Page 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Barracuda 2, 2HP Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST12450W/WD

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Product Manual, Volume 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Page 2

Page 3

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Barracuda 2, 2HP Disc Drive

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

ST12450W/WD

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Product Manual, Volume 1

○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○○

Page 4

© 1994 Seagate Technology, Inc. All rights reserved

Publication number: 83328900, Rev. B

October 1995

Seagate®, Seagate Technology®, and the Seagate logo are registered

trademarks of Seagate Technology, Inc. Barracuda™ is a trademark of

Seagate Technology, Inc. Other product names are registered trademarks

or trademarks of their owners.

Seagate reserves the right to change, without notice, product offerings or

specifications. No part of this publication may be reproduced in any form

without written permission from Seagate Technology, Inc.

Page 5

Revision status summary sheet

Sheets

Revision Date Writer/Engineer Affected

A (preliminary-01) 1/25/94 L. Newman/J. Olson All

A (preliminary-02) 2/15/94 L. Newman/J. Olson All

A 3/29/94 L. Newman/J. Olson All

B 10/3/95 L. Newman/J. Olson 8, 14, 15, 19, 24, 25,

26, 27, 29, 30, 32, 43,

44, 49, 51, 52, 53, 55,

60

Note. Product Manual 83328900 is Volume 1 of a two-volume

document with the SCSI interface information in the

SCSI-2 Interface Product Manual,

Part Number 77738479.

Volume 2

Page 6

Page 7

ST12450W/WD Product Manual, Rev. B v

Contents

1.0 Scope ................................................................................................................................. 1

2.0 Applicable standard and reference documentation ....................................................... 3

2.1 Standards ..................................................................................................................... 3

2.2 Applicable reference documents................................................................................... 3

3.0 General description........................................................................................................... 5

4.0 Standard features.............................................................................................................. 7

4.1 Performance ................................................................................................................. 7

4.1.1 Reliability............................................................................................................. 7

4.2 Unformatted and formatted capacities .......................................................................... 8

4.3 Options ......................................................................................................................... 8

4.4 Installation..................................................................................................................... 9

5.0 Performance characteristics ............................................................................................ 11

5.1 Internal drive characteristics ......................................................................................... 11

5.2 SCSI seek performance characteristics ........................................................................ 11

5.2.1 Seek time ............................................................................................................ 13

5.2.2 Format drive command execution time................................................................ 13

5.3 General performance characteristics ............................................................................ 14

5.4 Start/stop time............................................................................................................... 15

5.5 Prefetch/multi-segmented cache control ....................................................................... 15

5.5.1 Adaptive read lookahead..................................................................................... 16

5.6 Caching write data ........................................................................................................ 17

5.7 Synchronized spindle operation .................................................................................... 17

6.0 Reliability specifications................................................................................................... 21

6.1 Error rates..................................................................................................................... 21

6.1.1 Environmental interference.................................................................................. 21

6.1.2 Write errors ......................................................................................................... 21

6.1.3 Seek errors ......................................................................................................... 22

6.2 Reliability and service ................................................................................................... 22

6.2.1 Mean time between failures (MTBF).................................................................... 22

6.2.2 Air flow ................................................................................................................ 22

6.2.3 Preventive maintenance...................................................................................... 26

6.2.4 Service life........................................................................................................... 26

6.2.5 Service philosophy .............................................................................................. 26

6.2.6 Installation ........................................................................................................... 26

6.2.7 Service tools........................................................................................................ 26

6.2.8 Hot plugging Barracuda 2, 2HP disc drives ......................................................... 26

Page 8

vi ST12450W/WD Product Manual, Rev. B

7.0 Physical/electrical specifications ................................................................................... 29

7.1 AC power requirements ............................................................................................ 29

7.2 DC power requirements ............................................................................................ 29

7.2.1 Conducted noise immunity ............................................................................ 30

7.2.2 Power sequencing ......................................................................................... 30

7.2.3 12V current profile ......................................................................................... 31

7.3 Heat/power dissipation.............................................................................................. 32

7.4 Environmental limits.................................................................................................. 32

7.4.1 Temperature.................................................................................................. 32

7.4.2 Relative humidity ........................................................................................... 32

7.4.3 Effective altitude (sea level) ........................................................................... 32

7.4.4 Shock and vibration ....................................................................................... 33

7.4.5 Air cleanliness ............................................................................................... 34

7.4.6 Acoustics ....................................................................................................... 34

7.5 Electromagnetic compatibility.................................................................................... 34

7.6 Mechanical specifications ......................................................................................... 35

7.6.1 Drive orientation ............................................................................................ 36

7.6.2 Cooling .......................................................................................................... 36

8.0 Media characteristics ...................................................................................................... 37

8.1 Media description...................................................................................................... 37

9.0 Defect and error management ........................................................................................ 39

9.1 Defects and errors .................................................................................................... 39

10.0 Option/configuration headers......................................................................................... 41

10.1 Drive ID/option select headers .................................................................................. 41

10.2 Synchronized spindles interface ............................................................................... 44

10.2.1 Electrical description...................................................................................... 44

10.3 Grounding ................................................................................................................. 45

11.0 Interface requirements .................................................................................................... 47

11.1 General description ................................................................................................... 47

11.2 SCSI interface messages supported......................................................................... 47

11.3 SCSI interface commands supported........................................................................ 48

11.3.1 Inquiry data.................................................................................................... 50

11.3.2 Mode sense data ........................................................................................... 50

11.4 SCSI bus conditions and miscellaneous features supported ..................................... 53

11.5 Synchronous data transfer ........................................................................................ 54

11.5.1 Synchronous data transfer periods supported .............................................. 54

11.5.2 REQ/ACK offset............................................................................................ 54

11.6 DC cable and connector ........................................................................................... 54

Page 9

ST12450W/WD Product Manual, Rev. B vii

11.7 SCSI physical interface ............................................................................................. 55

11.7.1 Physical characteristics ................................................................................ 55

11.7.2 Connector requirements ............................................................................... 56

11.7.3 Electrical description ..................................................................................... 56

11.8 SCSI wide physical interface..................................................................................... 61

Index .......................................................................................................................................... 67

Figures

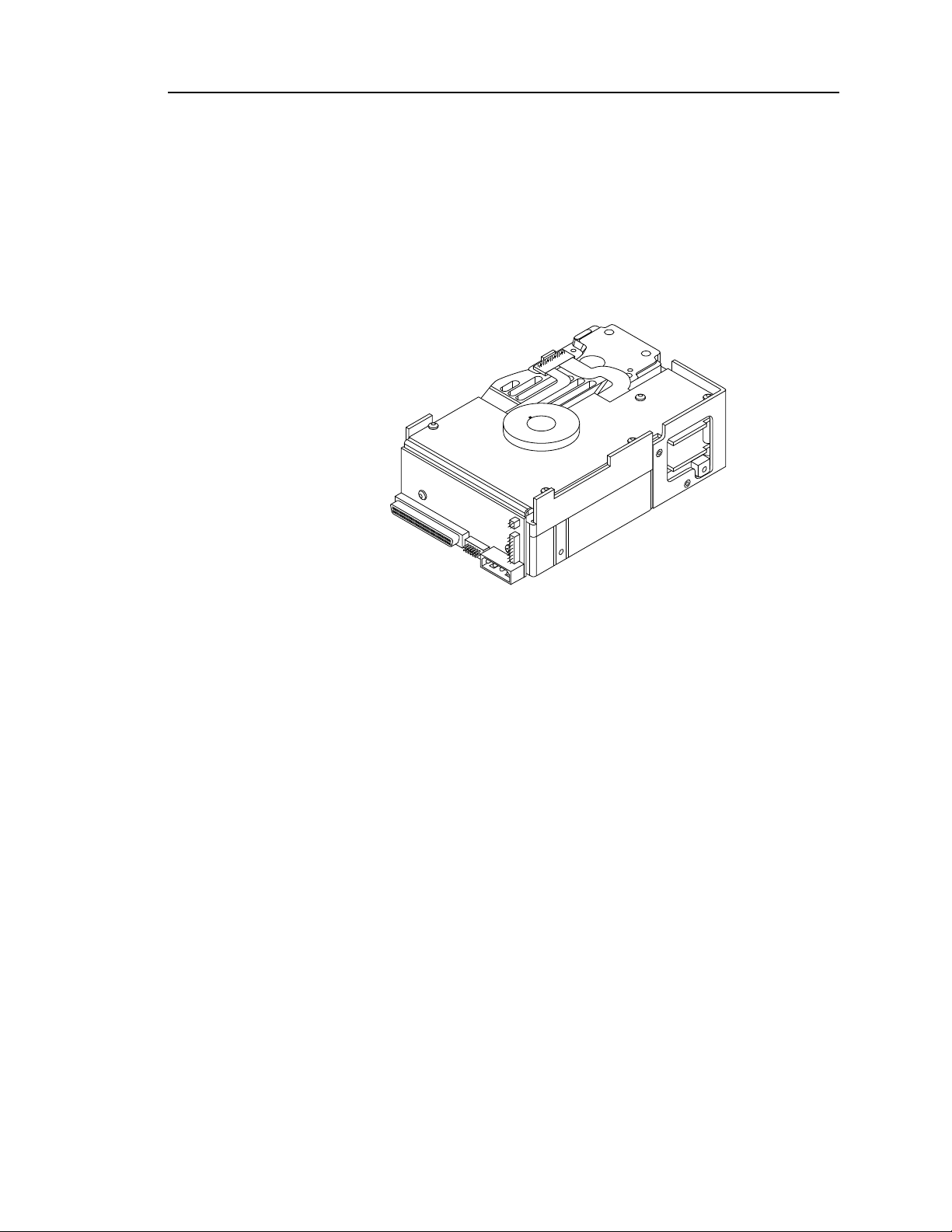

Figure 1. Barracuda 2, 2HP disc drive ...................................................................................... 1

