Image®6500 Laminator

Owners Manual - English

Gebrauchsanleitung •

Manuel d’ Utilisation • Manual del Usuario • Manuale Utente

Image®6500 Laminator

Kaschiermaschine • Machine laminer • Lamina Dora • Laminatore

SEAL®IMAGE®6500 LAMINATOR — TABLE OF CONTENTS

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Electrical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Workspace Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environment Conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Unpacking, Set-up and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-8

Important Safeguards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Safety Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Laminator Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Control Panels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-15

Checking Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Set-Up and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17-21

Feeding Images . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Webbing Films Without a Release Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Webbing Films With a Release Liner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Decaling (Heat-Activated) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Decaling (Pressure-Sensitive) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Encapsulating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Pre-Coating Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Low-Temp Vinyl Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Process Control Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cleaning/Maintaining Your Laminator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Periodic Maintenance Sheet . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Trouble Shooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Glossary of Terms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Spare Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

2

INTRODUCTION

Thank you for purchasing a SEAL®Image®6500 Laminator.

We have designed the SEAL Image 6500 to give you years of

reliable service. As you become familiar with your laminator,

you will appreciate the high quality of its production and the

excellence in its engineering design.

The SEAL Image 6500 is a true bi-directional laminator.

Designed for full-range, high-volume requirements including heat or pressure sensitive lamination, encapsulation and

hot or cold mounting of images. The two sets of symmetrical, bi-directional rollers speed production, running heatactivated materials from the front and cold pressure-sensitive

applications from the back.

By following the guidelines for proper care and use of the

SEAL Image 6500, you can depend on many years of

trouble-free profitability from your investment.

The purpose of this manual is to outline the materials

and process when using SEAL Brands supplies with your

laminator to create signs, displays, and flexible graphics

with professional results. The manual includes instructions

of various laminating procedures, which are meant to give

you comprehensive information needed for the efficient

use of your laminator.

Please read and fully understand the entire manual

before proceeding to use your laminator.

STATEMENT OF INTENDED USE

Your SEAL Image 6500 Laminator meets the CE

Machinery Safety Directive (89/392/EEC, including

91/368/EEC, 93/44/EEC and 93/68/EEC) and is cETL

listed (UL775, 1950/EN60950).

The SEAL Image 6500 laminator has been designed to be

used with SEAL Brands materials. When used with these

products, you are able to mount, mount and laminate, and

encapsulate prints in one step. Your laminator has been

tested with SEAL Brands supplies and we recommend

using these products for professional results.

WARNING! This laminator is designed for mounting

and laminating. Any use, other than the intended,

may cause damage to the laminator or physical harm

to the user.

LIABILITY STATEMENT

The details given in this manual are based on the most

recent information available to us. They may be subject to

change in the future. We retain the right to make changes

to the construction or the design of our products without

accepting any responsibility for modifying earlier versions

previously delivered.

CAUTION! Please pay attention to all passages marked

this way. This information is vital to preventing user

injury and/or damage to the unit. Failure to follow this

information could void the user’s warranties and transfer all safety obligations to the user.

3

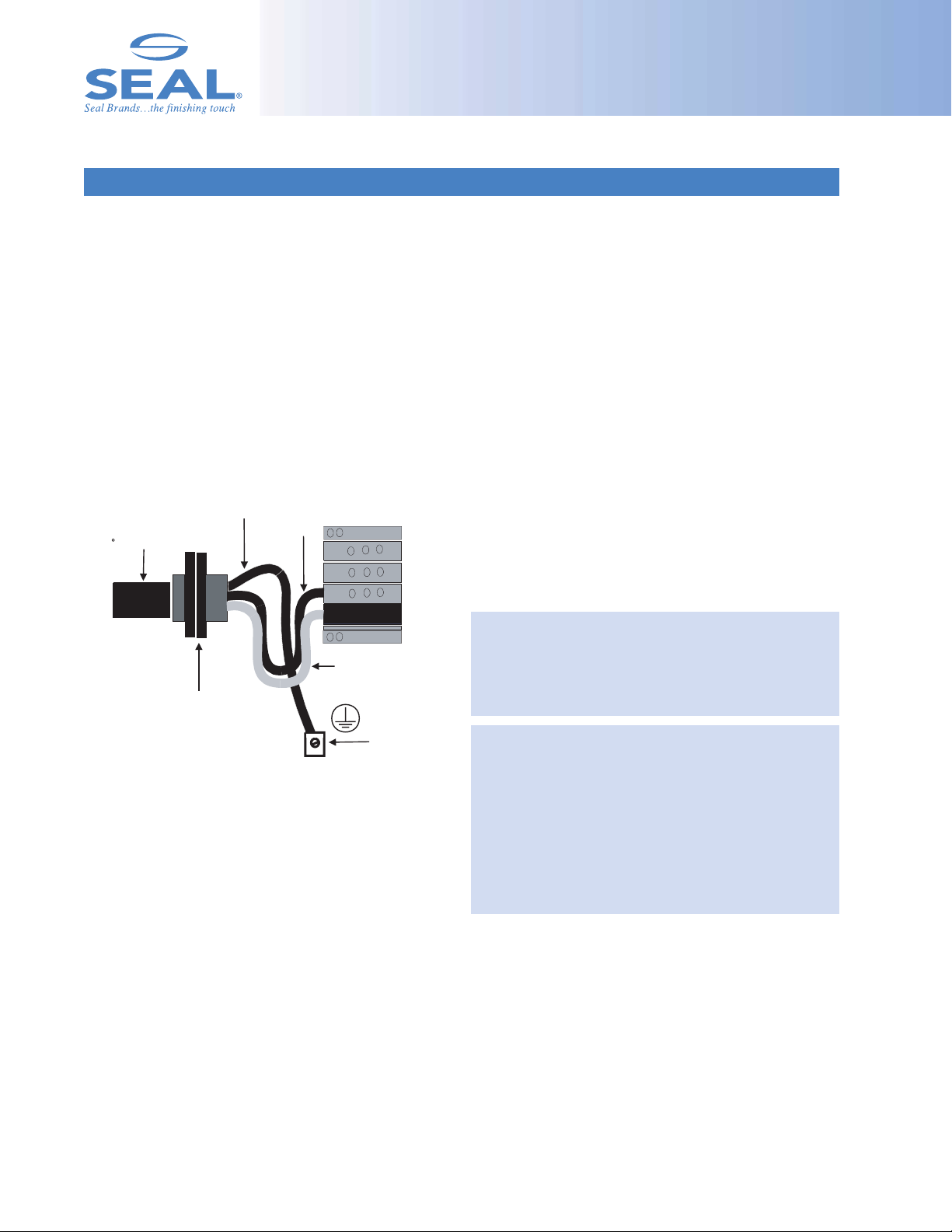

ELECTRICAL SPECIFICATIONS

Connect the laminator in accordance with the details

given on the identification plate attached to the rear

of the laminator. Refer also to the Technical

Specifications page for more information.

Single Phase Version:

(Part No. 60424)

For areas where the voltage requirements are

200-240V, the following is applicable:

Power cord:

3/6 AWG,

Type SOW-A/SO

90 C/194° F, 600 Volts

Power Cord Strain Relief:

Turn clockwise to tighten.

Figure 1. Wiring Diagram

Earth Ground

Black Wire

White Wire

Grounding Lug

**IMPORTANT: The ground (green wire) should be

two inches longer than the black and white wires

to fit into the grounding lug.

CONNECTING YOUR LAMINATOR

All domestic laminators will be shipped without a power

cord. It is required that only a qualified electrician provides

power to the laminator or the warranty will be void. We

recommend a Ground Fault Interrupter (GFI) circuit

breaker with a 60-amp load rating, not exceeding a

100-amp load rating. Use 3/6 AWG power cord, Type

SOW-A/SO rated to 90°C/194° F and 600 Volts. See

Figure 1 Wiring Diagram for detailed information. For

European laminators use a Residual Current Device

(RCD/RCCD). Once power is connected to your laminator, press the Stand-By Switch UP on the front control

panel to turn the laminator ON. If you have no display,

refer to the “Troubleshooting” page for problem-solving

information.

WARNING! Any unauthorized changes or modifications to this unit without our prior written approval

will void the user’s warranty and will transfer health

and safety obligations to the user.

IMPORTANT! SEAL Graphics recommends that a

licensed electrician, in accordance with electrical codes

in your area, install your mains power. Specifications

subject to change without notice.

IMPORTANT! The mains outlet should be fused no

higher than 60 Amp, Three-phase -or- 100 Amp,

Single-phase.

4

WORKSPACE REQUIREMENTS

• Keep the area around your laminator clear with adequate

space around it so you can feed, receive and trim mounted

and/or laminated images.

• An area 15' x 11' (4.5m x 3.4m) is the smallest area

recommended. We recommend a room size of 20' x 18'

(6.1m x 5.49m) to accommodate a laminator and 2

tables 4' x 8' (1.2m x 2.4m) on casters for finishing/

layout work. This area is required for loading and unloading

rolls of material onto the unwind shafts and feeding and

receiving the maximum mounting board lengths into the

laminator correctly.

