Page 1

Copy No.:

Instruction Manual

Model No. : Scott Heavy Duty Tab Cutter.................

Year of Manufacture : 2005.......

Manufactured by :..........

Document Number : TC--99999--1........

Issue : 1.....................

Date of Issue : July 2005..............

Page 2

ISSUE NOTE

This is Issue 1; Date of Issue: July 2005

Copyright 2005

Page 3

Table of Contents

III

Heavy Duty Tab Cutter

TABLE OF CONTENTS

1 INTRODUCTION & SAFETY 1--1...........................................................

1.1 Introduction 1--3....................................................................

1.1.1 Machine Specifications & Utility Requirements 1--4....................................

1.2 General Safety Guidelines 1--5.......................................................

1.3 Safety 1--6..........................................................................

1.3.1 General Machine Safety 1--6.......................................................

1.3.2 Machine Safety Features 1--7......................................................

1.3.3 Safety Switches 1--7..............................................................

1.3.4 Main Power Switch 1--7...........................................................

1.3.5 Guards and Covers 1--8...........................................................

1.3.6 Main Air Disconnect 1--8..........................................................

1.4 Warnings, Cautions & Notes 1--9.....................................................

1.4.1 Warnings 1--9....................................................................

1.4.2 Cautions 1--9....................................................................

1.4.3 Notes 1--9.......................................................................

1.5 On Machine Warnings 1--10...........................................................

1.5.1 Hazards 1--10....................................................................

1.6 Safety Procedures 1--11..............................................................

1.6.1 Appropriate Dress 1--11............................................................

1.6.2 Keep Area Clean 1--11.............................................................

1.6.3 Grease and Oil 1--11..............................................................

1.6.4 Manual Usage 1--11...............................................................

2 INSTALLATION 2--1......................................................................

2.1 Installation Requirements 2--3........................................................

2.2 Pre-Installation Requirements 2--4....................................................

2.3 Installation Of Scott Heavy Duty Tab Cutter 2--5.......................................

2.4 Assembly Instructions 2--5..........................................................

2.4.1 Start Up Adjustments 2--5.........................................................

3 OPERATION 3--1.........................................................................

3.1 GENERAL INFORMATION 3--3........................................................

3.1.1 Before Operating the Machine 3--3.................................................

3.2 Operator’s Controls 3--4.............................................................

3.2.1 Control Panel Layout 3--4.........................................................

3.2.2 Power On/OFF Selector Switch 3--4................................................

3.2.3 Machine Mode Selector Switch 3--4.................................................

3.2.4 Power On Indicator Lamp 3--5.....................................................

3.2.5 Foot Pedal 3--5..................................................................

3.2.6 Main Air ON/OFF 3--5.............................................................

3.2.7 Main Air Regulator & Lubricator 3--6................................................

3.3 Care and Adjustment of Tab Cutting Knives 3--7

.......................................

Page 4

Table of Contents

IV

HeavyDutyTabCutter

3.3.1 Before Adjusting Tab Cutting Knives: 3--7............................................

3.4 Setting Tab Cutting Knife Blades 3--8.................................................

3.4.1 Upper Knife Blades 3-- 8...........................................................

3.4.2 Lower Knife Blades 3-- 8...........................................................

3.4.3 Clearing the Blades 3--9...........................................................

3.4.4 To Adjust Knives for Different Tab Length 3--11........................................

3.4.5 To Change Knives for New Tab Extension 3--12.......................................

3.4.6 To Change Tab Position on Sheet 3--13...............................................

3.4.7 Cutting Speed of Knives 3--14.......................................................

3.4.8 Prevent Knives From Becoming Deeply Scored 3--15...................................

4 MAINTENANCE 4--1......................................................................

4.1 Care Of Air Cylinder 4--3.............................................................

4.1.1 Lubrication 4--3..................................................................

4.2 Heavy Duty Tab Cutter Spare Parts List 4--6...........................................

4.3 Machine Troubleshooting 4--7........................................................

4.3.1 Identify Leaks From Muffler 4--8....................................................

4.4 C01--1000 Series Filter -- Regulator Combination 4--9...................................

4.4.1 Installation 4--9..................................................................

4.4.2 Adjustment 4--9..................................................................

4.4.3 Maintenance & Cleaning 4--9......................................................

4.4.4 Vendor Contact Information 4--9....................................................

4.5 304--1000 & 2000 Series Lubricators 4--11..............................................

4.5.1 Installation 4--11..................................................................

4.5.2 Oil Adjustments 4--11..............................................................

4.5.3 Tamper Proof 4--11................................................................

4.5.4 Maintenance 4--11................................................................

4.5.5 Part Information 4--12..............................................................

4.5.6 Vendor Contact Information 4--12....................................................

5 PARTS 5-1..............................................................................

5.1 Knife Assembly 5-4......................................................................

5.2 Table Assembly 5-6.....................................................................

5.3 Paper Guide Assembly 5-8...............................................................

5.4 Air Cylinder Assembly 5-10................................................................

5.5 Air Valve Assembly 5-12..................................................................

5.6 Air Supply Assembly 5-14.................................................................

5.7 Knife Guard Assembly 5-16................................................................

5.8 Leg Extension Assembly 5-18..............................................................

5.9 Machine Mounting Rail Assembly 5-20......................................................

5.10 Bottom Support Rail Assembly 5-22.......................................................

5.1 1 Guard Assembly

5-24....................................................................

5.12 Controls Mounting Assembly 5-26.........................................................

6 SCHEMATICS 6-1........................................................................

Page 5

1 Introduction & Safety

1--1

Heavy Duty Tab Cutter Issue 1

1 INTRODUCTION & SAFETY

Heavy Duty Tab Cutter Issue 1

Page 6

1 Introduction & Safety

1--2

Heavy Duty Tab Cutter Issue 1

Page 7

1 Introduction & Safety

1--3

Heavy Duty Tab Cutter Issue 1

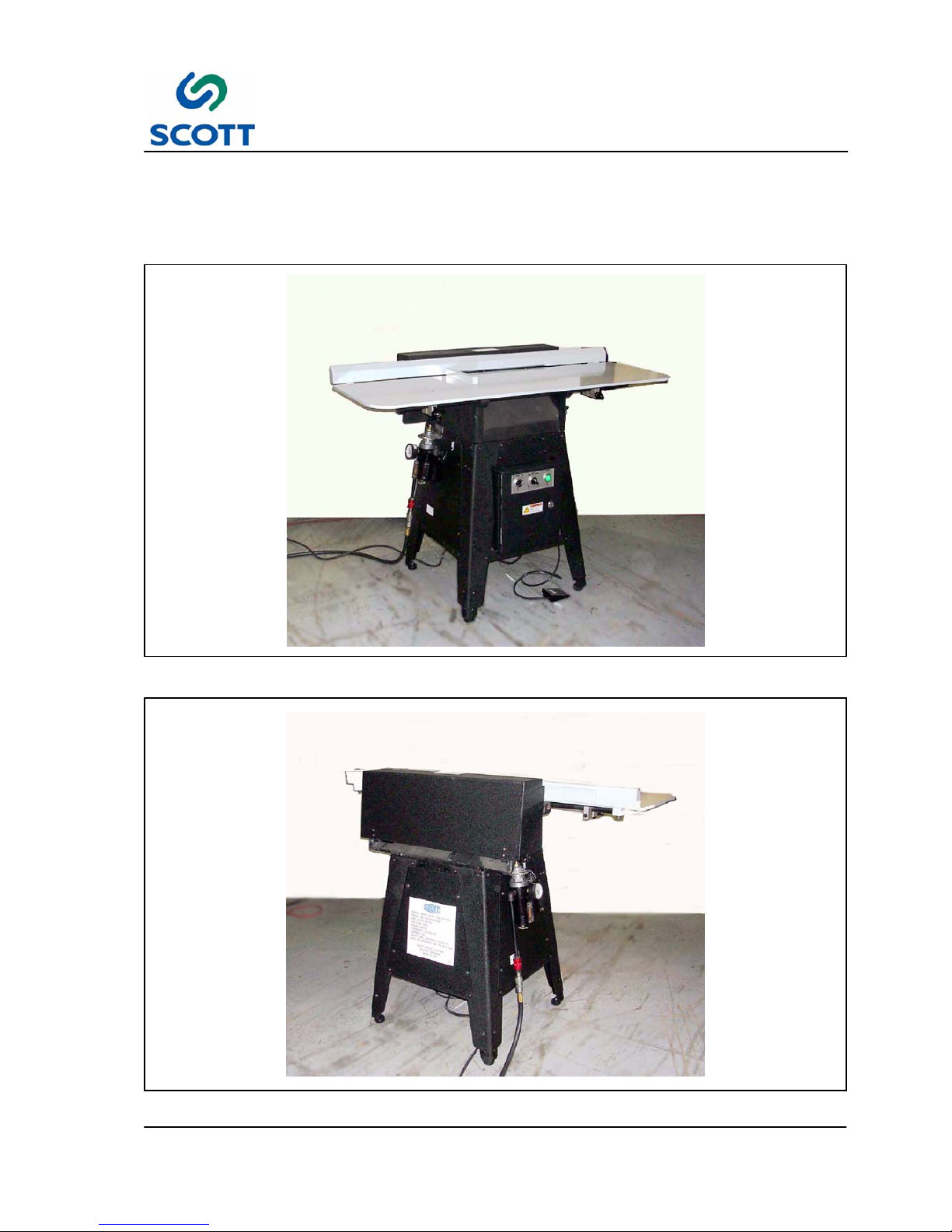

1.1 Introduction

The Scott Heavy Duty Tab Cutter machine cuts tabs on index stock at the rate of up to 3,000 sheets per

hour.

Fig. 1-1. Machine Front View

Fig. 1-2. Machine Rear View

Page 8

1 Introduction & Safety

1--4

Heavy Duty Tab Cutter Issue 1

1.1.1 Machine Specifications & Utility Requirements

Model Scott Heavy Duty Tab Cuttert

Speed

Up to 2200 sheets per hour.

Sheet Size

MIN: 140MM (5 1/2”) LENGTH

MAX: 381MM (15”) WIDE

Paper

6--POINT TO 25--POINT

Electrical Requirements

15 AMPS, 120 VAC SINGLE PHASE, 50 OR 60 HZ

Decibel Rating

90DB

Dimensions

1219MM (48”) L X 686MM (27”) W X 965MM (38”) H

Shipping Weight

152KG (335LBS)

Warranty

One year against defects in parts and workmanship. Labor Not Included.

Page 9

1 Introduction & Safety

1--5

Heavy Duty Tab Cutter Issue 1

1.2 General Safety Guidelines

Providing a safe working environment for operating your machine is the responsibility of the user. The

suggested precautions, material safety data and other suggestions that follow do not have preference over

the user’s own plant practices, regulations or safety committee recommendations.

Personal injury and equipment damage can be avoided by the continued adherence to the safety features

provided with this machine and in keeping with the necessary governmental requirements. The guarding

and interlocking safety switches have been installed on the machine for the operator’s safety. These items

should be maintained in good working order by the user.

It is assumed that the user’s safety department has established a safety program that is in keeping with a

complete analysis of industrial hazards. Before installing and operating or performing maintenance and

clean--up procedures on the machine, it is suggested that the safety program be reviewed to ensure that it

covers the possible hazards that might occur with the operation of this machine.

Due consideration must be given to those hazards which arise from the presence of electrical power, high

temperature, and cleaning materials used in the operational areas of the machine. Proper installation and

care of protective devices and over--pressure protective equipment should be considered an essential part of

any safety program.

