Seagate ST34571N-W-WC-WD-DC, ST34371N-W-WC-WD-DC, ST32171N-W-WC-WD-DC, ST32271N-W-WC-WD-DC User Manual

••••••••••••••••••••••••••

Barracuda 4LP

••••••••••••••••••••••••••

Disc Drive

••••••••••••••••••••••••••

ST34371N/W/WC/WD/DC

••••••••••••••••••••••••••

ST32171N/W/WC/WD/DC

••••••••••••••••••••••••••

ST34571N/W/WC/WD/DC

••••••••••••••••••••••••••

ST32271N/W/WC/WD/DC

••••••••••••••••••••••••••

Installation Guide

Contents

Preface ........................................................................................ 1

Electrostatic discharge protection.. ..............................................1

Important safety information and precautions. .............................2

Wichtige Sicherheitshinweise ......................................................4

European Union Compliance....................................................... 7

Technical support services...........................................................8

General description....................................................................12

Initial setup information..............................................................17

Kühlung des Systems................................................................27

Installation des Laufwerkes

und Anschluß der Kabel.......................................................... 29

N drives section......................................................................... 36

W/WD drives section ................................................................. 40

WC/DC drives section................................................................45

©1997 Seagate Technology, Inc. All rights reserved

Publication Number: 77767492, Rev. B

January 1997

Seagate, S eagate Technology, and the Seagate logo are regis-

tered trademarks of Seagate Technology, Inc. Barracuda,

SeaFAX, SeaFONE, SeaNET, SeaTDD, and SeaBOARD are

either trademarks or register ed trademarks of Seagate Technology, Inc. or one of its subsidiaries. All other trademarks or registered trademarks are the property of their respective owners.

No part of this publication may be re pro duced in any form without

written permission from Seagate Technology, Inc.

Barracuda 4LP Installation Guide, Rev. B 1

Preface

This manual contains information for users of the Seagate®

Barracuda 4LP SCSI disc drives. It provides support services,

performance specifications, and initial setup information. Additional information is available in the

Manual

(part number 77767491). Contact your Seagate sales

representative if you need to order this publication.

Electrostatic discharge p rotecti on

Caution. Removal of circuit boards by personnel not perform-

ing depot repair will damage components and may

void the warranty.

All drive electronic assemblies are sensitive to static electricity,

due to the electrostatically sensitive devices used within the

drive circuitry. Although some devices such as metal-oxide semiconductors are extremely sensitive, all semiconductors, as well

as some resistors and capacitors, may be damaged or degraded

by exposure to static electricity.

Electrostatic damage to electronic devices may be caused by

the direct discharge of a charged conductor or by exposure to

the static fields surrounding charged objects. To avoid damaging

drive electronic assemblies, observe the following precautions

when installing or servicing the drive:

• Ground yourself to the drive whenever the drive electronics

are or will be exposed. Connect yourself to ground with a wrist

strap (Seagate part number 12263496). Connection may be

made to any grounded metal assembly. As a general rule,

remember that you and the drive electronics must all be

grounded to avoid potentially damaging static discharges.

Barracuda 4LP Product

2 Barracuda 4LP Installation Guide, Rev. B

• Turn off the power before removing or installing the DC power

cable.

• Do not remove any circuit boards from the drive.

• Never use an ohmmeter on any circuit boards.

• When installing the drive on a carrier or tray, discharge the

carrier or tray prior to inserting it into the system.

Important safety inform ati on and precau tions

Caution. Use forced-air ventilation when bench-testing the

drive to ensure proper cooling of drive components.

Use proper safety techniques for safe, reliable operation of this

unit.

The procedures in this manual and labels on the unit contain

warnings and cautions that must be carefully read and followed

to minimize or eliminate the risk of personal injury. The warnings

point out conditions or practices that may endanger you or others. The cautions point out conditions or practices that may damage the unit, possibly making it unsafe for use.

Always observe the following warnings and precautions:

• Follow all cautions and warnings in the procedures.

• Use sound safety practices when operating, installing, or

removing the unit.

• Use caution when troubleshooting a unit that has voltages

present. Turn off power to the unit before removing it.

• Ensure that the internal temperature of the rack or cabinet

does not exceed the limits defined for the drive when the drive

is mounted in an equipment rack or cabinet. When units are

Barracuda 4LP Installation Guide, Rev. B 3

stacked vertically, pay special attention to the top where temperatures are usually highest.

• Follow the precautions listed above in “Electrostatic discharge

protection.”

• Do not remove any circuit boards from the drive. Return the

entire drive for depot repair if any circuit board is defective.

Removal of circuit boards by personnel not performing depot

repair will damage components and may void the warranty.

• Do not remove the head and disc assembly (HDA) from the

drive. Return the entire drive for depot repair if the HDA is

defective.

• Do not attempt to disassemble the HDA. It is not field repair-

able. If the sealed HDA is opened by personnel not performing

depot repair, this will damage components and void the

warranty.

As a component, this drive is d esigned to be installe d and op erated in accordance with UL1950, EN60950, CSA C22.2 950M89, and VDE0805.

Seagate takes all reasonable steps to ensure that its products

are certifiable to currently accepted standards. Typical applications of these disc drives include customer packaging and subsystem design. Safety agencies conditionally certify component

assemblies, such as the Barracuda disc drive, based on their

final acceptability in the end-use product. The subsystem

designers are responsible for meeting these conditions of

accepta b il ity in obtaining safety-regulatory agency compliance in

their end-use products and for certifying where required by law.

A necessary part of meeting safety requirements is the provision

for overcurrent protect ion on drive SELV supply voltages.

4 Barracuda 4LP Installation Guide, Rev. B

This unit is a component part and as such is not meant to comply

with FCC or similar national requirements as a stand-alone unit.

Engineering radiated emissions test results are available

through the Seagate Safety Department to assist the subsystem

designer.

Wichtige Sich erh eitsh in wei se

Vorsicht. Beim Testen des Laufwerks auf dem Prüftisch ist

Fremdbelüftung vorzusehen, um eine ausreichende Kühlung der

Laufwerkkomponenten sicherzustellen.

Verwenden Sie geeignete Sicherheits- um den sicheren, zuverlässigen Betrieb dieser Einheit zu gewährlei sten.

Die Verfahren in diesem Handbuch und die Aufkleber auf dem

Gerät enthalten Warn- und Vorsichtshinweise. Diese Hinweise

sind sorgfältig durchzulesen und zu beachten, um das Risiko

von Verletzungen auf ein Mindestmaß zu beschränken oder

ganz zu vermeiden. Die Warnhinweise machen auf Situationen

oder Praktiken aufmerksam, die Sie oder andere gefährden

könnten. Die Vorsichtshinweise machen auf Situationen oder

Praktiken aufmerksam, die Einheit beschädigen können, so daß

deren Gebrauch mit Risiko behaftet ist.

