○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Elite Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST43401N/ND

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST43402ND

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Reference Manual

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Contents

Preface ................................................................................................... iii

Electrostatic discharge protection........................................................... iii

Important safety information and precautions ......................................... iv

Technical support services ..................................................................... vi

Section 1. General maintenance information ......................................... 1

Section 2. Planning the system.............................................................. 5

Section 3. Interface functions ................................................................ 19

© 1994 Seagate Technology, Inc. All rights reserved

Publication number: 83327730, Rev. C

December 1994

Seagate®, Seagate Technology®, and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Elite™, SeaFAX™, SeaFONE™,

SeaTDD™, and SeaBOARD™ are trademarks of Seagate Technology, Inc.

Other product names are registered trademarks or trademarks of their

owners.

Seagate reserves the right to change, without notice, product offerings or

specifications. No part of this publication may be reproduced in any form

without written permission from Seagate Technology, Inc.

ST43401N/ND and ST43402ND Reference Manual, Rev. C iii

Preface

This is a reference manual for users of Seagate® ST43401N/ND and

ST43402ND Elite™ disc drives employing the SCSI interface. It supplements

the information presented in the user’s manual (publication 83327720). It is

intended to aid engineers who design subsystems using the drive and

customer engineers who install and check out the drive. This manual should

be used in conjunction with the user’s manual.

Electrostatic discharge protection

Caution. Removal of circuit boards by personnel not performing depot repair

will damage components and may void the warranty.

All drive electronic assemblies are sensitive to static electricity due to the

electrostatically sensitive devices used within the drive circuitry. Although

some devices such as metal-oxide semiconductors are extremely sensitive,

all semiconductors, as well as some resistors and capacitors, may be

damaged or degraded by exposure to static electricity.

Electrostatic damage to electronic devices may be caused by the direct

discharge of a charged conductor, or by exposure to the static fields surrounding charged objects. To avoid damaging drive electronic assemblies, service

personnel must observe the following precautions when servicing the drive:

• Ground yourself to the drive whenever the drive electronics are or will be

exposed. Connect yourself to ground with a wrist strap (Seagate part

number 12263496). Connection may be made to any grounded metal

assembly. As a general rule, remember that you and the drive electronics

must all be grounded to avoid potentially damaging static discharges.

• Turn off power before removing or installing the DC power cable.

• Do not remove any circuit boards from the drive.

• Never use an ohmmeter on any circuit boards.

iv ST43401N/ND and ST43402ND Reference Manual, Rev. C

Important safety information and precautions

Caution. Use forced-air ventilation when bench-testing the drive to ensure

proper cooling of drive components.

Use proper safety and repair techniques for safe, reliable operation of this unit.

Service should be done only by qualified persons. We recommend the

procedures in this manual as effective ways of servicing the unit. Some

procedures require the use of special tools. For proper maintenance and

safety, you must use these tools as recommended.

The procedures in this manual contain warnings and cautions that must be

carefully read and followed to minimize or eliminate the risk of personal injury.

The warnings point out conditions or practices that may endanger you or

others. The cautions point out conditions or practices that may damage the

unit, possibly making it unsafe for use.

You must also understand that these warnings and cautions are not exhaustive. We cannot possibly know, evaluate, and advise you of all the ways in

which maintenance might be performed or the possible risk of each technique.

Consequently, we have not completed any such broad evaluation. If you use

a non-approved procedure or tool, first ensure that the method you choose will

not risk either your safety or unit performance.

Always observe the following warnings and precautions:

• Perform all maintenance by following the procedures in this manual.

• Follow all cautions and warnings in the procedures.

• Use sound safety practices when operating or repairing the unit.

• Use caution when troubleshooting a unit that has voltages present. Remove

power from the unit before servicing it.

• Wear safety shoes when removing or replacing heavy parts.

• Ensure that the internal temperature of the rack or cabinet will not exceed

the limits defined for the drive when the drive is mounted in an equipment

rack or cabinet. When units are stacked vertically, pay special attention to

the top where temperatures are usually highest.

• Follow the precautions listed under “Electrostatic discharge protection”

above.

ST43401N/ND and ST43402ND Reference Manual, Rev. C v

• Do not remove any circuit boards from the drive chassis. Return the entire

drive for depot repair if any circuit board is defective. Removal of circuit

boards by personnel not performing depot repair will damage components

and may void the warranty.

• Do not remove the head and disc assembly (HDA) from the drive chassis.

Return the entire drive for depot repair if the HDA is defective.

• Do not attempt to disassemble the HDA. It is not field repairable. If the sealed

HDA is opened by personnel not performing depot repair, this will damage

components and void the warranty.

• As a component, this drive is designed to be installed and operated in

accordance with UL1950, IEC950, EN60950, CSA C22.2 950, and VDE0805.

Refer to Section 2 for information about installation.

• Ensure that the power supply meets the specifications in this manual and

is designed to be used in accordance with UL1950, IEC950, EN60950, CSA

C22.2 950, and VDE0805.

Seagate takes all reasonable steps to ensure that its products are certifiable

to currently accepted standards. Typical applications of these disc drives

include customer packaging and subsystem design. Safety agencies conditionally certify component assemblies, such as the Elite disc drive, based on

their final acceptability in the end-use product. The subsystem designers are

responsible for meeting these conditions of acceptability in obtaining safety/

regulatory agency compliance in their end-use products and in certifying

where required by law. A necessary part of meeting safety requirements is the

provision for overcurrent protection on drive SELV supply voltages.

This unit is a component part and as such is not meant to comply with FCC

or similar national requirements as a stand-alone unit. Engineering radiated

and conducted emissions test results are available through the Seagate

Safety Department to assist the subsystem designer.

vi ST43401N/ND and ST43402ND Reference Manual, Rev. C

Technical support services

Seagate Technology provides technical support literature and diagnostic

utilities to authorized distributors. Please contact your dealer for technical

support and installation troubleshooting. Product technical support is available for all Seagate products by calling the SeaFAX™, SeaFONE™,

SeaTDD™, or SeaBOARD™ services. These are toll calls if you dial from

outside of the number’s local dialing area.

SeaFAX:

USA (408) 438-2620; England 44-62-847-7080

Use a touch-tone telephone to access Seagate’s automated FAX system and

select technical support information by return FAX. This service is available

24 hours a day, 7 days a week.

SeaFONE: (408) 438-8222

Technical sup port specialis ts are available from 8:00 A.M. to 5:00 P.M. PST,

Monday through Friday. Recorded technical information for selected Seagate

products is accessible 24 hours a day, 7 days a week.

SeaTDD: (408) 438-5382

TDD is a telecommunication device for the deaf where two people can

communicate using a keyboard connected to the phone line. A TDD device is

required to access this service, which is available from 8:00 A.M. to 5:00 P. M.

PST, Monday through Friday.

SeaBOARD:

The Seagate Technical Support Bulletin Board System (BBS) is available 24

hours a day, 7 days a week. A modem is required to access this service. The

communications software must be set for 8 data bits, no parity, and 1 stop bit

(8N1). All BBS numbers operate at 9600 baud max. With this service you can

access:

• Specifications and jumper configurations for Seagate products

• Reprints of Seagate documentation

• A directory of information and helpful utilities that you can download to your

computer

ST43401N/ND and ST43402ND Reference Manual, Rev. C vii

Location Telephone number

USA, Mexico, Latin America (408) 438-8771

England 44-62-847-8011

Germany 49-89-140-9331

Singapore 65-292-6973

Australia 61-2-756-2359

Canada (416) 856-5581

France 33-1-40-67-1034

Korea 82-2-556-7294

ST43401N/ND and ST43402ND Reference Manual, Rev. C 1

Section 1. General maintenance information

This section contains general information relating to maintenance of the

drive. You should be familiar with the information in this section and with drive

operation before attempting any maintenance procedures. Information is

divided into the following areas:

• Maintenance tools and materials—lists the tools and materials required to

perform maintenance on the drive

• Testing the drive—provides information concerning testing drive electronics, including a procedure for checking DC voltages supplied to the drive

• Identifying assemblies in the drive—identifies the various parts of the drive

Note. Refer to the user’s manual (publication 83327720) for information

about arranging for depot repair, removing and replacing a drive or

power supply, and packing a drive for shipment.

