seagate ST39173N, ST34573N, ST39173W, ST39173WD, ST39173LW Product Manual

...

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Barracuda 9LP Family:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST39173N/W/WD/LW/WC/LC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST34573N/W/WD/LW/WC/LC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Barracuda 9LP Family:

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST39173N/W/WD/LW/WC/LC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ST34573N/W/WD/LW/WC/LC

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product Manual, Volume 1

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

© 1997, 1998 Seagat e Technology, Inc. All rights reserved

Publication number: 77767517, Rev. C

July 1998

Seagate, Seagate Technology, and the Seagate logo are registered trademarks of Seagate Technolo gy,

Inc. Barracuda, SeaFAX, SeaFO NE, SeaBOARD, and SeaTDD are either trademarks or registered trademarks of Seagate Tech nology, Inc. or one of its subsidiaries. All other trademarks or registered trademarks are the property of their respective owners.

Seagate reserves the right to chang e, without notice, product offerings or specifications. No part of this

publication may be reproduced in any form without written permission of S eagat e Technology, Inc.

Revision status summary sheet

Revision Date Writer/Engineer Sheets Affected

Rev. A 03/04/98 D . Ashby/S. Welty 1/1, v thru viii, 1-87

Rev. B 05/22/98 D. Ashby/S. Welty 10, 11, 31, 32, 46, 49, 50, 68, 73, 77, 78,

and 79.

Rev. C 07/24/98 D. A shby/S. Welty 4, 7, 10, 11, 19, 21, 44, 46, 52, 77, and 78.

Notice.

Product Manual 77767517 is Volume 1 of a two volume document with the SCSI Interface information in

the Volume 2 SC SI Interface P roduct Manual, par t number 7773 8479.

If the SCSI Interface information is needed the Volume 2 Interface Manual should be ordered,

part number 77738479.

Barracuda 9LP Product Manual, Rev. C v

Table of Contents

1.0 Scope . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and refe rence documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Electromagnetic susceptibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.3 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3.0 General descr iption . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.1 Standard features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.2 Media characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.3 Performance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.4 Reliabili ty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.5 Unformatted and formatted capacit ies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.6 Programmabl e drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.7 Factory installed accessorie s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.8 Options (factory i nstalled). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.9 Accessories (user installed). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.1 Internal drive characteristics (transparent to user). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2 SCSI performance characte ristics (visible to user) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.1 Access time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.2 Format comm and exec ution time (minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.2.3 Generalized performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5 Cache operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.5.2 Prefetch o peration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.1 Environmental inte rference. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.2 Read errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.3 Write errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.1.4 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2 Reliability and service. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 4

5.2.1 Mean time bet ween failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.2 Preve ntive maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.3 Service life . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.4 Service philosophy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.5 Service tools. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

5.2.6 Hot plugging Barracuda 9LP disc drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.7 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.8 Product warranty. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

6.0 Physical/electrical specific ations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2 DC power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.1 Conduct ed noise immunity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.3 Current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.3 Power dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4 Environmental limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.4.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

vi Barracuda 9LP Product Manual, Rev. C

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.4.3 Effective altitude (sea level). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

6.4.5 Air clea nliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.6 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.4.7 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26

6.5 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .27

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.1 Drive internal defects. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.2 Drive erro r recovery proced ures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

7.3 SCSI systems errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .32

8.0 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3 3

8.1 Drive ID/option select header . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

8.1.1 Notes for Figures 7a, 7b, 7c, 7d, 7e, and 7f. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

8.1.2 Function description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.2 Drive orientation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.3 Cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.3.1 Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

8.4 Drive mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

8.5 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

9.0 Interface requiremen ts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.1 General d escription. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.2 SCSI interface messages supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

9.3 SCSI interface commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

9.3.1 Inquiry Vital Product data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

9.3.2 Mode Sense data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

9.4 SCSI bus conditions and miscellaneous features supported . . . . . . . . . . . . . . . . . . . . . . . . .51

9.5 Synchronous data trans fer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.5.1 Synchro nous data transfer periods supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.5.2 REQ/ACK offset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6 Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6.1 DC cable and connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

9.6.2 SCSI interface physical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

9.6.3 SCSI interface cable requiremen ts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

9.6.4 Mating connectors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

9.7 Electrical description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 8

9.7.1 Single-ended drivers /receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .68

9.7.2 Differential drivers/receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .69

9.8 Terminator requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

9.9 Terminator power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

9.10 Disc drive SCSI timing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .74

10.0 Seagate Te chnology support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .77

Barracuda 9LP Product Manual, Rev. C vii

List of Figures

Figure 1. Barracuda 9LP family drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

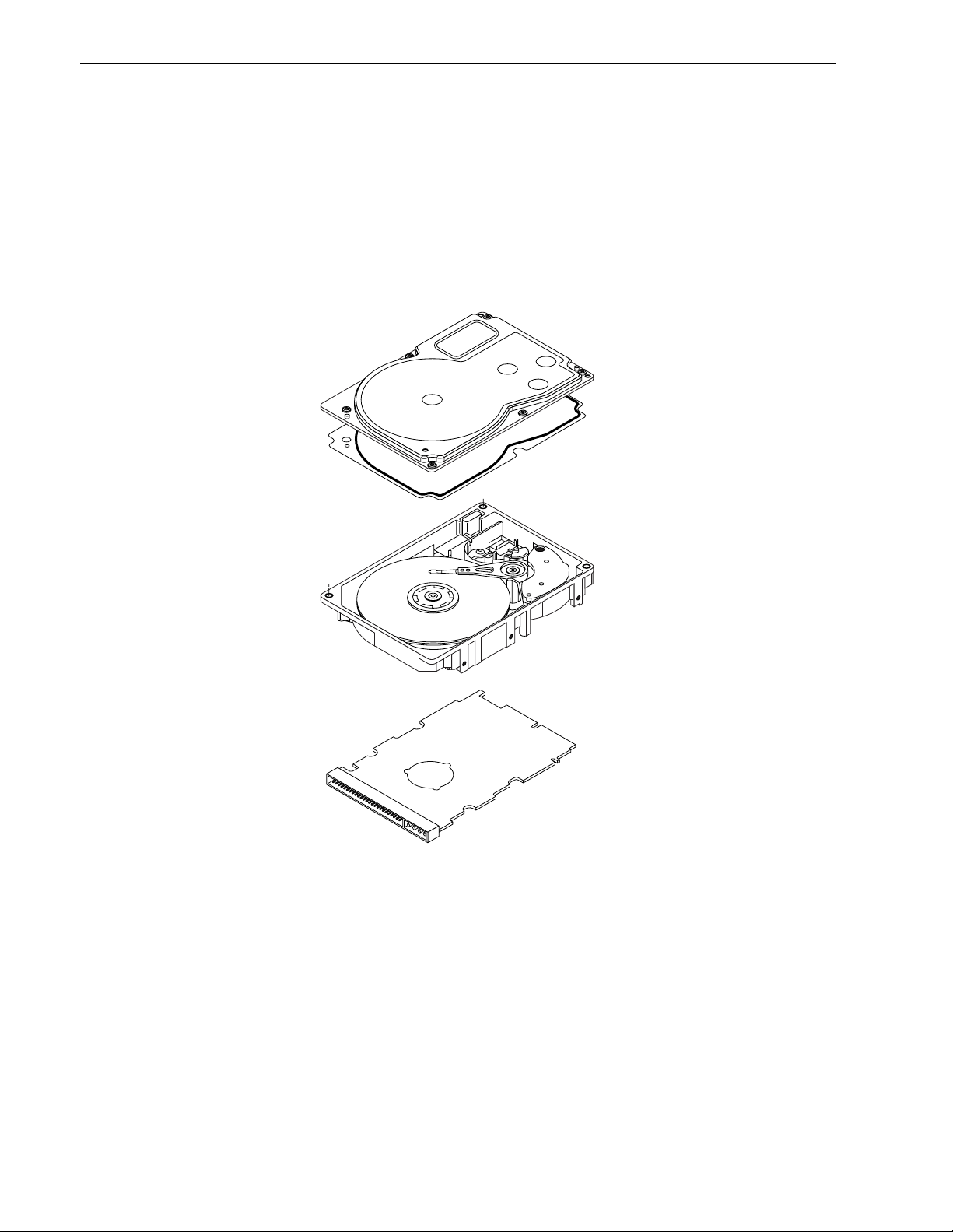

Figure 2. Barracuda 9LP family drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

