44Ultra

Laminator

Service Manual

SM110EN, Rev. 2.0

May 2003

SEAL 44 Ultra

Technical Service Manual

REV 1.1

Revision History

Amendments will be listed on this page, including their descriptions and dates.

REV Date Description

1.0 Jan 2001 Original version (pre-release).

1.1 Mar 2001 Changes in Sparepart list and Chapter 8 (Diagrams)

2.0 May 2003 Seal branding

Front Matter

Service Manual 44Ultra

110SM-2.0

ii

Front Matter

©2003,2000 SEAL® Graphics Europe BV

All technical and technological information included in this manual as well as any drawings and

technical specifications we have made available remain our property. They shall not be used (other

than for operation of this product), copied, reproduced, transmitted to or disclosed to third parties

without our prior written consent.

The Information contained herein is general and does not constitute any warranties or guarantees.

SEAL GRAPHICS EUROPE B.V.

Kanaaldijk O.Z. 3

P.O. Box 29

8100AA Raalte

The Netherlands

Tel: +31 572 345500

Fax: +31 572 345501

Internet:

www.SEALBrands.com

Seal Brands . . . the finishing touch

iii

Front Matter

Safety Statements

The SEAL 44 Ultra laminator has been designed with operator safety as a primary objective; however,

operators must be familiar with the controls, as well as the operation before using the unit.

The electrical and drive-system components are isolated from contact with the operator by enclosing

them within plastic end covers that are bolted on. Only qualified service technicians should remove

these protective covers after power to the machine is removed including disconnecting the power

cord.

Only qualified service technicians should remove covers for service purposes

Safety Features

The heating system is provided with an over-temperature device, which will shut off the top rollerheating element once a heating system failure occurs.

The rotation of the rollers will be switched off automatically when the light beam of the self-checking

photoelectric guard is interrupted. For example, if a panel is too thick relative to the roller nip setting,

or if a person’s hands or fingers approach the roller nip.

Once the roller rotation has been stopped and the photoelectric guard has been cleared, a deliberate

start signal has to be given in order to start the roller rotation again.

The machine has two emergency stop buttons that may be pressed in dangerous situations. The

rotation of the rollers will be stopped immediately. After releasing these buttons, a deliberate start

signal has to be given in order to start the roller rotation again.

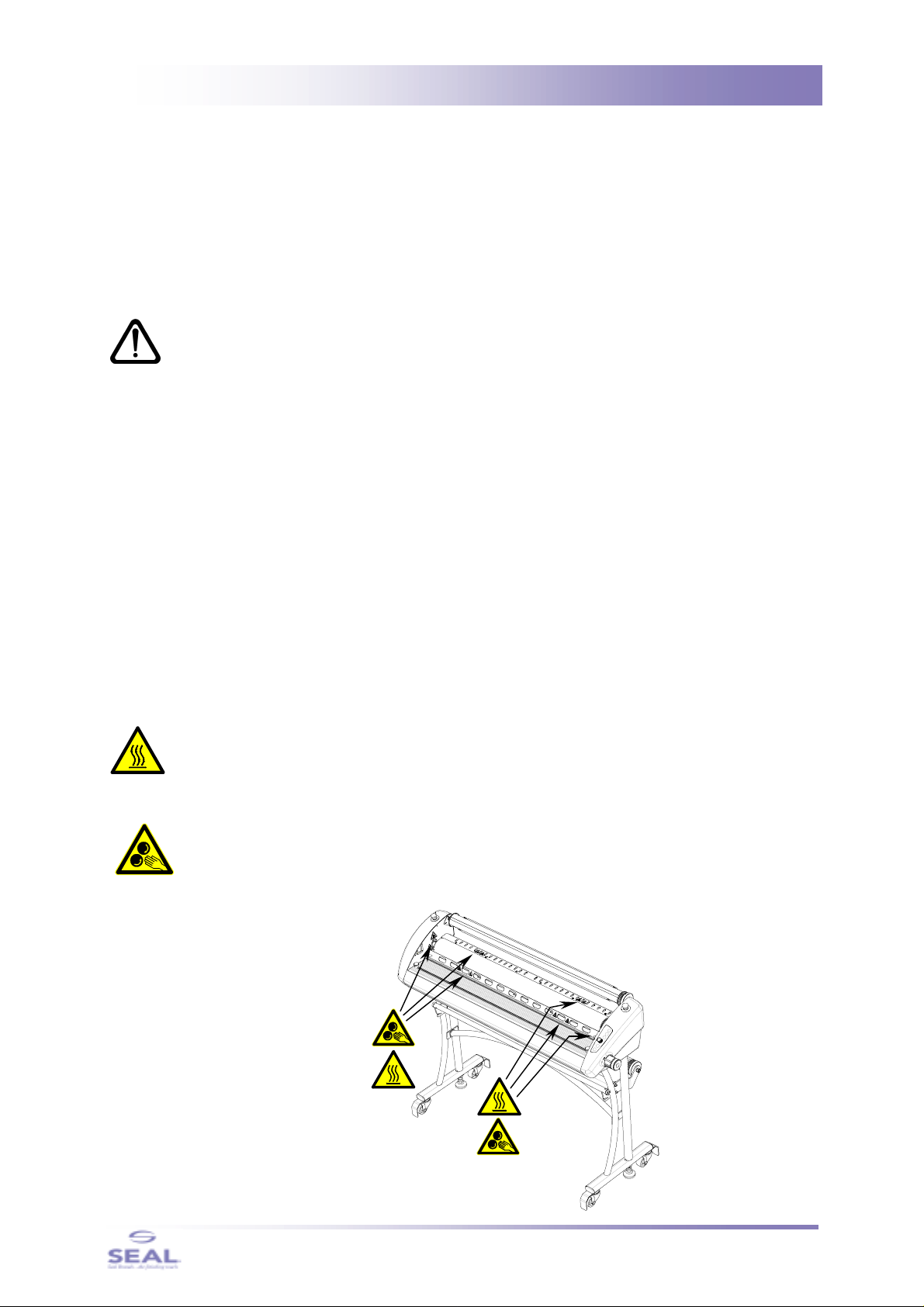

General Hazards

Danger of getting injured by hot parts

Be careful with parts marked with this symbol, to avoid burns. The heated top roller may

have a surface temperature of 135°C (275°F).

Do not touch the roller. Even after the machine has been switched off, the roller remains

hot for a long time.

Danger of getting injured by rotating parts

Everyone working around the laminator must avoid wearing loose fitting clothing (ties!) or

dangling jewelry, which co u ld catch in the laminator rollers.

Failure to use caution near exposed rollers could result in physical injury.

Location of the

safety labels

iv

Front Matter

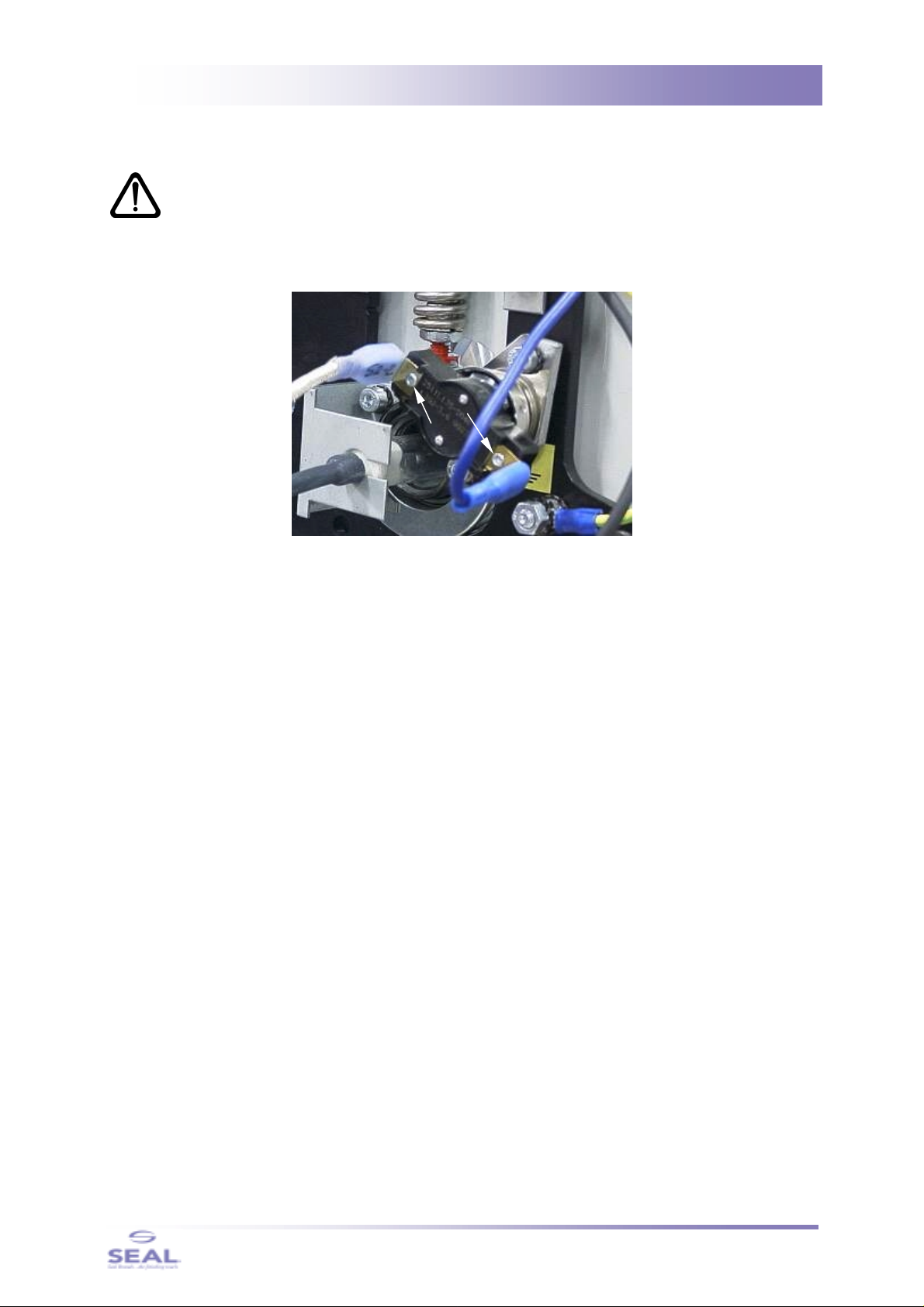

Note:

