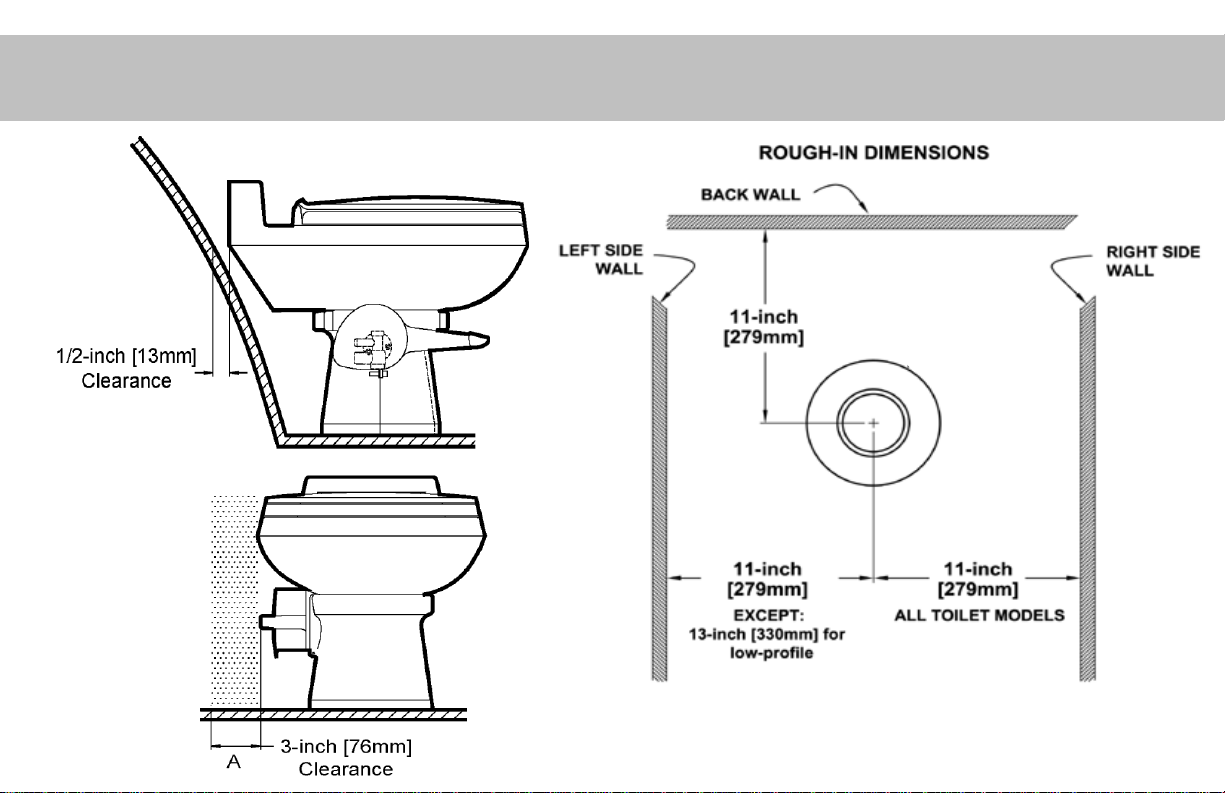

Critical Toilet Mounting Clearances

Location of the floor hole

for the toilet discharge

5

Above the Floor Discharge - Side and Rear

These joints require

SOLVENT BONDING per

procedure on page 11!

Cannot be used with models

90 Elbow Detail

ending in 147 or 148.