Die Warn- und Vorsichtshinweise sind nicht allumfassend! Es ist

uns einfach nicht möglich, alle Wartungsmethoden oder die

eventuellen Risiken jeder Methode zu kennen, zu beurteilen und

Sie entsprechend zu beraten. Aus diesem Grund haben wir auf

eine derartige umfassende Beurteilung verzichtet. Falls Sie ein

hier nicht beschriebenes Verfahren oder Werkzeug verwenden,

stellen Sie zuerst sicher, daß das gewählte Verfahren weder Ihre

persönliche Sicherheit noch die Leistung der Einheit gefährdet.

Barracuda 4LP Installation Guide, Rev. B 5

Beachten Sie in jedem Fall die folgenden Warn-und Vorsicht-

shinweise:

• Beachten Sie alle Warn- und Vorsichtshinweise in diesem

Handbuch.

• Treffen Sie beim Betrieb, bei der Installation oder bei der

Entfernung der Einheit angemessene Sicherheitsvorkehrungen.

• Wenn eine Einheit unter Spannung steht, gehen Sie bei der

Fehlerdiagnose besonders vorsichtig vor. Schalten Sie die

Einheit aus, bevor Sie mit den Installations-und Entfernungsarbeiten beginnen.

• Wenn das Laufwerk in einem Einbaugestell oder Gehäuse

montiert ist, sorgen Sie dafür, daß die Temperatur im Inneren

des Gestells oder Gehäuses die für das Laufwerk vorgegebenen Grenzwerte nicht übersteigt. Wenn Einheiten vertikal

übereinander betestigt werden, achten Sie besonders auf den

oberen Stapelbereich, da dort die Temperatur gewöhnlich am

höchsten ist.

• Befolgen Sie die oben unter “Electrostatic Discharge Protec-

tion” angegebenen Sicherheitsmaßnahmen.

• Nehmen Sie keine Platinen aus dem Laufwerk. Wenn eine

Platine defekt ist, muß das gesamte Laufwerk zur Reparatur

eingeschickt werden. Die Herausnahme von Platinen durch

andere Personen als die für die werkseitige Reparatur zuständigen kann zu einer Beschädigung der Komponenten und

Erlöschen des Garantieanspruchs führen.

6 Barracuda 4LP Installation Guide, Rev. B

• Die vormontierte Kopf- und Festplatteneinheit (HDA) nicht aus

dem Laufwerk nehmen! Falls die HDA beschä dig t ist, schicken

Sie das gesamte Laufwerk zur Reparatur ein.

• Die HDA ist nicht vor Ort reparierbar und darf nicht auseinan-

dergenommen werden! Öffnen der versiegelten HDA durch

andere Personen als die für die werkseitige Reparatur zuständigen hat eine Beschädigung der Komponenten und

Erlöschen des Garantieanspruchs zur Folge.

Als Teilkom ponente ist dieses Laufwerk für die Installation und

den Betrieb in Übereinstimmung mit UL 1950, EN60950, CSA

C22.2 950-M89 und VDE0805 vorgesehen.

Seagate ist ständig b emüht, die Zulassungsf ähigkeit von

Seagate -Produk ten im Rah men der ge genw ärtig gelten den

Standards zu gewährleisten. Zu den typischen Anwendungen

dieser Festplattenwerke zählen Systemeinbau durch den

Kunden un d die Ko nstruk tion von Unt ersystemen. Sicherheitsbehörden gewähren eine bedingte Zulassung für Komponenten

wie das Barracuda-Festplattenlaufwerk vorbeha ltlich der

endgültigen Zulasssung im Endprodukt. Designer von Untersystemen sind dafür verantwortlich, die Voraussetzungen für die

Einhaltung sicherhe its- oder aufsichtsbehö rdl ich er Vorschri ften

in ihren Endprodukten und - falls gesetzlich vorgeschrieben - für

die Zulassung zu schaffen. Eine Grundvoraussetzung zur Einhaltung der Sicherhei tsanforde rungen ist d ie Bereitst ellung

eines Überlastschutzes für die SELV-Versorgungsspannungen

des Laufwerks.

Dieses Gerät ist ei ne Baugruppe und unt erliegt als solche nicht

den Anforderungen der FCC oder ähnlicher nationaler Behörden

für eigenständige Geräte. Technische Testergebnisse zu elektro-

Barracuda 4LP Installation Guide, Rev. B 7

magnetische Strahlung sind für Designer von Untersystemen auf

Anfrage von der Seagate-Sicherheitsabteilung erhältlich.

European Uni on Compl iance

If this model has the CE Marking, it complies with the European

Union requirements of the Electromagnetic Compatibility Di rective 89/336/EEC of 03 May 1989 as amended by Directive 92/

31/EEC of 28 April 1992 and Directive 93/68/EEC of 22 July

1993.

Seagate uses an independent laboratory to confirm compliance

to the above directives. The drive was tested in a representative

system for typical applications. The sele cted system represents

the most popular characteristics for test platforms. The system

configurations include:

• 486, Pentium, and PowerPC Microprocessors

• 3.5-inch Floppy Disc Drive

• Keyboard

• Monitor/Display

• Mouse

• Printer

Although the test system with this Seagate model complies to

the directives, we cannot guarantee that all systems will comply.

The computer manufacturer or system integrator shall confirm

EMC compliance and provide CE Marking for their product.

8 Barracuda 4LP Installation Guide, Rev. B

Technical support services

If you need assistance installing your drive, consult your dealer.

Dealers are familiar with their unique system configurations and

can help you with system conflicts and other technical issues. If

you need additional assistance with your Seagate

other Seagate products, use one of the Seagate technical support services listed below.

SeaFONE® at 1-800-SEAGATE (1-800-732-4283)

Seagate’s 800 number allows toll-free access to automated selfhelp services, providing answers to commonly asked questions,

troubleshooting tips, and specifications for disc drives and ta pe

drives. This service is available 24 hours daily and requires a

touch-tone phone. If you need to speak to a technical support

engineer, dial this number and listen to the options for technical

support. (International callers can also reach this automated

self-help service by dialing 408-4 56-4496).

Seagate Technology online services

Using a modem, you can obtain troubleshooting tips, free utility

programs, drive specifications and jumper settings for Seagate’s

entire product line. You can also download software for installing

and analyzing your drive.

SeaNET

You can obtain technical information on Seagate drives, Seagate

software, and mu ch more ove r the Internet fro m Seagate’s

World Wide Web hom e page (http ://www.seagate.co m) or

Seagate’s ftp server (ftp://ftp.seagate.com).

™

®

drive or

Barracuda 4LP Installation Guide, Rev. B 9

SeaBOARD

SeaBOARD is a computer bulletin board system (BBS) that contains information about Seagate’s disc and tape drive products

and is available 24 hours daily. Set your communications software to eight data bits, no pari ty, and one stop bit (8-N-1). SeaBOARD phone numbers are listed in the following table.