When performing procedures that require the side covers to be opened, ensure

that the power cable is disconnected from the mains. Several parts, like the fast-on

connector strips of the overtemperature switch (white arrows in picture shown

below), could cause electrical shock if the power is not disconnected!

v

Front Matter

Table of Contents

1 Machine Characteristics ...................................................................................................................7

1-1 Machine Description..................................................................................................................7

1-2 Identification ..............................................................................................................................7

1-3 Features ....................................................................................................................................8

1-4 Specifications ............................................................................................................................9

2 Transport & Installation...................................................................................................................11

2-1 Transport.................................................................................................................................11

2-2 Workspace Requirements.......................................................................................................11

2-3 Setup & Installation .................................................................................................................11

2-4 Electrical Requirements ..........................................................................................................11

3 Theory of Operation........................................................................................................................13

3-1 Control Knob............................................................................................................................13

3-2 Roller Nip settings ...................................................................................................................13

3-3 Control Panel...........................................................................................................................14

3-4 Motor Control...........................................................................................................................15

3-5 Unwind Brakes ........................................................................................................................16

4 Disassembly/Reassembly Procedures...........................................................................................17

4-1 Plastic Covers..........................................................................................................................17

4-2 Heating Element......................................................................................................................18

4-3 Rear Panel...............................................................................................................................20

4-4 Control System Board & Software...........................................................................................21

4-4-1 Control System Board..........................................................................................................21

4-4-2 Software...............................................................................................................................21

4-5 Solid State Relay.....................................................................................................................22

4-6 Photoelectric Cells...................................................................................................................23

5 Adjustment Procedures ..................................................................................................................25

5-1 Laminating Pressure ...............................................................................................................25

5-1-1 Adjustment using Load Cells and Display Unit...................................................................25

5-1-2 Adjustment using Heat Sensitive Film................................................................................27

5-2 Roller Nip.................................................................................................................................29

5-3 Temperature............................................................................................................................30

5-4 Photoelectric Cells...................................................................................................................31

5-5 Drive Chain..............................................................................................................................32

5-6 Clutch ......................................................................................................................................32

5-7 Image Guide............................................................................................................................33

6 Maintenance...................................................................................................................................35

vi

Front Matter

7 Troubleshooting..............................................................................................................................37

8 Diagrams ........................................................................................................................................43

8-1 Installation Diagram.................................................................................................................43

8-2 Control Panel Diagram............................................................................................................44

8-3 Safety Control System Diagram..............................................................................................45

8-4 Certified Electrical Components List & Sparepart Codes .......................................................46

8-5 Mechanical Spare Parts List, Assembly Drawings & Exploded Views....................................47

8-5-1 Mechanical Spare Parts List................................................................................................47

8-5-2 Assembly Drawings & Exploded Views...............................................................................48

vii

Machine Characteristics

1 Machine Characteristics

1-1 Machine Description

The SEAL 44 Ultra laminator is an electro-mechanical device basically containing two siliconized

laminating rollers, two siliconized pull rollers and a top and bottom film unwind. Only the top roller is

heated. There are three temperature ranges; the speed can be set to any value between zero and

maximum speed. There is a set of nip values to accommodate for the various panel thicknesses.

The machine runs on a single-phase power supply.

The machine is able to perform the following processes:

• cold/hot mounting

• cold/hot laminating

• mounting & laminating in one pass

• decaling

• encapsulating

Process results can be controlled by:

• the temperature setting

• the speed setting

• the unwind tension of the film(s)

The SEAL 44 Ultra meets the Machinery Directive (89/392/EEC & applicable amendments). The

Notified Body’s TRF report (based on EN60950) is available.

It is ETL and cETL listed per directive UL 1950 3

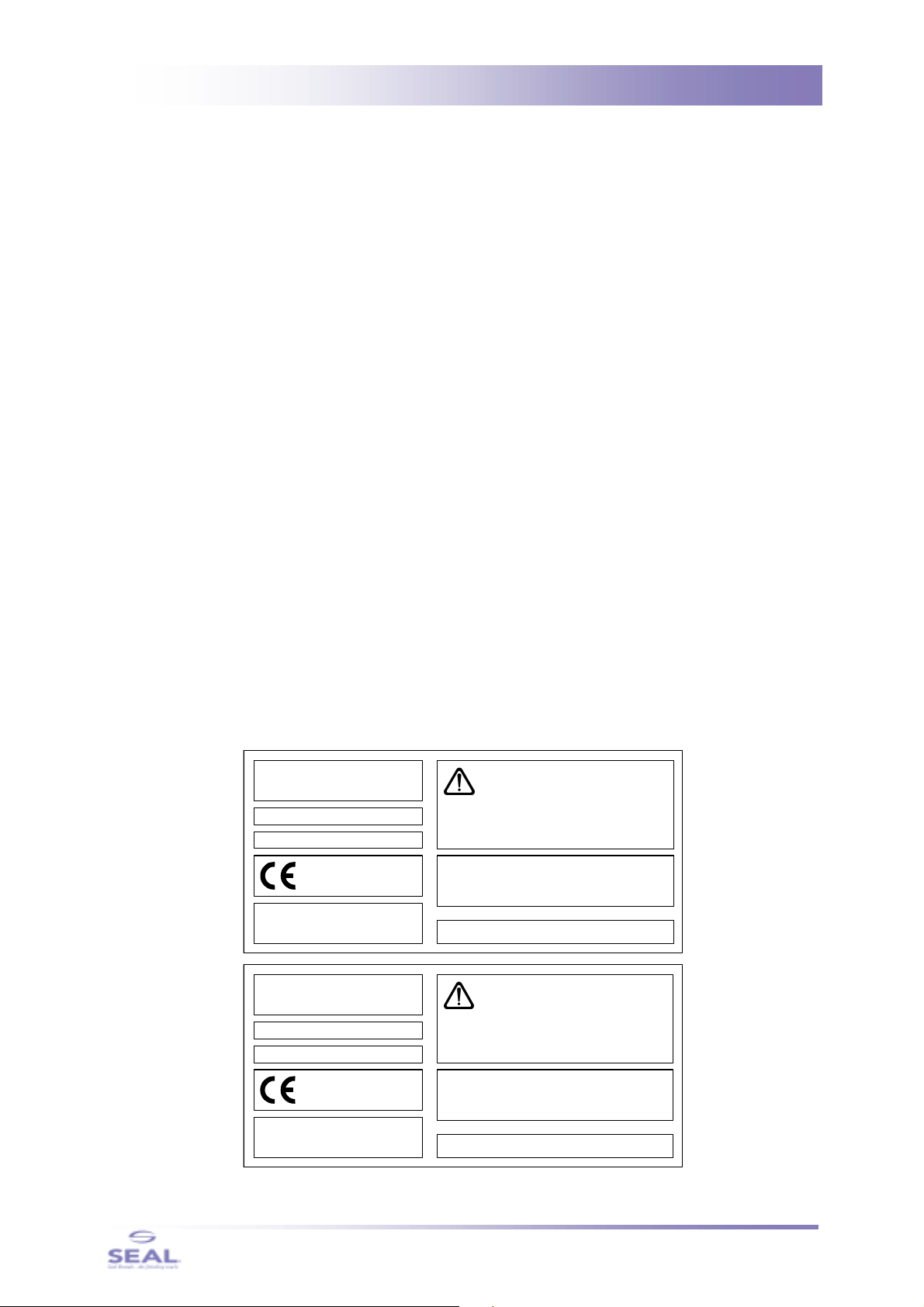

1-2 Identification

The machine identification label is located on the rear side of the machine.

The machine is available in two different voltages: 110VAC 50/60Hz and 230VAC 50/60Hz, see the

labels below.

MODEL: SEAL 44 ULTRA

POWER SUPPLY: 230VAC 50/60Hz

CURRENT: 9A

SERIAL NO:

MANUFACTURED:

EN 60950

EN 50081-1

EN 50082-1

FCC Part 15 (Class B)

Hunt Graphics Europe BV

Kanaaldijk O.Z. 3, P. O .B . 29

8100AA Raalte, The Netherlands

MODEL: SEAL 44 ULTRA

POWER SUPPLY: 110VAC 50/60Hz

CURRENT: 16A

SERIAL N O:

MANUFACTURED:

EN 60950

EN 50081-1

EN 50082-1

FCC Part 15 (Class B)

Hunt Graphics Europe BV

Kanaaldijk O.Z. 3, P. O .B . 29

8100AA Raalte, The Netherlands

rd

Edition 1995 and CAN/CSA C22.2 No. 950-95.

• EQUIPMENT TO BE CONNECTED TO EARTHED MAINS OUTLET

ONLY.

• TO PREVENT ELECTRIC SHOCK, DO NOT REMOVE COVER.

• NO OPERATOR SERVICEABLE PARTS INSIDE.

• REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

• CONECTAR EL PRODUCTO A RED DE ALIMENTACION CON TOMA DE TIERRA.

• PARE EVITAR UNA DESCARGA ELECTRICA, NO QUITE LA CUBIERTA.

• NO HAY PIEZAS REPARABLES POR EL USUARIO EN EL INTERIOR.

• REPARACIONES: CONTACTAR CON PERSONAL DE SERVICI O AUTO RIZ ADO .

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUST ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDI NG INT ERF ERENCE THAT MAY CAUSE

UNDESIRED OPERATION.

