Page 1

Installation and

User's Manual for

Ice Maker-Dispenser

Models MDT3F12 and MDT4F12

Page 2

MDT3F & MDT4F User Manual

Introduction

Purpose of this manual: To provide detailed

installation and operation instructions; to give

insights into how the machine works; and to list

possible causes for basic problems.

New Table of Contents

Specifications: ··········································· Page 2

To The Installer: ·········································· Page 3

For The Electrician ········································ Page 4

For The Plumber ········································· Page 5

Wall Mount Kit (KWB4): ······································ Page 6

Final Check List & Initial Start Up ································· Page 7

User Operation ·········································· Page 8

Mechanical Operation ······································· Page 9

Maintenance: ··········································· Page 10

The MDT3F and MDT4F are combination ice

makers and dispensers. The refrigeration system

is air cooled, using R-134a as a refrigerant. The

control system uses electric eyes as a bin control

and a water level sensor as the water safety

control. As ice is made, it fills a plastic storage bin.

When ice is needed, a motor rotates a stainless

steel vane inside the storage bin and sweeps the

ice into the spout.

Inspection: ············································ Page 11

Dispense Area Sanitation ····································· Page 12

Service Diagnosis ········································· Page 13

Service Diagnosis: Circuit Board ································· Page 14

November 2008

Page 1

Note this symbol when it appears.

It marks a possible hazard.