BBS Location Modem number

United States Disc: 408-434-1080;

England 44-1628-478011

France 33 1-48 25 35 95

Germany 49-89-140-9331

Singapore 65-292-6973

Thailand 662-531-8111

Australia 61-2-9756-2359

Taiwan 886-2-719-6075

®

Tape: 408-456-4415

Seagate Compu S erve Fo ru m

Online technical support for Seagate products is available on

CompuServe. To access our technical support forum, type

seagate

SeaBOARD. In addition, you can type questions or browse

through previous questions and answers on the forum messages.

. This forum provides information similar to that found on

go

10 Barracuda 4LP Installation Guide, Rev. B

Seagate Technology FAX services

SeaFAX

You can use a touch-tone telephone to access Seagate’s automated FAX system to receive technical support information by

return FAX. This service is available 24 hours daily.

Location Telephone number

United States 1-800-SEAGATE or 408-456-4496

England 44-1628-894084

Australia 61-2-9756-5170

®

Seagate techn ical suppo rt FAX

You can FAX questions or comments to technical support specialists 24 hours daily. Responses are sent during business

hours.

Location FAX number

United States 408-944-9120

England 44-1628-890660

France 33 1-46 04 42 50

Germany 49-89-1430-5100

Australia 61-2-9725-4052

Singapore 65-293-4722

Hong Kong 852-2368 7173

Taiwa n 886-2-715-2923

Korea 82-2-556-7294/4251

Seagate techn ical suppo r t

You can talk to a technical support specialist during business

hours Monday through Friday for one-on-one technical help.

Barracuda 4LP Installation Guide, Rev. B 11

Before calling, note your system configuration and dri ve model

number (ST

xxxx

). There are several technical support phone

numbers available for various Seagate products.

Location Telephone number

United States Please dial 1-800-SEAGATE for the specific

product telephone number. (6:00

1 1:15

A.M., 12:30 P.M. to 5:00 P.M., M–F)

England 44-1628-894083 (10:00

2:00

P.M. to 5:00 P.M., M–F)

France 33 1-41 86 10 86 (9:30

2:00

P.M. to 5:00 P.M., M–F)

A.M. to 1:00 P.M.,

A.M. to 12:30 P.M.,

A.M. to

Germany Disc: 49-89-140-9332; Tape: 49-89-140-9333

(9:30

A.M. to 12:30 P.M., 2:00 P.M. to 4:00 P.M.,

M–F)

Australia 61-2-9725-3366

Singapore 65-290-3998 or 65-485-3998 (9:00

12:00

P.M., 2:00 P.M. to 5:00 P.M., M–F)

A.M. to

Hong Kong 852-2368 9918

Taiwan 886-2-514-2237

Korea 82-2-556-8241

SeaTDD™ 408-944-9121

Using a telecommunications device for the deaf (TDD), you can

send questions or comments 24 hours daily and exchange messages with a technical support specialist between 6:00

11:15

A.M. and 12:30 P.M. to 5:00 P.M. (Pacific time) Monday

through Friday.

A.M. to

12 Barracuda 4LP Installation Guide, Rev. B

General description

Barracuda 4LP SCSI disc drives are high-speed, random-access

digital-data storage devices.

The drive i s a componen t for installation in an enclos ure

designed for the drive. This is often a rack within the system or

an external enclosure designed to house one or more disc d rives

or other peripheral units. In either case, the disc drive must

receive adequate cooling (refer to “Providing adequate cooling”)

and it must be sufficiently grounded and shielded from emissions. The

77767491) contains guidelines for a properly designed

enclosure.

Barracuda 4LP Pr oduct Manual

(part num ber

*

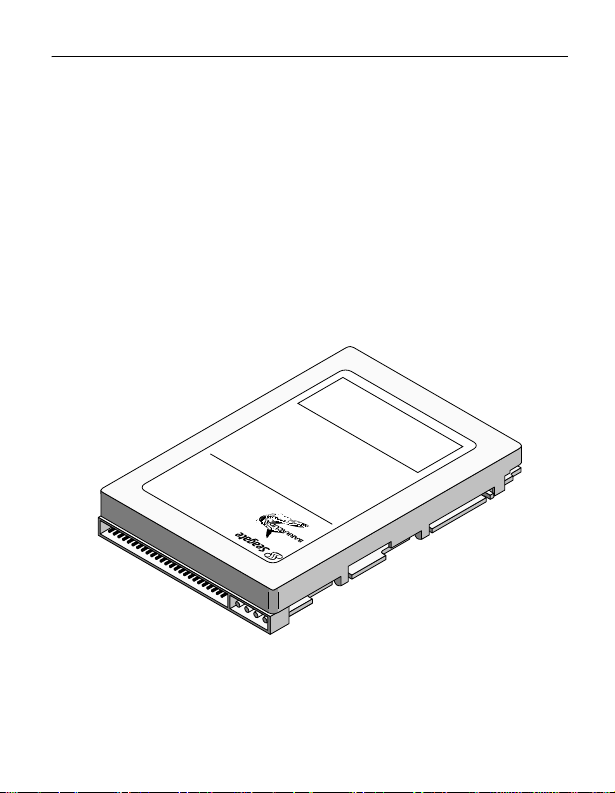

*Model “N” versio n with 50-pin SCSI I/O connector

Figure 1. Barracuda 4LP family drive

Barracuda 4LP Installation Guide, Rev. B 13

Table 1. Drive characteristics

Interface UltraSCSI [1]

Capacity Formatted [2] Unformatted

ST34371 4.35 Gbyte [2] 5.31 Gbyte

ST32171 2.16 Gbyte [2] 2.65 Gbyte

ST34571 4.55 Gbyte [2] 5.54 Gbyte

ST32271 2.26 Gbyte [2] 2.77 Gbyte

Recording

Cylinders (user) 5,178

Read/write data heads

ST32171/ST32271 5

ST34371/ST34571 10

Access time [3]

Average read 9.4 msec

Average write 10.4 msec

Disk rotation

RPM 7,200 r/min

Average latency 4.17 msec

Internal transfer rate (vari abl e with z one)

ST32171/ST34371 80–122 Mbits/sec

ST32271/ST34571 80–126 Mbits/sec

Maximum synchronous SCSI transfer rate

N model 20 Mbytes/sec

W/WD/WC/DC models 40 Mbytes/sec

Multi-segmented cache 442 Kbytes

[1] Can also be operated according to SCS I-1 and SCSI-2 pro tocols.

Referred to also as “SCSI Fast-20.”

14 Barracuda 4LP Installation Guide, Rev. B

[2] Standard facto ry unit s are fo rmatted 512 da ta byte s per secto r wit h

sparing equi valent to eight y spare sect ors per eight cylinder reg ion.

