Seagate ST3146854SS operation manual

Cheetah 15K.4 SAS

ST3146854SS

ST373454SS

ST336754SS

Cheetah 15K.4 SAS

ST3146854SS

ST373454SS

ST336754SS

©2004, 2005 Seagate Technology LLC All rights reserved

Publication number: 100350601, Rev. B

May 2005

Seagate and Seagate Technology are registered tradem arks of Seagate Technology LLC.

Cheetah, SeaTools, SeaF ONE, SeaBOARD, Sea TDD, and the Wave logo are eith er regis

tered trademarks or trademarks of Seagate T echnology LLC. Other product names are registered trademarks or trademarks of their owners.

Seagate reserves the right to ch ange, witho ut notice, product offerings or spec ifications . No

part of this publication may be reproduc ed in any form w ithout wr itte n per mi ssio n of Seagate

Technology LLC.

-

Revision status summary sheet

Revision Date Sheets Affected

Rev. A 11/22/04 All.

Rev. B 05/04/05 Pages 11, 37, 58, and 59.

Contents

1.0 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Standards, compliance and reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.2.1 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Programmable drive capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.7 Factory-installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.8 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.9 User-installed accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Internal drive characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Seek performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.1 Access time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2.2 Format command execution time (minutes) . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.3 General performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.3 Optimizing cache performance for desktop and server applications . . . . . . . . . 15

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Recoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Unrecoverable Errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.3 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.4 Interface errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Annualized Failure Rate (AFR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Preventive maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.5 Thermal monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.6 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 AC power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 DC power requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2.1 Conducted noise immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.2.3 Current profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Power dissipation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Cheetah 15K.4 SAS Product Manual, Rev. B i

6.4 Environmental limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

6.4.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.6 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

6.4.7 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.4.8 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

6.5 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.1 Drive internal defects/errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

7.3 SAS system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.0 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.1 Drive orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.2 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.3 Drive mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

8.4 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.0 Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1 SAS features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1.1 task management functions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1.2 task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.3 SCSI commands supported. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.3.1 Inquiry data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.3.2 Mode Sense data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

9.4 Miscellaneous operating features and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

9.4.1 SAS physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

9.4.2 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.4.3 Connector requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.4.4 Electrical description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.4.5 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.4.6 SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.4.7 Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.5 Signal characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.5.1 Ready LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.5.2 Differential signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

10.0 Seagate Technology support services . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 73

ii Cheetah 15K.4 SAS Product Manual, Rev. B

List of Figures

Figure 1. Cheetah 15K.4 SAS disc drive 1

Figure 2. Typical ST3146854SS drive +12V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 3. Typical ST3146854SS drive +5V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .28

Figure 4. Typical ST373454SS drive +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 5. Typical ST373454SS drive +5V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Figure 6. Typical ST336754SS drive +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 7. Typical ST336754SS drive +5V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Figure 8. ST3146854SS (3 Gbit) DC current and power vs. input/output operations per second . . . . . . . . . . . . . . . . .31

Figure 9. ST3146854SS (1.5 Gbit) DC current and power vs. input/output operations per second. . . . . . . . . . . . . . . .31

Figure 10. ST373454SS (3 Gbit) DC current and power vs. input/output operations per second . . . . . . . . . . . . . . . . . .32

Figure 11. ST373454SS (1.5 Gbit) DC current and power vs. input/output operations per second. . . . . . . . . . . . . . . . .32

Figure 12. ST336754SS (3 Gbit) DC current and power vs. input/output operations per second . . . . . . . . . . . . . . . . . .33

Figure 13. ST336754SS (1.5 Gbit) DC current and power vs. input/output operations per second. . . . . . . . . . . . . . . . .33

Figure 14. Location of the HDA temperature check point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

Figure 15. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .36

Figure 16. Physical dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

Figure 17. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Figure 18. Air flow . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .42

Figure 19. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

Figure 20. SAS connector dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .58

Figure 21. SAS connector dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

Figure 22. SAS transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

Figure 23. Receive eye mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 24. Reveive tolerance eye mask. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .63

Figure 25. Sinusoidal jitter mask . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Figure 26. Compliance interconnect test load . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 27. Zero-length test load. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 28. ISI loss example at 3.0 Gbps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70

Figure 29. ISI loss example at 1.5 Gbps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Cheetah 15K.4 SAS Product Manual, Rev. B 1

2 Cheetah 15K.4 SAS Product Manual, Rev. B

1.0 Scope

This manual describes Seagate Technology® LLC, Cheetah® SAS (Serial Attached SCSI) disc drives.

Cheetah drives support the SAS Pr oto co l spec ifi cati ons to the exte nt de sc ribe d in this man ual . The SAS Inter-

face Manual (part number 100293071) describes t he general SAS characteri stics of this and other Se agate

SAS drives.

Figure 1. Cheetah 15K.4 SAS disc drive

Cheetah 15K.4 SAS Product Manual, Rev. B 1

2 Cheetah 15K.4 SAS Product Manual, Rev. B

2.0 Standards, compliance and reference documents

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends on its host equip ment to provide adequate power and e nvironment for optimum performa nce

and compliance with appl icable i ndustry and g overnme ntal regulations. Special attention mu st be given in the

areas of safety, power distribution, s hielding, audible n oise control, and temperature regulat ion. In particular,

the drive must be securely mo unted to guar antee the spe cified pe rformance char acterist ics. Mountin g by bot

tom holes must meet the requirements of Section 8.3.

