Page 1

2500 Series

CASSETTE VACUUM TANK

OWNER’S MANUAL

Portable (2510) or Permanent (2520, 2521) Holding Tank System

for use with VacuFlush® Ceramic Toilet

NOTICE:

This product is

not recommended

for use on sailboats.

25102520

WARNING

!

This manual must be read and understood

before service or maintenance is performed.

Modification of this product can result in

property damage.

Dometic Corporation • Sanitation Systems

13128 State Rt. 226, P.O. Box 38

Big Prairie, OH 44611-0038 USA

SeaLand Product Hotline 1-800-321-9886

(8:00 a.m. - 5:00 p.m. ET)

www.DometicSanitation.com

1

Page 2

TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

For Your Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

System Components . . . . . . . . . . . . . . . . . . . . . . 2

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 - 6

Docking Platform Riser. . . . . . . . . . . . . . . . . . . .3

Docking Platform Base . . . . . . . . . . . . . . . . . . . . 3

Inserting cassette tank . . . . . . . . . . . . . . . . . . . .4

Connecting sanitation hose . . . . . . . . . . . . . . . .4

How to make installation easier . . . . . . . . . . . . .5

Sanitation hose layouts . . . . . . . . . . . . . . . . . . .5

Electrical installation . . . . . . . . . . . . . . . . . . . . . . 6

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . 7

These operating instructions should be kept in a safe place.

If this device is passed on to another owner, please include

these operating instructions with it.

INTRODUCTION

Do metic br ings the comf ort and effi ciency of

VacuFlush sanitation systems in an easy-to-use and

easy-to-maintain package.

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 - 9

Status panel . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Start-up checklist . . . . . . . . . . . . . . . . . . . . . . . .8

Flushing the toilet . . . . . . . . . . . . . . . . . . . . . . . .8

Removing cassette tank . . . . . . . . . . . . . . . . . . .8

Emptying cassette tank . . . . . . . . . . . . . . . . . . .9

Cleaning cassette tank, docking platform. . . . . .9

Changing vent filter. . . . . . . . . . . . . . . . . . . . . . . 9

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . 10

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Customer Service. . . . . . . . . . . . . . . . . . . . . . . . .11

Manufacturer’s One-Year Limited Warranty . . . . 12

FOR YOUR SAFETY

WARNING AND SAFETY NOTICES

Highly Efficient Freshwater Flushing – Uses very

little water to make water supplies last longer.

Very Low Power Consumption – 1.5 amps max.

Status Panel – Indicates vacuum status, holding

tank full level, tank removal status.

Removable Cassette Holding Tank – “No drip”

disconnect and built-in carry handle make it easy to

empty holding tank at disposal facility.

Integral Vent Filter – Prevents odors from escaping

the holding tank.

Safety Shut-off – Turns off vacuum pump when

tank reaches full level or is removed.

Compact, Flexible Installation – Cassette holding

tank takes up less than 1.6 cu. ft. (.045 cu. m), and

can be placed 20 feet (6 meters) from toilet.

!

DANGER

• When flushing the toilet, always keep the seat

lid closed.