Spares are located at the end of each sparing regio n.

[3] Includes controller overhead.

Table 2a. DC power requirements (Amps)

ST34371/ST34571

N/W/WC

Single-ended

WD/DC

Differential

Voltage +5V +12V +5V +12V

Regulation [5] ±5% ±5%[2] ±5% ±5% [ 2]

Max. operating current

DC3σ [1] 0.81 0.95 1.21 0.95

Avg. idle current DCX

[1] 0.46 0.54 0.70 0.54

Max. starting current

(peak DC) DC3σ [3]

(peak AC) AC3σ [3]

0.78 2.44

3.1

1.1 2.44

3.1

Delayed motor start (max)

DC3σ [1] [ 4] 0.48 0.20 0.90 0.20

Peak operating current

Typical DCX

Maximum DC3σ [1]

Maximum (peak) 3σ

[1][6]

0.75

0.81

1.5

0.76

0.95

2.5

1.05

1.21

2.0

0.76

0.95

2.5

Notes for this table follows Table 2b.

Barracuda 4LP Installation Guide, Rev. B 15

Table 2b. DC power requirements (Amps)

ST32171/ST32271

N/W/WC

Single-ended

Voltage +5V +12V +5V +12V

Regulation [5] ±5% ±5%[2] ±5% ±5% [ 2]

Max. operating current

DC3σ [1] 0.81 0.85 1.21 0.85

Avg. idle current DCX

Max. starting current

(peak DC) DC3σ [3]

(peak AC) AC3σ [3]

Delayed motor start (max)

DC3σ [1] [ 4] 0.50 0.20 0.90 0.20

Peak operating current

Typical DCX

Maximum DC3σ [1]

Maximum (peak) 3σ

[1] Measured with an average reading DC ammeter. Instanta-

neous +12V current peaks will exceed these values.

[2] A –10% droop is permissible during initial star t of the spindle

but must return to ±5% before reaching 7,200 RPM. The

±5% must be maintained after the drive signifies that its

power-up sequence has been completed and that the drive is

able to accept s election by the host initiator.

[3] See the +12V current profile in the

Manual

[4] This condition occurs when the Motor Start option is enabled

and the drive has not yet received a Start Motor command.

(publication number 77767491).

[1] 0.46 0.52 0.70 0.52

0.78 2.00

3.1

[1][6]

0.72

0.81

1.5

0.73

0.85

2.3

Barracuda 4LP Product

WD/DC

Differe ntial

1.1 2.00

3.1

0.91

1.21

2.0

0.73

0.85

2.3

16 Barracuda 4LP Installation Guide, Rev. B

[5] See “Conducted noise immunity” in the

uct Manual.

The specified voltage tolerance is inclusive of

Barracuda 4LP Prod-

ripple, noise, and transient response.

[6] Operating condition is defined as random seek read opera-

tions with a block count of 64.

General Notes from Tables 2a and 2b.

1. Minimum current loading for each supply voltage is not less

than 4% of the maximum operating current shown.

2. Use separate ground returns for +5V and +12V supplies.

3. Where power is provided to multiple driv es from a common

supply, carefully consider individual drive power requirements. Where multiple units are powered on simultaneously, be sure the peak starting current is available to

each device.

Table 3. Dimensions of the drive

inches mm

Height 1.00 25.4

Width 4.00 101.6

Depth 5.74 145.8

Weight 1.5 pounds (0.68 kilograms)

Barracuda 4LP Installation Guide, Rev. B 17

Initial setup information

The general information beginning on this page applies to all of

the Barracuda 4LP drive models. After reading the general information topics, refer to the appropriate drive-specific section

listed below for additional information about configuring and

installing your particular model.

Drive models Page

ST32171N ST32271N

ST34371N ST34571N 36

ST32171W/WD ST32271W/WD

ST34371W/WD ST34571W/WD 40

ST32171WC/DC ST32271WC/DC

ST34371WC/DC ST34571WC/DC 45

General information

The following general information topics are discussed:

• SCSI ID jumpers

• Drive termination

• Terminator power

• Interface drivers and data path width notes

• Other applicable jumper options

• Providing adequate cooling

• Mounting the drive and connecting cables

• Formatting the drive

1

This mounting procedure does not apply to “WC” or “DC” model

drives. To mount a “WC” or “DC” drive, plug the drive into the

system’s single connector attachment (SCA) position on the

system’s back panel.

1

18 Barracuda 4LP Installation Guide, Rev. B

SCSI ID jumpers

Each device on the SCSI chain must have a unique SCSI I D.

The host system’s SCSI controller usually uses the ID that has

the highest priority interrupt in the SCSI I/O system. This is

always ID7. ID0 is lowest priority i n an 8-bit I/O system. ID8 is

lowest priority in a 16-bit I/O system. The lower priority SCSI IDs

are normally used for other SCSI devices such as this Barracuda

disc drive.

Note. Most SCSI controllers (host adapters) allow you to skip a

SCSI ID. For example, you can have ID0, ID1, and ID3

(skipping ID2). Other controll ers do not allow this so be

sure to refer to your system or controller user’s manual

for details about its requirements for proper SCSI device

installati on.

Note. This drive is a SCAM (SCSI Configured Auto Magically)

compliant drive. If the system into which you are installing

this drive requires SCAM compliant drives, you do not

need to be concerned about the drive ID jumper settings,

as the system automatically assigns your new drive the

ID it wants it to have. The system may or may not use the

existing drive ID jumper settings. Setting the drive ID

doesn’t hurt anything, but is not necessary in a SCAM

compliant system.

Most Barracuda disc drives are factory set with the SCSI ID set

at 0. To change the SCSI ID, refer to the appropriate drive section for your model.

If, after completing the installation process, the drive’s LED does

not show on/off activity when the host is t rying to communicate

with the drive, a duplicate SCSI ID may be the problem. If this is

Barracuda 4LP Installation Guide, Rev. B 19

the case, change the ID so that each device on the SCSI chain

has its own unique ID. Also check your system or controller

user’s manual to ensure that you have not violated its SCSI ID

numbering recommendations.

Drive terminati on

If you are installing a Barracuda drive in a system that has other

SCSI devices installed, terminate only the end devices on the

SCSI chain. A SCSI “device” is any disc drive, scanner, tape

backup unit, or other piece of hardware co nnected to your system using the SCSI bus.

The top example in Figure 2 shows an internal hard disc at one

end of the SCSI bus with the SCSI controller at th e other end

(both are terminated). The bottom example shows two additional

SCSI devices connected externally—this means the SCSI controller is no longer on the end of the SCSI chain and should not

be terminated.