Special lock--out features are to prevent the possibility of applying power to the equipment at any time when

maintenance work is in progress.

In general, personnel should be guided by all basic rules of safety associated with the equipment and the

process. It should be further understood that information contained in this manual does not relieve operating

and maintenance personnel of the responsibility of exercising normal good judgment in operating and care of

the machine and its attendant equipment.

Page 10

1 Introduction & Safety

1--6

Heavy Duty Tab Cutter Issue 1

1.3 Safety

1.3.1 General Machine Safety

The Scott Heavy Duty Tabcutter is a safe machine if operated properly.

The machine’s operation should be explained to all operators so that they understand exactly how the

machine works.

THE FOLLOWING PRECAUTIONS SHOULD ALWAYS BE TAKEN:

● Always set toggle switch in center position when adjusting knives.

● Always tilt table up before making any knife adjustment.

● Always turn off air by means of the ball valve which is located at the lubricator assembly.

● Always adjust safety bar close to the knife blades so that there is no room for a person’s fingers between

the safety bar and knives. To make this adjustment, loosen the two wing nuts at each end of the safety

bar, move it close to the knives and tighten. All operators should be instructed to do this.

● Never let anyone operate the micro--switch with his finger. Use a piece of paper. The switch is a

hair--trigger and the machine is extremely fast.

● Instruct everyone to never put their hands near the knives, especially at the extreme ends. When the

machine is in operation no one should be behind it or put their hands near the knives.

Page 11

1 Introduction & Safety

1--7

Heavy Duty Tab Cutter Issue 1

A

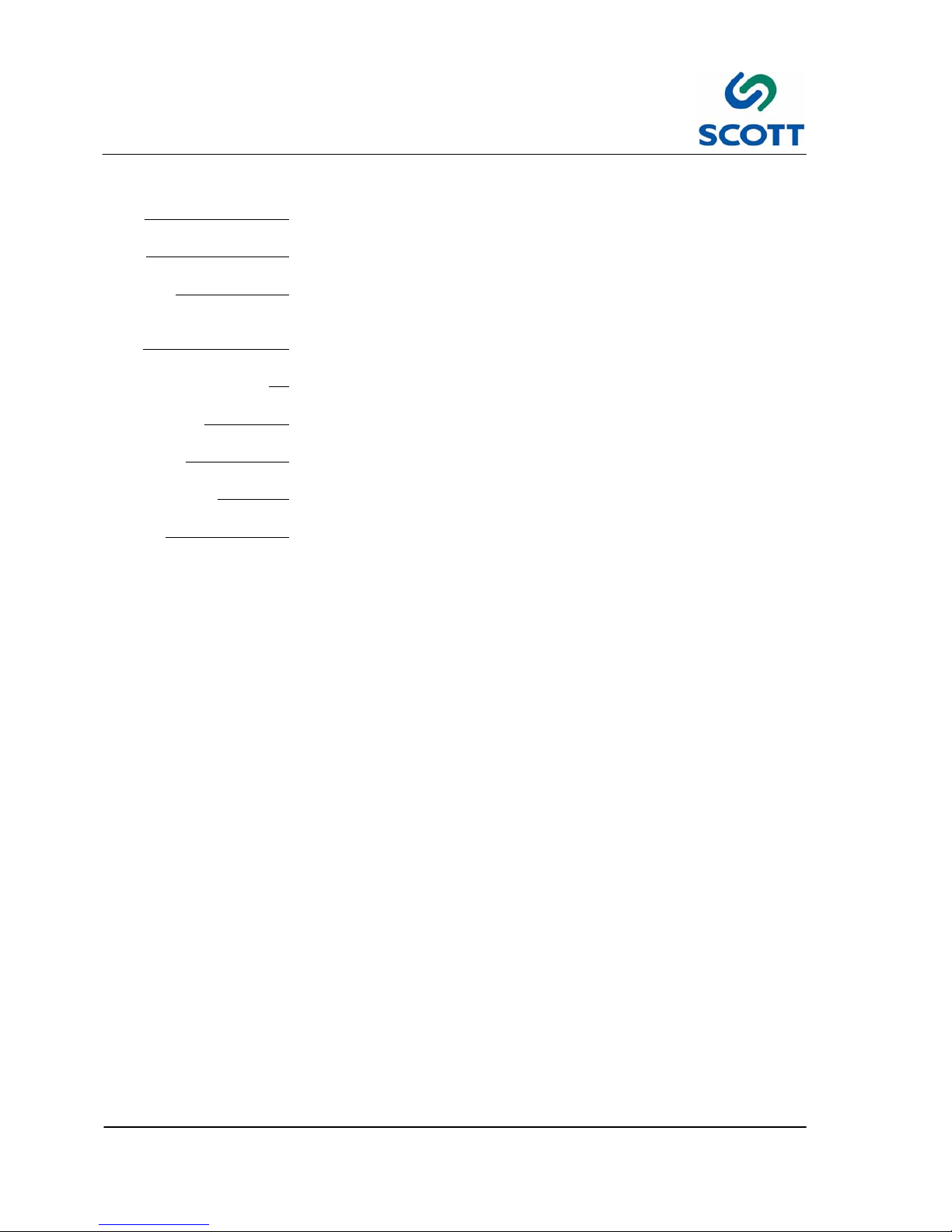

Fig. 1-3. Table Safety Switch

1.3.2 Machine Safety Features

1.3.3 Safety Switches

The machine is equipped with two safety switches.

The table switch (A) is located below the table on

the machine base. The knife guard switch (B) is

located on the base.

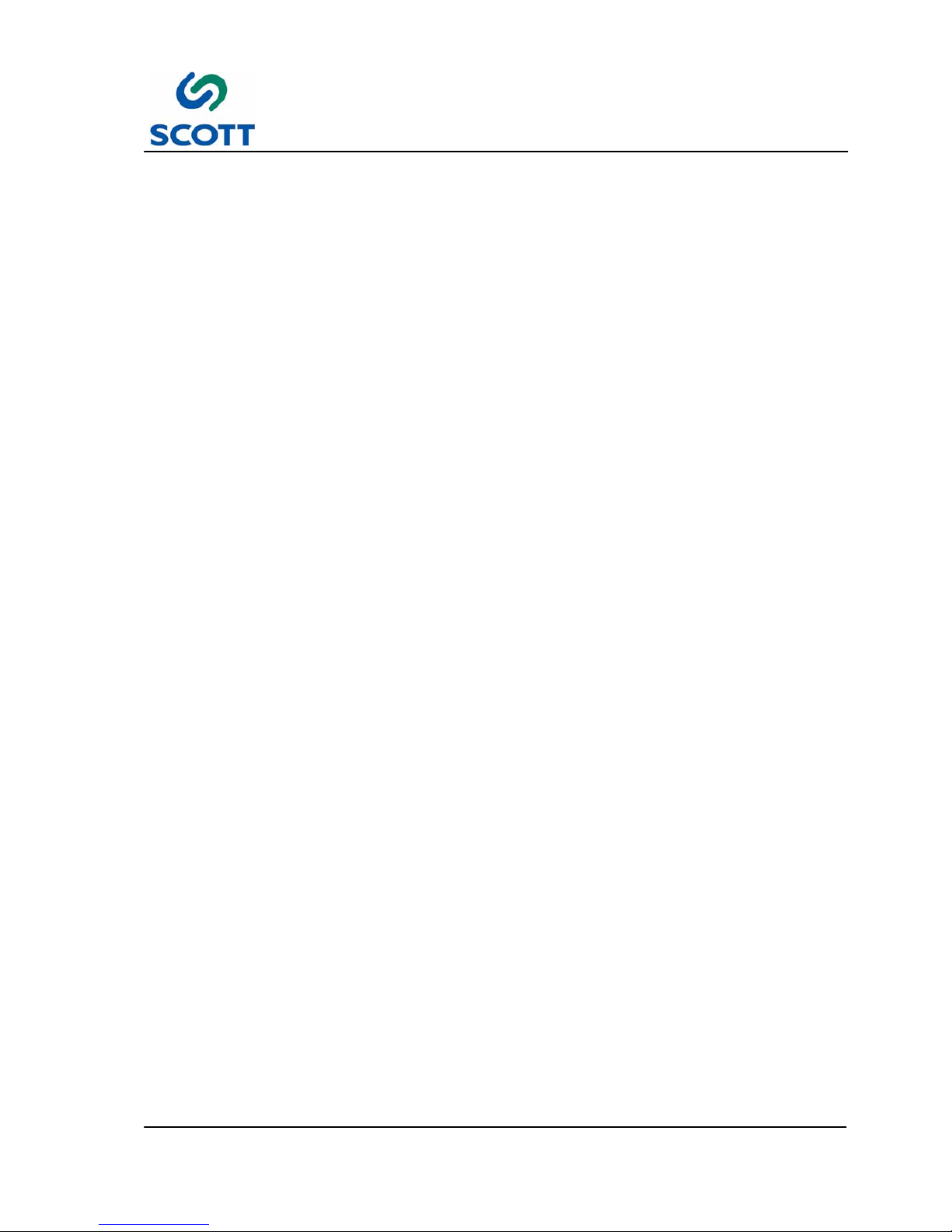

When either the table is tilted forward or the knife

guard is open, contact with the switch is broken

and the machine’s main power is disabled.

Once switch contact is broken, it is not necessary

to reset the machine. Machine power is

automatically restored when the table is tilted back

into its correct upright position or the knife guard is

closed.

