Seagate ST43400N-ND User Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Elite Disc Drive

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST43400N/ND

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

User ’s Manual

. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ii

Contents

Preface .................................................................................................... iii

Electrostatic discharge protection........................................................ iii

Important safety information and precautions...................................... iv

Technical support services.................................................................. vi

Section 1. General description ................................................................ 1

Section 2. Installation .............................................................................. 7

Section 3. Operation ............................................................................... 33

Section 4. Parts data............................................................................... 37

Section 5. Maintenance........................................................................... 39

© 1992 Seagate Technology, Inc. All rights reserved

Publication Number: 83327630, Rev. A

Seagate®, Seagate Technology®, and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Elite

SeaBOARDTM are trademarks of Seagate Technology, Inc. Other product

names are registered trademarks or trademarks of their owners.

No part of this publication may be reproduced in any form without written

permission from Seagate Technology, Inc.

TM,

SeaFAXTM, SeaFONETM, and

ST43400N/ND User’s Manual iii

Preface

This manual contains information for users of the Seagate ST43400N and

ST43400ND Elite disc drives employing the SCSI interface. It provides installation, operation, and maintenance information. This manual also lists the part

numbers for options and accessories available for these drives. Additional

information is available in the reference manual (publication 83327640).

Electrostatic discharge protection

Caution. Removal of circuit boards by personnel not performing depot repair

will damage components and may void the warranty.

All drive electronic assemblies are sensitive to static electricity, due to the

electrostatically sensitive devices used within the drive circuitry. Although

some devices such as metal-oxide semiconductors are extremely sensitive,

all semiconductors, as well as some resistors and capacitors, may be

damaged or degraded by exposure to static electricity.

Electrostatic damage to electronic devices may be caused by the direct

discharge of a charged conductor or by exposure to the static fields surrounding charged objects. To avoid damaging drive electronic assemblies, observe the following precautions when installing or servicing the drive:

• Ground yourself to the drive whenever the drive electronics are or will be

exposed. Connect yourself to ground with a wrist strap (refer to accessories

in Section 4 for part numbers). Connection may be made to any grounded

metal assembly. As a general rule, remember that you and the drive electronics must all be grounded to avoid potentially damaging static discharges.

• Turn off the power before removing or installing the DC power cable.

• Do not remove any circuit boards from the drive.

• Never use an ohmmeter on any circuit boards.

iv

Important safety information and precautions

Caution. Use forced-air ventilation when bench-testing the drive to ensure

proper cooling of drive components.

Use proper safety and repair techniques for safe, reliable operation of this unit.

Service should be done only by qualified persons. We recommend the procedures in this manual as effective ways of servicing the unit. Some procedures

require the use of special tools. For proper maintenance and safety, you must

use these tools as recommended.

The procedures in this manual and labels on the unit contain warnings and

cautions that must be carefully read and followed to minimize or eliminate the

risk of personal injury. The warnings point out conditions or practices that may

endanger you or others. The cautions point out conditions or practices that may

damage the unit, possibly making it unsafe for use.

You must also understand that these warnings and cautions are not exhaustive.

We cannot possibly know, evaluate, and advise you of all the ways in which

maintenance might be performed or the possible risk of each technique.

Consequently, we have not completed any such broad evaluation. If you use a

non-approved procedure or tool, first ensure that the method you choose will not

risk either your safety or unit performance.

Always observe the following warnings and precautions:

• Perform all maintenance by following the procedures in this manual.

• Follow all cautions and warnings in the procedures.

• Use sound safety practices when operating or repairing the unit.

• Use caution when troubleshooting a unit that has voltages present. Turn off

power to the unit before servicing it.

• Wear safety shoes when removing or replacing heavy parts.

• Provide a means to isolate the drive from the main power in case of fire or other

emergency.

• Ensure that the internal temperature of the rack or cabinet does not exceed

the limits defined for the drive, when the drive is mounted in an equipment rack

or cabinet. When units are stacked vertically, pay special attention to the top

where temperatures are usually highest.