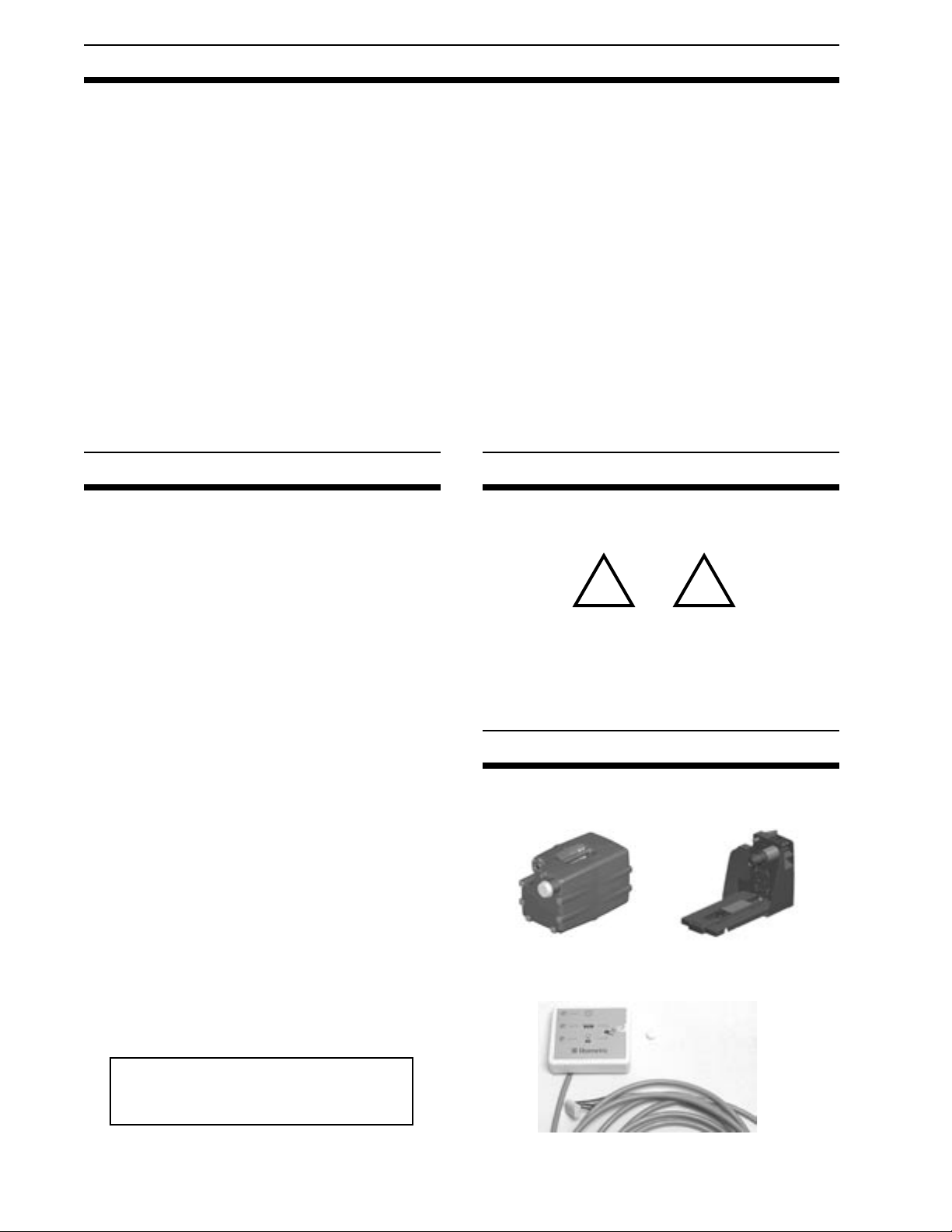

SYSTEM COMPONENTS

Each cassette vacuum tank includes:

• Portable cassette

vacuum tank

ATTENTION

• Cassette docking

platform

Dometic reserves the right

to change specifications

without notice.