• NOTE: Maximum board lengths are up to 12 feet long/3.6m.

• The work area should be level, flat, and well lit.

61"/155 cm

Rolls of Media

Minimum Room Width =15 feet/4.5 meter

Rolls of Media

Maximum board length

21"/53cm

Maximum board length

31 inch (Door clearance)

78 cm

59"/150 cm

Room Length = 2 x max. board length + 59" (150 cm)

Minimum Room Length = 11 feet / 3.4 meter

61"/155 cm

21"/53cm

Figure 2. Workspace Area Diagram

5

ENVIRONMENT CONDITIONS

The following environmental conditions are ideal for

the best operation of the laminator.

AMBIENT TEMPERATURE

The best temperature for the SEAL Image 6500 is

between 50°F and 86°F (10°C and 30°C).

Do not expose the laminator to direct sunlight as output

quality may be affected.

RELATIVE HUMIDITY

For best results, the ambient relative humidity for the

SEAL Image 6500 should be between 70-90% non-condensing. Too much humidity will affect the prints being

laminated causing problems with film adhesion.

WATER AND MOISTURE

If the laminator is installed in a damp room or near water,

the electrical power supply must be in accordance with the

standards prevailing in the country concerned.

SURROUNDINGS

Install the laminator in surroundings that are as clean and

dust-free as possible in order to obtain the highest quality

output.

The background dust level must not exceed that found in

a typical office/computer room environment.

The materials that are used on this laminator can have an

electrostatic charge and will attract dust, adversely affecting the output.

POWER SUPPLY

Connect the laminator in accordance with the details

given on the identification plate attached to the rear of the

laminator. Refer also to the Technical Specifications page

for more information.

6

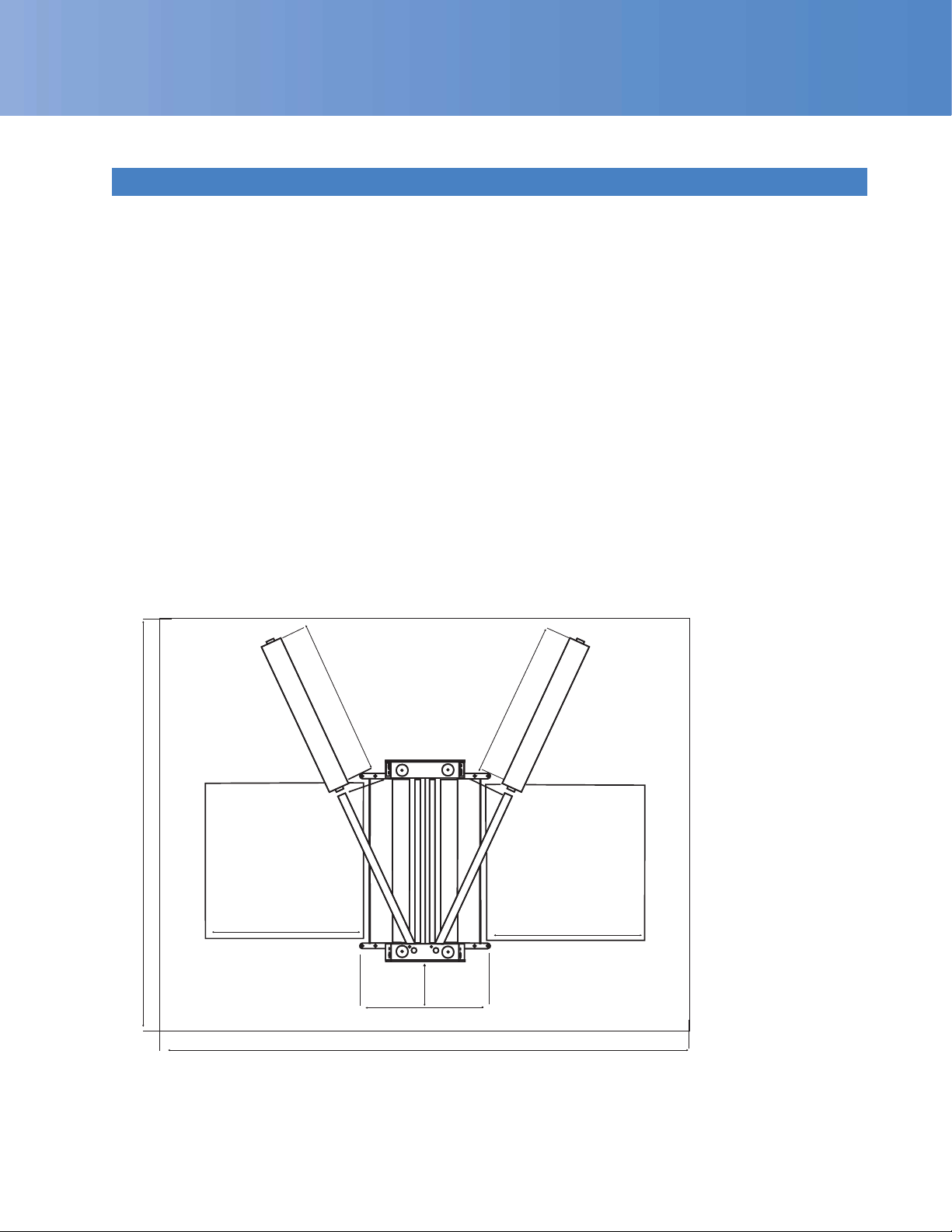

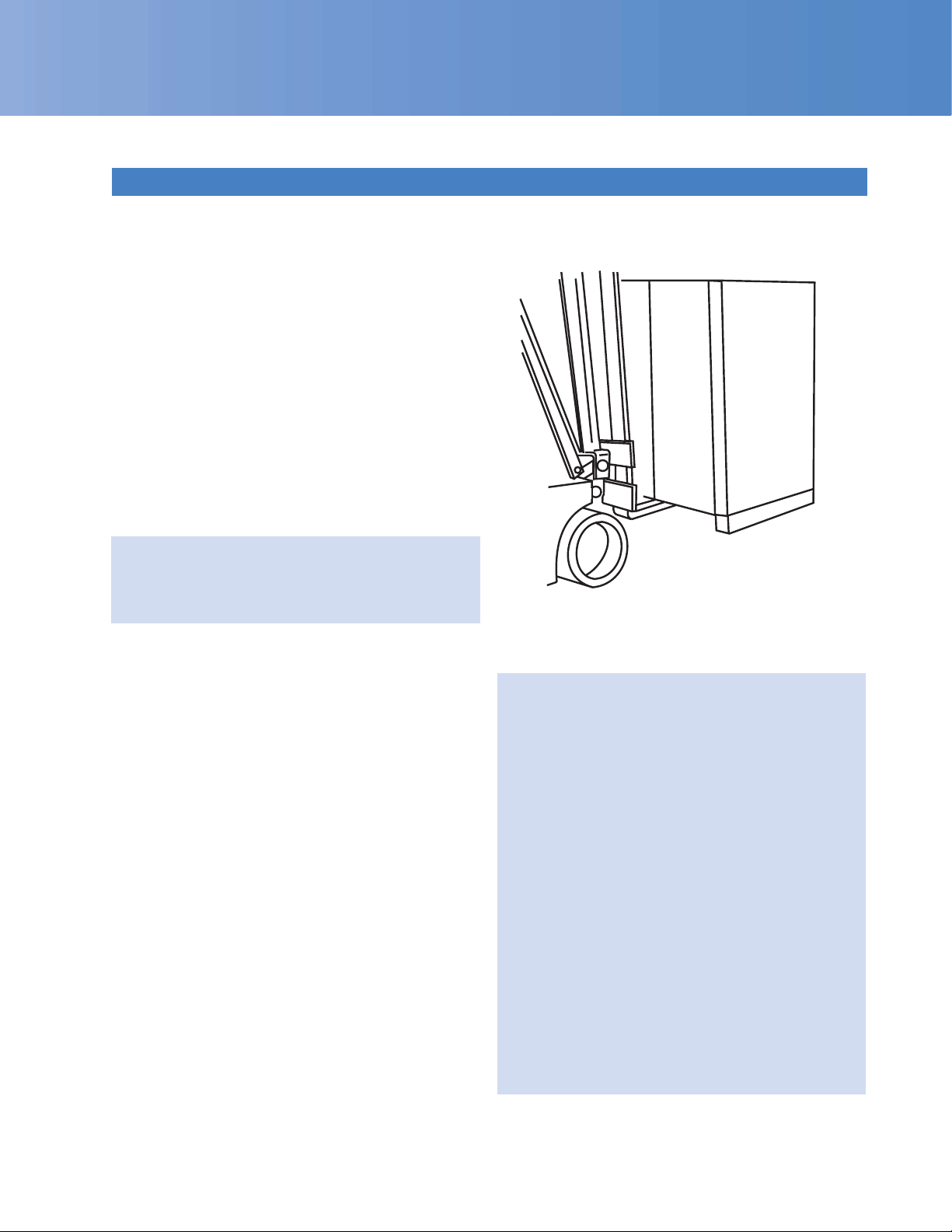

UNPACKING, SET-UP AND INSTALLATION

Only skilled personnel should perform installation.