Maintenance tools and materials

The procedures described in this section require the use of certain special

tools, test equipment, and materials. These are listed below along with the

Seagate part number. Note that the list includes only special tools. We assume

that you have normal maintenance tools.

Description Seagate part number

Static ground wrist strap 12263496

6 1/2 to 8 inch wrist

Volt/ohmmeter Ballantine 345 or equivalent digital voltmeter

Testing the drive

During testing and troubleshooting, the drive normally performs various

operations such as reading and writing test data. System software can be

used to control the drive during these operations. Refer to manuals or other

documentation applicable to the specific system or subsystem for information

concerning the system software routines.

The drive also has built-in diagnostic tests. These diagnostic tests may be

performed through the interface as described in Section 3.

2 ST43401N/ND and ST43402ND Reference Manual, Rev. C

The following procedure provides an overall check of the DC voltages used

by the drive. Before performing this procedure, you should be familiar with the

other information in this section and the safety information in the preface.

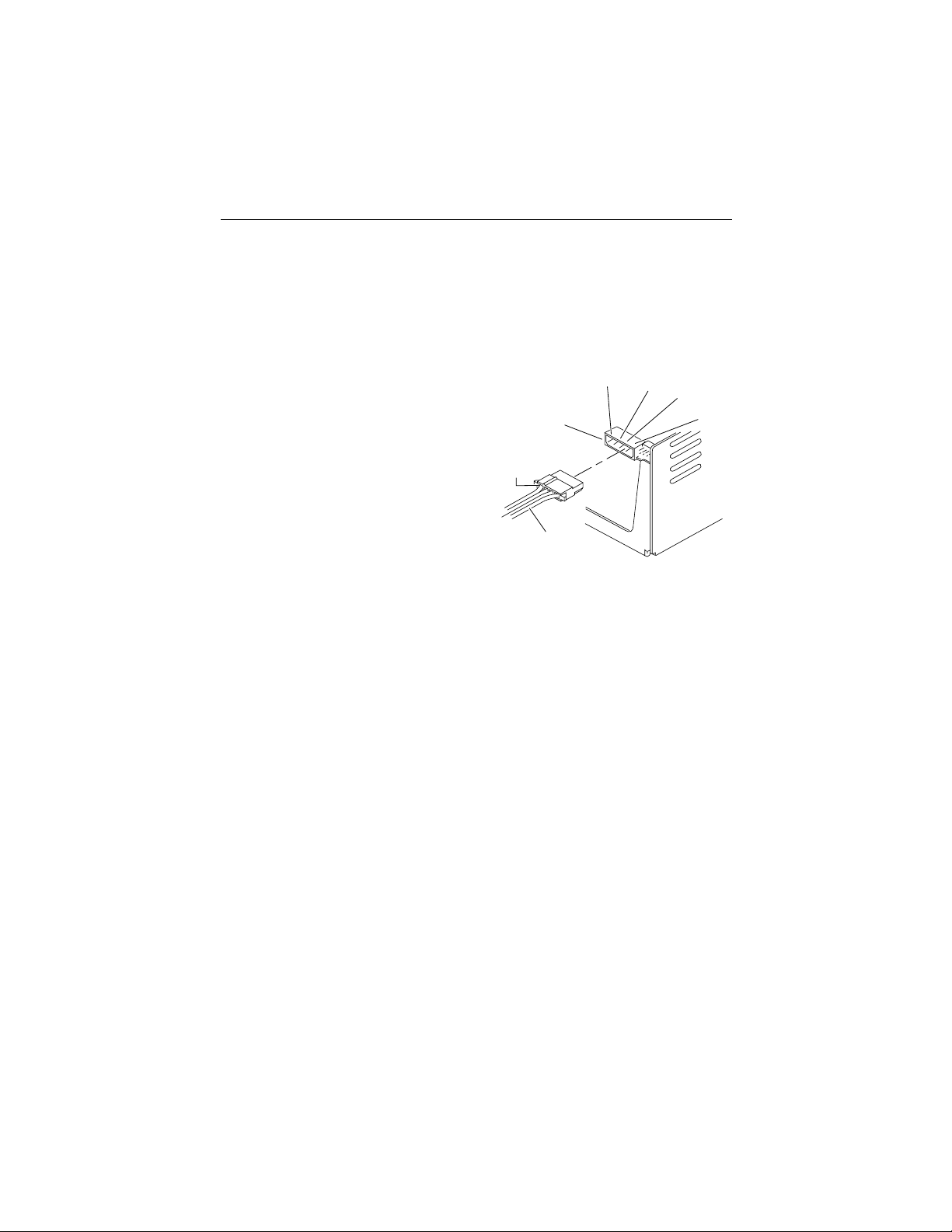

The illustration to the right shows where

the individual voltages appear on the

drive’s DC power connector (J15).

Insert your test probe into the contact

openings on the back surface of the 4pin DC cable connector.

1. Using system software, command

continuous read/write operations

DC Power

Connector

J15

Insert

Probe

Here

+12 V

Pin 1

+12 V

Return

Pin 2

+5 V

Return

Pin 3

+5 V

Pin 4

with the drive on a single cylinder.

2. Connect the voltmeter ground lead

to J15 - Pin 3 (+5 V Return [Ground]).

3. Measure at the appropriate conn ec tion point to check the following

DC

Power

Cable

voltages:

Voltage Connection Specification

+5.0 volts J15 - Pin 4 +4.75 to +5.25 volts

+12 volts J15 - Pin 1 +11.4 to +12.6 volts

Identifying assemblies in the drive

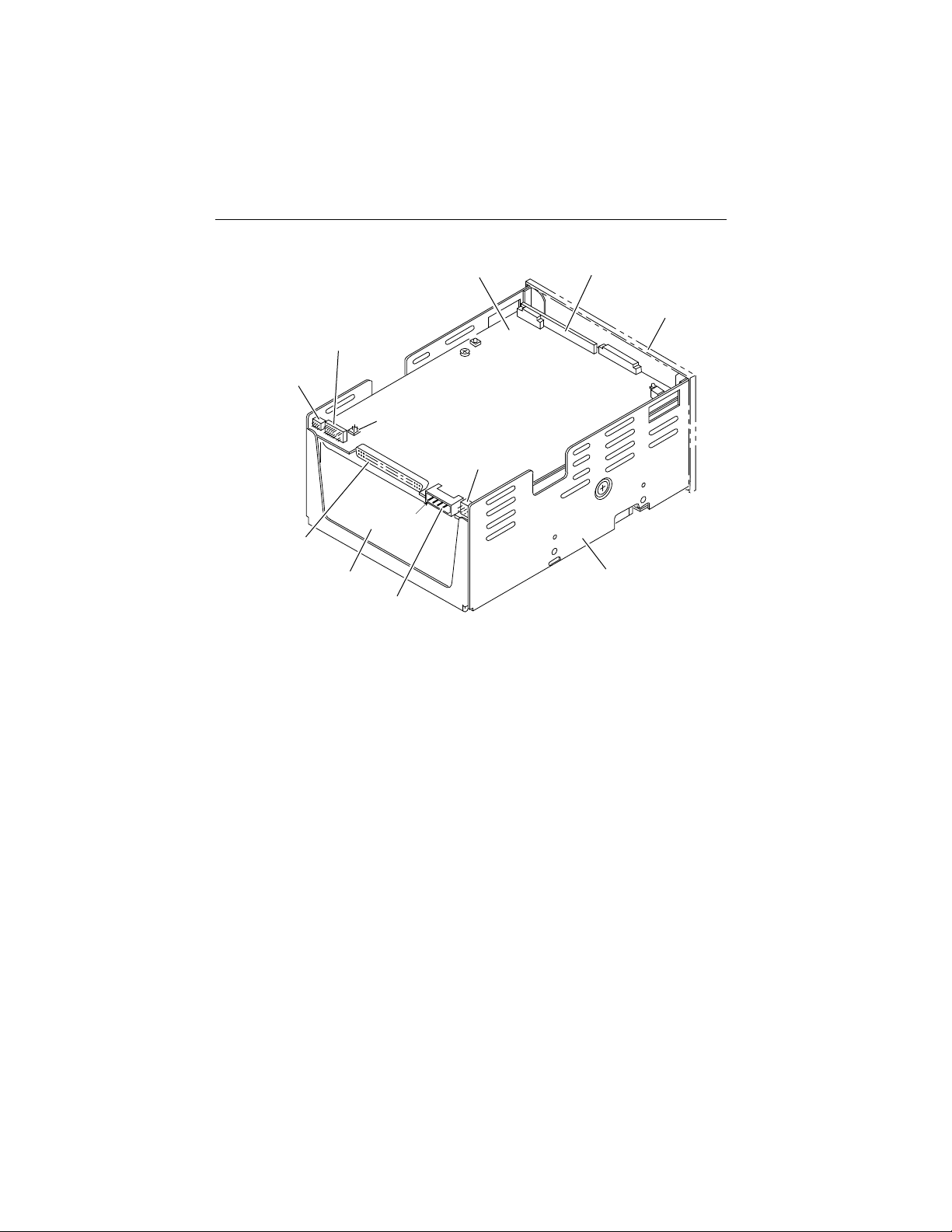

The drive’s major assemblies and components are shown in Figures 1 and 2.