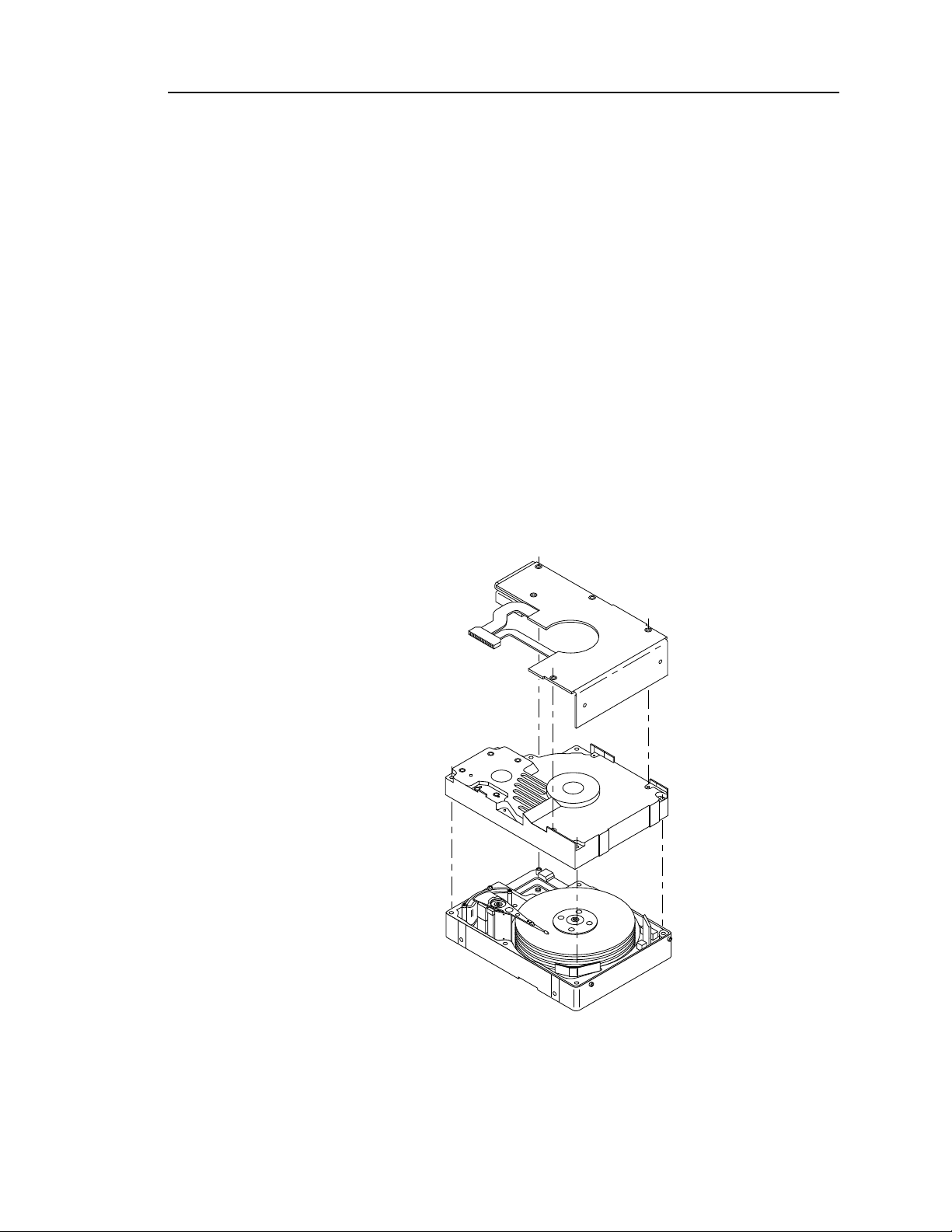

Figure 2. Barracuda 2, 2HP disc drive (exploded view) ............................................................ 5

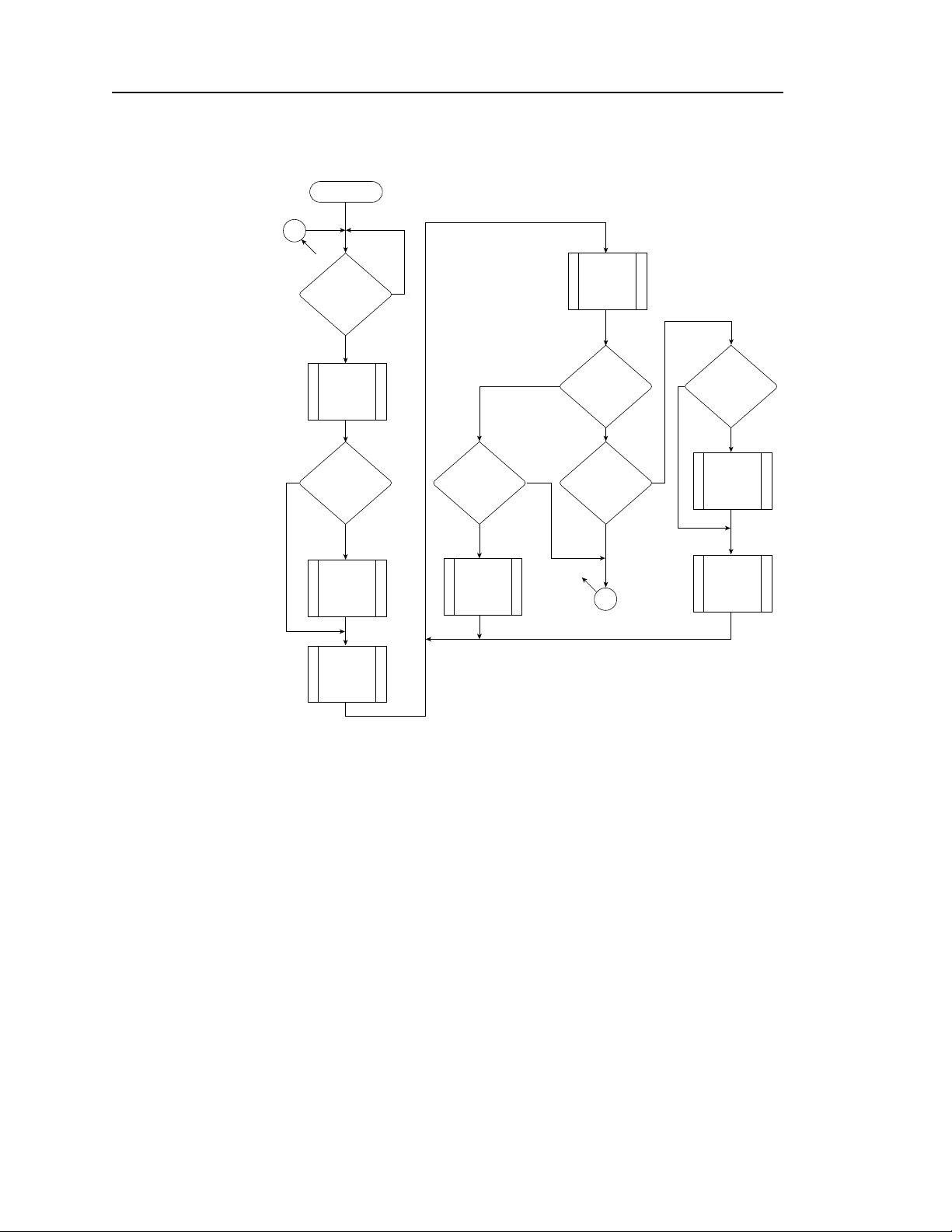

Figure 3. OEM interruptible thermal calibration implementation ................................................ 12

Figure 4. Synchronized drive interconnect diagram .................................................................. 17

Figure 5. Synchronized reference signal characteristics........................................................... 18

Figure 6. Air flow....................................................................................................................... 23

Figure 7. GYHX temperature measurement locations .............................................................. 24

Figure 8. RYGX temperature measurement locations .............................................................. 25

Figure 9. Temperature measurement location .......................................................................... 25

Figure 10. Typical Barracuda 2, 2HP drive +12V current profile ................................................. 31

Figure 11. Mounting configuration dimensions............................................................................ 35

Figure 12. Recommended mounting........................................................................................... 36

Figure 13. Barracuda 2, 2HP drive physical interface ................................................................. 41

Figure 14. Barracuda drive ID and option select headers ........................................................... 42

Figure 15. SCSI reference index signal driver/receiver combination........................................... 44

Figure 16. J5 configuration select header specification............................................................... 45

Figure 17. Barracuda 2, 2HP physical interface.......................................................................... 55

Figure 18. Single-ended transmitters and receivers.................................................................... 57

Figure 19. Typical differential I//O line transmitter/receiver and terminators................................ 59

Figure 20. Wide SCSI device connector ..................................................................................... 61

Page 10

Page 11

ST12450W/WD Product Manual, Rev. B 1

1.0 Scope

This manual describes Seagate Technol ogy®, Inc. Barracuda™ 2, 2HP

(2 head parallel) disc drives.