2.1 Standards

The Cheetah SAS family com pl ies wi th Se aga te s tandar ds a s no ted in the app ropr iat e se cti on s of this ma nual

and the Seagate SAS Interface Manual, part number 100293071.

The Cheetah disc drive is a UL recognized component per UL1950, CSA certified to CAN/CSA C22.2 No. 950-

95, and VDE certified to VDE 0805 and EN60950.

2.1.1 Electromagnetic compatibility

The drive, as delivered , is designed for system integrati on and installation into a suitable encl osure prior to

use. The drive is supplied as a suba ssembly and is not subject to Sub part B of Part 15 of the FCC Rules and

Regulations nor the Radio Interference Regulations of the Canadian Department of Communications.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides

reasonable shielding. T he drive is ca pable of meeting the Cl ass B limits of the FCC Rules and Regulati ons of

the Canadian Department of C omm uni ca tio ns whe n p ro per ly pack ag ed; howe ve r, it is the user’s responsibil ity

to assure that the dri ve meets the approp riate EMI r equirements in thei r system. Sh ielded I/O c ables may be

required if the enclosure does not prov ide adequate shie lding. If the I/O cables are external to the enc losure,

shielded cables should be used, with the shields grounded to the enclosure and to the host controller.

-

2.1.1.1 Electromagnetic susceptibility

As a component a ssembly, the drive is not requ ired to meet any susc eptibi lity perfor mance requ irements. It is

the responsibilit y of those integrating the dr iv e wit hin the ir sy ste ms to pe rfo rm th os e te sts r eq ui red a nd des ig n

their system to ensure th at equipment operating in the same sy stem as the drive or external to the syste m

does not adversely affect the performance of the drive. See Tables

Cheetah 15K.4 SAS Product Manual, Rev. B 3

2 and 3, DC power requirements.

2.2 Compliance

2.2.1 Electromagnetic compliance

Seagate uses an inde pendent laborato ry to confirm comp liance with the directives/standa rds for CE Markin g

and C-Tick Marking. The drive was tested in a representative system for typical applications. The selected sys

tem represents the most popular characteristics for test platforms. The system configurations include:

• Typical current use microprocessor

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

• Printer

• External modem

•Mouse

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee

that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance

and provide the appropriate marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it co mplies with the European Union requirements of the El ectromagnetic

Compatibility Directive 89 /336/EEC of 03 May 1989 as amend ed by Dir ective 92 /31/ EEC of 28 Apri l 1992 an d

Directive 93/68/EEC of 22 July 1993.

-

Australian C-Tick

If this model has th e C-Tick Marking it complies with the Austr alia/New Zeal and Standard AS/NZS3548 199 5

and meets the Electromagnet ic Compatibility (EMC) Framework requi rements of Australia’s Spectrum Man

agement Agency (SMA).

Korean MIC

If this model has the Korean Ministry of Information and Communication (MIC) logo, it complies with paragraph

1 of Article 11 of the Electromagnetic Compatibility (EMC) Control Regulation and meets the Electroma gnetic

Compatibility Framework requirements of the Radio Research Laborator y (RRL) Ministry of Information and

Communication Republic of Korea.

Taiwanese BSMI

If this model has t wo Chine se words meani ng “E MC ce rtifica tion” follo wed by an eig ht digi t identifi catio n n umber, as a Marking, it complies with Chinese National Standard (CNS) 13438 and meets the Electromagnetic

Compatibility (EMC) Fra mework requ irements of the Taiwanese Bureau of Standards, Metrology, and Inspec

tion (BSMI).

-

-

4 Cheetah 15K.4 SAS Product Manual, Rev. B

2.3 Reference documents

Cheetah 15K.4 SAS Installation Guide

Seagate part number: 100350602

SAS Interface Manual

ANSI SAS Documents

ANSI Small Computer System Interface (SCSI) Documents

Specification for Acoustic Test Requirement and Procedures

Package Test Specification

Package Test Specification

In case of conflict between this document and any referenced document, this document takes precedence.

Seagate part number: 100293071

SFF-8323 3.5” Drive Form Factor with Serial Connector

SFF-8460 HSS Backplane Design Guidelines

SFF-8470 Multi Lane Copper Connector

SFF-8482 SAS Plug Connector

ANSI INCITS.xxx Serial Attached SCSI (SAS) Standard (T10/1562-D)

ISO/IEC 14776-xxx SCSI Architecure Model-3 (SAM-3) Standard (T10/1561-D)

ISO/IEC 14776-xxx SCSI Primary Commands-3 (SPC-3) Standard (T10/1416-D)

ISO/IEC 14776-xxx SCSI Block Commands-2 (SBC-2) Standard (T10/1417-D)

X3.270-1996 (SCSI-3) Architecture Model

Seagate part number: 30553-001

Seagate P/N 30190-001 (under 100 lb.)