The components are supported by a chassis, and the head and disc assembly

(HDA) is supported by shock mounts attached to the chassis. The control

board is mounted above the HDA. The power board has a right-angle

connection to one end of the control board. An optional bezel is available.

ST43401N/ND and ST43402ND Reference Manual, Rev. C 3

Control

Board

Option Jumpers and

Spindle Sync

Connector

Option

Jumpers

Option

Jumpers

Option

Jumpers

Pin 1

I/O

Connector

Head and Disc

Assembly (HDA)

DC Power

Connector

Figure 1. ST43401N/ND drive components

Power

Board

Optional

Bezel

Chassis

4 ST43401N/ND and ST43402ND Reference Manual, Rev. C

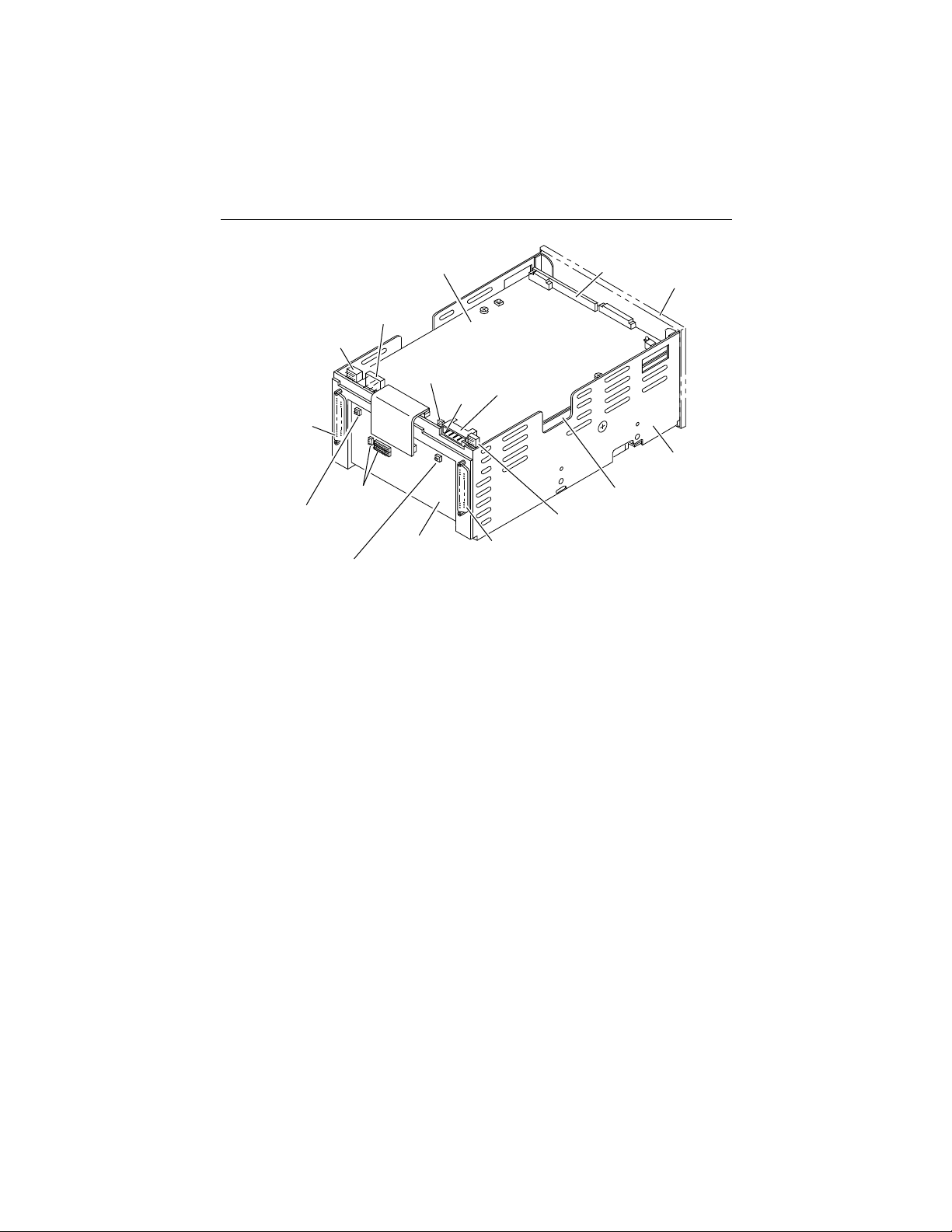

Control

Board

Spindle Sync

Remote Operator

Panel Connector

Port B

I/O Connector

Port B

Terminator

Power

Terminator

Figure 2. ST43402ND drive components

Connector

Option

Jumpers

Port A

Power

I/O Board

Power

I/O

Board

Pin 1

I/O Connector

DC Power

Connector

Port A

Option

Jumpers

Power

Board

Head and Disc

Assembly (HDA)

Optional

Bezel

Chassis

ST43401N/ND and ST43402ND Reference Manual, Rev. C 5

Section 2. Planning the system

This section supplements the installation instructions presented in the user’s

manual (publication 83327720). To aid in configuring the drive for specific

system requirements, the following subjects are discussed:

• Guidelines for enclosure design

• Guidelines for proper air flow

• Guidelines for I/O cabling

• Using the sweep cycle function

Guidelines for enclosure design

The drive is a component for installation in an enclosure that you have

designed. The enclosure design must provide for mounting the drive and

power supply, cable routing, and cooling. See the next topic for guidelines on

providing proper cooling.

The system designer is responsible for obtaining any needed agency approvals such as UL, CSA, and VDE.