Read and comply with all warnings and follow the

proper installation procedures and safety guidelines.

• Refer to outside of crate for Uncrating/Recrating

instructions.

• Take into account the weight of the laminator (1,800lb./818 kg net weight) when moving. Use equipment

with which the weight can be safely lifted. The laminator

is transported on a wooden pallet (skid). If your laminator is still on its skid, you can move it with a forklift to

put it near its place of use.

IMPORTANT! Set the forks of the forklift to the maximum lifting width of the laminator so the laminator’s

center of gravity is central between the forks.

• NOTE: We recommend that you save the transport

bolts, nuts and plates of the shipping crate for any major

moves that you plan to make with the laminator in the

future.

• Remove the transport bolts from the skid’s transport

plates with a 1/2" open-end wrench or adjustable

wrench. Using the wrench on the bolt’s flat, back the

bolt up into the cabinet enough to clear the cabinet

casters for ease in moving.

• Your laminator has casters to allow for easy moving.

Roll the laminator to the location it will be used.

(See Workspace Area Diagram – Figure 2).

• Lock the casters once it is in place and remember to

unlock them before moving the laminator again.

Figure 3. Moving the laminator with a forklift.

Accessories Included:

• 4 Foot Levelers

• 1/2" Wrench

• 3/16" Allen Wrench

• Grease Gun Kit

• Spare Fuses (inside cabinet)

• Tape Measure

• Snitty

®

Safety Knife

• Image Roll Cleaner

• Terry Cloth Towel

• Spare Core for Wind-Up Shafts

• Owner’s Manual

• Installation Instruction Sheet

7

UNPACKING, SET-UP AND INSTALLATION

UNPACKING YOUR LAMINATOR

• Remove the transport packing and the plastic shrinkwrap the laminator is wrapped in to avoid moisture

penetration.

• Remove the accessory kit package from the top of the

laminator, which includes the necessary tools for

installation.

• Remove the foot switches from the top of the laminator

and remove the foam wrapped around them. Place a

foot switch on each side of the laminator for operator

use while feeding images.

• Remove the front and back tables (in cardboard boxes)

from the top of the laminator. Remove the tables from

the cardboard boxes and set them aside.

• Remove the protective foam wrapped around the front

and back table arms.

• Follow the Installation Instruction sheet in the accessory

pack to reattach the table arms.

• Once reattached, insert the tables into position.

• Remove the roll easel shaft from the crate and remove

the packing wrap.

WARNING! Do not use open blades to remove the

protective paper on the rollers.

• Roller damage caused by improper use of cutting tools

will void the user’s warranty. Small cuts and imperfections in the rollers greatly affect the quality of the output

and roller replacement costs are expensive.

LEVELING YOUR LAMINATOR

• Thread the leveling feet included in the accessory pack

onto each of the four transport bolts located in the

corners of the cabinets. Tighten securely.

• Use the 1/2" wrench to turn the transport bolts down

until the leveling feet are positioned flat against the floor.

• Insert a 3' x 1' (91cm x 30cm) piece of foam board

across the two center chill idlers and place the level in

the center on top of this foam board.

• Adjust the leveling feet for each side cabinet until level.

• Next, place the level on the tops of each of the cabinets

lengthwise and adjust the leveling feet from the front to

the rear of the cabinet as needed.

• Place the roll easel shaft into the table receivers and lock

into place.

• The top rollers will go up automatically when air is

connected.

• Remove the foam placed between the top and bottom

rollers.

• Remove the stickers securing the protective paper on

the rolls using your fingers only.

• Then gently pull the paper towards you to unwind off

the roll.

8

IMPORTANT SAFEGUARDS

SAFETY SYMBOLS USED ON THE LAMINATOR

IMPORTANT! Read and make sure you understand

these safety and operating guidelines.

Rotating Parts: Risk of Injury

Failure to use caution near rotating

rollers could result in physical injury.

Be careful that items such as loose clothing, long hair and jewelry do not

become entangled in rotating parts.

The laminator is equipped with photoelectric eyes to prevent contact with the rotating rollers. Make sure that these

safety provisions are always in operation/installed.

IMPORTANT! The laminator operation will cease

immediately when the photoelectric eyes, set directly

in the path of the front and back of the rollers, are

blocked. THIS WILL NOT HAPPEN when using the

footswitch in which case a BUZZER will sound and

the laminator runs in slow mode at a rate of 2.0-ft

(0.6m) per minute.

Hot Surface: Risk of Injury on Contact

The laminator contains a heated toproller, which may reach temperatures

of 275°F (135°C). There is a danger

of severe burns if the heated top-roller

is touched during use. Even after

switching off the laminator, the roller

remains hot for a long time.

Electrical Parts – Danger of being injured by

electricity.

Do not open the locked doors because

of the risk of being injured by voltage.

Only authorized maintenance and service technicians or safety personnel

should have access to the keys for

mechanical upkeep or repair.

WARNING! Make sure the door interlock on the leftside cabinet is disengaged when opening the right-side

cabinet door for any maintenance. The door interlock

automatically shuts the laminator power off when the

door is opened.

IMPORTANT! Do not place heavy objects on the

power supply cord.

PREVENTATIVE MEASURES:

Do not feed objects such as staples, paper clips and rough

or abrasive materials through the laminating rollers.

Keep all objects, such as tools, rulers, pens, markers or

knives away from the roller opening. Refrain from leaving

such items on the front table to prevent them from accidentally being fed into the rollers.

IMPORTANT! NEVER cut or slice directly on the

rollers as any cuts or gouges will destroy them. ALWAYS

use cutters with enclosed blades to prevent cutting the

rollers and to avoid extensive replacement costs.

WARNING! Always adjust the shim wheels to create a

gap between the laminating rollers to prevent flat spots

from developing when the laminator is not in use. Flat

spots will affect the quality of the output and void the

warranty replacement.

IMPORTANT! The main roller should be down and

turning while heating up to prevent uneven hot spots

on the roller. A stationary roller will develop concentrated heat in one area, which will damage the roller.

SERVICING AND REPLACEMENT PARTS

Service and maintenance must be performed fully in

accordance with the instructions. Servicing by any

unauthorized technician voids the warranty. The service

technician must use replacement parts specified by

SEAL Graphics.

Service Technicians must perform safety checks after

completing any service or repairs to the laminator.

9

SAFETY FEATURES

The SEAL Image 6500 Laminator is designed

with safety and protective devices with the user’s

safety of utmost consideration. However, following

safe operating guidelines is still the responsibility of

the operator.

Hand-Operated Emergency Stop Buttons:

Emergency Stop buttons are located on each side of the

cabinets for easy access. Once pressed, they immediately

cease the laminator’s operation and raise the rollers. Use

these only in the case of an emergency or you may damage

an image during a process.

NOTE: Once pressed, these buttons lock and must be

turned clockwise to reset.

After resetting the Emergency Stop button, you must turn

the heaters back on (if being used) and push one of the

Motor Direction switches to begin processing again.

Foot-Operated Emergency Tap Switches:

Photoelectric Safety Eyes:

A light beam path set directly in front and back of the

laminating roller openings prevents foreign objects from

passing between the rollers. (The eyes are set for use at the

factory and checked by the service representative.)

Locking Cabinets:

The cabinets that house the inner workings of the laminator include locks that maintenance or safety personnel can

open only with the supplied keys.

WARNING! Use of the inside of the cabinets for storage

may cause possible personal injury and/or damage to

the inner workings and will void the warranty.

Door Interlock

Located on the left-side cabinet (facing front of laminator), it automatically shuts the laminator power off when

the door interlock switch is turned to the OFF position.

Located on both sides of the laminator, pressing on these

tap switches will immediately cease the laminator’s operation and raise the rollers.

Covered Foot Switches:

One on each side of the laminator allows for complete user

control when initially feeding an image into the nip or for

feeding a delicate image through the rollers. The cover prevents accidentally stepping on the foot switch and starting

the laminator.

WARNING! The foot switch overrides the photoelectric

eyes. When the photoelectric eye is blocked, the laminator runs in slow mode at a speed of 2.0 ft. (0.6m) per

minute. A BUZZER sounds if an operator blocks a

photoelectric eye, warning of proximity to the nip. Use

care to keep hands clear of the rollers while using the

foot switch to prevent possible injury.

10

WARNING! For any servicing, ALWAYS turn the

door interlock switch to the OFF position and the

main power circuit breaker off before opening the

side cabinets.