• Status panel

2

Page 3

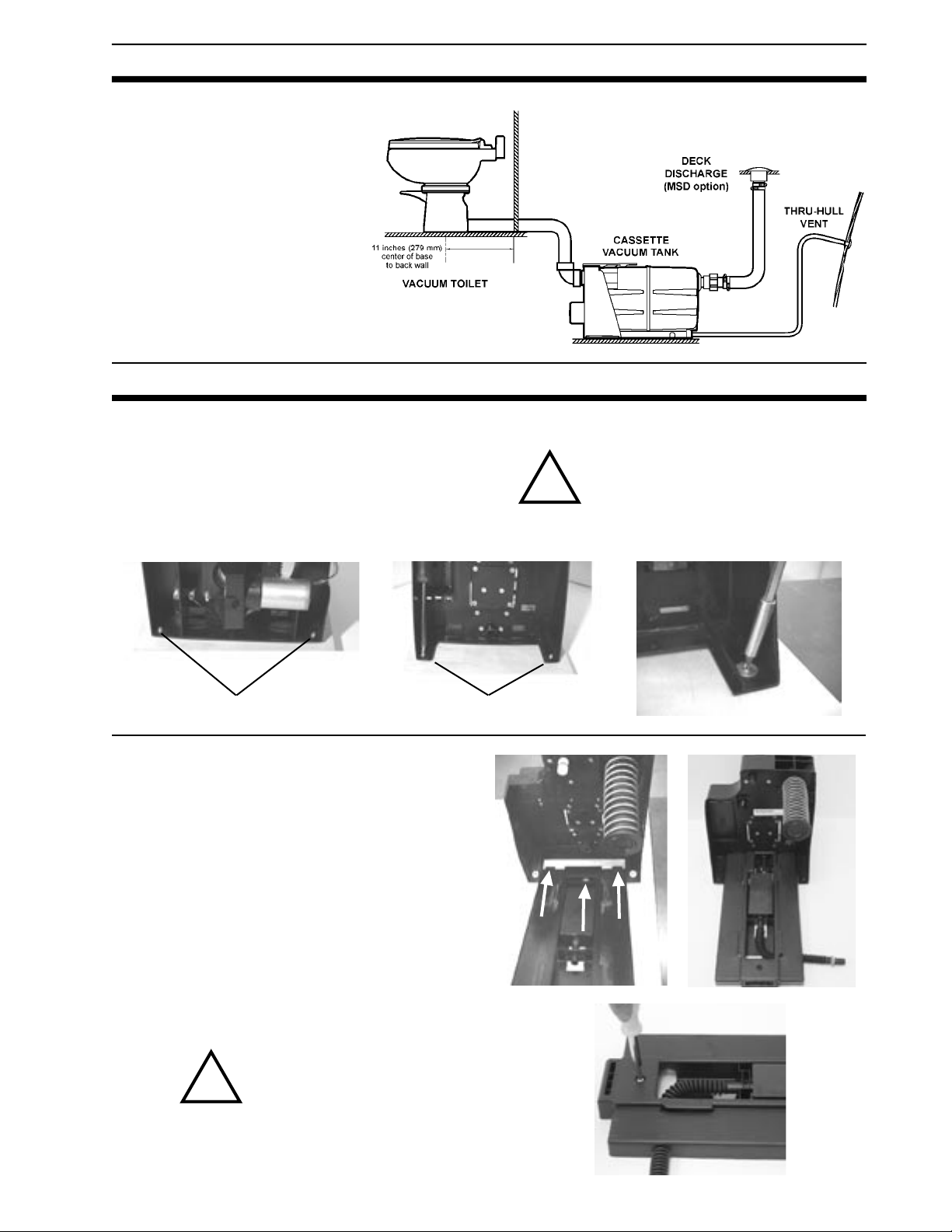

SANITATION SYSTEM LAYOUT

SYSTEM GUIDELINES

1. Cassette vacuum tank must be

used with VacuFlush toilet.

2. VacuFlush toilet must be

connected to pressurized

water supply (not shown).

3. Centerline of toilet base must

be 11 inches (279 mm) from

back wall.

4. 5/8-inch (16mm) ID vent hose

must be attached to vent fitting

(not included).

