Page 1

Users Guide

Cheetah 10K.7 FC

ST336807FC

Page 2

Page 3

Users Guide

Cheetah 10K.7 FC

ST336807FC

Page 4

©2005, Seagate Technology LLC All rights reserved

Publication number: 100384022, Rev. A

August 2005

Seagate and Seagate Technology are reg istered trademarks of Seagate Technology LLC.

Cheetah, SeaTools, SeaFONE, Se aBOARD, SeaTDD, and th e Wave logo are either regis tered trademarks or trademarks of Seagate Technology LLC. Other product names are registered trademarks or trademarks of their owners.

Seagate reserves the right to ch ange, witho ut notice, product offerings or spec ifications . No

part of this publication may be reproduc ed in any form w ithout wr itte n per mi ssio n of Seagate

Technology LLC.

Page 5

Revision status summary sheet

Revision Date Sheets Affected

Rev. A 05/04/05 All. Initial release.

Page 6

Page 7

Contents

1.0 Scope. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0 Applicable standards and reference documentation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1 Standards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.1 Electromagnetic compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.1.2 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2.2 Electromagnetic compliance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2.3 European Union Restriction of Hazardous Substances (RoHS) . . . . . . . . . . . . . . . . . . . . . 4

2.4 Reference documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

3.0 General description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3.1 Standard features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Media description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Reliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Formatted capacities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5.1 Programmable drive capacity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.6 Factory-installed accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.7 Factory-installed options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.8 User-installed accessories. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

4.0 Performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1 Internal drive characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.2 Seek performance characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.1 Access time [4]. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.2 Format command execution time (in minutes). . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2.3 Generalized performance characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.3 Start/stop time . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.4 Prefetch/multi-segmented cache control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5 Cache operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

4.5.1 Caching write data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4.5.2 Prefetch operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4.5.3 Optimizing cache performance for desktop and server applications . . . . . . . . . 15

5.0 Reliability specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1 Error rates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.1 Recoverable Errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

5.1.2 Unrecoverable errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.3 Seek errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1.4 Interface errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2 Reliability and service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.1 Annualized Failure Rate (AFR) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.2 Preventive maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.2.3 Hot plugging the drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.4 S.M.A.R.T. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.2.5 Thermal monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

5.2.6 Drive Self Test (DST). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

5.2.7 Product warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cheetah 10K.7 36GB FC Product Manual, Rev. A v

Page 8

6.0 Physical/electrical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.1 AC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2 DC power requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.2.1 Conducted noise immunity. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.2 Power sequencing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

6.2.3 Current profiles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

6.3 Power dissipation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.4 Environmental limits. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.1 Temperature. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.2 Relative humidity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.3 Effective altitude (sea level) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

6.4.4 Shock and vibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.4.5 Air cleanliness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.6 Corrosive environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

6.4.7 Acoustics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.4.8 Electromagnetic susceptibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

6.5 Mechanical specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

7.0 Defect and error management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.1 Drive internal defects/errors. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.2 Drive error recovery procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

7.3 FC-AL system errors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4 Background Media Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

7.4.1 Media Pre-Scan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

8.0 Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.1 Drive ID/option selection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

8.2 LED connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2.1 J6 connector requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.3 Drive orientation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.4 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

8.5 Drive mounting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

8.6 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

9.0 Interface requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1 FC-AL features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1.1 Fibre Channel link service frames . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

9.1.2 Fibre Channel task management functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.3 Fibre Channel task management responses . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

9.1.4 Fibre Channel port login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

9.1.5 Fibre Channel port login accept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.1.6 Fibre Channel Process Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

9.1.7 Fibre Channel Process Login Accept . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1.8 Fibre Channel fabric login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1.9 Fibre Channel fabric accept login. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

9.1.10 Fibre Channel Arbitrated Loop options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.2 Dual port support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

9.3 SCSI commands supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

9.3.1 Inquiry data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.3.2 Mode Sense data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

9.4 Miscellaneous operating features and conditions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

9.5 FC-AL physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.5.1 Physical characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

9.5.2 Connector requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

9.5.3 Electrical description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

9.5.4 Pin descriptions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

vi Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 9

9.5.5 FC-AL transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.5.6 Power. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.5.7 Fault LED Out . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

9.5.8 Active LED Out. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.5.9 Enable port bypass signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.5.10 Motor start controls . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.5.11 SEL_6 through SEL_0 ID lines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

9.5.12 Device control codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.6 Signal characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.6.1 TTL input characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67

9.6.2 LED driver signals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.3 Differential PECL output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

9.6.4 Differential PECL input. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

10.0 Seagate Technology support services. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 71

Cheetah 10K.7 36GB FC Product Manual, Rev. A vii

Page 10

viii Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 11

List of Figures

Figure 1. Cheetah 10K.7 FC family disc drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Figure 2. Typical ST336807FC drive, 2 Gbit, +12V current profile . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 3. Typical ST336807FC drive, 2 Gbit, +5V current profile. . . . . . . . . . . . . . . . . . . . . . . . . . 27

Figure 4. ST336807FC DC current and power vs. input/output operations per second. . . . . . . . . 28

Figure 5. Location of the HDA Temperature check point . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Figure 6. Recommended mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Figure 7. Mounting configuration dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Figure 8. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 9. LED indicator connector . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Figure 10. Air flow. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

Figure 11. Physical interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 12. Port bypass circuit physical interconnect. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Figure 13. FC-AL SCA device connector dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Figure 14. J6 connector dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Figure 15. FC-AL transmitters and receivers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Figure 16. Transmit eye diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 8

Figure 17. Receive eye diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 9

Cheetah 10K.7 36GB FC Product Manual, Rev. A ix

Page 12

x Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 13

1.0 Scope

This manual describes Seagate Technology® LLC, Cheetah® 10K.7 FC 36GB (Fibre Channel) disc drives.

Cheetah 10K.7 FC drives support the Fibre Channel Arbitrated Loop and SCSI Fibre Channel Protocol specifi-

cations to the extent desc ribed in this manual. The F ibre Channel Interface Ma nual (part number 77767496)

describes the gener al Fibre Channe l Arbitrated Loop char acteristics o f this and other Seagate Fibre Channel

drives.

Figure 1. Cheetah 10K.7 FC family disc drive

Cheetah 10K.7 36GB FC Product Manual, Rev. A 1

Page 14

2 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 15

2.0 Applicable standards and reference documentation

The drive has been developed as a system peripheral to the highest standards of design and construction. The

drive depends upon its host equ ipment to provide adequate power and envi ronment in order to achi eve opti-

mum performance and co mpliance with applicable indus try and governmental regulations. Special attention

must be given in the areas of safety, power distribution, shielding, audible noise control, and temperature regu-

lation. In particula r, the drive must b e s ecur el y mou nted i n o rde r to gua ra nte e th e s pe ci fie d p er formance char-

acteristics. Mounting by bottom holes must meet the requirements of Section 8.5.

2.1 Standards

The Cheetah 10K.7 FC family comp lies with Seagate standards as noted in th e appropriate sections of this

manual and the Seagate Fibre Channel Interface Manual, part number 77767496.

The Cheetah 10K.7 FC disc drive is a UL recognized component per UL1950, CSA certified to CAN/CSA

C22.2 No. 950-95, and VDE certified to VDE 0805 and EN60950.

2.1.1 Electromagnetic compatibility

The drive, as delivered , is designed for system integrati on and installation into a suitable encl osure prior to

use. As such the d rive is supplied as a subassembly and is not subject to Subpart B of Part 15 of the FCC

Rules and Regulation s nor the Radio Interference Reg ulations of the Canadian Departm ent of Communica-

tions.