Note. Some controllers prefer to remain terminated even if they

are in the middle of the chain. Also, some controllers treat

the internal and external chains as separate logical

buses. This means you may need to terminate both the

first and last devices on both logical buses to achieve

proper termination. If necessary, refer to your system or

controller documentation to see how this is handled in

your particular system.

20 Barracuda 4LP Installation Guide, Rev. B

For information about how to terminate your drive, refer to the

appropriate drive-specific section.

Internal SCSI cable

Internal

SCSI device

Internal

SCSI device

Internal SCSI cable

Internal

SCSI device

Internal

SCSI device

Terminate

Controller

Terminate

Controller

External

SCSI

cable

External

SCSI device

External

SCSI device

Figure 2. SCSI bus termination

Terminator po wer

You usually will not need to change this option and can normally

leave the drive configured as it was shipped from the factory. For

information about how to change the terminator power option on

your drive, refer to the appropriate drive-specific section.

I/O circuits and data path widths

• “WD” and “DC” models use differential I/O circuits. You cannot

mix these models with single-ended models (“N,” “W,” “WC”)

on the same SCSI bus. The circuits are incompatible with

each other.

• “W,” “WD,” and “WC” models have a “wide” (16-bit) SCSI data

bus rather than the standard (non-wide) 8-bit SCSI data bus;

however, you can use these wide drives on a standard (non-

wide) 8-bit data bus.

Barracuda 4LP Installation Guide, Rev. B 21

Figures 3a, 3b, 3c, and 3d show typical drive connections. The

following table lists the maximum cable lengths and number of

devices with single-ended I/O circuits allowed on a daisy-chain

cable for <

10 and <20 M transfers/sec I/O data transfer rates.

Table 4. Cable chara cteristics for single-ended circuits

I/O transfer rate

Maximum number of

devices on line

Maximum cable

length allowed

<10 M transfers/s 8 (reg. SCSI bus) 6 meters (19.7 ft.)

10 M transfers/s 16 (wide SCSI bus) 6 meters (19.7 ft.)

<

20 M transfers/s 4 (reg./wide SCSI bus) 3 meters (9.8 ft.)

<

20 M transfers/s 8 (re g./wide SCSI bus) 1.5 meters (4.9 ft.)

<

For devices having differential I/O circuits, a maximum cable

length of 25 meters (82 feet) is allowed. A maximum of 8 devices

can be connected on an 8-bit wide data bus, and a maximum of

16 devices can be connected on a 16-bit wide data bus.

22 Barracuda 4LP Installation Guide, Rev. B

HDA

Pin 1

Figure 3a. Fifty pin I/O connection to drive

HDA

Pin 1

Figure 3b. Sixty-eight pin connection to drive

Barracuda 4LP Installation Guide, Rev. B 23

“N” Model

Drive

SCSI ID X

(or last drive)

[1]

SCSI ID 1

SCSI ID 0

Additional

SCSI devices

Pin 1

(check your

adapter for Pin 1 location)

SCSI ID 7

Host

Adapter

PCB

[1] “X” means up to 6 or the maximum allowable number of devices on

the SCSI bus. See Table 4 and system documentation.

Figure 3c. Multiple drive connection to host adapter

24 Barracuda 4LP Installation Guide, Rev. B

“W” Model

Drive [1]

SCSI ID X

(or last drive)

[2]

SCSI ID 1

SCSI ID 0

“WD” Model

Drive [1]

Additional

SCSI devices

Pin 1

(check your

adapter for Pin 1 location)

SCSI ID 7

Host

Adapter

PCB

[3]

[1] Do not mix “W” and “WD” mode l drives on the daisy chai n.

[2] “X” means up to 15 or the maximum allowable number of devices on

the SCSI bus. See Table 4 and system documentation.

[3] External terminator.

Figure 3d. Multiple-dr ive connection to host adapter

Barracuda 4LP Installation Guide, Rev. B 25

Note. This drive model plugs directly into a backplane connec-

tor and therefore uses no cables.

Figure 3e. Drive model “WC” or “DC” with single 80-pin I/O

and power connector

26 Barracuda 4LP Installation Guide, Rev. B

Providin g adequ ate cool ing

The enclosure design must ensure adequate cooling for the

drive. The maximum ambient temperatur e is 50°C.

The drive’s product manual (77767491) describes how to evaluate the air-flow design. The evaluation consists of ensurin g that

the case temperature of certain critical components remains

within acceptable limits during drive operation.

We recommend orienting the drive or directing the air flow in a

way that creates the l east amount of air-flow resistance while

providing air flow above the circuit boards and around the head

and disc assembly (HDA). Also, choose the shortest possible

path between the air inlet and exit. This minimizes the distance

traveled by air that is heated by the drive and by other n earby

heat sources.

Figure 4 shows two design approaches with one or more fans

used to generate air flow. The air-flow patterns can be created

by the fans either pushing or drawing air . The overall flow pattern

can be directed from front to back, back to front, or side to side.

Barracuda 4LP Installation Guide, Rev. B 27

Kühlung des System s

Die Gehäusekonstruktion m uß eine ausr eichende Kühlung d es

Laufwerk es gewährl eisten . Die Umge bungste mperatur darf

maximal 50°C betragen.

Die Produkthandbuch Barracuda 4LP (Dokument 77767491)

enthalten Anwei sungen zur Beur teilung der Luftst romkonstruktion. Die Beurteilu ng muß sicherst ellen, daß sich die Ge häusetemperatur bestimmter kritischer Komponenten bei

Laufwerkbetrieb innerhalb zugelassener Grenzen hält.

Wir empfehlen, das Laufwerk so zu orientieren oder den Luftstrom so zu lenke n, daß der gering ste Luftstrom widerstand

erzeugt wird und gleichzeitig ein Luftstrom über den Platinen

und um die Kopf- und Festplatteneinheit (HDA) gegeben ist.

Wählen Sie einen möglichst kurzen Weg zwischen Lufteinlaß

und -auslaß. Dadurch wird die Strecke, die die vom Laufwerk

und anderen nahegelegenen Hitzequellen aufgewärmte Luft

zurücklegt, auf ein Minimum beschränkt.

Abbildung 4 zeigt zwei Konstruktionsmöglichkeiten, bei denen

ein oder mehrere Lüfter den Luftstrom erzeugen. Der Luftstro m verlauf wird durch die Lüfter gesteuert, die entweder Luft einblasen oder abziehen. Generell kann der Luftstrom entweder von

vorne nach hinten oder von hinten nach vorne verlaufen.

28 Barracuda 4LP Installation Guide, Rev. B

H

.