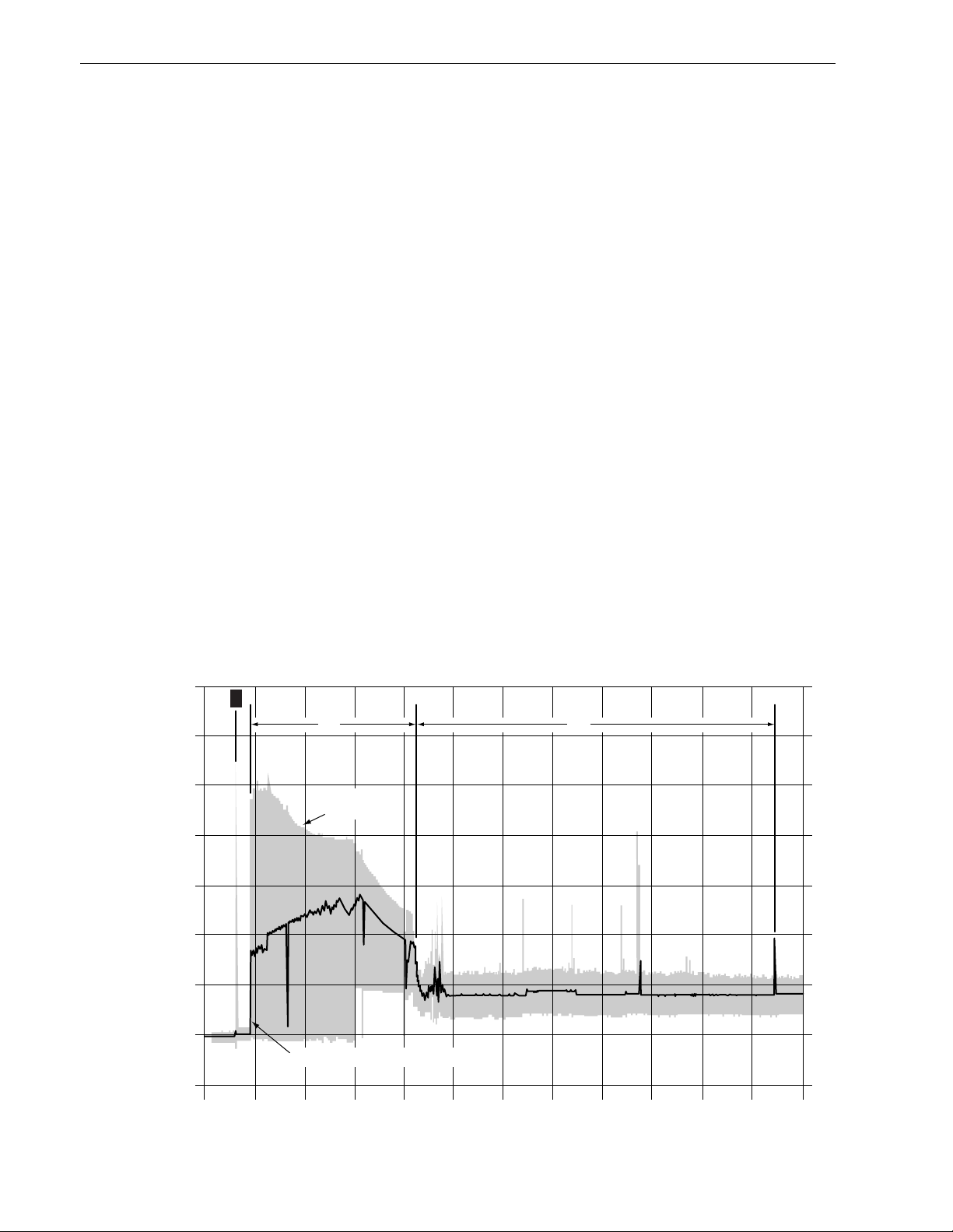

Figure 3a. Typical Barracuda 9LP family drive +12 V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Figure 3b. Typical Barracuda 9LP family drive +5 V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Figure 4. Locations of PCB components listed in Table 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Figure 5. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Figure 6a. Mounting configuration dimensions for models “N” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 6b. Mounting configuration dimensions for models “W,” “WD,” and “LW” . . . . . . . . . . . . . . . . . . 28

Figure 6c. Mount ing configuration dimens ions for models “WC” and “LC” . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 7a. Barracuda 9LP family drive ID select header for models “N”. . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 7b. Barracuda 9LP family drive ID select for models “W,” “WC,” “WD,” “LW,” and “LC” . . . . . . . 35

Figure 7c. Barracuda 9LP family drive ID select header J5 for models “W,” “LW,” and “WD”

(J5 Pins 1A - 12A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Figure 7d. Barracuda 9LP family drive option select header for models “N,” “W,” and “WD” . . . . . . . . . 37

Figure 7e. Barracuda 9LP family drive option select header for “WC” model . . . . . . . . . . . . . . . . . . . . . 37

Figure 7f. Barracuda 9LP family drive option select header for models “LC” and “LW”. . . . . . . . . . . . . 38

Figure 8. Air flow (suggested) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 9a. Physical interface for “N” model drives. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 3

Figure 9b. Model “W,” “WD,” and “LW” drive physical interface (68 pin J1 SCSI I/O connector) . . . . . . 54

Figure 9c. Model “WC” and “LC” drive physical interface (80 pin J1 SCSI I/O connector and

DC power connector). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Figure 10. SCSI daisy chain interface cabling for “N,” “W,” “WD,” and “LW” model drives. . . . . . . . . . . 58

Figure 11a. Nonshielded 50 pin SCSI device connector used on “N” models. . . . . . . . . . . . . . . . . . . . . . 59

Figure 11b. Nonshielded 68 pin SCSI device connector used on “W,” “WD,” and “LW” models. . . . . . . . 59

Figure 11c. Nonshielded 80 pin SCSI “SCA-2” connector, used on “WC” and “LC” models . . . . . . . . . . . 60

Figure 12. Single-ended transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Figure 13. HVD output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Figure 14. Typical high-voltage differential I/O line transmitter/receiver and external terminators . . . . . 70

Figure 15. LVD output signals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Figure 16. Typical SE-LVD alternative transmitter receiver circuits . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Barracuda 9LP Product Manual, Rev. C 1

1.0 Scope

This manual describes the Seagate Technology®, Inc. Barracuda 9LP™ disc drives.

Barracuda 9LP drives suppor t the small computer system interface (SCSI) as descr ibed in the ANSI SCSI,

SCSI-2, and SCSI-3 (Fast-20 and Fast-40) interface specifications to the extent described in this manual. The

SCSI Interface Product Manual

this and other families of Seagate drives.

From this point on in this product manual the reference to Barracuda 9LP models is referred to as “the drive”

(unless references to individual models are necessary).