Seagate P/N 30191-001 (over 100 lb.)

Cheetah 15K.4 SAS Product Manual, Rev. B 5

6 Cheetah 15K.4 SAS Product Manual, Rev. B

3.0 General description

Cheetah drives combin e giant magnetoresisti ve (GMR) heads, partia l response/maximum likelihood (PRML)

read channel electroni cs, e mbedded servo te chnol ogy, and a Serial Attached SCSI (SA S) inter face t o provid e

high performance, h igh c apaci ty d ata s tor age f or a v ari ety o f sy st ems inc l uding engineering workstations, net

work servers, mainframes, and supercomputers. The Serial Attached SCSI interface is designed to meet next-

generation computing demands for performance, scalability, flexibility and high-density storage requirements.

Cheetah drives are rando m ac c ess s to ra ge d evic es de si gne d to support the Serial Attached SCS I P rotoc ol as

described in the ANSI spec ifications , this documen t, and the SAS Inte rface Manual ( part number 1002 93071)

which describes the g eneral interface characteristics o f this drive. Chee tah drives are classi fied as intelligen t

peripherals and provide level 2 confo rm ance ( hig hes t lev el) with the A NSI SC SI- 1 s tandard. Th e SA S connec

tors, cables and elec trical interface are com patible with Serial ATA (SATA), giving future user s the choice of

populating their systems with either SAS or SATA hard disc drives. This allows you to continue to leverage your

existing investment in SCSI while gaining a 3Gb/s serial data transfer rate.

The head and disc assembly (HD A) is sealed at the factory. Air recircul ates within the HDA through a non-

replaceable filter to maintain a contamination-free HDA environment.

Note. Never disassemb le the HDA and do not attemp t to service items in the sealed enclosure (heads,

media, actuator, etc.) as this requires special facilities. The drive does not contain user-replaceable

parts. Opening the HDA for any reason voids your warranty.

Cheetah drives use a dedicated landing zone at the innermost radius of the media to eliminate the possibility of

destroying or degrading data by landing in the data zone. The heads automatically go to the landing zone when

power is removed from the drive.

-

-

An automatic shipping lock prevents potential damage to the heads and discs that results from movement dur-

ing shipping and h andling. The shipping lock disengages and th e head load process be gins when power is

applied to the drive.

Cheetah drives decode track 0 location data from the servo data embedded on each surface to eliminate

mechanical transducer adjustments and related reliability concerns.

The drives also use a high-performance actuator assembly with a low-inertia, balanced, patented, straight arm

design that provides excellent performance with minimal power dissipation.

Cheetah 15K.4 SAS Product Manual, Rev. B 7

3.1 Standard features

Cheetah drives have the following standard featur es:

• 1.5 / 3 Gbit Serial Attached SCSI (SAS) interface

• Integrated dual port SAS controller supporting the SCSI protocol

• Support for SAS expanders and fanout adapters

• Firmware downloadable using the SAS interface

• 64 - deep task set (queue)

• Supports up to 32 initiators

• Jumperless configuration.

• User-selectable logical block size (512 to 528 bytes per logical block) in any multiple of 4 bytes.

• Industry standard SFF 2.5-inch dimensions

• Programmable logical block reallocation scheme

• Flawed logical block reallocation at format time

• Programmable auto write and read reallocation

• Reallocation of defects on command (Post Format)

• ECC maximum burst correction length of 320 bits

• No preventive maintenance or adjustments required

• Dedicated head landing zone

• Embedded servo design

• Automatic shipping lock

• Embedded servo design

• Self diagnostics performed when power is applied to the drive

• Zone bit recording (ZBR )

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 8,192 Kbyte data buffer (see Section 4.5).

• Drive Self Test (DST)

• Background Media Scan (BGMS)

•Power Save

3.2 Media description

The media used on the drive has an alumi num sub st rat e co ated with a thin fi lm magn eti c mater ia l, over coate d

with a proprietary protective layer for improved durability and environmental protection.

3.3 Performance

• Programmable multi-segmentable cache buffer

• 300 Mbytes/sec maximum instantaneous data transfers.

• 15k RPM spindle. Average latency = 2.0 msec

• Background processing of queue

• Supports start and stop commands (spindle stops spinning)

• Adaptive seek velocity; improved seek performance

8 Cheetah 15K.4 SAS Product Manual, Rev. B

3.4 Reliability

• Annualized Failure Rate (AFR) of 0.62%

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• Incorporates industry-standard Self-Monitoring Analysis and Reporting Technology (S.M.A.R.T.)

• 5-year warranty

3.5 Formatted capacities

Standard OEM models are formatted to 512 bytes per block. The block size is sele ctable at format time an d

must be a multiple of 4 by tes. Users having the necessary equi pment may modify the data block size before

issuing a format command and obtain different formatted capacities than those listed.