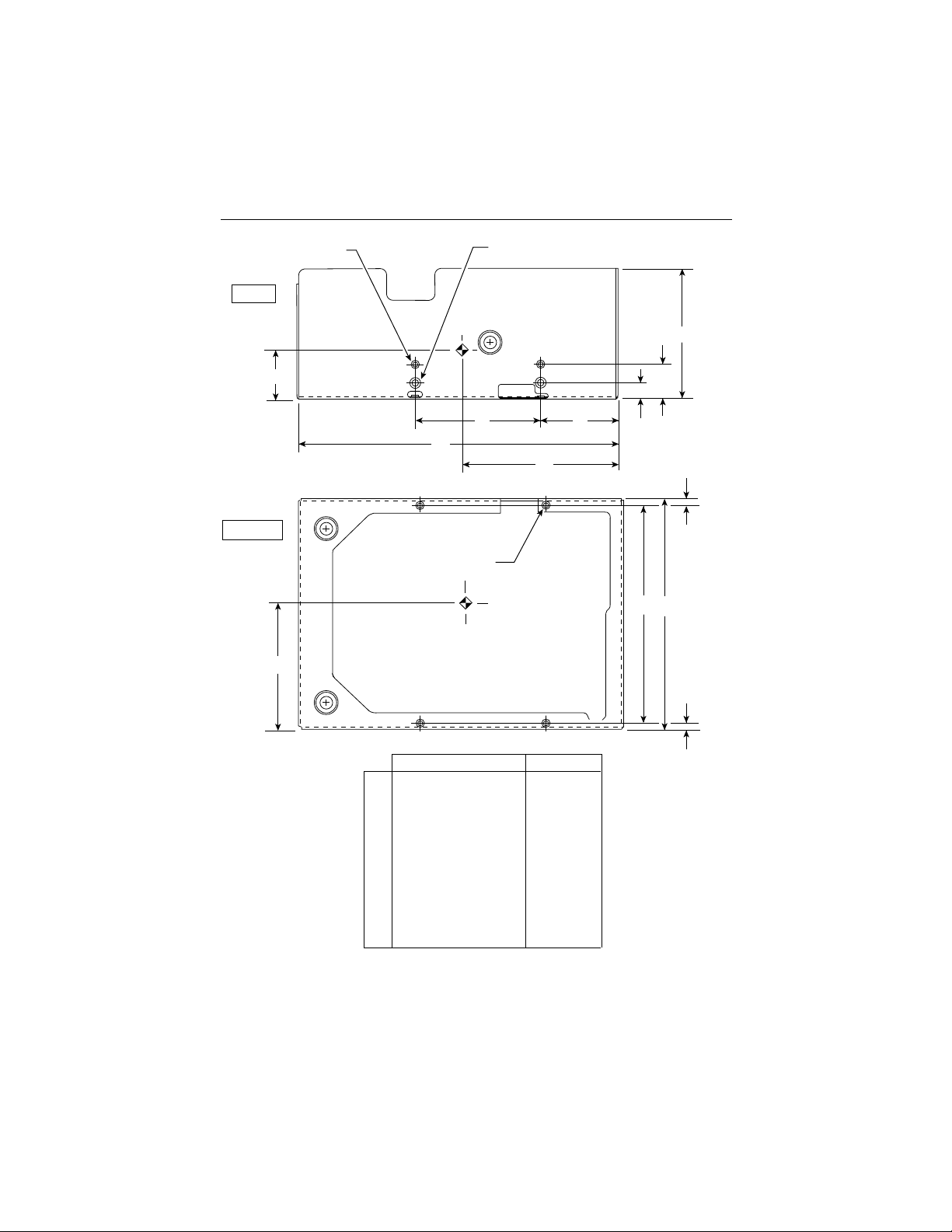

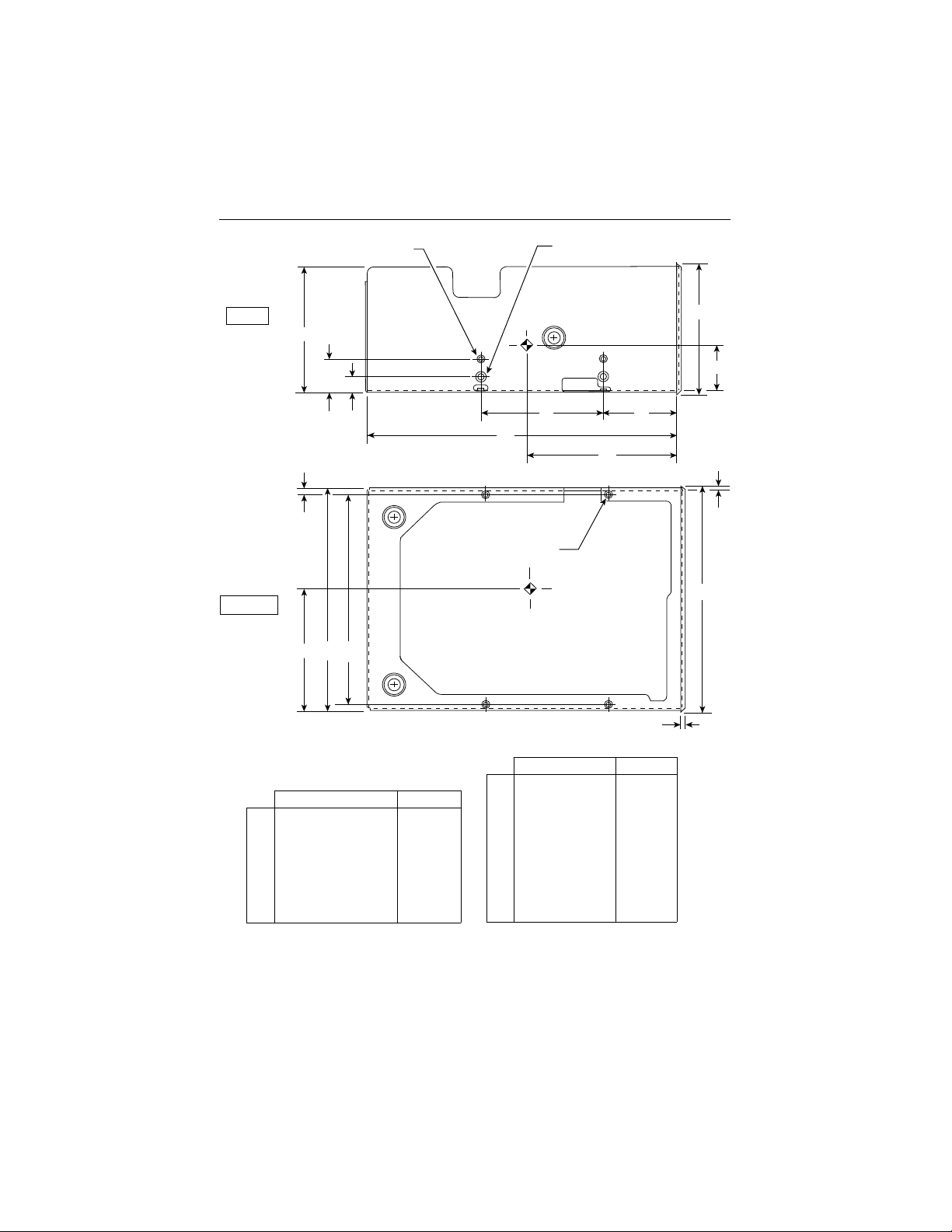

Figure 3 provides mounting dimensions for ST43401N/ND and ST43402ND

drives without a bezel. Figure 4 provides the same information for ST43401N/

ND drives with the optional bezel attached. As described in the user’s manual,

the drive can be mounted using either side-mounting screws or bottommounting screws.

6 ST43401N/ND and ST43402ND Reference Manual, Rev. C

6-32 Threads (4)

Side

K

Bottom

L

C.G.

F

6-32 Threads (4)

C.G.

M4 x .70 Metric Threads (4)

E

D

J

A

B

C

I

G

H

I

in

A

B

C

D

E

F

G

H

I

J

K

L

3.25

0.86

0.39

1.93

3.120

8.60

5.50

5.75

0.12

3.96

1.58

3.13

±

±

±

±

±

±

±

±

±

±

±

±

0.01

0.01

0.01

0.01

0.005

0.03

0.01

0.01

0.01

0.05

0.05

0.05

mm

82.55

21.84

9.91

49.02

79.25

218.44

139.70

146.05

3.05

100.58

40.13

79.50

Figure 3. Mounting dimensions for ST43401N/ND and ST43402ND drives

without a bezel

ST43401N/ND and ST43402ND Reference Manual, Rev. C 7

Side

Bottom

6-32 Threads (4)

A

B

C

I

H

P

G

C.G.

F

6-32 Threads (4)

C.G.

M4 x .70 Metric Threads (4)

E

D

N

K

O

J

L

in

H

in

A

3.25

B

0.86

C

0.39

D

1.87

E

3.120

F

8.00

G

5.50

±

±

±

±

±

max

±

0.01

0.01

0.01

0.02

0.005

0.01

mm

82.55

21.84

9.91

47.50

79.24

203.20

139.70

5.75

I

0.12

J

0.06

K

3.38

L

5.88

M

0.19

N

3.90

O

1.58

P

3.13

0.01

±

0.01

±

0.02

±

0.02

±

0.01

±

0.01

±

0.05

±

0.05

±

0.05

±

Figure 4. Mounting dimensions for ST43401N/ND with a bezel

M

mm

146.05

3.05

1.52

85.85

149.35

4.83

99.06

40.13

79.50

8 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Guidelines for proper air flow

Your enclosure design must ensure adequate cooling for the drive.

We recommend orienting the drive or directing the air flow in a way that creates

the least amount of air-flow resistance while providing air flow above the circuit

boards and around the head and disc assembly (HDA). Also, choose the

shortest possible path between the air inlet and exit. This minimizes the

distance traveled by air that is heated by the drive and by other nearby heat

sources.