Barracuda drives support the Small Computer System Interface-2 (SCSI-

2) as described in the ANSI SCSI and SCSI-2 interface specifications to the

extent described in this manual. This manual defines the performance

characteristics of the Barracuda 2, 2HP drives. The

Pr oduct Manual

characteristics of this and other families of Seagate drives.

(part number 77738479) describes general SCSI interface

SCSI-2 Interface

Figure 1. Barracuda 2, 2HP disc drive

Page 12

Page 13

ST12450W/WD Product Manual, Rev. B 3

2.0 Applicable standard and

reference documentation

Seagate takes all reasonable steps to insure that its products are certifiable

to currently accepted standards. Typical applications of these disc drives

include customer packaging and subsystem design.

Safety agencies conditionally certify component parts, such as the Barracuda disc drive, based on their final acceptability in the end-use product. The

subsystem designer is responsible for meeting these conditions of acceptability in obtaining safety/regulatory agency compliance in their end-use

product and certifying where required by law.

2.1 Standards

The Barracuda disc drive is a UL recognized component per UL1950, CSA

certified to CSA C22.2 No. 950-M89, and VDE certified to VDE 0805 and

EN60950.

The Barracuda disc drive is supplied as a component part. It is the responsibility of the subsystem designer to meet EMC/regulatory requirements.

Engineering test characterizations of radiated emissions are available from

the Seagate safety department.

2.2 Applicable reference documents

Barracuda 2, 2HP Installation Guide

Seagate part number: 83328890

SCSI-2 Interface Product Manual (volume 2)

Seagate part number: 77738479

ANSI small computer system interface (SCSI) documents

ANSI X3.131-1986 (SCSI-1)

X3T9.2/86-109 Rev. 10H (SCSI-2)

X3T9.2/91-010 Rev. 10 (SCSI-3) Parallel Interface

In case of conflict between this document and any referenced document, this

document takes precedence.

Page 14

Page 15

ST12450W/WD Product Manual, Rev. B 5

3.0 General description

Barracuda drives are low-cost, high-performance, random-access storage

devices designed to meet the needs of the original equipment manufacturer

(OEM) marketplace.

The Barracuda 2, 2HP drive has two read/write channels on the circuit board.

The SCSI-2 controller chip is modified to process data for two read/write

channels at once. This technology effectively doubles the internal data

transfer rate when compared to a conventional Barracuda 2 disc drive.

The Barracuda drive’s interface supports multiple initiators, disconnect/

reconnect, self-configuring host software, and automatic features that relieve the host from knowing the physical characteristics of the targets (logical

block addressing is used).

The head and disc assembly (HDA) is environmentally sealed at the factory.

Air circulates within the HDA through a non-replaceable filter to maintain a

contamination-free HDA environment.

Refer to Figure 2 for an exploded view of the drive. This exploded view is for

information only—never disassemble the HDA and do not attempt to service

items in the sealed enclosure (heads, media, actuator, etc.) as this requires

special facilities. The drive contains no replaceable parts. Opening the HDA

voids your warranty.

Figure 2. Barracuda 2, 2HP disc drive (exploded view)

Page 16

6 ST12450W/WD Product Manual, Rev. B

Barracuda drives use a dedicated landing zone at the innermost radius of the

media to eliminate the possibility of destroying or degrading data by landing

in the data zone. The drive automatically goes to the landing zone when the

power is removed.

An automatic shipping lock prevents potential damage to the heads and

discs that results from movement during shipping and handling. The shipping

lock disengages when power is applied to the drive and the head load

process begins.

Barracuda drives decode track 0 location data from the dedicated servo

surface to eliminate mechanical transducer adjustments and relate d r eliability concerns.

A high-performance actuator assembly with a low-inertia, balanced, patented, straight-arm design provides excellent performance with minimal

power dissipation.

Page 17

ST12450W/WD Product Manual, Rev. B 7

4.0 Standard features

Barracuda 2, 2HP drives have the following standard features:

• 2 head parallel technology

• Integrated SCSI controller

• Single-ended or differential SCSI drivers and receivers

• Asynchronous and synchronous data-transfer protocols

• Firmware downloadable using a SCSI interface

• Selectable sector size from 180 to 4,096 bytes per sector

• Programmable sector-reallocation scheme

• Flawed sector reallocation at format time

• Programmable auto-write and auto-read reallocation

• Reallocation of defects on command (post format)

• 96-bit Reed-Solomon error-correction code

• Sealed head and disc assembly (HDA)

• No preventive maintenance or adjustments required

• Dedicated head-landing zone

• Automatic shipping lock

• Automatic thermal compensation

• Embedded Grey Code track address to eliminate seek errors

• Self-diagnostics performed at power-on

• 1:1 interleave

• Zone bit recording (ZBR)

• Vertical, horizontal, or top-down mounting

• Dynamic spindle brake

• Permanently mounted IC terminators (ST12450W models only)

• 1,024 Kbyte data buffer (see Section 5.5)

4.1 Performance

• Simultaneously processes data for two read/write channels (heads)

• Programmable multi-segmentable cache buffer

• 7,200 RPM spindle; average latency = 4.17 msec

• Command queuing of up to 64 commands

• Background processing of queue

• Supports start and stop commands

• Provides synchronized spindle capability

• Low audible noise for office environment

• Low power consumption

4.1.1 Reliability

• 500,000 hour MTBF

• Adaptive seek velocity; improved seek performance

• LSI circuitry

• Balanced low-mass rotary voice-coil actuator

Page 18

8 ST12450W/WD Product Manual, Rev. B

4.2 Unformatted and Formatted Capacities

Standard OEM models are formatted to have 512-byte sectors.

ST12450 drives have nine (9) spare sectors per cylinder and one (1) spare

cylinder per unit.

Formatted Unformatted

1,849 Mbytes 2,437 Mbytes

Users having the necessar y equipment may modify t he data block size

before issuing a format command to obtain different formatted capacities.

User-available capacity also depends on the spare reallocation scheme

selected . See the Mode Sel ect command and the Fo rmat comm and in the

SCSI-2 Interface Product Manual

(part number 77738479).

4.3 Options

The capacity shown in Section 4.2 is normally provided. Other capacities

can be ord ered depend ing on the spar ing scheme an d sector size requested.

The following options are incorporated at the time of production or are

available separately.

• Front panel (green lens), part number 70869751

The standard front panel is black plastic. You may order other colors. Each

panel has a single rectangular green LED indicator lens that, when

glowing, indicates the drive is selected.

•

Barracuda 2, 2HP Installation Guide,

This manual provides basic information on the care and handling of

Winchester disc peripherals in general. Some drive installation information is included to assist those persons not familiar with the produc t. It

also includes basic information to assist in obtaining service for the drive.

• Single-unit shipping pack kit

The drive is shipped in bulk packaging to provide maximum protection

against transit damage. Units shipped individually require additional

prot ection as provided by the single-unit shi pping pack.

• Adapter accessory frame kit, part number 75790701

This kit contains the frame to allow a 3.5-inch drive to be mounted in

a 5.25-inch drive bay. It includes mounting hardware, front panel with a

green lens, an LED with cable that connects to the remote LED connector,

and installation instructions.

part number 83328890

Page 19

ST12450W/WD Product Manual, Rev. B 9

4.4 Installation

For option jumper locations and definitions refer to Figure 14. Drive default

mode parameters are not normally needed for installation. Refer to

Section 11.3.2 for default mode parameters if you need them.

• Ensure that the SCSI ID of the drive is not the same as the host adapter.

• If multiple devices are on the bus, set the drive’s SCSI ID to one that is not

presently used by other devices on the bus.

• If the drive is the only device on the bus, attach it to the end of the SCSI bus

cable. Internal termination is available on single-ended (ST12450W)

drives by enabling this feature with a jumper (see Figure 14). External

terminators are required for differential (ST12450WD) drives. These

external terminators m ust be prov ided by the user , sy stems int egrator , or

host equipment manufacturer.

• If you attach the drive to a bus that contains other devices, and the new

drive is not attached to the end of the bus, remove termination from the new

drive.