Above unit

Über der Einheit

Note. Air flows in the direction shown (back to front)

or in reverse direction (front to back)

inweis. Luftstrom in der angezeigten Richtung

(von vorne nach hinten) oder in umgekehrter

Richtung (von hinten nach vorne)

Note. Air flows in the direction shown or

in reverse direction (side to side)

Hinweis. Luftstrom in der angezeigten Richtung oder in

umgekehrter Richtung (von Seite zu Seite)

Under unit

Unter der Einheit

Above unit

Über der Einheit

Under unit

Unter der Einheit

Figure 4. Suggested air flow

Abbildung 4. Empfohlener Luftstromverlauf

Barracuda 4LP Installation Guide, Rev. B 29

Mounting the drive and co nne ctin g cable s

Do not touch the connector pins or any components on the control board without observing static-discharge precautions.

Always handle the drive by the frame only.

The drive may be mounted in any orientation (horizontall y, vertically, and any combination thereof); however, you must ensure

that the drive receives adequate air flow for cooling.

1. Mount the drive to the host system’s chassis using four 6-32

UNC screws. Two mounting holes are in each side of the

drive and there are four mounting holes in the bottom of the

drive.

The maximum length that the screws should extend into the

chassis mounting holes is 0.15 inch (3.81 m m), measured

from the outer surface of the chassis. Tighten the screws

down evenly. Do not over-tighten or force the screw if it

does not seem to screw in easily, because this means the

threads are not properly aligned. In this case, back the

screw out and try again.

Installatio n des Laufwer kes

und Anschluß der Kabel

Beachten Sie beim Handhaben und Anfassen der Anschlußstifte

und Komponenten die Vorsichtsmaßnahmen zur Verhinderung

statischer Aufladung. Fassen Sie das Laufwerk nur am Rahmen

an.

Das Laufwerk kann in beliebiger Orientierung (horizontal, vertikal oder schräg) installiert w erden; jedoch muß dafür gesorgt

werden, daß ein ausreichender Luftstrom zur Kühlung des Laufwerkes vorhanden ist.

30 Barracuda 4LP Installation Guide, Rev. B

1. Befestigen Sie das Laufwerk mit vier 6-32-UNC-Schrauben

am Gehäuse des Host- Systems. Die beiden Se iten des

Laufwerkes sind mit jeweils zwei Befestigungslöchern

versehen, die Unterseite des Laufwerkes weist vier weitere

Befestigungslöcher auf.

Gemessen von der Außenfläch e des Gehäuses dürfen die

Schrauben maximal 3,81 mm in die Befestigungslöcher des

Gehüus es hinei nragen. D ie Sch rauben m üssen gleichmäßig, jedoch nicht zu fest, angezogen werden. Wenn sich

eine Schraube nicht ohne Widerstand einschrauben läßt,

sind die Gewinde ni cht korrekt aneinander ausger ichtet. In

diesem Fall die Schraube nicht in das Gewindeloch

forcieren, sondern die Schraube herausnehmen und erneut

in das Gewindeloch einführen.

2. Verify that all connections between the drive and the host

system are correctly installed.

2. Prüfen Sie, ob alle Verbindungen zwischen dem Laufwerk

und dem Host-System korrekt hergestellt sind.

3. Verify that you have correctly installed jumpers.

3. Stellen Sie sicher, daß die Kennungsbrücken installiert sind.

4. Connect the SCSI cable into the drive’s SCSI connector.

Take care not to stretch or crimp this cable, and do not block

the system’s cooling air flow with the cable.

The drive receives DC power through a 4-pin connector

mounted next to the SCSI connector. The output of a power

supply must meet SELV (safety extra low voltage) as

Barracuda 4LP Installation Guide, Rev. B 31

Power

Cable

DC Power

Connector

4321

Pin

1

2

3

4

Power

+12V

+12V ret

+ 5V ret

+ 5V

Pin

1

2

3

4

Gleichstrom

+12V

+12V Rückleitung

+ 5V Rückleitung

+ 5V

defined in IEC 950. Figure 5 provides the pin information for

the DC power connector. To connect the DC power cable to

the drive, simply insert the cable end into the drive’s DC

power connector.

4. Schließen Sie das SCSI-Kabel an den SCSI-Steckverbinder

des Laufw erkes an. Das Kabel d arf nicht gedehnt ode r

gedrückt werden und es darf den Luftstrom zur Kühlung des

Systems nicht behindern.

Das Laufwerk wird über einen 4-poligen, neben dem SCSIAnschluß befestigten Steckverbinder mit Gleichs trom versorgt. Der Ausgang eines Netzteils muß SELV (safety extra

low voltage) na ch IEC 950 entspr echen. Abbildung 5 zeigt

die Steckerbelegung für den Gleichstromanschluß. Zum

Anschluß des Gleichstromkabels an das Laufwerk das

Kabelende in den Gleichstromanschluß des Laufwerkes

stecken.

Figure 5. DC power connector

Abbildung 5. Gleichstromanschluß

32 Barracuda 4LP Installation Guide, Rev. B

Note. Signal ground on the power control board (PCB) and the

head and disc assembly (HDA) are connected together in

this drive and you cannot separate them. The equipment

in which you have mounted the drive is connected

directly to the HDA and PCB without electrically isolating

shock mounts. Maximizing the conductive contact area

between HDA ground and system ground may reduce

radiated emissions.

If you do not want the system chassis to be connected to

the HDA/PCB ground, you must provide a nonconductive

(electrically isolating) method of mounting the drive in the

host system. This may increase radiated emissions and

is the system designer’s responsibility.

Hinweis :

Die Signalerde auf der Stromregelungskarte (PCB) und

der Kopf- und Festplatteneinheit (HDA) sind in diesem

Laufwerk miteinander verbunden und können nicht

getrennt werden. Das Gerät, in das Sie das Laufwerk

eingebaut haben, ist ohne elektrisch isolierende

Stoßdämpfer direkt an die HDA und PCB angeschlos sen.

Die elektromagnetische Strahlung kann reduziert werden, indem Sie eine möglichst große leitende Kontakfläche zwischen der HDA-Erdung und der Systemerdung

vorsehen.

Wenn Sie das Systemgehäuse nicht an die HDA/PCBErdung anschließen wollen, müssen S ie das Laufwerk

auf nichtleitende Weise (galvanisch isoliert) im Host-Sys-

Barracuda 4LP Installation Guide, Rev. B 33

tem einbauen. Die daraus u.U. resultierende verstärkte

elektromagnetische Strahlung fällt in den Zuständigkeitsbereich des Systemdesigners.

5. Replace the host system’s cover.

5. Setzen Sie das Gehäuseoberteil des Host-Systems wieder

auf.

34 Barracuda 4LP Installation Guide, Rev. B

[4]

[3]

C

G

L

[1]

B

J

[2]

H

K

N

[4]

M

D

F

A

E

Notes:

[1] Mounting holes three on each side, 6-32 UNC.

Max screw length into side of drive 0.15 in.

(3.81 mm). Screw tightening torque 6.0 in-lb

(.675 NM) max with minimum thread

engagement of 0.12 in. (3.05 mm).

[2] Mounting holes four on bottom, 6-32 UNC.

