Seagate ST425 Service Manual

'$I;-~fS:L~.

-'!w""'t"

'~,~"r):;ty;

'.- ..

Manhattan House

Bridge Road

Maidenhead

Berkshire SL6 8DB

Telephone:

Maidenhead

(0628) 75851

Telex:

847898 MANSKY

Facsimile:

(0628) 782812

•

ST425 WINCHESTER DISC DRIVE

SERVICE MANUAL

June 28, 1984

•

Manhatt.n ~

Bridge Road

Maidenhead

BerkshireSL6 808

- J

Seagate. 920 Disc Drive. Scotts Valley,CA95066 • (408)438-6550

•

TABLE OF CONTENTS

•

SECTION

l.e

INTRODUCTION ••

1.1 Specification Summary •••••••••••••••••••••••••• 2

1.1.1 Physical Specifications •••••••••••••••••• 2

1.1.2 Reliability Specifications ••••••••••••••• 3

1.1.3 Performance Specifications ••••••••••••••• 4

1.1.4 Functional Specifications •••••••••••••••• 4

2.e THEORY OF OPERATIONS ••••••••••••••••••••••••••••••• 5

2.1 General

2.1.1 Recording Format ••

2.1.2 Track

2.1.3 Read/Write Heads •.••••••••••••••••••••••• 8

2 •1 • 4 DiBe s ••••••••••..••••••••••••••••••••••••• 8

..............

Interface Description •

For mat... 0 ••••••••••••••••••••••••• 7

·.~ .

.............

PAGE

•1

••5-6

•7· .

2.1.5 Air Filtration System •••••••••••••••••••• 8

2.2 Mechanical Theory •.••••••••••••••.••••••••••••• 9

2.2.1 Track 0 Sensor .....•.•...•..........•••.. 9

2.2.2 Index Sensor ••...•..•..••••.....•..•..... 9

2.2.3 Ground Spring •••••

2.3 Electrical Theory ••••••••••••••••••••••

2.3.1 Main Control PC Board 2e321-eel •

2.3.2 Microprocessor Operation ••••••••••••• 11-12

2.3.3 Drive Select •••••••••••••••••••••••••••• 13

2.3.4 Read Operation ••••

2.3.5 Write Operation •••

· .• • •9

•le-18

.... le

· .

· .

•14-15

•16-17

I

2.3.6 Fault Detection •••••••••••••••••

2.4 Test Point Data - PC Board 20321-001 •••••.• 19-21

..... 18

2.5 Schematics

3.0 FIELD SERVICE AND ADJUSTMENTS •

3.1 Removals and Adjustments •••••••••••••••••••••• 26

3.1.1 Main Control PCB ••••••••••.•.••••••••••• 26

Index Sensor •••3.1.2

3.1.3

3.1.4

3.1.5

3.1.6

3.1.7 Track

ILLUSTRATED PARTS CATALOG - INDEX.

4.0

Interface Connectors ••

4.1

4.2

Exploded View •••.••••

Ground Spring ••

Front

Front Cover LED •••

Frame ...•.••••••

- Index •••••••••

· .

· .

Cover ••••••

o

Sensor •••

.....................

· .

..............

................•25-32

......................

.....................

.....................

•••••22

.26

•27

•27

•27

•28

•28

•• 29

••• 30

••• 31

4.3

Component Locations ••••••••••••••

4.4 Parts List - PC Board 20321-001 •••••••••••• 33-34

5.0 FIELD SALES OFFICES •.••••••••••••••••••••••••••••• 35

..........

•••32

II

J

ILLUSTRATIONS

FIGURE PAGE

1.0 Test Point Layout - PC Board 20321-001 •••••••••••• 20

2.0 Test Point Timing - PC Board 20321-001 •••••••••••• 21

3.0 Interface Connectors •••••••••••••••••••••••••••••• 30

4.~ Exploded View ......•..............•..•.•........•. 31

5.0 Component Locations PC Board 20321-001 •••••••••••• 34

III

1.8 INTRODUCTION

The ST425 is Seagate's 25.52 Megabyte, 5 1/4 inch

Winchester disc drive. The ST425 has a formatted

capacity of 20.0 Megabytes.

The ST425 is the newest addition to the ST400 family of

disc drives, and has the same interface, power supply

and controller requirements as the industry standard

Seagate ST406/412/419 series.

Minislider heads and an advanced stepper motor design

enable higher track density. The new head design allows

increased bit packing which utilizes more of the disc

surface. High reliability is assured through the use of

Seagate's proven metal band-actuator, stepper motor head

positioner and a direct-drive brushless DC spindle

motor. The spindle motor assembly is aynamically

balanced and the Head Disc Assembly (HDA) is shock-

mounted to reduce vibration.