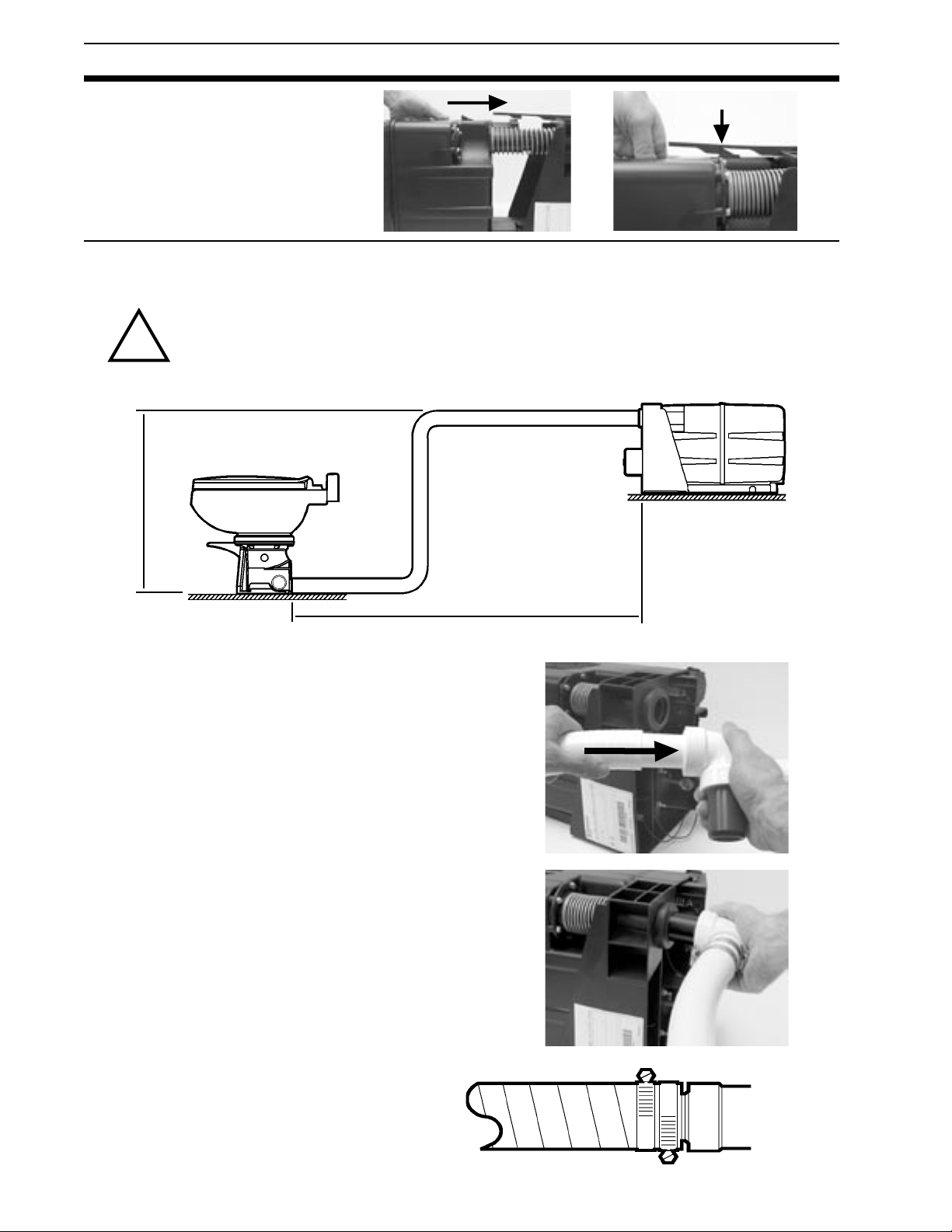

INSTALLATION

DOCKING PLATFORM RISER

1. The riser section of the docking platform is

mounted on a level floor using four screws (not

supplied). The floor must be strong enough

to support the weight of the cassette when full

(about 40 lbs. – 18 kg).

BACK FRONT

DOCKING PLATFORM BASE

1. The base section of the docking platform is attached to the riser. The base has two tabs (A)

that must be pushed into the respective slots

in the rear wall of the riser. Make sure that the

connection (B) for the carbon filter fits into the

space provided.

2. The ventilation hose (C) is routed out the side of

the base. Using barbed hose adapter provided,

route reinforced 5/8-inch (16mm) vent hose (not

supplied) to an outside vent fitting.

3. Fasten the base of the docking platform to the

surface (D).

ATTENTION

A

B

The riser and base sections

must be assembled on the

same level surface.

A

C

Make sure that the carbon

filter fits into the space

provided (B) and is

properly connected at

both ends

.

D

3

Page 4

INSTALLATION (cont’d)

INSERTING CASSETTE TANK

Place the cassette tank on the dock-

ing platform, then push the cassette

tank toward the back of the docking

platform until the latch engages (A).

CONNECTING SANITATION HOSE

A.

Maximum difference in height

from toilet to cassette is 3 ft.