To provide a stable target capacity environment and at the same time provide users with flexibility if they

choose, Seagate recommends product planning in one of two modes:

1. Seagate designs specify capacit y p oi nts at cer tain b lock siz es tha t S eag ate guarantees current and fut ur e

products will meet. We recommend custo mers use this capacity in their project pl anning, as it ensures a

stable operating point with backw ard and forward c ompatibi lity from gener ation to generati on. The curren t

guaranteed operating points for this product are:

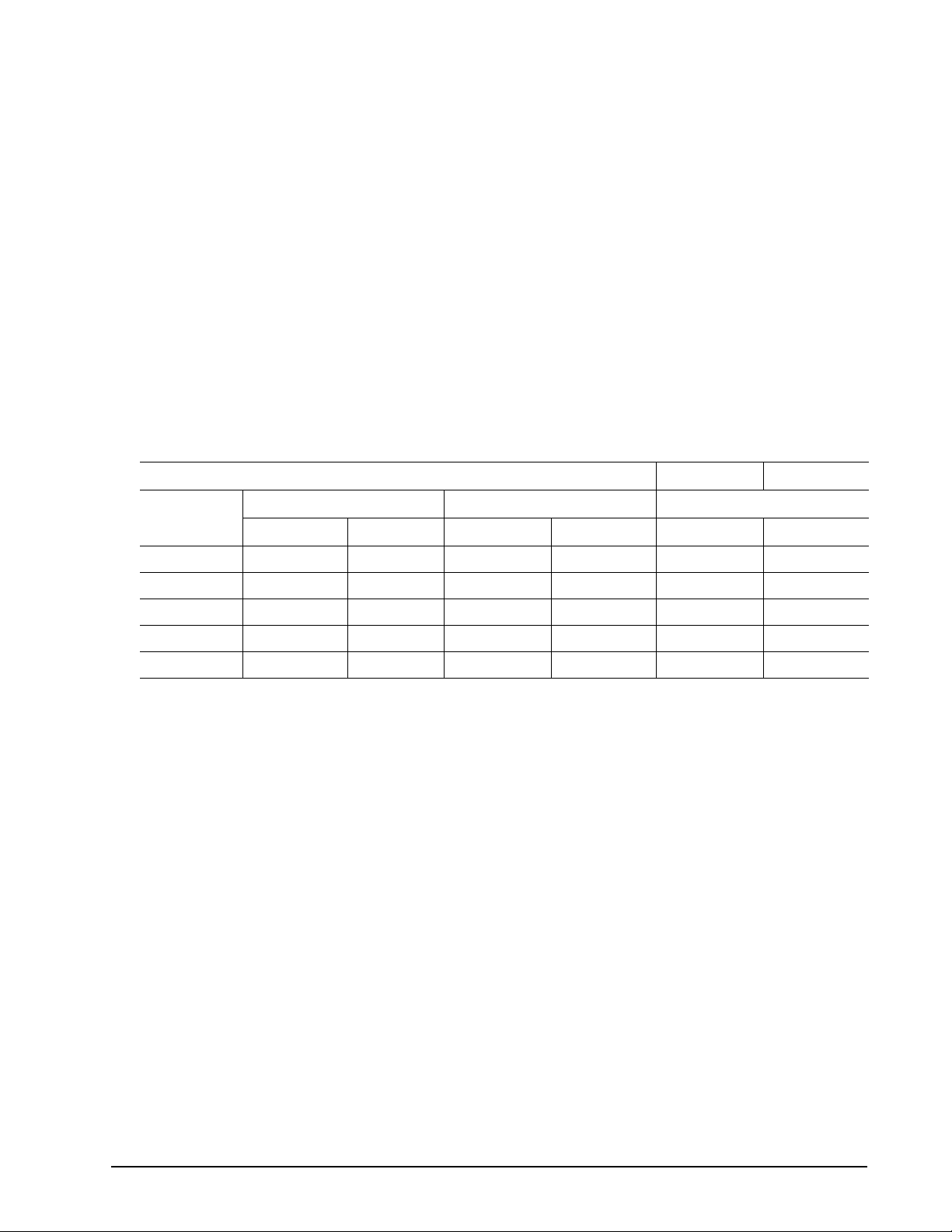

Capacity (Blocks)

ST3146854SS ST373454SS ST336754SS

Sector Size

Decimal Hex Decimal Hex Decimal Hex

512 286,749,488 11177330 143,374,744 88BB998 71,687,372 445DCCC

514 282,050,768 10CFC0D0 141,025,384 867E068 70,512,692 433F034

520 280,790,184 10BC84A8 140,395,092 85E4254 70,197,546 42F212A

522 279,041,740 10A1D6CC 139,463,602 8500BB2 68,914,176 41B8C00

524 275,154,368 106685C0 137,577,184 83342E0 68,766,592 4194B80

2. Se aga te dri ve s a ls o m ay be u se d at the max im um av ail ab le c apacit y at a given block size, but the excess

capacity above the gua rantee d l ev el wi ll v ar y between other drive fami li es an d from generation to genera

tion, depending on how eac h block size actually formats out for zo ne frequencies and splits over servo

bursts. This added capaci ty potent ial may range from 0.1 to 1.3 percent above th e guarant eed capacities

listed above. Us ing th e dr ives in th is mann er gi ves the ab so lute m aximu m capacity poten tial, but the user

must determine if the extra ca pacity potential is useful, or whether their assurance of backward and for

ward compatibility takes precedenc e.

3.6 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the

Mode Select (6) parameter list table in the SAS Interface Ma nual, part numb er 100293071. A value of z ero in

the Number of Blocks field indicates that the drive will not change the capacity it is currently formatted to have.