B

Fig. 1-4. Knife Guard Switch

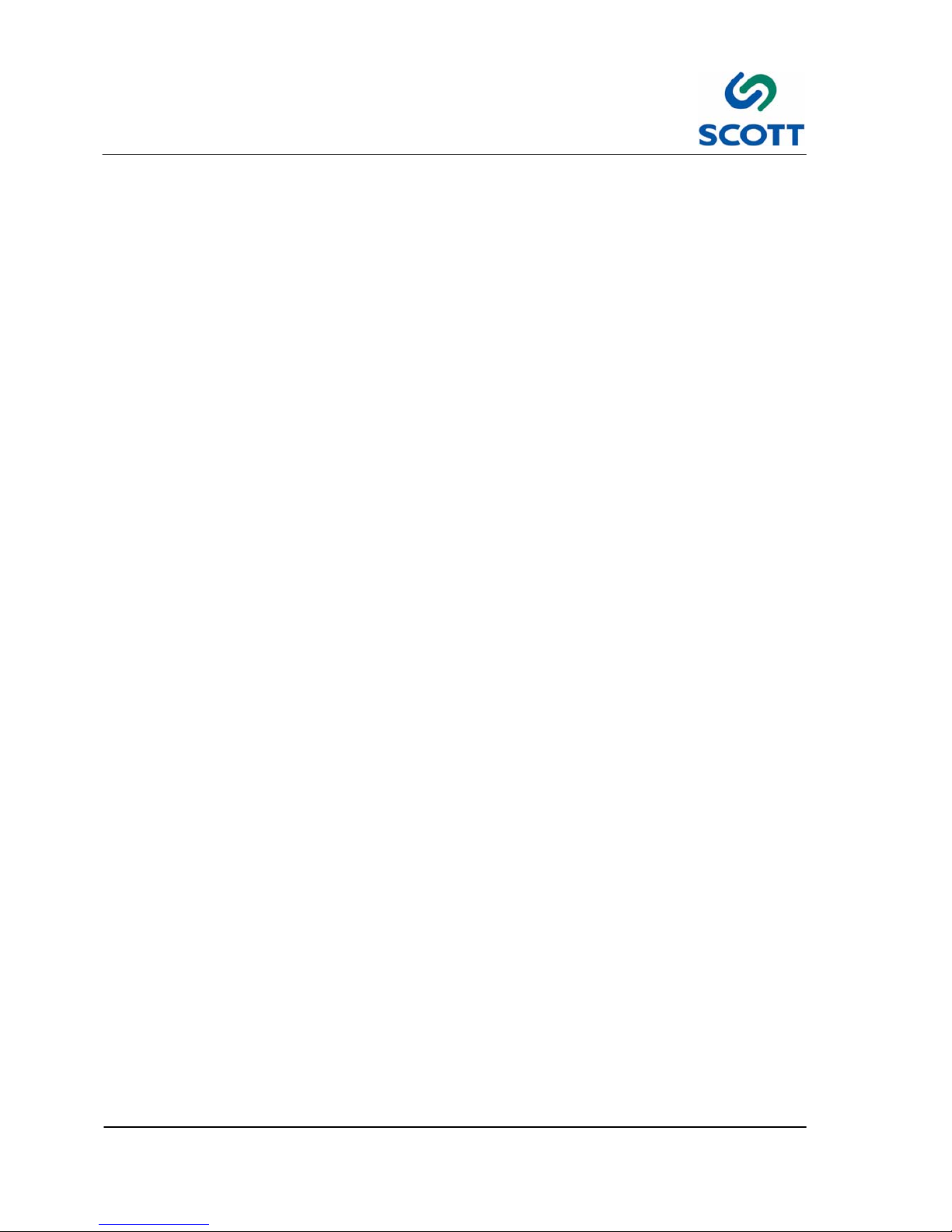

Fig. 1-5. Turn Machine Off Before Making

Adjustments

1.3.4 Main Power Switch

If machine is to be shut down for adjustments or

repairs, turn the power supply to the machine off.

Page 12

1 Introduction & Safety

1--8

Heavy Duty Tab Cutter Issue 1

Fig. 1-6. Table and Knife Guard Must Be In

Place to Run Machine

1.3.5 Guards and Covers

The table assembly and the knife guard MUST be

in place and securely fastened before operating

the machine. Safety switches will not allow

machine operation unless the table is in the proper

closed position.

Fig. 1-7. Shut Off Main Air Before Working on

Machine

1.3.6 Main Air Disconnect

Shut off main air before making any machine

adjustments.

Page 13

1 Introduction & Safety

1--9

Heavy Duty Tab Cutter Issue 1

1.4 Warnings, Cautions & Notes

In order to emphasize certain areas in the interest of personal safety and a properly operated and maintained

machine, you will encounter the words WARNING, CAUTION, and NOTE throughout this manual.

WARNING!

Fig. 1-8. Warnings Indicate Personal Danger

1.4.1 Warnings

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH IF NOT

CORRECTLY FOLLOWED, COULD

RESULT IN PERSONAL INJURY OR

LOSS OF LIFE.

WARNING!

CAUTION!

Fig. 1-9. Cautions Indicate Potential Damage to

Equipment

1.4.2 Cautions

AN OPERATING PROCEDURE,

PRACTICE, ETC. WHICH, IF NOT

STRICTLY OBSERVED, COULD RESULT

IN DAMAGE TO OR DESTRUCTION OF

EQUIPMENT.

CAUTION!

Note !

Fig. 1-10. Notes Indicate Essential Information

1.4.3 Notes

An Operating Procedure, Condition,

etc. Which is Essential To Highlight.

Note !

Page 14

1 Introduction & Safety

1--10

Heavy Duty Tab Cutter Issue 1

1.5 On Machine Warnings

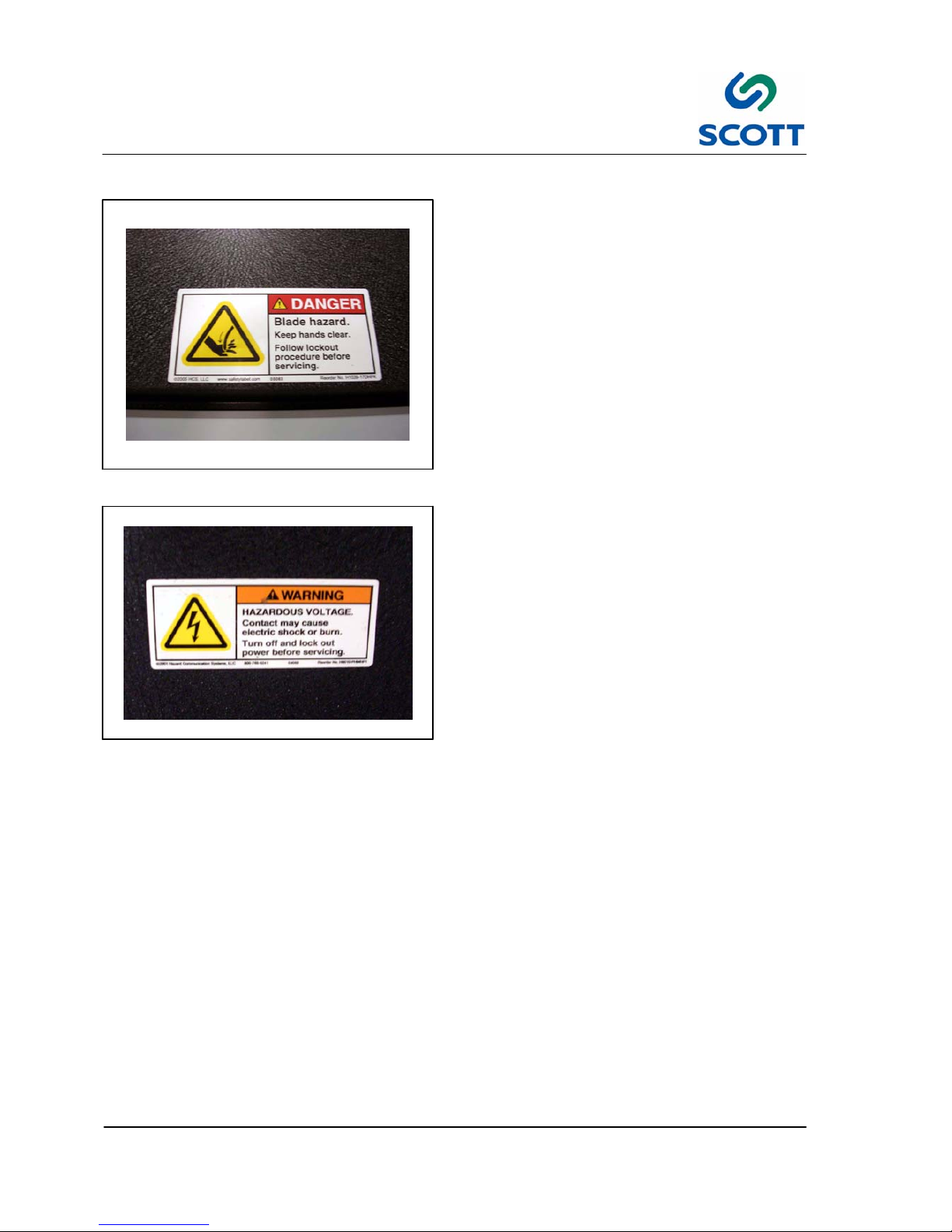

Fig. 1-11. Cutting Blade Hazard

1.5.1 Hazards

Observe Blade Hazard signs.

Fig. 1-12. Voltage Warning

There is a hazardous voltage warning on the main

electrical cabinet below the operator’s controls.

Page 15

1 Introduction & Safety

1--11

Heavy Duty Tab Cutter Issue 1

1.6 Safety Procedures

Fig. 1-13. Wear Proper Clothing

1.6.1 Appropriate Dress

Personnel working in the machine operation area

must remove jewelry and neckties. Personnel

must wear clothing appropriate for the work area.

Fig. 1-14. Keep Work Area Clean and Neat

1.6.2 Keep Area Clean

Loose materials, tools and equipment, not

essential to the operation of the machine, must be

removed from the machine work area.

Fig. 1-15. Clean Up Oil and Grease Spills

1.6.3 Grease and Oil

Clean up all oil and grease spills around the

machine work area.

Fig. 1-16. Read Manuals First

1.6.4 Manual Usage

Read and understand the instructions in the

manual before operating, adjusting or servicing

machine.

Page 16

2 Installation

2--1

Heavy Duty Tab Cutter Issue 1

2 INSTALLATION

Heavy Duty Tab Cutter Issue 1

Page 17

2 Installation

2--2

Heavy Duty Tab Cutter Issue 1

Page 18

2 Installation

2--3

Heavy Duty Tab Cutter Issue 1

2.1 Installation Requirements

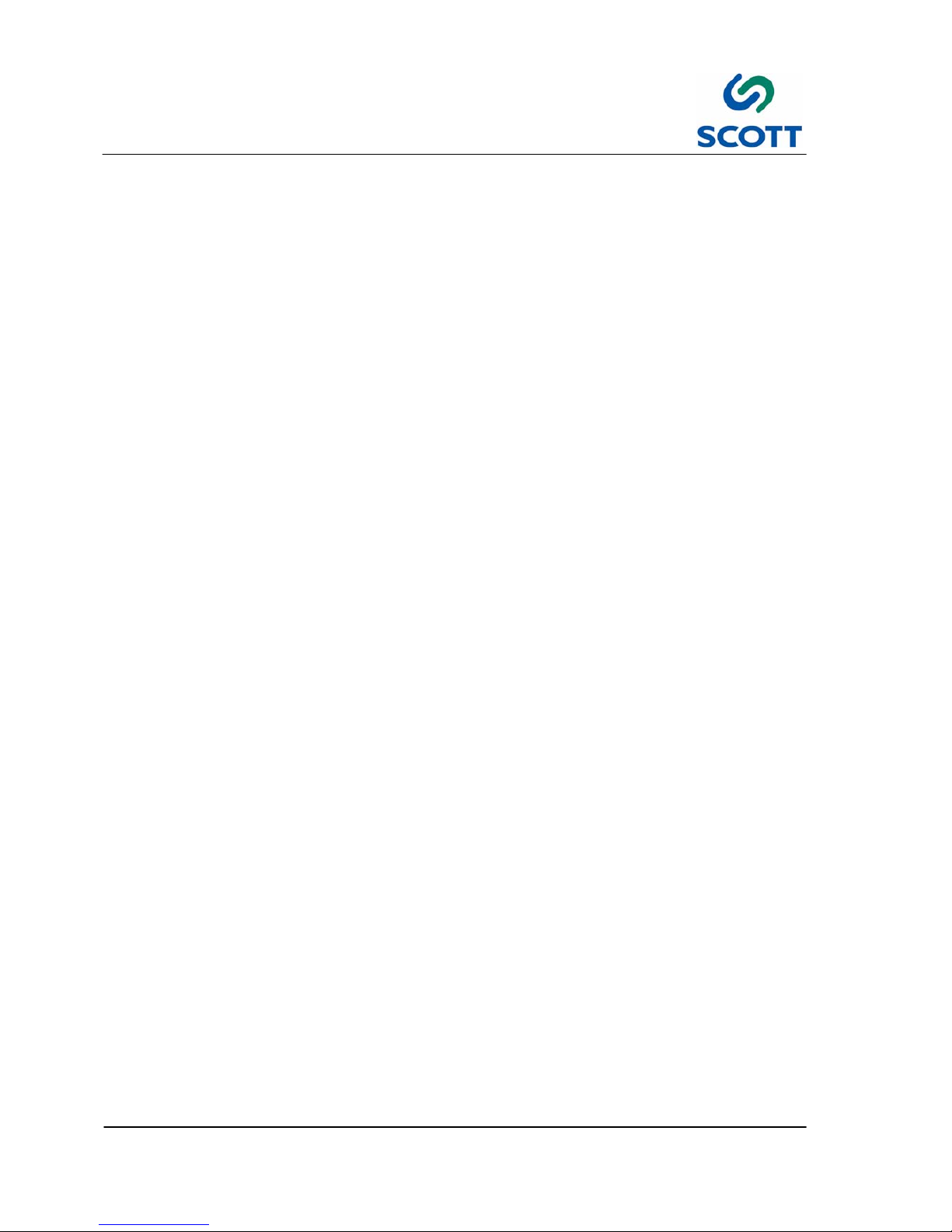

Fig. 2-1. Scott Heavy Duty Tab Cutter on Shipping Skid

All procedures in this section provide advance planning and site preparation data for installation of the Scott

Heavy Duty Tab Cutter. Environmental requirements, unpacking instructions, electrical and physical

specifications are included. This information should be used as a reference during the development of site

preparation plans before you install your machine.