(1 m).

A

B.

Maximum length of hose

between toilet and cassette is

20 ft. (6 m).

A

1. Route the sanitation hose from the toilet outlet

to to the cassette tank inlet (see tips for routing

hose on next page).

2. Connect 1 1/2-in. (38 mm) ID sanitation hose to

the white adapter fitting of the elbow assembly

(see tips for connecting hose on next page).

After pushing hose and fitting together, use two

hose clamps to tighten the connection.

3. Push the black adapter fitting of the elbow

assembly into the cassette vacuum tank.

Turn adapter and hose to best angle.

Dometic recommends that each hose

connection be secured with two hose clamps

to prevent any leaks.

B

Position hose clamp screws 180°

apart from each other and tighten

clamps.

4

Page 5

INSTALLATION (cont’d)

HOW TO MAKE SYSTEM INSTALLATION (AND MAINTENANCE) EASIER

When connecting flexible hose to plastic fittings, use liquid dish soap on end of fitting and

inside hose end to make connection easier. A clockwise twist of the fitting while inserting it into

the hose makes connection easier.

Do not use any other lubricants, sealants or adhesives when connecting sanitation hoses and fittings.

Do not restrict the ability to pull the hose or pipe.

EXCELLENT

HOSE LAYOUTS

Trough sup-

port

YES

YES

Avoid binding corners and sharp bends.

Do not use wire ties to secure the hose or pipe.

Vertical hose runs should be installed as vertical as possible (no long runs at

an angle) for maximum vacuum efficiency.

YES

YES

YES

NO!

5

Page 6

INSTALLATION (cont’d)

ELECTRICAL INSTALLATION

Electrical installation

must be performed by

qualified personnel only!

The 12V DC connection to the toilet electronics

is shown in the photo.

Connect by correct polarity:

RED + WHITE –

The connection wire must be 14-gauge stranded

copper wire, and must be protected by a 5-amp

fuse (see wiring diagram).

POSITIVE +NEGATIVE

–

RED

WHITE

WARNING: Power wire s mus t be

WARNING : Power wires must be

connected as shown. Unit will not

connected as shown. Incorrect wiring

operate until power wires are properly

will damage circuit board.

connected.

Connecting Status Panel to

Docking Platform Circuit Board

The status panel’s 4-stranded cable connects to

the circuit board (shown below right).

.

Circuit board

location

6

Page 7

WIRING DIAGRAM

1 – “Tank Full” Float Switch

2 – Tank Interlock Switch

3 – Vacuum Switch

4 – Vacuum Pump Motor

7

Page 8

OPERATION

DISPLAY PANEL.

GREEN – Ready to flush.

RED – Cassette full, or cassette

LED

START-UP CHECKLIST

removed, or undervoltage.

Toilet cannot be flushed.

YELLOW – Vacuum pump is running.

Do not flush toilet.

Before first-time use of the 2500 series sanitation

system, check the following:

• The vacuum cassette tank is inserted correctly.

• The fresh water supply tank is full.

• The power supply is on.

FLUSHING THE TOILET

1. Make sure there is enough water in the bowl to

cover the flush ball and seal in bottom of bowl. Lift

pedal to add water to bowl (if needed for flushing

solids).

2. To flush, press pedal down to floor and hold down

for 2 or 3 seconds. Keep seat lid closed to reduce

noise.

3. The toilet will flush liquids effectively with only

1 pint (0.4 liters) of water per flush.

Never flush toilet while

sitting on open toilet seat,

or if the seat lid is up.

Do not flush any solid or

non-dissolving objects

such as paper towels,

plastic cans. They can

plug or damage system.

The yellow LED illuminates for about one minute.

Then the green LED illuminates.

THE SYSTEM IS READY FOR OPERATION.

4. Use only rapid-dissolving toilet paper designed

for low water flow toilets. Some residential bath

tissues may clog the system.

Flush toilet only when

green LED is illuminated.

5. If the cassette tank is full, the

tank is removed from the docking

platform, or the voltage is too low,

the red LED illuminates and the

system switches off. The system

cannot be used until the cassette

is emptied, inserted properly in the

docking platform, and the correct

voltage is restored.