MADE IN HOLLAND

• EQUIPMENT TO BE CONNECTED TO EARTHED MAINS OUTLET

ONLY.

• TO PREVENT ELECTRIC SHOCK, DO NOT REMOVE COVER.

• NO OPERATOR SERVICEABLE PARTS INSIDE.

• REFER SERVICING TO QUALIFIED SERVICE PERSONNEL.

• CONECTAR EL PRODUCTO A RED DE ALIMENTACION CON TOMA DE TIERRA.

• PARE EVITAR UNA DESCARGA ELECTRICA, NO QUITE LA CUBIERTA.

• NO HAY PIEZAS REPARABLES POR EL USUARIO EN EL INTERIOR.

• REPARACIONES: CONTACTAR CON PERSONAL DE SERV ICI O AUT ORI Z ADO.

THIS DEVICE COMPLIES WITH PART 15 OF THE FCC RULES. OPERATION IS

SUBJECT TO THE FOLLOWING TWO CONDITIONS: (1) THIS DEVICE MAY NOT

CAUSE HARMFUL INTERFERENCE, AND (2) THIS DEVICE MUS T ACCEPT ANY

INTERFERENCE RECEIVED, INCLUDI NG INTE RFE RE NCE THAT M AY CAUSE

UNDESIRED OPERATION.

MADE IN HOLLAND

7

Machine Characteristics

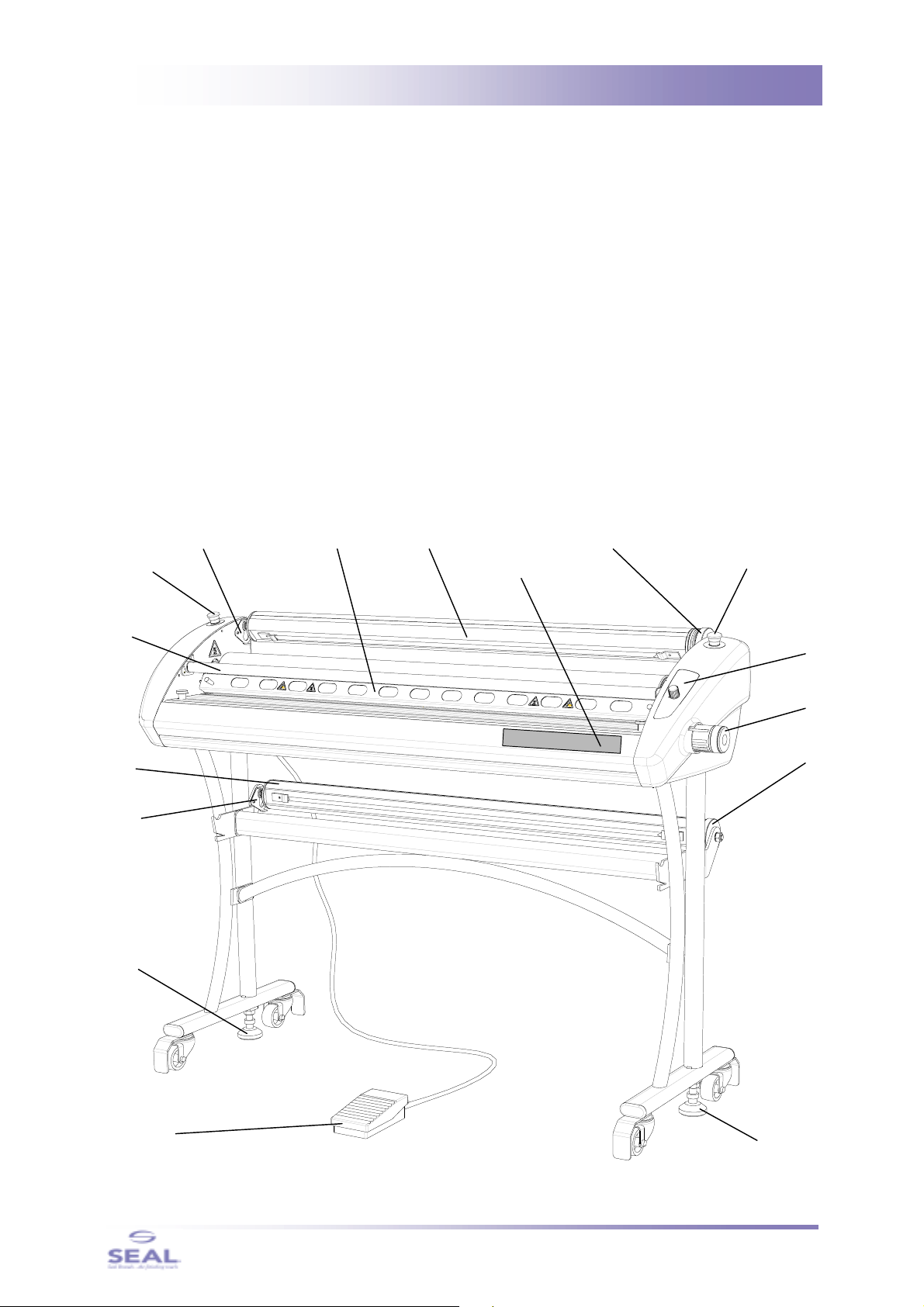

1-3 Features

Identification of parts

1 Wind-up idler Idler (removable) to support the wind-up core for the release-liner

2 Emergency stop buttons Stop the rotation of the rollers immediately

3 Image guide To help feed-in images. It is removable when mounting

4 Upper unwind shaft The shaft is suitable for rolls having a 3-inch core

5 Unwind brake A simple means of setting the unwind tension

6 Control panel Controls rotation of the rolls, temperature and standby

7 Nip knob To adjust the gap between the rollers

8 Process control sheet Shows how to preset the machine

9 Lower unwind shaft The shaft is suitable for rolls having a 3-inch core

10 Foot switch To engage slow mode

11 Safety device Prevent the supply rolls from falling out

12 Floor anchor Renders the machine immovable once installed

The ID-label is located on the rear side of the machine.

11

2

1

9

11

12

10

3 4

5

8

7

2

6

7

5

12

8

Machine Characteristics

1-4 Specifications

Dimensions & weights Uncrated Crated

depth 56 cm (22 in) 63 cm (24.8 in)

width 148 cm (58.3 in) 160 cm (63 in)

height 111 cm (43.7 in) 72 cm (28.4 in)

weight 101 kg (222 lbs) 135 kg (297 lbs)

Electrical specifications

Part no. 60958 230VAC 50/60Hz 9A

Part no. 60959 110VAC 50/60Hz 16A

Metric Imperial

Material specifications

Maximum material width (processes up to 50°C) 1118 mm 44 in

Maximum material width (processes up to 125°C) 1067 mm 42 in

Maximum material diameter (top unwind) 160 mm 6.3 in

Maximum material diameter (bottom unwind) 200 mm 8 in

Maximum material diameter (release liner windup) 125 mm 5 in

Maximum panel thickness 10 mm 3/8 in

Core size 76.2 mm 3 in

Machine specifications

Nip settings 0 (nip closed)

2 mm 1/16 in

3 mm 1/8 in

5 mm 3/16 in

6 mm 1/4 in

8 mm 5/16 in

10 mm 3/8 in

Linear pressure 0.97 N/mm 5.54 lbf/in

Roller torque (bottom roller driven) 29 Nm 257 lbfin

Maximum process speed 1.5 m/min 4.92 ft/min

Maximum roller temperature 135 °C 275 °F

Temperature settings off (ambient temperature)

50 °C 125 °F

90 °C 195 °F

120 °C 250 °F

Noise level < 70 dB(A)

9

Machine Characteristics

10

Transport & Installation

2 Transport & Installation

2-1 Transport

Only use a pallet jack or forklift to lift and transport the machine.

The machine is transported on a wooden pallet, which is an integral part of the packaging. The

machine is wrapped in plastic film to avoid moisture penetration.

2-2 Workspace Requirements

• This unit should be situated away from heat sources such as heat registers or stoves.

• There should be enough space around the laminator to feed-in, exit, and trim mounted and/or

laminated images.

• The background dust level must not exceed that found in a typical office/computer room

environment.

• The work area should be level, flat, and well lit.

2-3 Setup & Installation

Refer to the Unpacking/Set Up Instruction Sheet which is packed inside the crate, on top of the inner

box.

2-4 Electrical Requirements

This unit should only be connected to a power supply outlet having the voltage and amperage as

shown on the Identification Label (see Identification, 1-2). The 110VAC version of the SEAL 44 Ultra is

provided with a powercable having a NEMA 20Amp plug; the 230VAC version is provided with two

powercables: one having a BS 1363 plug, the other has a Schuko plug.

The electrical specifications of the machines are shown in 1-3, Electrical specifications.

The Seal 44 Ultra machines must be installed next to the power outlet; extension

cords are not to be used. The plug and the outlet must be easily accessible by the

operator.