The design characteristics of the drive serve to minimize radiation when installed in an enclosure that provides

reasonable shielding. As such, the drive is capable of meeting the Class B limits of the FCC Rules and Regula-

tions of the Canadian Department of Communications when properly packaged. However, it is the user’s

responsibility t o assure that the drive mee ts the appropriate EMI re quirements in their system. S hielded I/O

cables may be requir ed if the en closure do es not provi de adequate shieldi ng. If the I/O cab les are exte rnal to

the enclosure, shielded cables should be used, with the shields grounded to the enclosure and to the host con-

troller.

2.1.2 Electromagnetic susceptibility

As a component a ssembly, the drive is not requ ired to meet any susc eptibi lity perfor mance requ irements. It is

the responsibilit y of those integrating the dr iv e wit hin the ir s y ste ms to perform those tests req uire d a nd des ig n

their system to ensure th at equipment operating in the same sy stem as the drive or external to the syste m

does not adversely affect the performance of the drive. See Section Table 11, DC power requirements.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 3

Page 16

2.2 Electromagnetic compliance

Seagate uses an inde pendent laborato ry to confirm comp liance with the directives/standa rds for CE Markin g

and C-Tick Marking. The drive was tested in a representative system for typical applications. The selected system represents the most popular characteristics for test platforms. The system configurations include:

• Typical current use microprocessor

• 3.5-inch floppy disc drive

• Keyboard

• Monitor/display

• Printer

• External modem

•Mouse

Although the test system with this Seagate model complies with the directives/standards, we cannot guarantee

that all systems will comply. The computer manufacturer or system integrator shall confirm EMC compliance

and provide the appropriate marking for their product.

Electromagnetic compliance for the European Union

If this model has the CE Marking it co mplies with the European Union requirements of the El ectromagnetic

Compatibility Directive 89 /336/EEC of 03 May 1989 as amend ed by Dir ective 92 /31/ EEC of 28 Apri l 1992 an d

Directive 93/68/EEC of 22 July 1993.

Australian C-Tick

If this model has th e C-Tick Marking it complies with the Austr alia/New Zeal and Standard AS/NZS3548 199 5

and meets the Electromagnet ic Compatibility (EMC) Framework requi rements of Australia’s Spectrum Management Agency (SMA).

Korean MIC

If this model has the Korean Ministry of Information and Communication (MIC) logo, it complies with paragraph

1 of Article 11 of the Electromagnetic Compatibility (EMC) Control Regulation and meets the Electroma gnetic

Compatibility Framework requirements of the Radio Research Laborator y (RRL) Ministry of Information and

Communication Republic of Korea.

Taiwanese BSMI

If this model has the Chinese National Standard (CNS) 13438 marking, it complies with Chinese National Standard (CNS) 13438 an d meets the Electromagnetic Compatibil ity (EMC) Framework requ irements of the Taiwanese Bureau of Standards, Metrology, and Inspection (BSMI).

2.3 European Union Restriction of Hazardous Substances (RoHS)

A new law, the European Union Restri ction of Hazardous Substances (RoHS) di rective, will res trict the pressence of chemical sub stances, includi ng Lead (Pb), in el ectronic pro ducts effective July 200 6. The directiv e’s

requirements have not been finalized. This drive is manufactured with components and materials that are

expected to comply with the RoHS directive when the directive takes effect.

4 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 17

2.4 Reference documents

Cheetah 10K.7 36GB FC Installation Guide Seagate part number: 100384023

Fibre Channel Interface Manual Seagate part number: 77767496

ANSI Fibre Channel Documents

X3.230-1994 FC Physical and Signaling Interface (FC-PH)

X3.297.1997 FC-PH-2 Fibre Channel Physical and Signaling Interface-2

X3.303.1998 FC-PH-3 Fibre Channel Physical and Signaling Interface-3

X3.272-1996 FC Arbitrated Loop (FC-AL)

X3.269-1996 Fibre Channel Protocol for SCSI (FCP)

NCITS TR-19 Private Loop SCSI Direct Attach (PLDA)

NCITS TR-20 Fabric Loop Attachment (FC-FLA)

SFF-8045 Specification for 40-pin SCA-2 Connector with Parallel Selection

SFF-8067 Specification for 40-pin SCA-2 Connector with

Bidirectional Encl os ur e Servi ce s Interfa ce

ANSI Small Computer System Interface (SCSI) Documents

X3.131-1994 (SCSI-2)

X3.270-1996 (SCSI-3) Architecture Model

NCITS 305-199X (SCSI-3) Enclosure Services

Specification for Acoustic Test

Requirement and Procedures Seagate part number: 30553-001

Package Test Specification Seagate P/N 30190-001 (under 100 lb.)

Package Test Specification Seagate P/N 30191-001 (over 100 lb.)

In case of conflict between this document and any referenced document, this document takes precedence.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 5

Page 18

6 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 19

3.0 General description

Cheetah 10K.7 FC drives com bi ne gi ant m agn etores i stive (GMR) heads, partial respo nse/ma xi mu m li ke li hoo d

(PRML) read channel ele ctronics , embedded ser vo technolog y, and a Fibre Channel interface to pr ovide hig h

performance, high capac ity data storage f or a variety of systems including engineering wo rkstations, netwo rk

servers, mainframes, and supercomputers.

Cheetah 10K.7 FC drives supp ort the Fibre C hannel Ar bitrated Loo p (FC-AL) an d SCSI Fi bre Channel P roto-

col as described in the ANSI specifications, this document, and the Fibre Channel Interface Manual (part num-

ber 77767496) which describes the general interface characteristics of this drive. Cheetah 10K.7 FC drives are

classified as intellige nt peripherals and prov ide level 2 conformanc e (highest level) with the ANSI SCSI stan-

dard.

Never disassemble the HDA a nd do not at tempt to service ite ms in the sealed enclo su re (hea ds , m edi a, ac tu-

ator, etc.) as this requires special faci lities. The drive contains no parts replaceable by the user an d opening

the HDA for any reason voids your warranty.

Cheetah 10K.7 FC drives use a dedicated landing zone at the innermost radius of the media to eliminate the

possibility of d estroying or degrading d ata by landing in the data zone. The drive automatically goes to the

landing zone when power is removed.

An automatic shipping lock prevents potential damage to the heads and discs that results from movement dur-

ing shipping and handl in g. T he s hip pin g lo ck auto mat ic all y dis eng age s whe n powe r i s ap plied to the drive and

the head load process begins.

A high-performance ac tuator assembly with a low-inertia, balan ced, patented, straight arm design provides

excellent performance with min im al powe r diss ipation .

Cheetah 10K.7 36GB FC Product Manual, Rev. A 7

Page 20

3.1 Standard features

Cheetah 10K.7 FC drives have the following standard featur es :

• Integrated dual port FC-AL controller

• Concurrent dual port transfers

• Support for FC arbitrated loop, private and public attachment

• Differential copper FC drivers and receivers

• Downloadable firmware using the FC-AL interface

• Supports SCSI enclosure services via interface connector

• 128-deep task set (queue)

• Supports up to 32 initiators

• Drive selection ID and configuration options are set on the FC-AL backpanel or through interface commands. Jumpers are not used on the drive.