Page 3

MDT3F & MDT4F User Manual

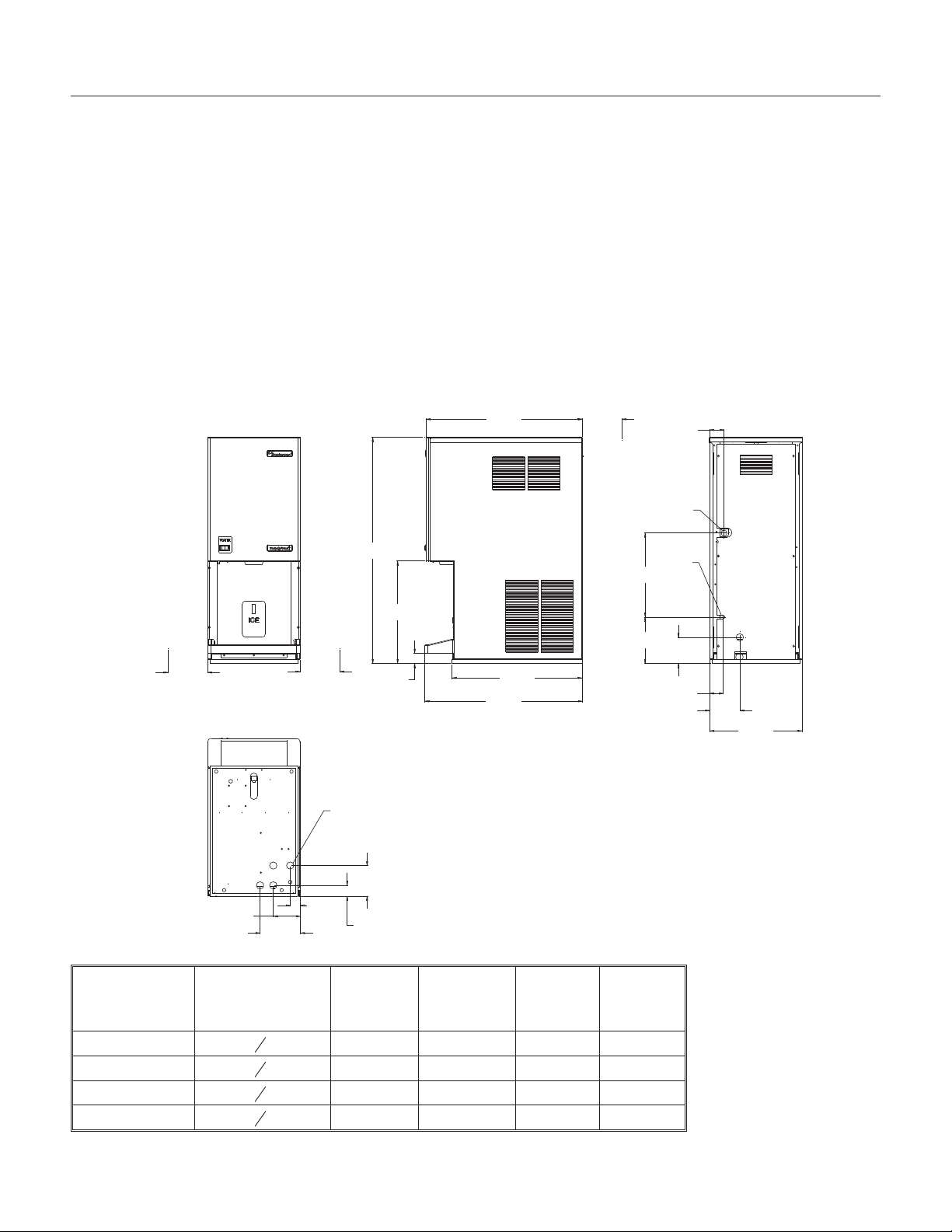

SIDE

AIR

INTAKE

15.24 CM

6.00 IN

15.24 CM

6.00 IN

SIDE

EXHAUST

FRONT

RIGHT SIDE

BACK

BOTTOM

15.24 CM

6.00 IN

87.00 CM

34.25 IN

50.09 CM

19.72 IN

39.41 CM

15.52 IN

3.99 CM

1.57 IN

60.11 CM

23.63 IN

60.67 CM

23.89 IN

MINIMUM

CLEARENCE

MINIMUM

CLEARENCE

MINIMUM

CLEARENCE

35.56 CM

14.00 IN

32.32 CM

12.73 IN

5.61 CM

2.21 IN

10.08 CM

3.97 IN

17.86 CM

7.03 IN

5.22 CM

2.06 IN

11.60 CM

4.57 IN

ELECTRICAL

FLARE

WATER

INLET

4.13 CM

1.63 IN

11.75 CM

4.63 IN

3.98 CM

1.57 IN

10.48 CM

4.13 IN

15.56 CM

6.13 IN

OPTIONAL WATER INLET,

DRAINS, & ELECTRICAL

1.00 IN

2.54 CM

Specifications:

Scotsman ice machines, like the MDT3F or

MDT4F, are designed to be installed indoors, in a

controlled environment. The minimum and

maximum operating conditions are:

Minimum Air Temperature: 50oF.

·

Maximum Air Temperature: 100oF.

·

Minimum Water Temperature: 40oF.

·

Maximum Water Temperature: 100oF.

·

60 Hz voltage may vary between 104 and 126

·

volts.

Water Pressure may vary between 20 and 80

·

psi.

Operating the machine outside these conditions

constitutes misuse and voids the warranty.

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of UL, NSF and CUL.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of parts and/of other components not

specifically approved by Scotsman.

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Specifications:

Model Number Dimensions

W"xD"xH"

MDT4FA-1A 14 x 23

MDT4FA-6A 14 x 23

MDT3FA-1A 14 x 23

MDT3FA-6A 14 x 23

7

x 34¼ 115/60/1 14 oz. 15.1 20

8

7

x 34¼ 230/50/1 14 oz. 7.5 15

8

7

x 34¼ 115/60/1 12 oz. 9.4 15

8

7

x 34¼ 230/50/1 12 oz. 5.3 15

8

Basic

Electrical

Refrigerant

Charge

(R134a)

Min.

Circuit

Ampacity

Max Fuse

Size

November 2008

Page 2

Page 4

MDT3F & MDT4F User Manual

To The Installer:

A professional installation of any product is critical

to the long term satisfaction of the user. The ice

maker-dispenser is designed to be installed either

on a counter, or, using a wall hanging kit, hung

from a wall.