A number other than z er o a nd less tha n t he maximum number of L BA s in the Num ber of B lock s field c han ges

the tota l d rive capacity t o t he v al u e in t h e N umb er o f Bl o cks f ie l d. A v al u e gr ea t er t han t h e m ax im u m nu m be r of

LBAs is rounded down to the maximum capacity.

-

-

3.7 Factory-install ed accessories

OEM standard drives are shipped with the Cheetah 15K.4 SAS Installation Guide (part number 100350602).

Cheetah 15K.4 SAS Product Manual, Rev. B 9

3.8 Factory-install ed options

You may order the following items which ar e incorporated at the manufac turing facility during produ ction or

packaged before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shipping pack. The drive is normally shipped in bulk packaging to provide maximum protec tion

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

• The Cheetah 15K.4 SAS Installatio n Guid e, part numb er 1003 50602, is u suall y included with each standar d

OEM drive shipped, but extra copies may be ordered.

• The Safety and Regulatory Agency Specifications, part number 75789512, is usually included with each

standard OEM drive shipped, but extra copies may be ordered.

3.9 User-installed accessories

The following accessories are available. All kits may be installed in the field.

• Single-unit shipping pack.

10 Cheetah 15K.4 SAS Product Manual, Rev. B

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of

Cheetah drives.

4.1 Internal drive characteristics

ST3146854SS ST373454SS ST336754SS

Drive capaci ty 146.8 73.4 36.7 Gbytes (formatted, rounded off value)

Read/write data heads 8 4 2

Bytes per track 471,916 471,916 471,916 Bytes (average, rounded off values)

Bytes per surface 18,351 18,351 18,351 Mbytes (unformatted, rounded off value)

Tracks per surface (total) 50,864 50,864 50,864 Tracks (user accessible)

Tracks per inch 85,000 85,000 85,000 TPI

Peak bits per inch 628 628 628 KBPI

Internal data rate 685-1,142 685-1,142 685-1,142 Mbits/sec (variable with zone)

Disc rotation speed 15k 15k 15k rpm

Avg rotational latency 2.0 2.0 2.0 msec

4.2 Seek performance characteristics

See Section 9.4.1, "SAS physical interface" on page 57 and the SAS Interface Manual (part number

100293071) for additional timing details.

4.2.1 Access time

Not Including controller overhead

(msec)

Read Write

Average Typical 3.5 4.0

Single track Typical 0.2 0.4

Full stroke Typical 7.4 7.9

1. Typical access times are measured under nominal conditions of temperature, voltage, and horizontal orientation as measured on a representative sample of drives.

2. Access to data = access time + latency time.

1, 2

Cheetah 15K.4 SAS Product Manual, Rev. B 11

4.2.2 Format command execution time (minutes)

ST3146854SS ST373454SS ST336754SS

Maximum (with verify)

Maximum (without veri fy )

90 60 30

45 30 15

4.2.3 General performance characteristics

Minimum sect or interleave 1 to 1

Data buffer to/from disc media (one 512-byte logical block)*

Minimum 685 Mbits/sec

Maximum 1,142 Mbits/sec

SAS Interface maximum instantaneous transfer rate 300 Mbytes/sec* per port

Logical block sizes

Default is 512-byte data blocks

Variable 512 to 704 byt es per sector in even number of bytes per sector. If n (number

of bytes per sector) is odd, then n-1 will be used.

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact (for flaws reallocated at format time using

the spare sectors per sparing zone reallocation scheme.)

Average rotation al lat enc y 2.0 msec

*Assumes no errors and no relocated logical blocks. Rate measured from the start of the first logical block transfer to or

from the host.

(dual port = 600 Mbytes/sec*)

Negligible

4.3 Start/stop time

The drive accepts the comma nds list ed in the SAS Inte rface Man ual less than 3 seconds after DC power has

been applied.

If the drive receives a NOTIFY (ENABLE SPINUP) primitive through either port and has not received a START

STOP UNIT command with the START bit equal to 0, the drive becomes ready for normal operations within 20

seconds (excluding the error recovery procedure).

If the drive receives a START STOP UNIT command with the START bit equal to 0 before receiving a NOTIFY

(ENABLE SPINUP) primitive, the drive waits for a START STOP UNIT command with the START bit equal to 1.

After receiving a START STOP UNIT command with the START bit equal to 1, the drive waits for a N OTIFY

(ENABLE SPINUP) primit ive. After receiving a NOTIFY (ENA BLE SPINUP) primitive throu gh either port, the

drive becomes ready for normal operations within 20 seconds (excluding the error recovery procedure).

12 Cheetah 15K.4 SAS Product Manual, Rev. B

If the drive receives a START STOP UNIT command with the START bit and IMMED bit equal to 1 and d oes

not receive a NOTIFY (ENABL E SPINUP) primitive within 5 seco nds, the drive fails the START STOP UNIT

command.

The START STOP UNIT command may be used to command the drive to stop the spindle. Stop time is 30 seconds (maximum) from removal of DC power. There is no power control switch on the drive.