• Follow the precautions listed above in “Electrostatic discharge protection.”

• Do not remove any circuit boards from the drive chassis. Return the entire

drive for depot repair if any circuit board is defective. Removal of circuit boards

by personnel not performing depot repair will damage components and may

void the warranty.

ST43400N/ND User’s Manual v

• Do not remove the head and disc assembly (HDA) from the drive chassis.

Return the entire drive for depot repair if the HDA is defective.

• Do not attempt to disassemble the HDA. It is not field repairable. If the sealed

HDA is opened by personnel not performing depot repair, this will damage

components and void the warranty.

As a component, this drive is designed to be installed and operated in

accordance with UL1950, IEC950, EN60950, CSA C22.2 950, and VDE0806.

Refer to section 2 for information about installation.

If you do not use a Seagate power supply, ensure that the supply meets the

specifications in this manual and is designed to be used in accordance with

UL1950, IEC950, EN60950, CSA C22.2 950, and VDE0806.

Seagate takes all reasonable steps to ensure that its products are certifiable to

currently accepted standards. Typical applications of these disc drives include

customer packing and subsystem design. Safety agencies conditionally certify

component parts, such as the Elite disc drive, based on their final acceptability

in the end-use product. The subsystem designers are responsible for meeting

these conditions of acceptability in obtaining safety/regulatory agency compliance in their end-use products and for certifying where required by law. A

necessary part of meeting safety requirements is the provision for overcurrent

protection on drive SELV supply voltages.

This unit is a component assembly and as such is not meant to comply with FCC

or similar national requirements as a stand-alone unit. Engineering radiated and

conducted emissions test results are available through the Seagate Safety

Department to assist the subsystem designer.

vi

Technical support services

Seagate Technology provides technical support literature and diagnostic utilities to authorized distributors. Please contact your dealer for technical support

and installation troubleshooting. Product technical support is available for all

Seagate products by calling the SeaFAX, SeaFONE, or SeaBOARD services.

These are toll calls if you dial from outside of the number’s local dialing area.

SeaFAX: (408) 438-2620

You can use a Touch-Tone telephone to access Seagate’s automated FAX

delivery system and select technical support information by return FAX. This

service is available twenty-four hours a day, seven days a week.

SeaFONE: (408) 438-8222

The enhanced phone system provides recorded technical information on

selected Seagate products while you are on hold. Technical support specialists

are available to answer questions from 8:00 A.M. to 5:00 P.M. PST, Monday

through Friday. Recordings are accessible twenty-four hours a day, seven days

a week.

SeaBOARD:

The Seagate Technical Support Bulletin Board System (BBS) is available

twenty-four hours a day, seven days a week. A modem is required to access this

service. The communications software must be set for eight data bits no parity

and one stop bit (8N1). With this service you can access:

• Specifications and jumper configurations for all Seagate products

• Reprints of Seagate documentation

• A directory of information and helpful utilities that you can download to your

own computer

Location Telephone Number Maximum Baud Rate

United States/Canada (408) 438-8771 9600

England 44-62-847-8011 9600

Germany 49-89-140-9331 2400

Singapore 65-227-2217 9600

Australia 61-2-756-2359 9600

Note. This is a toll call if you dial from outside of the number’s local dialing area.