The low mass/load force of the MiniWinchester heads and

the lubricated oxide coated media provide reliable

start/stop operation. Each disc surface is read by two

read/write heads. The HDA, which includes the read/write

heads, discs and band-actuator assembly, is completely

sealed and protected by a captured-air-space

recirculation system employing a 0.3 micron absolute

filter. A filtered port permits ambient air pressure

equalization.

Thermal stabilization delays are unnecessary with the

ST425. The spindle pump assures adequate air flow and

uniform temperature distribution throughout the HDA.

This allows significantly greater off-track margin and

immediate read/write ability after power-up.

Only DC voltages (+5 and +12 V DC) are required. All

electronics are packaged a single printed circuit board.

The board is mounted outside the sealed media area

allowing easy field access without risking media

integrity. Simplification of mechanical and electrical

design provides a projected service life of more than

11,000 hours Mean Time Between Failures (MTBF).

1

1.1 SPECIFICATION SUMMARY

1.1.1 Physical Specifications

Environmental Limits

Ambient Temperature Limits

Operating:

Non-Operating:

Maximum Temperature Gradient

Operating: 18oF/hour (l~oC/hour)

Non-Operating: Below Condensation

-4eo to 14~oF (-4eo to 6eoC)

•

5~o to 1130F (l~O to 450C)

Relative Humidity:

Maximum Wet Bulb:

Maximum Elevation

Operating:

Non-Operating:

Maximum Shock Without Incurring Physical Damage

[11 msec shock pulse, half sine wave]

Operating:

Longitudinal:

Lateral:

Vertical:

Non-Operating:

No mechanical damage

specified limits.

Maximum Vibration

Operating:

Frequency

2--22 Hz

22-5ee Hz

5~e--22 Hz

22---2 Hz

Without Incurring Soft Errors:

8 to 8e% non-condensing

78.8oF (260C)

-l,~ee feet to le,e~e feet

-l,~~~ feet to 3~,~~0 feet

GiS

3

5 GiS

7 GiS

35 GiS

will occur within the above

.~10"

~.25

0.25

.01~"

double amplitude

G (peak)

G (peak)

double amplitude

•

Maximum Vibration Without

Non-operating:

Frequency

2--22 Hz

22-5~~ Hz

5~~--22 Hz

22--2 Hz

DC Power Requirements

+12 Volts +5%

+5 Volts ±5

Maximum Ripple:

Incurring Physical Damage.

.~4~"

l.~

1.0

.e40"

1.6 A Typ., 3.5 A (at power-on)

1.1 A Typ., 1.7 A (Max.)

5e mV peak to peak (12 V, 5 V)

2

double amplitude

G (peak)

G (peak)

double amplitude

Heat Dissipation

Typical:

Maximum:

Mechanical Dimensions

Height:

Width:

Depth:

Weight:

Shipping Weight:

1.1.2 Reliability Specifications

25 Watts

29 Watts

3.26

5.75

8.00

4.6

7.0

inches

inches

inches

pounds

pounds

Maximum

[2.1 Kg]

[3.2 Kg]

MTBF:

MTTR:

PM:

The component design life

Read error Rates (Based on bit-jitter reduction)

Soft Read Errors :

Hard Read Errors :

Seek Errors:

Bit-jitter reduction determines the relationship between

the leading edge of read data and the center of the data

window. The data separator must provide at least -40 dB

of bit-jitter reduction at 2F with an offset error of

1.5 nsec shift from the center of the data window.

:*Recoverable within 16 retries

Not recoverable within 16 retries

~/

*

**

11,000 POH

30 minutes

Not required

is 5 years.

1 per 1010 bits read

1 per 1012 bits read

1 per 106 seeks

@250C Typ. usagt

\

3

1.1.3 Performance Specifications

CAPACITY

Per Drive:

Per Surface:

Per Track:

Access Time:

Seek Times Including Settling

Single Track: 19.67 msec

Buffered Seek (from last Step pulse to SEEK COMPLETE)

Average Seek: 65 msec

Full Seek: 140 msec

Transfer Rate:

Average Latency:

1.1.4 Functional Specifications

Rotational Speed:

Recording Density:

Flux Density:

Track Density:

Cylinders:

Tracks:

Read/Write Heads:

Discs:

FORMATTED

20.0 MB

5.0 MB

8,192 Bytes

5.0 MBits/sec

8.33 msec

3,600 RPM ±l%

10,568 Bits per inch (Maximum)

10,568 Flux changes per inch (Maximum)