Section I

6

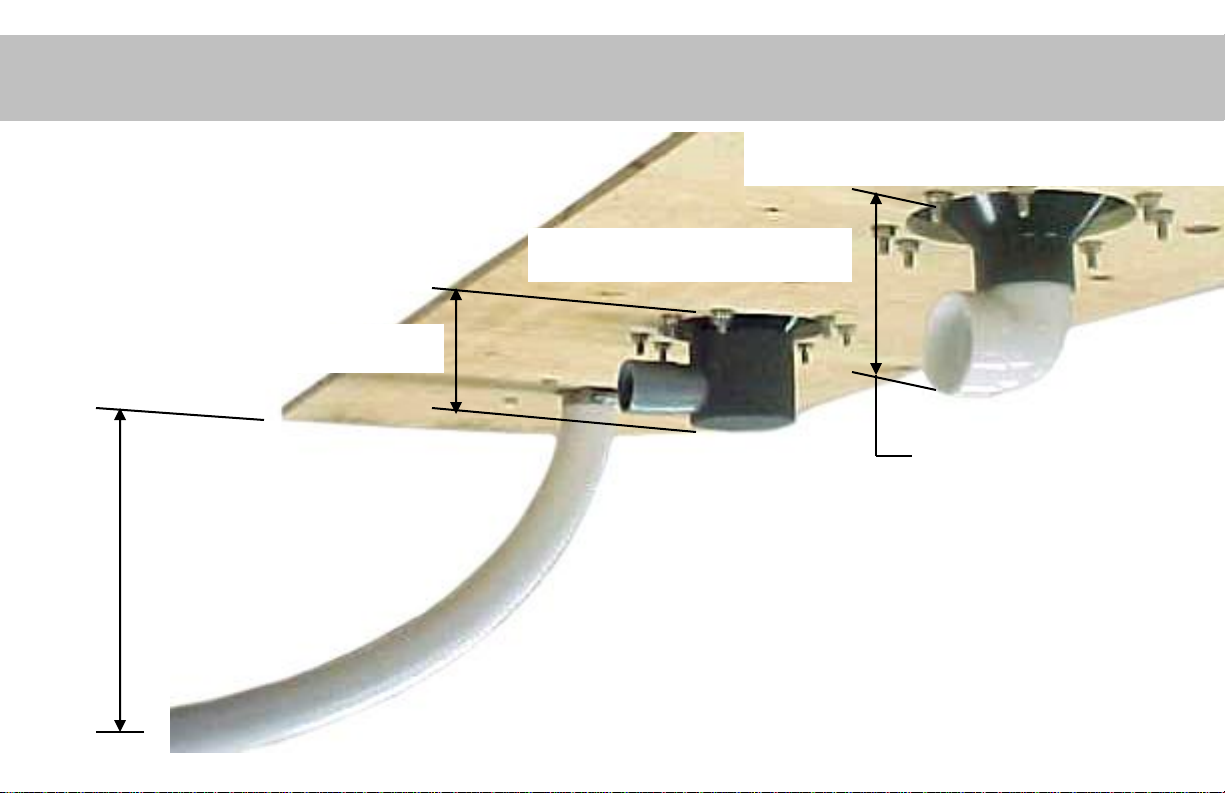

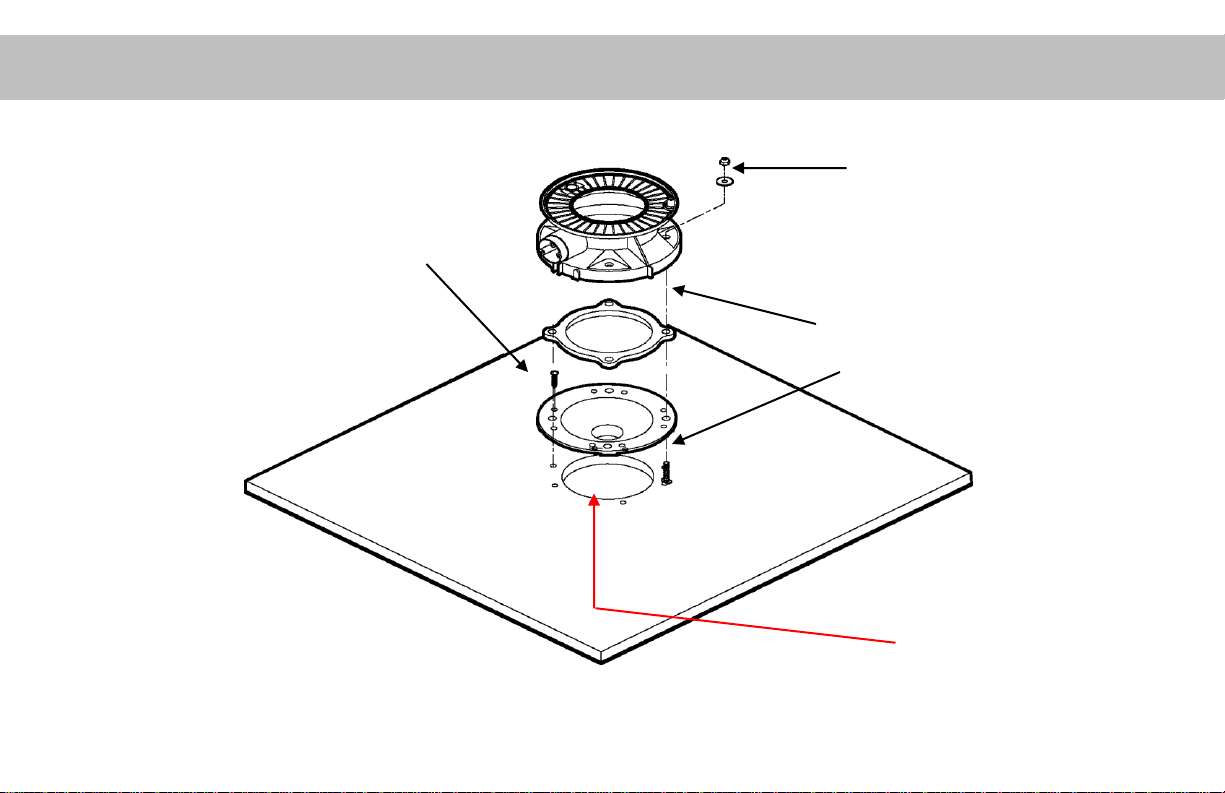

Through Floor Funnel Comparison

Standard through the floor funnel

Quick turn funnel

2 3/4” (70mm)

4” (102mm)

8 1/2” (216mm)

minimum bend

radius

Standard below the floor discharge with hose

7

Below the Floor Discharge

This joint requires

SOLVENT BONDING per

procedure on page 11!

-08 Model Detail

Section I

8

Toilet Base & Through-floor Funnel Installation Guidelines

Through-floor funnels must…

• be mounted securely with 8

screws (not provided).