11

Transport & Installation

12

Theory of Operation

3 Theory of Operation

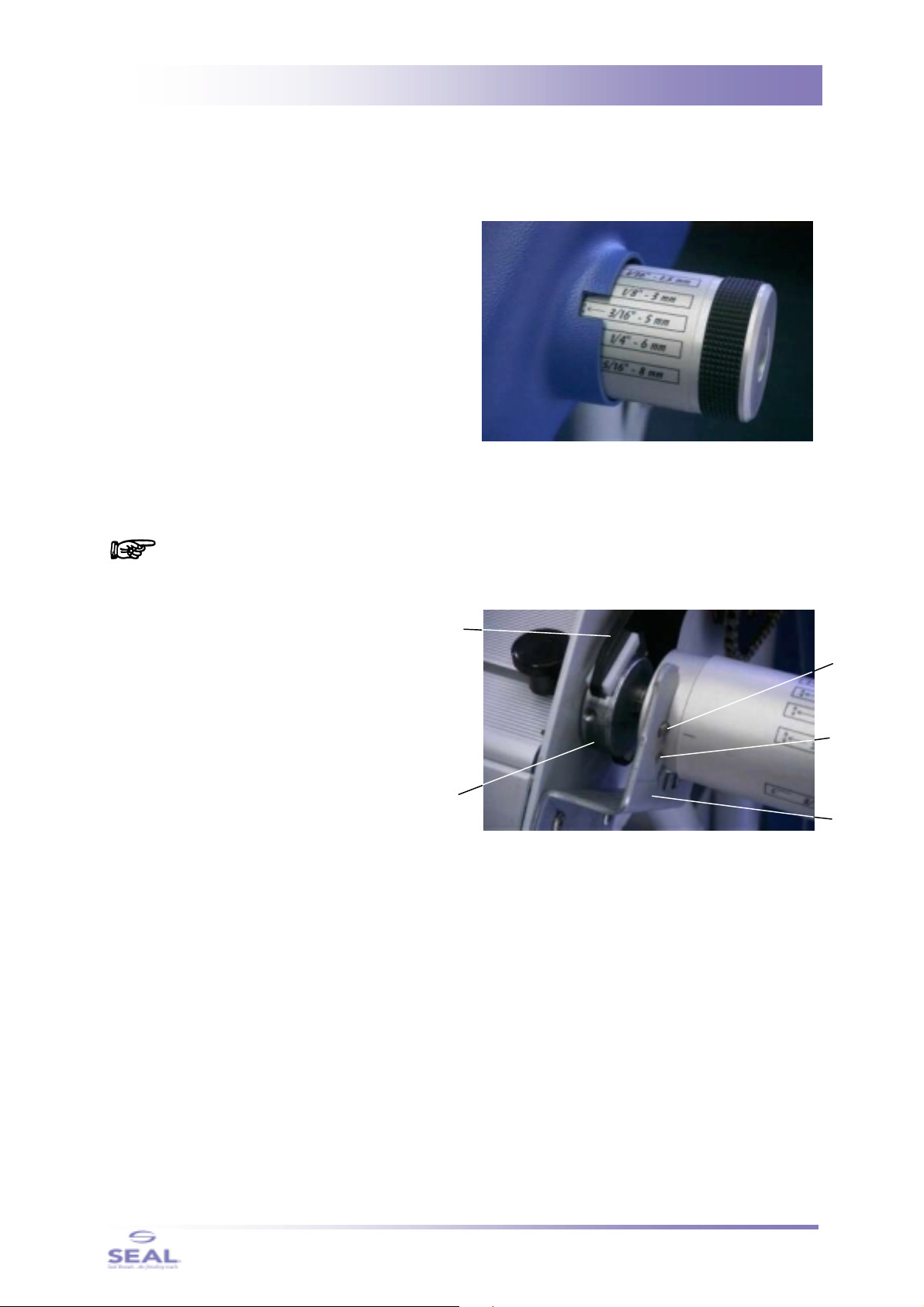

3-1 Control Knob

The Control Knob (see figure 1) is located on the

right hand side of the laminator and is operated

from the front of the machine.

The Control Knob can be operated by pushing it in

approximately 6mm (1/4”) to the left. Once the

knob has disengaged from the stop, it may be

rotated forward or backward (clockwise or counterclockwise, viewed from the right hand side of the

unit).

Continue to rotate the knob until the desired nip

setting corresponds with the indicator window at

the base of the knob. Inside the window, the

possible rotation directions are shown. Select the

value that corresponds to the thickness of the material you will be using with the machine.

Releasing the knob so that it moves back to the right and clicks into place will set the rollers for use.

Select the next lower value in case there is no match for the thickness of the used

substrate.

Internal functionality

See figure 2.

Inside the machine, a rod is mounted

between the left- and right-hand framesheets.

The knob is mounted on the rod; it allows

axial movement, but no radial movement.

The knob is provided with a pin (1), that falls

in the indents (2) of a bracket (3). The same

rod is provided with an eccentric (4) on either

side of the machine. These eccentrics push

or pull the arms (5), where the top roller is

mounted in, upward or downward.

3-2 Roller Nip settings

Whenever you mount onto a board, etc., it is important to adjust the rollers to create a gap nearly

equal to the thickness of the board being used. This is done so that anything passing between the

rollers will receive the right amount of pressure and prevent damage to the rubber surface of the roller

(and possibly the board).

fig. 1

5

4

fig. 2

1

2

3

13

Theory of Operation

y

p

g

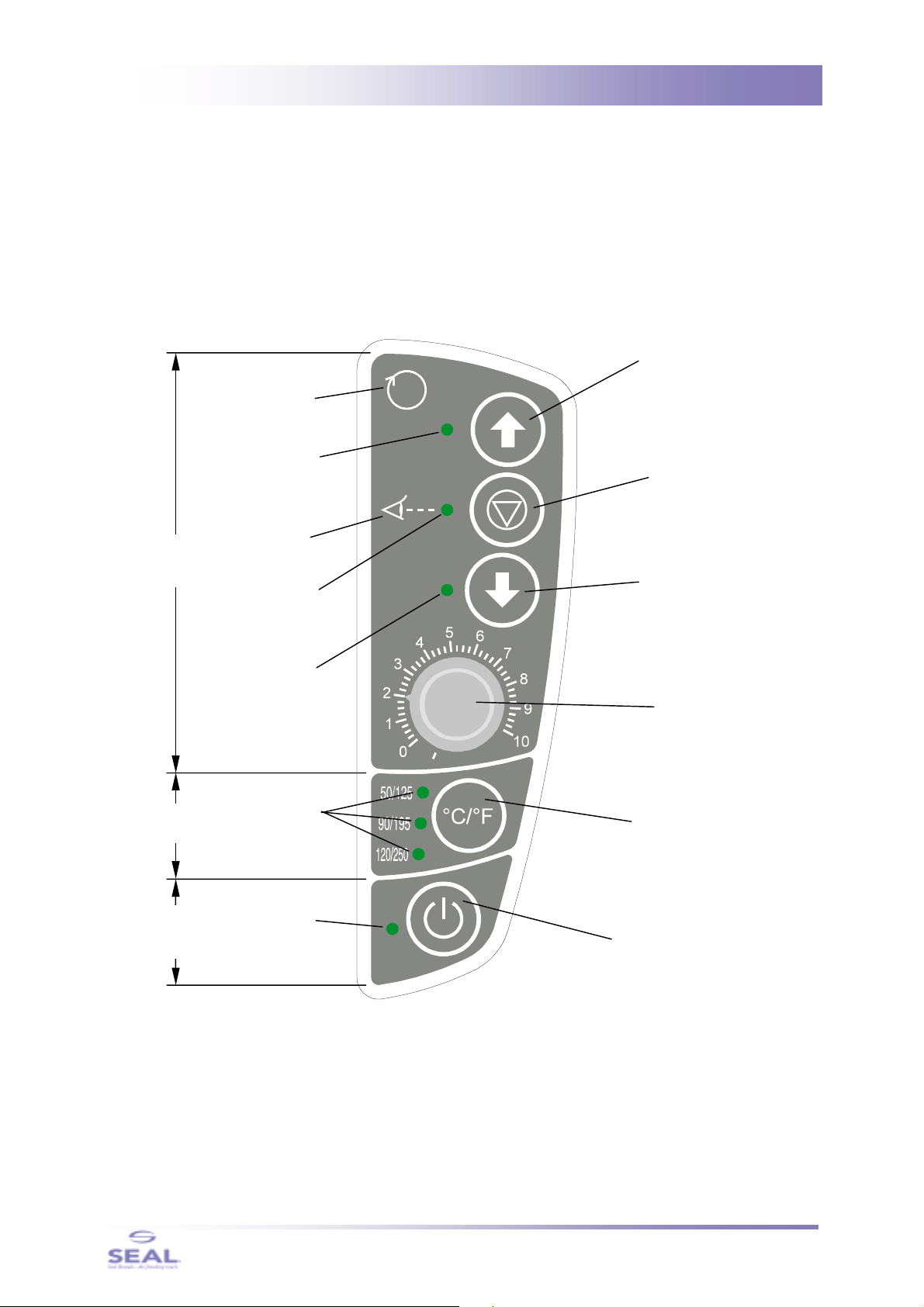

3-3 Control Panel

The Control Panel is located on the front right of the machine and has seven LED indicators. A

diagram of the Control Panel is shown in figure 3.

Pushbutton

Starts the forward

process direction of

Drive

mechanism

mbol

s

the rollers

speed

control

area

temperature

control area

LED (green)

Lit when machine

runs forward

Safety eye

symbol

LED (green)

Lit when safety

eyes are NOT

LED (green)

machine runs

LED’s (green)

temperature

interru

Lit when

reverse

Three

settin

ted

s

Pushbutton

Stops any roller

movement

Pushbutton

Runs the rollers in

reverse direction

(as long as the

button is pressed)

Speed

adjustment

knob

Pushbutton

To cycle through the

temperature presets

Press 2 seconds to

switch the heater on or

off

power

control

area

fig. 3

LED (green)

Lit when machine

is switched on

To switch the power on or off

Pushbutton

(standby-function)

14

Theory of Operation

3-4 Motor Control

The speed of the rollers is continuously adjustable between 0 and 1.5 m/min. (0 and 4.9 ft/min.)

Pressing the key runs the rollers in forward direction, pressing the key reverses the direction of

the rollers (as long as this button is pressed). The stop key stops the roller movement.

Slow-mode

The machine has a so-called slow-mode, which can be activated by pressing the foot switch. To

maintain slow-mode, keep the foot switch pressed.

Once the machine is running in slow-mode, interrupting the Photoelectric Cells does

NOT stop the machine; an audible beep will be heard, and the roller speed will be 0.6

m/min (2”/min) only. Releasing the foot switch will stop the machine.