Determine the location from the anticipated use

and any options planned for.

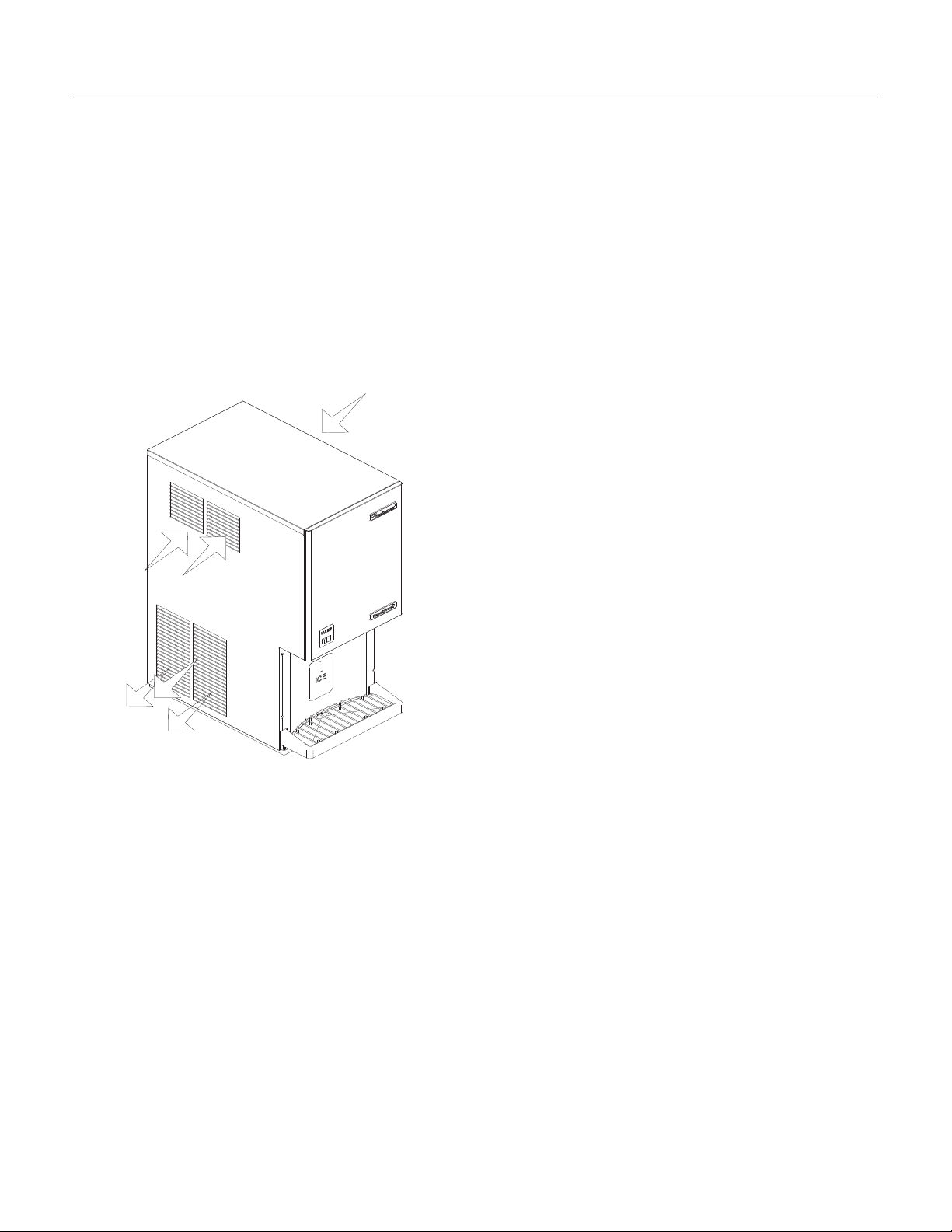

This machine is air cooled and blows air out the

lower left side of the cabinet. Do not install the

machine where the side to side air flow might be

blocked.