Figure 5 shows the design approach with one or more fans installed. The airflow patterns can be created by the fans either pushing or drawing air. The

overall flow pattern can be directed from front to back, back to front, or side

to side.

ST43401N/ND and ST43402ND Reference Manual, Rev. C 9

Above unit

Under unit

Note. Air flows in the direction shown (front to back)

or in reverse direction (back to front)

Note. Air flows in the direction shown or

in reverse direction (side to side)

Figure 5. Suggested air flow

Above unit

Under unit

10 ST43401N/ND and ST43402ND Reference Manual, Rev. C

To evaluate the air-flow design, place the drive in its final mechanical position

and perform random read and write operations. After the temperatures

stabilize, measure the surface (case) temperatures of the components listed

in the appropriate table below. The mean time between failures (MTBF)

values assume that the drive operates below the specified reliability guidelines.

Table 1. ST43401N/ND air-flow evaluation

Office Computer

environment room

MTBF MTBF Max

200k hours 300k hours allowable

Card Component Reference case temp* case temp* case temp*

S/RYFX PERI-2 D540 45 35 60

S/RYFX Video AMP F826 55 45 70

S/RYFX RDS G115 55 45 70

S/RYFX ECLTTL D212 47 37 62

S/RYFX SCRAM C051 44 34 59

S/RYFX DRAM B405 42 32 57

FYEX Motor control U10(A211) 51 41 66

HDA housing Figure 6 60

*Temperature in

o

C

Table 2. ST43402ND air-flow evaluation

Office Computer

environment room

MTBF MTBF Max

200k hours 300k hours allowable

Card Component Reference case temp* case temp* case temp*

AYGX PERI-2 U40 (D540) 45 35 60

AYGX Video AMP U44 (F826) 52 42 67

AYGX RDS U56 (G115) 56 46 71

AYGX ECLTTL U33 (D709) 46 36 61

AYGX SCRAM U6 (B145) 45 35 60

AYGX Driver U26 (B107) 45 35 60

FYEX Motor control U10 (A211) 49 39 64

BYGX ECLTTL U7 (D417) 52 42 67

HDA housing Figure 6 60

*Temperature in

o

C

ST43401N/ND and ST43402ND Reference Manual, Rev. C 11

Guidelines for I/O cabling

This topic provides recommendations for I/O cabling and lists the parts that

can be used in various cables. There are three general cabling schemes, as

illustrated in the following figures:

• Figure 7 describes how to design cables when the initiator and all the drives

are located in one cabinet

• Figure 8 describes how to design cables when the initiator is located in one

cabinet and all the drives are located in another cabinet

• Figure 9 describes how to design cables when the initiators and drives are

distributed within three cabinets

Refer to the appropriate figure to determine the types of components required

for your installation. All three figures show how drives inside a cabinet are

connected by continuous unshielded I/O cables that have a connector for

each drive. In some cases, these internal cables connect to a bulkhead that

allows external shielded cables to be connected. Shielded cables must be

used if the cables run between cabinets.

Cumulative cable length in a daisy-chain system cannot exceed 25.0m

(82.0 ft) for drives using differential I/O. With single-ended I/O, cumulative

cable length cannot exceed 3.05m (10.0 ft).

1.75

4.81

Figure 6. Temperature measurement location on the HDA (bottom)

12 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Drives and initiator in one cabinet

Terminator

2 x 34 Pin

Drive

0

Drive

N

Connector

68 Conductor

Flat Cable or

Twisted Pair

Initiator

Notes:

1. Cables and terminators shown are unshielded.

2. Flat cable can be used with single-ended drivers.

Twisted-pair flat cable must be used with differential

drivers.

3. Total length of cables and stubs cannot exceed 25m

(82.0 ft) with differential drivers or 3.05m (10.0 ft)

with single-ended drivers.

Figure 7. Cabling with one cabinet

Terminator

ST43401N/ND and ST43402ND Reference Manual, Rev. C 13

Drives and initiator in separate cabinets

Unshielded

Terminator

Drive

0

Terminator

Shielded

Connector

2 x 34 Pin

Connector

Flat Cable

or

Twisted Pair

Shielded

Connector

Shielded

Cable

Initiator

Bulkhead

Drive

1

Drive

2

Drive

3

Bulkhead

Cabinet BCabinet A

Notes:

1. Initiator in one cabinet (A).

2. All drives in another cabinet (B).

3. Both bulkheads have shielded connectors.

4. Flat cable can be used with single-ended drivers. Twisted-pair

flat cable must be used with differential drivers.

5. Total length of cables and stubs cannot exceed 25m (82.0 ft)

with differential drivers or 3.05m (10.0 ft) with single-ended

drivers.

Figure 8. Cabling with two cabinets

14 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Drives in separate cabinets

Drive

0

Drive

1

Drive

4

Initiator

ID 5

Bulkhead

Shielded

Terminator

Cabinet A

Shielded Cable

Drive

2

Drive

3

Figure 9. Cabling with three cabinets

Initiator

ID 6

Drive

7

Bulkhead

Shielded Cable

Cabinet B Cabinet C

Bulkhead

Shielded

Terminator

ST43401N/ND and ST43402ND Reference Manual, Rev. C 15

Table 3 lists the parts needed to construct unshielded I/O cables. Table 4 lists

part numbers and lengths of synchronized spindle cables. Table 5 provides

part numbers of external terminators and resistor-pak terminators.

ST43402ND (dual port) drives have both I/O connectors (one for Port A and

the other for Port B) located on the I/O board. You must use an adapter (part

number 70935801) to terminate each I/O cable following the last drive in the

daisy chain.

ST43401N/ND (single-ended) drives are shipped with resistor-pak terminators installed on the control board. Each end of the daisy-chain I/O cable must

be terminated. If the resistor-pak terminators are in place on the drive, external

terminators are not needed. Single-ended terminators and differential terminators have different part numbers and electrical characteristics (they cannot

be interchanged).

Table 3. Unshielded I/O cabling components

Vendor

part number Description

Connectors for cable ends

AMP-786090-7 Connector, unshielded male, straight

Connectors in daisy chain

AMP-786096-7 Connector, shielded male, straight

(two used per cable)

Cable

Hitachi-A3007-51-68T Flat cable, twisted-pair, 68-conductor, 30 AWG

(for single-ended or differential I/O)

16 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 4. Synchronized spindle cables

Seagate

Length part number

1.5 feet (0.46 meter) 70703929

3 feet (0.91 meter) 70703921

5 feet (1.52 meter) 70703922

7 feet (2.13 meter) 70703923

10 feet (3.05 meter) 70703924

20 feet (6.09 meter) 70703925

30 feet (9.14 meter) 70703926

40 feet (12.19 meter) 70703927

50 feet (15.24 meter) 70703928

Table 5. Terminators

Seagate

Description part number

Terminator resistor-pak, single-ended 96752447

Terminator resistor-pak, differential 70906701

Terminator, external shielded single-ended 89501152

Terminator, external shielded differential 89501030

Terminator, external unshielded single-ended 15387807

Terminator, external unshielded differential 15459255

Terminator, adapter for dual-port drives 70935801

ST43401N/ND and ST43402ND Reference Manual, Rev. C 17

Using the sweep cycle function

The sweep cycle is a feature that periodically moves the heads to different

locations on the discs during intervals when the drive is idle. The following are

highlights of the sweep cycle function:

• Using the sweep cycle enhances drive reliability. We encourage you either

to enable the drive sweep cycle or to use a sweep cycle controlled by the

host (initiator). Consult with an analyst in making this choice.

• The sweep routine consumes approximately 11 seconds of a 13-hour

period. The drive is available to the system more than 99.98 percent of the

time.

• You may disable the sweep cycle (described below) without affecting the

specified mean time between failures (MTBF) or warranty agreements.

The drive is preset during manufacturing with the sweep cycle option selected.

A jumper on the control board makes the selection, as shown in Figure 10. The

other jumpers on the control board are discussed in the user’s manual.

The jumper is identified as Sweep Cycle Option, which either enables or

disables the sweep cycle function. The jumper can be positioned as follows:

• Jumper disconnected—disables the sweep cycle function

• Jumper connected—enables the sweep cycle function

Sweep movements, if enabled, can occur only in conjunction with seeks

required by the controller or with any SCSI read or write operation having an

implied seek. Each time the drive performs a sweep cycle, it starts a 12-minute

timeout. When the timeout has elapsed, the drive performs another sweep

cycle only when it receives the Seek command. When combining a sweep

cycle with a seek, the drive performs the sweep cycle first and then executes

the Seek command.