• During slow mode (keep the foot switch pressed), press the (forward) button on the control

• Next, release the foot switch.

• Finally, release the (forward) button.

Reversing the machine

To reverse the rotation of the rollers, press the (reverse) button. As long as this button is pressed,

the machine will run in reverse direction, at a speed of 0.6 m/min (2”/min) only. Releasing this button

will stop the machine.

The rotation of the rollers will stop when:

Changing from slow-mode to normal running mode without stopping (to prevent stop

marks on the substrate):

panel. The machine will run at its pre-set speed.

Changing from normal mode to slow-mode without stopping:

Press the foot switch

NOTE: Releasing the foot switch will stop the machine.

Care must be taken not to have loose clothing, long hair, jewelry and fingers pinched

between the pull rollers at the rear side of the machine.

• The Photoelectric Cells in front of the main rollers are interrupted

NOTE: This does NOT happen when the foot switch is used (slow-mode)

• An emergency stop button is pressed

• The foot switch is pressed for a short moment

• Excessive unwind tensions are set (the motor will be shut off electronically, press

the stop button on the control panel to reset)

• The stop button on the control panel is pressed

15

Theory of Operation

3-5 Unwind Brakes

Tighten the unwind brake so that it applies sufficient tension to laminate. Turning the knurled collar in

a clockwise direction increases the unwind tension applied to the laminate. Turning the collar counterclockwise decreases the tension. The best setting for the brake tension is determined by the materials

you are using and is learned through experience.

Note: In general, no or light unwind tensions will be required.

16

Disassembly / Reassembly Procedures

4 Disassembly/Reassembly Procedures

4-1 Plastic Covers

Necessary tools: hexalobular screwdriver TX25, Allen key 4mm.

Approximate time: 5 minutes

To remove the side covers, perform the following steps:

1. Remove the two self-tapping screws, using the TX25 driver, as shown in figure 4. The right hand

cover is shown here.

fig. 4

fig. 5

2. Remove the self-tapping screw, situated at the rear side of the machine, using the TX25 driver, as

shown in figere 5.

3. Remove, using the Allen key 4mm, the two M5

socket screws, situated at the bottom of the

cover. See figure 6.

fig. 6

4. Carefully remove the right hand cover from the

frame of the machine. Now, a patchcable

connected to the controlpanel PCB and the

wires from the emergency stop will become

visible (see figure 7).

Hold the cover with one hand, whilst removing

the patchcable and the contactblock from the

emergency stop.

Push the little pin downward on top of the

socket and pull the connector out (see arrow in

figure 7).

fig. 7

17

Disassembly / Reassembly Procedures

1

5. The emergency stop contactblock can be removed using a little screwdriver which can inserted

below the clamping spring and the contact block.

See the arrow on figure 8.

6. The procedure for the left-hand side cover is

similar, though it’s obvious that there’s no

patchcable on this side.

The assembly of the covers is in reverse order.

Make sure that all connectors are

fitted when mounting the covers.

fig. 8

4-2 Heating Element

Necessary tools: Allen key 3mm

Approximate time: 10 minutes

Note:

To disassemble / reassemble the heating element,

it is necessary to perform the ‘Plastic Side Covers’

procedure, described in Se c tion 4- 1

Make sure that the power cord is

disconnected from the mains!

The heating element (see figure 9), is a quartz

tube, having a spiral wound filament mounted

inside.

The quartz tube is fragile; take care when

handling the element.

To exchange the the heating element, perform the following procedure:

1. See figure 10. Remove, on the left-hand

side of the machine, the blue fast-on

conector 1 from the overtemperature

switch.

2. Slide the he ater wir e out of the slot 2

that’s in the heater bracket.

fig. 9

2

fig. 10

18

Disassembly / Reassembly Procedures

2

3. See figure 11. Disconnect the white

connector 1, located on the right-hand side

of the machine from the heater wire.

Remove the heater bracket by removing

the two bolts 2. Take care not to loose the

serrated washers.

The heating element can now be taken out of

the roller.

When a heating element has to

be installed into the roller, the

quartz tube has to be cleaned

first.

Proceed as follows:

Insert the heating element, with the end having the shortest wire, into the roller core. Make sure,

that the short wire is bent straight, to smoothen the insertion.

Whilst inserting, clean the quartz tube with a lint-free cloth, lightly dampened with IPA (Isopropanol).

Do not touch the quartz tube with your fingers!

This is important, because fingerprints will burn when the heater is on, and can possibly damage the

quartz tube. See figure 12.

Always be very careful when using IPA! IPA is very flammable!

The flash point of IPA is 11°C (51.8°F). The self-ignition temperature is 400°C

(752°F).

Once the element is placed in the roller,

reassemble all parts in reverse order.

1

fig. 11

fig. 12

19

Disassembly / Reassembly Procedures

4-3 Rear Panel

Necessary tools: Phillips crosshead screwdriver (medium), open-ended spanner 8mm, and knife.

Approximate time: 10 minutes.

Perform the following steps:

1. Remove the seven self-tapping screws from the rear panel. Take care not to loose the serrated

washers and the 3 plastic straps.

2. See figure 13: carefully pull the rear panel backward a bit; next swing the rear panel a quarter turn

away from the machine.

3. Disconnect the 3 fast-on connectors from the appliance inlet (see white arrows in figure 13).

fig. 13

fig. 14

4. See figure 14: remove the connector marked J10 (to disconnect the footswitch).

5. The rear panel can now be removed.

6. To mount the rear panel back to the machine again, connect the wires on the rear side of the

appliance inlet and connect the footcable.

7. Push the rear panel back into its position, and make sure that the two slots, on either side in the

panel, fit around the two bent parts at the underside either framesheet.

8. Refit the seven selftapping screws which secure the rear panel. The 3 middle screws are also

used for mounting the plastic straps.

20

Disassembly / Reassembly Procedures

4-4 Control System Board & Software

4-4-1 Control System Board

To change the Control System Board, it is necessary to disassemble Rear Panel, as described in

section 4-3.

1. Remove all connectors.

2. Remove the five M3 socket screws.

3. Remove the print.

Assemble in reverse order.

Never

change the settings of the three potmeters, marked 1, 2 and 3 in figure 15.

4-4-2 Software

The Control System of the Seal 44 Ultra is software driven.

The software resides in a small embedded controller, mounted on the Control System Board.

1 2

3

4

fig. 15

Necessay tools: IC extractor

Approximate time: 1 minute

To change / upgrade the software, it is necessary to perform the ‘Rear Panel’ Procedure, described in

section 4-3.

Make sure that the power cord is disconnected from the mains !

1. See figure 15. Arrow #4 points to the processor (it usually has a sticker showing the software

version). Carefully remove it using the IC extractor.

2. To insert the new processor, make sure that its pins are not bent, and that the small notch on the

side of the processor matches the symbol, printed on the PCB (arrow #4 actually points to the

notch). Use the extractor to insert the new processor.

3. Discard the old processor.

21

Disassembly / Reassembly Procedures

4-5 Solid State Relay

Necessary tools: medium flat-head screwdriver, Allen key 3 mm.

Approximate time: 20 minutes.

Note:

To remove the Solid State Relay, it is necessary to perform the Rear Panel disassembly

procedure (see Section 4-3) first.

Perform the following steps:

1. Loosen all four screws that clamp the wires. They are marked 1 through 4. See figure 16.

2. Bend the wires a bit away from the Solid State Relay.

3. Remove the two M4 bolts that hold the Solid State Relay.

4. Now you can remove the Solid State Relay.

5. When mounting the Relay, make sure that the four clamping screws and the two M4 bolts are

tight. Don’t forget the serrated washers that belong under the M4 bolt heads.

fig. 16

Note: make sure, that the relay is mounted in the proper way: the coding on the

wires must correspond with the numbers on the relay.

Apply a bit heat-conductive paste on the underside of the Solid State Relay, and

spread it out a bit.

22

Disassembly / Reassembly Procedures

4-6 Photoelectric Cells

Note: to perform the following adjustments, it is necessary to remove both plastic side covers first. See

section 4.1: Disassembly / Reassembly plastic side covers.

Necessary tools: small flat head screwdriver, Allen key 3mm

Necessary materials: two tie-wraps (2.5 – 3 mm wide), per Photoelectric Cell.

Approximate time: 10 minutes.

Note: perform the Photoelectric Cells Adjustment procedure once the Photoelectric

Cell(s) have been replaced.

The Photoelectric Cells are fitted on the arms of the upper roller. Viewed from the front-side of the

machine, the transmitter is mounted at the left-hand side and the reciever is mounted at the right-hand

side of the machine.

The difference between the transmitter and the receiver is shown below.

fig. 17

Disassembly reciever or transmitter.

1. With the aid of a small screwdriver, remove the springclip (see figure 18).

fig. 18

fig. 19

2. Cut and discard the two tie-wraps.

3. Pull the connector out of the Photoelectric Cell (see figure 19).

23

Disassembly / Reassembly Procedures

4. Rem ove the two M4 bolts (see the white arr o ws in

figure 20, the left hand Photoelectric Cell is shown

here).

5. The Photoelectric Cell can now be removed.

Reassembly

6. When reassembling the Photoelectric Cell, make

sure that the bracket is positioned in such a wa y,

that the M4 bolt is in the middle of the vertical slot as

in figure 20 (three white lines). The same procedure

counts for the other Photoelectric Cell.

7. Insert the connector and secure it with the metal spring clip.

8. Assemble the new tie-wraps as shown in figure 20.

fig. 20

24

Adjustment Procedures

5 Adjustment Procedures

5-1 Laminating Pressure

Note:

To perform the following adjustments, it is necessary to remove both plastic side covers first.

See Section 4-1: Disassembly / Reassembly Plastic Side Covers.

There are two ways to adjust the laminating pressure:

1. Adjustment using load cells and display unit.

2. Adjustment using Heat Sensitive Film (JetGuard 5mil or Thermashield 5mil).

This procedure is preferred if the adjustment has to be done in the field, at the site of

the end-user.