If any questions arise while performing any of the following procedures, contact:

Note ! A forklift is required to lift the machine off the shipping skid and place it on the floor.

Page 19

2 Installation

2--4

Heavy Duty Tab Cutter Issue 1

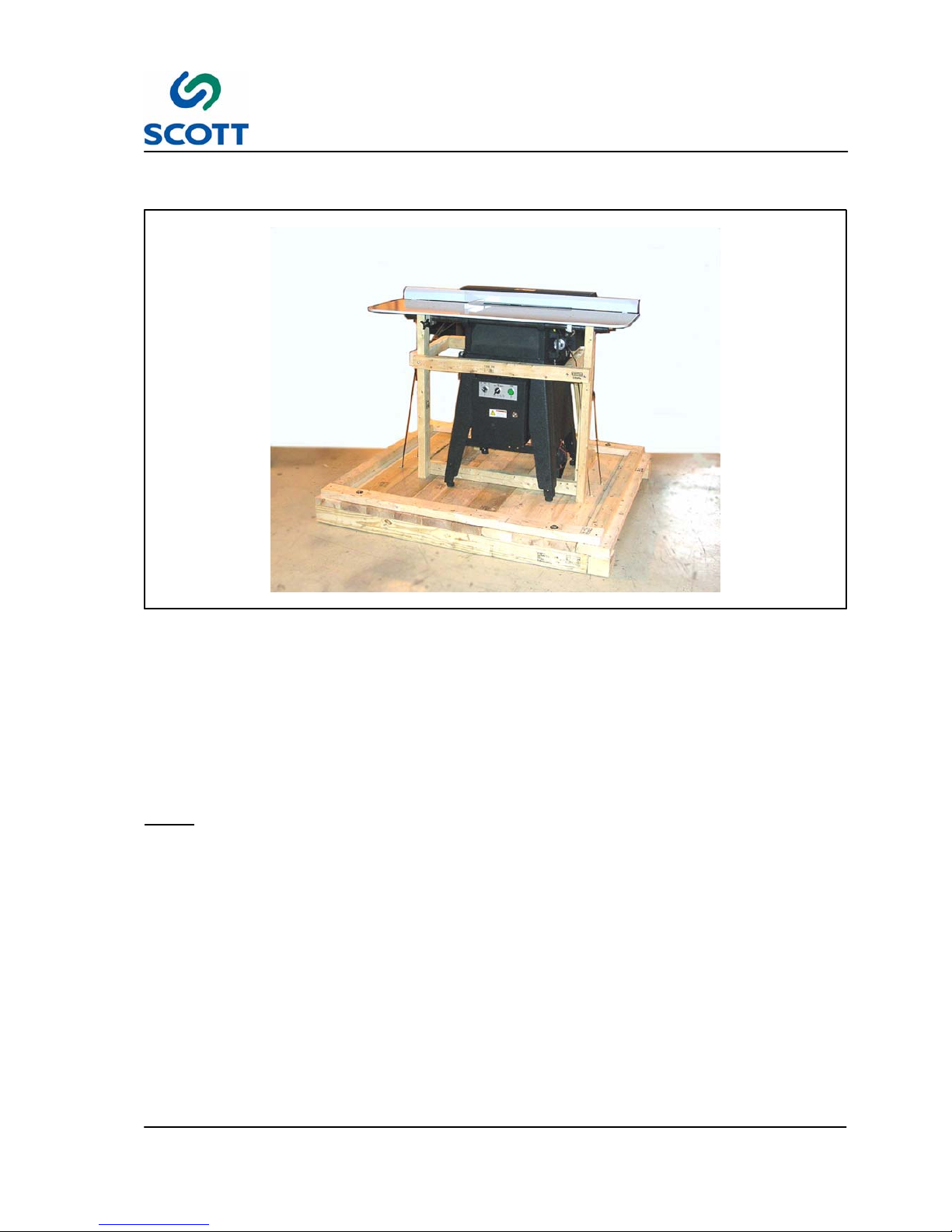

2.2 Pre-Installation Requirements

The environmental requirements of the Scott Heavy Duty Tab Cutter must be considered well in advance of

the actual installation. Providing a well suited operating environment will help ensure a trouble free

installation process. Consideration should be given to the following items:

● Power, location and rating of power connections.

● Floor strength

● Level floor

● Adequate space must be provided around all four sides of the machine to permit normal operation and

maintenance procedures. The figure shows the minimum space required.

3’ (914mm)

3’ (914mm)

3’ (914mm)

3’ (914mm)

Fig. 2-2. Scott Tab Cutter Space Requirements

● Space should be allocated near the paper tray for a small table that can be used for small jobs, samples,

etc.

● Provide plenty of space In front of the machine so large jobs can be easily moved in and out with skids or

carts.

Page 20

2 Installation

2--5

Heavy Duty Tab Cutter Issue 1

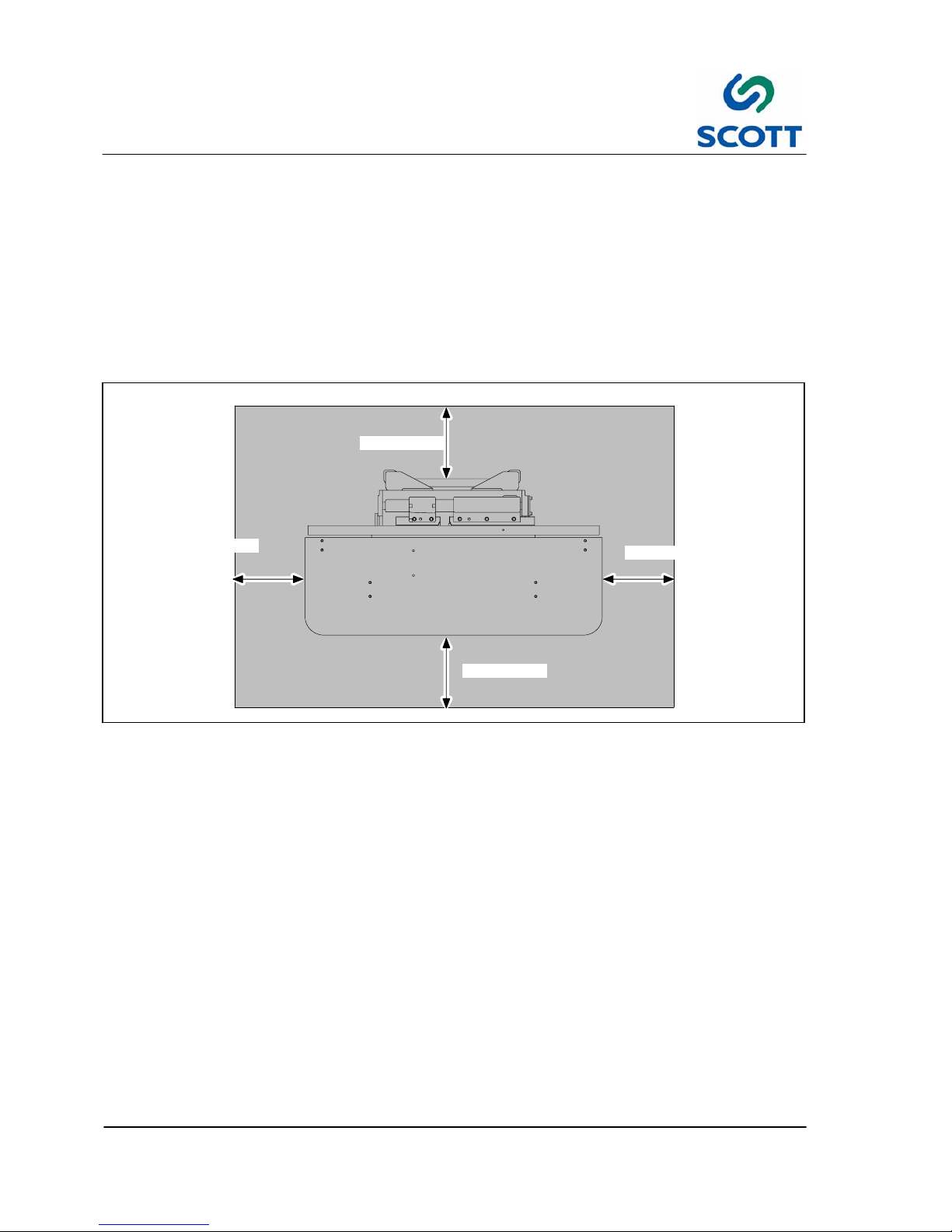

2.3 Installation Of Scott Heavy Duty Tab Cutter

The machine will arrive in one crate. Inspect the external condition of the crates for visible signs of damage

before opening. If damage is noticeable, notify the carrier and Scott Equipment before proceeding with the

installation.

To assist in the ease of installation, the machine is disassembled prior to shipping and requires some minor

assembly before the machine is operational.

2.4 Assembly Instructions

Fig. 2-3. Attach Air Line and Fill Oil Reservoir

2.4.1 Start Up Adjustments

Step: 1. The machine is shipped assembled.

Step: 2. Read labels telling where hoses are

attached. The two lines on the right go to

the air cylinder on the right side of the

machine. The line on the left goes to

elbow on Lubricator Assembly. The

lead--in hose (10’ rubber hose) attaches

to the ball valve (rear) end of the filter

regulator lubricator assembly.

Step: 3. The other end of this hose goes to your

air source.

Step: 4. One pint of non--detergent oil has been

provided with your machine. Remove

fill--plug on top of lubricator assembly,

and fill with oil to the proper level.