REMOVING CASSETTE TANK

(model

1. Raise the latch (A). Holding the carrying

2. When reattaching cassette tank, make sure

2510)

handle (B), pull cassette straight back.

it is placed correctly on docking platform.

Make sure latch engages after pushing tank

into platform.

B

A

8

Page 9

OPERATION (cont’d)

EMPTYING CASSETTE TANK (model 2510)

1. Carry cassette tank to disposal facility.

2. With tank sitting level, open large cap (A), and

pour contents into disposal receptacle.

3. If possible, rinse the casse tte with fresh

water each time it is emptied.

A

EMPTYING CASSETTE TANK (

1. Turn off water to toilet and electrical power

to cassette vacuum tank.

2. Connect dockside discharge pump nozzle to

deck-mounted discharge fitting.

models

2520, 2521)

3. Flush valve in toilet should be held open (by press

ing down on flush pedal) when dockside pump is

used to empty holding tank.

4. Turn on dockside pump to discharge contents of

cassette tank.

CLEANING CASSETTE TANK AND DOCKING PLATFORM

Occasionally, clean the connection points

on the cassette tank and docking platform

where efflue nt may accumulate. See

photos for these locations.

-

CHANGING THE VENT FILTER

The filter in the docking platform should be changed about every year, depending on frequency of system use.

See parts list for part number to order.

1. Push filter toward platform riser.

2. Lift filter out of platform base. When inserting

new filter, make sure holes in filter line up

with vent line fittings.

9

Page 10

TROUBLESHOOTING

TROUBLESHOOTING

Problem Possible Cause Service Instructions

1. Vacuum pump will not run.

a. No electrical power.

b. Loose or broken electrical wiring.

c. Improper electrical connections.

d. Faulty vacuum switch.

e. Faulty motor.

f. Shut-down relay prevents pumping.

g. Replace motor.

h. Cassette tank not fully engaged in

docking platform.

a. Check input power, circuit breaker

and fuse.

b. Tighten or reconnect wires at docking

platform.

c. Be sure power wires and wires at

vacuum switch are connected to

proper terminals.

d. Replace vacuum switch.

e. Replace motor.

f. Empty the cassette tank. If cassette

is not seated in docking platform

properly, put cassette tank back into

docking platform until locking latch

engages.

g. Charge battery.

h. Engage cassette tank until latch

secures tank to platform.

2. Vacuum pump will not

shut off.

3. Vacuum pump is running too

slow, overheating, blowing

fuses or circuit breaker.

4. Toilet will not flush.

a. A vacuum leak exists in system.

b. Insufficient vacuum (pump creates less

than 10 inches Hg).

c. Faulty vacuum switch (pump creates

more than 10 inches Hg).

d. Diaphragm not pumping.

e. Blockage in inlet of vacuum pump.

a. Motor is worn or defective.

b. Plugged vent line or vent filter.

c. Improper wire size.

d. Improper voltage.

e. Vacuum pump clogged with tissue.

a. There is a blockage in the toilet.

b. Hose between toilet and cassette tank

is collapsed or kinked.

c. Foreign objects were flushed, causing

blockage in system.

d. Pump will not run.

a. Check for vacuum leaks in system

with vacuum gauge tester.

b. Isolate cassette tank (remove elbow

assembly) and use vacuum gauge to

check vacuum capability. Could be

worn valves.

c. Replace vacuum switch.

d. Tighten set screw in eccentric to mo-

tor shaft. Otherwise, check for damage to diaphragm and motor shaft.

Replace if necessary.

e. Clear blockage from pump inlet.

a. Check motor and replace if

necessary.

b. Disassemble and clean out vent line.

Replace vent filter if

necessary.

c. Wire size too small. Check

“Electrical Installation” section

for proper wire size.

d. Check input power for low voltage.

e. Remove and clean pump

assembly.

a. Open flush ball and check the

1-inch (25mm) orifice at the bottom of

the base for blockage and dislodge it.