If a sweep segment was initiated by the Seek command, the drive performs

the sweep function and then moves the heads to the cylinder requested by the

controller. If about 15 minutes elapse with no disc access commands received

from the SCSI bus, the SCSI I/O logic sends a one-track seek command to the

drive logic. This command causes the drive to perform its sweep cycle.

18 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Sweep Cycle

Option

J4B

ST43401N/ND

Sweep Cycle

Option

ST43402ND

Figure 10. Control board jumpers

J4B

ST43401N/ND and ST43402ND Reference Manual, Rev. C 19

Section 3. Interface functions

This section provides an overview of the small computer system interface

(SCSI) as it is used in the Elite drive. It is beyond the scope of this manual to

provide a detailed description of all the features, capabilities, variations, and

protocol of SCSI-2. This information is provided in the SCSI Interface

Specification for the Elite Product Family (document 64721702).

All communications between drive and controller must pass through the

interface. This communication includes all commands, status, control signals,

and read/write data transfers. The interface consists of the I/O cables and the

logic (on part of the control board) required to process the signals sent

between the drive and controller.

Dual port drive (ST43402ND) considerations

ST43402ND dual port drives have some different operating limits from the

single port drives discussed in this manual. These differences are listed

below.

• Dual port drives have separate sense buffers, synchronous transfer agreements, and unit attention conditions for each initiator on both ports.

• Any initiator may place commands in the queue on either port.

• Data placed in the cache by one port may be used to satisfy a read request

from the other port. A write from one port may cause data cached by a read

request from the other port to be purged from the cache.

SCSI bus configuration

Figure 11 illustrates the SCSI bus configuration. The SCSI bus can have a

maximum of 16 devices connected to it, and communication can occur

between any 2 devices at any given time. The device that originates an

operation is referred to as the initiator and the device that performs the

operation is the target.

The drive uses one unshielded I/O cable to attach it to the SCSI bus. You must

supply all unshielded cables (see “Guidelines for I/O cabling” in Section 2).

Shielded cables are typically used for connections between cabinets where

electromagnetic compatibility (EMC) and electrostatic discharge (ESD) protection are required. The I/O cable carries commands, data, and status

information across the SCSI bus. Figure 12 shows the lines (except those not

used) in the I/O cable. The function of each of these lines is explained in

Table 6.

20 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Initiator Target

Host

Host

Each device must have a unique SCSI

ID, assigned by its SCSI ID bit.

Host

Adaptor

Initiator Target

Host

Adaptor

SCSI Bus

Embedded

Controller

Embedded

Controller

To same or other SCSI

units. Total must be

16 or less.

Drive

(logical

unit)

Drive

(logical

unit)

Data Bus Bit

SCSI ID

Data Bus Bit

SCSI ID

Figure 11. SCSI bus configuration

DB (7)7DB (6)6DB (5)5DB (4)4DB (3)3DB (2)2DB (1)1DB (0)

DB (15)15DB (14)14DB (13)13DB (12)12DB (11)11DB (10)10DB (9)9DB (8)

0

8

ST43401N/ND and ST43402ND Reference Manual, Rev. C 21

Data Bus Bits 0-15 (plus parity)

Busy (BSY)

Select (SEL)

Reset (RST)

Initiator Target

Attention (ATN)

Acknowledge (ACK)

Request (REQ)

Message (MSG)

Input/Output (I/O)

Control/Data (C/D)

Figure 12. SCSI bus signal lines

22 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 6. SCSI bus signal lines

Signal Source Function

Data Bus (DB 15–0+P) I–T Sixteen data-bit signals, plus a parity bit signal

that form the Data Bus. DB(15) is the mostsignificant bit and has the highest priority during the Arbitration phase. Bit number, significance, and priority decrease downward to

DB(0). A data bit is defined as 1 when the signal

is true and 0 when false. Data parity DB(P) is

odd. The use of parity is a selectable option and

is not valid during the Arbitration phase.

Busy (BSY) I–T An “or-tied” signal that indicates to the initiator

or target that the bus is being used.

Select (SEL) I–T Used by an initiator to select a target, or by a

target to reselect an initiator.

Reset (RST) I–T An “or-tied” signal that indicates the Reset

condition exists.

Attention (ATN) I Driven by the initiator to indicate an Attention

condition.

Acknowledge (ACK) I Driven by the initiator to acknowledge a REQ/

ACK data transfer handshake.

Request (REQ) T Driven by the target to indicate a request for a

REQ/ACK data transfer handshake.

Message (MSG) T Driven by target during the Message phase.

Input/Output (I/O) T Driven by the target to control the direction of

data movement on the data bus with respect to

the initiator. True indicates input to the initiator.

Also used to distinguish between Selection

and Reselection phases.

Control/Data (C/D) T Driven by the target to indicate whether control

or data information is on the data bus. True

indicates control.

T = target and I = initiator

ST43401N/ND and ST43402ND Reference Manual, Rev. C 23

I/O signal processing

The following paragraphs describe the basic SCSI bus communication

process. They describe the bus phases, a typical command sequence,

command set, and message codes. The Request Sense command and the

Receive Diagnostic Results command provide information to the initiator

about drive functions. The coding of this information is explained later in this

section.

SCSI bus phases

Communication on the SCSI bus occurs in eight phases depending on the

type of operation or information transfer being performed. The bus phases

pertain to the condition or state of the lines at a given time. The SCSI bus can

never be in more than one phase at any given time.

The information phases are defined by the MSG, C/D, and I/O signals as

shown in Table 7. The SCSI bus phases are listed and described in Table 8.

Table 7. Information transfer phases

MSG C/D I/O Phase Name Direction of Transfer

0 0 0 Data Out Initiator------>Target

0 0 1 Data In Target-------> Initiator

0 1 0 Command Initiator------> Target

0 1 1 Status Target-------> Initiator

1 0 0 Reserved

1 0 1 Reserved

1 1 0 Message Out Initiator------>Target

1 1 1 Message In Target-------> Initiator

0 = false, 1 = true

24 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 8. SCSI bus phase descriptions

Phase Description

Bus Free No SCSI device asserts Busy or Select for at least one bus

settle delay.

Arbitration Allows one SCSI device to gain access to the bus based on its

priority ID bit.

Selection Allows an initiator to select a target. The I/O line must not be

asserted in this phase.

Reselection Allows a target to reconnect to an initiator so it can continue an

operation started by an initiator but suspended by the target

before it was complete. The I/O line must be asserted during this

phase.

Command Allows the target to request command information from the

initiator.

Data The Data In phase allows the target to request that data be sent

to the initiator from the target.

The Data Out phase allows the target to request that data be

sent from the initiator to the target.

Status Allows the target to request that status information be sent from

the target to the initiator.

Message The Message In phase allows the target to request that mes-

sages be sent to the initiator from the target.

The Message Out phase allows the target to request that

messages be sent from the initiator to the target. The target can

invoke this phase at its convenience in response to an Attention

signal created by the initiator.

ST43401N/ND and ST43402ND Reference Manual, Rev. C 25

SCSI command execution

Figure 13 illustrates the basic flow of a command sequence. The sequence

illustrated cannot and does not represent all variations. Refer to the SCSI

Interface Specification for the Elite Product Family (document 64721702) for

command descriptions, execution details, and timing constraints. The following information appears at the end of this topic:

• Table 9 describes the command set for the drive

• Table 10 lists the message codes and shows the direction of flow for each

• Table 11 describes the status codes

As shown in Figure 13, the communication sequence starts with the SCSI bus

in the Bus Free phase. This phase indicates that no other SCSI devices are

using the bus and it is free for use by other devices. Each device detects the

Bus Free phase when the Select and Busy lines are both false.

The Bus Free phase is followed by an Arbitration phase where the initiator

attempts to gain access to the bus. Access to the bus is based on the device

priority ID bit. Arbitration occurs when the device asserts Busy and its ID on

the data bus. This ID bit is a single bit on the data bus that corresponds to the

unique SCSI address assigned to each device when it was installed. The other

15 bits are released by the SCSI device. The SCSI device examines the data

bus. If a higher priority SCSI ID bit is true (data bus bit 15 is the highest) the

SCSI device loses arbitration and the device releases its signals. If no higher

priority bit is true, the device wins arbitration.