Cooling Air Flow

Water Quality:

The quality of the water supplied to the machine

will directly affect the purity of the ice and the

reliability of the machine. While the condition of the

water supplied to a building is normally out of the

control of the user, water can be treated at the

point of use.

There are two major types of water impurities:

suspended solids (those that are carried along with

the water and may be filtered out) and dissolved

solids (those that are part of the water and have to

be treated). A water filter is always a good idea,

but does require regular maintenance to change

the cartridge. In some water conditions, water

treatment may be required. Generally this means a

polyphosphate feeder of some kind. Water

softeners are not recommended.

General Installation:

Place the machine in its final location. Remove the

top, right and left side panels:

1. Remove two screws at the bottom of the front

panel.

Cooling Air

Flow

Warm Air

Exhaust

The machine will require electrical power, water

and a drain. Follow all local codes. Rough in the

utilities before placing the machine into position

(see For The Electrician and For The Plumber).

2. Disconnect wires from water switch.

3. Remove two screws at the front of the top panel.

Lift the top panel and remove it.

4. Remove screws from the sides (top and bottom)

of the side panels and from the splash panel.

5. Pull the side panels back and off the machine.

Plumbing connections may be made thru holes in

the back of the cabinet or thru the base.

·

Route the sink drain to the back of the cabinet.

Route the bin drain to the back panel.

·

Route the electrical power cord from the

junction box inside the cabinet. thru the back

panel .

·

Route the inlet water line thru the back panel or

base to the flare fitting inside the cabinet.

After all plumbing and internal wiring has been

done, replace the side and back panels.

Level the unit front to back and left to right.

The machine does not require sealing to the

counter due to the gasket on the base.