• Mounted flush with floor

• Screw heads must be flush or

lower than the top of the floor

flange funnel.

Through-floor funnels

are pre-assembled

and can be positioned

at 90 points from front

of toilet.

Use FULL scale template for cutting holes

(available in the SuperTech Manual).

Toilet base must be

securely fastened with 4

fasteners (provided).

Bottom of the toilet base and

the bottom of the through-

floor funnel must be

mounted on the same

surface.

No gaps allowed

between funnel and

floor.

Follow SOLVENT

BONDING per procedure

per page 11 for

connecting fitting to

bottom of the funnel!

9

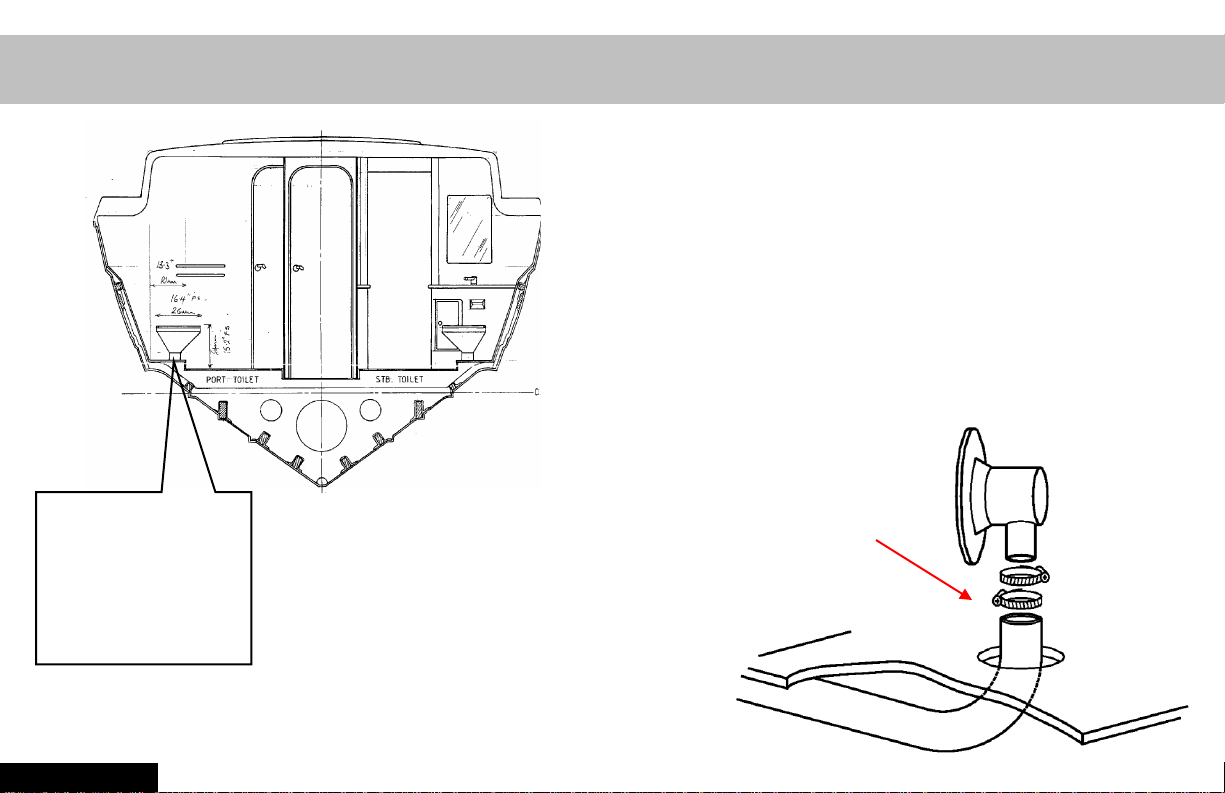

When there is NO room…. Use this Quick Turn Funnel

Special Quick Turn Funnel - must be

special ordered - P/N 385310550

(Can only be installed with models that

use a separate floor flange funnel, like

the models ending in -06.)

This joint requires PROPER

HOSE CONNECTION per

Limited space

under the

deck, despite

the size of the

boat.

procedure on pages 34-36!