Never use drain-opening or other

household plumbing chemicals.

b. Inspect hose and replace if collapsed

or kinked.

c. Clear foreign objects from system.

DO NOT flush any non-dissolving

items (i.e. sanitary napkins, facial

tissue, wet strength tissue, paper

towels, etc.) or excessive tissue.

Before flushing solids, be sure to add

water by lifting the flush lever.

d. See problem 1.

5. Tank will not discharge using dockside pump (model

2520/2521).

a. Tank is not adequately vented.

b. Blockage in check valve at tank outlet.

c. Blockage at bottom of discharge

diptube inside the tank.

10

a. Open flush valve in toilet by pressing

on pedal.

b. Disassemble the check valve and

remove blockage.

c. Remove diptube from tank and clear

blockage.

Page 11

SPECIFICATIONS

CASSETTE VACUUM TANK SPECIFICATIONS

Model Empty Weight Max. Weight Waste Capacity Power Pump Run Time

2510 13.3 lbs. (6 Kg) 42.1 lbs. (19.1 Kg) 3.6 gal. (14 L)

2520

2521

Specifications subject to change without notice.

14.3 lbs. (9.1 Kg) 43.1 lbs. (19.6 Kg) 3.0 gal. (11.5 L)

DIMENSIONS

MODEL 2510 MODEL 2520, 2521*

(MSD)

* Model 2521 (not shown) uses a 90° elbow discharge fitting.

Dimensions are same as Model 2520 with straight discharge fitting.

CUSTOMER SERVICE

There is a strong, worldwide network to assist in servicing

and maintaining your sanitation system. For the Authorized

Service Center near you, please call from 8:00 a.m. to 5:00

p.m. (ET) Monday through Friday. You may also write us at

Dometic Corp., P.O. Box 38, Big Prairie Ohio 44611.

Telephone: 1 800-321-9886 U.S.A. and Canada

330-496-3211 International

You may also contact or have your local dealer contact the

Parts Distributor nearest you for quick response to your

replacement parts needs. They carry a complete inventory

for the SeaLand product line.

Fax: 330-496-3097 U.S.A. and Canada

330-496-3220 International

12 VDC,

1.5 amp

approx. 60-70 sec.

U.S.A.

MASTER SANITATION

DISTRIBUTORS

U.S.A. – North Central

(IL, IN, KY, MI, OH)

Midwest Marine Supply

24300 Jefferson Ave.

St. Clair Shores, MI 48080

Tel: 586-778-8950

800-860-1540

Fax: 586-778-6108

E-mail: midwestmarine@yahoo.com

U.S.A. - Northeast

(CT, DE, DC, MA, MD, ME, NH, NJ,

NY, PA, RI, VA, VT, WV)

Northeast Marine Sanitation

69 Florida Street

Farmingdale, NY 11735

Tel: 631-752-7606

800-352-4323

Fax: 631-752-7615

888-283-7606

E-mail: northeast@northeastsanitation.

com

U.S.A. - Northwest

(AK, ID, MT, OR, WA, WY)

Marine Sanitation, Inc.

1900 N. Northlake Way, Suite 121

Seattle, WA 98103

Tel: 206-633-1110

800-624-9111

Fax: 206-633-0317

E-mail: marinesan@mindspring.com

U.S.A. - South Central

(AR, KS, LA, MO, MS, NM, OK, TX)

AER Supply

P.O. Box 349

2301 Nasa Road #1

Seabrook, TX 77586

Tel: 281-474-3276

800-767-7606

Fax: 281-474-2714

E-mail: sales@aersupply.com

U.S.A. - Southeast

(AL, FL, GA, NC, PR, SC, TN, VI)

Environmental Marine

111 S.W. 23rd Street, Suite A

Fort Lauderdale, FL 33315

Tel: 954-522-2626

800-522-2656

Fax: 954-522-5152

E-mail: info@environmentalmarine.

com

U.S.A. - Southwest

(AZ, CO, NV, UT, CA-south)

Ardemco Marine Specialties

778 West 17th Street

Costa Mesa, CA 92627

Tel: 949-722-7672

800-253-0115

Fax: 949-642-9582

E-mail: info@ardemco.com

U.S.A. – Upper Midwest

(IA, MN, NE, ND, SD, WI)