• Fibre Channel worldwide name uniquely identifies the drive and each port

• User-selectable logical block size (any multiple of four bytes, 512 to 528 bytes per logical block)

• Selectable frame sizes from 256 to 2,112 bytes

• Industry standard 3.5-inch low profile form factor dimensions

• Programmable logical block reallocation scheme

• Flawed logical block reallocation at format time

• Programmable auto write and read reallocation

• Reed-Solomon error correction code

• Sealed head and disc assembly (HDA)

• No preventive maintenance or adjustments required

• Dedicated head landing zone

• Automatic shipping lock

• Embedded Grey Code track address and servo wedge address to eliminate seek errors

• Self-diagnostics performed at power on

• 1:1 interleave

• Zone bit recording (ZBR )

• Vertical, horizontal, or top down mounting

• Dynamic spindle brake

• 8,192 Kbyte data buffer. See Section 4.5.

• Drive Self Test (DST)

• BackGround Media Scan (BGMS)

• Data Integrity Check

•Power Save

• Embedded servo design

• Reallocation of defects on command (Post Format)

• Fibre Channel interface transports SCSI protocol

3.2 Media description

The media used on the drive has an alumi num sub st rat e co ated with a thin fi lm magn eti c mater ia l, over coate d

with a proprietary protective layer for improved durability and environmental protection.

8 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 21

3.3 Performance

• Programmable multi-segmentable cache buffer

• 200 Mbytes/sec maximum instantaneous data transfers per port

• 10K RPM spindle; average latency = 3.0 msec

• Command queuing of up to 128 commands

• Background processing of queue

• Supports start and stop commands

3.4 Reliability

• Annualized Failure Rate (AFR) of 0.62%

• LSI circuitry

• Balanced low mass rotary voice coil actuator

• Self-Monitoring Analysis and Reporting Technology (S.M.A.R.T.)

• Dithering

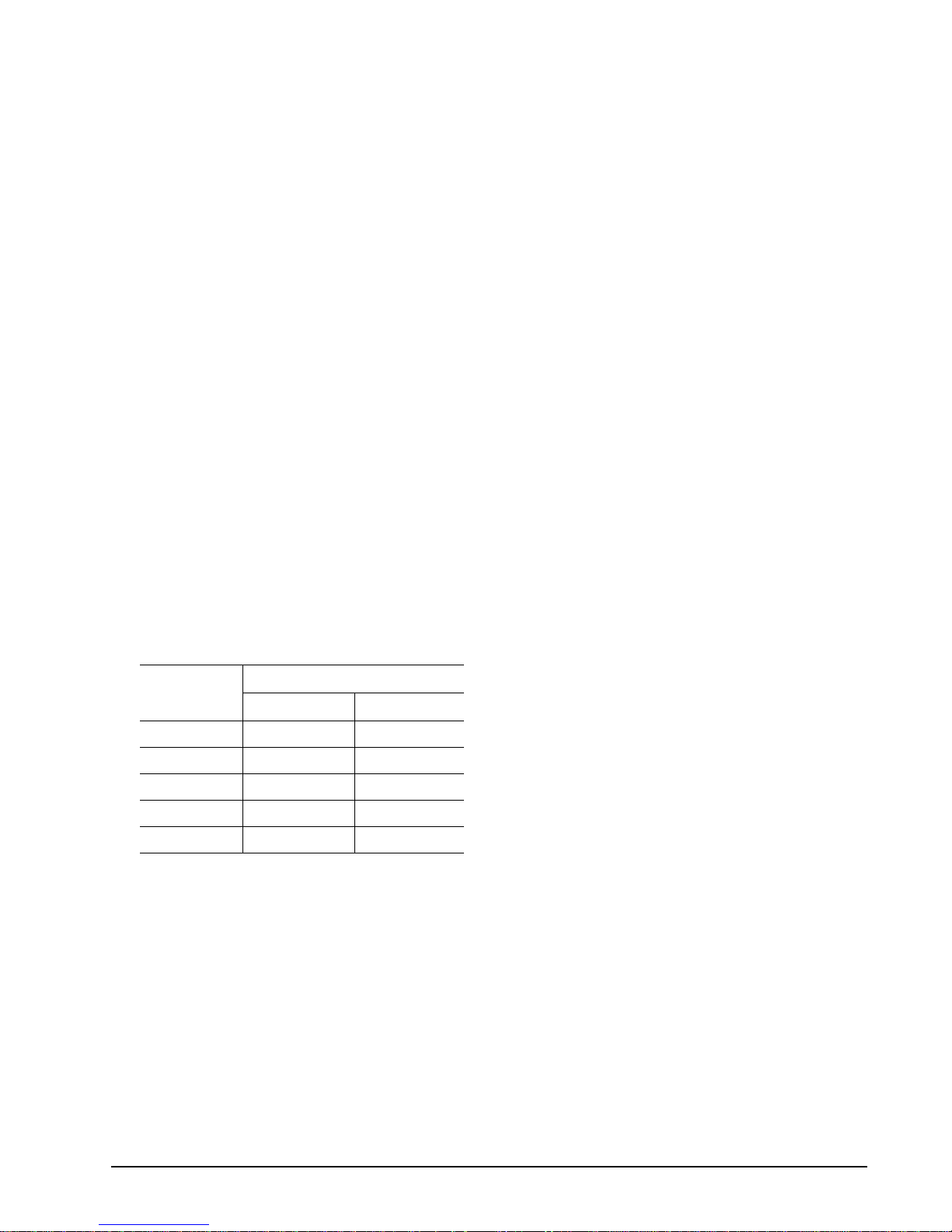

3.5 Formatted capacities

Standard OEM models are formatted to 512 bytes per block. The sector size is selectable at format time. Users

having the necessary equipm ent may mo dify the data block s ize before issuing a fo rmat comm and and obtain

different formatted capacities than those listed.

For 2 gigabit operation, sector sizes must be divisible by 8.

To provide a stable target capacity environment and at the same time provide users with flexibility if they

choose, Seagate recommends product planning in one of two modes:

1. Seagate designs specify capacity points at certain sector sizes that Seagate guarantees current and future

products will meet. We recommend custo mers use this capacity in their project pl anning, as it ensures a

stable operating point with bac kward and forwar d com patibility from gen eration to gener ation. The curren t

guaranteed operating points for this product are:

ST336807FC

Sector Size

Decimal Hex

512 71,687,372 445DCCC

514 70,512,692 433F034

520 70,197,546 6C4CCA

522 69,731,801 42805D9

524 68,788,592 419A170

2. Seagate drives also may be used at the maximum available capacity at a given sector size, but the excess

capacity above the guaranteed level will vary between 10K and 15K families and from generation to generation, depending on how each sector si ze actually for mats out for zone frequencies an d splits over serv o

bursts. This added capaci ty potent ial may range from 0.1 to 1.3 percent above th e guarant eed capacities

listed above. Us ing th e dr ives in th is mann er gi ves the ab so lute m aximu m capacity poten tial, but the user

must determine if the extra ca pacity potential is useful, or whether their assurance of backward and forward compatibility takes precedenc e.

3.5.1 Programmable drive capacity

Using the Mode Select command, the drive can change its capacity to something less than maximum. See the

Mode Select Parameter List table in the SCSI Interface Product Manual. Refer to the Parameter list block

descriptor number of blocks field. A value of zero in the number of blocks field indicates that the drive shall not

Cheetah 10K.7 36GB FC Product Manual, Rev. A 9

Page 22

change the capacity it i s currently forma tted to have. A number in the n umber of block s field that is less than

the maximum numbe r of LBAs changes th e total driv e capacity t o the val ue in the block des criptor number of

blocks field. A value greater than the maximum number of LBAs is rounded down to the maximum capacity.

3.6 Factory-install ed accessories

OEM standard drives are shipped with the Cheetah 10K.7 36GB FC Installation Guide (part number

100384023).