(part num ber 77738479) descr ibes general SCSI interface characteristics of

*

*Model “N” version with 50 pin SCSI I/O connector

Figure 1. Barracuda 9LP famil y drive

Barracuda 9LP Product Manual, Rev. C 3

2.0 Applicable standards and reference documentation

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends upon its hos t equipment to provide adeq uate power and environment in order to a chieve optimum performance and compliance with applicable industry a nd governmental regulations. Special attention

must be given in the areas of safety, power distribution, shielding, audible noise control, and temperature regulation. In par ticular, the drive must be securely m ount ed in o rder to guarante e th e spec ified pe rformanc e characteristics. Mounting by bottom holes must meet the requirements of Section 8.4.

2.1 Standards

The Barracuda 9LP family complies with Seagate stand ards as noted in the appropr iate sections of this Manual and the Seagate

The Barracuda 9LP disc dr ive is a UL recognized component per UL1950, CSA cer tified to C AN/CSA C22.2

No. 950-95, and VDE certified to VDE 0805 and EN60950.

2.1.1 Electromagnetic compatibility

The drive, as delivered, is designed f or s ystem integr ation and installation into a suitable enclosure prior to use.

As such the drive is supplied as a subassembly and is not subjec t to Subpart B of Part 15 of the FCC Rules

and Regulations nor the Radio Interference Regulations of the Canadian Department of Communications.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides

reasonable shielding. As such, the drive is capable of meeting the Class B limits of the FCC Rules and Regulations of the Canadian Department of Communications when properly packaged. However, it is the user’s

responsibility to assure that the drive meets the appropriate EMI requirements in their system. Shielded I/O

cables may be required if the enclosure do es not provide adeq uate shielding. If the I /O cables are extern al to

the enclosure, shielded cables should be used, with the shields grounded to the enclosure and to the host controller.

SCSI Interface Product Manual

, part number 77738479 (Vol. 2).

2.1.2 Electromagnetic susceptibility

As a component assem bly, the drive is not required to me et any suscep tibility perform ance requi rements. It is

the responsibility of those integrating the dri ve within their systems to perform t hose t ests req uired a nd des i gn

their system to ensure that equipm ent operating in the same system as the drive or external to the system

does not adversely affect the perf ormance of the drive. S ee Section 5.1.1 and Table 2, DC power requirements.

2.2 Electromagnetic compliance

Seagate uses an independen t laboratory to confirm com pliance to the directives/standard(s) for CE Marking

and C-Tick Marking. The drive was tested in a representative system for typical applications. The selected system represents the most popular characteristics for test platforms. The system configurations include:

• 486, Pentium, and PowerPC microprocessors

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

• Printer

• External modem

•Mouse

Although the test system with this Seagate m odel com pli es to the direct ives/standard(s), we cannot guarantee

that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compli ance

and provide CE Marking and C-Tick Marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it complies with the European Union requirements of the Electromagnet ic

Compatibility Directive 89/336/EEC of 03 M ay 198 9 as amended by Directive 92/31/EEC of 28 April 1992 and

Directive 93/68/EEC of 22 July 1993.

4 Barracuda 9LP Product Manual, Rev. C

Australian C-Ti ck

If this model has the C-Tick Marking it complies with the Au stralia/New Zealand Standard AS/NZS3548 1995

and meets the Electromagnetic Compatibility (EMC) Framework requirements of Aust ral ia’s Spectrum Management Agency (SMA).

2.3 Reference documents

Barracuda 9LP Installation Guide

SCSI Interface Product Manual

ANSI small computer system interface (SCSI) document numbers:

X3.131-1994 SCSI-2

X3T10/855D SPI

X3T10/1071D Fast-20 (also called “Ultra SCSI”)

X3T10/1142D SPI-2

X3T10/1143D

SFF-8046 Specification for 80-pin connector for SCSI disk drives

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specification Seagate P/N 30191-001 (over 100 lb.)

Specification, Acoustic Test Requirements, and Procedures Seagate P/N 30553-001

In case of conflict between this document and any referenced document, this document takes precedence.

Seagate P/N 77767518

Seagate P/N 77738479

Barracuda 9LP Product Manual, Rev. C 5

3.0 General description

Barracuda 9LP drives combine magnetoresistive (MR) heads, partial response/maximum likelihood (PRML)

read channel electronics, embedded servo technology, and a SCSI-3 (Fast -20 and Fast-40) interface to provide

high performance, high capacity dat a storage for a variety o f systems includi ng e nginee rin g work st ations, network servers, mainframes, and supercomputers.

Fast-20 and F ast-40 (also known as Ultra-1 SCSI and Ultra-2 SCSI, respectively) are negotiated transfer rates .

These tran sfer rat es w ill oc c u r o nly if you r h os t ad apter also sup p orts thes e data transfer rate s. Th is dr i ve als o

operates at SCSI-1 and SCS I-2 data transfer rates for backward compatibility with non-Fast-20/Fast-40 capable SCSI host adapters.

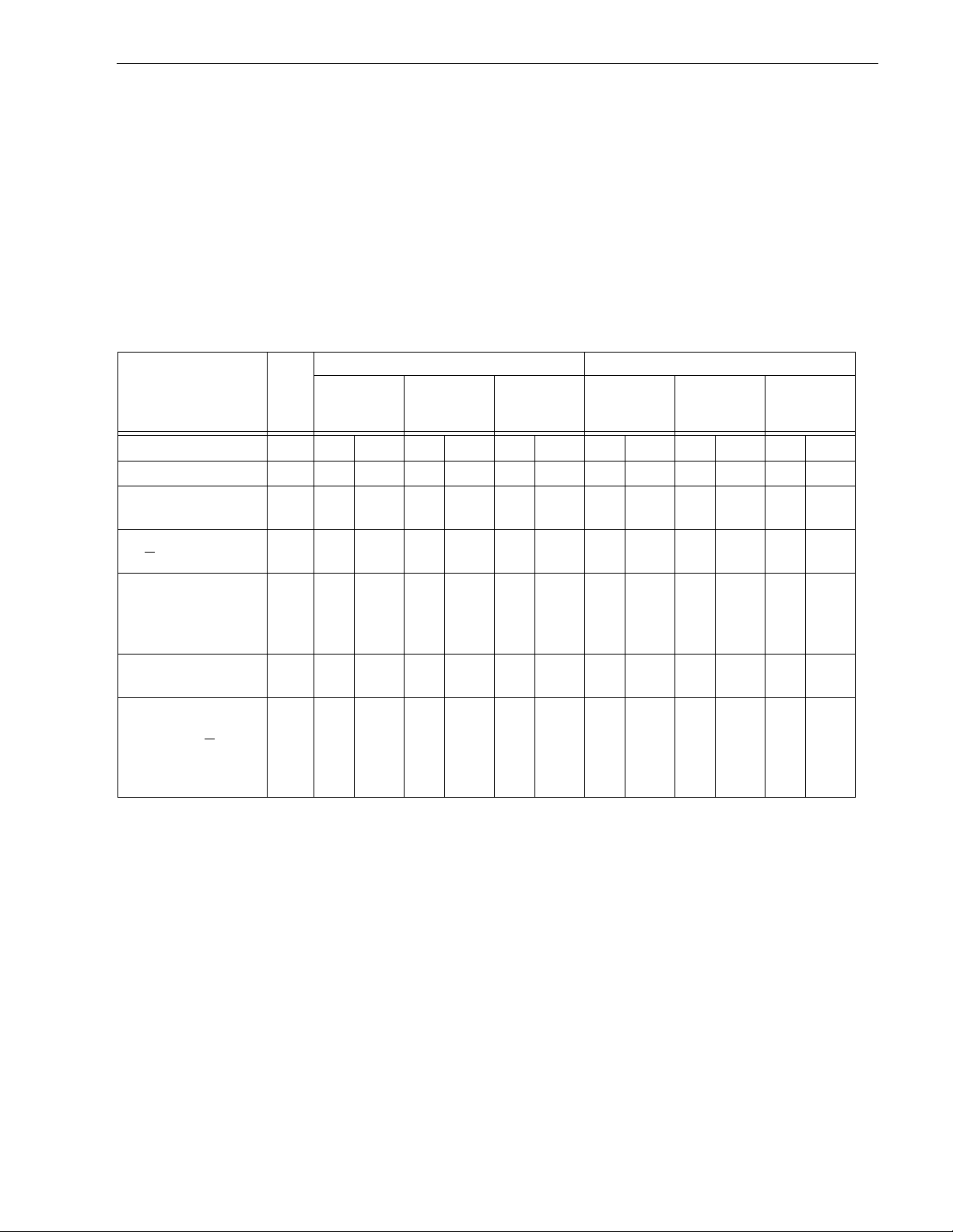

Table 1 lists the features that differentiate the various Barracuda 9LP models.