• Set all approp riat e optio n jump ers prio r to ap plying po we r to th e driv e. If

you change j umpers after applying power, recycle the drive’s power to

make th e new settings eff ecti v e .

Formatting

• It is not necessary to low-level format this drive. The drive is shipped from

the factory low-level formatted in 512-byte sectors.

• Reformat the drive if:

a. You select a different sector size.

b. You select a different spare-sector allocation scheme.

Page 20

Page 21

ST12450W/WD Product Manual, Rev. B 11

5.0 Performance characteristics

This section provides performance-related characteristics and features of

Barracuda 2, 2HP drives.

5.1 Internal drive characteristics

Drive capacity, Mbytes unformatted 2,437

Read/write data heads, maximum (physical) 18

Read/write data heads, maximum (logical) 9

Bytes per track, average bytes 99,536

Bytes per surface, Mbytes unformatted 271.4

Cylinders/tracks per surface, user accessible 2,710

Tracks per inch 3,047

Bits per inch 52,187

Servo heads 1

Internal data rate per physical head, Mbits/sec, 34.3 to 56.5

variable with zone

Internal data rate per logical head, Mbits/sec, 68.6 to 113.0

variable with zone

Disc rotation speed 7,200 ± 0.5%

Average rotational latency, msec 4.17

5.2 SCSI seek performance characteristics

All performance charact eristics assume that automatic adaptive thermal

compensation is not in process when the drive receives the SCSI command.

Automatic adaptive thermal compensation will not interrupt an active SCSI

comma n d. If ad apt i ve ther mal c ompensa ti on i s in pr oce ss whe n a SCSI

command is received, the command is queued until the compensation for

the specific head bei ng compensated completes. When compensation

completes for the specific head being compensated, the first queued SCSI

command executes. When execution of the first queued command is

complete, the drive continues the compensation for the remaining head(s).

The above procedure continues until compensation for all heads has

completed, or until 10 mi nutes have elapsed. The drive initiates an automatic adaptive thermal compensation cycle once on power-up before

completing its initialization sequence and then once after 1 minute from the

end of initialization. After this, the drive initiates an automatic adaptive

thermal compensation cycle approximately once every 10 minutes. Noninterruptible automatic thermal compensation occurs at other times but

should be transparent to the user (e.g., during format, Re-zer o command,

at spindle-up, during read-error recovery, and during reassign-block functions) . You can use the R e-ze ro command t o r eset the t hermal compens ation timer back to its start so that the host knows when the interruption for

thermal compensation will occur.

Page 22

12 ST12450W/WD Product Manual, Rev. B

Refer to Section 11.8 and to the

SCSI-2 Interface Product Manual

number 77738479) for additional timing details.

Start

A

Has

10 min.

No

timer

expired?

Set

10 minute

timer

Is

SCSI

command in

progress?

Complete

Command

Yes

Yes

No

All

heads

calibrated?

No

Select

next

head

No

Yes

received a SCSI

command?

calibrated?

TCAL

head

Has

target

All

heads

A

Yes

Yes

No

No

(part

Has

target

received a SCSI

command?

Yes

Target

completes

SCSI

command

Seek to

TCAL cyl

and select

next head

Seek to

TCAL cyl

and select

head zero

Figure 3. OEM interruptible thermal calibration implementation

Page 23

ST12450W/WD Product Manual, Rev. B 13

5.2.1 Seek time

Drive level Drive including

Barracuda controller overhead

msec without disconnect

read write read write

Average typical* 8.0 9.0 9.0 10.0

Single track typical* 0.6 0.9 1.6 1.9

Full stroke typical* 17 19 18.0 20.0

*Typical seek values ar e measured under nominal condi tions o f temper a-

ture, voltage, and horizontal orientation on a representative sample of

drives.

5.2.2 Format drive command execution time

≥≥

for

≥ 512-byte sectors

≥≥

Maximum (with verify) 18 minutes

Maximum (without verify) 12 minutes

Page 24

14 ST12450W/WD Product Manual, Rev. B

5.3 General performance characteristics

Minimum sector interleave 1 to 1

Data buffer to/from disc media (512-byte sector)

Data transfer rate (≤ 1 sector)

Minimum 8.56 Mbytes/sec*

Maximum 14.11 Mbytes/sec*

Data transfer rate (< 1 track)

Minimum 6.2 Mbytes/sec*

Maximum 10.3 Mbytes/sec*

SCSI interface data

Asynchronous transfer rate Asynchronous*

Maximum instantaneous 10.0 Mbytes/sec**

Sector sizes

Default 512-byte data blocks

Variable in even-sector sizes 180 to 4,096 bytes

Synchronous transfer rate, 2 bytes wide 5.0 to 20 Mbytes/sec

Read/write consecutive sectors on a track Yes

Flaw reallocation performance impact Negligible

(for flaws reallocated using the spare

sectors per track reallocation scheme)

Flaw reallocation performance impact Negligible

(for flaws reallocated using the spare

sectors per cylinder reallocation scheme)

Flaw reallocation performance impact 35 msec (typical)

(for flaws reallocated using the spare

tracks per volume reallocation scheme)

Overhead time for head switch 0.7 msec

Overhead time for one-track cylinder switch 1.6 msec (typical)

Average rotational latency 4.17 msec

* Rate measured from the start of the first sector transfer to or from the host.

**Assumes s ystem abi lity to support 5.0 Mbytes/s ec, 2 bytes wid e, and no

cable loss.

Page 25

ST12450W/WD Product Manual, Rev. B 15

5.4 Start/stop time

Disabling the Motor Start option causes the drive to become ready within 30

seconds after DC power is applied at nominal voltage. This means the motor

starts as soon as power is applied. If a recoverable error condition is detected

during the start sequence, the drive will execute a recovery procedure and

may cause the time to become ready to exceed 30 seconds. During this time

the drive responds to some commands over the SCSI interface. Stop time is

less than 30 seconds (maximum) from removal of DC power.

Enabling the Motor Start option causes the internal controller to accept the

commands listed in the

than 3 seconds after applying DC power. After receiving the Motor Start

command, the drive becomes ready for normal operations within 30 seconds

(excluding error recovery procedure). The Motor Start command can also be

used to command the drive to stop the spindle (see the Start/Stop command

information in the

There is no power control switch on the drive.

SCSI-2 Interface Product Manual

SCSI-2 Interface Product Manual).

(77738479) less

5.5 Prefetch/multi-segmented cache control

The drive provides a prefetch/multi-segmented cache algorithm, which in

man y c ase s e nhan ces sys tem perf orma nce . T o sele ct th is f ea ture, the host

sends the Mode Select command with the proper values in the applicable

bytes in page 08h (see the

prefetch and cache operation enabled.

SCSI-2 Interface Product Manual).

Default is

Of the 1,024 Kbytes physical buffer space, approximately 960 Kbytes can be

used as a cache. The cache can be divided into logical segments from which

data is read and to which data is written.

The drive keeps track of the logical block addresses of the data stored in each

segment of the cache. If the cache is enabled (see RCD bit, Table 5.2.1-27

in the

SCSI-2 Interface Product Manual),

read command is retrieved from the cache before any disc access is initiated.

Data in contiguous logical blocks immediately beyond that requested by the

Read command can be retrieved and stored in the cache for immediate

transfer to the initiator on subsequent read commands. This is referred to as

the prefetch operation. Since data that is prefetched may replace data

already in the cache segment, an initiator can limit the amount of prefetch

data to optimize system performance. The drive never prefetches more

sectors than the number specified in bytes 8 and 9 of Mode page 08h (see

the

SCSI-2 Interface Product Manual).

Kbytes of the buffer are used as a circular buffer for read/writes, with no

prefetch operation and no segmented cache operation.

The following is a simplified description of the prefetch/cache operation:

Case A. A read command is received and the first logical block is already in

the cache.

1. The drive transfers to the initiator the first logical block requested plus all

subsequent contiguous logical blocks that are already in the cache. This

data may be in multiple segments.

data requested by the host with a

If the cache is not enabled, 960

Page 26

16 ST12450W/WD Product Manual, Rev. B

2. When a re quest ed logica l block is rea ched that is not in an y s egment,

the d rive fetches i t and any r emaining re quested logi cal block a ddresses

from the d isc and p uts them in a se gment of the cache. The drive

transfers the remaining requested logical blocks from the cache t o the

initiator in accordance with the “buffer-full” ratio specification given in

Mode Select Disconnect/Reconnect parameters, page 02h (see the

SCSI-2 Int erfac e Pr o duct Man ual

3. The drive prefetches additional logical blocks contiguous to those

transferred in step 2 above and stores them in the segment. The drive

stops filling the segment when the maximum prefetch v alue has been

transferred (s ee the

Case B. A read command is received and the first logical block address

requested is not in any segment of the cache.

1. The drive fetches the requested logical blocks from the disc and

transfers them into a segment, then from there to the initiator in

accordance with the “buffer-full” ratio specification given in Mode Select

Disconnect/Reconnect parameters, page 02h (see the

face Pr oduct Manual

2. The drive prefetches additional logical blocks contiguous to those transferred in Case A, step 2 above and stores them in the segment. The drive

stops filling the segment when the maximum prefetch value has been

transferred.