3.7 Factory-install ed options

You may order the follow ing items which are incorpor ated at the manufacturing fa cility during production or

packaged before shipping. Some of the options available are (not an exhaustive list of possible options):

• Other capacities can be ordered depending on sparing scheme and sector size requested.

• Single-unit shippi ng pack. The drive is normally shipped in bulk packag ing to provide maximum p rotection

against transit damage. Units shipped individually require additional protection as provided by the single unit

shipping pack. Users planning single unit distribution should specify this option.

• The Cheetah 10K.7 36GB FC Installation Guide, part number 100384023, is usually included with each

standard OEM drive shipped, but extra copies may be ordered.

• The Safety and Regulatory Agency Specifications, part number 75789 512, is usually included with each

standard OEM drive shipped, but extra copies may be ordered.

3.8 User-installed accessories

The following accessories are available. All kits may be installed in the field.

• Evaluation kit, part number 73473644.

This kit provides an adapter card (“T-card”) to allow cable connections for two FC ports and DC power.

• Single-unit shipping pack.

10 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 23

4.0 Performance characteristics

This section provides detailed information concerning performance-related characteristics and features of

Cheetah 10K.7 FC drives.

4.1 Internal drive characteristics

ST336807FC

Drive capacity 36.8..................... ................................Gbytes (formatted, rounded off value)

Read/write data heads 1

Bytes per track 556...................... ................................Kbytes (average, rounded off values)

Bytes per surface 50.5..................... ................................Gbytes (unformatted, rounded off value)

Tracks per surface (total) 90,774................. ................................Tracks (user accessible)

Tracks per inch 105,000............... ................................TPI

Peak bits per inch 658...................... ................................KBPI

Internal data rate 470-944 .............. ................................Mbits/sec (variable with zone)

Disc rotation speed 10,000................. ................................rpm (+

Avg rotational latency 3.0....................... ................................msec

0.5%)

Cheetah 10K.7 36GB FC Product Manual, Rev. A 11

Page 24

4.2 Seek performance characteristics

4.2.1 Access time [4]

Not including controller overhead

(without disconnect) [1]

Drive level

Read Write

msec

Average—Typical [2] 4.9 5.4

Single Track—Typical [2] 0.45 0.65

Full Stroke—Typical [2] 9.9 10.5

4.2.2 Format command execution time (in minutes)

ST336807FC

Maximum (with verify)

Maximum (without veri fy )

4.2.3 Generalized performance characteristics

Minimum sector interleave 1 to 1

25

13

Data buffer transfer rate to/from disc media (one 512-byte sector):

ST336807FC

Minimum [3]* 59 MBytes/sec

Maximum [3] 118 MBytes/sec

Sustainable disc transfer rate:

ST336807FC

Minimum [3]* 39 MBytes/sec

Maximum [3] 80 MBytes/sec

Fibre Channel Interface maximum instantaneous transfer rate

1 GHz 2 GHz

106 Mbytes/sec* per port

(dual port = 212 Mbytes/

sec*)

Note. 1 Megabyte (MB) = 1,000,000 bytes.

Sector Sizes

Default is 512-byte data blocks.

212 Mbytes/sec* per

port (dual port = 424

Mbytes/sec*)

Logical block sizes

Default is 512-byte data blocks

Variable 512 to 528 bytes per sector in a multiple of 4 bytes per sector

Read/write consecutive sectors on a track Yes

12 Cheetah 10K.7 36GB FC Product Manual, Rev. A

.

Page 25

Flaw reallocation performance impact (for flaws reallocated at format time

using the spare sectors per sparing zone reallocation scheme.)

Overhead time for head switch in sequential mode

Overhead time for one track cylinder switch in sequential mode

Average rotational latency

*Assumes no errors and no relocated logical blocks. Rate measured from the start of the first logical block transfer to or

from the host.

Negligible

0.8 msec

1.2 msec (typical)

3.0 msec

Notes for Section 4.2.

[1] Execution time measured from receipt of the last byte of the Com mand Descriptor Block (CDB) to th e

request for a Status Byte Transfer to the Initiator (excluding connect/disconnect).

[2] Typi cal acc ess ti mes are meas ured under nomin al conditi ons o f tempe ratur e, voltage, and horiz ontal ori-

entation as measured on a representative sample of drives.

[3] Assumes system ability to support the rates listed and no cable loss.

[4] Access to data = access time + latency time.

4.3 Start/stop time

If the Motor Start option is disabled, the drive becomes ready within 25 seconds after DC power is applied. If a

recoverable error condition is detected during the start sequence, the drive executes a recovery procedure and

the time to become ready may exceed 25 seconds. Stop time is less than 30 seconds (maximum) from

removal of DC power.

If the Motor Start option is enabled, the internal controller accep ts the commands listed in the Fibre Channel

Interface Manual less than 3 s econds after DC power has been appli ed. After the Motor Start command has

been received, the drive becomes ready for normal operations within 25 seconds (excluding the error recovery

procedure). The Motor Start command can also be used to command the drive to stop the spindle.

There is no power control switch on the drive.

4.4 Prefetch/multi-segmented cache control

The drive provides a prefetch ( read look-ahead) and multi-se gmented cache control algori thms that in many

cases can enhan ce system performance. Cac he refers to the drive buffer stor age space when it is used in

cache operations . To sel ect this feature, th e host sends the Mode Sel ect command with the p roper values in

the applicable bytes in page 08h. Prefetch and cache operations are independent features from the standpoint

that each is enabled and dis abled indepe ndently using the Mode Select c ommand; however, in actual operation, the prefetch feature overlaps cache operation somewhat as described in sections 4.5.1 and 4.5.2.

All default cache and prefetch mode paramete r values (Mode Page 08 h) for standard OEM versions of this

drive family are given in Table 25.

4.5 Cache operation

Note. Refer to the Fibre Channel Interface Manual for more detail concerning the cache bits.

Of the 8,192 kbytes physical buffer space in the drive, 6,991 kbytes can be used as a cache. The buffer can be

divided into logical segments (using Mode Select Page 08h, byte 13) from which data is read and to which data

is written.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 13

Page 26

The drive keeps track of the logical block addresses of the data stor ed in each segment of the buffer. If the

cache is enabled (see RCD bit in the Fibre Chann el In ter fac e M anua l), data reque ste d by the ho st wi th a r ea d

command is retrieved from the buffer, if possible, before any disc access is initiated. If ca che operation is not

enabled, the buffer (still segm ented with the required number of segments) is still used, but only as ci rcular

buffer segments during disc medium rea d operations (disregar ding Prefetch operation for the moment). That

is, the drive does not check in the buffer segments for the requested read data, but goes directly to the medium

to retrieve it. The retrieved data merely passes through some buffer segment on the way to the host. O n a

cache miss, all data transfers to the host are in accordance with buffer-full ratio rules. On a cache hit, the drive

ignores the buffer-full ratio rules. See the explanation provided with the information about Mode Page 02h (disconnect/reconnect control) in the Fibre Channel Interface Manual.

The following is a simplified description of the prefetch/cache operation:

Case A—read command is received and the first logical block is already in the cache:

1. Drive transfers to the initiator the first logical block requested plus all subsequent contiguous logical blocks

that are already in the cache. This data may be in multiple segments.

2. When a requested log ical block i s reached that is not in an y cache se gment, the dri ve fetches it and any

remaining requested lo gical b lock a ddres ses from th e disc and puts them in a seg ment o f the cache . The

drive transfers the r emaining requested l ogical blocks from t he cache to the host in a ccordance with the

Mode Select Disconnect/Reconnect parameters, page 02h.

3. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

Case B—A Read command requests data, and the first logical block is not in any segment of the cache:

1. The drive fetches th e requested logical blocks f rom the dis c and trans fers them into a se gment, and then

from there to the host in accordance with the Mode Select Disconnect/Reconnect parameters, page 02h.

2. If the prefetch feature is enabled, refer to section 4.5.2 for operation from this point.

During a prefetch, the drive cross es a cylinder boundary to fetc h data only if the Disco ntinui ty (DISC) bit is se t

to 1 in bit 4 of byte 2 of the Mode Select parameters page 08h. Default is zero for bit 4.

Each cache se gment is actually a s elf-contained circula r buffer whose length is an integer number of logical

blocks. The wrap-ar ound capability of the individual segm ents greatly enhances the cache’s overa ll performance, allowing a wide range of user-sele ctable configurations. The d rive supports operation of any integer

number of segments from 1 to 32. D ivide the 6 ,877 Kbyt es in the b uffer by the numbe r of seg ments to get the

segment size in bytes; then divide by the sector size to get the number of sectors per segment, any partial sectors remaining are not used. Default is 3 segments.

Note. The size of each segment is not reported by Mode Se nse command page 08h, bytes 14 and 15.

The value 0XFFFF is always reported regardless of the actual size of the segm ent . Se ndi ng a siz e

specification using the Mode Select command (byt es 14 and 15) does not set up a new segment

size. If the STRICT bit in Mode page 00h (byte 2, bit 1) is set to one , the driv e respon ds as it does

for any attempt to change an unchangeable parameter.

4.5.1 Caching write data

Write caching is a write operation by the drive th at mak es use of a drive buffer sto ra ge area where the data to

be written to the medium is stored while the drive performs the Write command.

If read caching is enabled (RCD=0), then data written to the medium is retained in the cache to be made available for future read cache h its. The same buffer space an d segme ntation is use d as set up for read functions .

The buffer segmentation s cheme is set up or changed independently, having nothing to do with the state of

RCD. When a write command is issued, i f RCD=0, the cache is first checke d to see if any logical blocks tha t

are to be written are a lready stored in the cache f rom a previous read or write comman d. If there are, the

respective cache segments are cleared. The new data is cached for subsequent Read commands.

14 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 27

If the number of write data logical blocks exceed the size of the segment being written into, when the end of the

segment is reached, the data is written into the beginning of the same cache segment, overwriting the data that

was written there at the beginning of the operation; however, the drive does not overwrite data that has not yet

been written to the medium.

If write caching is enabled (WCE=1), then the drive may return Good status on a write command after the data

has been transferred into the cache, but befor e the data has been written to the medium. If an error oc curs

while writing the data to the medium, and Good status has already been returned, a deferred error will be generated.

The Synchronize Cache command may be used to force the drive to write all cached write data to the medium.

Upon completion of a Synchronize Cache command, all data received from previous write commands will have

been written to the medium.

Table 25 shows the mode default settings for the drive.

4.5.2 Prefetch operation

If the Prefetch fea ture i s ena bl ed, data in co nti guo us lo gi cal b lock s on t he d is c immediately beyond tha t whi ch

was requested by a Read c ommand are retrieved and stored in the buffer for immediate transfer from the

buffer to the host on subsequ ent Read com mands that request t hose logica l block s (this is tr ue even if cache

operation is disabled). Though the prefetch operation uses the buffer as a cache, finding the requested data in

the buffer is a prefetch hit, not a cache operation hit.

To ena ble Prefetch, use Mode S elect page 08h, byte 12, bit 5 (Disable Read Ahead—DRA bit). DRA bit = 0

enables prefetch.

Since data that is pr efetch ed r eplaces data alre ady in som e buffer s egmen ts, the ho st c an li mit the amou nt of

prefetch data to optimize system per formance. The Max Prefetch field (bytes 8 and 9) limits the amount of

prefetch. The drive does not use the Prefetch Ceiling field (bytes 10 and 11).

During a prefetch operation, the drive cros ses a cylinder boundary to fetch more data only if Mode param ete rs

page 08h, byte 2, bit 4 is set to 1 (Discontinuity—DISC bit).

When prefetch (read look -ahead) is enabled (enabled by DRA = 0), it opera tes under the control of ARLA

(Adaptive Read Look-Ahead). If the host uses software interleave, ARLA enables prefetch of contiguous

blocks from the disc when it senses that a prefetch hit will likely occur, even if two consecutive read operations

were not for physically co ntiguous blocks of data (e.g. “software interleave ”). ARLA disables pr efetch when it

decides that a prefetch hit will not likely occur. If the host is not using software interleave, and if two sequential

read operations are no t for c ontigu ous bloc ks of data, ARLA d isables prefetc h, but as long as se quentia l read

operations request contiguous blocks of data, ARLA keeps prefetch enabled.

4.5.3 Optimizing cache performance for desktop and server applications

Desktop and server applications require different drive caching operations for optimal performance. This

means it is difficult to provide a single configuration that meets both of these needs. In a desktop environment,

you want to con figure the cache to respond q uickly to repetitive ac cesses of multiple s mall segmen ts of data

without taking the time to “look ahea d” to the next conti guous segmen ts of data. In a server environ ment, you

want to configure the cac he to provide large volumes of seque ntial data in a non-repetitive manner. In this

case, the ability of the cache to “look ahead” to the next contiguous segmen ts of sequential data is a good

thing.

The Performance Mode (PM) bit contr ols the way the drive switches the cache buffer into different modes o f

segmentation. In “server mode” (PM bit = 0), the drive can dynamically cha nge the number of cache buffer

segments as needed to opt imize the performa nce, based on the command st ream from the hos t. In “desktop

mode” (PM bit = 1), the number of segments is maintained at the value defined in Mode Page 8, Byte 13, at all

times. For additio nal information about the PM bit , refer to the Unit Attention Parame ters page (00h) of the

Mode Sense command (1Ah) in the Fibre Channel Interface Product Manual, part number 77767496.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 15

Page 28

16 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 29

5.0 Reliability specifications

The following reli ability specifica tions assume co rrect host and drive operational interfa ce, including al l interface timings, power supply voltages, environmental requirements and drive mounting constraints

Seek error rate Less than 10 errors in 10

Read Error Rates

1

Recovered Data Less than 10 errors in 10

Unrecovered Data Less than 1 sector in 10

Miscorrected Data Less than 1 sector in 10

Interface error rate Less than 1 error in 10

Less than 1 error in 10

(see Section 9.6.4, "Differential PECL input." on page 68)

AFR 0.62%

Service life 5 years

Preventive maintenance None required

1. Error rate specified with automatic retries and data correction with ECC enabled and all flaws reallocated.

5.1 Error rates

8

seeks

12

bits transferred (OEM default settings)

15

bits transferred

21

bits transferred

12

bits transferred with minimum receive eye

14

bits transferred with typical receive eye

The error rates stated in this manual assume the following:

• The drive is operated in accordance with this manual usi ng DC power as defined in paragraph 6.2, " DC

power requirements."

• Errors caused by host system failures are excluded from error rate computations.

• Assume random data.

• Default OEM error r ecovery settings are applied. Thi s includes AWRE, ARRE, full read retries, fu ll write

retries and full retry time.

5.1.1 Recoverable Errors

Recovereable errors are those detected and corrected by the drive, and do not require user intervention.

Recoverable Data errors will use co rrection, although ECC on -the-fly is not considered for purposes of recov-

ered error specifica tio ns.

Recovered Data error rate is determine d using read bits transfer red for recove rable errors occurring dur ing a

read, and using write bits transferred for recoverable errors occurring during a write.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 17

Page 30

5.1.2 Unrecoverable errors

15

Unrecoverable Data Errors (Sense Ke y = 03h) are s pecified at les s than 1 sect or in error per 10

bits trans-

ferred. Unrecoverable Data Errors resulting from the same cause are treated are 1 error for that block.