Section 1. General description

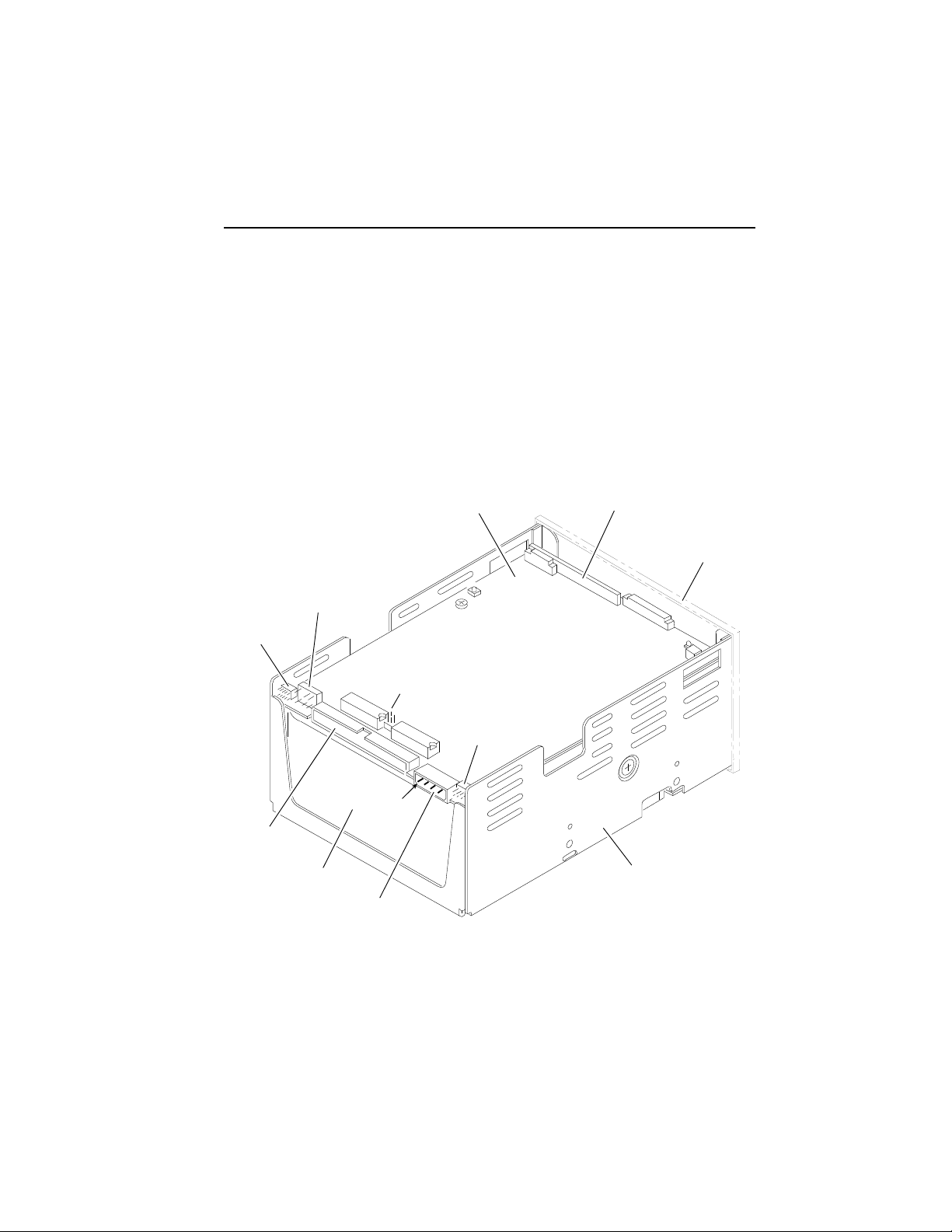

The Seagate ST43400N/ND Elite 3 disc drives are high speed, random access

digital data storage devices. They communicate with an initiator using the Small

Computer System Interface (SCSI). The drive is shown in Figure 1, and its

specifications are listed in Table 1 on the following page.

The drive is a component for installation in an enclosure designed for the drive.

The enclosure design must ensure adequate cooling for the drive, and it must

address the requirements for grounding and for shielding of emissions. The

reference manual (publication 83327640) presents guidelines for designing the

enclosure, but the design is your responsibility.