SCSI-2 Inter fac e Pr oduct Manual

).

).

).

SCSI-2 Inter-

During a prefetch, the drive crosses a cylinder boundary to fetch data only

if the Discontinuity (DISC ) bit is set to 1 in bit 4 of byte 2 of the Mode Select

parameters page 8h. Default is zero for bit 4 (see the

Pro duct Manual

Each cache segment is ac tually a self-c ontained circular buffer whose

length is an integer number of sectors. The wrap-around capability of the

individual segments greatly enhance s the cache’s overall performance,

allowing a wide range of user-selectable configurations including a pu re

prefetch strategy. The drive supports operation of any integer number of

segments from 1 to 1 6. Divide the 976, 896 bytes in the buffer by the number

of segments to get the segment size . Default is 3 segments. (See the

2 Interfac e Pr o duct Manual.

).

)

5.5.1 Adaptive read lookahead

Read lookahead causes the drive to continue reading data from the disc

following a normal read I/O until the read-ahead parameters are satisfied

(prefetch). If subsequent I/O requests can be satisfied from the prefetched

data in the data buffer, there is a significant improvement in performance

since a disc access is eliminated. If subsequent I/O requests cannot be

satisfied from the prefetched data, there is a reduction in performance due

to prefetch overhead.

The adaptive read lookahead feature suspends the prefetch operation if

three subsequent read I/O requests are not satisfied from the prefetched

data. This improves performance because unnecessary prefetches are

avoided.

SCSI-2 Interface

SCSI-

Prefetch is reinstated if an I/O request is sequential to a previous I/O request.

Page 27

ST12450W/WD Product Manual, Rev. B 17

Master Sync

Source

Host

(or other drive)

Spindle

Control

Drive 1

+5V

R

T

J5

11

12

Spindle

Control

Drive 2

+5V

R

T

J5

11

12

Spindle

Control

Drive n

+5V

R

T

J5

11

12

Sync Interface

System

Interface

5.6 Caching write data

Write caching is a drive-write operation, which uses a drive’s buffer storage

area where data to be written to the disc is stored while the drive performs

the Write command.

Write caching is enabled along with read caching. Default is cache enabled.

For write caching, the same buffer space and segmentation is used as set

up for read functions. When a write command is issued, the cache is first

checked to see if any logical blocks to be written are already stored in the

cache from a previous read or write command. If there are, the respective

cache segments are cleared. The new data is cached for subsequent read

commands.

If a 10-byte CDB write command (2Ah) is issued with the data page out (DPO)

bit set to 1, no write data is cached, but the cache segments are still checked

and cleared, if needed, for any logical blocks that are being written (see the

SCSI-2 Interface Product Manual).

If the number of write data logical blocks exceeds the size of the segment

being written into when the end of the segment is reached, data is written into

the beginning of the same cache segment, overwriting data that was written

there at the beginning of the operation. However, the drive does not overwrite

data that has not yet been written to the disc.

5.7 Synchronized spindle operation

The synchronized spindle operation allows several drives operating from the

same host to operate their spindles at the same synchronized rotational rate.

Drives operating in a system in synchronized mode increase the system’s

capacity and transfer rate in a cost-effective manner.

The int erface consists of a twisted-pair cabl e, which connects the driv es in

the synchronized system in a daisy-chain configuration as shown in

Figure 4.

Figure 4. Synchronized drive interconnect diagram

Page 28

18 ST12450W/WD Product Manual, Rev. B

The host can reconfigure the drive any time after power-up to be the master

or a slave by u sing the Mo de Sel ect c om mand on th e Rig id Disc Drive

Geometry page. The master provides the reference signal to which all other

drives phase-lock, including the master. There is only one master per

system, and th at c an be a d r ive or t he h ost co mp uter. All dr ives may be

configured as slaves allowing the host to provide the reference signal.

Each drive also can be configured for the non-synchronized mode in which

it ignores any referenc e sign al that m ig ht be present— th is is the default

mode as shipped from the factory. Connect the synchronized reference

signal to the host only if the host provides the reference signal. If the host

does not provide the reference signal, do not connect the host.

Rotational position locking

Note. Mode Select page 4, byte 17, bits 1 and 0.

RPL Description

00b Spindle synchronization is disabled (default value)

01b The target operates as a synchronized-spindle slave

10b The target operates as a synchronized-spindle master

11b The target operates as a synchronized-spindle master control

(not supported by the disc drive)

The VIC 2 LSI on the master drive provides the reference signal (SSREF +).

The index signal generates a 120 Hz signal. The signal is normally

false/negated (n ominal 0V) and makes a transition to the true/asserted

(nominal +5V) leve l to indicate the reference position during the revolution

period. Master and slave drives use the trailing (falling) edge of the

refere nce signal to phase lock their spindles. A maximum of 1 0 s econds is

allowed for a slave to synchronize with the reference signal. Figure 5 shows

the characteristics of the reference s ig nal.

T

1

SSREF +

Figure 5. Synchronized reference signal characteristics

0

1.0 µsec min.

1.37 µsec max.

T = 0.0083 seconds (± 1.0% max)

± 10 microseconds cycle-to-cycle variance

± 20 microseconds phase error while synchronized

Page 29

ST12450W/WD Product Manual, Rev. B 19

SCSI interface factors

The Rotational Position Loc k i ng (RPL) field in byte 17 (bits 0 and 1) of the

Rigid Disc Drive Geometry mode par amete rs page (p age 04h) i s used for

enabling and disabling spindle synchronization m ode (see the

Interface Product Manual

creates a unit attention to all initiators. The sense key is set to Unit Attention

and the additional sense code is set to Spindles Synchronized (5C01).

After reaching synchronization, if the target detects a change of synchronization and:

1. If the logical unit is not executing an I/O process for the initiator, then the

target creates a unit attention condition. The sense key is set to Unit

Attention and the additional sense code is set to Spindle Synchronized

(5C01) or Spindle Not Synchronized (5C02).

2. If the logical unit is executing an I/O process and no other error occurs,

then the target returns Check Condition status. The sense key is set to

Recovered Error if the target is able to complete the I/O process or to

Hardware Error if the target is unable to complete the I/O process. The

additional sense code is set to Spindle Synchronized (5C01) or Spindle

Not Synchronized (5C02).

You may operate the drive with a rotational skew when synchronized. The

rotational skew is applied in the retarded direction (lagging the synchronizedspindle master control). A rotational offset of up to 255/256 of a revolution

lagging may be selected. Select the amount of offset by using the Mode

Select command, Rigid Disc Drive Geometry page (page 04), byte 18 (see

the

SCSI-2 Interface Product Manual).

numerator of a fractional multiplier that has 256 as the denominator. For

example, 40h selects 40h/FFh or 1/4 of a revolution lagging skew, 80h

selects 1/2 of a revolution lagging skew, etc. Since the drive supports all

offset values from 0 to 255, values sent by the initiator are not rounded off.

The drive’s translation of the digital offset values to physical rotational offsets

results in offset values whose phase error lies within the ± 20 microseconds

phase error with respect to the supplied 120 Hz reference signal.

). When the target reaches synchronization, it

The value in byte 18 (0–FFh) is the

SCSI-2

The drive does not have the capability to adjust the rotational offset value

requested by the initiator to a physical offset in the drive that corresponds in

any way to sector boundaries or changes in ZBR zones. The initiator must

formulate these boundaries or changes, if required, to calculate the value of

offset it sends to the drive.

Page 30

Page 31

ST12450W/WD Product Manual, Rev. B 21

6.0 Reliability specifications

The following reliability specifications assume correct host and drive

interface, including all interface timings, power supply voltages, and

environmental requirements.

Seek error rate Less than 10 errors in 108 seeks

Recoverable error rate Less than 10 errors in 1011 bits transferred

(using default settings)

Unrecovered data Less than 1 sector in 1014 bits transferred

Miscorrected data Less than 1 sector in 1021 bits transferred

MTBF 500,000 hours

Service life 5 years

Preventive maintenance None required

6.1 Error rates

The error rates stated in this manual assume the following:

• The drive is operated per this manual using DC power as defined in

Section 7 .2.

• The drive has been formatted with the SCSI format commands.

• Errors caused by media defects or host system failures are excluded from

error rate computations. Refer to Section 9.0.

6.1.1 Environmental interference

When evaluating system operation under conditions of electromagnetic

interference (EMI), the performance of the drive within the system is

considered acceptable if the drive does not generate an unrecoverable

condition.

An unrecoverable error or condition is defined as one that:

• is not detected and corrected by the drive itself;

• is not capable of being detected from the error or fault status provided

through the drive or SCSI interface; or

• is not capable of being recovered by normal drive or system recovery

procedures without operator intervention.

6.1.2 Write errors

Write errors can occur as a result of media defects, environmental interference, or component malfunction. Therefore, write errors are not predictable

as a function of the number of bits passed.