5.1.3 Seek errors

A seek error is defined as a fail ur e of the dr i ve to pos it ion the heads to the addressed t rack . After dete cti ng a n

initial seek error, the drive automatically performs an error recovery process. If the error recovery process fails,

a seek positioning error (Error code = 15h or 02h) will be reporte d with a Hardware error (04h) in t he Sense

Key. Recoverable seek errors are specified at Less than 10 er rors in 10

8

seeks. Unre covera ble se ek erro rs

(Sense Key = 04h) are classified as drive failures.

5.1.4 Interface errors

An interface error is defin ed as a failure of the receiver on a port to recover the d ata as transmitted by the

device port connected to the receiver. The error may be detected as a running disparity error, illegal code, loss

of word sync, or CRC error. The total error rate for a loop o f devices is the sum of the individu al device error

rates.

5.2 Reliability and service

You can enhance the r eliability of Cheetah 10K.7 SCS I disc drives by ensuring that the drive receives a dequate cooling. S ection 6.0 provides temperature measurements and other informa tion that may be used to

enhance the service life of the drive. Section 8.3 provides recommended air-flow information.

5.2.1 Annualized Failure Rate (AFR)

The production disc dr ive shall achieve an AFR of 0.62% when oper ated in an environm ent that ensures th e

HDA case temperatur es spec ified in Sectio n 6. 4 are not exce eded. S hort -term ex cursi ons u p to th e spec ification limits of the operating e nvironment will not affect AFR perfor mance. Continual or sustained operation at

case temperatures above the values shown in Section 6.4.1 may degrade product reliability.

Estimated power-on operation hours means power-up hours per disc drive times the total number of disc

drives in service. Ea ch dis c drive shall h ave accu mulate d at le ast nine months of operatio n. Data sha ll be ca lculated on a rolling average base for a minimum period of six months.

AFR is based on the following assumption s:

• 8,760 power-on hours per year.

• 250 average on/off cycles per year.

• Operations at nominal voltages.

• Systems will prov ide adequate coolin g to ensure the case temperatures specified in Sec tion 6.4.1 are not

exceeded.

Drive failure means any stoppage or substandard performance caused by drive malfunction.

A S.M.A.R.T. predictive failure indic ates that the drive i s deterior ating to an immin ent failu re and is co nside red

an AFR hit.

5.2.2 Preventive maintenance

No routine scheduled preventive maintenance is required.

18 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 31

5.2.3 Hot plugging the drive

Inserting and removin g the drive on the FC-AL will i nterrupt loop o peration. T he interrupti on occurs when th e

receiver of the nex t device in t he loop mus t synchro nize to a differen t input si gnal. FC e rror detecti on mechanisms, character sync, running disparity, word sync, and CRC are able to detect any error. Recovery is initiated

based on the type of error.

The disc drive defau lts to the FC- AL Mo nitoring state, Pas s-thro ugh state, w hen it is powe red- on by swi tchin g

the power or hot plugg ed. The cont rol line to an optiona l port bypass c ircuit (exte rnal to th e drive), def aults to

the Enable Bypass state. If the bypass circuit is present, the next device in the loop will continue to receive the

output of the previous device to the newly inserted device. If the bypass circuit is not present, loop operation is

temporarily disrupted until the next device starts receiving the output from the newly inserted device and

regains synchronization to the new input.

The Pass-through state is disabled while the drive performs self test of the FC interface. The control line for an

external port bypass circuit remains in the Enable Bypass state while self test is running. If the bypass circuit is

present, loop operation may continue. If the bypass circuit is not present, loop operation will be halted while the

self test of the FC interface runs.

When the self test completes successfully, the control line to the bypass circuit is disabled and the drive enters

the FC-AL Initializing state. The receiver on the next device in the loop must synchronize to output of the newly

inserted drive.

If the self-test fails, the control line to the bypass circuit remains in the Enable Bypass state.

Note. It is the responsibili ty o f the sy s tems in teg ra tor to a ss ur e th at no tem per atu re, en ergy, voltage haz-

ard, or ESD potential haza rd is presented dur ing the hot connect/di sconnect oper ation. Discharge

the static electricity from the drive carrier prior to inserting it into the system.

Caution. The drive motor must come to a complete stop prior to changing the plane of operation. This time is

required to insure data integrity.

5.2.4 S.M.A.R.T.

S.M.A.R.T. is an acronym for Self-Mon itoring Ana lysis and Re porting Technology. Thi s technology is intende d

to recognize conditio ns that indicate imminent drive failure and is des igned to provide sufficient warn ing of a

failure to allow you to back up the data before an actual failure occurs.

Note. The drive’s firmware monitors specific attributes for degradation over time but can’t predict instanta-

neous drive failures.

Each monitored a ttrib ute has b een sele cted to moni tor a specifi c se t of fai lure c onditi ons in th e oper ating performance of the drive and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions

Control mode page (1Ch). Use th e DEXCPT bit to ena ble or disab le the S.M. A.R.T. feature. Setting th e DEXCPT bit disables all S.M.A.R.T. functions. When enabled, S.M.A.R.T . collects on-line data as the drive performs

normal read and write operations. When the PERF bit is set, the drive is consi dered to be in “On-line Mod e

Only” and will not perform off-line functions.

You can measure off-line attr ibutes and for ce the drive to sa ve the data by usi ng the Rezero Uni t command.

Forcing S.M.A.R.T. resets the timer so that the next scheduled interrupt is in two hours.

You can interrogate the drive through the host to determine the time remaining before the next scheduled measurement and data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E.

This allows you to c ontrol when S.M.A.R.T. interruptions occur. Forcing S.M.A.R.T. w ith the RTZ command

resets the timer.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 19

Page 32

Performance impact

S.M.A.R.T. attribute data is saved to the disc so that the events that ca used a predictive fai lure can be recr eated. The drive measures and sav es paramete rs once ever y two hours su bject to an id le period on the FC-A L

bus. The process o f meas uring off-l ine att ribute da ta and saving data to the di sc is uninte rruptable. The max imum on-line only processing delay is summarized below:

Maximum processing delay

S.M.A.R.T. delay times

On-line only delay

DEXCPT = 0, PERF = 1

60 milliseconds

Fully-enabled delay

DEXCPT = 0, PERF = 0

370

milliseconds

Reporting control

Reporting is controlled by the MRIE bits in the Inform ational Exceptio ns Control mode page (1Ch). Subject to

the reporting metho d, t he firmw are w ill is sue to the h ost a n 0 1-5Dxx sense code. The error code is pr eserve d

through bus resets and power cycles.

Determining rate

S.M.A.R.T . monitors the rate at which errors occur and signals a predictive failure if the rate of degraded errors

increases to an unacceptable level. To determine rate, error events are logged and compared to the number of

total operations for a given attribu te. The in terval de fine s the numb er of operati ons over which to mea sure the

rate. The counter that keeps track of the current number of operations is referred to as the Interval Counter.

S.M.A.R.T. measures error rates. All errors for each monitored attribute are recorded. A counter keeps track of

the number of errors for the current interval. This counter is referred to as the Failure Counter.

Error rate is the number of errors per operation. The algorithm that S.M.A.R.T. uses to record rates of error is to

set thresholds for the number of errors an d their inte rval. If the nu mber of error s exceed s the thr eshold bef ore

the interval expires, the error rate i s considered to be unacc eptable. If the number of errors does not exceed

the threshold before the interval expires, the error rate is considered to be acceptable. In either case, the interval and failure counters are reset and the process starts over.