Table 1: Drive model number vs. differentiating features

Model number

Number

of heads I/O circuit type [1]

Number of I/O

connector pins

ST39173N 10 single-ended 50 8

ST39173W 10 single-ended 68 16

ST39173WD 10 differential (HVD) 68 16

ST39173LW 10 differential (LV D) 68 16

ST39173WC 10 single-ended 80 16

ST39173LC 10 differential (LV D) 80 16

ST34573N 5 single-ended 50 8

ST34573W 5 single-ended 68 16

ST34573WD 5 differential (HVD) 68 16

ST34573LW 5 differential (LVD) 68 16

ST34573WC 5 single-ended 80 16

ST34573LC 5 differential (LVD) 80 16

[1] See Section 9.6 for details and definitions.

Number of I/O

data bus bits

The drive records and recovers data on 3.5-inch (86 mm) non-removeable discs.

The drive supports the Small Computer System Interface (SCSI) as describe d in the ANSI SCSI-2/SCSI-3

SPI-2 interface specifications to the extent described in this manual (volume 1), which defines the product performance characteristics of the Barracuda 9LP family of drives, and the

SCSI Interface Product Manual

(volume 2), part number 77738479, which descr ibe s the general interface characteristics of this and other families

of Seagate SCSI drives.

The drive’s interface supports multiple initiators, disconnect/reconnect, self-configuring host software, and

automatic features that relieve the host from the necessity of knowing the physical characteristics of the targets

(logical block addressing is used).

The head and disc assembly (HDA) is sealed at the factory. Air circulates within the HDA through a nonreplaceable filter to maintain a contamination-free HDA environment.

Refer to Figure 2 for an exploded view of the drive. This exploded view is for information only—never disassemble the HDA a nd do not attempt to ser vice items in the sealed enclosure (heads, media, actuator, etc.) as this

requires special facilities. The drive contains no replaceable parts. Opening the HDA voids your warranty.

6 Barracuda 9LP Product Manual, Rev. C

Barracuda 9LP drives use a ded icated landi ng zone at th e inner m os t radius of the me dia to eli minat e the pos sibility of destroying or degrading data by landing in the data zone. The drive automatically goes to the landing

zone when power is removed.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement during shipping and handling. The shipping lock autom atically diseng ages when power is applied t o the drive and

the head load process begins.

Barracuda 9LP drives decode track 0 location data from the servo data embedded on each surface to eliminate

mechanical transducer adjustments and related reliabilit y concer ns.

A high-performance actuator assembly with a low-inertia, balanced, patented, s traig ht-arm design provides

excellent performance with minimal power dissipation.

Figure 2. Barracuda 9LP famil y drive

Barracuda 9LP Product Manual, Rev. C 7

3.1 Standard features

The Barracuda 9LP family has the following standard features:

• Integrated SCSI controller

• Single-ended or high voltage differential SCSI drivers and receivers, or low voltage differential drivers and

receivers (“LC” and “LW” models only)

• 8 bit or 16 bit I/O data bus models available

• Asynchronous and synchronous data transfer protocol

• Firmware downloadable via SCSI interface

• Selectable even by te sector sizes from 512 to 4,096 bytes/sector

• Programmable drive capacity

• Programmable sector reallocation scheme

• Flawed sector reallocation at format time

• Programmable auto write and read reallocation

• Reallocation of defects on command (post format)

• Enhanced ECC correction capability up to 185 bits

• Sealed head and disc assembly

• No preventative maintenance or adjustment required

• Dedicated laser textured head landing zone

• Embedded servo data rather than a separate servo data surface

• Self diagnostics performed when power is applied to the drive

• 1:1 Interl eave

• Zoned bit recording (ZBR)

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• Active IC terminators enabled by jumpers (“N” and “W” models only)

• 512 Kbyte data buffer or 2 Mbyte optional; “LW” and “LC” model drives have 1 Mbyte, or optional 4 Mbyte

data buffer

• Hot plug compatibility (section 9.6.4.3 lists proper host connector needed) for “WC” and “LC” model drives

• SCAM (SCSI Configured AutoMagically) plug-n-play level 2 compliant, factory set to level 1 (not user select-

able)

• Low audible noise for office environment

• Low power consumption

3.2 Media characteristics

The media used on t he drive has a diameter of approximately 3.5 inches (86 m m ). The alum inum substrate is

coated with a thin film magnetic material, overcoated with a proprietar y protec tive layer for i mproved durability

and environmental protection.

3.3 Performance

• Supports indus try standard Fast-20 and Fast-40 (“LC” and “LW” d rives only) SCSI interfaces (also called

“Ultra-1 SCSI” and “Ultra-2 SCSI,” respectively)

• Programmable multi-segmentable cache buffer (see Section 4.4)

• 7200 RPM spindle. Average latency = 4.17 ms

• Command queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands (spindle stops spinning)

3.4 Reliability

• 1,000,000 hour MTBF

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• Incorporates industr y -standa rd Self-Monitoring, Analysis and Reporting Technology (S.M.A.R.T.)

8 Barracuda 9LP Product Manual, Rev. C

• Incorporates Seek To Improve Reliability algorithm (STIR)

• 5-year warranty

3.5 Unformatted a n d formatted capacities

Formatted capacity depends on the number of spare reallocation sectors reserved and the number of bytes per

sector. The following table shows the standard O EM model read capacities data. Total L BAs = read capac ity

data shown below +1.

Formatted data block size

512 bytes/sector [1]

ST39173 10F59C7h (9,105 GB) [2]

ST34573 87A25Bh (4,551 GB) [2]

Notes.

[1] Sector size selectable at format time. Users having the necessary equipment may modify the data block

size before issuing a format command and obtain di fferent formatted capacities than those listed. See

Mode Select Command and Format Command in the

SCSI Interface Product Manual

, part number

77738479.

[2] User available capacity depends on spare reallocation scheme selected. The number of data tracks per

sparing zone and the num ber of alternat e sectors (LBAs) p er sparing zone can be determined by using

the Mode Sense command and reading Mode Page 03h. Total LBAs(h) x 200(h) = total byte capacity.

3.6 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See

Table 5.2.1-13 in the

SCSI Interface Product Manual

, part number 77738479 . Refer to the Parameter list block

descriptor number of blocks field. A value of zero in the number of blocks field indicates that the drive shall not

change the capacity it is currently formatted to have. A number in the number of blocks field that is less than

the maximum number o f LBAs chan ges the tot al drive capacity to t he value in the block de scriptor num ber of

blocks field. A va lue greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.7 Factory installed accessories

OEM Standard drives a re shipped with the

Barracuda 9LP Inst allation Guide

, part number 77767518 (unless

otherwise specified). The factory also ships with the drive a small bag of jumper plugs used for the J2, J5, and

J6 option select jumper headers.