1

Spindle Sync

Option

Jumpers

I/O

Connector

Head and Disc

Assembly (HDA)

Connector

Option

Jumpers

Pin 1

DC Power

Connector

Control

Board

Option

Jumpers

Power

Board

Optional

Bezel

Chassis

Figure 1. The ST43400N/ND disc drive

2

Table 1. Drive specifications

Characteristics Conditions Specifications

Size Dimensions See “Space requirements”

in section 2

Weight (drive only) 3.6 kg (8.0 lb)

Weight (power supply only) 2.3 kg (5.0 lb)

Interface Fast SCSI-2

Recording Total capacity 3,554,871,600 bytes

(unformatted)

Bytes per track

(unformatted)

Inner track 49,000 bytes

Outer track 72,800 bytes

Formatted capacity*

(256-byte sectors) 2,538,290,688 bytes

(512-byte sectors) 2,916,687,360 bytes

(1,024-byte sectors) 3,150,686,208 bytes

Number of discs 11

Recording heads 21

Servo heads 1

Physical heads per surface 1

Cylinders per head/disc assy 2,738 (includes 2 spares)

Cylinders available to user 2,736

Spare cylinders 1

System cylinders 1

Diagnostic cylinders 1

Spare sectors per cylinder 6

Modulation 1,7 code

* Excluding spare sectors, spare cylinders, diagnostic cylinders, and system cylin-

ders.

continued

General description 3

continued from previous page

Characteristics Conditions Specifications

SCSI transfer rate, burst 10.0 Mbytes/sec max

Seek time

(time required to move heads

to a different track address—

excluding SCSI I/O overhead)

Typical full 23.5 msec

Typical average 11.5 msec

Typical one-track 1.7 msec

Typical access times Write Read

Typical single track

seek msec 1.7 0.9

Average seek msec 11.5 10.5

Maximum seek msec 23.5 22.5

Latency

(time required to reach a

particular track address after

head positioning is complete)

Average 5.55 msec

(disc rotation

at 5400 RPM)

Maximum 11.17 msec

(disc rotation

at 5373 RPM)

Start time** 30 sec max

Stop time 30 sec max

** Following the power sequence delay, once DC power is applied and start

conditions are present.

4

The drive contains all the circuits and mechanical devices necessary to record

data on and recover it from its discs. The drive requires DC voltage input from

an external power supply, which receives its AC input power from the site main

power source. A power supply and DC power cable are available accessories.

The drive consists of a head and disc assembly (HDA) and two circuit boards,

mounted on a common chassis. The circuit boards contain the electronics

required for drive operation. The HDA is a sealed unit containing the electromechanical components used for data retrieval and storage. These components

include the discs, spindle, drive motor, actuator, heads, and preamplifiers.

The 11 discs provide the recording medium for the drive. These discs are

mounted on a spindle, and the spindle is coupled directly to the drive motor. The

drive motor rotates the discs at 5400 RPM and produces a circulation of air

within the sealed HDA.

The built-in SCSI controller directs all drive functions, receives commands

from the initiator (host computer), interprets them, and then transfers the

necessary commands to the drive. The controller therefore allows the

initiator to start an operation and then disconnect to service another device.

Refer to the reference manual for a description of interface functions.