Section I

10

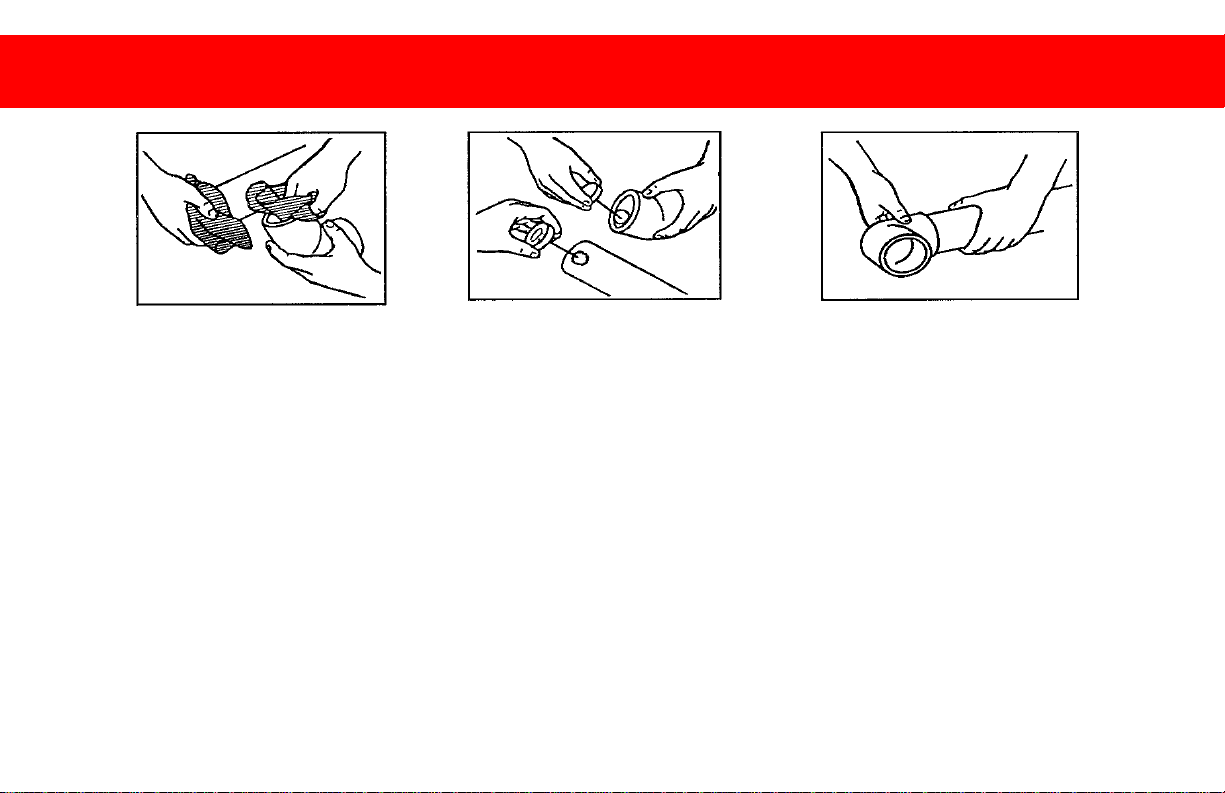

Solvent Bonding For Rigid Pipe & Fittings

1 2 3

Cleaner

Cement Twist

The most important steps:

1. Use a PVC cleaner on both bonding surfaces.

2. Use a PVC cement (must contain

Tetraheyrofuran) on both bonding surfaces.

3. Connect parts using a twist and hold motion until

the glue is set.

4. Let joint cure for at least four hours or per

instructions on the container. (Cold temperatures

require longer cure times.)