April 2010

Page 3

Page 5

MDT3F & MDT4F User Manual

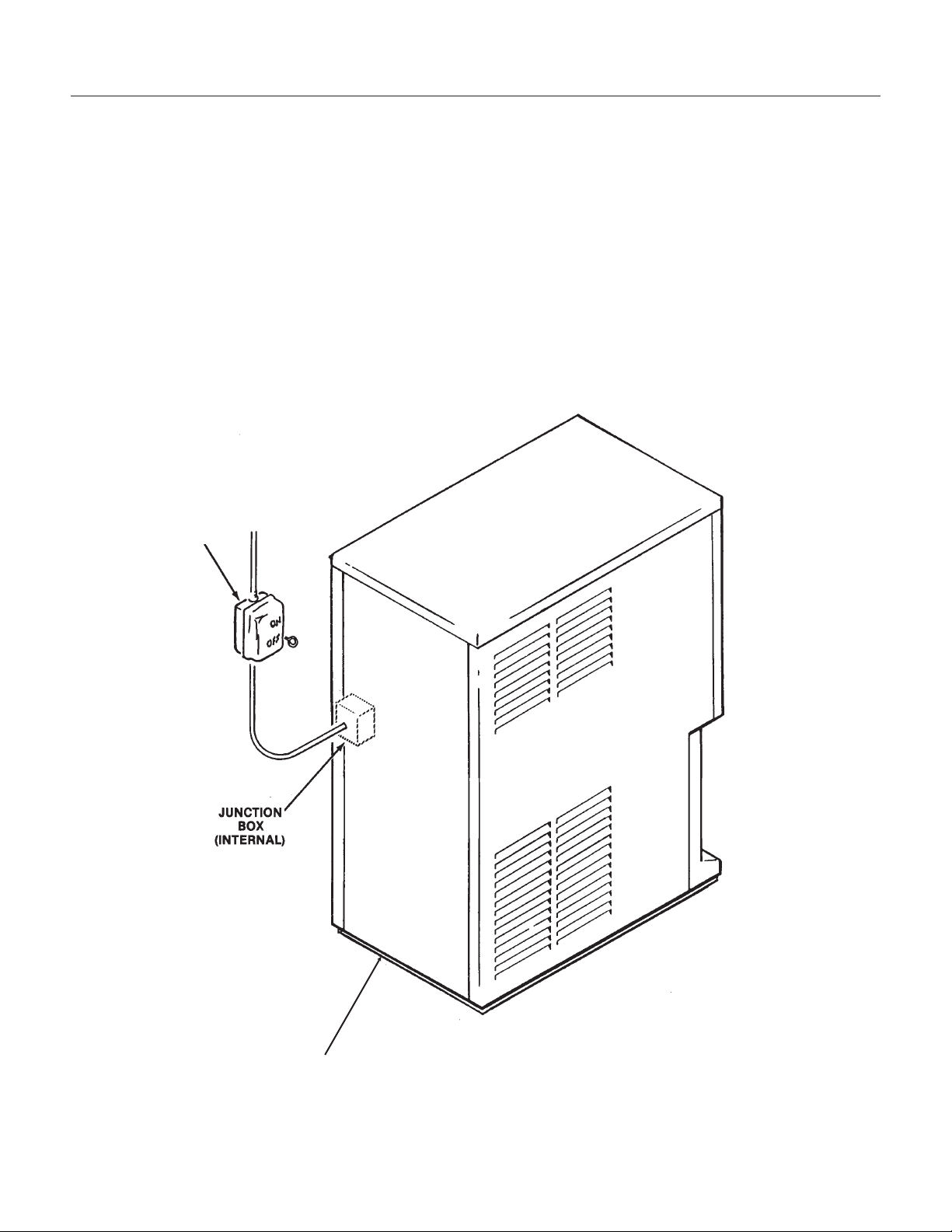

For The Electrician

Electrical connections:

Check the nameplate for voltage and current

requirements. An electrical cord is not supplied.

Connect the MDT3F or MDT4F to a separate

electrical circuit. Wiring to the machine must

conform to all codes. A licensed electrician may be

required in some situations.

Remove the back panel to make the electrical

connection. The electrical connection is made on

the terminal strip in the junction box inside the

machine. Replace the back panel when the

electrical connections are complete.

FOLLOW ALL APPLICABLE LOCAL, STATE

AND NATIONAL CODES

This Unit MUST BE GROUNDED

Electrical

Power

Remove Back Panel To

Expose Junction Box

November 2008

Page 4

Page 6

MDT3F & MDT4F User Manual

For The Plumber

Drains:

The dispenser requires a gravity drain. The pitch

on the drain tubes must be at least ¼ inch fall per

foot of horizontal run. On long horizontal runs, a

vent at the back of the cabinet will improve

draining, and is recommended.

There are two drains to connect: A sink drain, a

ID plastic tube; and the bin drain, a

5

” ID plastic

8

tube. Install rigid tubing between the machine and

the building drain. Route the drains separately to

the building drain.

7

”

8

Water supply:

Connect cold, potable water to the machine. The

inlet water fitting is a 1/4" male flare located on a

wall inside the cabinet.

A hand valve near the

Water Inlet Fitting - 1/4"

location is

recommended. A water

filter is also a good

idea.

Follow all local codes.

Strainer or

Filter

FOLLOW ALL APPLICABLE LOCAL, STATE

AND NATIONAL CODES

Male Flare

(Inside Cabinet)

Water Supply

Bin and Reservoir

Overflow Drains

Sink Drain

Building Drain

(Typical)

November 2008

Page 5

Page 7

MDT3F & MDT4F User Manual

1.75

26.34

1.75

16.00

16.00

Wall Mount Kit (KWB4):

Contents:

1. Top Case Hanger Bracket: Attaches to the frame

of the dispenser.

2. Top Wall Bracket: Mounts to the wall and

engages the top case hanger bracket to support

the dispenser.