3.8 Options (factory installed)

All customer reques ted options are inco rporated during prod uction or packaged at the manufactur ing facility

before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and secto r size requested.

• 2 Mbyte optional buffe r size for “N,” “W,” “WD,” and “WC” models.

• 4 Mbyte optional buffe r size for “LC” and “LW” models.

• Single unit shipping pack. T he drive is n ormally ship ped in bulk packaging to provide m aximum protecti on

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

•The

Barracuda 9LP Installation Guide

, part number 77767518, is included with each standard OEM drive

shipped, but extra copies may be ordered.

3.9 Accessories (user installed)

The following accessories are available. All accessories may be installed in the field.

• Single unit shipping pack.

Barracuda 9LP Product Manual, Rev. C 9

4.0 Performance characteristics

4.1 Internal drive characteristics (transparent to user)

ST39173 ST34573

Drive capacity 9,100 4,550 GByte (formatted, rounded off values)

Read/write he ads 10 5

Bytes/track 155,000 155,000 Bytes (average, unformatted, rounded off values)

Bytes/surface 1,165 1,165 Mbytes (unformatted, rounded off values)

Tracks/surface (total) 7,501 7,501 Tracks (user accessible)

Tracks/inch 8,250 8,250 TPI

Peak bits/inch 180 180 KBPI

Internal data rate 120-190 120-190 Mbits/sec (variable with zone)

Disc rotational speed 7,200 7,200 r/min

Average rotational latency 4.17 4.17 msec

Recording code 16/17 16/17 EPR4

4.2 SCSI performance characteristics (visible to user)*

The values given in Section 4.2.1 apply to all models of the B arracuda 9LP family unless otherwise s pecified.

Refer to Section 9.10 and to the

details.

SCSI Interface Product Manual

, part number 77738 479, for additional timing

4.2.1 Access time [8]

Including controller overhead

(without disconnect) [1] [4]

Driv e l e ve l

Read Write

msec

Averag e – Typical [3] 7.4 8.2

Single Track – Typical [3] 1.1 1.4

Full Stroke – Typical [3] 16 18

4.2.2 Format command execution time (minutes) [1]*

ST39173 ST34573

Maxim um (wit h verify) 40 25

Maximum (no verify) 20 13

4.2.3 Generalized performa nce chara cterist ics

Minimum sector interleave 1 to 1

Data buffer transfer rate to/from disc media (one 512-byte sector):

Min. [4]*

Avg. [4]

Max. [4]

15.2

20.4

23.7

MByte/sec

MByte/sec

MByte/sec

Data buffer transfer rate to/from disc media: (< 1 track):

Min. [4]

Avg. [4]

Max. [4]

MByte/sec divided by (interleave factor)

10.8

MByte/sec divided by (interleave factor)

16.0

MByte/sec divided by (interleave factor)

17.0

*[ ] All notes for Section 4.2 are listed at end of Section 4.2.3.

10 Barracuda 9LP Product Manual, Rev. C

SCSI interface data transfer rate (asynchronous) [5]:

Maximum instantaneous 6.0 Mbytes/sec [6]

Maximum average 6.0 Mbytes/sec [7]

Synchronous transfer rate for SCSI Fast-20 (Ultra-1 SCSI):

8 bit data bus models 20 Mbytes/sec

16 bit data bus models 40 Mbytes/sec

Synchronous transfer rate for SCSI Fast-40 (Ultra-2 SCSI):

8 bit data bus models 40 Mbytes/sec

16 bit data bus models 80 Mbytes/sec

Synchronous transfer rate for fast SCSI-2:

8 bit data bus models 1.25 to 10 Mbytes/sec

Synchronous transfer rate for fast SCSI-2:

16 bit data bus models 2.5 to 20 Mbytes/sec

Sector Sizes:

Default 512 byte user data blocks

Variable 180 to 4,096 bytes per sector in even number of

bytes per sector.

If n (number of bytes per sector) is odd, then n-1

will be used.

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact (for flaws reallocated at format time using

Negligible

the spare sectors per sparing region reallocation scheme.)

Overhead time for head switch (512 byte sectors) in sequential mode 1.2 msec

Overhead time for one track cy linder switch in sequential mode 1.2 msec (typical)

Average rotational latency 4.17 msec

Notes for Section 4.2.

[1] Execution time measured from receipt of the last By te of the Command Descriptor Block (CDB) to the

request for a Status Byte Tr ansf er to the Initiator (excluding connect/disconnect).

[2] Maximum times are specified over the worst case conditions of temperatu re, voltage margins and dr ive

orientation. When comparing spec ified access times, care should be taken to distinguish between typical

access times and maximum access times. The best comparison is obtained by system benchmark tests

conducted under identical conditions. Maximum times do not include error recovery.

[3] Typical Access times are measured under nomin al conditions of temperature, voltage, and horizontal ori-

entation as measured on a representative sample of drives.

[4] Assumes no errors and no sector has been relocated.

[5] Rate measured from the start of the first sector transfer to or from the Host.

[6] Assumes system ability to suppor t the rates listed and no cable loss.

[7] Simulated.

[8] Access time = controller overhead + average seek time

Access to data = controller overhead + avera ge seek time + latency time

4.3 S tart/stop time

After DC power at nominal voltage has been applied, the drive typically becomes ready within 30 seconds if the

Motor Start Opt ion is disabled, such as the m otor start s as soon as th e power has been applied. If a recoverable error condition is detected during the star t sequ ence, the drive executes a recovery procedure which may

cause the time to become ready to exceed 30 seconds, but to become ready within 50 seconds. During spin up

to ready time, the drive responds to some commands over the SCSI interface in less than 1.5 seconds after

application of power. The supported commands include the Test Unit Ready command which can be used to

Barracuda 9LP Product Manual, Rev. C 11

provide information indicating the status of the spin up, such as the drive is still in process of coming ready or

the drive requires intervention (see

than 20 seconds from removal of DC power.

SCSI Interface Product Manual

, part number 77738479). Stop time is less

If the Motor Start Opt ion is enabled, the internal cont roller accepts the comm ands listed in the

Product Manual

been received the drive becomes ready for normal operations within 13 seconds typical ly (excluding an error

recovery procedure). The M otor Star t Command can also be used to command t he drive to stop the spindle

SCSI Interface Product Manual

(see

There is no power control switch on the drive.

4.4 Prefetch/multi-segmented cache control

The drive provides prefetch (read look-ahead) and multi-segmented cache control algorithms that in many

cases can enhance system performance. “Cache” as used herein refers to the drive buffer storage space when

it is used in “cache” operat ions. To select pre fetch and cache features the host s ends the Mode S elect command with the proper values in the a pplicable bytes in Mode Page 08h (see

part number 77738479). Prefetch and cache operation are independent features from the standpoint that each

is enabled and disabled independently via the Mode Select command. However, in actual operation the

prefetch feature overlaps cache operation somewhat as is noted in Section 4.5.1 and 4.5.2.

All default cache and prefetch Mode parameter values (Mode Page 08h) for standard OEM versions of this

drive family are given in Tables 9a and 9b.

4.5 Cache operation

In general, all but 100 Kbytes of the physical buffer space in the drive can be used as storage space for cache

operations. The buffer ca n be divided into logical segments (Mode Select Page 08h, byte 13) from which data

is read and to which dat a is written. The dr ive maintains a t able of lo gical block disk medium addresses of the

data stored in each segment of the buff er. If cache operation is enabled (RCD bit = 0 in Mode Page 08h, byte 2,

bit 0, see

command is retrieved from the buffer (if it is there), before any disc access is initiated. If cache operation is not

enabled, the buffer (still segmented with required number of segments) is still used, but only as circular buffer

segments during disc medium read operations (disregarding Prefetch operation for the moment). That is, the

drive does not check in the buffer segments for the requested read data, but goes directly to the medium to

retrieve it. The retrieved data merely passes through some buffer segment on the way to the host. On a c ache

“miss”, all data transfers to the host are in accordance with “buffer-full” ratio rules. On a cache “hit” the drive

ignores the “buffer-full” ratio rules. See explanations associated with Mode page 02h (disconnect/reconnect

control) in the

less than 3 seconds after DC power has been applied. After the Motor Start Command has

, part number 77738479).