11

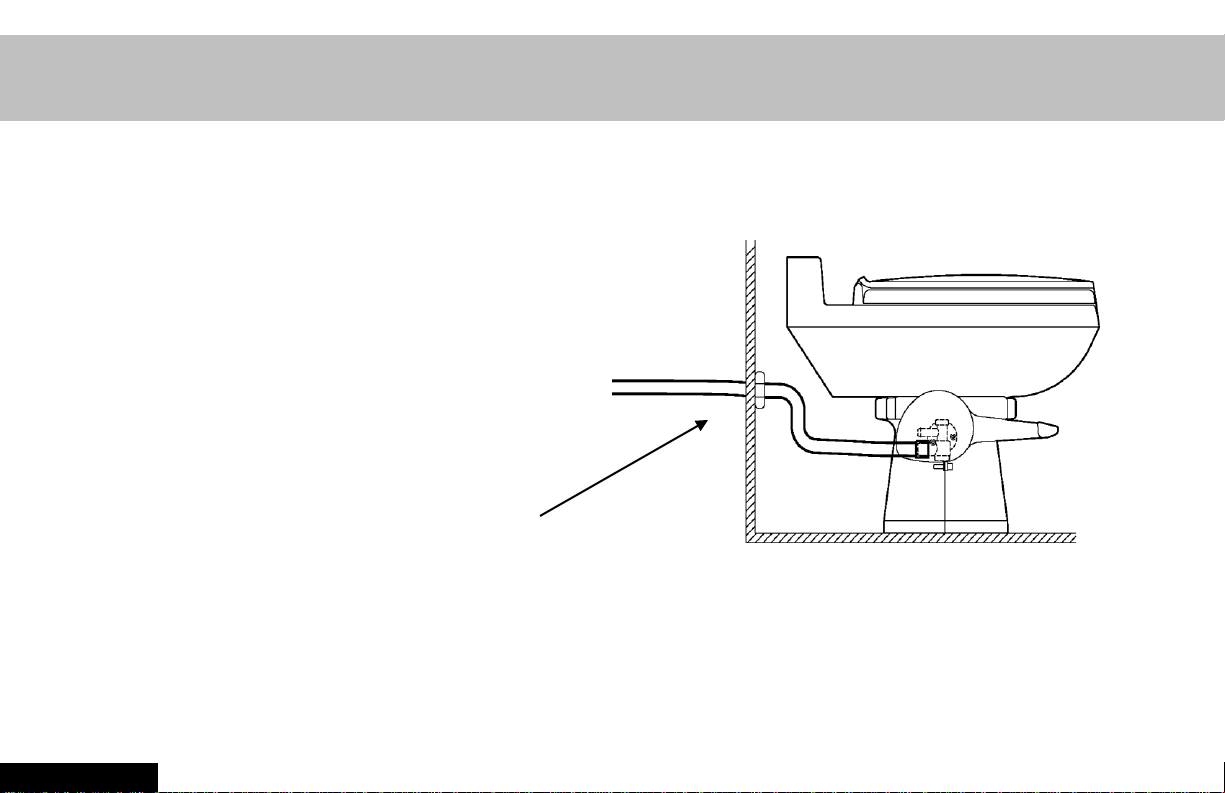

Incoming Water Supply

The incoming water line MUST…

• Be cold water ONLY

• Be ½” (13mm) MINIMUM ID

• Provide a MINIMUM flow of 2

gallons/min (7.6 liters/min) at the

toilet. This requires a 2.8 GPM

(10.6 l/m) demand pump, or

greater depending on line

restrictions.

• Include a SHUT-OFF valve for

maintenance purposes

Fresh water is highly recommended. If the choice is made to use salt or

brackish flush water, SeaLand requires the use of a primary and secondary

filter. The secondary filter must be 100 mesh or less.

Section I

12

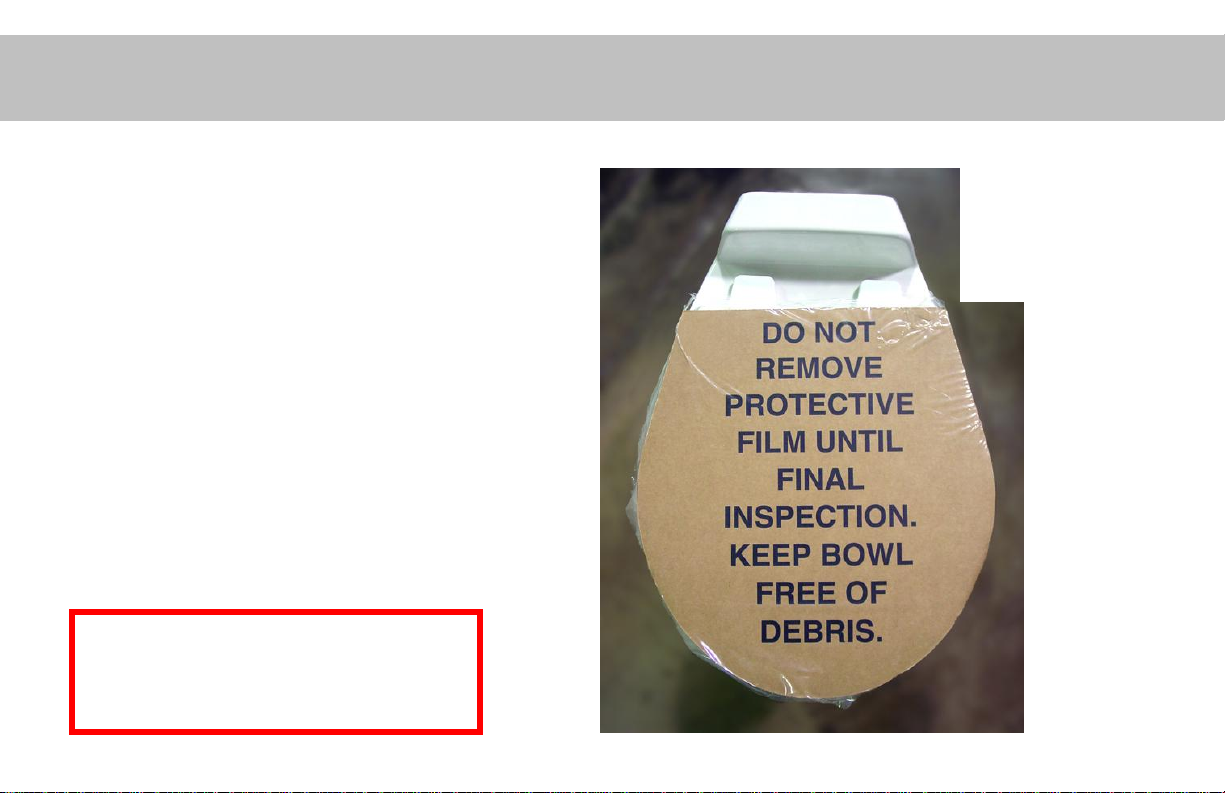

Keep Debris Out of the Toilet

• To prevent leaks, THE BALL

SEAL MUST BE PROTECTED

FROM DEBRIS. Keep the toilet

bowl covered.

• Lag bolts and/or T-bolts MUST

be securely fastened in FOUR

locations, or toilet wobble will

result.

• Should debris collect under the

ball seal, use the brush and

cleaner samples to remove

(provided with toilet).

Ball seal debris is THE MOST

COMMON installation

problem!!

Leave this

protective cover

in place until

final delivery.

13

Critical Guidelines – Toilet Installations

1. Allow proper clearances from rear and side objects (bulkheads,

partitions, etc).

2. When installing a funnel, secure the funnel flat against the floor

using 8 fasteners.