LAMINATOR FEATURES

3

2

1

12

Features

1. Control panel system

• For independent control of pressure, temperature and read-out of

speed and material usage.

2. Shim Wheels (4)

• Dial-in roller height adjustment for fast and accurate roller nip set

ting, which adjusts for the thickness of the material to be processed.

3. Integral Braking System

• A simple braking system with a knurled collar provides the means of

adjusting the brake tension for the films and images. Fitted on both

the roll easel shaft and the four unwind shafts.

4. Swing-Out Autogrip Unwind Shafts (4)

• Easy loading and positioning of materials. No need for manual lock

ing keys. Suitable for rolls wound onto a 3" ID core.

5 Autogrip Wind-Up Idlers (4)

• Removable shafts for winding up the release liner, finished images

or other laminate material. Use with 3" ID spare cores.

6. Top Motor Control Panels

• Controls in-feed direction and processing speed from all four

corners.

7. Interchangeable In-Feed Tables (For North America/UK):

• User preference for flat table with image guide or print guide table,

interchangeable from front to rear of laminator. For ROW the

laminator is equipped with flat tables, front and back.

8. Emergency Stop Buttons (4)

• Immediately ceases the laminator’s operation and raises the rollers.

4

6

5

10

11

9. Autogrip Roll Easel Shaft

• Removable media unwind shaft for images on a roll. Allows for rollto-roll laminating in continuous operation when used with the

wind-up idler. Interchangeable from front to rear of laminator.

10. Foot-Operated Emergency Tap Switches (2) (Auxiliary Stop)

• Immediately ceases the laminator’s operation and raises the rollers.

11. Covered Foot Switches (2)

• Allows for complete user control when initially feeding in an image.

12. Door Interlock

• Automatically shuts the laminator power off when the Door

Interlock switch is turned to the Off position.

** Bi-Directional Operation

• Eliminates the need for cool-down allowing quick application

changeovers.

** Dual-Position Cooling Tube

• Offers quick and uniform cooling for smooth, flat output during

heat-activated processes. Can be positioned above or below the chill

idlers and can be rotated to direct airflow as desired.

** Drive System

• Heavy-Duty Clutch and simplified drive system – Provides

smoother performance at all speeds and different film thickness.

** Heating Elements

• Electric High-Wattage Heating Elements and Temperature Controls

with Infrared Temperature Sensors – provide for rapid, even heating

to 275°F (135°C) and maximum accuracy.

7

8

9

Figure 4. Laminator Features

11

FRONT CONTROL PANEL

1. Air Pressure Gauge: Indicates the PSI reading for the

downward pressure of the top main roller. The standard

setting for the normal operation is 35-55 PSI.

2. Air Regulator Knob: Adjusts the downward pressure of

the top roller. Turn clockwise to increase the pressure.

3. Roller Up/Down Switch (Front, Top): Press up to raise

the roller. Press down to lower the roller.

4. Cooling Fan On/Off Button:Turns On/Off the cooling fan. The corresponding LED will be lit when the fan

is ON.

5. Reset Button: Press this button to reset the material

total usage counter to zero. Totalizer Display must be

showing to be able to zero out.

6. Ratemeter/Totalizer Button: Pressing this button will

toggle between the roller speed readout or total material

usage. Press this button to track and display the total

number of feet or meters run in a given period, which can

help to monitor film usage. The total will be stored even

after the laminator is turned off and adds to the total

whenever the bottom main roller is turning. The corresponding LED will be lit when the totalizer is being used.

11. Bottom Roller Temperature Increase Button: Press

this button once to view the temperature set point. Press

and hold the button to raise the bottom roller temperature.

12. Bottom Roller Temperature Readout: Displays both

the set and actual temperature of the bottom roller.

13. Bottom Roller Temperature Decrease Button: Press

this button once to view the temperature set point. Press

and hold the button to lower the bottom roller temperature.

14. Bottom Roller Temperature On/Off Button: Turns

On/Off the bottom roller heater. The corresponding LED

will be lit when the heater is ON.

15. Top Roller Temperature On/Off Button: Turns

On/Off the top roller heater. The corresponding LED will

be lit when the heater is ON.

16. Stand-By On/Off Switch: Press this switch up to turn

on the laminator. Press this switch down to put it on

Standby. In Standby, the laminator power is still on, but

all functions are disabled.

7. Ratemeter/Totalizer Readout: Displays the rate of

speed of the main rollers in either feet or meters per

minute, or displays the total number of feet or meters run

in a given period.

8. Top Roller Temperature Increase Button: Press this

button once to view the temperature set point. Press and

hold the button to raise the top roller temperature.

9. Top Roller Temperature Readout: Displays both the

set and actual temperature of the top roller.

10. Top Roller Temperature Decrease Button: Press this

button once to view the temperature set point. Press and

hold the button to lower the top roller temperature.

12

Figure 5. Front Control Panel

BACK CONTROL PANEL

1. Air Pressure Gauge: Indicates the PSI reading for the

downward pressure of the top pull roller. The standard

setting for the normal operation is 35-55 PSI.

2. Air Regulator Knob: Adjusts the downward pressure

of the top pull roller. Turn clockwise to increase the

pressure.

3. Roller Up/Down Switch (Rear, Top): Press the

switch up to raise the roller. Press the switch down to

lower the roller.

4. Reset Button: Press this button to reset the material

total usage counter to zero. Totalizer Display must be

showing to be able to zero out.

5. Ratemeter/Totalizer Button: Pressing the button will

toggle between the roller speed readout or total material

usage. Press this button to track and display the total

number of feet or meters run in a given period, which

can help to monitor film usage. The total will be stored

even after the laminator is turned off and adds to the

total whenever the bottom main roller is turning. The

corresponding LED will be lit when the totalizer is

being used.

Figure 6. Back Control Panel

6. Ratemeter/Totalizer Readout: Displays the rate of

speed of the main rollers in either feet or meters per

minute, or displays the total number of feet or meters

run in a given period.

13

CLUTCH CONTROL PANEL

The Clutch Control Panel is located on the left-side

cabinet when facing the rear of the laminator. The

operator can adjust the amount of tension that is

directly applied to the laminate between the main

and pull rollers. The amount of tension applied

affects the output and extreme pull tension will

stretch the hot films causing outfeed waves in the

finished product. This is a factor with films such as

Print Guard®, which stretches easily. Excessive tension

will also cause downward curl in the finished product. The standard setting for normal operation is

40-60 PSI.

IMPORTANT! Excessive pull clutch tension will cause

premature wear to the drive system and may cause

damage to the laminator. Use the minimum amount

required for the laminating process.

1. AIR PRESSURE GAUGE

Indicates the PSI reading for the pulling tension of the

bottom pull roller. The standard setting for normal operation is 40-60 PSI.

2. AIR REGULATOR KNOB

This knob adjusts the pulling tension of the bottom pull

roller. Pull out the knob and turn to adjust; push back in

to set. Turn clockwise to increase the amount of pull tension and turn counter-clockwise to decrease the amount.

14

Figure 7. Clutch Control Panel

TOP MOTOR CONTROL PANELS

The Motor Control Panels are centrally located on

the top of both side cabinets. This location provides

easy access from all sides of the laminator. Right- or

left-handed operators can use either panel to make

speed or direction processing adjustments from the

front or rear of the laminator. A change made to

either panel affects the settings of both panels.

1. Speed Adjustment Knob

Use this knob to adjust the speed of the roller rotation.

Turn the knob clockwise to increase the speed of the roller

rotation and counter-clockwise to decrease the speed. The

speed of the rollers is continuously adjustable between 0

and 15 ft./min. (0 and 4.5m/min.). The roller speed can

be viewed in the top display readouts on both the front

and back control panels.

2. Reverse Roller Direction Switch

Pressing this switch runs the rollers in the reverse direction

when standing at the front of the laminator. This direction

will be used when processing cold pressure-sensitive films

from the rear of the laminator through the pull rollers.

3. Motor Stop Switch

Pressing this switch stops the roller rotation.

NOTE: You must press this switch before you can press

the opposite direction switch.

4. Forward Roller Direction Switch

Pressing this switch runs the rollers in the forward direction when standing at the front of the laminator.

Figure 8. Top Motor Control Panel

15

CHECKING OPERATION

After you are familiar with the control panels and

their functions, check all operations.

Check the Main Power

• Press the Stand-By switch up and the front and back

displays on the control panels should be lit.

• The center red switch on both top cabinet control panels

should be illuminated.

Check the Emergency Stop Buttons

• Press one of the Emergency Stop buttons and the

laminator will shut down.

• Rotate the Emergency Stop button clockwise to reset.

• Repeat this procedure with all four Emergency Stop

buttons.

Check the Heater Controls

• Press the top heater On/Off button once; the corresponding LED should be lit.

• The readout will display the ambient temperature.

• Press and hold the top heater Up arrow to increase the

temperature set point. Watch the readout for 5 minutes

to verify that the temperature increases.

• Press and hold the Down arrow to decrease the temperature set point.