If an unrecoverable write error occurs because of a component malfunction

in the drive, the error is classified as a failure affecting MTBF. Unrecoverable

write errors are those that cannot be corrected within two attempts at writing

the record with a read verify after each attempt (excluding media defects).

Page 32

22 ST12450W/WD Product Manual, Rev. B

6.1.3 Seek errors

A seek error is defined as a failure of the drive to position the heads at the

addressed track. There must be no more than one recoverable seek error in

107 physical seek operations. After detecting an initial seek error, the drive

automatically reseeks to the addressed track up to three times. If a reseek

is successful, the extended sense report indicates a seek-positioning error

(15h), no-seek-complete error (02h), or track-follow error (09h), and the

sense key reports a recovered error (1h). If all three reseeks fail, a seekpositioning error (15h) is reported with a medium (3h) or hardware error (4h)

reported in the sense key. This is an unrecoverable seek error. Unrecoverable seek errors are classified as failures for MTBF calculations. Refer to

Section 5.1.1.2 of the

77738479).

SCSI-2 Interface Product Manual

(part number

6.2 Reliability and service

You can enhance the reliability of Barracuda 2, 2HP disc drives by ensuring

that the drive receives adequate cooling. This section provides recommended air-flow information, temperature measurements, and other information that may be used to enhance the service life of the drive.

6.2.1 Mean time between failures (MTBF)

The production disc drive achieves an MTBF of 500,000 hours when

operated in an average local disc drive ambient temperature of 95°F (35°C)

or less. Short-term excursions up to the specification limits (122°F, 50°C) of

the operating environment will not affect MTBF performance.

The following expression defines MTBF:

MTBF =

Estimated power-on operating hours means the estimated total power-on

hours for all drives in service.

Drive failure means any stoppage or substandard performance caused by

drive malfunction.

Data is calculated on a rolling-average base for a minimum period of six

months.

6.2.2 Air flow

The rack, cabinet, or drawer environment for the Barracuda 2, 2HP drive

must provide cooling of the electronics and head and disc assembly (HDA).

You should confirm that adequate cooling is provided using the temperature

measurement guidelines described below.

Orient the drive or direct air flow so that the least amount of air-flow resistance

is created while providing air flow to the electronics and HDA. Also, choose

the shortest possible path between the air inlet and exit to minimize the travel

length of air heated by the Barracuda 2, 2HP drive and other heat sources

within the rack, cabinet, or drawer environment.

Estimated power-on operating hours in the period

Number of drive failures in the period

Possible air-flow patterns are shown in Figure 6. Create the air-flow patterns

by using one or more fans, either forcing or drawing air as shown in the

illustrations. Other air-flow patterns are acceptable as long as the temperature measurement guidelines are met.

Page 33

ST12450W/WD Product Manual, Rev. B 23

Above unit

Note. Air flows in the direction shown (back to front)

or in reverse direction (front to back)

Note. Air flows in the direction shown or

in reverse direction (side to side)

Figure 6. Air flow (ST12450W shown)

Under unit

Above unit

Under unit

Page 34

24 ST12450W/WD Product Manual, Rev. B

To confirm that required cooling for the Barracuda electronics and HDA is

provided, place the drive in its final mechanical configuration, perform

random write/read operations and, after the temperatures stabilize, measure

the case temperature of the components listed below.

Maximum allowable operating temperatures are listed in the last column.

Operation above these values may adversely affect the drive’s ability to meet

functional specifications.

Air-flow cooling

ST12450W

single-ended

MTBF

500k hours

Card Component Reference case temperature (°C)

GYHX Transmitter 1 64

GYHX Detector 2 73

GYHX VIC 2 3 59

GYHX Flash PROM 4 59

HDA housing Figure 9

The air-flow pattern with which the temperature guidelines above were

generated is shown in Figure 6. Local average air velocities were 0.61 msec

(120 lfpm) and inlet air temperature to the drive was 30°C (86°F).

The maximum allowable HDA case temperature is 60°C.

2

1

Figure 7. GYHX temperature measurement locations

34

Page 35

ST12450W/WD Product Manual, Rev. B 25

Air-flow cooling

ST12450WD

differential

MTBF

500k hours

Card Component Reference case temperature (°C)

RYGX Transmitter 1 64

RYGX Detector 2 73

RYGX VIC 2 3 59

RYGX Flash PROM 4 59

HDA housing Figure 9

The air-flow pattern with which the temperature guidelines above were

generated is shown in Figure 6. Local average air velocities were 0.61

msec (120 lfpm) and inlet air temperature to the drive was 30°C (86°F).

The maximum allowable HDA case temperature is 60°C.

2

1

Figure 8. RYGX temperature measurement locations

34

Measure the HDA housing temperature at the location specified in Figure 9.

1.00

Figure 9. Temperature measurement location

.50

Page 36

26 ST12450W/WD Product Manual, Rev. B

6.2.3 Preventive maintenance

No preventive maintenance is required.

6.2.4 Service life

The drive has a useful service life of five years. Depot repair or replacement

of major parts is permitted during this period.

6.2.5 Service philosophy

Spec ial equ ipm ent is re quired to repair the d rive’s H DA. To achieve the

5-year service life, repairs must be performed only at a properly equipped

and staffed s ervice and repair facility. T r ou bleshooti ng and repai r of PCB s

in the field is not recommended because of the extensive diagnostic

equipment req uir ed for ef fective s ervicing. A lso, the re are no spare parts

available for this drive. T he drive’ s warranty is voided if the HDA is opened.

6.2.6 Installation

The drive is designed, manufactured, and tested with a “plug in and play”

installation philosophy. This philosophy minimizes the requirements for

highly trained personnel to integrate the drive into the OEM’s system,

whether in a factory or field environment. Refer to the

Installation Guide

(83328890) for installation instructions.

Barracuda 2, 2HP

The drive has been low-level formatted at the factory and does not need to

be reformatted.

6.2.7 Service tools

No special tools are required for site installation or recommended for site

maintenance. Refer to Section 6.2.3. The depot repair philosophy of the drive

precludes the necessity for special tools. Field repair of the drive is not

practical because users cannot purchase individual parts for the drive.

6.2.8 Hot plugging Barracuda 2, 2HP disc drives

Caution. Hot-plug drives are not designed for simultaneous power discon-

nection and physical removal.

During power-up and power-down periods, the hot SCSI connect/disconnect

capability does not produce glitches or any corruptions on an active SCSI

bus. Barracuda 2, 2HP drives conform to the SCSI-3 standard requirements

for glitch-free power-on and power-off. The drive maintains the high-impedance state of the device connector contacts during a power cycle until the

transceiver is enabled.

Note. The systems integrator must ensure that no temperature, energy, or

voltage hazard is presented during the hot connect/disconnect operation.

Procedure:

1. Configure the drive with no connection between the drive and the

TRMPWR signal on the SCSI bus. To accomplish this, remove all

jumpers from connector J1.

Page 37

ST12450W/WD Product Manual, Rev. B 27

2. Ensure that all SCSI devices on the bus have receivers that conform to

the SCSI-3 standard.

3. Eliminate all I/O processes for the drive.

4. Wait until the drive motor and discs have come to a complete stop prior

to changing the plane of operation, ensuring data integrity.

5. Insert or remove the drive after meeting the following conditions:

Caution. Do not hot-plug the first or last device on the SCSI bus (the

SCSI bus termination must be external to the drive you are

inserting or removing).

a. If you are inserting the drive, connect its power ground and logic

ground at least 1 millisecond before coming into contact with the bus

connector. Maintain these ground connections during and after connecting the device to the bus.

b. If you are removing the device, maintain its power ground and logic

ground connection for at least 1 millisecond after disconnecting the

device from the bus.

c. You may simultaneously switch the power to the electronics and

mechanics of the drive with the bus contacts, if the power distribution

system is able to maintain adequate power stability to other devices

during the transition and if you have met the grounding requirements

given in steps 5a and 5b.

d. Ensure that the drive carrier discharges all static electricity prior to

inserting the drive into the system.

Note. Do not remove or add terminator power or resistance to the SCSI bus

while hot plugging a disc drive.

Page 38

Page 39

ST12450W/WD Product Manual, Rev. B 29

7.0 Physical/electrical specifications

This section provides information relat ing to the physical and electrical

characteristics of Barracuda 2, 2HP drives.

7.1 AC power requirements

None.

7.2 DC power requirements

The voltage and current requirements for a single drive are shown below.

Value s indicated apply at the drive ’s power connector.