550 Tracks per inch

306

2,448

8

2

UNFORMATTED

25.52 MB

6.38 MB

10,416 Bytes

4

2.0 THEORY OF OPERATIONS

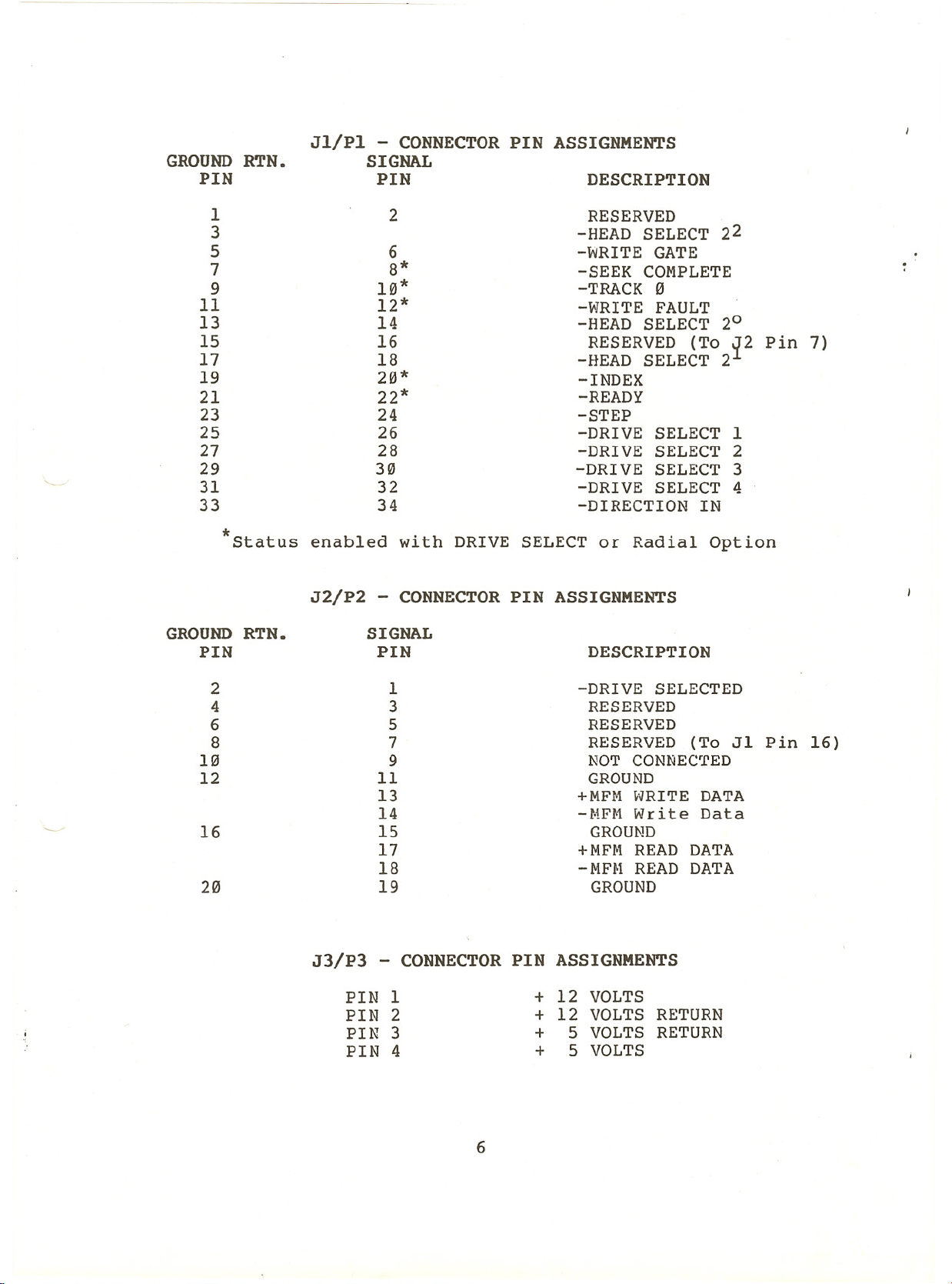

2.1 General Interface Description

The ST425 Winchester supports the Seagate ST506/412

Interface.

The interface consists of a 34 pin control connector, a

20 pin read/write connector and a 4 pin DC connector.

The 34 pin connector provides 10 control signals to the

drive and returns 5 status signals to the controller.

The 20 pin connector handles the Modified Frequency

Modulation (MFM) data to/from the drive and supplies the

drive-selected status to the controller. The 4 pin

connector provides +5 and +12 Volts DC.

In general, the control connector is "daisy-chain"

terminated throughout the user system, while the

read/write connector is terminated radially. The

following tables indicate the ST425 interface

requir'ements.