SCSI Interface Product Manual,

SCSI Interface Product Manual,

SCSI Interface Product Manual

par t number 77738479), data requested by the host with a Re ad

.

SCSI Interface

The following is a simplified description of a read operation with cache operation enabled:

Case A - A Read command is received and the first logical block (LB) is already in cache:

1. Drive transfers to the initiator the first LB requested plus all subsequent contiguous LB’s that are already in

the cache. This data may be in multiple segments.

2. When a requested LB is reached that is not in any cache segment, the drive fetches it and any remaining

requested LBs from the disc and puts them in a segment of the cache. The drive transfers the remaining

requested LBs from t he cac he to the hos t in accordance with the disc onnect /recon nect specifica tion m entioned above.

3. If the prefetch feature is enabled, refer to Section 4.5.2 for operation from this point.

Case B - A Read command requests data, the first LB of which is not in any segment of the cache:

1. The drive fetches the requested LB’s from the disc and transfers them into a segment, and fro m there to

the host in accordance with the disconnect/reconnect specification referred to in case A.

2. If the prefetch feature is enabled, refer to Section 4.5.2 for operation from this point.

Each buffer segment is actually a self-contained circular storage (wrap-around occurs), the length of which is

an integer number of disc medium sectors. The wrap-around capability of the individual segments greatly

enhances the buffer’ s ov erall performance as a cache storage, allowing a wide range of user selectable configurations, which includes their use in the prefetch operation (if enabled), even when cache operation is disabled

12 Barracuda 9LP Product Manual, Rev. C

(see Section 4.5.2). The number of segm ents may be selected using the Mode Select com mand, but the size

can not be directly selected. Size is s el ected on ly as a by-product of s ele cting the segment number spec ification. The size in Kbytes of each segment is not reported by the Mode Sense command page 08h, bytes 14 and

15. The value 0XFFFF is always reported. If a size specification is sent by the host in a Mode Select command

(bytes 14 and 15) no new segm ent s ize is set up by the drive, and if the “ST RICT” bit in M ode page 00h (byte

2, bit 1) is set to one, the drive responds as it does for any attempt to change unchangeable parameters (see

SCSI Interface Product Manual,

of segments from 1 to 16.

4.5.1 Caching write data

Write caching is a write operation by the drive that makes use of a drive buffer storage area where the dat a to

be written to the medium is stored in one or more segments while the drive performs the write command.

If read caching is enabled (RCD=0), t hen dat a written to the medium is retained in the cache to be made available for future read cache hi ts. The s am e buffer space and segmentation is used as set up for read functions.

The buffer segmentation scheme is set up or changed indep endently, having nothing to do with the state of

RCD. When a write command is issued, if RCD=0, the cache is first checked to see if any logical blocks that

are to be written are already stored in the cache from a previous read or write command. If there are, the

respective cache segments are cleared. The new data is cached for subs equen t Read command s.

If the number of write dat a logical blocks exceeds the size of the segment being wr itten into, when the end of

the segment is reached, the data is written into the beginning of the same cache segment, overwriting the data

that was written there at the beginning of the operation. Howev er, the drive does not overwrite data that has not

yet been written to the medium.

part number 77738479). The drive supports operation of any integer number

If write caching is enabled (WCE=1), then t he drive may return GOOD status on a wri te command after the

data has been transferred into the cache, but before the data has been written to the medium. If an error occurs

while writing the dat a to the medium, and G OOD status has already bee n returned, a deferred error will be

generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium.

Upon completion of a Synchronize Cache command, all data received from previous write commands will have

been written to the medium. The Start/Stop co mmand with the stop bit set will force a sync cache operation

before the drive stops.

Tables 9a and 9b show Mode default settings for the drives.

4.5.2 Prefetch operation

If the Prefetch feature is enabled, data in contiguous logical blocks on the disc i mm edi ately beyond that wh ich

was requested by a Read command can be retrieved and stored in the buffer for immediate transfer from the

buffer to the host on subsequent Read comm and s that request those logical blocks (this is true even if “cache”

operation is disabled). Though the prefetch operation uses the buffer as a “cache”, finding the requested data

in the buffer is a prefetch “hit”, not a “cache” operation “hit”. Prefetch is enabled using Mode Select page 08h,

byte 12, bit 5 (Disable Read Ahead - DRA bit). DRA bit = 0 enables prefetch. Since data that is prefet ched

replaces data already in some buffer segment(s), the host can limit the amount of prefetch data to optimize

system performance. The max prefetch field (bytes 8 and 9) limits the am ount of prefetch. The drive does not

use the prefetch “ceiling” field ( byte s 10 and 11).

During a prefetch operation, the drive crosses a cylinder bo undary to fetch more data only if the Di scontinuity

(DISC) bit is set to one in bit 4 of byte 2 of Mode parameters page 08h.

Whenever prefetc h (read look-ahead) is enabled (enabled by DRA = 0), it operates under the control of ARLA

(Adaptive Read Look-Ahead). If the host uses software interleave, A RLA enables prefetch of contiguous blocks

from the disc when it senses t hat a prefetch “hit” w ill l ikely occu r, even if two consecutive read operations were

not for phy sically contiguous bloc ks of data (e .g. “software interleav e”). ARLA disables prefetch when it decides

that a prefetch “hit ” w ill not likely o ccur. If the h ost is not using software int er leave, and if two sequenti al re ad

operations are not for contiguous blocks of data, ARLA disables prefetch, but as long as sequential read operations request contiguous blocks of data, ARLA keeps prefetch enabled.

Barracuda 9LP Product Manual, Rev. C 13

5.0 Reliability specifications

The following reliability specifications assume correct host/drive operational interface, including all interface

timings, power supply voltages, environmental requirements and drive mounting constraints (see Section 8.4).

Seek Errors

Less than 10 in 10

Read Error Rates [1]

Recovered Data Less than 10 errors in 10

Unrecovered Data Less than 1 sector in 10

Miscorrected Data Less than 1 sector in 10

MTBF 1,000,000 hours

Service Life 5 years

Preventive M aintenance Non e required

Note.

[1] Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

The error rates stated in this specification assume the following:

• The drive is operated per this specification using DC power as def ined in this manual (see Section 6.2).

• The drive has been formatted with the SCSI FORMAT commands.

• Errors caused by media defects or host system failures are excluded from error rate computations. Refer to

Section 3.2, “Media Characteristics.”

8

seeks

12

bits transferred (OEM default settings)

15

bits transferred (OEM defa ult settings)

21

bits tran sferred

5.1.1 Environmental interference

When evaluating syste ms operation under conditions of Electromagnetic Interference (EMI), th e performance

of the drive within the system shall be considered acc eptable if the drive does not g enerate an unrecoverable

condition.

An unrecoverable error, or unrecoverable condition, is defined as one that:

• Is not detected and corrected by the drive itself;

• Is not capable of being detected from the error or fault status provided through the drive or SCSI interface; or

• Is not capable of being recovered by normal drive or system recovery procedures without operator intervention.

5.1.2 Read errors

Before determination or measurement of read error rates:

• The data that is to be used for measurement of read error rates must be v erifi ed as being written correctly on

the m edia.