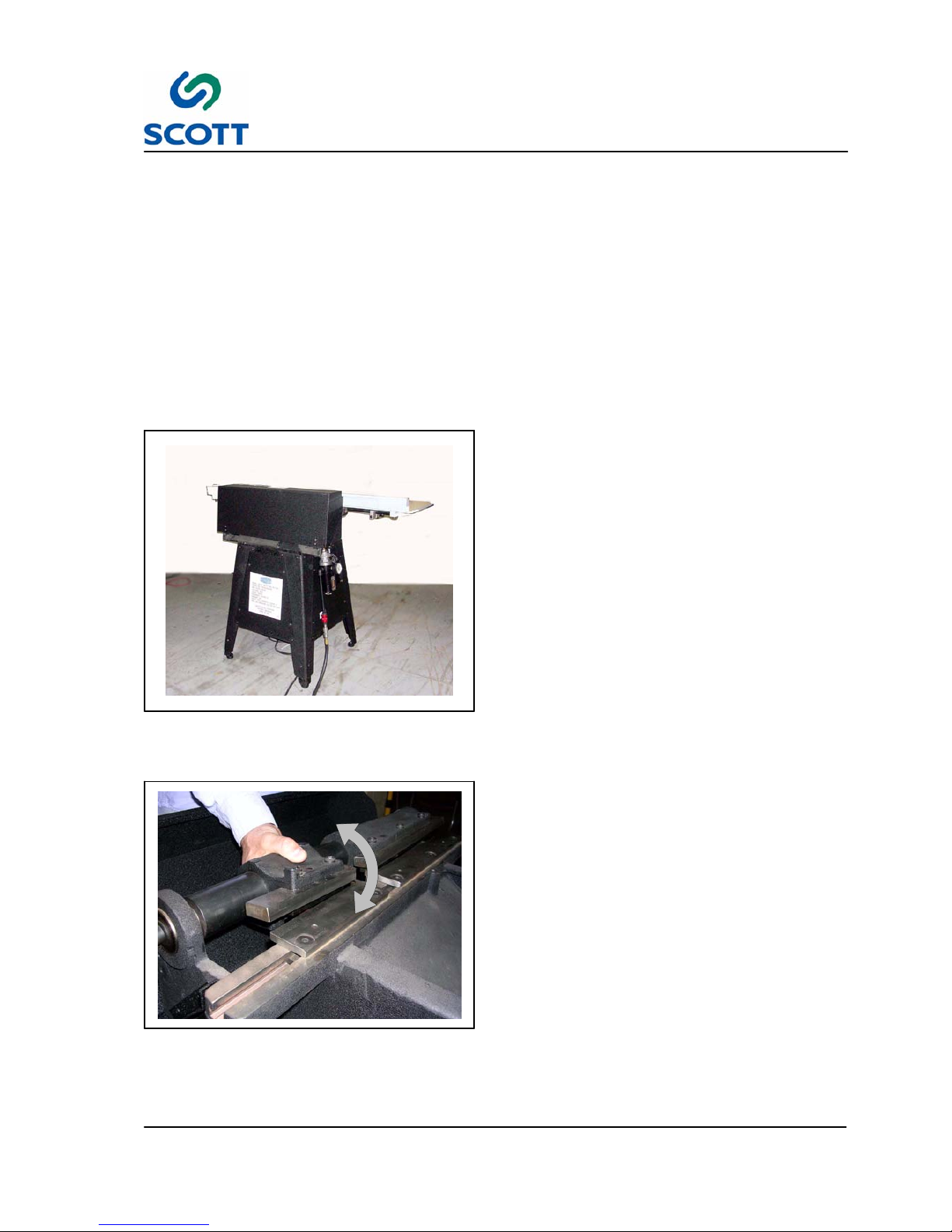

Fig. 2-4. Clear Knife Blades

Step: 5. Operate the rotating knife by hand to

check that the shipping did to disturb the

setting.

If the blades clear without hitting,

proceed to tie air into unit from your air

source with the 10’ rubber lead in hose.

Additional adjustment can be made.

The speed of cutting blades are

adjustable by turning a needle valve on

the under side of machine.

Step: 6. Adjust speed so that the action of the

knives does not interfere with the feeding

of stock by the operator.

This helps to take some of the slop out of

the knife action and allows a better

registration by the operator.

Page 21

2 Installation

2--6

Heavy Duty Tab Cutter Issue 1

Note ! There are no other adjustments necessary other than the adjustment of the cutting force

which is done by changing the air pressure.

Fig. 2-5. Connect Air Line

Step: 7. Supply a 1/4 NPT air line with 5 ScFm @

80psi (142LPM @ 5.3bar) to the air shut

off valve located at the back of the

machine.

Note ! The compressed air line at the main

AIR IN features a ON/OFF valve for

safety. Place the valve in the closed

(down) position when connecting the

machine to the plant air supply.

Fig. 2-6. Main Air Regulator Set to 50Lbs.

Step: 8. Set the main air regulator to 50psi

(3.4bar). (60lbs is recommend pressure

to use).

Note ! Unit will not operate properly at less

than 50lbs. pressure.

Step: 9. Plug electrical cord plug into a 110 volt

power source.

Page 22

2 Installation

2--7

Heavy Duty Tab Cutter Issue 1

Fig. 2-7. Adjust Lubricator

Step: 10.Locate the Mode Selection switch on the

operator’s panel.

Note ! In the Auto mode, the machine action

is activated by a switch as paper is

inserted.

In the Manual position, the machine is

activated only by the footswitch.

Step: 11.With the Mode switch in the Manual

position, adjust oil flow at lubricator

assembly with screw driver on screw

beside the fill plug. Operate machine

until oil drops appear in the transparent

dome on top of lubricator.

Step: 12.Adjust screw in a clockwise direction until

approximately 10 to 15 cycles of the

machine produce one drop of oil.

See Chapter 4 Maintenance Section for

more information on Lubricator Assembly.

Note ! Keeping oil in lubricator and the filter

clean periodically is your basic

service on the machine.

Page 23

3 Operation

3--1

Heavy Duty Tab Cutter Issue 1

3 OPERATION

Heavy Duty Tab Cutter Issue 1

Page 24

3 Operation

3--2

Heavy Duty Tab Cutter Issue 1

Page 25

3 Operation

3--3

Heavy Duty Tab Cutter Issue 1

3.1 GENERAL INFORMATION

3.1.1 Before Operating the Machine

AVOID SERIOUS INJURY OR EQUIPMENT

DAMAGE. RESTRICT OPERATION OF THIS

MACHINE TO TRAINED, QUALIFIED

PERSONNEL ONLY.

EACH OPERATOR SHOULD KNOW THE

LOCATION AND FUNCTION OF ALL

MACHINE STOPPING CONTROLS.

REVIEW MANUAL FOR EMERGENCY

STOP BUTTON LOCATION.

Do not attempt to operate the machine before reading and understanding the manual. Pay close attention to

all WARNINGS, CAUTIONS and NOTES. Failure to do so may cause serious injury and extensive machine

damage.

Read through the inspection and pre--start procedures before starting the machine. Make these checks part

of your routine to insure efficiency and quality during the production run.

Page 26

3 Operation

3--4

Heavy Duty Tab Cutter Issue 1

3.2 Operator’s Controls

3.2.1 Control Panel Layout

Fig. 3-1. Operator’s Control Panel

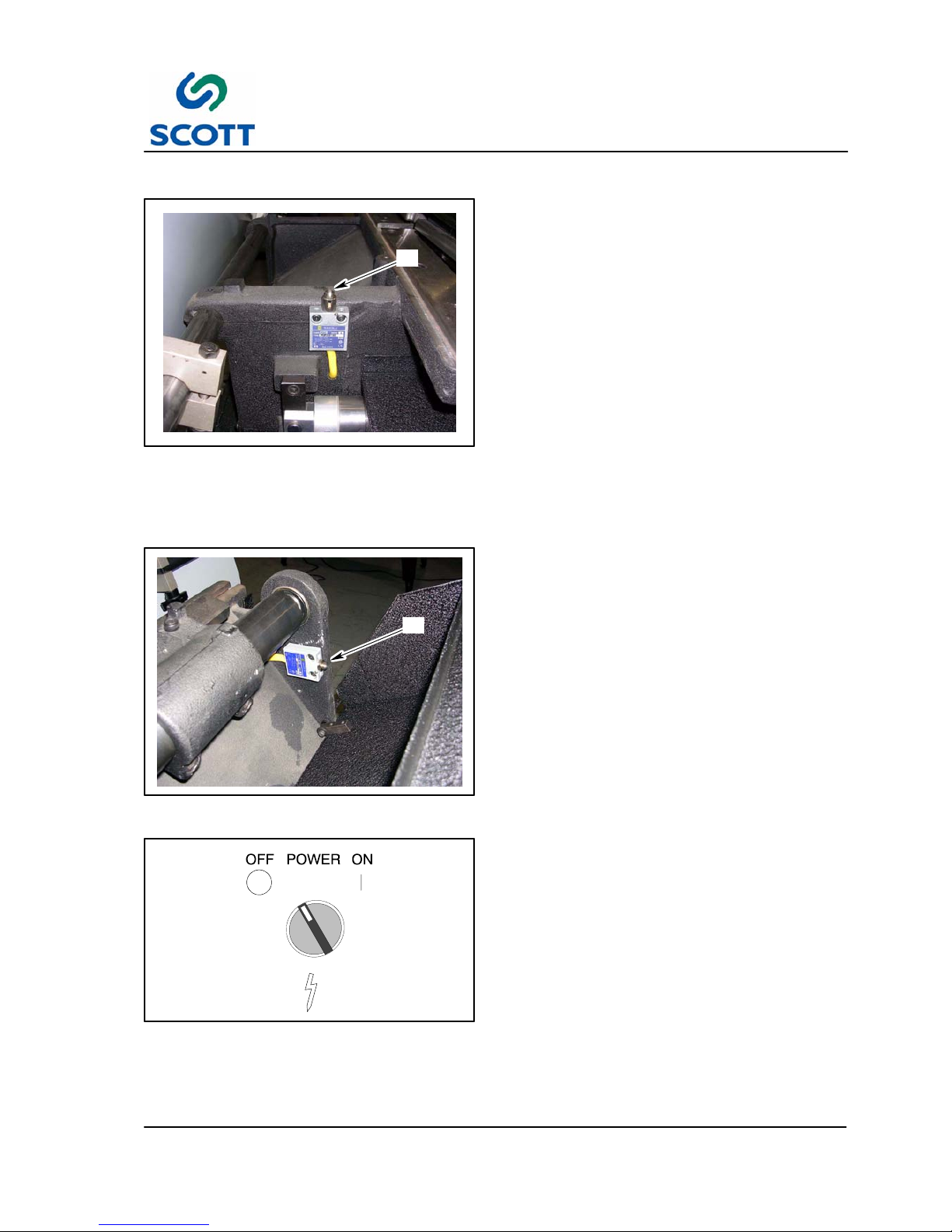

Fig. 3-2. Power On/OFF Selector Switch

3.2.2 Power On/OFF Selector Switch

OFF -- Turns Power off to the machine.

ON -- Brings power to the machine.

Fig. 3-3. Machine Mode Selector Switch

3.2.3 Machine Mode Selector Switch

This selector switch determines the operational

mode of the machine.

AUTO -- When the selector switch is in the Auto

mode, the tab cutting blades will operate when a

sheet is inserted into the cutting area. By inserting

a sheet into the cutting area, contact is made with

a switch activating the blades to cut one tab.

OFF -- Tab cutting blades cannot be activated in

this mode.

MANUAL -- When the switch is in this position, the

switch in cutting area is bypassed allowing the tab

cutting operation to be performed using the foot

pedal.

Page 27

3 Operation

3--5

Heavy Duty Tab Cutter Issue 1

Fig. 3-4. Power On Indicator Lamp

3.2.4 Power On Indicator Lamp

Lamp is illuminated when power (power switch in

ON position) is on and all safety switches are in the

“safe” position.

Fig. 3-5. Operator’s Foot Pedal

3.2.5 Foot Pedal

The foot pedal is used by the operator to activate

the tab cutting blades.