Predictive failures

S.M.A.R.T. signals predictive failures when the drive is performi ng unacc eptably for a peri od of time. The fir mware keeps a running count of the number of times the error rate for each attribute is unacceptable. To accomplish this, a cou nter is i ncremen ted each time the error rat e is un acceptable and decr emented (not to e xceed

zero) whenever t he error ra te is a cceptabl e. If the co unter contin ually in crem ents such that it reache s the pr edictive threshol d, a predictive failure is signaled. This counter is r eferred to as the Failure H istory Counter.

There is a separate Failure History Counter for each attribute.

5.2.5 Thermal monitor

Cheetah 10K.7 SCSI drives implement a temperature warning system which:

1. Signals the host if the temperature exceeds a value which would threaten the drive.

2. Signals the host if the temperature exceeds a user-specified value.

3. Saves a S.M.A.R.T. data frame on the drive which exceed the threatening temperature value.

A temperature sensor monito rs the drive temperature and is sues a warning over the int erface when the temperature exceeds a s et threshol d. The temper ature is measured at power-up an d then at te n-minute intervals

after power-up.

20 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 33

The thermal monitor syste m generates a wa rning code of 01- 0B01 when the temp erature exceed s the specified limit in compl iance with the SCSI standard. T he drive temperature is repo rted in the FRU code field o f

mode sense data. You can use this information to determine if the warning is due to the temperature exceeding

the drive threatening temperature or the user-specified temperature.

This feature is controlled by the Enable Warning (EWasc) bit, and the reporting mechanism is controlled by the

Method of Reporting Informational Exceptions field (MRIE) on the Informational Exceptions Control (IEC)

mode page (1Ch).

The current algorithm impl ements two temperature trip points. The first trip point is set at 68°C which is the

maximum temperatur e limit a ccordi ng to th e dri ve spec ific ation. T he secon d trip point is us er-se lectable using

the Log Select command. The reference temperature parameter in the temperature log page (see Table 1) can

be used to set this trip point. The default value for this drive is 68°C, however, you can set it to any value in the

range of 0 to 68°C. If you specify a temperature g reater than 68°C in this fi eld, the temperature is rou nded

down to 68°C. A sense code is sent to the host to indicate the rounding of the parameter field.

Table 1: Temperature Log page (0Dh)

Parameter Code Description

0000h Primary Temperature

0001h Reference Temperature

When the first temperature trip point is exceeded, S.M.A.R.T. data is collected and a frame is saved to the disc.

5.2.6 Drive Self Test (DST)

Drive Self Test (DST) is a technolo gy designed to recognize dri ve fault conditions that qualify the drive as a

failed unit. DST validates the functionality of the drive at a system level.

There are two test coverage options implemented in DST:

1. Extended test

2. Short text

The most thorough option is the extended test that performs various tests on the drive and scans every logical

block address (LBA ) of the drive. The s hort test is time-r estricted and limited i n length—it does n ot scan the

entire media surface, but does some fundamental tests and scans portions of the media.

If DST encounters an er ror during either of these tests, i t reports a fault condition. If the dr ive fails the test,

remove it from service and return it to Seagate for service.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 21

Page 34

5.2.6.1 DST Failure Definition

The drive will presen t a “diagnostic failed” con dition through the self-te sts results value of the diagnos tic log

page if a functional failur e is enco untered du ring DST. The channel and servo parameters are not mod ified to

test the drive more strin gently, and the number of retries are not redu ced. All retries and recovery proce sses

are enabled during the test. If data is recoverable, no failure condition will be reported regardless of the number

of retries required to recover the data.

The following conditions are considered DST failure conditions:

• Seek error after retries are exhausted

• Track-follow error after retries are exhausted

• Read error after retries are exhausted

• Write error after retries are exhausted

Recovered errors will not be reported as diagnostic failures.

5.2.6.2 Implementation

This section provides all of the information necessary to implement the DST function on this drive.

5.2.6.2.1 State of the drive prior to testing

The drive must be in a ready state before issuing the Send Diagno stic command . There are multipl e reasons

why a drive may not be ready, some of which are valid conditions, and not errors. For example, a drive may be

in process of doing a format, or another DST. It is the responsibility of the host application to determine the “not

ready” cause.

While not technically part of DST, a Not Ready condition also qualifies the drive to be returned to Seagate as a

failed drive.

A Drive Not Ready condition is reported by the drive under the following conditions:

• Motor will not spin

• Motor will not lock to speed

• Servo will not lock on track

• Drive cannot read configuration tables from the disc

In these conditions, the drive responds to a Test Unit Ready command with an 02/04/00 or 02/04/03 code.

5.2.6.2.2 Invoking DST

To in voke DST, submit the Send Diagnostic comman d with the ap propriate Fun ction Code (001b for the short

test or 010b for the extende d test) in bytes 1, bits 5, 6, and 7. Ref er to the Fibre Channel Interf ace Product

Manual, part number 77767496, for additional information about invoking DST.

5.2.6.2.3 Short and extended tests

DST has two testing options:

1. short

2. extended

These testing options are described in the following two subsections.

Each test consists of th ree s egm ents: a n el ec tric al test segm ent, a servo test segment , and a rea d/v er ify s ca n

segment.

22 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 35

Short test (Function Code: 001b)

The purpose of the short test is to provide a time-l imit ed te st tha t t e sts as m uch of the drive as possible within

120 seconds. The shor t test does not scan the entire me dia surface, but does some funda mental tests and

scans portions of the media. A complete read/verify scan is not performed and only factual failures will report a

fault condition. This option provides a quick confidence test of the drive.

Extended test (Function Code: 010b)

The objective of the extended test option is to empirically test critical drive components. For example, the seek

tests and on-track operations tes t the pos it ion ing mec han ism. T he read operation tests the read head element

and the media surface. The write element is tested throu gh read/write/read operations. The inte grity of the

media is checked through a r ead/verif y scan of the med ia. Motor functio nality is tested by d efault as a part of

these tests.

The anticipated length of the Extended test is reported through the Control Mode page.

5.2.6.2.4 Log page entries

When the drive begi ns DST, it creates a new entry in the Self -te st Resul ts Log page . The new entr y is c reated

by inserting a new self-test parameter block at the beginning of the self-test results log parameter section of the

log page. Existing da ta will be moved to make room f or the new parameter block. The dr iv e rep or ts 20 par ameter blocks in the log page. If there are more than 20 parameter blocks, the least recent parameter block will be

deleted. The new parameter block will be initialized as follows:

1. The Function Code field is set to the same value as sent in the DST command

2. The Self-Test Results Value field is set to Fh

3. The drive will store the log page to non-volatile memory

After a self-test is complete or has been aborted, the dr i ve upda tes the Sel f- Test Results Val ue fiel d in its Se lf-

Test Results L og pa ge in n on- v ola til e m emo ry. The host may use Log Sense to read the results from up to th e

last 20 self-tests performed by the drive. The self-test results value is a 4-bit field that reports the results of the

test. If the field is zero, the drive passed with no erro rs detected by the DST. If the field is not zero, the test

failed for the reason reported in the field.

The drive will report th e failure condition and LBA (i f applicable) in the Self-tes t Results Log parameter. The

Sense key, ASC, ASCQ, and FRU are used to report the failure condition.

5.2.6.2.5 Abort

There are several ways to abort a diagnostic. You can use a SCSI Bus Reset or a Bus Device Reset message

to abort the diagnostic.

You can abort a DST executing in backgrou nd mode by us ing the abor t code in the DS T Functio n Code field .