• All media defect induced errors must be excluded from error rate calculations.

5.1.3 Write errors

Write errors can occur a s a result of media defects, environmental interference, or equipment malfunction.

Therefore, write errors are not predictable as a function of the number of bits passed.

If an unrecoverable writ e error occurs because of an equipment malfunction in the drive, the error is classified

as a failure affecting MTBF. Unrecoverable write errors are those which cannot be corrected within two

attempts at writing the record with a read verify after each attempt (exc luding media defects).

14 Barracuda 9LP Product Manual, Rev. C

5.1.4 Seek errors

A seek error is defined as a failure of the drive to position the heads to the address ed track. There s hal l be no

more than ten recoverable seek errors in 10

8

physical seek operations. After detecting an initial seek error, the

drive automatically performs an error recovery process. If the error recovery process fails, a seek positioning

error (15h) is reported with a Medium error (3h) or Hardware error (4h) rep orted in the Sense Key. This is an

unrecoverable seek error. Unrecoverable seek errors are classified as failures for MTBF calculations. Refer to

Section 5.1.1.2 of the

SCSI Interface Product Manual,

part number 77738479, for Request Sense information.

5.2 Reliability and service

You can enhance the reliability of Barracuda 9LP disc drives by ensuring that the drive receives adequate cooling. Section 6.0 provides tem perature measurem ents and other i nformation that may be used t o enhance t he

service life of the drive. Section 8.3.1 provides recommended air-flow information.

5.2.1 Mean time between failure

The production disc dri ve shall achieve an MTBF of 1,000,000 hours w hen operated in an environment that

ensures the case temperatures specified in Section 6.4.1, Table 3, Colum n 2 are not exc eeded. Short-term

excursions up to the specification limits of the operating environment will not affect MTBF performance. Continual or sustained operation at case temperatures above the values shown in Table 3, Column 2 may degrade

product reliability.

The following expression defines MTBF

Estimated power-on operating hours in the period

MTBF per measurement period =

Number of drive failures in the period

Estimated power-on operation hours means power-up hours per disc drive times the total number of disc drives

in service. Each disc drive shall have accumulated at least nine months of operation. Data shall be calculated

on a rolling average base for a minimum perio d of six months.

Drive failure means any s t oppag e or substandard perform ance caus ed by drive malfunction.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance shall be required.

5.2.3 Service life

The drive shall have a usef ul service life of five years. Depo t repair or replacement of major parts is permitt ed

during the lifetime (see Section 5.2.4).

5.2.4 Servi c e philosophy

Special equipment is required to repair the drive HDA. In order to achieve the above service life, repairs must

be performed only at a properly equipped and st affed service and repai r facility. Troubleshooting and repair of

PCBs in the field is not rec ommended, because of the extensive diagnost ic equipment required for effective

servicing. Also, there are no spare parts available for this drive. Drive warranty is vo ided if the HDA is opened.

5.2.5 Service tools

No special tools are required for site installation or recommended for site maintenance. Refer to Section 5.2.4.

The depot repair philosophy of the drive precludes the necessity for special tools. Field repair of the drive is not

practical since there are no user purchasable parts in the drive.

Barracuda 9LP Product Manual, Rev. C 15

5.2.6 Hot plugging Barracuda 9LP disc drives

The ANSI SPI-2 (T10/1142D) docum ent defines the physical requirements for removal and insertion of SCSI

devices on the SCSI bus. Four cases are addressed. The cases are differentiated by the state of the SCSI bus

when the removal or insertion occurs.

Case 1 A ll bus devices powered off during removal or insertion

Case 2 RST signal asser ted continuousl y during rem oval or insertion

Case 3 Current I/O processes not allowed during insertion or removal

Case 4 Current I/O process allowed during insertio n or removal, except on the device being changed

Seagate Barracuda disc drives support four hot plugging cases. Provision shall be made by the system such

that a device being inserted makes power and ground connections prior to the connection of any device signal

contact to the bus. A device being removed shall maintain power and ground connections af ter the disc onnection of any device signal contact from the bus (see SFF-8046, SCA-2 specification).

It is the responsibility of the systems integrator to assure that no hazards from temperature, energy, voltage, or

ESD potential are presented during the hot connect/disconnect operation .

All I/O processes for the SCSI device being inser ted or removed shall be quiesce nt. All SCSI devices on the

bus shall have receivers that conform to the SPI-2 standard.

If the device being hot plugged uses single-ended (SE) drivers and the bus is currently operating in low voltage

differential (LVD) mod e, then a ll I /O processes for all devices on the bus must be co mplete d, and the bus q uiesced, before attempting to hot plug. Following the insertion of the newly installed device, the SCSI host

adapter must issue a B us Rese t, followed by a synchronous transfer negotiation. Failure to perform the SCSI

Bus Reset could result in erroneous bus operations.

The SCSI bus termination and termination power source shall be external to the device being inserted or

removed.

End users should not mix devices with high voltage differential (HVD) drivers and receivers and devices with

SE, LVD, or multimode drivers and receivers on the same SCSI bus since the common mode voltages in the

HVD environment may not be controlled to safe levels for SE and LVD devices (see ANSI SPI-2).

The disc drive spindle must come to a complete stop pri or to completely removing the drive from the cabinet

chassis. Use of the Stop Spindle command or partial withdrawal of the drive, enough to be disconnected from

the power source, prior to removal are methods for insuring that this requirement is met. During drive insertion,

care should be taken to avoid exceeding the limits stated in Section 6.4.4, "Sh ock and vibration," o f this manual.

5.2.7 S.M.A . R . T.

S.M.A.R.T. is an acronym for Self-Monitoring Ana lysis and Repor ting Techn ology. This tec hnology is intended

to recognize conditions that indicate a drive failure and is designed to provide sufficient warning of a failure to

allow data back-up before an actual failure occurs.

Note. The firmware will monitor specific attributes for degradation over time but cannot predict instantaneous

drive failures.

Each attribute has been selecte d to m onitor a spec ific s et of failure conditions in th e operat ing pe rformanc e of

the drive, and the thresholds are optimized to minimize “false” and “fa iled” predictions.

Controllin g S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DE XCPT bit and the PERF bit of the “Informational

Exceptions Control Mode Page” (1Ch). The DEXCPT bit i s used to e nable or disable the S.M.A.R.T. process.

Setting the DEXCPT bit will disable all S.M.A.R.T. functions. When enabled, S.M.A.R.T. will collect on-line data

as the drive performs normal read/write operations. When the PERF bit is set, the drive is considered to be in

“On-line Mode Only” and will not perform off-line functions.

The process of meas uring off-line attri butes and saving data can be forced by the RTZ (return to zero) command. Forcing S.M.A.R.T. will res et the timer so that the next scheduled interrupt will be two hours.

16 Barracuda 9LP Product Manual, Rev. C

The drive can be interrogated by the host to determine the time remaining before the next scheduled measurement and data logging process will occur. This is accomplished by a log sense command to log page 0x3E.

The purpose is to allow the customer to control when S.M.A.R.T. interruptions occur. As described above, forcing S.M.A.R.T by the RTZ command will reset the timer.

Performance impact

S.M.A.R.T. attribute data will be saved to the disc for the purpose of recreating the events that caused a predictive failure. The drive will measure and save parameters once every two hours subject t o an idle period on the

SCSI bus. The process of measuring off-line attribute data and saving data to the disc is uninterruptable and

the maximum delay is summarized below:

Maximum processing delay

On-line only delay Fully enabled delay

DEXCPT = 0, PERF = 1 DEXCPT = 0, PERF = 0

S.M.A.R.T. delay times 30 milliseconds 200 millisecond s

Repor tin g c on t rol

Reporting is controlled in the “Informational Exceptions Control Page” (1Ch). Subject to the reporting method,

the firmware will issue to the “host” an 01-5D00 sense code. The error code is preserved through bus resets

and power cycles.