Both ways need the following necessary tools: 10mm open-ended spanner, small flat-head

screwdriver, Allen key 3 mm.

Approximate time: 15 minutes.

5-1-1 Adjustment using Load Cells and Display Unit

To adjust or set the laminating pressure, a

Pressure Display Unit is required. These units

come in various sizes and/or shapes; however, the

load cells typically look like figure 21.

The top roller must be at room

temperature!

Proceed as follows:

1. Set the nip setting knob to 10 mm (3/8”).

2. Remove the support brackets for the Image

Guide (see figure 22, the RH bracket is shown

here). The two bolts that have to be removed in

order to remove the RH bracket, are shown in

figure 23 (in later versions of the machine the way these bolts and nuts are mounted, is reversed).

3. Loosen the adjustment strip on either side of the machine. See figure 23, right-hand strip shown.

Note that the strips must not touch the top roller bearing housing during the pressure adjustment

procedure.

fig. 21

fig. 22

25

fig. 23

adjustment

strip

remove

Adjustment Procedures

4. Position the load cells at either side of the rollers, between the journals, as shown in figure 24.

fig. 24 fig. 25

5. Push and rotate the nip adjustment knob until the pin, mounted in the knob, falls into the last notch

(relative to top) from the indent bracket (see figure 25, white arrow).

The pressure will be applied to the pressure sensors, and the pressure can be read on the PDU.

6. To change the pressure, place the 10mm

open-ended spanner on the M6 nut, that is

directly under the compression spring (so, the

upper jamnut, see figure 26, white arrow).

7. On the left-hand side of the machine, it is best

to remove the blue connector from the

overtemperature switch, to eas e acces s with

the spanner. See figure 10, arrow #1.

8. Rotate clockwise to decrease the pressure,

counter-clockwise to increase the pressure

(seen from top).

9. The pressure readout for each load cell (so, for

either side of the machine) should be 55 kgf (121 lbf). If necessary, change these values as

described above.

10. After the adjustment, remove the pressure sensors.

11. Assemble all parts in reverse order.

Now, it is mandatory to continue with the Image Guide Adjustment procedure,

section 5.6

fig. 26

26

Adjustment Procedures

5-1-2 Adjustment using Heat Sensitive Film

This procedure refers to the pressure adjustment to be done at the customer’s site.

Note: as this procedure is performed using heat sensitive film (JetGuard 5 mil or

Thermashield 5 mil), the top roller temperature should be set to 120

1. Remove any film from the machine.

2. Remove the Image Guide.

3. Cut several sheets of film from the supplyroll. The offcut size should be 43’’ by 8’’ (so it’s easy if

43’’ film is used).

4. Set the nip to its maximum position (10mm or

3/8’’).

5. Place two sheets, with their adhesive sides

facing each other, between the rollers, as

shown in figure 27.

6. Close the nip , and wait 30 s econds .

7. Open the nip to its maximum position, and

remove the sheets. Now, they’re stuck

together. Mark the sheets (using a felt tip

pen) how its position was, relative to the

machine.

fig. 27

A small part of the sheets is

1

shown in figure 28. The

footprint (the area where the

rollers touch each other) is

very clearly visible, and it

2

has roughly a width of

10mm (3/8’’). At either side

of the footprint, the films are

molten together partially (2)

and various air-entrapm ents

roughly

10mm (3/8’ ’)

Footprint

(3) are visible. The rest of

the two sheets is still

opaque (1).

3

fig. 28

• If the roll pressure is correct, then the footprint looks like:

The difference in width measured in the middle of the footprint, and 25mm (1’’) from either

side, must not be larger than 0.5mm (0.02’’).

If this is the case, the pressure adjustment is correct, and the side covers can be

assembled.

°C (250ºF).

43’’

27

Adjustment Procedures

• If the roll pressure is too high, then the footprint looks like:

This is the case if the ends of the footprint (measured 1’’ from either side) are at least 1mm (0.04’’)

wider than the middle.

Change the pressure as described below.

• If the roll pressure is too low, then the footprint looks like:

This is the case if the ends of the footprint (measured 1’’ from either side) are at least 1mm (0.04’’)

smaller than the middle.

Change the pressure as described below.

• If the footprint is narrower (or wider) at one end, and the other

end has the same width as the middle of the footprint, then the

pressure at only that narrower (or wider) end of the machine

should be increased (or decreased).

In general: for either side of the machine counts:

end narrower than the middle

end wider than the middle

Changing the pressure

8. To change the pressure, place the 10mm

open-ended spanner on the M6 nut, that is

directly under the compression spring (so, the

upper jamnut, see figure 29, white arrow).

9. Rotate clockwise to decrease the pressure,

counter-clockwise to increase the pressure

(seen from top).

Rotate the jamnut only half a turn on either

side

10. Make a new footprint (go back to step 5)

increase pressure at that end

decrease pressure at that end

fig. 29

or

28

Adjustment Procedures

5-2 Roller Nip

Note: to perform the following adjustments, it is necessary to remove both plastic side covers first.

See section 4-1: Disassembly / Reassembly Plastic Side Covers.

Necessary tools: Allen Key 4mm, a set of metric thickness gauges.

Approximate time: 5 minutes

Note: the top roller must be at room temperature, before this procedure is being performed.

1. Set the roller opening to its minimum position by pushing and turning the nip setting knob fully

counter-clockwise. (nip 0mm)

2. Loosen the bolts that hold the adjustment strip in such a way, that the strip can be moved up- and

downward, but does not slide downward by its own weight.

3. Place a 0.6mm (0.0236 inch) gauge between the bearing housing and the adjustment strip. See

figure 30: the white arrow points to the 0.6mm wide opening, caused by the gauge.

4. Push the adjustment strip upward against the gauge (figure 30) and fasten the M5 bolts while

leaving the gauge in place. See figur e 31.

push strip

upward

fig. 30

fig. 31

5. When done, remove the gauge.

6. Perform steps 2 thru 5 at either side of the machine.

29

Adjustment Procedures

5-3 Temperature

Necessary tools: Infrared temperature meter, small flat-head screwdriver.

Approximate time: 30 - 45 minutes.

1. Set the roller nip to 10mm (3/8’’).

2. Set the top roller temperature to the 120°C setting on the control panel; the roller is being heated

up.

3. After approx. 5 minutes, turn the top roller

roughly a quarter of a turn, and repeat this

every 2 minutes, until the green LED, next to

the 120°C setting, is steady.

4. Measure the temperature on top of the roller,

close to the middle of the machine. See figure

32, white arrow.

Turn the top roller by hand until you see a

more or less constant value in the read-out of

the temperature meter.

The temperature should be 135°C +/- 4° C

(275°F +/- 7°F).

5. To change the temperature setting, insert the

screwdriver into the small hole situated in the rear panel. Carefully turn the screwdriver until you

feel that it snaps into the slot in the potentiometer.

See the arrow in figure 33.

6. Rotating clockwise increases the temperature,

counter clockwise rotation will decrease the

temperature.

A five-degree turn of the trimpot will change

the temperature by approximately 10°C

(18°F).

7. After the adjustment, allow the roller to change

its temperature for some 15 minutes, and

repeat the sequence at point 4.

fig. 32

30

fig. 33

Adjustment Procedures

5-4 Photoelectric Cells

Note: to perform the following adjustments, it is necessary to remove both plastic side covers first. See

section 4-1: Disassembly/Reassembly Plastic Side Covers.

Necessary tools: small flat-head screwdriver.

The Photoelectric Cells are mounted on the arm assemblies of the upper roller. Viewed from the front-

side of the machine, the transmitter is mounted at the left-hand side and the reciever is mounted at the

right-hand side of the machine.

1. Switch the machine on.

Caution! The electric parts of the machine are now live. From now on, do not touch any electrical

components. Do not place fingers between the chain or other moving parts.

2. See figure 34, white arrow. Make sure, that

the slit in the mode selector is pointing to the

‘D’ position (the setscrew is rotated fully

counter-clockwise).

3. See figure 35. Rotate the setscrew in the

transmitter (at the left-hand side of the

machine) fully counter-clockwise. The

transmitter will now emit very little light.

As a result of this, on the receiver (figure 34)

the red LED will be lit (meaning: there’s no

signal), and the green LED will be lit as well

(meaning: the ‘no-light’ situation is stable)

4. Now rotate the setscrew on the transmitter

very slowly clockwise until the the green LED

on the reciever starts to fade out, next rotate a

bit further clockwise until the red LED goes

out, and finally rotate a bit further clockwise

until the green LED is just fully lit (which is

only a few degrees more!).

Note that the red LED gives a faint flash every

two seconds: this is the self-check sequence.

The Photoelectric Cells are now correctly adjusted.

Switch off the machine and disconnect it from the

mains.

Replace the plactic covers.

fig. 34

fig. 35

31

Adjustment Procedures

5-5 Drive Chain

Necessary tools: Allen key 4mm, medium flat-head screwdriver.

Approximate time: 8 minutes.

Note: to perform the following adjustments, it is necessary to remove the right-hand side cover first.

See section 4-1: Disassembly / Reassembly Plastic Side Covers.

The chain guide ensures that the chain has

sufficient grip on the clutch assembly.

4

See figure 36. If the lower section of the chain

(black arrow) has more play than 6 mm (1/4’’), then

the tensioner should be adjusted.

1. To do this, loosen the M5 socket screw half a

turn, and rotate the chain adjuster a bit

clockwise (white arrow).

2. Tighten the M5 bolt again whilst holding the

adjuster with the flat-head screwdriver.

3. Check the play of the lower part of the chain

again (black arrow). There should be a play of

roughly 1-2 mm, so the chain must never be

too taut.

fig. 36

2

3

Replace the plactic covers.

5-6 Clutch

Necessary tools: open-ended spanner 19mm.