4.4 Prefetch/multi-segmented cache control

The drive provides a prefetch ( read look-ahead) and multi-se gmented cache control algori thms that in many

cases can enhan ce system performance. Cac he refers to the drive buffer stor age space when it is used in

cache operations . To select this feature, th e host sends the Mode Select command with the p roper values in

the applicable bytes in page 08h. Prefetch and cache operations are independent features from the standpoint

that each is enabled and dis abled indepe ndently using the Mode Select c ommand; however, in actual opera

tion, the prefetch feature overlaps cache operation somewhat as described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode paramete r values (Mode Page 08 h) for standard OEM versions of this

drive family are given in Table

9.3.2.1.

4.5 Cache operation

Note. Refer to the SAS Interface Manual for more detail concerning the cache bits.

Of the 8,192 kbytes p hysical buffer space in the dri ve, approximately 7,077 kbytes can be u sed as a cache.

The buffer can be divided into logical segments (using Mode Select Page 08h, byte 13) from which data is read

and to which data is written.

-

The drive keeps track of the logical block addresses of the data stor ed in each segment of the buffer. If the

cache is enabled (see RCD bit in the SAS Interface Manual

is retrieved from the buffer, if possible, before any disc access is initiated. If cache operation is not enabled, the

buffer (still segmented with the required number of segments) is still used, but only as circular buffer segments

during disc medium read oper ations (di sregardin g Prefetch oper ation for th e moment). That i s, the drive does

not check in the buffer segments for the requested read data, but goes directly to the medium to retrieve it. The

retrieved data merely passes throug h some buffer seg ment on the wa y to the hos t. On a c ache miss, all data

transfers to the host are in accorda nce with bu ffer-full ratio rules. On a c ache hit , the drive ig nores the bufferfull ratio rules. See the explanation provided with the information about Mode Page 02h (disconnect/reconnect

control) in the SAS Interface Manual.

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and the first logical block is already in the cache:

1. Drive transfers to the initiator the first logical block requested plus all subsequent contiguous logical blocks

that are already in the cache. This data may be in multiple segments.

2. Wh en a requested logical block is reached that is not in any cache se gment, the d rive fetches it and any

remaining requested lo gical b lock a ddres ses from th e disc and puts them in a seg ment o f the cache . The

drive transfers the r emaining requested logical blocks from t he cache to the host in a ccordance with the

Mode Select Disconnect/Reconnect parameters, page 02h.

3. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Case B—A Read command requests data, and the first logical block is not in any segment of the cache:

1. The drive fetc hes the req uested lo gical bloc ks from t he disc and transfers them int o a segme nt, and the n

from there to the host in accordance with the Mode Select Disconnect/Reconnect parameters, page 02h.

), data requested by the host with a read command

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Cheetah 15K.4 SAS Product Manual, Rev. B 13

During a prefetch, the drive cross es a cylinder boundary to fetc h data only if the Disco ntinui ty (DISC) bit is se t

to 1 in bit 4 of byte 2 of the Mode Select parameters page 08h. Default is zero for bit 4.

Each cache se gment is actually a s elf-contained circula r buffer whose length is an integer number of logical

blocks. The wrap-ar ound capability of the individual segm ents greatly enhances the cache’s overa ll perfor

mance, allowing a wide range of user-sele ctable configurations. The d rive supports operation of any integer

number of segments from 1 to 16. D ivide the 7 ,077 Kbyt es in the b uffer by the numbe r of seg ments to get the

segment size. Default is 3 segments.

Note. The size of eac h segment is not reported by Mode Sense command page 08h, bytes 14 and 15.

The value 0XFFFF is always reported regardless of the actual size of the segm ent . Se ndi ng a siz e

specification using the Mode Select command (byt es 14 and 15) does not set up a new segment

size. If the STRICT bit in Mode page 00h (byte 2, bit 1) is set to one , the driv e respon ds as it does

for any attempt to change an unchangeable parameter.

4.5.1 Caching write data

Write caching is a write operation by the drive th at mak es u se of a drive buffer storage ar ea wher e the da ta to

be written to the medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read cache hits. The s ame buffer space an d segme ntation is use d as set up for read func tions.

The buffer segmentation s cheme is set up or changed independently, having nothing to do with the state of

RCD. When a write command is issued, i f RCD=0, the cache is first checke d to see if any logical blocks tha t

are to be written are a lready stored in the cache f rom a previous read or write comman d. If there are, the

respective cache segments are cleared. The new data is cached for subsequent Read commands.

-

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the

segment is reached, the data is written into the beginning of the same cache segment, overwriting the data that

was written there at the beginning of the operation; however, the drive does not overwrite data that has not yet

been written to the medium.

If write caching is enabled (WCE=1), then the drive may return Good status on a write command after the data

has been transferred into the cache, but befor e the data has been written to the medium. If an error oc curs

while writing the data to the medium, and Good status has already been returned, a deferred error will be gen

erated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium.

Upon completion of a Synchronize Cache command, all data received from previous write commands will have

been written to the medium.

Table 9.3.2.1 shows the mode default settings for the drive.