3. Fasten toilet securely to floor using 4 fasteners.

4. When installing a funnel, the bottom of the toilet base and the

bottom of the funnel flange must be mounted on the same surface.

5. Follow proper solvent bonding procedure for rigid PVC on page 11

when required.

6. Assure minimum incoming water supply of 2 gallons per minute

(7.6 liters/min) at the toilet.

7. Keep debris out of the toilet bowl/funnel DURING INSTALLATION to

avoid vacuum or water leakage through the ball seal.

Section I

14

Section II: Vacuum Sources

Low-Profile Vacuum

Generator

Vacuum Tank and

Pump

Vacuum Generator

15

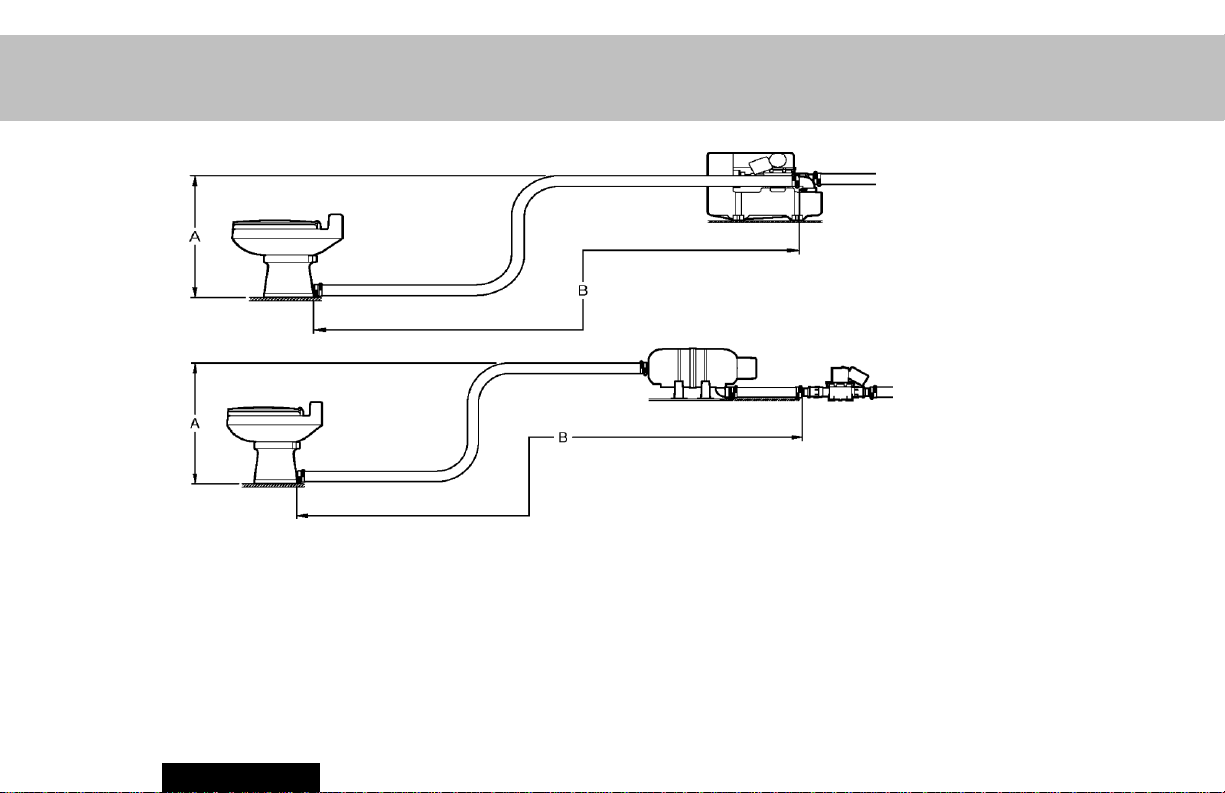

Locating the Vacuum Source

Each toilet must

have a separate

vacuum source

(vacuum

generator or

tank/pump).

A. Maximum height of vacuum piping from toilet outlet to vacuum source inlet is

6 feet (1.8 meters).

B. Maximum length of vacuum piping from toilet outlet to vacuum source inlet is

30 feet (9.1 meters).

Section II

16

Supporting the Vacuum Hose

Do not let the hose go

unsupported (up or down). It

will pull the fitting out of the

seal, creating a leak.

The inlet hose of the vacuum

generator must not have a side

load (see picture below).

Support the hose, as necessary.