Table 1. DC power requirements

ST12450W ST12450WD

[8]

Voltage 5V

regulation

Max operating current DC 3σ [1] 1.32a 0.91a 1.65A 0.91A

Max start current

(peak) DC 3σ [3] [6] 1.3A 2.18A 1.43A 2.18A

(peak) AC 3σ [3] — 3.1A — 3.1A

Delay motor start (max) DC 3σ [1] [4] 1.25A 1.5A 1.31A 1.5A

Peak operating current

Typical DC X [1] [7] 1.3A 0.84A 1.6A 0.84A

Maximum DC 3σ [1] 1.32A 0.91A 1.65A 0.91A

Maximum (peak) AC 3σ 1.4A 1.85A 2.4A 1.85A

Track following at

OD DC X [1] 1.3A 0.78A 1.4A 1.85A

ID DC X [1] 1.3A 0.82A 1.4A 0.78A

Read track

OD DC 3σ [1] [11] 1.4A 0.81A 1.9A 0.81A

AC 3σ 1.5A 1.16A 2.5A 1.16A

Seeking

Typical DC X [1] [10] 1.3A 1.06A 1.4A 1.06A

Maximum DC 3σ [1] 1.3A 1.14A 1.44A 1.14A

Maximum (peak) AC 3σ 1.3A 1.85A 2.2A 1.85A

[5]

Notes

±±

±5%

±±

12V 5V

[2]

±±

±5%

±±

±±

±5%

±±

[8]

12V

±±

±5%

±±

[2]

Notes:

[1] Measured with average reading DC ammeter . Instantaneous +1 2V cur rent

peaks will exceed these values.

[2] A – 1 0% tolerance i s permissible during initial start of the spindle a nd must

return to ±5% be fore 7,200 RPM is reached. The ±5% must be maintained

after the drive signals that its power- up sequence has been completed

and that it can accept selection by the host initiator.

[3] See Figure 10.

[4] This condition occurs when the Motor Start Option is enabled and the

drive has not yet received a Start Motor command.

[5] See Section 7.2.1 “Conducted noise immunity.” Specified voltage to ler-

ance includes ripple, noise, and transient response.

continued

Page 40

30 ST12450W/WD Product Manual, Rev. B

continued from previous page

[6] At power-up, the motor current regulator limits the 12V current to an

average value of less than 2.0A, although instantaneous peaks may

exceed this value. These peaks should measure 5 msec duration or

less.

[7] Operating condition is defined as a third-stroke seek at OD and read

one track. A command is issued every 0.07 sec. (differential); 0.075

sec. (single-ended).

[8] No terminator power. See Section 11.7.3.4.

[9] All power-saving features enabled.

[10] Seeking is defined as a third-stroke seek at OD. A command is issued

every 20 msec.

[11] Read track is defined as repeat reads of track 15 with a 60% duty cycle.

Notes:

1. Minimum current loading for each supply voltage is not less than 3%

of the maximum operating current shown.

2. The +5V and +12V supplies employ separate ground returns.

3. Where power is provided to multiple drives from a common supply,

careful consideration for individual drive power requirements should

be noted. Where multiple units are powered on simultaneously, the

peak starting current must be available to each device.

7.2.1 Conducted noise immunity

Noise is specified as a periodic and random distribution of frequencies

covering a band from DC to 10 MHz. Maximum allowed noise values given

below are peak-to-peak measurements and apply at the drive’s power

connector.

0 to 100 kHZ 100 kHz to 10 MHz

++

+5V 150 mV 100 mV

++

++

+12V 150 mV 100 mV

++

7.2.2 Power sequencing

The drive does not require power sequencing. The drive protects against

inadvertent writing during power-up and down. Daisy-chain operation requires that power be maintained on the terminated device to ensure proper

termination of the peripheral I/O cables.

To automatically delay motor start based on the target ID (SCSI ID), select

the Delay Motor Start option and deselect the Enable Motor Start option on

the J4 connector. See Section 10.1 for pin selection information.

To delay the motor until the drive receives a Start Unit command, select the

Enable Motor Start option on the J4 connector.

Page 41

ST12450W/WD Product Manual, Rev. B 31

7.2.3 12V current profile

Figure 10 identifies the drive’s +12V current profile. The current during the

various times is as shown.

3.0

2.85

2.5

2.0

1.9

1.5

+12V CURRENT (A)

1.0

0.5

T0

0.0

Peak AC

Nominal (average) curve

Minimum AC

T2

T1

0 5 10 15 20 25 30

Figure 10. Typical Barracuda 2, 2HP drive

T3

T5

T4

TIME (S)

T6

++

+12V current profile

++

T7

T0 Power is applied to the drive.

T1 Controller self-tests are performed.

T2 The spindle begins to accelerate under current limiting after performing

internal diagnostics. See Note 1 of Table 1.

T3 The spindle is up to speed and the head-arm restraint is unlocked.

T4 Heads move from the landing zone to the data area.

T5 The adaptive calibration sequence is performed.

T6 Thermal calibration.

T7 Calibration is complete and the drive is ready for reading and writing.

Note. All times and currents are typical. See Table 1 for maximum current

requirements.

Page 42

32 ST12450W/WD Product Manual, Rev. B

7.3 Heat/power dissipation

The heat and power dissipation values for your drive are listed below.

ST12450W ST12450WD

Typical seek and read 16W 18W

power dissipation of DC power (54 BTUs/hr) (62 BTUs/hr)

average at nominal voltages

Typical power dissipation 15W 16W

under track following conditions (51 BTUs/hr) (54 BTUs/hr)

7.4 Environmental limits

Temperature and humidity must not cause condensation within the drive.

Altitude and atmospheric pressure specifications are referenced to a standard day at 58.7°F (14.8°C). Maximum wet bulb temperature is 82°F (28°C).

7.4.1 Temperature

a. Operating

The MTBF specification for the drive is based on operating at a local

ambient temperature of 95°F (35°C). Occasional excursions to drive

ambient temperatures of 122°F (50°C) may occur without impact to

specified MTBF. The enclosure for the drive should be designed such that

the temperatures at the locations specified in Figures 7 and 8 are not

exceeded. Air flow may be needed to achieve these temperatures.

Continual or sustained operation at case temperatures above these

values may degrade MTBF.

The d rive mee ts all specifications within a 4 1 ° to 1 22 °F ( 5° to 50°C) drive

ambient temperature range with a maximum gradient of 36°F (20°C) per

hour.

b. Non-operating

Non-operating temperatur e should r emain betw een –40° to 1 5 8° F (– 40°

to 70°C) package ambient with a maximum gradient of 36°F (20 °C)

per hour. This assumes that the drive is packaged in the shipping

container designed by Seagate.

7.4.2 Relative humidity

The values below assume that no condensation on the drive occurs.

a. Operating

5% to 95% relative humidity with a maximum gradient of 10% per hour

b. Non-operating

5% to 95% relative humidity

7.4.3 Effective altitude (sea level)

a. Operating

–1,000 to +10,000 feet (–305 to +3,048 meters)

b. Non-operating

–1,000 to +40,000 feet (–305 to + 12,210 meters)

Page 43

ST12450W/WD Product Manual, Rev. B 33

7.4.4 Shock and vibration

Shock and vibrati on limits are measured directly on the drive’s chassis.

Ensure that you use an enclosure that buffers and restri cts the drive’s

movements to meet the shock and vibra tion requirements listed below.

The limits of shock and vibration defined within this manual a r e s pecified

with the drive mounted in one of the two met ho ds shown in Figure 12.

7.4.4.1 Shock

a. Operating in a normal environment

The drive as installed for normal operation operates error free while

subjected to intermittent shock not exceeding:

2.0 Gs at a maximum duration of 11 msec (half-sinewave)

Shock may be applied in the X, Y, or Z axis.

b. Operating in an abnormal environment

The drive as installed for normal operation does not incur physical

damage while subjected to intermittent shock not exceeding:

10 Gs at a maximum duration of 11 msec (half-sinewave)

Shock occurring at abnormal levels may degrade operating performance

during the abnormal shock period. Specified operating performance

continues when normal operating shock levels resume.

Shock may be applied in the X, Y, or Z axis. Shock is not to be repeated

more than two times per second.

c. Non-operating

The limits of non-operating shock apply to all conditions of handling and

transportation. This includes both isolated drives and integrated drives.

The drive does not cause drive damage or performance degradation

while subjected to non-repetitive shock not exceeding:

50 Gs at a maximum duration of 11 msec (half-sinewave)

Shock may be applied in the X, Y, or Z axis.

d. Packaged

The drive as packaged by Seagate for general freight shipment with stands a drop test against a concrete floor or equivalent with specifications n ot e x ce e ding :

20 pounds (8.95 kg) for pack’s gross weight

42 inches (1,070 mm) for distance dropped

Drop test applies to a single or multiple drive pack.

Page 44

34 ST12450W/WD Product Manual, Rev. B

7.4.4.2 Vibration

a. Operating in a normal environment

The drive as installed for normal operation operates error free while

subjected to continuous vibration not exceeding:

5-400 Hz @ 0.5 G

Vibration may be applied in the X, Y, or Z axis.

b. Operating in an abnormal environment

Equipment as installed for normal operation does not incur physical

damage while subjected to periodic vibration not exceeding:

15 minutes of duration at major resonant frequency

5-400 Hz @ 0.75 G

Vibration occurring at these levels may degrade operating performance

during the abnormal vibration period. Specified operating performance

continues when normal operating vibration levels are resumed—this

assumes system recovery routines are available.