Approximate time: 15 minutes.

Note: to perform the following adjustments, it is necessary to remove the right-hand side cover first.

See section 4-1: Disassembly / Reassembly Plastic Side Covers.

To ensure that the film is not slipping between the pull rollers, yet receiving sufficient tension, the

clutch has to be adjusted properly.

Proceed as follows:

1. Set the machine up for encapsulation using JetGuard 5mil gloss or Thermashield 5mil gloss. Run

the process at 120°C setting, whereas the speed setting should be 2 (which is lower than the

values on the Process Control sticker!). Don’t process any images.

2. While the machine is running, turn the large nut (see figure 36, arrow 3) clockwise, until the friction

discs (arrows 4) are NOT moving in respect of each other. The film, running through the pull

rollers, may create a squeeking noise now.

3. Next, turn the large nut slowly anti-clockwise, just until the discs start moving in respect of each

other again. Continue running the encapsulation process for two minutes to ensure that this

situation is stable.

Replace the plactic covers.

32

Adjustment Procedures

5-7 Image Guide

To perform the following adjustment, it is necessary to remove both plastic side covers first. See

Section 4-1: Disassembly/Reassembly Plasic Side Covers.

Necessary tools: allen key 3mm, gauge 2mm.

The distance between the upper edge of the Image Guide and the roll surface must be 2±0.5mm

(0.0787±0.0196 inch), see figure 37.

1. To adjust the Image Guide, it is

necessary to position it in front of the

top roller, onto the two support

brackets (see arrow #1).

2. Slide the Image Guide all the way

towards the roll; make sure that the

front edge of the Guide is under the

bolt mounted in the support bracket

(see arrow #2).

3. If necessary, loosen the two socket

screws (arrows #3), that hold the

support bracket, half a turn. Perform

this at either side of the machine.

4. Reposition the support brackets until

the previously mentioned distance of

2 mm has been achieved.

Thighten the socket screws and

reassemble the plastic covers.

2

3

1

fig. 37

33

Adjustment Procedures

34

Troubleshooting

6 Maintenance

Cleaning of the Machine

The equipment must be disconnected from the mains before cleaning.

The laminator may be cleaned by the operator with a lint-free cloth, lightly dampened with a mild soap

and water solution. Spray-on cleaners are not to be used. No part of the machine is to be immersed in

water or other liquids.

Do not use an abrasive cleaner, which can damage the painted surfaces.

Do not allow water or liquids to enter the electrical circuits, which may cause personal injury and / or

damage the equipment when power is appli ed.

Roller cleaning

To clean the rollers: use the Image roll-cleaner to remove the excess adhesive from the rollers. This is

done best while the rollers are hot.

When cleaning the upper roller, place a piece of scrap foam board under the roller

to prevent the removed adhesive remnants from falling onto the lower roller.

For adhesive that is difficult to remove, allow the rollers to cool and use isopropyl alcohol (IPA) and a

clean, lint-free cloth. Never pour isopropyl alcohol (IPA) directly onto the unit.

CAUTION! Always use care when using Isopropyl Alcohol! (IPA)

IPA is very flammable. The flash point of IPA is 11°C (51.8°F). The self-ignition

temperature is 400°C (752°F)

Unwind Shafts

Clean the rubber ropes at least once a week.

If a rubber rope becomes too slack after a longer period of time, unscrew one of the clamps, cut off

1cm (0.5’’) of the rope, and fasten it again using the clamp.

35

Troubleshooting

36

Troubleshooting

7 Troubleshooting

Note:

The ‘Causes’, as described below, are placed in a logical order of occurrence; please

follow this sequence in order to solve the problem.

Problem:

The power LED does not come on, when the standby pushbutton is pressed.

Causes:

The power cable has not been plugged in the mains wall outlet.

Solution:

Plug the power cable into the mains outlet.

The (external) mains circuit breaker is tripped.

Solution:

Reset the mains circuit breaker.

The standby pushbutton is not pressed long enough.

Solution:

Press this button for 2 seconds (this is done to prevent accidental switchingon of the machine). When it switches on, you’ll hear a short beep.

The processor, containing the software, is not installed.

Solution:

Install the software (see Software Installation, Section 4-4).

The processor, containing the software, is installed the wrong way around.

Solution:

Install the software properly (see Software Installation, Section 4-4).

The patchcable, coming from the control system board is not connected with the control panel

PCB.

Solution:

Check if the right-hand side cover is assembled correctly (see Plastic

Covers, Section 4-1)

There is no secondary (supply) voltage.

Solution:

Check fuse F3 (see diagrams 8-1 and 8-3). This fuse is accessible through

the rear panel. See the Spare Parts List for type and voltage.

If the F3 fuse is OK, check if the Photoelectric transmitter (at the left-hand

side of the machine) emits red light: if not, replace the Control System

Board.

There is no primary (supply) voltage.

Solution:

Check fuse F1 and F2 (see diagrams 8-1 and 8-3). To access these fuses,

the rear panel has to be removed (see Section 4-3, Rear Panel). These

fuses are located on the Control System Board (see diagram 8-1). See the

Spare Parts List for type and voltage.

The machine is set for 230V whereas the supply voltage is 110V.

Solution:

Check the rating label attached on the rear panel!

Else:

There is an internal Control System Board error. In this case, check the Miscellaneous Control

System Board Error Messages list at the end of this section.

37

Troubleshooting

Problem:

The power LED does come on, but it is flashing at a low rate. This is an error-condition.

Cause:

The supply voltage is too low.

Problems like these occur usually if extension cords are used; in particular extension cords, that

have a (too) low rating. When the heater of the machine is switched on, the voltage usually

drops.

Solution:

Do not use extension cords.

Check if the power supply of the office/building, where the 44 Ultra is used,

supplies enough voltage to power the machine.

For the 110V unit, the supply voltage should lie between 90V and 130V.

For the 230V unit, the supply voltage should lie between 200V and 250V.

Problem:

The power LED does come on, but it is flashing at a high rate. This is an error-condition.

Cause:

The supply voltage is too high.

Solution:

It’s not likely that this error will occur; however, you should check the rating

label. If this is a 110V unit that’s attached to a 230V supply, the F1 and/or

the F2 fuse should blow.

For the 110V unit, the supply voltage should lie between 90V and 130V.

For the 230V unit, the supply voltage should lie between 200V and 250V.

Problem:

The LED for the Photoelectric Cells on the control panel does not come on; the machine does not run

forward.

Cause:

An object is interrupting the lightbeam.

Solution:

Remove the Image Guide (if applicable); check if something is sticking on

the edge of the infeed table (a piece of paper or tape).

The Photoelectric Cells are misaligned.

Solution:

Perform the adjustment procedure described in Section 5-4.

The Photoelectric Cells are defective. The green LED on the receiving photocell does not come

on at all, when the transmitter is set to its maximum position (see Section 4-6).

Solution:

Replace the Photoelectric Cel ls as descr ib ed in Sec ti on 4-6.

Next, perform the adjustment procedure described in Section 5-4.

The Control System Board is defective. This is the case if the adjustment procedure is

functional, but the green LED on the panel still does not come on.

Solution:

Remove the rear panel as described in Section 4-3, and replace the Control

System Board.

Problem:

The LED for the Photoelectric Cells on the control panel is flashing.

Cause:

The internal self-check signal for the photoelectric cells is not present.

Solution:

Remove the rear panel as described in Section 4-3, and replace the Control

System Board.

38

Troubleshooting

Problem:

The Forward LED on the control panel is flashing; the machine has stopped.

Cause:

The drive motor has been overloaded.

Solution:

Press the start button. The LED will cease flashing and will be lit

continuously.

Problem:

The Reverse LED on the control panel is flashing; the machine has stopped.

Cause:

The drive motor has been overloaded.

Solution:

Press the reverse button. The LED will cease flashing and will be lit

continuously (as long as the button is pressed).

Problem:

The Forward LED and Reverse LED on the control panel are flashing simultaneously.

Cause:

The power relay on the Control System Board is not switching off after a stop signal (a contactweld).

Solution:

Remove the rear panel as described in Section 4-3, and replace the Control

System Board.

Problem:

The Forward LED is lit, but the motor is not running.

Cause:

The speed setting is zero (or close to zero).

Solution:

Set the speed (a bit) higher.

The drive motor is not connected to the Control System Board.

Solution:

Remove the rear panel as described in Section 4-3, and check connector J9

on the Control System Board.

The drive motor is defective.

Solution:

Change the drivemotor.

The Control System Board is defective.

Solution:

Replace the Control System Board.

Problem:

The Reverse LED is lit, but the motor is not running.

Cause:

The drive motor is not connected to the Control System Board.

Solution:

Remove the rear panel as described in Section 4-3, and check connector J9

on the Control System Board.

The drive motor is defective.

Solution:

Change the drivemotor.

The Control System Board is defective.

Solution:

Replace the Control System Board.

39

Troubleshooting

Problem:

The motor is not running when the Forward or Reverse buttons are pressed, the Forward or Reverse

LED’s do not come on either; however the LED for the Photoelectric Cells on the control panel is lit.

Cause:

One or both Emergency Stop buttons have been engaged.

Solution:

Check if the E-stop buttons are clear: rotate the red knob clockwise until it

pops out.

Problem:

All three LED’s in the heater section on the control panel are flashing at a fast rate, whether or not the

heater has been switched on. The top roller temperature is way too high (at least higher than 150°C or

302°F).

Cause:

The Solid State Relay is defective.

Solution:

Check the AC voltage on points 1 and 2 on the Solid State Relay. If the

voltage is close to 0V, while the red LED on the relay is off, change the Solid

State Relay as described in Section 4-5.

Problem:

All three LED’s in the heater section on the control panel are flashing at a fast rate, whether or not the

heater has been switched on. The top roller is at room temperature.

Cause:

The Temperature Sensor is defective, or one of its wires is loose.

Solution:

Check the wires, or change the Temperature Sensor.