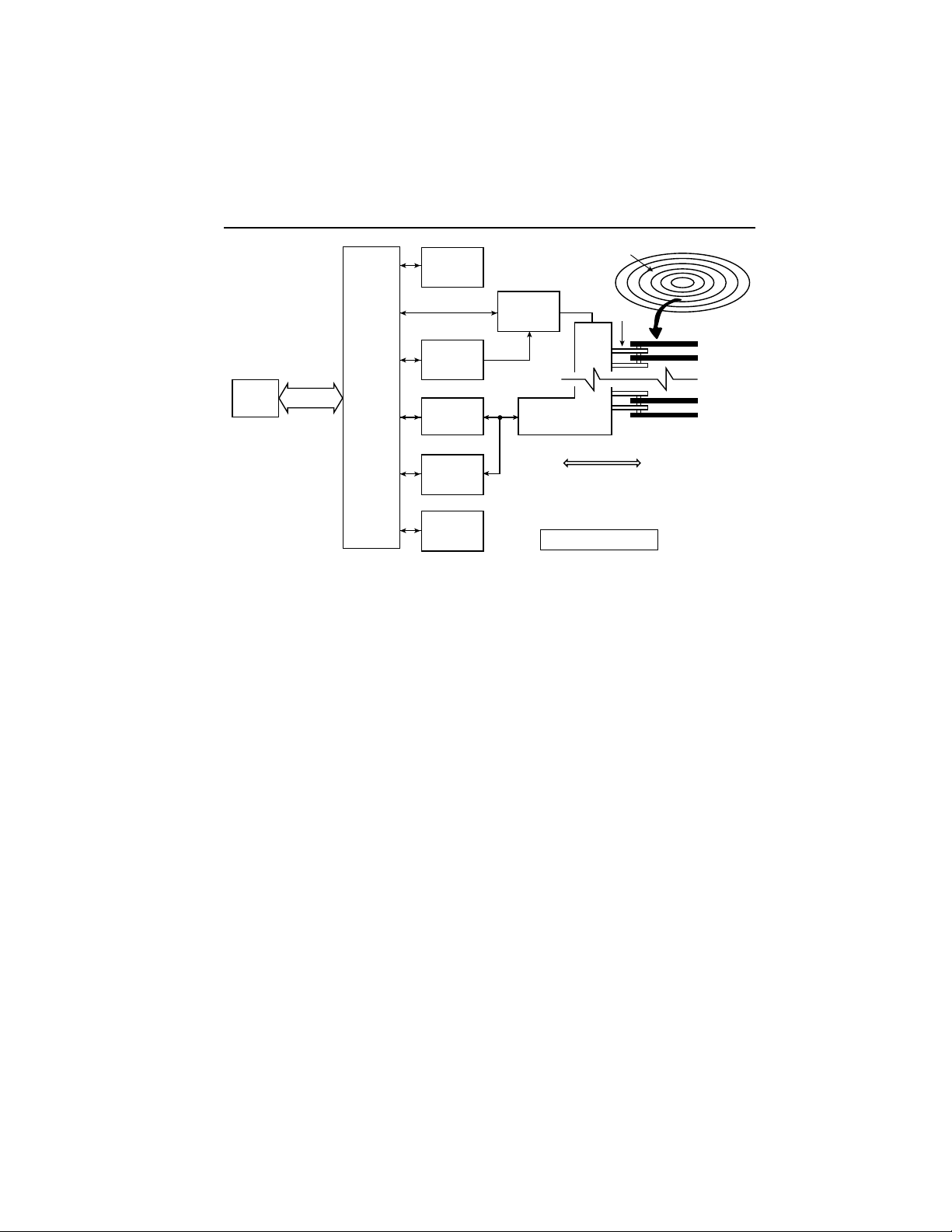

All drive operations are related to data recovery and storage (normally referred

to as reading and writing). The actual reading and writing is performed by heads

that are positioned over the rotating discs’ recording surfaces. There is one

head for each data surface. The heads are positioned in such a way that data

is written in concentric tracks around the disc surfaces (see Figure 2).

Before any read or write operation can be performed, the controller must

instruct the drive to position the heads over the desired cylinder (called

seeking) and to use the head located over the surface (head selection) where

the operation is to be performed.

The heads are mounted on the actuator, and the actuator moves the heads over

the rotating discs. There are 22 heads; a servo head to sense actuator

positioning and 21 data heads used for data transfers to and from the discs. The

actuator has a voice coil that moves in a permanent magnetic field in response

to signals from the servo positioning circuitry. The voice coil moves the heads in

an arc across the rotating discs.

When the drive is not powered on, the heads rest on the disc surface in a

preassigned landing zone located beyond the data zone. The actuator automatically latches in this position to protect the drive in the event that it is moved or

shipped. When the drive is activated to bring the discs up to speed, the heads

fly on a cushion of air close to the disc surface.