NOTE! Machine Mode switch must be in the

Manual position to operate by foot

pedal.

Fig. 3-6. Main Air

3.2.6 Main Air ON/OFF

Slide the quick disconnect up to allow air to the

machine or down to shut it off.

Page 28

3 Operation

3--6

Heavy Duty Tab Cutter Issue 1

A

B

Fig. 3-7. Main Air Regulator & Lubricator

3.2.7 Main Air Regulator & Lubricator

The main air regulator (A) controls the flow of air to

the cutting blade air cylinder. It works in

conjunction with the lubricator (B) to supply a

steady amount of oil to the air cylinder.

Page 29

3 Operation

3--7

Heavy Duty Tab Cutter Issue 1

3.3 Care and Adjustment of Tab Cutting Knives

The Scott tab cutting knives are made of the finest tool steel, hardened and ground. With proper care they

will last indefinitely and will seldom require sharpening.

All personnel should be instructed to handle them with proper care.

They should not be dropped since hardened tool steel will break. They should not be bumped against other

hard surfaces or against themselves since they will nick. Your tab cutting knives are expensive valuable tools

and should be treated as such. When not in use, cover the knives with a thin coat of oil and store in a safe

place.

Fig. 3-8. Turn Off Air, Mode Switch to OFF

3.3.1 Before Adjusting Tab Cutting

Knives:

Before adjusting your tab cutting knives always do

the following:

Step: 1. Shut off Main Air by sliding quick

disconnect down. This allows you to work

the knives up and down by hand and is

is a safety precaution.

Step: 2. Set Mode Switch to OFF.

Fig. 3-9. Loosen Pinch Lock Handles

Step: 3. Loosen the two pinch lock handles at

front under table.

Fig. 3-10. Tilt Table Forward

Step: 4. Tilt the table up.

It will not be possible to adjust the

stationary knives unless the table is in

this position. By tilting the table, the

electricity is disconnected and the knives

will not accidently move.

Page 30

3 Operation

3--8

Heavy Duty Tab Cutter Issue 1

3.4 Setting Tab Cutting Knife Blades

3.4.1 Upper Knife Blades

Before locking the upper knife blades, be sure that both the blades and the paper stops (located under the

blades) are pushed to the back of the knife holder castings. After the upper blades are locked, set the lower

blades as explained below:

3.4.2 Lower Knife Blades

Caution ! IMPORTANT: THE FOLLOWING PROCEDURE MUST BE FOLLOWED OR YOU WILL

DAMAGE YOUR KNIFE BLADES.

Fig. 3-11. Rotate Upper Blade Down

Set only one blade at a time. The following

instructions apply to both the long and short knife

blades.

Step: 1. Rotate the upper blade down as low as

the machine will permit.

Fig. 3-12. Loosen Lower Mounting Blade

Screws

Step: 2. Loosen the lower blade mounting screws.

Page 31

3 Operation

3--9

Heavy Duty Tab Cutter Issue 1

Fig. 3-13. Fit Lower Blade Against Upper Blade

Step: 3. Place the lower blade against the upper

blade so that the lower “fits” the upper at

the contour and the straight edge. Install

the screws but do not tighten yet.

Fig. 3-14. Clear Blade

3.4.3 Clearing the Blades

Then you must “clear the blades”. This is done as

follows:

Step: 1. Remove your hand from the lower blade

so that when you rotate the upper blade,

it will push the lower away.

Step: 2. Grasp the casting holding the upper

blade and rotate it upward to its highest

position and then back downward to its

lowest position. If the lower blade was

too close to the upper, this rotating

procedure will push the lower away from

the upper. The lower blade is now

“cleared”.

Fig. 3-15. Hold Blade and Tighten Mounting

Screws

Step: 3. Hold the lower blade in this “cleared

position” being careful not to push it

against the upper blade. While holding,

tighten screws.

Page 32

3 Operation

3--10

Heavy Duty Tab Cutter Issue 1

Fig. 3-16. Rotate Blades to Make Sure They

Clear

Step: 4. Rotate the upper blade upward and

downward slowly to make sure there is

no bumping or rubbing of the two blades.

If there is bumping or rubbing, repeat the

above procedure for “clearing the

blades”.

Fig. 3-17. Test Cutting Sample Tab

Step: 5. After the blades are “cleared” and locked

in position with no bumping or rubbing,

insert the paper you will be cutting and

rotate the upper blade down to cut. If the

paper does not cut cleanly, repeat the

above procedure.

NOTE! The above procedure must be

followed for both the long and short

lower knife blades.

CAUTION

! NEVER JAM THE BLADES

TOGETHER TO MAKE THEM CUT.

THIS WILL RUIN YOUR BLADES.

If you have followed the procedure

and the knives do not cut well, send

them to Scott Office Systems for

sharpening.

Page 33

3 Operation

3--11

Heavy Duty Tab Cutter Issue 1

Fig. 3-18. Tab Length

3.4.4 To Adjust Knives for Different

Tab Length

It is very simple to change the tab length since only

the short knives must be moved. The long knives

are never adjusted when changing tab length. To

adjust the short knives, do the following:

Fig. 3-19. Loosen Mounting Screws on Small

Stationary Knife

Step: 1. Loosen the two screws holding the small

stationary knife so that it can slide from

left to right or vice versa. Do not remove

the screws, just loosen.

Fig. 3-20. Loosen Mounting Screws on Small

Stationary Knife

Step: 2. Loosen the two bolts at the back of the

casting holding the small rotating knife so

that you can slide the entire unit to the

position on the steel arbor to the position

you want. Do not remove screws, just

loosen.

Page 34

3 Operation

3--12

Heavy Duty Tab Cutter Issue 1

Fig. 3-21. Move to Size, Tighten Mounting

Screws

Step: 3. Slide the small rotating knife casting to

the position desired. The small side

should be approximately level with the

long side.

Step: 4. Tighten mounting screws.

Step: 5. See 3.4 Procedure for Setting Tab

Cutting Knife Blades.

CAUTION

! MAKE SURE YOU HAVE

TIGHTENED SCREWS ON BOTH

KNIVES SECURELY AND NEVER

WORK THE MACHINE

AUTOMATICALLY UNTIL YOU

HAVE DONE IT BY HAND TO

CHECK YOUR SETTING.

Step: 6. Tilt table top down tighten pinch lock

handles, turn on air pressure with ball

valve at lubricator assembly, the machine

is ready for tab cutting.

Fig. 3-22. Loosen Stationary Knife Screws

3.4.5 To Change Knives for New Tab

Extension

To change the tab extension, it is necessary to

remove all four knives and replace with a new set

of four. This is easily done as follows:

Step: 1. Loosen the two screws holding the short

stationary knife. Do not remove screws,

just loosen.

Fig. 3-23. Slide the Knife Out of the Key Slot

Step: 2. Slide lower knife out of its key slots.

Leave the screws and nuts attached for

quick changing the next time you use

knife. Be very careful not to bump, drop

or nick knife. Do the same with the large

stationary knife (three screws to loosen).

Page 35

3 Operation

3--13

Heavy Duty Tab Cutter Issue 1

Fig. 3-24. Loosen Rotating Knife Screws

Step: 3. Loosen the two screws holding the small

rotating knife in the casting and remove

knife by sliding forward. Do not remove

screws, just loosen. Be careful not to

drop bump or nick knife. Do the same

with the large rotating knife (three screws

to loosen).

Fig. 3-25. Store Knives in a Safe Place

Step: 4. Store the four knives in a safe place

where they will not be damaged. Before

storing, put thin coat of oil on all pieces.

Step: 5. Install the new set of four knives.

Step: 6. Set the knives as explained above under

heading Procedure Extension.

NOTE! Remember, after knives are set, work

them all by hand to make sure they do

not bump or rub. Check by cutting a

piece of paper w ith them by hand.

After this, tilt table down, turn on air

with 3- way valve.

Fig. 3-26. Loosen the Table Handles

3.4.6 To Change Tab Position on

Sheet

To change the tab position:

Step: 1. Loosen the two handles at front of

machine so that table will slide from right

to left and left to right.

Page 36

3 Operation

3--14

Heavy Duty Tab Cutter Issue 1

A

Fig. 3-27. Find Position For Feed Guide

Step: 2. Insert a sheet of paper into the cutting

area to find the proper position for feed

guide (A).

Step: 3. Slide the table horizontally so that the

edge of the feed guide is flush with the

sheet edge.

Step: 4. Tighten the two pinch lock handles.

Fig. 3-28. Adjustment for Knife Speed

3.4.7 Cutting Speed of Knives

There is a needle valve under the machine in the

center of the machine. If the knives rotate with too

much or too little speed, you can adjust the speed

with this needle valve.

Page 37

3 Operation

3--15

Heavy Duty Tab Cutter Issue 1

Fig. 3-29. Burrs in Knife Blades

3.4.8 Prevent Knives From Becoming

Deeply Scored

Your knives are made in such a way that they are

“self--clearing” and, theoretically, they should never

touch each other at the cutting edges. They are

made to set very close but should not bump or rub

in operation.

However, it is possible to set them so they do rub

(or possible for grit or foreign matter to get

between them); therefore, it is possible that they

will begin to score.

ANYTIMEYOUNOTICEA“SCORELINE”

APPEARING, STOP THE MACHINE AND CHECK

FOR A BURR.

A small burr, caught in time, will not hurt the cutting

ability of the tab cutting knives. But, a small burr

will eventually work up to become a large burr and

will score the knives deeply. If such a burr is not

removed at once, it will:

● Keep getting larger and score the knives

deeper until they cannot be repaired.

● A burr will prevent you from setting knives

properly since it will not let you set them close

enough.

● Cause poor cutting and ragged edges at cut.

NOTE! Therefore, when you see a “score

line”, contact Scott Office Systems

for information concerning knife

sharpening policy and return

procedures.

Page 38

4 Maintenance

4--1

Heavy Duty Tab Cutter Issue 1

4 MAINTENANCE

Heavy Duty Tab Cutter Issue 1

Page 39

4 Maintenance

4--2

Heavy Duty Tab Cutter Issue 1

Page 40

4 Maintenance

4--3

Heavy Duty Tab Cutter Issue 1

A

Fig. 4-1. Air Cylinder

4.1 Care Of Air Cylinder

4.1.1 Lubrication

The air cylinder actuates the cutting blades.

There is very little that can go wrong with the air

cylinder (A) if it is lubricated properly by the

lubricator. The following will help you to determine

if your Scott is being properly lubricated:

B

Fig. 4-2. Look for Slight Oil Accumulation on

Underside of Valve Muffler

● There should be a slight oil accumulation on the

underside of the exhaust valve’s muffler (B)

This assembly is located directly under the

center of the machine.

Page 41

4 Maintenance

4--4

Heavy Duty Tab Cutter Issue 1

C

Fig. 4-3. Lubricator

Recommended Oil: Mobil DTE24 or Equivalent.

CAUTION

! DO NOT USE DETERGENT OIL;

This type of oil will quickly ruin the

rubber parts in the air cylinder.

USE LIGHT WEIGHT

NON- DETERGENT OIL ONLY. Use

machine oil, spindle oil or mineral oil

only.

Note !DO NOT USE AUTOMOBILE OIL.

With the oil feed clearly seen through the

sightdome (C) in the lubricator, it is possible to

adjust the oil feed to the proper amount of

lubrication. The principle of oil “misting” in

conjunction with the integral automatic by--pass

valve, eliminates the possibility of flooding the

equipment.