4.5.2 Prefetch operation

If the Prefetch fea ture i s ena bl ed, data in co nti guo us lo gic al b lock s on t he d is c immediately beyond tha t whi c h

was requested by a Read c ommand are retrieved and stored in the buffer for immediate transfer from the

buffer to the host on subseque nt Read com mands that request t hose logica l block s (this is tr ue even if cache

operation is disabled). Though the prefetch operation uses the buffer as a cache, finding the requested data in

the buffer is a prefetch hit, not a cache operation hit.

To enable Prefetch, use Mod e Select page 08h, byte 12, bit 5 (Di sable Read Ahead - DRA bit). DRA bit = 0

enables prefetch.

-

Since data that is pr efetch ed r eplaces data alr eady in som e b uffer segmen ts, the ho st can limit the a mount o f

prefetch data to optimize system per formance. The Max Prefetch field (bytes 8 and 9) limits the amount of

prefetch. The drive does not use the Prefetch Ceiling field (bytes 10 and 11).

14 Cheetah 15K.4 SAS Product Manual, Rev. B

During a prefetch operation, the drive cros ses a cylinder boundary to fetch more data only if Mode paramete rs

page 08h, byte 2, bit 4 is set to 1 (Discontinuity--DISC bit).

When prefetch (read look -ahead) is enabled (enabled by DRA = 0), it opera tes under the control of ARLA

(Adaptive Read Look-Ahead). If the host uses software interleave, ARLA enables prefetch of contiguous

blocks from the disc when it senses that a prefetch hit will likely occur, even if two consecutive read operations

were not for physically co ntiguous blocks of data (e.g. “software interleave ”). ARLA disables pr efetch when it

decides that a prefetch hit will not likely occur. If the host is not using software interleave, and if two sequential

read operations are no t for c ontigu ous bloc ks of data, ARLA d isables prefetc h, but as long as se quentia l read

operations request contiguous blocks of data, ARLA keeps prefetch enabled.

4.5.3 Optimizing cache performance for desktop and server applications

Desktop and server applications require different drive caching operations for optimal performance. This

means it is difficult to provide a single configuration that meets both of these needs. In a desktop environment,

you want to con figure the cache to respond q uickly to repetitive ac cesses of multiple s mall segmen ts of data

without taking the time to “look ahea d” to the next conti guous segmen ts of data. In a server environ ment, you

want to configure the cac he to provide large volumes of seque ntial data in a non-repetitive manner. In this

case, the ability of the cache to “look ahead” to the next contiguous segmen ts of sequential data is a good

thing.

The Performance Mode (PM) bit contr ols the way the drive switches the cache buffer into different modes o f

segmentation. In “server mode” (PM bit = 0), the drive can dynamically cha nge the number of cache buffer

segments as needed to opt imize the performa nce, based on the command st ream from the hos t. In “desktop

mode” (PM bit = 1), the number of segments is maintained at the value defined in Mode Page 8, Byte 13, at all

times (unless changed by using a Mode Select command). For additional information about the PM bit, refer to

the Unit Attention Pa rameters page (00h) of the Mod e Sense command (1Ah) in the SAS Interface Manual,

part number 100293071.

Cheetah 15K.4 SAS Product Manual, Rev. B 15

16 Cheetah 15K.4 SAS Product Manual, Rev. B

5.0 Reliability specifications

The following reli ability specifica tions assume co rrect host and drive operational interfa ce, including al l interface timings, power supply voltages, environmental requirements and drive mounting constraints.

Seek error rate: Less than 10 errors in 108 seeks

Read Error Rates

Recovered Data Less than 10 errors in 1012 bits transferred (OEM default settings)

Unrecovered Data Less than 1 sector in 1015 bits transferred

Miscorrected Data Less than 1 sector in 1021 bits transferred

Interface error rate: Less than 1 error in 1012 bits transferred

Annualized Failure Rate (AFR): 0.62% (see section 5.2.1)

Service Life 5 years

Preventive maintenance: None required

1. Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated in accordance with this manual using DC p ower as defined in paragraph 6.2, "DC

power requirements."

• Errors caused by host system failures are excluded from error rate computations.

• Assume random data.

• Default OEM error recovery settings are applied. This includes AWRE, ARR E, full read retries, full write

retries and full retry time.

1

5.1.1 Recoverable Errors

Recovereable errors are those detected and corrected by the drive, and do not require user intervention.

Recoverable Data errors will use co rrection, although ECC on -the-fly is not c onsidered for purposes of recov-

ered error specifica tio ns.

Recovered Data error rate is determine d using read bits transfer red for recove rable errors occurring dur ing a

read, and using write bits transferred for recoverable errors occurring during a write.

5.1.2 Unrecoverable Erro rs

An unrecoverable data erro r is defined as a fail ure of the drive to rec over data from the me dia. These errors

occur due to head/medi a or write problems . Unrecoverable data errors are only detected du ring read opera

tions, but not caused by the r ead. If an unrec overable data erro r is detected, a ME DIUM ERROR (03 h) in the

Sense Key will be reported. Multiple unrecoverable data errors resulting from the same cause are treated are 1

error.