General description 5

Data recorded in

concentric tracks

Head

Selection

Logic

Heads

Discs

Power Supply

Initiator

I/0 Lines

SCSI

Controller

Unit

Selection

Logic

Read/Write

Logic

Seek

Logic

Track

Orientation

Logic

Error

Detection

Logic

Figure 2. Drive functional block diagram

After arriving at the data track and selecting a head, the controller locates the

portion of the track where the data is to be read or written. This is called track

orientation. Signals from the drive indicate the beginning of each track. The

controller uses these signals to determine the position of the head on the track.

When the head is above the desired track location, the controller commands the

drive to actually read or write the data. During a read operation, the drive

retrieves data from the discs, processes it, and transmits it to the controller.

During a write operation, the drive receives data from the controller, processes

it, and stores it on the discs.

The drive can also recognize certain errors that may occur during its

operation. When an error is detected, it is indicated to the initiator by the SCSI

controller.

Section 2. Installation

The information contained in this section describes installation and initial

checkout of the drive.

Site requirements

The site requirements considered are environment, airflow, space, power,

grounding, and interface.

Environmental requirements

All environmental requirements for the drive are listed in Table 2 below.

Table 2. Drive environmental requirements

Conditions Specifications

Operating environment

Temperature Range of 5

maximum change of 20oC (36oF) per hour

Humidity Range of 5% to 95% relative

A maximum wet bulb temperature of 26

no condensation

Barometric pressure -305 m to 3,048 m (-1,000 ft to 10,000 ft);

104 kPa to 69 kPa (30 in Hg to 20 in Hg)

o

C to 50oC (41oF to 122oF) with a

o

C (79oF)

7

Non-operating environment

(unpacked)

Temperature Range of -40oC to 60oC (-40oF to 140oF) with a

maximum change of 20oC (36oF) per hour

Humidity Range of 5% to 95% relative

A maximum wet bulb temperature of 26

no condensation

Barometric pressure -305 m to 12,192 m (-1,000 ft to 40,000 ft);

104 kPa to 19 kPa (30 in Hg to 6 in Hg)

Storage/transit environment

(packed)

Temperature Range of -40

o

C to 60oC (-40oF to 140oF) with a

maximum change of 20oC (36oF) per hour

Humidity Range of 5% to 95% relative

Barometric pressure -305 m to 12,192 m (-1,000 ft to 40,000 ft);

104 kPa to 19 kPa (30 in Hg to 6 in Hg)

o

C (79oF)