D

Fig. 4-4. Adjustment Screw

The Oil Adjustment Screw (D) in the top head of

the lubricator unit may be opened for full flow

(counter--clockwise) or closed completely

(clockwise).

The adjustment screw is held captive by the

hold--down ring on the sightdome, preventing the

screw from being backed out all the way.

Page 42

4 Maintenance

4--5

Heavy Duty Tab Cutter Issue 1

E

Fig. 4-5. Drain Air Regulator Reservoir

Regularly

4.1.1.1 Drain Air Regulator

Operation is entirely automatic and no adjustments

are necessary. To get effective performance, drain

reservoir (E) regularly.

Note ! IF MOISTURE FILLS RESERVOIR

ABOVE LOWER BAFFLE, IT MAY BE

CARRIED OVER INTO THE AIR LINE.

To drain reservoir open drain valve on

filter base.

Fig. 4-6. Clean Air Cylinder Filter Regularly

CAUTION

! TURN OFF AIR BEFORE

DISASSEMBLING.

Step: 1. Unscrew filter base and lower baffle

assembly to remove reservoir and filter

element.

Step: 2. Rinse in petroleum solvent such as

kerosene.

Note !DO NOT USE ACETONE,

ETHYL- ACETATE, TOLUENE, ETC...,

Note ! NEVER EXPOSE PLASTIC BOWL

FILTERS OR LUBRICATORS TO

LUBRICATING OILS OR

COMPRESSOR LUBRICANTS

CONTAINING PHOSPHATE ESTERS.

Step: 3. Clean the plastic bowl units with

household soaps or detergents only.

(See service manual’s enclosed)

Step: 4. Blow out filter element with air hose.

Page 43

4 Maintenance

4--6

Heavy Duty Tab Cutter Issue 1

4.2 Heavy Duty Tab Cutter Spare Parts List

The following are perishable parts. To avoid down--time Scott Office Systems recommend that you keep

them in stock in the quantities shown:

This is a list of all parts on the machine

Part Numbers Part Description Qty.

-- Set of Knife Blades 1

TC--109 Air Cylinder 1

HW--97113 Limit Switch

Page 44

4 Maintenance

4--7

Heavy Duty Tab Cutter Issue 1

4.3 Machine T roubleshooting

Symptom Cause Remedy

Knives pounding in

operation

-- Broken fitting

-- Air Pressure set too high and petcock not adjusted

properly

Locate & Replace

Leak coming from

-- Broken or cracked fitting Locate & Replace

up under valve

plate

-- Broken valve stem

plate

-- Internal airline not sealing

Won’t operate at all -- Not plugged into outlet Plug into outlet

-- Table tilted and interlock not depressed Unclamp table and lay flat

on table rest.

-- Broken or loose wire Inspect wiring & replace or

tighten connection

-- Air Pressure under 50lbs. & valves won’t operate Machine pressure must be

set at a minimum 50lbs.

Adjust

-- Interlock switch vibrated loose & out of locations un-

der safety rod.

Check Interlock

Check mounting screws lo-

cated on valve plate

Operates when using foot pedal but

-- Bent Finger Switch Bend switch finger to trip at

proper point.

notwhen using

f

i

n-

ger switch

-- Defective finger switch Replace Finger Switch

Slow Knife Action -- Lack of Lubrication Check Lube.

You must use Oil Dump Air

and operate manually.

-- Valve blocked or bad. Check Valve & replace if

needed.

-- Muffler blocked. Remove muffler & clean or

replace.

-- Low Air Pressure Check Pressure Gage.

(Min. pressure is 50lbs.)

-- Speed control valve turned too low. Set petcock or needle valve

properly.

-- Blocked filter Clean Lube Assembly Filter

Leaking from Muffler

-- Bad Valve (leaking internally) Locate valve & replace

e

(See 4.3.1 Identify

Leaks From Muffler)

-- Bad Cylinder -- Cylinder is leaking from one side of

the piston inside the cylinder.

Replace Cylinder.

Page 45

4 Maintenance

4--8

Heavy Duty Tab Cutter Issue 1

Fig. 4-7. Disconnect Air Line From Air Cylinder

4.3.1 Identify Leaks From Muffler

If you can hear an air leak from the muffler, use the

following procedure to trouble shoot the problem.

Step: 1. Disconnect the off rod end air line at the

cylinder on the side of the machine and

find out if you have air coming from the

line you just disconnected or from the

fitting you disconnected the line form.

● If air comes from the line, the valve is at fault.

● If air comes from the elbow on the cylinder then

it is the cylinder that is at fault.

There should be no air in this side of the line when

the machine is not electrically energized.

Page 46

4 Maintenance

4--9

Heavy Duty Tab Cutter Issue 1

4.4 C01--1000 Series Filter -- Regulator Combination

4.4.1 Installation

Blow out line to remove foreign matter. Install unit with air flow entering port marked ”IN” or direction of flow

shown on head of unit. Mount in vertical position as close to equipment to be protected as possible. Unit has

dry seal pipe threads, use dope or tape sparingly on male threads only. WARNING: For use in industrial

compressed air systems only. Do not exceed recommended temperature and pressure. Polycarbonate bowl

units can be damaged and burst if exposed to solvents, strong alkalies, fire resistant and synthetic

compressor oils. Use metal bowl in all applications where a plastic bowl could come in contact internally or

externally with chemicals or lubricants incompatible with polycarbonate.

OPERATING SPECIFICATIONS BOWLS

MAX. RECOMMENDED PLASTIC METAL

TEMPERATURE 120_ F 200_ F

PRESSURE 150 PSI 250 PSI

4.4.2 Adjustment

Turning adjustment tee or knob clockwise increases secondary pressure. Adjust secondary pressure with

typical flow conditions (static setting will be slightly higher) and tighten lock nut. Regulator may have a slight

bleed out of bonnet relief hole. This will not affect operation.

4.4.3 Maintenance & Cleaning

A Repair Kit Should be on Hand Unit may be disassembled without removal from airline. SHUT OFF

AIRLINE. Bleed off airline until pressure gauge reads zero. Back off adjustment knob or screw until

compression spring is fully relieved. Refer to drawing as a guide in disassembly. Clean valve seat and

poppet, inspect for pitting, scoring, and roughness. Replace worn or doubtful parts. Filter bowl can be

cleaned with mild soap and water or kerosene. DO NOT USE ANY SOLVENTS. In reassembly, use drawing

as a guide. Do not over--tighten base nut as it shoulders on stud (50--60 lbs.).

ORDER PARTS FROM YOUR LOCAL MONNIER DISTRIBUTOR.

IF ANODIZED, PLEASE INDICATE COLOR.

4.4.4 Vendor Contact Information

Page 47

4 Maintenance

4--10

Heavy Duty Tab Cutter Issue 1

Fig. 4-8. C01--1000 Series Filter--Regulator Combination

Page 48

4 Maintenance

4--11

Heavy Duty Tab Cutter Issue 1

4.5 304--1000 & 2000 Series Lubricators

4.5.1 Installation

WARNING: For use in industrial compressed air systems only. Do not exceed recommended temperature

and pressure. Polycarbonate bowl units can be damaged and burst if exposed to solvents, strong alkalies,

fire resistant and synthetic compressor oils. Use metal bowl in all applications where a plastic bowl could

come in contact internally or externally with chemicals or lubricants incompatible with polycarbonate.

OPERATING SPECIFICATIONS BOWLS

MAX. RECOMMENDED PLASTIC METAL

TEMPERATURE 120_ F 200_ F

PRESSURE 150 PSI 250 PSI

Reservoir can be filled without turning off inlet supply pressure. Remove self--venting fill plug. Fill with good

grade of petroleum lubricating oil approximately 80 to 150 SSU at 100 F (SAE *5 or *10) to within 1/4” of top

of bowl. Unless temperature extremes are present, lighter oils may not wet out and heavier oils could cause

sluggish operation. Replace fill plug hand tight only.

4.5.2 Oil Adjustments

● Clockwise -- Decrease

● Counterclockwise -- Increase

Close oil needle adjustment by turning clockwise. With air flowing through unit, open oil needle adjustment

until you see approximately 2 drops of oil per minute in sight tube for each 20 SCFM. This will vary with air

flow, line pressure, devices lubricated and oil viscosity.

4.5.3 Tamper Proof

After final oil adjustment, unit can be made tamper proof by pressing tamper proof ball in top of sight dome.

TO REMOVE TAMPER PROOF BALL SHUT OFF AIR LINE and bleed off air by removing fill plug. Remove

sight dome assembly. Separate the inner and outer dome. Push tamperproof ball completely out of outer

dome from the inside. Reassemble dome assembly making sure oil adjust needle and small ”0” ring on

needle are assembled into inner dome. Push inner and outer domes together. Make sure ”0” ring, bottom of

inner dome and ”0” ring under hex of outer dome are in position. Reassemble dome assembly and fill plug.

Turn on air supply and follow oil adjustment instructions.

ORDER PARTS FROM YOUR LOCAL MONNIER DISTRIBUTOR. IF ANODIZED, PLEASE INDICATE

COLOR.

4.5.4 Maintenance

SHUT OFF AIR SUPPLY. Loosen oil fill plug to vent bowl. Bowl can now be removed by removing base nut

for cleaning with mild soap and water or kerosene. Do not use solvents, thinners or carbon tetrachloride. If

bowl seal remains in head, remove, inspect and replace if necessary. Open adjustment needle full

(counterclockwise). Use blow gun to blow air through oil pickup tube and sight dome assembly . To

reassemble unit make sure bowl seal is into head groove or on top of bowl. Position bowl in place and install

base nut with ”0” ring. Turn bowl slightly to make sure bowl centers into head groove. Do not attempt to over

tighten base nut as it shoulders on stud. Follow procedure for filling reservoir and oil adjustment.

Page 49

4 Maintenance

4--12

Heavy Duty Tab Cutter Issue 1

Fig. 4-9. 304--1000 & 2000 Lubricators

4.5.5 Part Information

Bowl Kit Series

21557 1000

21558 1200

21559 P or T 1300

22520 P or T 2200

22521 P or T 2300

Suffix P--Polycarbonate

T--Trogamid

Seal Kit 21555

4.5.6 Vendor Contact Information

Page 50

5Parts

Page 5-1

Heavy Duty Tab Cutter Issue 1 07/2005

5 PARTS

Heavy Duty Tab Cutter

TC--99999--1

Issue 1 07/2005

Page 51

Page 5-2

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

SCOTT OFFICE SYSTEMS PARTS ORDERING INFORMATION

1. When corresponding or ordering parts from Scott Office Systems include complete Business Name, Street Ad-

dress, City, State, Country, Zip Code and Machine Serial Number.

2. Order by part number and description as shown in the manual.

3. Specify how shipments are to be made -- Freight, Parcel Post, or Express. If routing is not specified, we will use

our own judgement and not be responsible for the additional costs or delays.

4. Always confirm fax or phone orders by clearly marking “Confirmation”.

5. Address all correspondence to:

Page 52

5Parts

Page 5-3

Heavy Duty Tab Cutter Issue 1 07/2005

PARTS RETURN

To enable us to handle credit efficiently and promptly, and to save our Customers unnecessary expense and delay, the

following procedures have been established.

1. Customers are requested not to return parts of any kind without first communicating by letter or telephone with the

Parts Service Department. We will advise what procedures to follow to expedite the issue of credit and the applicable

restocking charge. A Return Material Code Number indicating the authorization to return parts will be issued. NOTE:

Proof of purchase must be established before credit can be approved.