• Press the top heater On/Off button again once; the

corresponding LED should not be lit.

• Repeat this procedure for the bottom heater.

Check the Motor and Foot Switches

Check both motor control panels as follows:

• Press the green Motor Reverse switch and the rollers

should rotate in the reverse direction.

• As you turn the Speed Control knob clockwise the speed

of the rollers should increase and the speed readout (top

display on front and rear control panels) should increase

in number.

• Turning the Speed Control knob counter-clockwise

should decrease the speed of the rollers and the speed

readouts should decrease in number.

• Press the center red Motor Stop switch and the rollers

should stop rotating.

• Press the foot switch and the rollers should rotate in

whichever roller direction that was last pressed. Check

both foot switches for operation.

CHECKING THE ROLLERS

Your laminator has a pneumatic pressure adjustment with

fine-tune control for a smooth, flat finish. Correct adjustment of the pressure rollers’ height is essential for safe and

proper operation. Check this prior to every use.

Check the vertical movement of the top rollers as

follows:

• Press the roller switch UP. The top roller should rise

smoothly and evenly on both ends.

• Press the roller switch DOWN. The top roller should

lower smoothly and evenly on both ends.

• Repeat this procedure for both front and back top

rollers.

IMPORTANT! The silicone covering of the rollers is

soft. Do not scratch the surface with a sharp object or

fingernail.

• Push the green Motor Forward switch and the rollers

should rotate in the forward direction.

16

WARNING! If your laminator does not operate correctly, contact Technical Service immediately.

SET-UP AND OPERATION

TEMPERATURE SETTINGS

• Select the film(s) that you will use on the top (and

bottom) of the images.

• Check which temperature setting is recommended for

your SEAL

Brands material (see literature enclosed in

®

your material box).

• Refer to the Control Panel diagrams for information

on setting the temperature.

NOTE: If a process requires heat, turn ON the heaters

approximately 45 minutes before use to ensure that the

rollers are at the correct operating temperature.

IMPORTANT! The main roller should be down and

turning to prevent uneven hot spots on the roller. A

stationary heated roller will develop concentrated heat

in one area, which will damage the roller.

SHIM WHEEL SETTINGS

HOW TO SET THE SHIM WHEELS

• First, determine the thickness of the board that you will

use for mounting.

• You must first raise the rollers and then turn the shim

wheels until the desired measurement corresponds with

the thickness of board being used.

WARNING! Too much pressure can crush the board

being used and even damage the top and bottom

rollers. Normally, a press of .025" (0.6mm) is

sufficient.

Whenever you mount onto a board, etc., it is important

to adjust the rollers to create a gap nearly equal to the

thickness of the board being used. This is done so that

anything passing between the rollers will receive the right

amount of pressure.

Equivalent Press Measurements

Inches Metric (mm) Decimal

1 25 mm 1.000

3/4 19 mm 0.75

1/2 13 mm 0.50

3/8 10 mm 0.375

1/4 6 mm 0.25

3/16 5 mm 0.1825

1/8 3 mm 0.125

1/16 2 mm 0.0625

-1/16 -2 mm -0.0625

0 0 0

1

9

m

3

m

/

4

i

n

2

5

m

m

1

i

n

-

2

m

m

0

-

1

/

1

6

i

n

Figure 9. Shim Wheel Adjustment

m

n

i

m

6

5

1

/

3

m

m

3

n

i

8

m

/

m

2

1

1

n

i

6

1

/

17

SET-UP AND OPERATION

LOADING A ROLL OF MATERIAL

• Turn the unwind brake fully towards you so there is no

brake tension on the unwind shaft (until no gap is visible

between the unwind brake and the lock collar).

• Swing out the desired unwind shaft towards you and

slide a roll of material onto the unwind shaft. Ensure

that the rubber blocking cords are on the top and bottom of the shaft for easy loading (see below).

Figure 11. Locking Receiver

• Remember to lock the receiver on the bottom unwind

shaft so the film tracks correctly and the unwind shaft

does not pull out of the receiver.

• Center the films on the unwind shafts using the rulers

on the unwind shafts for alignment.

Figure 10. Loading Roll of Material

• For the bottom unwind shafts rotate the outer section of

the locking receiver towards you to open the receiver so

the shaft can be pulled out and loaded with material (see

Figure 11).

IMPORTANT! Make certain that you place the roll of

film on the unwind shaft so that the material will feed

with the adhesive side facing away from the rollers.

IMPORTANT! Swing the unwind shaft in towards the

receiver making sure to align the cutout notch in the

end of the unwind shaft with the receiver notch. Press

the unwind shafts firmly into the receivers to prevent

tension and tracking problems.

NOTE: If the end of the shaft is not correctly aligned

you will not be able to adjust the brake tension properly, causing tracking problems and possibly damaging

the end of the shaft.

IMPORTANT! The position of all films, boards, rolls

of media and cardboard cores for wind-ups must be set

central in the laminator to ensure optimum quality

and correct tracking.

• For alignment accuracy, pull a length of film forward off

the top unwind shaft until it drapes over the film on the

bottom unwind shaft. Make sure the edges of both film

rolls line up.

• Now secure the rolls of material onto the shafts by gripping the shafts with one hand while rotating the rolls of

material with the other hand in the direction it will be

pulled off the unwind shafts. The rubber blocking cords

will catch on the inside of the material core and hold the

material secure on the shaft.

• If material needs to be rotated, turn the shafts, not the

rolls of film otherwise the roll of film will no longer be

secure to the shaft.

Unwind shaft cord adjustment

NOTE: Over time the rubber blocking cords will

stretch and need to be shortened slightly. To adjust the

cord, unfasten the cord at one end and cut off .39"

(1cm). Re-fasten the cord under the cord retainer clip.

18

SET-UP AND OPERATION

PIVOTING TABLE USE FOR WEBBING

• First, remove the roll easel shaft from its brackets and

set aside.

• Pull out both retaining plungers of the roll easel brackets

and pivot the brackets down and forward as shown in

Figure 12.

Figure 12. Pivoting Roll Easel Bracket Down

• Remove the top and bottom wind-up idlers for easy

webbing and set them aside.

• Pull the film up and place it over the top roller.

• Reposition the table by lifting the outer edge upwards

and pivot in towards the roller (Figure 14).

• With the table resting on the table bracket standoffs, lift

the outer edge of the table and push the table in towards

the roller (see Figure 15). The non-locking retaining

plunger will catch automatically.

• Moving to the right-hand side of the table release the

locking retaining plunger so it locks in place.

• The table operation is the same front and rear.

• On the right-hand side of the table, pull out the locking

retaining plunger and turn sideways to lock with plunger

recessed (see Figure 13).

• Move to the left side and pull out the non-locking

retaining plunger on the left-hand side of the table.

• Allow the table brackets to slide outwards and down.

• Grasp the front edge of the table and, lifting up, pivot

the table towards you, away from the rollers (see

Figure 13).

• Reach through the opening between the table and rollers

and pull the bottom film up and pass it behind the bottom idler.

Figure 13.

Releasing Retaining Plunger

Figure 15.

Pivoting Table Forwards

Figure 14

Pivoting Table Up

19

SET-UP AND OPERATION

SETTING THE UNWIND BRAKE TENSION

Refer to the Features Page for identification.

IMPORTANT! The brake tension greatly affects the

smooth flow of the laminating film.

• Adjust the unwind brake so that it applies sufficient

tension to the laminate.

• Turning the unwind brake in

a counter-clockwise direction

increases the braking tension

applied on the laminate.

• Turning the unwind brake in

a clockwise direction decreases the braking tension.

• The best setting for the unwind brake tension is determined by the materials you are using and is learned

through experience.

COOLING SYSTEM

• The SEAL Image 6500 has a dual-position cooling tube,

which can be placed above or below the center chill

idlers to cool heat-activated materials.

• While the majority of the time the cooling fan tube will

be used in the position below the chill idlers, it can be

used in the position above the chill idlers to assist with

cooling down the top main roller. Pivot the airflow holes

towards the top main roller.

Figure 16. Unwind Brake

To remove the cooling tube from the bottom

location:

• Grasp the cooling tube with fingers or you can use your

fingers in the airflow holes to lift the closed end of the

cooling tube out of the bracket.

• Lift upwards at an angle, pulling the opposite open tube

end out of the cabinet opening.

• Lower the open end at an angle until you can clear the

upper bracket with the opposite end.

• Pull the tube up through the center of the chill idlers.

To insert the cooling tube in the top location:

• Insert the open tube end at an angle into the cabinet

opening.

• Lower the closed tube end to place it in the bracket.

• Reverse the above procedures to change from the top

location to the bottom location.

• The cooling tube can also be rotated to direct the airflow

as needed.

• The majority of processes do not require the use of the

cooling tube, but for extensive running time, it is recommended to use the cooling tube to cool off the chill

idlers quicker.

• Pivot the cooling tube airflow holes towards the front

idler, which receives the most heat from the heated main

roller.