Max screw length into bottom of drive 0.20 in.

(5.08 mm). Screw tightening torque 6.0 in-lb

(.675 NM) max with minimum thread

engagement of 0.12 in. (3.05 mm).

[3] Power and interface connectors can extend

past the "A" dimension by 0.040 in. (1.02 mm).

[4] Decorative front panel (optional).

[5] Although the illustration shows the 50 pin I/O

connector drive model, mounting hole locations

are the same for all Barracuda 4LP models.

Inches

5.74

A

4.00

B

1.00

C

2.362

D

.620

E

4.000

F

.250

G

1.750

H

P

3.750

J

2.370

K

1.00

L

4.000

M

0.19

N

0.015

P

± .010

± .010

+ .021

– .009

± .010

± .020

± .010

+ .010

– .005

± .010

± .010

± .020

± .010

± .010

± .010

max

Millimeters

145.80

101.60

25.40

60.00

15.75

101.60

6.35

44.45

95.25

60.20

25.4

101.6

4.83

0.381

Figure 6. Mounting configuration dimensions

± .25

± .25

+ .53

– .22

± .25

± .50

± .25

+ .25

– .12

± .25

± .25

± .50

± .25

± .25

± .25

max

Barracuda 4LP Installation Guide, Rev. B 35

Formatting the drive

Warning. Formatting a drive erases all user data. Be sure that

you understand this principle before formatting any

hard disc drive. It is not necessary to format a drive

that previously has been used to store data, unless

your intention is to erase all user data.

Note. Seagate is not responsible for lost user data.

1. Turn on DC power.

2. Boot the system from a system floppy disc or from a previously installed hard disc drive if there is one.

3. Format the disc drive. Barracuda 4LP disc drives are

designed to operate with a variety of operating systems.

Please refer to your system or SCSI controller manual for

information about formatting a nd setting up the drive. Some

quick desktop system notes are provided below.

Quick reference desktop system notes

Note. Refer to your system or util ity manual for detailed instruc-

tions)

• DOS. Set the drive type in CMOS to “

hard drive installed

tems that have operating system Windows 95 release 950B or

later do not need to partition the drive.

• Macintosh. Use a third-party drive utility (Apple’s HD Setup

utility only works with drives having special Apple firmware).

.” Use FDISK.EXE and FORMA T.EXE. Sys-

Zero,” “None,”

or “

No

36 Barracuda 4LP Installation Guide, Rev. B

N drives

N/ND drives sectionSetting the SCSI ID jumpe rs

Use the J6 connector to set the SCSI ID (see Figure 7). To

change the SCSI ID, i nstall jumpers on the appropriate pins as

shown in the illustration.

Drive

Front

Jumper Plug

(enlarged to

show detail)

SCSI ID = 0

SCSI ID = 1

SCSI ID = 2

SCSI ID = 3

SCSI ID = 4

SCSI ID = 5

SCSI ID = 6

SCSI ID = 7

Reserved

J6

L

R

R

E

E

E

A2A1A

D

S

S

Pin 1

0

(default)

Figure 7. Setting the SCSI ID on model N drives

Barracuda 4LP Installation Guide, Rev. B 37

N drives

Termina tin g the drive

“N” model drives are terminated with permanently mounted IC

active terminators. If you install one of these drives and it is not

on the end of the SCSI bus, disable the terminators by removing

the jumper “TE” from pins 15 and 16 of connector J2 (see Figure 8). If you install the drive on the end of the SCSI bus, enable

termination by installing a jumper on pins 15 and 16 of connector

J2.

J2

T

D

M

W

P

E

S

E

P

D

Enable SCSI terminator (default)

Disable SCSI terminator

Pin 1

R

E

T

T

S

P

P

J6

Drive

J2 Jumper Type

(enlarged to

show detail)

Front

Figure 8. Terminating the drive

J2

SCSI I/O

Connector

DC Power

Connector

J1

38 Barracuda 4LP Installation Guide, Rev. B

N drives

Terminator po wer

There are three possible terminator power (TP ) configurations

for “N” model drives (see Figure 9). You will not normally need to

change this option and can leave the drive configured as it was

shipped from the factory.

J2

T

D

M

W

P

E

S

E

P

“N” model drives

D

Term. Power from Drive (default)

Term. Power to SCSI Bus

Term. Power from SCSI Bus

Position A

Pin 1

R

E

T

T

S

P

P

J2

SCSI I/O

Connector

DC Power

Connector

J2 Jumper Type

(enlarged to

show detail)

J6

Drive

Front

Figure 9. Setting terminator power jumpers

J1

Barracuda 4LP Installation Guide, Rev. B 39

N drives

Other appli cab le jumper options

Several other jumper opti ons are available as illustrated.

Drive with

HDA up, PCB

down, viewed

from front

Reserved

Reserved

Remote

LED

Shipped with cover installed.

Do not remove.

Do not install jumpers

on these four positions.

Drive Front

DC Power

Connector

SCSI I/O

Connector

Pin 1

HDA

L

R

R

E

E

E

A2A1A

D

S

S

11

12

J6

J2

J1

J2 Jumper Type

(enlarged to

show detail)

J6

0

CATH

Jumper Type

(enlarged to

show detail)

Pin 1

End

Pin 1

J6

Reserved

Delay Motor Start option

(valid only if the Enable

Motor Start jumper is

not connected)

Disable the Delay Motor

Start option.

Motor start delay equal

to the SCSI ID multiplied

by 12 seconds. For

example, if the SCSI

ID = 2, the drive starts

in 24 seconds.

Motor Start option

Disable motor start.

The drive starts

according to the

Delay Motor Start option.

Enable motor start. The

drive waits for the Start

Unit command from the

host before starting the

spindle motor.

Write Protect option

Write protect = Off

(enables writing).

Write protect = On

(disables writing).

Parity Check option

Enable parity check of

SCSI bus.

Disable parity check.

Figure 10. Additional jumper options

J2

Pin 1

(default)

(default)

(default)

(default)

40 Barracuda 4LP Installation Guide, Rev. B

W/WD drives

W/WD drives sectionSetting the SCSI ID jumpe rs

Use the J6 jumper block to set the SCSI ID (Figure 11). To

change the SCSI ID, install jumpers on the appropriate pins as

shown in the illustration. Optional connections to switching circuits in host equipment are provided on J1 auxiliar y to set the

SCSI ID (see Figure 12).