PowerHouse Marine

518 Logan

La Crosse, WI 54603

Tel: 608-784-9580

888-752-4539

Fax: 608-784-8422

E-mail: dave@powerhousemarine.com

U.S.A. – Northern California

Fox Marine

6545 Caballero

Buena Park, CA 95131

Tel: 800-826-2873

Fax: 562-983-6766

E-mail: foxmarco@pacbell.net

11

CANADA

MASTER SANITATION

DISTRIBUTORS

Canada - East

Eastern Marine Systems, Inc.

12-A Leslie Street

Toronto, Ontario M4M 3H7

Tel: 416-465-1668

888-764-1111

Fax: 416-465-2098

E-mail: info@eastmar.com

Canada - West

Western Marine Company

1494 Powell Street

Vancouver, BC V5L 5B5

Tel: 604-253-7721

800-663-0600

Fax: 604-253-2656

800-663-6790

E-mail: sales@westernmarine.com

INTERNATIONAL

SEALAND SANITATION SYSTEM

DISTRIBUTORS

Call 1-800-321-9886, email us at

sealand@dometicusa.com, or visit

www.DometicSanitation.com for the

distributor nearest you.

Page 12

MANUFACTURER’S ONE-YEAR LIMITED WARRANTY

Dometic Corporation warrants, to the original purchaser only, that this product, if used for personal, family

or household-like purposes, and if installed according to Dometic’s recommended procedures, is free from

defects in material and workmanship for a period of one year from the date of purchase.

If this Dometic product is placed in commercial or business use, it will be warranted, to the original purchaser only,

to be free of defects in material and workmanship for a period of ninety (90) days from the date of purchase.

Dometic reserves the right to replace or repair any part of this product that proves, upon inspection by Dometic,

to be defective in material or workmanship. All labor and transportation costs or charges incidental to warranty

service are to be borne by the purchaser-user.

EXCLUSIONS

IN NO EVENT SHALL DOMETIC BE LIABLE FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, FOR

DAMAGES RESULTING FROM IMPROPER INSTALLATION, OR FOR DAMAGES CAUSED BY NEGLECT,

ABUSE, ALTERATION OR USE OF UNAUTHORIZED COMPONENTS. ALL IMPLIED WARRANTIES,

INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR

PURPOSE, ARE LIMITED TO A PERIOD OF ONE YEAR FROM DATE OF PURCHASE.

IMPLIED WARRANTIES

No person is authorized to change, add to, or create any warranty or obligation other than that set forth

herein.

Implied warranties, including those of merchantability and fitness for a particular purpose, are limited to one (1)

year from the date of purchase for products used for personal, family or household purposes, and ninety (90)

days from the date of purchase for products placed in commercial or business use.

OTHER RIGHTS

Some states do not allow limitations on the duration of an implied warranty and some states do not allow

exclusions or limitations regarding incidental or consequential damages; so, the above limitations may not

apply to you. This warranty gives you specific legal rights, and you may have other rights which may vary from

state to state.

To obtain warranty service, first contact your local dealer from whom you purchased this product.

Dometic is a customer driven, world-leading provider of innovative leisure

products for the caravan, motorhome and marine markets. Dometic offers

a complete range of air conditioners, refrigerators, awnings, cookers,

sanitation systems, lighting, windows, doors and other equipment that

makes leisure life more comfortable away from home.

Dometic also provides refrigerators for specific use in hotel rooms,

offices and for storage of medical products and wine. Dometic’s products

are sold in almost 100 countries and are produced mainly in Dometic’s

own production facilities around the world. Dometic has more than

4,400 employees.

600344940 5/05

Dometic Corporation • Sanitation Systems

13128 State Rt. 226, P.O. Box 38

Big Prairie, OH 44611-0038 USA

330-496-3211

1-800-321-9886 • Fax: 330-496-3097

www.DometicSanitation.com

® Registered; ™ Trademark of Dometic Corporation.

© Dometic Corporation

12

Loading...

Loading...