Figure 17. Inserting Cooling Tube

20

• Always web the film over the first idler to cool the backside of the print first, thus preventing marks on the hot

front side of the print, which could affect the finished

appearance.

• When using mounting adhesive on the back of images it

is best to run the film over both idlers. Running the film

under the second idler may cause the backing to separate

from the release liner.

SET-UP AND OPERATION

AUTO-RUN OPERATION

• The continuous-run operation allows the user to set the

direction of the roller rotation and adjust the roller speed

by turning either of the Speed Control knobs on the

tops of the cabinets.

• This feature is useful for long runs that don’t require

much user control and, when used in combination with

the roll easel shaft and wind-up shafts, can be efficient in

an auto-run mode.

• Press the motor direction switch for the processing direction desired.

• Turn the Speed Control knob on either of the Motor

Control Panels to adjust the speed of the rollers (refer to

the Top Motor Control Panel page).

IMPORTANT! If the photoelectric eyes become blocked

during continuos-run operation, the roller rotation

will stop immediately.

IMPORTANT! Take care not to stop the motor or

block the photoelectric eyes while an image is being

laminated as this can cause marks in the output.

FOOT SWITCH OPERATION

• The function of the foot switch is to permit the rotation

of the rollers to be controlled in a hands-free manner.

• This feature can be used when webbing materials onto

the laminator or feeding delicate images and overrides

the photoelectric safety eyes.

• Pressing the foot switch runs the laminator in the direction that was pressed last (the Active Directional Switch

will be illuminated).

• The rollers will run at the speed last set which is indicated in the top display on either front or back control

panels.

• The speed can be adjusted when using the foot switch

by turning either Speed Control knob on the top of the

cabinets.

WARNING! While using the foot switch, interrupting

the photoelectric safety eyes does NOT stop the laminator. An audible beep will be heard, the Motor

Directional Switch will be blinking and the roller

speed will run in ‘slow mode’ at a speed of 2ft./min.

(0.6 m/min.). Releasing the foot switch will stop the

laminator .

• After clearing the photoelectric eye blockage the buzzer

will stop.

• To resume the pre-set speed, press the blinking directional switch.

CHANGING FROM FOOT SWITCH OPERATION

TO AUTO-RUN MODE WITHOUT STOPPING

(to prevent stop marks on the substrate):

• During foot switch operation (keep the foot switch

pressed), then press Motor Direction switch desired on

either Motor Control panel. The laminator will run at

the pre-set speed.

• Next, release the foot switch.

IMPORTANT! Do not stop the motor or block the

photoelectric eyes while an image is being laminated

as this can cause marks in the output.

THE ROTATION OF THE ROLLERS WILL STOP

WHEN:

• The photoelectric eyes in the front or back of the rollers

are interrupted.

NOTE: This does NOT happen when the foot switch

is used.

• An Emergency Stop button is pressed.

• An emergency tap switch is pressed.

• The Stop button on the motor control panel is pressed.

21

FEEDING IMAGES

BASIC STEPS TO FEEDING IMAGES

NOTE: For good results, the process requires that the

images be fed through correctly.

• Make sure the leading edge of each image is flat all the

way across or any wrinkles or creases in the image will

show when laminated – perhaps even magnified.

• A straight leading edge will aid in feeding in the image.

• Feed the image into the laminator ensuring that the

leading edge is parallel to the roller.

NOTE: Do not stop the motor while an image is being

finished as this can cause marks in the output.

USING THE PRINT GUIDE TABLE

• Your laminator may be equipped with a Front Print

Guide Table to assist in feeding images into the nip.

Feeding images under the print guide, directly into the

nip, prevents the images from lifting up and interrupting

the photoelectric eyes.

USING THE IMAGE GUIDE ON THE FLAT TABLE

• To aid with feeding in images, the rear table is provided

with an “Image Guide”.

• This device can be positioned in front of the roller and it

prevents the images from interrupting the photoelectric

eyes.

• The Image Guide can be removed when mounting

boards.

USING THE ROLL EASEL ATTACHMENT

The Roll Easel Attachment is used to encapsulate images

digitally reproduced with a color plotter. The rolls of

images simply slip on and off the roll easel, which lifts on

and off the front of the laminator.

• Mount the roll of prints on the attachment. The rolls of

images should unwind with the images facing up and

should be centered on the attachment so that the laminate covers the images.

Ball Nose Spring Plunger End Braking Notched Locking End

• Press the Ball Nose spring plunger shaft end into the

matching receiver on the right side of the table.

• Align the Braking Notched shaft end with the notch of

the receiver on the left side of the table and set in place.

• Make sure the auto-grip section of the shaft rotates, not

the ends in the receivers.

• For the roll of images, leave some blank space at the

beginning and in this space, cut out a V-shaped area to

allow for an easier and cleaner start to the laminating

process.

• To position the Image Guide, push it completely in

towards the roller aligning the outer notches with the

thumbscrews in the table.

• Tighten the thumbscrews down to secure the Image

Guide in place. You are ready to feed images.

• To assist with this, the edge of the image can be seen

through the windows in the “Image Guide”, which is in

front of the rollers.

22

• Once the prints are running through the laminator, set

the brake tension for the roll easel to exert a significant

amount of tension so the prints feed through without

wrinkles (refer to “Setting the Unwind Brake Tension”

section).

• Set the speed control to 2-3 feet or (0.6–1.0) meters per

minute. Use the footswitch until the images are tracking

correctly. Then press the Forward Direction switch and

go into auto-run mode. Don’t remove your foot from the

foot switch until you have pushed the Forward Direction

switch, otherwise, the laminator will stop, affecting the

quality of your image’s finish.

WEBBING FILMS WITHOUT A RELEASE LINER

The following are the basic webbing procedures for

webbing films without a release liner:

• Select films slightly wider than the image to allow for a

border without film waste. A border of 1/8" to 1/4"

(3-6mm) is adequate.

• Ensure the main roller’s temperatures are set according

to the recommendations of the laminates being used

(see literature enclosed in your material box).

WARNING! The rollers should be down and turning

while heating up to provide even heat distribution and

prevent roller flat spots from developing.

• Once the laminator reaches correct operating temperature, stop the laminator and raise the top roller.

• Load and center the films on top and bottom unwind

shafts with the dull adhesive side facing out and the

unwind brake tension released.

NOTE: Check if the film widths of the lower and

upper web are the same!

• Feed the leader-board over the first chill idler and under

the second chill idler.

NOTE: For top and bottom film combinations of

10 mil (250 microns) or less, feed over the first idler

and under the second. For film combinations of 10 mil

or over, feed over both chill idlers.

• Raise the top pull roller and advance the leader board

through the pull rollers.

• Holding the leader board up against the top edge of the

top pull roller lower the roller. Make sure the rear Shim

Wheels are set to 0" (0mm).

• Return to the front of the laminator and set the front

Shim Wheels to -1/16" (-2mm).

• Using the foot switch advance the films, applying light

unwind brake tension gradually on both unwind shafts

until there are no wrinkles in the film as it goes into

the nip.

You are now ready to feed images!

• TOP FILM: Pull the film down from the top unwind

shaft, behind the top center idler and place it evenly over

the face of the top roller.

• BOTTOM FILM: Pull the film up from the bottom

unwind shaft, behind the front bottom idler and place it

evenly over the top film draped over the face of the top

roller.

• The two films will then heat and stick together.

• Set the Shim Wheels to 1/16" (2mm) to allow for the

thickness of the leader-board.

• Use a leader-board to push the film(s) through the main

roller nip.

• Lower the top roller and pivot the in-feed table into

position.

• Moving to the rear of the laminator, use the foot switch

to advance the leader-board.

Rear

Roll

Easel

Covered

Foot

Switch

Rear

Rear Top

Wind-up

Rear Table

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Shim Wheel

Rear Top

Supply Shaft

Top

Pull

Roller

Bottom

Pull

Roller

Top

Idler

Chill

Idlers

Fan

Tube

Bott

Idler

Shim Wheel

Front Top

Supply Shaft

Bott

Idler

Figure 18. Webbing films w/o Release Liners

Top

Main

Roller

Bottom

Main

Roller

Front

Front Top

Wind-up

Print Guide

Front Table

Front

Bottom

Wind-up

Front

Bottom

Supply

Shaft

Roll

Easel

Covered

Foot

Switch

Front

23

WEBBING FILMS WITH A RELEASE LINER

The following are the basic webbing procedures for

webbing films with a release liner:

• Select films slightly wider than the image to allow for a

border without film waste. A border of 1/8" to 1/4"

(3-6mm) is adequate.

• Load and center the films on top and bottom unwind

shafts with the dull adhesive side facing out and the

unwind brake tension released.

NOTE: Check if the film widths of the lower and

upper web are the same!

• TOP FILM: (film with a release liner) Pull the film

down from the top unwind shaft, behind the top center

idler and place it evenly over the face of the top roller.