Determining rate

S.M.A.R.T. monitors the rate at which errors occur and s ig nals a predictive failure if the rate of degraded error

rate increases to an unacceptable level. To determ ine rate, error events are logged and compared to the num ber of total operations for a gi ven attribute. The interval defines the number of operations over which to measure the rate. The counter that keeps track of the current number of operations is referred to as the Inter val

Counter.

S.M.A.R.T. measures error rate, hence for each attribute the occurrence of an “error” is recorded. A counter

keeps track of t he num ber of errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is simply the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of

error is to set thresholds for t he number of errors and the interval. If the number of errors exceeds the threshold

before the interval expires, then the error rate is considered to be unacceptable. If th e number of errors does

not exceed the threshold before the interval expires, then the error rate is considered to be acceptable. In either

case, the interval and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is p erforming unac cept ably for a period of tim e. The firm ware keeps a running count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a counter is incremented whenever the error rate is unac ceptable and decremented (not to exceed

zero) whenever the error rate is acceptable. Should the counter continually be incremented such that it reaches

the predictive threshold, a predictive failure is signaled. This counter is referred to as the Failure History

Counter. There is a separate Failure History Counter for each attribute.

5.2.8 P roduct warranty

Beginning on the date of shipment to customer and continuing for a period of five years, Seagate warrants that

each product (including components and subassemblies) or spare part that fails to function properly under normal use due to defect in materials on workmanship or due to nonconformance to the applicable specifications

will be repaired or replaced, at Sea gate’s option and at no charge to customer, if returned by customer at customer’s expense to Seagate’s designated facility in accordance with Sea gate’s Warranty Procedure. Seagate

will pay for transporting the rep air or replacement item to customer. For more detailed warranty information

refer to the Standard terms and conditions of Purchase for Seagate products.

Barracuda 9LP Product Manual, Rev. C 17

Shipping

When transpor ting or shipping a drive, a Seagate approved container must be us ed. Keep your original box.

They are easily identified by the Seagate App roved Package labe l. Shipping a drive in a non-approved container voids the drive warranty .

Seagate repair centers may refuse recei pt of components improperly packaged or obviously dam aged in transit. Contact your Authorized Seagate Distributor to purchase additional boxes. Seagate recommends shipping

by an air-ride carrier experienced in handling computer equipment.

Product repair and return information

Seagate customer service cent ers are the only facil ities authorized to service Seagate drives. Seagate does

not sanction any third-party repair facilities. Any unauthorized repair or tampering with the factory-seal voids

the warranty.

Barracuda 9LP Product Manual, Rev. C 19

6.0 Physical/electrical specifications

This section provides information rela ting to the physical and electrical characteristics of the Barracuda 9LP

drive.

6.1 AC power requirements

None.

6.2 DC power requirements

The voltage and current requirements for a single drive are shown in the following table. V al ues indicated apply

at the drive power connector. The single ended power requirements includes the internal disc drive SCSI I/O

termination. The table shows current values in Amperes.

T able 2: DC power requirements

ST39173 ST34573

N/W/WC

Notes

Singleended

WD

Differential

LC/LW

LVD

Vol tage +5 V +12 V +5 V +12 V +5 V +12 V +5 V +12 V +5 V +12 V +5 V +12 V

Regulation [5][2] ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5% ±5%

Maximum operating

current DC [1] 1.15 .95 1.23 .95 1.4 .95 1.15 .95 1.23 .95 1.4 .95

Average idle current

DCX

[1] .75 .5 .78 .5 .75 .5 .75 .5 .78 .5 .75 .5

Maximum start ing

current

(peak DC)

(peak AC)

[3]

[3]

1.2 1.7

2.9

1.23 1.7

2.9

1.2 1.7

2.9

Delayed motor start

(max) DC [1][4] .65 .06 .67 .06 .65 .06 .65 .06 .67 .06 .65 .06

Peak operating

current

[1][6]

1.05

Typical DCX

Maximum DC

Maximum (Peak)

[1]

1.15

1.7

.9

.95

2.4

1.16

1.23

2.00

.9

.95

2.4

1.2

1.4

1.7

.9

.95

2.4

N/W/WC

Singleended

1.2 1.7

2.9

1.05

.9

1.15

.95

1.7

2.4

WD

Differential

1.23 1.7

2.9

1.16

.9

1.23

.95

2.00

2.4

LC/LW

LVD

1.2 1.7

2.9

1.2

.9

1.4

.95

1.7

2.4

[1] Measured with average reading DC ammeter. Instantaneous +12 V current peaks will exceed these val-

ues.

[2] For +12 V, a –10% droop is permissible during initial start of spindle, and must return to ±5% before 7,200

rpm is rea ched. The ±5% must be maintained a fter the drive signifies that its power-up sequence has

been completed and that the drive is able to accept selection by the host initiator.

[3] See +12 V current profile in Figure 3a.

[4] This condition occurs when the Motor Sta rt Option is enabled and the drive has not yet received a Start

Motor co mmand.

[5] See Section 6.2.1 “Co nducted Noise Immunity.” Specified voltage tolerance is inclusive of ripple, noise,

and transient response.

[6] Operating condition is defined as random seek read operations with a block count of 64.

General Notes from Table 2:

1. Minimum current loading for each supply voltage is not less than 4% of the maximum operating current

shown.

2. T he +5 and +12 volt supplies shall employ separate ground returns.

3. Where power is provided to multiple drives from a common supply, careful consideration for individual drive

power requirements should be noted. Where multiple units are powered on simultaneously, the peak starting current must be available to each device.

20 Barracuda 9LP Product Manual, Rev. C

6.2.1 C ondu cted noise immunity

Noise is specified as a per iodic and random distri bution of frequencies covering a band from DC to 10 MHz.

Maximum allowed noise values given below are peak to peak measurements and apply at the drive power connector.

+5 V = 150 mV pp from 0 to 50 kHz and 100 mV pp from 50 kHz to 10 MHz.

+12 V = 150 mV pp from 0 to 50 kHz and 100 mV pp from 50 kHz to 10 MHz.

6.2.2 Power sequencing

The drive does not req uire power sequencing. T he dr ive protects against ina dvertent wr iting duri ng power-up

and down. Daisy-chain operation requ ires that power be mainta ined on the ter minat ed drive to ensure p roper

termination of the peripheral I/O c ables. To automatically del ay motor start based on t he target ID (SCSI I D)

enable the Delay Motor Start option and disable the Enable Motor Star t option on the J2 conne ctor. See Section 8.1 for pin selection info rmation. To delay the motor until the drive receives a S tar t Unit command, enable

the Enable Motor Start option on the J2 connector.

6.2.3 Curr ent profil e

Figures 3a and 3b identify the drive +5 V and +12 V current profile. The current during the various times is as

shown:

T - Power is applied to the drive.

T1 - Controller se l f tests are performed.

T2 - Spindle begins to accelerate under current limiting after performing drive internal

diagnostics. See Note 1 of Table 2.

T3 - The heads move from the landing zone to the data area.

T4 - The adaptive servo calibration sequence is performed.

T5 - Calibration is complete and the drive is ready for reading and writing.

Note. A ll times and currents are typical. See Table 2 for maximum current requirements.

4.0

T3

T4

8 18 2422

TIME (seconds)

+12V

Current

(amps)

T

3.5

3.0

2.5

2.0

1.5

1.0

0.0

T1

0.0 2 4 6 10 12 14 16 20

T2

AC

Component

Nominal (average) DC curve

T5

Figure 3a. Typical Barracuda 9LP family drive +12 V current profile

Loading...

Loading...