2. All shipments returned MUST contain a copy of the Invoice Number or Packing List that parts were received on and

the reason for return noted. Shipments may be refused if the above procedure is not followed.

3. No parts are to be returned without a Return Authorization Number issued by Parts Service.

4. Requests for credit of returned parts must contain Invoice Number and Date of Purchase.

5. Parts are to be returned “Prepaid”.

6. Parts shipped out over one (1) year cannot be accepted. Any parts for which an invoice (proof of purchase) cannot

be found, will not be accepted.

7. Return all Parts to

8. Restocking charge is $25.00 or 10% whichever is greater.

9. Warranty Part Shipments -- Shipment of parts under warranty will be handled by U.P.S. Ground. Customer will incur

all shipping expenses by other than U.P.S. Ground.

Page 53

A

VIEW-- A

Page 5-4

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.1 Knife Assembly

Page 54

5Parts

5.1 Knife Assembly

Page 5-5

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 0001 BODY 1

2 HW--51540 SCREW, SOC HD, 2

3 HW--41920 WASHER, FLAT HARDENED, 2

4 HW--66090 BEARING, BALL, 2

5 HW--54200 SCREW, FLAT HD, 5

6 TC-- 0072 KNIFE, LOWER LH, 1

7 TC-- 0073 KNIFE, LOWER RH, 1

8 TC-- 0012 NUT 5

9 TC-- 0005 SHAFT, PIVOT 1

10 TC--0003 KNIFE HOLDER, LH 1

11 TC--0002 KNIFE HOLDER, RH 1

12 HW--56200 PIN, DOWEL, 2

13 HW--51500 SCREW, SOC. HD, 5

14 HW--51490 SCREW, SOC. HD, 4

15 TC--0071 KNIFE, UPPER LH, 1

16 TC--0004 PAPER STOP, SHORT LH 1

17 TC--0074 KNIFE, UPPER RH, 1

18 TC--0007 PAPER STOP, LONG RH 1

19 HW--51380 SCREW, SOC. HD, 2

20 TC--0006 CAP, BEARING 1

Page 55

REF:

TC--0001 BOD Y, TAKEN

FROM PREVI O US PAGE.

Page 5-6

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.2 Table Assembly

Page 56

5Parts

5.2 Table Assembly

Page 5-7

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 0009 TABLE 1

2 HW--51290 SCREW, SOC. HD, 8

3 TC-- 0020 BRACKET, PAPER GUIDE MTG. 2

4

TC--0011 GUIDE, SIDE 1

HW--53200 SCREW, BUTTON HD, 2

HW--49040 WASHER, FLAT 2

5 TC-- 0010 SHAFT, TABLE 1

6 HW--81100 KNOB, 4--PRONG, 2

7

TC--0014 TABLE, LOCK 2

HW--57030 PIN, SPRING, 2

8 HW--55420 SCREW, HEX HD, 2

9 HW--56140 PIN, DOWEL, 1

Page 57

REF:

ASSEMBLY TAKEN FRO M

PREVIOUS PAGE.

Page 5-8

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.3 Paper Guide Assembly

Page 58

5Parts

5.3 Paper Guide Assembly

Page 5-9

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 0024 PAPER GUIDE, KNIFE COVER 1

2 HW--51490 SCREW, SOC. HD, 2

Page 59

REF:

TC--0001 BOD Y, TAK EN FROM

KNIFE ASSEMBLY PAGE.

REF:

TC--0002 KNIFE HO L DER, TAKEN

FROM KNIFE ASSEMBLY PAGE.

Page 5-10

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.4 Air Cylinder Assembly

Page 60

5Parts

5.4 Air Cylinder Assembly

Page 5-11

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1

TC--0022--1 PIN, CLEVIS LONG 1

HW--57510 PIN, COTTER, 1

2 TC-- 0015 BAR, CYLINDER MTG. 1

3 HW--51460 SCREW, SOC. HD, 2

4

TC--0023 PIN, CLEVIS SHORT 1

HW--57510 PIN, COTTER, 1

5 TC-- 0109 AIR CYLINDER 1

6 HW--63500 ELBOW, 2

7 TC-- 0027 GUARD, CYLINDER 1

8

HW--53140 SCREW, BUTTON HD, 3

HW--49040 WASHER, FLAT 3

9 TC-- 0022 CLEVIS 1

10

HW--52020 SCREW, SET, 1

HW--84010 BALL, NYLON 1

Page 61

AIR CYLINDER

FRONT PORT

AIR CYLINDER

BACK PORT

TO AIR SUPPLY

Page 5-12

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.5 Air Valve Assembly

Page 62

5Parts

5.5 Air Valve Assembly

Page 5-13

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 0013 PLATE 1

2

HW--53200 SCREW, BUTTON HD, 2

HW--49040 WASHER, FLAT 2

3 TC-- 0018 PLATE 1

4

HW--97013 SWITCH, MICRO, 1

HW--55190 SCREW, THUMB, 2

5 HW--47100 MUFFLER,

6 TC-- 0019 BRACKET, SWITCH 1

7

HW--63500 ELBOW, 5

HW--63140 TUBING, URETHANE 10 FT.

8 TC-- 0197 AIR VALVE, 4--WAY 1

9 HW--63480 TEE, STREET 1

10 HW--63490 NEEDLE, VALVE, 1

Page 63

AIR SUPPLY IN

REF:

S--1004 SIDE RAIL , TAKEN

FROM STAND ASSEMBLY.

FROM PORT #1

Page 5-14

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.6 Air Supply Assembly

Page 64

5Parts

5.6 Air Supply Assembly

Page 5-15

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1

HW--63500 ELBOW, 1

HW--63140 TUBING, URETHANE REF

2

HW--53180 SCREW, BUTTON HD, 1

HW--49040 WASHER, FLAT 1

HW--60290 NUT, HEX 1

3 AIR SUPPLY 1

Page 65

REF:

TC--0001 BOD Y, TAK EN FROM

KNIFE ASSEMBLY PAGE.

REF:

TC--0013 PLATE, TAKEN

FROM PREVIOUS PAGE.

Page 5-16

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.7 Knife Guard Assembly

Page 66

5Parts

5.7 Knife Guard Assembly

Page 5-17

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1

HW--51370 SCREW, SOC. HD, 4

HW--49050 WASHER, FLAT 4

2

TC--0028 GUARD, RIGHT END KNIFE 1

HW--53140 SCREW, BUTTON HD, 2

3

TC--0029 GUARD, LEFT END KNIFE 1

HW--53140 SCREW, BUTTON HD, 2

4

HW--55040 BOLT, SHOULDER, 2

HW--49090 WASHER, TOOLING 4

5 TC-- 0025 BLOCK, HINGE 2

6 TC-- 0026 GUARD, KNIFE 1

7

HW--53060 SCREW, BUTTON HD, 4

HW--49080 WASHER, FLAT HARDEN, 4

8

HW--97011 SWITCH, PLUNGER LIMIT, 1

HW--53080 SCREW, BUTTON HD, 2

9

HW--97012 SWITCH, ROLLER LIMIT, 1

HW--53080 SCREW, BUTTON HD, 2

Page 67

Page 5-18

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.8 Leg Extension Assembly

Page 68

5Parts

5.8 Leg Extension Assembly

Page 5-19

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 1016 STAND, LEFT FRONT LEG 1

2 TC-- 1017 STAND, RIGHT FRONT LEG 1

3 R-- 1002 LEG STAND EXTENSION 4

4

HW--53180 SCREW, BUTTON HD, 8

HW--60290 NUT, HEX 8

HW--49040 WASHER, FLAT 8

5

HW--53202 SCREW, BUTTON HD, 4

HW--49040 WASHER, FLAT 4

HW--60290 NUT, HEX 4

HW--99232 BUMPER, RUBBER

MCMASTER/CARR,

4

6 S--1008 STAND, LEG 2

Page 69

REF:

TC--1017 FRON T RIGHT LEG STAND

TAKEN FROM PREVIOUS PAGE.

REF:

TC--1016 FRON T LEFT LEG STAND

TAKEN FROM PREVIOUS PAGE.

REF:

S--1008 LEG STAND TAKEN

FROM PREVIOUS PAGE.

Page 5-20

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.9 Machine Mounting Rail Assembly

Page 70

5Parts

5.9 Machine Mounting Rail Assembly

Page 5-21

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 1004 RAIL, SIDE 4

2

HW--54130 SCREW, FLAT HD, 4

HW--60290 NUT, HEX 4

3 S--1002 RAIL, MACHINE MTG. 2

4 TC-- 1005 CLIP, RAIL MTG. 4

5

HW--53180 SCREW, BUTTON HD, 12

HW--60290 NUT, HEX 12

HW--49040 WASHER, FLAT 12

Page 71

REF:

TC--1016 FRON T LEFT LEG STAND TAKEN

FROM LEG EXTENSION ASSEMBLY PAGE.

REF:

TC--1017 FRON T RIGHT LEG STAND TAKE N

FROM LEG EXTENSION ASSEMBLY PAGE.

REF:

S--1008 LEG STAND TAKEN FROM LEG

EXTENSION ASSEMBLY PAGE.

Page 5-22

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.10 Bottom Support Rail Assembly

Page 72

5Parts

5.10 Bottom Support Rail Assembly

Page 5-23

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 1004 RAIL, SIDE 4

2

HW--54130 SCREW, FLAT HD, 4

HW--60290 NUT, HEX 4

3 S--1003 RAIL, BOTTOM SUPPORT 2

4 TC-- 1005 CLIP, RAIL MTG. 4

5

HW--53180 SCREW, BUTTON HD, 8

HW--60290 NUT, HEX 8

HW--49040 WASHER, FLAT 8

Page 73

REF:

TC--1016 FRON T LEFT LEG STAND TAKEN

FROM LEG EXTENSION ASSEMBLY PAGE.

REF:

TC--1017 FRON T RIGHT LEG STAND TAKE N

FROM LEG EXTENSION ASSEMBLY PAGE.

REF:

S--1008 LEG STAND TAKEN FROM LEG

EXTENSION ASSEMBLY PAGE.

Page 5-24

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.11 Guard Assembly

Page 74

5Parts

5.11 Guard Assembly

Page 5-25

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1

HW--53180 SCREW, BUTTON HD, 14

HW--49040 WASHER, FLAT 14

2 TC-- 1018 GUARD, FRONT ENCLOSURE 1

3 S--1016 GUARD, SIDE 3

4 TC-- 1020 TAG, MAIN MACHINE 1

Page 75

REF:

TC--1016 FRON T LEFT LEG STAND TAKEN

FROM LEG EXTENSION ASSEMBLY PAGE.

REF:

TC--1017 FRON T RIGHT LEG STAND TAKE N

FROM LEG EXTENSION ASSEMBLY PAGE.

Page 5-26

5Parts

Heavy Duty Tab Cutter Issue 1 07/2005

5.12 Controls Mounting Assembly

Page 76

5Parts

5.12 Controls Mounting Assembly

Page 5-27

Heavy Duty Tab Cutter Issue 1 07/2005

ITEM # PART # DESCRIPTION #REQ ITEM # PART # DESCRIPTION #REQ

1 TC-- 1019 ENCLOSURE ASSEMBLY 1

2

HW--53180 SCREW, BUTTON HD, 6

HW--49040 WASHER, FLAT 6

3 TC-- 1015 ENCLOSURE MOUNT 1

Loading...

Loading...