Cheetah 15K.4 SAS Product Manual, Rev. B 17

-

5.1.3 Seek errors

A seek error is defined as a fail ur e of the dr i ve to pos it ion the heads to the addressed track. After detecting an

initial seek error, the drive automatically performs an error recovery process. If the error recovery process fails,

a seek positioning error (Error code = 15h or 02h) will be reporte d with a Hardware error (04h) in t he Sense

Key. Recoverab le seek er rors are sp ecifi ed at Less than 10 erro rs in 10

8

seeks. Unrecoverable seek errors

(Sense Key = 04h) are classified as drive failures.

5.1.4 Interface errors

An interface error is defin ed as a failure of the receiver on a port to recover the d ata as transmitted by the

device port connected to the receiver. The error may be detected as a running disparity error, illegal code, loss

of word sync, or CRC error.

5.2 Reliability and service

You can enhance the r eliability of Cheetah disc drives by ensuring that the drive recei ves adequate cooling.

Section 6.0 provides te mperature mea surements and othe r informatio n that may be used to en hance the service life of the drive. Section 8.2 provides recommended air-flow information.

5.2.1 Annualized Failure Rate (AFR)

The production disc dr ive shall achieve an AFR of 0.62% when oper ated in an environmen t that ensures the

HDA case temperatur es spec ified in Sectio n 6. 4 are not exce eded. S hort -term ex cursi ons u p to th e spec ification limits of the operating e nvironment will not affect AFR perfor mance. Continual or sustained operation at

case temperatures above the values shown in Section 6.4.1 may degrade product reliability.

Estimated power-on operation hours means power-up hours per disc drive times the total number of disc

drives in service. Ea ch dis c drive shall h ave accu mulate d at le ast nine months of operatio n. Data sha ll be ca lculated on a rolling average base for a minimum period of six months.

AFR is based on the following assumption s:

• 8,760 power-on hours per year.

• 250 average on/off cycles per year.

• Operations at nominal voltages.

• Systems will provide adequa te cooling to ensure the case temper atures specified in Section 6.4.1 are not

exceeded.

Drive failure means any stoppage or substandard performance caused by drive malfunction.

A S.M.A.R.T. predictive fail ure indic ates that the dri ve is deter iorating to an immin ent failu re and is co nside red

an AFR hit.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

5.2.3 Hot plugging the drive

When a disc is powered on by switchin g the powe r or hot plugged, the drive run s a self test befor e attemp ting

to communicate o n its’ interfaces. When the self test co mpletes successfull y, the drive initiates a Link R eset

starting with OOB. An attached devic e should respond to the link rese t. If the link reset attempt fails, or any

time the drive looses sync, the drive initiated l ink reset. The drive will i nitiate link reset once p er second but

alternates between por t A and B. Therefor e each port will atte mpt a link reset on ce per 2 seconds assuming

both ports are out of sync..

If the self-test fails, the does not respond to link reset on the failing port.

18 Cheetah 15K.4 SAS Product Manual, Rev. B

Note. It is the respon si bi li ty o f the sy s tems in tegrator to assure that no tem per atu re, energy, voltage haz-

ard, or ESD potential haza rd is presented dur ing the hot connect/di sconnect oper ation. Discharge

the static electricity from the drive carrier prior to inserting it into the system.

Caution. The drive motor must come to a complete stop prior to changing the plane of operation. This time is

required to insure data integrity.

5.2.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Se lf-Moni toring Analy sis and Repor ting Technology. This technology is intende d

to recognize conditio ns that indicate imminent drive failure and is desig ned to provide sufficient warn ing of a

failure to allow you to back up the data before an actual failure occurs.

Note. The drive’s firmware monitors specific attributes for degradation over time but can’t predict instanta-

neous drive failures.

Each monitored a ttrib ute has b een sele cted to moni tor a specifi c se t of fai lure c onditi ons in th e oper ating per formance of the drive and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions

Control mode page (1Ch). Use th e DEXCPT bit to ena ble or disab le the S.M.A.R. T. feature. Se tting the DE X

CPT bit disables all S.M.A.R.T. functions. When enabled, S.M.A.R.T. collects on-line data as the drive performs

normal read and write operations. When the PERF bit is set, the drive is consi dered to be in “On-line Mod e

Only” and will not perform off-line functions.

-

You can measur e off-line attributes a nd force the dri ve to save the data by using the Rez ero Unit command .

Forcing S.M.A.R.T. resets the timer so that the next scheduled interrupt is in two hours.

You can interrogate the drive through the host to determine the time remaining before the next scheduled measurement and data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E.

This allows you to c ontrol when S.M.A.R.T. interruptions occ ur. Forcing S.M.A.R.T. with the RTZ command

resets the timer.

Performance impact

S.M.A.R.T. attribute data is saved to the disc so that the events that caused a predi ctive failure can be recreated. The drive measures and saves paramete rs once every two hour s subject to an idle pe riod on the drive

interfaces. The pro cess o f meas uring off-line attribute data a nd sa ving data to th e disc is u ninterr uptable. Th e

maximum on-line only processing delay is summarized below:

Maximum processing delay

S.M.A.R.T. delay times

On-line only delay

DEXCPT = 0, PERF = 1

50 milliseconds

Fully-enabled delay

DEXCPT = 0, PERF = 0

300 milliseconds

Cheetah 15K.4 SAS Product Manual, Rev. B 19

Loading...

Loading...