Drive

Front

Jumper Plug

(enlarged to

show detail)

L

R

Reserved

E

E

D

SCSI ID = 0 (default)

SCSI ID = 1

SCSI ID = 2

SCSI ID = 3

SCSI ID = 4

SCSI ID = 5

SCSI ID = 6

SCSI ID = 7

SCSI ID = 8

SCSI ID = 9

SCSI ID = 10

SCSI ID = 11

SCSI ID = 12

SCSI ID = 13

SCSI ID = 14

SCSI ID = 15

S

J6

A2A3A1A

Pin 1

0

Figure 11. Set ting the SCSI ID on model W/WD drives

Barracuda 4LP Installation Guide, Rev. B 41

W/WD drives

68 Pin SCSI I/O

Connector

J1

SCSI ID = 0

SCSI ID = 1

SCSI ID = 2

SCSI ID = 3

SCSI ID = 4

SCSI ID = 5

SCSI ID = 6

SCSI ID = 7

SCSI ID = 8

SCSI ID = 9

SCSI ID = 10

SCSI ID = 11

SCSI ID = 12

SCSI ID = 13

SCSI ID = 14

SCSI ID = 15

not used

Host Alternate

Usage Plug

+5V

Dashed area is optional host circuitry (external to the

drive) connected to host supplied optional usage plug.

Pin 1

+5V

N.C.

Ground

Drive Activity LED

+5V

Ground

A

3A2A1

1197531

12 10 8 6 4 2

J1-Auxiliary

Pin 1A

4P 3P2P 1P

(default)

For ID selection use

jumpers as shown or

connect a cable for

remote switching as

shown below.

A

0

A0A1A2A

3

Drive

PCB

HDA

Rear

J1-DC Power

Pins 1, 3, 5, and 7 are

optional connections to

switching circuits in host

equipment to establish

drive ID.

Remote Switches

Pins 2, 4, 6, and 8 are normally

not grounded. They are driven low

(ground) for 250 ms after a Reset or

PWR ON to allow drive to read

SCSI ID selected. Pin 8 may

also be used to drive the cathode

of an external Activity LED.

Figure 12. Usi ng J1-Auxillary connector for model “W”

and “WD” drive alternate ID select and LED

connection

42 Barracuda 4LP Installation Guide, Rev. B

W/WD drives

Termina tin g the drive

“W” model drives are terminated with permanently mounted IC

active terminators. If you install one of these drives and it is not

on the end of the SCSI bus, disable the terminators by removing

the jumper “TE” from pins 15 and 16 of connector J2. If you

install the drive on the end of the SCSI bus, enable termination

by installing a jumper on pins 15 and 16 of connector J2 (see

Figure 13).

Note. Use active (ANSI SCSI-2 Alternative 2) terminators when

terminating the bus.

“WD” model drives do not have internal terminators or any other

way of adding internal termination to the drive. You must provide

external differential termination to these drives when termination

is required.

J2

T

D

M

W

E

S

E

P

*Enable SCSI terminator (default)

*Disable SCSI terminator

*“W” model only

Pin 1

R

P

E

T

T

D

S

P

P

J2

SCSI I/O

Connector

DC Power

Connector

J1

J2 Jumper Type

(enlarged to

show detail)

J6

Drive

Front

Figure 13. Terminating the drive (“W” model shown)

Barracuda 4LP Installation Guide, Rev. B 43

W/WD drives

Terminator po wer

There are three possible terminator power (TP ) configurations

for “W” model drives (see Figure 14). You will not norm ally n e ed

to change this option and can leave the drive configured as it

was shipped from the factory.

There are two possible terminator power (TP) configurations for

“WD” model drives (see Figure 14).

J2

T

D

M

W

P

E

S

E

P

“W” model drives

D

Term. Power from Drive (default)

Term. Power to SCSI Bus

Term. Power from SCSI Bus

“WD” model drives

Position A

Term. Power to SCSI Bus (default)

Host adapter or other device provides

term. power to external terminator.

Pin 1

R

E

T

T

S

P

P

J2

SCSI I/O

Connector

DC Power

Connector

J2 Jumper Type

(enlarged to

show detail)

J6

Drive

Front

Figure 14. Setting terminator power jumpers

J1

44 Barracuda 4LP Installation Guide, Rev. B

W/WD drives

Other appli cab le jumper options

Other option jumpers are available as illustrated below.

Drive with

HDA up, PCB

down, viewed

from front

Reserved

Reserved

Remote

LED

Shipped with cover installed.

Do not remove.

Do not install jumpers

on these four positions.

Drive Front

DC Power

Connector

SCSI I/O

Connector

Pin 1

HDA

L

R

E

E

A2A3A1A

D

S

11

12

J6

J2

J1

J2 Jumper Type

(enlarged to

show detail)

J6

0

CATH

Jumper Type

(enlarged to

show detail)

Pin 1

End

Pin 1

J6

Reserved

Delay Motor Start option

(valid only if the Enable

Motor Start jumper is

not connected)

Disable the Delay Motor

Start option.

Motor start delay equal

to the SCSI ID multiplied

by 12 seconds. For

example, if the SCSI

ID = 2, the drive starts

in 24 seconds.

Motor Start option

Disable motor start

(default). The drive

starts according to the

Delay Motor Start option.

Enable motor start. The

drive waits for the Start

Unit command from the

host before starting the

spindle motor.

Write Protect option

Write protect = Off

(enables writing.

Write protect = On

(disables writing).

Parity Check option

Enable parity check of

SCSI bus.

Disable parity check.

Figure 15. Additional jumper options

J2

Pin 1

(default)

(default)

(default)

(default)

Barracuda 4LP Installation Guide, Rev. B 45

WC/DC drives

WC/DC drive s sectio nSetting the SCSI ID jumpe rs

The SCSI ID for “WC” and “DC” model drives is normally set

over the SCSI bus by the host system using connector contacts

39 (ID0), 40 (ID2), 79 (ID1), and 80 (ID3). Users need not install

jumpers to select SCSI ID.

Termina tin g the drive

“WC” and “DC” model dr ives do not have internal terminator s or

any other way of adding internal term ination to the dri ve. External termination f or these dr ives is normally supplied by the host

equipment when termination is required.

46 Barracuda 4LP Installation Guide, Rev. B

WC/DC drives

Applica bl e jump er op tio n s

Option jumpers are available as i llustrated below.

J2

Delay Motor Start option

The host system has complete

control over motor start functions. Do

not install a jumper on these pins.

Enable Motor Start option

The host system has complete

control over motor start functions. Do

not install a jumper on these pins.

Write Protect option

Write protect = Off

(enables writing)

Write protect = On

(disables writing)

Parity Check option

Enable parity check of SCSI bus.

Disable parity check.

T

D

M

W

E

S

E

P

Pin 1

R

P

E

T

T

D

S

P

P

(default)

(default)

J6

Drive

J2 Jumper Type

(enlarged to

show detail)

Front

Figure 16. Jumper options

J2

SCSI I/O

Connector

DC Power

Connector

J1

Seagate Technology, Inc.

920 Disc Drive, Scotts Valley, CA 95066-4544, USA

Publication Number: 77767492, Rev. B, Printed in USA

Loading...

Loading...