• Place a spare core over the front top wind-up idler.

Separate the film from the release liner. Attach the

release liner to the spare core using a piece of tape.

• BOTTOM FILM: Pull the film up from the bottom

unwind shaft, behind the front bottom idler and place it

evenly over the top film draped across the face of the top

roller. The two films will stick together.

• Set the Shim Wheels to 1/16" (2mm) to allow for the

thickness of the leader-board.

• Raise the top pull roller and advance the leader-board

through the pull rollers.

• Holding the leader-board up against the top edge of the

top pull roller, lower the roller. Make sure the rear Shim

Wheels are set to 0" (0mm).

• Return to the front of the laminator and set the front

Shim Wheels to –1/16" (-2mm).

• Using the foot switch advance the films applying light

unwind brake tension gradually on both unwind shafts

until there are no wrinkles in the film as it goes into

the nip.

YOU ARE NOW READY TO FEED IMAGES!

Rear

Roll

Easel

Covered

Foot

Switch

Rear

Rear Top

Wind-up

Rear

Table

Bottom

Wind-up

Rear

Shim Wheel

Rear Top

Supply Shaft

Top

Pull

Roller

Bottom

Pull

Roller

Rear

Shaft

Bottom

Supply

Idler

Idler

Chill

Idler

Top

Fan

Tube

Bott

Front Top

Chill

Idler

Shim Wheel

Supply Shaft

Bott

Idler

Top

Main

Roller

Bottom

Main

Roller

Front

Front Top

Wind Up

Print Guide

Front Table

Front

Bottom

Wind-up

Front

Bottom

Supply

Shaft

Front

Roll

Easel

Covered

Foot

Switch

• Use a leader-board to push the film(s) through the nip.

• Lower the top roller and pivot the in-feed table into

position.

• Moving to the rear of the laminator, use the foot switch

to advance the leader-board.

• Feed the leader-board over the first chill idler and under

the second chill idler.

NOTE: For top and bottom film combinations of

10 mil (250 microns) or less, feed over the first idler

and under the second. For film combinations of 10 mil

(250 microns) or over, feed over both chill idlers.

24

Figure 19. Webbing for North America

Shim Wheel

Rear

Rear Top

Wind-up

Rear Top

Rear

Roll

Easel

Covered

Foot

Switch

Rear

Table

Supply Shaft

Top

Pull

Roller

Bottom

Pull

Roller

Rear

Bottom

Wind-up

Rear

Bottom

Supply

Shaft

Chill

Idler

Bott

Idler

Fan

Tube

Idler

Idler

Chill

Top

Figure 20. Webbing for Europe & Asia

Shim Wheel

Front Top

Supply Shaft

Top

Main

Roller

Bottom

Main

Roller

Bott

Idler

Front

Front Top

Wind-up

Print Guide

Front

Table

Front

Bottom

Wind-up

Front

Bottom

Supply

Shaft

Front

Roll

Easel

Covered

Foot

Switch

DECALING (HEAT-ACTIVATED)

This process involves applying a hot film to the top

and a cold backing adhesive to the bottom of the

graphic. This process can be used to create self-adhesive images for mounting down onto various substrates. After performing this process, follow the

Mounting Instructions in the manual to apply the

decal to a substrate.

MEDIA: Ink Jet, Electrostatic and Photographic

FILMS:

-- -- -- Top Unwind Shaft: Heat-Activated Laminate

3–5 Mil (75-125 microns)

_____ Bottom Unwind Shaft:Pressure-sensitive mounting

adhesive

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: 205-215F° (96-102°C)

Bottom Roller Temp.: OFF

Main Roller Pressure: 35-40 PSI

Cooling Fan: OFF

Note: When using Mounting Adhesive on the back of

images it is best to run over both idlers. Running the

film under the second idler may cause the backing to

separate from the release liner.

Top

Fan

Tube

Front Top

Supply Shaft

Chill

Idler

Bottom

Supply

Front

Shim Wheel

Top

Main Roller

Bottom

Main Roller

Bott

Idler

Shaft

Front

Front Top

Wind-up

Print Guide

Front Table

Front

Note: Remove Bottom Front

Bot.

Wind-up Idler for webbing

ease and to prevent adhesive

Wind-up

from sticking onto it when

webbing.

Rear

Rear Top

Wind-up

Shim Wheel

Top

Pull Roller

Bottom

Pull Roller

Rear

Bottom

Wind-up

Rear Top

Supply Shaft

Rear

Roll

Easel

Covered

Foot

Switch

Rear Table

Rear

Bottom

Supply

Shaft

Figure 21. Webbing for Decaling

(Heat-activated films)

Chill

Idler

Idler

Bott

Idler

Front

Roll

Easel

Covered

Foot

Switch

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 35-40 PSI

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Forward

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension T op: Medium

Web Tension Bottom: Light

Chill Idlers: Over 1st / Over 2nd:

Shim Wheel Settings: -1/16" (-2mm)

25

DECALING (PRESSURE-SENSITIVE)

This process involves applying a cold pressure-sensitive over-laminate to the top and a cold pressuresensitive mounting adhesive to the bottom of a

graphic. This process can be used to create selfadhesive images for mounting down onto various

substrates. After performing this process, follow

the Mounting Instructions in the manual to apply

the decal to a substrate.

MEDIA: Ink Jet, Electrostatic, and Photographic

FILMS:

-- -- -- Top Unwind Shaft: Pressure-sensitive over-laminate

____ Bottom Unwind Shaft: Pressure-sensitive mounting

adhesive

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: OFF

Bottom Roller Temp.: OFF

Main Roller Pressure: 35-40 PSI

NOTE: Pressure-sensitive films, not requiring heat, can

be run from the front or rear of the laminator

NOTE: When using Mounting Adhesive on the back of

images, it is best to run over both idlers. Running the

film under the second idler may cause the backing to

separate from the release liner.

Fan

Tube

Front Top

Top

Idler

Chill

Idler

Supply Shaft

Bott

Idler

Shim Wheel

Top

Main Roller

Bottom

Main Roller

Front

Front Top

Wind-up

Hint: Lower top main roller

onto films during webbing

to pull film taut. Raise top roller

after tracking is correct.

Print Guide

Front Table

Front

Bottom

Wind-up

Front

Bottom

Supply

Shaft

Covered

Foot

Switch

Front

Roll

Easel

Rear

Rear

Roll

Easel

Rear Table

Note: Move Choice of Table

to Rear of Laminator for

Feeding Prints.

Note: Remove Bottom Rear

Wind-up Idler for webbing

ease and to prevent adhesive

from sticking onto it when

webbing.

Covered

Foot

Switch

Shim Wheel

Wind-up

Pull Roller

Pull Roller

Rear

Top

Top

Bottom

Rear

Bottom

Wind-up

Rear Top

Supply Shaft

Rear

Bottom

Supply

Shaft

Idler

Chill

Bott

Idler

Cooling Fan: OFF

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 35-40 PSI

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Reverse

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension T op: Light

Web Tension Bottom: Light

Chill Idlers: Over 1st/Over 2nd

Shim Wheel Settings: -1/16" (-2mm)

Shim Wheel Settings: -1/16" (-2mm)

26

Figure 22. Webbing for Decaling

(Pressure-sensitive films)

MOUNTING

This process involves mounting previously prepared

decals onto a substrate. No films or adhesives are

required for this process.

TO MOUNT DECALS ONTO A SUBSTRATE

• Place the mounting board on a flat surface.

• Lay your image face down on the mounting board and

expose approximately 1" (25mm) of the adhesive by

peeling back the release liner along one of the edges.

• Fold the release liner back making an even crease.

• Turn the image over and carefully position the exposed

adhesive edge of the image squarely onto the board.

• Once positioned correctly, press the exposed adhesive

edge of the image firmly down onto the board from the

center toward the edges to ensure a smooth surface. This

is the edge that will be fed into the rollers first.

IMPORTANT! Ensure that the Shim Wheel settings of

the rollers correspond to the board thickness.

• At this point, continuous run can be selected by pressing

the Forward Motor Direction switch.

NOTE: Take care that the rollers do not grab the liner.

• If the board is accidentally sent in too far at first, the

release liner will get caught and will be impossible to pull

back. In this case, stop and reverse the motor until the

liner can be pulled away.

• The image must be held against the roller while the

board feeds through to prevent wrinkles.

NOTE: Take care that the release liner does not trip

the photoelectric eye.

• As the process becomes more familiar, the speed of the

laminator may be increased to make the process more

efficient.

• Remove the mounted image from the rear of the laminator, trim it to size and display it.

• Push the edge of the board into the rollers and depress

the foot switch until the board and image are just caught

by the nip.

• Flip the un-tacked portion of the image over the top

roller with one hand so that the release-liner can be

peeled off the image with the other hand.

• Depress the foot switch to feed the board through the

rollers.

IMPORTANT! Because the foot switch overrides the

photoelectric eye, be sure to keep your hands clear of the

rollers to prevent injury.