X

17

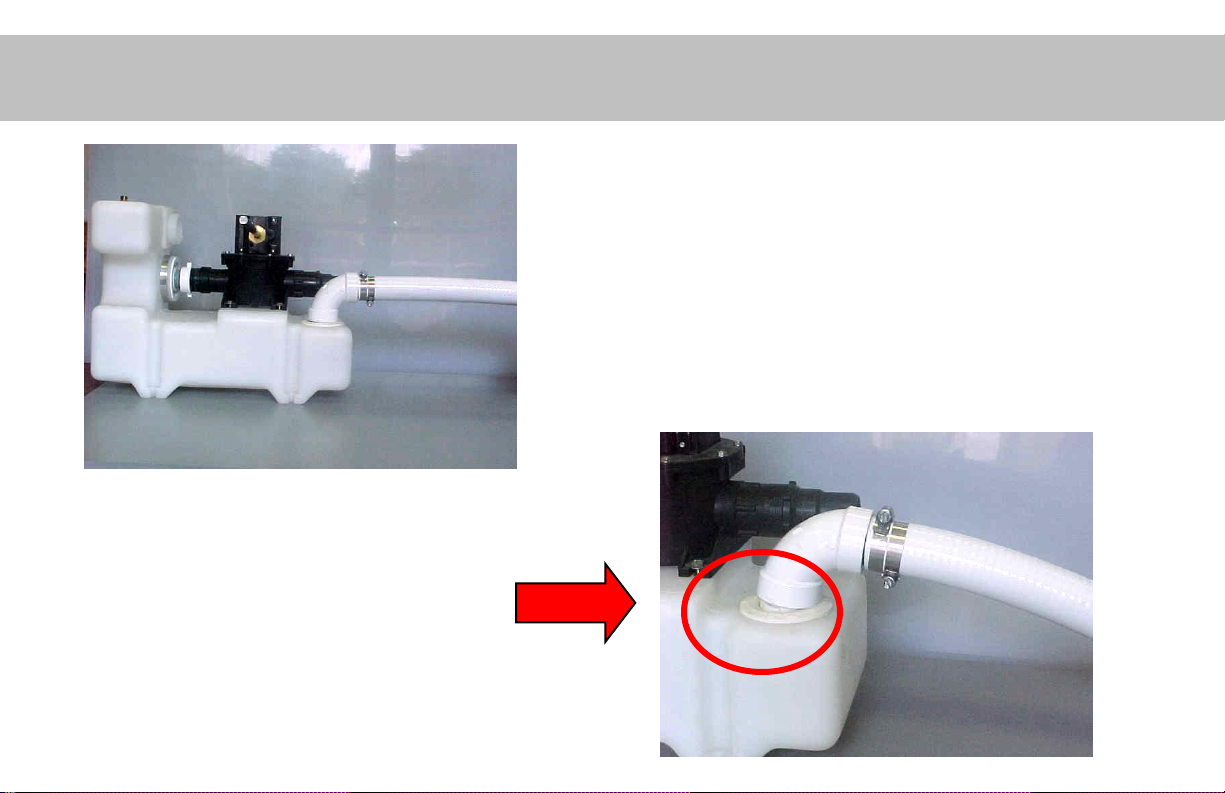

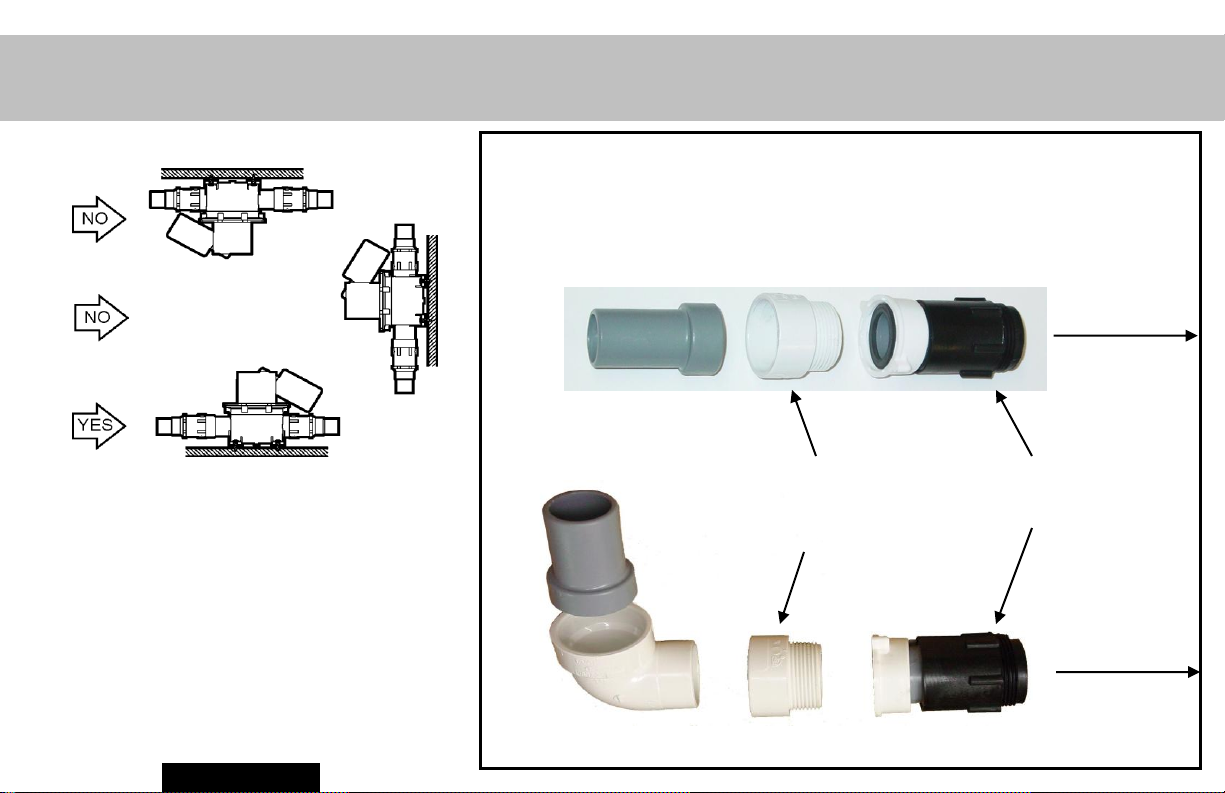

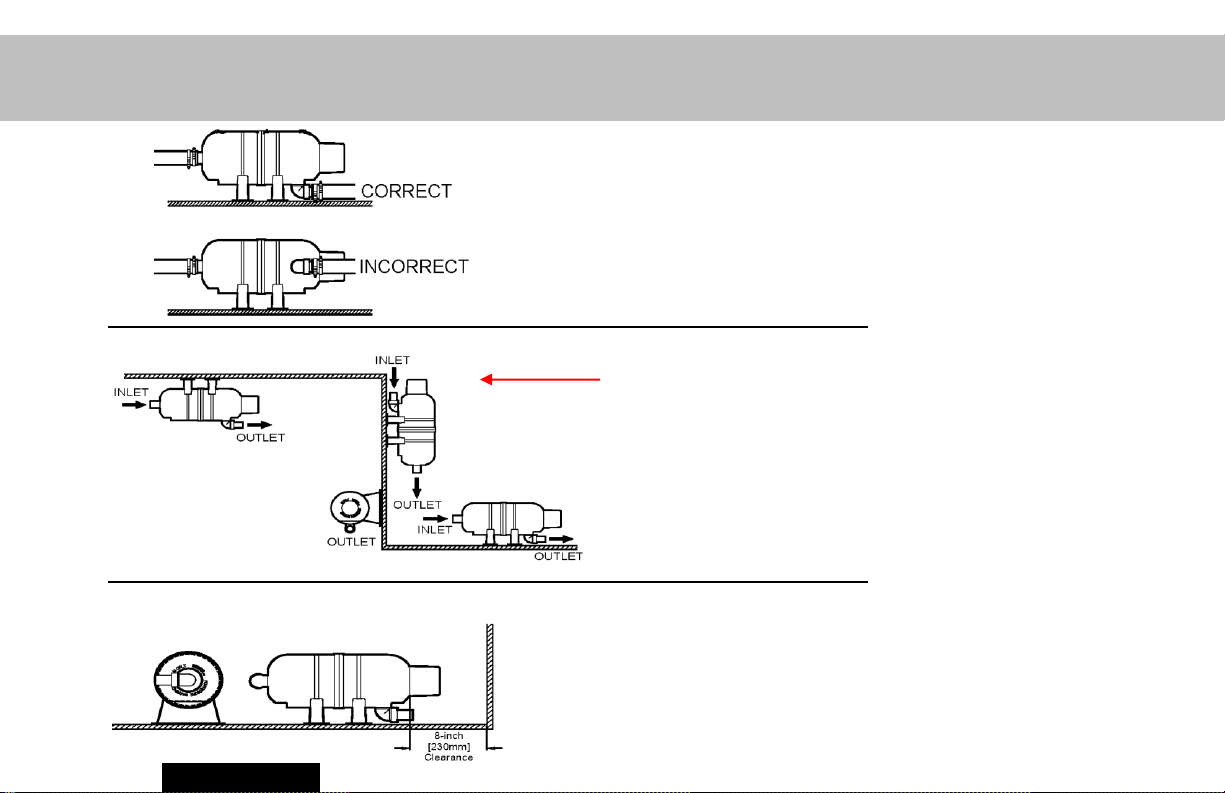

S-Series Vacuum Pump

• Mount pump horizontally

• Mount pump at same level or

lower than vacuum tank outlet.

Do not mount the pump higher

than the vacuum tank outlet.

Optional straight or 90º swivel quick-

disconnect fittings are available for suction &

discharge sides of vacuum pump.

307341513 –

hose connector

307341425 –

threaded fitting

To pump

385310728 –

swivel fitting

assembly

To pump

Section II

307341161 –

elbow

18

Sailboat Pump Mounting

Mounted athwartship (at

right angle to keel), need

15 incline to be

Mounted parallel

with keel, no incline

is needed.

acceptable.

When mounting S-Pump or Vacuum Generator athwartships (at right angle to keel) on

sailing vessels, compensate with a 15º incline on the discharge side.

19

Vacuum Tanks Do’s & Don’ts

• The outlet of the

vacuum tank must be

at the lowest level.

• The vacuum switch

must be on the top

when mounted

vertically.

• Proper clearance

must be allowed for

access to the

vacuum switch.

Never tamper

Vacuum levels

can ONLY be

adjusted at

with the

vacuum

switch!

factory!

Section II

20

Accessibility is Critical!

• EASY access is needed to service

• Pumps

• Vacuum Switches

• Tank inlet and outlet fittings

• Vent Filters

• All pumps and tanks must have access to

replace if necessary.

Do NOT do this!! Insufficient

access.

X

Vacuum Generator is located behind an

appliance, difficult to access and entire unit can

not be replaced.

21

Loading...

Loading...