After winning the Arbitration, the initiator selects the target (Selection phase).

The initiator places the SCSI ID of the target on the bus (asserts the data bus

bit), as well as its own ID. After a delay, the initiator asserts the Select line. The

target determines it is selected when its SCSI bus ID bit and the Select line are

true, and the Busy and I/O lines are false. Selection with Attention informs the

target that the initiator has a message ready.

Note. For dual port drives, a SCSI hard reset causes a unit attention condition

for all initiators on the port receiving the reset. Commands, reservations, wide negotiations, and synchronous negotiation agreements

associated with the alternate port are not affected.

26 ST43401N/ND and ST43402ND Reference Manual, Rev. C

The selected device responds to the initiator by entering the Message Out

phase if the initiator has Attention asserted. In this phase, the target

requests that the initiator send messages to it. The Message, Control/

Data, and Input/Output lines are used in combinations to indicate the

various information transfer phases. The state of the three signal lines is

controlled by the target, and the phase selected by the state of these three

signal lines is shown earlier in Table 7.

In this example, the Identify message is the first message sent by the initiator

after the Selection phase. This message identifies the physical path for the

logical unit (only logical unit 0 is supported) specified by the initiator. The

Identify message is also the first message sent by the target following the

Reselection phase. The initiator can request a Message Out phase by

asserting Attention.

Following the Message Out phase, the initiator responds to the Command

phase and, in this example, issues a Read command to the drive. The

Message In phase is entered (Disconnect message) followed by the Bus Free

phase. The Arbitration phase is again entered, followed by the Reselection

and the Message In (Identify message) phases. Reselection is a phase that

allows the target to reconnect to the initiator so it can continue an operation

that was started by an initiator but suspended by the target before it was

complete. The requested read data is then transferred to the initiator.

Following the Data In phase, the target enters the Message In phase and, in

this example, requests the initiator to Save Data Pointer. There are current

(also called active) pointers that represent the state of the interface and point

to the next command, data, or status byte to be transferred between the

initiator’s memory and the target. Current pointers are used with the target

currently connected to the initiator.

Another set of pointers called saved pointers is provided for each active

command, whether or not it is currently connected. The command pointer

points to the start of the command descriptor block for that command. The

saved data pointer points to the start of the data area at the beginning of each

command and it remains at this value until the target sends the Save Data

Pointer message to the initiator. In response to this message, the initiator

stores the value of the current data pointer into the saved data pointer. Only

the saved pointer values are retained when a device disconnects from the

bus. The current pointer values are restored from the saved values at the next

reconnection.

ST43401N/ND and ST43402ND Reference Manual, Rev. C 27

At this point, the Message In phase is entered with a Disconnect message

code. Following the disconnect, the bus is in the Bus Free phase in preparation

for the Arbitration and Reselection phases.

After Reselection, the process continues with the Message In and Data In

phases previously described. The Status phase occurs at the end of the

operation. It allows the target to send status information to the initiator.

Status codes are contained in bits 5 to 1 of the status byte. The various

codes are shown in Table 11. The process ends with the Message In

phase and a Command Complete message followed by the Bus Free

phase.

Bus

Free

Arbitration

Selection

with

Attention

Message

Out

(identify)

Command

(read)

Message

In

(disconnect)

Bus

Free

Arbitration

Reselection

Message

In

(identify)

Data

In

Message

In

(save

pointer)

Message

In

(disconnect)

Bus

Free

Arbitration

Reselection

Message

In

(identify)

Data

In

Status

Message

In

(command

complete)

Bus

Free

Figure 13. Sequence of a typical command

28 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 9. Command set

Group 0 commands for direct access devices

Op code Command name

00 Test Unit Ready

01 Rezero Unit

02

03 Request Sense

04 Format Unit

05–06

07 Reassign Blocks

08 Read

09

0A Write

0B Seek

0C–10

11 Port Status (0 dual port only)

12 Inquiry

13–14

15 Mode Select

16 Reserve (see note 1)

17 Release

18–19

1A Mode Sense (see note 2)

1B Start/Stop Unit

1C Receive Diagnostic Results

1D Send Diagnostic

1E–1F

Note 1. For dual port drives, when a reservation is granted to an initiator on

one port, all initiators on both ports receive reservation conflict status.

Note 2. Dual port drives do not support Mode Sense. Dual port drives support

Expanded Mode Sense (page 08h), which includes all previous

functions supported by Mode Sense (page 38h).

continued

ST43401N/ND and ST43402ND Reference Manual, Rev. C 29

continued from previous page

Group 1 and 2 Commands for Direct Access Devices

Op Code Command Name

20–24

25 Read Capacity

26–27

28 Read Extended

29

2A Write Extended

2B Seek Extended

2C–2D

2E Write and Verify

2F Verify

30–36

37 Read Defect Data

38–3A

3B Write Buffer

3C Read Buffer

3D

3E Read Long

3F Write Long

40 Change Definition

30 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 10. Message code descriptions

Code

(Hex) Initiator Target Description Direction of Transfer

00 M M Command complete Target ------>Initiator

01//00 O O Modify data pointer Target ------>Initiator

01//01 O O Sync data transfer request Target <-----> Initiator

02 O O Save data pointer Target ------>Initiator

03 O O Restore pointers Target ------> Initiator

04 O O Disconnect Target ------>Initiator

05 O M Initiator detected error Initiator------>Target

06 O M Abort Initiator------>Target

07 M M Message reject Target <-----> Initiator

08 M M No operation Initiator------>Target

09 M M Message parity error Initiator------>Target

0A O O Linked command complete Target ------> Initiator

0B O O Linked command complete Target ------> Initiator

with flag

0C O M Bus device reset (see note 1) Initiator ------> Target

0D O M Abort tag Initiator------>Target

0E O O Clear queue (see note 2) Initiator------>Target

0F-13 Reserved — —

14 O O Reset other port message Initiator ------> Target

15-1F Reserved — —

20 O O Simple queue tag (two bytes) Target <-----> Initiator

21 O O Head of queue tag (two bytes) Initiator ------> Target

22 O O Ordered queue tag (two bytes) Initiator------>Target

23-7F Reserved — —

80-FF M M Identify (establishes the Target <-----> Initiator

communication path between

an initiator and target for a

logical unit)

continued

ST43401N/ND and ST43402ND Reference Manual, Rev. C 31

continued from previous page

Bit 7 = 1: Indicates an Identify message

Bit 6 = 1: Indicates the initiator allows disconnection and reselection

Bit 6 = 0: Indicates that disconnection is not allowed

Bit 5 = 0: Indicates the I/O is directed to or from a logical unit

Bit 5 = 1: Indicates the I/O is directed to or from a target routine

Bits 4 to 3: Reserved

Bits 2 to 0: Specify a logical unit number or target routine number,

depending on bit 5

M = Mandatory for SCSI-2

O = Optional for SCSI-2

Note 1. For dual port drives, a bus device reset message from either port causes a

unit attention condition for all initiators on both ports. Commands, reservations, wide negotiations, and synchronous negotiation agreements associated with the alternate port are not affected.

Note 2. For dual port drives, a clear queue message from either port causes all

commands from that port to be cleared. A unit attention condition is set for

all initiators on that port except the one that sent the Clear Queue message.

Commands for the other port are not affected.

32 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 11. Status codes

Status Byte:

Bit

7 6 54 32 1 0

Byte

RESVD RESVD <<---------- Status Byte Code ---------->> RESVD

Status Byte Codes:

Bits of the Status Byte*

7 6543210 Status Description

0 0000000 Good

0 0000010 Check condition

0 0000100 Condition met

0 0001000 Busy

0 0010000 Intermediate

0 0010100 Intermediate-condition met

0 0011000 Reservation conflict

0 0100010 Command terminated

0 0101000 Queue full

*All other codes are reserved

ST43401N/ND and ST43402ND Reference Manual, Rev. C 33

The Request Sense command

The Request Sense command (03H) requests that the target transfer sense

data to the initiator. This data is returned in the extended sense format. Within

this format are the following three levels of information:

• Sense key—defined in Table 12.