Afterwards, perform the temperature adjustment procedure as described in

Section 5-3.

Problem:

All three LED’s in the heater section on the control panel are flashing at a slow rate, whether or not the

heater has been switched on. The top roller is at room temperature.

Cause:

The Temperature Sensor is defective, or its wires are short-circuited.

Solution:

Check the wires, or change the Temperature Sensor.

Afterwards, perform the temperature adjustment procedure as described in

Section 5-3.

Problem:

After stopping a hot lamination process, the LED for the set temperature starts flashing at a fast rate (a

temperature overshoot occurs).

Cause:

This is a normal phenomenon, which occurs more often at high temperature settings or speeds.

Solution:

None.

40

Troubleshooting

Problem:

The temperature-ready LED keeps on flashing at a slow rate (after 20 minutes), once the heating has

been activated.

Causes:

The heating element is defective, or one of its connectors had not been installed.

Solution:

Check the voltage between point 1 and 2 on the Solid State Relay. If the

voltage is close to 0V, while the red LED on the Relay is lit, check the wiring

to the heating element, and perform the Heating Element

assembly/reassem bl y procedure, se e Sec ti on 4-4.

The Solid State Relay is defective (it has a permanent ‘open’ state).

Solution:

Check the voltage between point 1 and 2 on the Solid State Relay. If the

voltage is close to the power supply voltage, while the red LED on the Relay

is lit, replace the Solid State Relay, see Section 4-1.

The overtemperature switch is defective (it has a permanent ‘open’ state; in this case, the line

voltage can be measured between it’s connectors).

Solution:

Check the voltage between point 1 and 2 on the Solid State Relay. If the

voltage is close to 0V, while the red LED on the Relay is lit, replace the

overtemperature switch.

The Control PCB is defective (if the previous checks are OK).

Solution:

Replace the Control System Board.

Problem:

The quality of the lamination is poor: silvery areas on dark surfaces are visible, or the edges of the

image are not sealed well.

Causes:

The roller temperature setting is too low.

Solution:

Check the materials used for the process, and the Process Control sticker

that is attached on the machine.

The wrong nip setting has been chosen.

Solution:

Measure the thickness of the boards, and set the next lower value on the

adjustment knob.

The speed setting is too low.

Solution:

Check the materials used for the process, and the Process Control sticker

that is attached on the machine.

Increase the speed if necessary.

The roller pressure is too low.

Solution:

Perform the Laminating Pressure Adjustment procedure (see Section 3-1).

Problem:

The quality of the lamination is poor: especially laminated inkjet prints show bubbles.

Causes:

The roller temperature setting is too high.

Solution:

Check the materials used for the process, and the Process Control sticker

that is attached on the machine.

The speed setting is too high.

Solution:

Check the materials used for the process, and the Process Control sticker

that is attached on the machine.

Reduce the speed if necessary.

41

Problem:

The quality of the lamination is poor: wrinkles and/or creases show up in the output.

Cause:

The laminating pressure setting is wrong.

Solution:

Perform the Laminating Pressure Adjustment Procedure described in

Section 5-1.

Miscellaneous Control System Board Error Messages

Error:

LED no. L6 is NOT lit.

Cause:

The +5V voltage is not present.

Solution:

Check the fuses F1, F2 and F3.

If OK, check if there are no loose connections in the cable harness.

If this is OK as well, replace the Control System Board.

Error:

LED no. L7 is NOT lit.

Cause:

The voltage for the motorcontroller is not present.

Solution:

Check the Emergency Stops.

If OK, check if there are no loose connections in the cable harness.

If this is OK as well, replace the Control System Board.

Troubleshooting

42

8 Diagrams

8-1 Installation Diagram

Diagrams

43

8-2 Control Panel Diagram

Diagrams

44

8-3 Safety Control System Diagram

Diagrams

45

A

A

8-4 Certified Electrical Components List & Sparepart Codes

DWG

NAME MANUFACTURER TYPE TECHNICAL DETAILS UL LISTING SPAREPART NO:

Ref.

SSR1 solid state relay Omron G3NA-220B 240Vac / 20A E64562 SP 961-0001

heater 44 Ultra

E1

110V/1850W

heater 44 Ultra

E1

230V/1850W

S1 overtemp switch Elmwood 2511L135-2040 AC 250V/ 25A MH8267 SP 961-6003

M1 motor Dunker

print 44 Ultra

P1

control system

board

F1,F2 fuseholders Schurter FPG4 250Vac /10A E39328

F3 fuseholders Schurter FPG5 250Vac /10A E39328

F1 ,F2 fuse ELU 179200 250Vac /800mA **

F3 fuse Littelfuse 239.002 250Vac /2A E10480

C2 Capacitor Philips 33620105

L1 Twin coil Siemens

J10 print connector Phoenix MSTBT AC 250V/12A E60425

Mini Fit JR Free

J1,J9

Receptacle

PET1-

photo electric

PER1

sensor

S2 ,S3 emergency stop Telemecanique

S4 footpedal Telemecanique XPE-A110 AC240V/3A **

T1 transformer 115V Amplimo 2N1249 115V-25V-50VA E179800 SP147-078

Quartz Tubing Inc. 147-124 120Vac /1850W ** SP 147-124

Quartz Tubing Inc. 147-119 230Vac /1850W ** SP 147-119

GR 42x40

I=312.5:1

Hunt Graphics 963-0018 see underneath ** SP 963-0018

B82722-A2501N1

Molex 39-01-2xx0 250Vac/8A E29179

Keyence PZ2-51 NP 12-24Vdc

ZB6 AS834

ZB6Z4B

24V DC In=1,22A ** SP 964-0000

275V a c (x1,X2)

250V ac(Y2)

2x27mH 250Vac/0,5A

AC 250V/ 6 A

Diagrams

T1 transformer 230V Amplimo 2N1250 230V-25V-50VA E179800 SP147-079

mains lead 44

Ultra America

mainslead

England

mains lead

Europe

footpedal cable General cable 3XAWG16

tri rated

internal wiring

(black)

tri rated

internal wiring

(blue)

tri rated

internal wiring

(green/yellow

Free socket for

115VAC

Inlet 115VAC

flange Fixing

Inlet 230VAC

flange Fixing

snap bushing Heyman `2066 11,1mm UL94V-2 SP 961-0005

nut cable gland Hugro 587.13.01 polyamid E79903 SP 961-0012

coupling nut Hugro 184.1312.01 polyamid V-0 SP 961-0011

TS1 temperture sensor Exergen

print control panel

P2

44 Ultra

controlpanel De Naamplaat BV ** ** ** SP147-021

any make

Feller

Feller

Multico mp

Multico mp

Multico mp

Schurter

Schurter R4506000 250Vac/16A

Bulgin PX 0575 250Vac/10A

Hunt graphics ** ** ** SP963-0019

Nema 5 -20P C19/20A-250V

V11H05RRF3G1.00C13

V11H05RRF3G1.00C13

AWG14-AWG18AWG22

AWG14-AWG18AWG22

WG14

AWG22

R61000601(104-

08)

IRT/C.01-J180F/90F

SJT 3x12AWG

250V~ 10A ** SP 961-0017

250V~ 10A ** SP 961-0016

SOW3 OR SJOW3 AWG

16

WG14 AWG18

AWG22

AWG14

AWG18 A W G22

AWG14

AWG22

250Vac/16A

J180/90C ** SP 961-0034

E4154 2

LL14903

UL1007 or

UL1015

UL1007 or

UL1015

UL1007 or

UL1015

SP 961-0006

46

Diagrams

8-5 Mechanical Spare Parts List, Assembly Drawings & Exploded Views

8-5-1 Mechanical Spare Parts List

Item Sparepart code Dwg added

Assy bottom roller ProSea l 44 SP 144-004 Y

Assy nipknob ProSeal 44 SP 144-021 Y

Assy rh arm pull roller SP 144-190 Y

Assy lh arm pull roller SP 144-191 Y

Clutch pull roller SP 147-001 Y

Assy bottom pull roll Seal 44 Ultra SP 147-005 Y

Sprocket wheel Z=29 SP 147-007 N

Assy mounting plate control system 230V SP 147-011 Y

Assy mounting plate control system 110V SP 147-125 Y

Assy lh cover Seal 44 Ultra SP 147-025 Y

Assy unwind brake SP 147-027 Y

Assy autogrip shaft SP 147-033 Y

Assy lh cone SP 147-039 Y

Assy stand Seal 44 Ultra SP 147-040 Y

Assy idler windup SP 147-062 Y

Assy cover Seal 44 Ultra SP 147-067 Y

Assy rh frame Seal 44 Ultra SP 147-070 Y

Assy lh frame Seal 44 Ultra SP 147-072 Y

Assy rh arm Seal 44 Ultra SP 147-075 Y

Tension wheel SP 147-080 N

Chain tensioner SP 147-081 N

Assy lh arm Seal 44 Ultra SP 147-082 Y

Assy top pull roller SP 147-088 Y

Assy tie-bar SP 147-103 Y

Bracket image guide rh side SP 147-108 N

Assy image guide SP 147-109 Y

Bracket image guide lh side SP 147-113 N

Feed-in table assy Seal 44 Ultra SP 147-114 Y

Assy rear sheet Seal 44 Ultra 230V SP 147-117 Y

Assy top roller Seal 44 Ultra SP 147-120 Y

Assy rear sheet Seal 44 Ultra 110V SP 147-069 Y

Drive chain SP 956-0004 N

Chain joint SP 956-0005 N

Sticker nipknob SP 147-085 N

Owners manual SP 977-0041 N

Leader board SP 9990022 N

Heater 44 Ultra 230V / 1850W SP 147-119 N

Heater 44 Ultra 110V / 1850W SP 147-124 N

47

8-5-2 Assembly Drawings & Exploded Views

These assembly drawings are available on request.

Diagrams

48

Loading...

Loading...