8

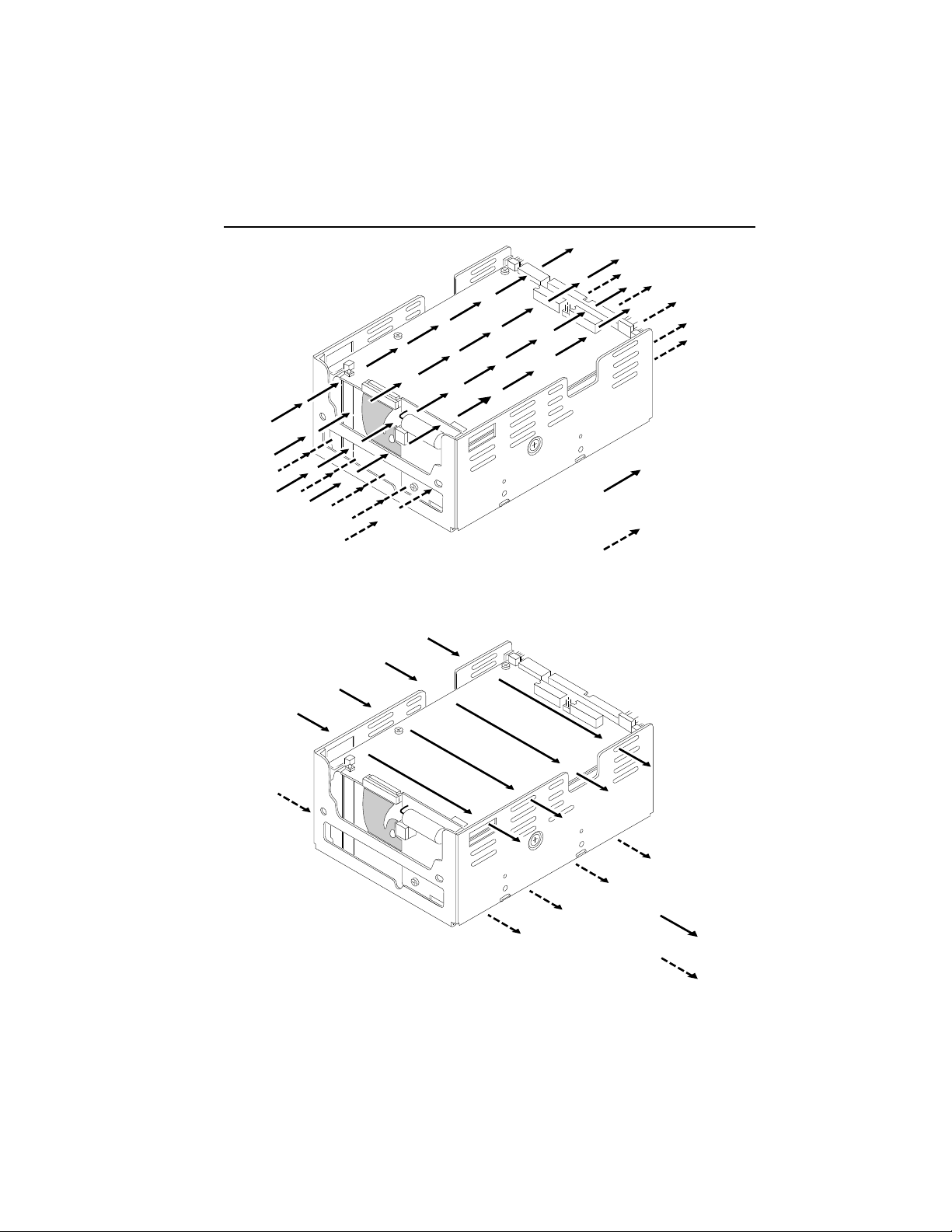

Airflow requirements

The enclosure design must ensure adequate cooling for the drive. Note that the

fan in the power supply cools only the power supply’s internal parts.

The drive’s product specification (document 64403601) describes how to

evaluate the airflow design. The evaluation consists of ensuring that the case

temperatures of certain critical components remain within acceptable limits

during drive operation.

We recommend orienting the drive or directing the airflow in a way that creates

the least amount of airflow resistance while providing airflow above the circuit

boards and around the head and disc assembly (HDA). Also, choose the

shortest possible path between the air inlet and exit. This minimizes the

distance traveled by air that is heated by the drive and by other nearby heat

sources.

Figure 3 shows two design approaches with one or more fans used to

generate air flow. The airflow patterns can be created by the fans either pushing

or drawing air. The overall flow pattern can be directed from front to back, back

to front, or side to side.

Installation 9

Above unit

Note. Air flow in the direction shown (front to back)

or in reverse direction (back to front)

Note. Air flow in the direction shown or

in reverse direction (side to side)