This will cause a 01 ( self-test aborted b y the application cl ient) code to appear i n the self-test results v alues

log. All other abort mechanisms will be reported as a 02 (self-test routine was interrupted by a reset condition).

5.2.7 Product warranty

Beginning on the date of shi pm ent to the cu stomer and continuing for a per i od of five years, Seagate warrants

that each product (inclu ding componen ts and subassemb lies) that fails to fu nction prope rly under normal use

due to defect in materials or workmanship or due to noncon formance to the applicable spec ifications will be

repaired or replaced, at Seag ate’s option and at no charge to the customer, if returned by customer at customer’s expens e to Seagate’s designated faci lity in accordance wit h Seagate’s warranty proced ure. Seagate

will pay for transporting the repair or replacement item to the customer. For more detailed warranty information,

refer to the standard te rms and conditio ns of purchase fo r Seagate produc ts. Refer to Section 1 0 for contact

information.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 23

Page 36

Shipping

When transporting or shipping a drive, use only a Seagate-approved container. Keep your original box.

Seagate approved containers are easily identified by the Seagate Approved Package label. Shipping a drive in

a non-approved container voids the drive warranty.

Seagate repair center s may refuse receipt of co mponents improperly packaged or obviously da mag ed in tr ansit. Contact your au thorized S eagate dist ributor to purchas e additio nal boxe s. Seagat e recom mends sh ipping

by an air-ride carrier experienced in handling computer equipment.

Product repair and return information

Seagate customer se rvice centers are th e only facilities au thorized to service Sea gate drives. Seagate d oes

not sanction any third-party repair fac ilities. Any unauthorized repair or tamper ing with the factory seal voids

the warranty.

24 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 37

6.0 Physical/electrical spe cifications

This section provides information relating to the physical and electrical characteristics of the drive.

6.1 AC power requirements

None.

6.2 DC power requirements

The voltage and current requi rements for a single drive are shown below. Values indicated apply at the drive

connector.

Table 11:

Voltage +5V +12V [2] +5V +12V [2]

Regulation [5] ±5% ±5% [2] ±5% ±5% [2]

Avg idle current DC X [1] [7]

Maximum starting current

(peak DC) DC 3σ [3]

(peak AC) AC 3σ [3]

Delayed motor start (max) DC 3σ [1] [4]

Peak operating current:

Typical DC X [1] [6]

Maximum DC 3σ [1]

Maximum (peak) DC 3σ

ST336807FC DC power requirements

ST336807FC

1 Gbit 2 Gbit

Notes (Amps) (Amps) (Amps) (Amps)

0.86 0.34 0.92 0.34

1.02 1.58 1.08 1.57

1.18 3.48 1.50 3.57

0.60 0.09 0.62 0.09

0.93 0.77 0.99 0.80

0.94 0.78 1.00 0.81

1.78 2.44 1.86 2.50

[1] Measured with average reading DC ammeter. Instantaneous +12V curren t peaks will excee d these val-

ues. Power supply at nominal voltage. Number of drives tested = 6, 35 Degrees C ambient.

[2] For +12 V, a –10 % tol er an ce is allowed during initi al sp in dle s tart but must return to ±5% before reaching

10,000 RPM. The ±5% must be maintained after the drive signifi es that its power-up seq uence has bee n

completed and that the drive is able to accept selection by the host initiator.

[3] See +12V current profile in Figure 2.

[4] This condition occurs when the M otor Start option is enabled and the driv e has not yet receiv ed a Start

Motor command.

Cheetah 10K.7 36GB FC Product Manual, Rev. A 25

Page 38

[5] See paragraph 6.2.1, "Conducted noise immunity." Specified voltage tolerance includes ripple, noise, and

transient response.

[6] Operating condition is defined as random 8 block reads at 254 I/Os per second.

Current and power sp ecified at no minal voltages . Decreasi ng +5 volt s upply by 5 % increase s 5 volt cur rent by <0.5%. Decreasing +12 volt supply by 5% increases 12 volt current by 1.4%.

[7] During idle, the drive heads are relocated every 60 seconds to a random l ocation within the ban d from

track zero to one-fourth of maximum track.

General DC power requirement notes.

1. Minimum current l oading fo r each sup ply voltage is not les s than 1. 2% of the ma ximum o perating current

shown.

2. The +5V and +12V supplies should employ separate ground returns.

3. Where power is provided to multiple drives from a common supply, careful consideration for individual

drive power requirem ents s hou ld b e no ted. Whe re mul ti ple uni ts are pow er ed o n s imu ltaneou sl y, the peak

starting current must be available to each device.

4. Parameters, other than spindle start, are measured after a 10-minute warm up.

5. No terminator power.

6.2.1 Conducted noise immunity

Noise is specified a s a periodic an d random distri bution of frequenc ies covering a band from DC to 10 MHz.

Maximum allowed noise values given below are peak to peak measurements and apply at the drive power connector.

+5 V = 250 mV pp from 100 Hz to 20 MHz.

+12 V = 800 mV pp from 100 Hz to 8 KHz.

450 mV pp from 8 KHz to 20 KHz.

250 mV pp from 20 KHz to 5 MHz.

6.2.2 Power sequencing

The drive does not require power sequenci ng. The drive prote cts against inadver tent writing dur ing power-up

and down.

26 Cheetah 10K.7 36GB FC Product Manual, Rev. A

Page 39

6.2.3 Current profiles

Figures 2 and 3 identify the drive current profiles. The current during the various times is as shown:

Note: All times and currents are typical. See Table 11 for maximum current requiremST336807FC

Figure 2. Typical ST336807FC drive, 2 Gbit, +12V current profile

Figure 3. Typical ST336807FC drive, 2 Gbit, +5V current profile

Cheetah 10K.7 36GB FC Product Manual, Rev. A 27

Page 40

6.3 Power dissipation

ST336807FC

Typical power dissipation under idle conditions is 8.38 watts (28.60 BTUs per hour) during 1 Gbit operation.

Typical power dissipation under idle conditions is 8.68 watts (29.62 BTUs per hour) during 2 Gbit operation.

To obtain operati ng power for typical random read opera tions, refer to the follo wing I/O rate curve (see Figure

4). Locate the typica l I/O rate for a drive i n your syst em on the h orizontal axis and read th e correspond ing +5

volt current, +12 vol t c ur rent, and tota l wa tts on the v er ti cal a xi s. To calculate BTUs per hour, multiply watts by

3.4123.

ST373207FC DC CURRENT/POWER vs THROUGHPUT (1Gb ) Random 8 Block Reads

1.8 00

1.6 00

1.4 00

1.2 00

18 .00

16 .00

14 .00

12 .00

5Volt A

12 Vo l t A

Watts

Power (watts)

1.0 00

0.800

Amperes

0.600

0.400

0.200

0.000

0.0 50.0 100.0 150.0 200.0 250.0 300.0

I/Os per Second

ST373207FC DC CURRENT/POWER vs THROUGHPUT (2Gb) Random 8 Block Re ad s

1.800

1.600

1.400

1.200

1.000

0.800

Amperes

0.600

0.400

10 .00

8.00

6.00

4.00

2.00

0.00

18 .00

16 .00

14 .00

12 .00

10 .00

8.00

6.00

4.00

5Volt A

12 V o lt A

Watts

Power (watts)

0.200

0.000

0.0 50.0 100.0 150.0 200.0 250.0 300.0

I/Os per Second

Figure 4. ST336807FC DC current and power vs. input/output operations per second

28 Cheetah 10K.7 36GB FC Product Manual, Rev. A

2.00

0.00

Page 41

6.4 Environmental limits

H

C