..

5

PIN

GROUND RTN.

24

28

-DRIVE SELECT 3

32

34

PINDESCRIPTION

2

18

8*

10*

-STEP

26-DRIVE SELECT 1

-DRIVE SELECT 2

30

22*

-DIRECTION IN

16

-HEAD SELECT 2

20*

SIGNAL

RESERVED

6-WRITE GATE

14

-DRIVE SELECT 4

12*

-READY

-INDEX

-TRACK "

Jl/Pl - CONNECTOR PIN ASSIGNMENTS

-HEAD SELECT

-SEEK COMPLETE

-~lRITE FAULT

RESERVED (To ~2 Pin 7)

-HEAD SELECT 22

20

*Status enabled with DRIVE SELECT or Radial Option

PIN

J2/P2 - CONNECTOR PIN ASSIGNMENTS

5

11

PIN

3 RESERVED

RESERVED

7

9NOT CONNEC£ED

GROUND

+MFH HRITE DATA

-HFH Write Data

15 GROUND

+MFr-lREAD DATA

-fvlFHREAD DATA

GROUND RTN. SIGNAL

19 GROUND

DESCRIPTION

1

-DRIVE SELECTED

RESERVED (To J1 Pin 16)

J3/P3 - CONNECTOR PIN ASSIGNMENTS

PIN 1

PIN 2

PIN 3

PIN 4

+ 12 VOLTS

+ 12 VOLTS RETURN

+ 5 VOLTS RETURN

+ 5 VOLTS

6

I P

2.1.1 Recording Format

The ST425 uses Modified Frequency Modulation (MFM) as

the encoding method to record data. This double-density

encoding scheme increases disc capacity by replacing

clock bits with data bits. Clock bits are written only

when data bits are not present in both the preceding and

current bit cell. Clock bits are written at the

beginning of the bit cell, while data bits are written

in the midd Ie.

Due to predictable bit-shift phenomena, the ST425

requires pre-compensation of write data on cylinders 128

through 305. This function must be provided by the

controller to ensure data integrity at the specified

error rate. The data pattern determines which bits must

be pre-compensated. The recommended amount of pre-

compensation is 12 nsec for both early and late written

bits. All other data patterns are written on time.

2.1.2 Track Format

The ST425 uses a slightly modified version of the IBN

System-34 double-density format. This format is common

to many industry standard floppy-disc drives.

When formatted, each sector is identified by a unique

identification field, containing cylinder, head and

sector information, address mark and error checking

polynomials. The Seagate format uses Cyclic Redundancy

Checking (CRC) for error correction. This format also

allows for a plus or minus speed variation of

aproximately 3%. The specification for spindle speed

variation is 1% over the specified environmental and

power limits.

7

2.1.3 Read/Write Heads

When operational, the read/write heads fly on an air

bearing created by the rotating disc. There is no

dedicated landing zone. The head and flexure (supporting

arm) are designed for contact start/stop operation •

The Winchester heads are loaded toward the disc surface

at 9.5 ~l grams. This is a typical value to allow the

required stability in all operating conditions. A

typical flying height measured at an inner radius is 15

±2 microinches. At an outer radius the height is 25 ~3

microinches.

The head/flexure assembly incorporates a low mass

design that is resistive to head and/or media damage.

2.1.4 Discs

The ST425 employs two non-removable double-sided 5 1/4

inch discs. These discs are designed using current iron

oxide technology. Disc dimensions are 40mm inside

diameter by l30mm,outside diameter. The thickness of the

magnetic coating is 20 microinches at the ID and

increases linearly to 40 microinches at the ODe

..

I-

/-

..:.

The disc surface is coated with a flourocarbon lubricant

25 to 55 Angstroms in thickness. The lubricant has

sufficient abrasion resistance to withstand a minimum of

10,000 start/stop cycles.

2.1.5 Air Filtration System

The ST425 incorporates a captured-air-space air

filtration system. The 0.3 micron filter maintains Class

100 standards within the sealed Head Disc Assembly (HDA)

and requires no maintenance during the life of the

drive. A filtered port allows ambient pressure

equalization. During normal operation there is no

measurable air flow between the HDA and the outside

environment.

2.2 Mechanical Theory

2.2.1 Track 0 Sensor

The Track 0 optical interrupter provides an output

whenever the Winchester heads are positioned over

Cylinder Zero. This signal is used by the internal drive

control electronics during the power-on/auto-recalibrate

routine. The Track 0 signal is also output to the drive

interface for use by the controller. Note that the

signal at the interface is really Track 0/Phase A. The

8

Loading...

Loading...