Abnormal vibration may be applied in the X, Y or Z axis.

c. Non-operating

The limits of non-operating vibration apply to all conditions of handling

and transportation. This includes both isolated drives and integrated

drives.

The drive does not incur physical damage or degraded performance as

a result of continuous vibration not exceeding:

5-22 Hz @ 0.040 inches (1.02 mm) displacement

22-400 Hz @ 2.00 Gs

Vibration may be applied in the X, Y, or Z axis.

7.4.5 Air cleanliness

The drive is designed to operate in a typical office environment with minimal

environmental control.

7.4.6 Acoustics

Sound power during idle mode (when the drive is not seeking, reading, or

writing) is 4.7 bels typical when measured to ISO 7779 specifications.

7.5 Electromagnetic compatibility

As a component assembly, the drive is n ot r equired to meet any susceptibility performa nce requirements. The system integrator is responsible for

performing tests to ensure th at equi pment operating in the same system as

the drive does not adversely affect t he performance of t he d rive. See

Table 1 a nd Section 7 .2 “D C p ow er r e quirements.”

Page 45

ST12450W/WD Product Manual, Rev. B 35

7.6 Mechanical specifications

The following nominal dimensions do not include the decorative front-panel

accessory. Refer to Figure 11 for detailed mounting configuration dimensions.

Height 1.63 in 41.4 mm

Width 4.00 in 101.6 mm

Depth 5.97 in 151.6 mm

Weight 2.3 lb 1.04 kg

T

U

[1]

R

F

[2]

G

W

J

[4]

ED

K

L

A

M

Notes:

[1]

Mounting holes two on each

side, 6-32 UNC. Max screw

length into side of drive is

0.15 in. (3.81 mm).

[2]

Mounting holes five on

B

Z

H

S

V

bottom, 6-32 UNC. Max

screw length into bottom of

drive is 0.15 in. (3.81 mm).

[3]

Power and interface

connections.

[4]

Decorative front panel.

Inches Millimeters

±

5.740

A

±

4.000

B

±

1.620

C

±

.615

D

±

4.000

E

±

.250

F

±

1.750

G

±

3.750

H

±

2.370

J

±

5.420

K

±

5.565

L

±

5.968

M

±

.190

N

±

.347

P

±

1.725

R

±

4.100

S

±

.190

T

max

0.015

U

±

0.265

V

±

2.145

W

±

1.755

Z

0.010

0.010

0.034

0.020

0.005

0.005

0.010

0.010

0.010

0.020

0.010

0.035

0.015

0.015

0.010

0.010

0.010

0.020

0.010

0.010

[3]

N

C

P

145.80

101.60

41.14

15.68

101.60

6.35

44.45

95.25

60.20

137.69

141.35

151.58

4.826

8.81

43.82

104.14

4.83

0.381

8.50

54.48

44.58

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

±

max

±

±

±

.25

.25

.86

.50

.13

.13

.25

.25

.25

.50

.25

.90

.38

.38

.25

.25

.25

.50

.25

.25

Figure 11. Mounting configuration dimensions

Page 46

36 ST12450W/WD Product Manual, Rev. B

7.6.1 Drive orientation

The balanced rotary arm actuator design of the drive allows it to be mounted

in any orientation. All drive performance evaluations, however, have been

done with the drive in horizontal (discs level) and vertical (drive on its side)

orientations, which are the two preferred mounting orientations.

Figure 12. Recommended mounting

7.6.2 Cooling

Ensure that the enclosure you use provides adequate cooling so that th e

ambient temperature immediately surrounding the drive does not e xceed

tempe ratur e condition s specif ied in Section 7.4. 1 . E nsure th at y ou pro vide

adequa te air circul ation around the printed circuit boards (PCBs) to meet

the requirements of Section 6 .2 .2.

Page 47

ST12450W/WD Product Manual, Rev. B 37

8.0 Media characteristics

This section provides information regarding the media used in Barracuda 2,

2HP disc drives.

8.1 Media description

The media used on the drive has a diameter of approximately 95 mm (3.7

inches). The aluminum substrate is coated with a thin-film magnetic material,

which has a proprietary protective layer for improved durability and environmental protection.

Page 48

Page 49

ST12450W/WD Product Manual, Rev. B 39

9.0 Defect and error management

The drive, as delivered, complies with this product manual. The read error

rates and specified storage capacities are not dependent on using defectmanagement routines by the host (initiator).

Defect and error management in the SCSI system involves the drive’s

internal defect/error management and SCSI system error considerations

(errors in communications between the initiator and the drive). Tools for

designing a defect/error management plan are briefly outlined in this section.

References to other sections are provided when necessary.

9.1 Defects and errors

Identified defects are recorded on the drive’s defects list (referred to as the

primary or ETF defect list). These known defects are reallocated during the

initial drive format at the factory. (See Format Unit command Section 5.2.1.2

in the

SCSI-2 Interface Product Manual,

correction by ECC recovers data from additional flaws if they occur.

Details of the SCSI commands supported by the drive are described in the

SCSI-2 Interface Product Manual.

Error Recovery philosophy is presented in Section 6 of the

Product Manual.

Also, more information about the drive’s

part number 77738479.) Data

SCSI-2 Interface

Page 50

Page 51

ST12450W/WD Product Manual, Rev. B 41

SCSI I/O

Connector

DC Power

Connector

J4

J01

J5

10.0 Option/configuration headers

This section describes ho w to configure Barracuda 2, 2HP drives using the

option headers on the drives. These option headers may be used to

customiz e many functions of the drives for your particular system.

10.1 Drive ID/option select headers

The headers desc ribed in this section enable you to configure the drive to

meet specific functionality requirements.

Figure 13. Barracuda 2, 2HP drive physical interface

Page 52

42 ST12450W/WD Product Manual, Rev. B

Figure 14 illustrates the drive’s ID and option select jumper connectors.

SCSI ID = 0

SCSI ID = 1

SCSI ID = 2

SCSI ID = 3

SCSI ID = 4

SCSI ID = 5

SCSI ID = 6

SCSI ID = 7

SCSI ID = 8

SCSI ID = 9

SCSI ID = 10

SCSI ID = 11

SCSI ID = 12

SCSI ID = 13

SCSI ID = 14

SCSI ID = 15

Remote LED Connector

Spindle Sync

Cable Connector

SSREF

J5

Pin 1

Connector

J5

Power

Connector

SCSI

Pin 1

Pin 1

Pin 1

J4

Pin 1

Pin 1

J01

J4

Reserved

Enable Drive Terminators*

Parity Disable

Enable Motor Start

Delay Motor Start

Write Protect

Pin 1

Term. Power from Drive

*

Term. Power from SCSI Bus

*

Term. Power to SCSI Bus

Term. Power to SCSI Bus and Drive

*

* Valid for single ended drives only.

Figure 14. Barracuda drive ID and option select headers

Pin 3

J01

Pin 1

Pin 2

Page 53

ST12450W/WD Product Manual, Rev. B 43

Block Pins Function

J01 1 & 2* Terminator power supplied by the drive.

2 & 4* Terminator power supplied from the SCSI bus.

1 & 3 Terminator power supplied to the SCSI bus.

1 & 3 and Terminator power supplied to the SCSI bus and

2 & 4* drive.

J4 1 & 2 Write Protect option. Jumper installed protects the entire

disc drive. Default is no jumper.

3 & 4 Delay Motor Start option. Jumper installed waits for ten

(10) seconds for each target ID number plus a maximum

power-up delay of 3 seconds before starting the spindle

motor automatically. Default is no jumper.

Example:

If target ID is equal to two (2)

(2 x 10) + 3 = 23

Target spindle motor starts

in twenty-three (23) seconds.

5 & 6 Enable Motor Start option. Jumper installed causes the

target to wait for the Start Unit command from the SCSI

host. No jumper installed causes the unit to look at the

Delay Motor Start jumper. Default is no jumper.

7 & 8 Parity Disable option. Jumper installed causes parity

checking and error reporting to be disabled. Default is no

jumper.

9 & 10 Reserved. Default is no jumper.

11 & 12* Enable Single-Ended Drive Terminator. Jumper installed

enables the drive terminator. Jumper removed disables

the drive terminator. Default is no jumper.

13 & 14 Reserved. Default is no jumper.

15 & 16 Reserved. Default is no jumper.

J5 1 & 2** SCSI Target ID 0

3 & 4** SCSI Target ID 1

5 & 6** SCSI Target ID 2

7 & 8** SCSI Target ID 3

9 & 10 Remote LED connector. Pin 9 is cathode (neg), Pin 10 is

anode (pos). Pin 10 is current limited through a 1K ohm,

1/10W resistor.

11 & 12 Spindle sync cable connector. Pin 11 is the SSREF+ or

reference index signal. Pin 12 is Gnd.

* Valid for single-ended (ST12450W) drives only.

**See Figure 14 to set the SCSI ID.

Page 54

44 ST12450W/WD Product Manual, Rev. B

10.2 Synchronized spindles interface

The synchronized spindles interface (SSI) allows several drives operating

from the same host to operate their spindles at a synchronized rotational rate.