Under unit

Above unit

Under unit

Figure 3. Suggested airflow

10

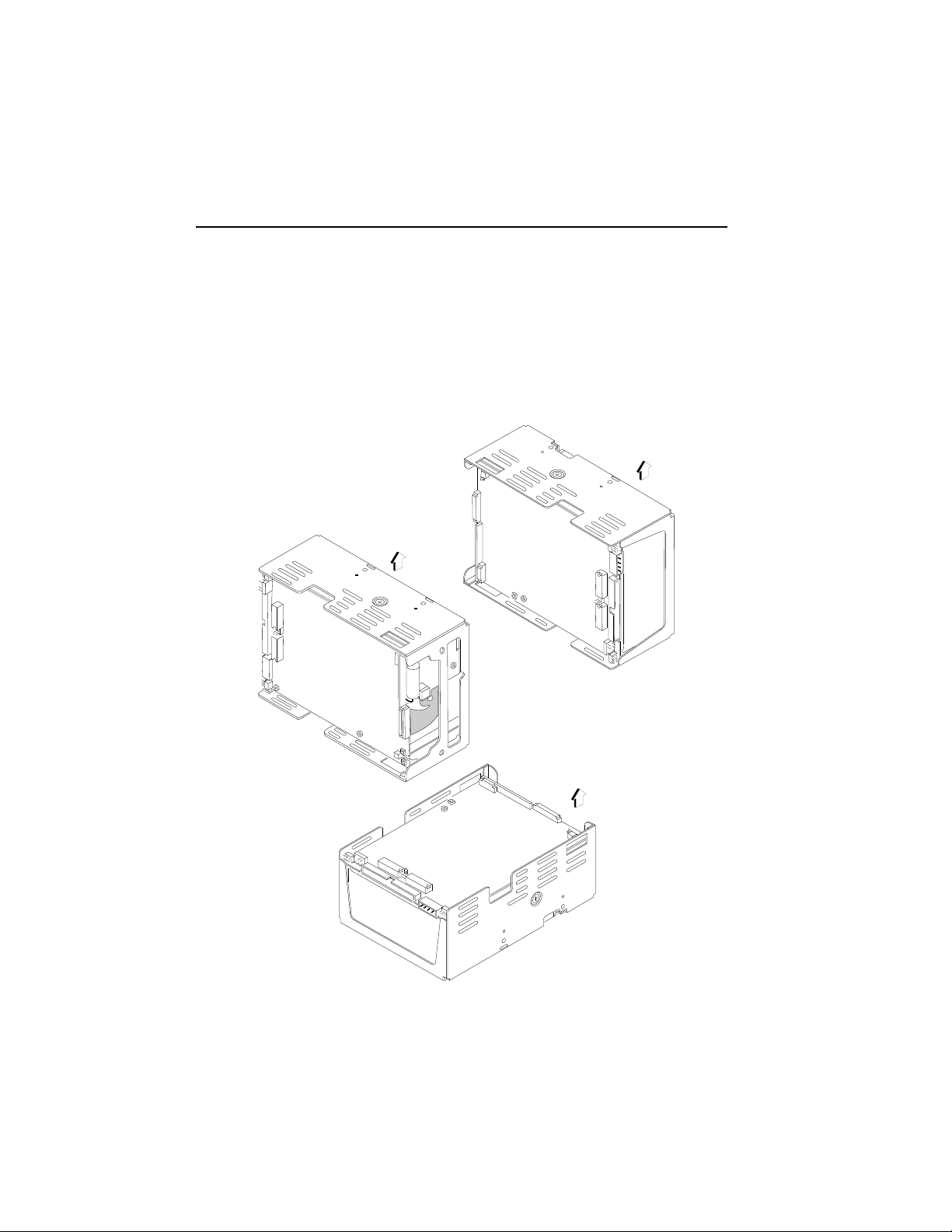

Space requirements

The drive is designed to be mounted in one of the three orientations shown

in Figure 4. The drive may be mounted on its base or on either side. Mounting

orientations other than those shown are not permitted. The physical dimensions of the drive and power supply are shown in Figure 5. The drive itself

weighs 3.6 kg (8.0 lb).

For details about designing an enclosure to match the drive mounting dimensions, refer to the drive’s product specification.

Up

Up

Figure 4. Mounting orientations

Up

Loading...

Loading...