27

ENCAPSULATING

This process involves completely sealing an image

between two films. Follow the webbing instructions

for films specific for your location.

MEDIA: Ink Jet, Electrostatic, and Photographic

FILMS:

-- -- -- Top Unwind Shaft: Heat-Activated Laminate

3–5 Mil (75-125 microns)

____ Bottom Unwind Shaft: Heat-Activated Laminate

3–5 Mil (75-125 microns)

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: 205-215°F (96-102°C)

Bottom Roller Temp.: 205-215°F (96-102°C)

Main Roller Pressure: 35-40 PSI

Cooling Fan: OFF

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 35-40 PSI

Rear

Rear

Bottom

Rear

Shaft

Rear Top

Wind-up

Shim Wheel

Top

Pull Roller

Bottom

Pull Roller

Rear Top

Supply Shaft

Idler

Chill

Bott

Idler

Idler

Fan

Tube

Top

Rear

Roll

Easel

Covered

Foot

Switch

Rear Table

Wind-up

Bottom

Supply

Figure 24. Webbing for Encapsulating

Front Top

Supply Shaft

Chill

Idler

Shim Wheel

Top

Main Roller

Bottom

Main Roller

Bott

Idler

Front

Front Top

Wind-up

Front

Roll

Front

Bottom

Supply

Shaft

Easel

Covered

Foot

Switch

Print Guide

Front Table

Front

Bottom

Wind-up

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Forward

Motor Speed Setting: 3-5 FPM (1-1.5 MPM)

WEBBING SETTINGS

Web Tension T op: Medium

Web Tension Bottom: Medium

Chill Idlers: Over 1st/Under 2nd

Shim Wheel Settings: -1/16" (-2mm)

28

PRE-COATING BOARDS

This process is used to coat substrates with a selfadhesive coating onto which images can be mounted.

Preparation:

IMPORTANT! Ensure that the Shim Wheel settings of

the rollers correspond to the board thickness.

• Load the roll of pressure-sensitive adhesive onto the top

unwind shaft of the laminator with the exposed adhesive

facing you.

• Use a leader-board of the same thickness as the boards to

be coated.

• Pull the adhesive down from the top unwind shaft and

place evenly across the face of both rollers.

• Press the foot switch and using the leader-board, push

the adhesive into the roller nip.

• Release the foot switch when the rear edge of the leaderboard is almost leaving the roller nip.

Roll

Easel

Covered

Foot

Switch

Rear

Bottom

Rear Top

Wind-up

Shim Wheel

Top

Pull Roller

Bottom

Pull Roller

Rear

Shaft

Rear Top

Supply Shaft

Bottom

Supply

Idler

Bott

Idler

Chill

Rear

Foamboard

Rear

Rear Table

Wind-up

Fan

Tube

Top

Idler

Idler

Chill

Bott

Idler

Shim Wheel

Front Top

Supply

Shaft

Top

Main Roller

Bottom

Main Roller

Front

Front Top

Wind-up

Front

Roll

Easel

Print Guide

Front Table

Front

Bottom

Wind-up

Front

Bottom

Supply

Shaft

Covered

Foot

Switch

• Position the board to be coated into the nip and choose

a speed setting.

NOTE: When coating boards, ensure that the next

board to be coated follows the previous board without

any gaps.

NOTE: Follow the last board being coated with the

leader-board again to allow the final board to clear the

laminating rollers and then stop the motor and raise

the top roller.

Figure 25. Pre-Coating Boards

29

LOW-TEMP VINYL TRANSFER

This process involves transferring an image onto a

flexible vinyl. Top roller temperature and amount of

main roller downward pressure is dependent on the

type of toners. Use the minimum amount of pressure

required for successful transfer.

MEDIA: Electrostatic

FILMS:

-- -- -- Top Unwind Shaft: Media with Toners

____ Bottom Unwind Shaft: Banner Vinyl

LAMINATOR SETTINGS:

Front Control Panel

Top Roller Temp.: 250-275°F (121-135°C)

Bottom Roller Temp.: 140-150°F (60-65°C)

Main Roller Pressure: 80-100 PSI

Cooling Fan: ON (Under chill idlers)

Roll

Easel

Covered

Foot

Switch

Rear

Finished Product

Rear

Media after

toners removed

Rear Table

Rear Top

Wind-up

Shim Wheel

Top

Pull Roller

Bottom

Pull Roller

Rear

Bottom

Wind-up

Shaft

Rear Top

Supply Shaft

Rear

Bottom

Supply

Chill

Idler

Top

Idler

Bott

Idler

Fan

Tube

Front Top

Supply Shaft

Fan

Tube

Idler

Bott

Idler

Chill

Shim Wheel

Main Roller

Main Roller

Front

Bottom

Supply

Bottom

Bottom

Wind-up

Shaft

Front

Front Top

Wind-up

Top

Front

Media with

toners facing out

Print Guide

Front Table

Vinyl Material

Front

Roll

Easel

Covered

Foot

Switch

Back Control Panels

Pull Rollers: Down

Pull Roller Pressure: 40-60 PSI

Pull Clutch Tension: 40-60 PSI

Motor Control Panel

Motor Direction: Forward

Motor Speed Setting: 1.5-5 FPM (.5-1.5 MPM)

WEBBING SETTINGS

Web Tension T op: Medium to Heavy

Web Tension Bottom: Light to Medium

Chill Idlers: Over 1st/Under 2nd

Shim Wheel Settings: -1/16" (-2mm)

30

Figure 26. W ebbing for Vinyl Transfer

PROCESS CONTROL SHEET

Process: ______________________________________

Application Use: _______________________________

Top Unwind Shaft: ______________________________

Bottom Unwind Shaft: ___________________________

Front Control Panel Settings

Top Roller Temp.: ______________________________

Bottom Roller Temp.: ____________________________

Main Roller Pressure: ____________________________

Cooling Fan: On/Off ____________________________

Back Control Panel Settings

Pull Rollers: Up/Down: __________________________

Pull Roller Pressure: _____________________________

Pull Clutch Tension: _____________________________

Motor Control Panel Settings

Motor Direction: Forward/Reverse _________________

Motor Speed Setting: ____________________________

NOTE: We recommend that you make a photocopy of

this page. With each successfully run application,

record the process and settings and a diagram of the

webbing procedure. Keep the record so the application

can be repeated at a later date.

HINT: If a standard image is made available for each

new process then sales materials and samples can be

developed for reference.

Front Top

Supply Shaft

Top

Idler

Chill

Idler

Shim Wheel

Top

Main Roller

Bottom

Main Roller

Bott

Idler

Front

Front Top

Wind-up

Roll

Front

Bottom

Supply

Shaft

Easel

Covered

Foot

Switch

Print Guide

Front Table

Front

Bottom

Wind-up

Rear

Roll

Easel

Covered

Foot

Switch

Rear

Rear Table

Rear Top

Wind-up

Shim Wheel

Top

Pull Roller

Bottom

Pull Roller

Rear

Bottom

Wind-up

Rear Top

Supply Shaft

Rear

Bottom

Supply

Shaft

Chill

Idler

Bott

Idler

Tube

Fan

Tube

Fan

Front

Webbing Settings

Chill Idlers: [Over/Under] 1st/2nd __________________

Web Tension T op Unwind Shaft: ___________________

Light/Med./Heavy ______________________________

Web Tension Bottom Unwind Shaft: ________________

Light/Med./Heavy ______________________________

Shim Wheel Settings: Front/Back _________________

Images: Sheet Fed/Roll Easel ______________________

31

CLEANING/MAINTAINING YOUR LAMINATOR

WARNING! Turn the door interlock to the OFF

position and then disconnect the laminator from the

power supply before cleaning or greasing the bearings.

CLEANING THE LAMINATOR

• The laminator may be cleaned with a lint-free cloth,

lightly dampened with a mild soap and water solution.

Do not use spray-on cleaners. Do not immerse any part

of the laminator in water or other liquids.

• Do not use an abrasive cleaner, which can damage the

painted surfaces.

• Do not allow water or liquids to enter the electrical circuits, which may cause personal injury and/or damage

the equipment when power is applied.

GREASING THE BEARINGS

• You must grease the top and bottom roller bearings once

each month or every 200 hours. Refer to the Grease Gun

Kit included in your accessory kit for supplies and

instructions.

WARNING! Failure to lube bearings will cause premature wear, which may cause costly repairs and will void

your warranty.

Call SEAL Graphics Technical Service for further

assistance (see rear cover).

CLEANING THE ROLLERS

IMPORTANT! Clean the laminating rollers every

day to prevent adhesive build-up and to ensure quality

output. Adhesive build up may eventually damage the

rollers.

• When laminating, a small amount of adhesive will

squeeze out between the laminate films and onto the top

and bottom rollers. This residue accumulates through

normal use and can be easily cleaned off the rollers.

• Use the Image Roll Cleaner (included) to remove the