• Additional Sense Code—see byte 12 listing in Table 13.

• Additional Sense Code qualifiers—see byte 13 listing in Table 13. These

qualifiers differentiate between related definitions all having the same

Additional Sense Code.

All codes not shown in Table 13 are reserved.

Table 12. Sense key descriptions

Sense

Key Description

0

H

1

H

2

H

3

H

4

H

5

H

6

H

7

H

8

H

9

H

A

H

B

H

C

H

D

H

E

H

F

H

No sense

Recovered error

Not ready

Medium error

Hardware error

Illegal request

Unit attention

Data protect

Reserved

Reserved

Reserved

Aborted command

Reserved

Reserved

Miscompare

Reserved

34 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Table 13. Additional sense codes and their qualifiers

Byte 12 Byte 13 Description

00 00 No additional sense information

01 00 No index/sector signal

02 00 No seek complete

03 00 Peripheral device write fault

04 00 Logical unit not ready—cause not reportable

04 01 Logical unit is in process of becoming ready

04 02 Logical unit not ready—initializing command required

04 03 Logical unit not ready—mutual intervention required

04 04 Logical unit not ready—format in progress

05 00 Logical unit does not respond to selection

06 00 No reference position found (track zero or equivalent)

08 00 Logical unit communication failure

08 01 Logical unit communication time-out

08 02 Logical unit communication parity error

09 00 Track-following error

0A 00 Error log overflow

0C 01 Write error recovered with auto reallocation

0C 02 Write error—auto reallocation failed

10 00 ID CRC or ECC error

11 00 Unrecovered read error

11 01 Read retries exhausted

11 02 Error too long to correct

11 03 Multiple read errors

11 04 Unrecovered read error—auto reallocate failed

11 0A Miscorrected error

12 00 Address mark not found for ID field

13 00 Address mark not found for data field

14 00 Recorded entity not found

14 01 Record not found

15 00 Random positioning error

15 01 Mechanical positioning error

15 02 Positioning error detected by read of medium

16 00 Data synchronization mark error

17 00 Recovered data with no error correction applied

17 01 Recovered data with retries

continued

ST43401N/ND and ST43402ND Reference Manual, Rev. C 35

continued from previous page

Byte 12 Byte 13 Description

17 02 Recovered data with positive head offset

17 03 Recovered data with negative head offset

17 05 Recovered data with previous sector ID

17 06 Recovered data without ECC—data auto-reallocated

18 00 Recovered data with error correction applied

18 01 Recovered data with error correction and retries applied

18 02 Recovered data with ECC and/or retries—data auto-reallocated

19 00 Defect list error

19 01 Defect list not available

19 02 Defect list error in primary list

19 03 Defect list error in grown list

1A 00 Parameter list length error

1B 00 Synchronous data transfer error

1C 00 Defect list not found

1C 01 Primary defect list not found

1C 02 Grown defect list not found

1D 00 Miscompare during verify operation

1E 00 Recovered ID with ECC correction

20 00 Invalid command operation code

21 00 Logical block address out of range

24 00 Invalid field in CDB—check field pointer in sense data

25 00 Logical unit not supported

26 00 Invalid field in parameter list—check field pointer in sense data

26 01 Parameter not supported—check field pointer in sense data

26 02 Parameter value invalid—check field pointer in sense data

26 03 Threshold parameters not supported

27 00 Write protected

28 00 Not ready to ready transition—medium may have changed

29 00 Power on, reset, or bus device reset occurred

29 00 Device reset message, bus reset (dual port only)

29 01 Power on, reset (dual port only)

2A 00 Parameters changed

2A 01 Mode parameters changed

2A 02 Log parameters changed

2B 00 Copy cannot execute since host cannot disconnect

2C 00 Command sequence error

continued

36 ST43401N/ND and ST43402ND Reference Manual, Rev. C

continued from previous page

Byte 12 Byte 13 Description

2F 00 Commands cleared by another initiator

30 01 Cannot read medium—unknown format

30 02 Cannot read medium—incompatible format

31 00 Medium format corrupted

31 01 Format command failed

32 00 No defect spare location available

32 01 Defect list update failure

37 00 Rounded parameter

39 00 Saving parameters not supported

3A 00 Medium not present

3D 00 Invalid bits in identify message

3E 00 Logical unit has not self-configured yet

3F 00 Target operating conditions have changed

3F 01 Microcode has been changed

3F 02 Changed operating definition

3F 03 Inquiry data has changed

40 NN Diagnostic failure—more description in ASCQ (Byte 13

codes 80H–FFH)

40 00 RAM failure (should use 40 NN)

41 00 Data path failure (should use 40 NN)

42 00 Power on or self-test failure (should use 40 NN)

43 00 Message error

44 00 Internal target failure

45 00 Select/reselect failure

46 00 Unsuccessful soft reset

47 00 SCSI parity error

48 00 Initiator detected error message received

49 00 Invalid message error

4A 00 Command phase error

4B 00 Data phase error

4C 00 Logical unit failed self-configuration

4E 00 Overlapped commands attempted

53 02 Medium removal prevented

5A 00 Operator request or state change input (unspecified)

5A 01 Operator medium removal request

5A 02 Operator selected write protect

continued

ST43401N/ND and ST43402ND Reference Manual, Rev. C 37

continued from previous page

Byte 12 Byte 13 Description

5A 03 Operator selected write permit

5B 00 Log exception

5B 01 Threshold condition met

5B 02 Log counter at maximum

5B 03 Log list codes exhausted

5C 00 RPL status change

5C 01 Spindles synchronized

5C 02 Spindles not synchronized

XX Additional Sense Codes in the range of 80H–FFH are

vendor unique

XX Additional Sense Code Qualifiers in the range of 80H–FFH

are vendor unique

The Receive Diagnostic Results command

The Receive Diagnostic Results command (1CH) requests that analysis

data be sent to the initiator after completion of a Send Diagnostic

command. The results of power on initialization tests are available through

the Request Sense command as well as this command. Diagnostic data

return bytes are shown in Table 14.

Table 14. Diagnostic data return bytes

Byte Description

0 Additional length (bit 7 = most significant bit)

1 Additional length (bit 0 = least significant bit)

2 FRU code (most probable)

3 FRU code

4 FRU code

5 FRU code (least probable)

6 Error code (bit 7 = most significant bit)

7 Error code (bit 0 = least significant bit)

Additional length field

This two-byte field indicates the number of additional bytes included in the

diagnostic data list. This value will always be 0006H. This means there are six

additional bytes (bytes 2–7).

38 ST43401N/ND and ST43402ND Reference Manual, Rev. C

Field replaceable unit (FRU) code

In the event of a failure, the FRU code byte identifies the assembly that may

have failed. The codes are listed in probability order with the most probable

assembly listed first and the least probable listed last. FRU codes are shown

in Table 15.

Table 15. SCSI online FRU codes

Code Description

00H No information or unknown

01H Replace entire drive

02H Undefined

03H Undefined

ST43401N/ND and ST43402ND Reference Manual, Rev. C 39

Error code

This two-byte value provides information about what part of the diagnostic

operation has failed. The error codes are shown in Table 16.

Table 16. Error codes

Code Description

0001H Formatter diagnostic error

0002H Microprocessor RAM diagnostic error

0004H No drive ready

0008H No sector or index detected

0009H Fatal hardware error while doing drive diagnostics

000CH No drive command complete

0010H Unable to set drive sector size

0014H Unable to clear drive attention

0018H Unable to start spindle motor

0020H Unable to recalibrate drive

0030H Unable to send write current data to drive

0034H Unable to issue drive seek command

0040H Unable to read user table from drive

0041H Ran out of sectors while doing drive diagnostics

0042H Unable to read reallocation table

0043H Unable to read ETF log

0044H Unable to read firmware stored on disc

0045H Firmware read from disc or sent by host has an invalid checksum

0060H Thermal calibration failure

0070H Microprocessor internal timer error

0080H Buffer controller diagnostic error

0081H Buffer RAM diagnostic error

00C1H Data miscompare while doing drive diagnostics

00F0H PROM checksum error

00F1H CPU error

00F2H SCSI protocol chip error

00F3H ECC subsystem error

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, CA 95066-4544, USA

Publication Number: 83327730, Rev. C, Printed in USA

Loading...

Loading...