3. Bottom Wall Bracket: Mounts to the wall and

spaces the base of the dispenser away from the

wall.

4. Bottom Fittings Cover: Fastened to the bottom

wall bracket to hide the utility connections.

5. Junction box cover.

1

2

5

Top Wall Bracket:

1. Hold the bracket on the wall where it will be

mounted.

2. Mark the positions of the holes in the bracket

onto the wall.

3. If needed, drill pilot holes for the fasteners.

4. Secure the bracket to the wall with fasteners of

sufficient strength to hold up the dispenser.

Connect all internal utilities. Route tubes and

wires out the bottom.

Junction box cover. Install on the junction box.

Bottom Wall Bracket:

1. Lift up and hang the dispenser from the top wall

bracket.

2. Position the bottom wall bracket so that the

molding on the dispenser base bottoms in the

channel of the wall bracket.

3. Secure the bracket to the wall.

Bottom Fitting Cover:

1. Connect electrical power, water inlet, bin drain

and sink drain of the dispenser thru the bottom of

the case.

4

Installation: Check building wall for the strength

required to support a machine of this weight and

size. Note that if at least 6" of space is not left

above the machine, cleaning and most service of

the machine will require removal of the machine

from the wall mounts. All utilities are to be routed

thru the base. The back panel is not used when

the machine is hung from the wall.

Top Case Hanger Bracket

1. Remove back panel.

2. Place top hanger bracket on the inside of the

frame and position it in line with the pre-punched

holes in the frame.

3. Fasten the bracket to the frame with four¼-20

screws from the kit.

2. Secure bottom fitting cover to the bottom wall

bracket with the four sheet metal screws provided

3

in this kit.

Bottom

Cover

Secure With

Screws

Top Case

Bracket

Wall

Brackets

November 2008

Page 6

Page 8

MDT3F & MDT4F User Manual

Final Check List & Initial Start Up

1. Is the machine located indoors where the

temperature limitations are not exceeded?

2. Is there at least 6" clearance on both sides of

the cabinet for adequate air flow?

3. Is the water supply adequate, and has a shut off

valve been installed?

4. Is the cabinet level?

5. Have all of the electrical and drain connections

been made?

Initial Start Up

1. Remove 2 screws at the bottom of the front

panel.

2. Disconnect wires at water switch.

3. Remove screws and the top and side panels.

4. Open the water supply shut off valve.

5. Watch the water fill the reservoir. Check that

water flows in and fills the reservoir near to the

mark molded into the side of the reservoir. Check

that the float shuts off the water flow when the tank

is full. Check for leaks. Tighten hose clamps as

needed.

6. Plug the unit in or switch on the electrical power.

After about 15 seconds the machine should start.

7. Let the machine operate, listen for any unusual

noises. If needed, reposition tubing & panels to

eliminate vibration.

After the unit has been operating for about 10

minutes, there should be enough ice in the bin to

test the dispense system.

8. Using a container, place in in front of the glass

sensor and below the ice chute. See that ice is

dispensed (the bin drive motor continues to run as

long as the container is in place).

9. Move the water switch (rocker switch on the

front panel) to ON. Place the container in front of

the glass sensor and under the ice chute. Both

water and ice should be dispensed.

10. Pour water into the sink and check that the

drain does not leak but drains the water rapidly.

11. Explain to the user the maintenance

requirements and operation of the machine.

12. Fill out the Warranty Registration and

Customer Evaluation form. Mail it to Scotsman.

13. Leave the service manual with the owner/user

and explain who should be called if service is

needed.

April 2010

Page 7

Page 9

MDT3F & MDT4F User Manual

User Operation

The MDT3F and the MDT4F are automatic ice

vending machines. All either requires is cool air,

clean water and an adequate supply of electrical

power.

To Vend Ice:

Place a container in front of the Touch Free sensor

and below the ice spout. Hold it there until the

container is full of ice. Do NOT overfill the

container or a build up of ice in the sink or a back

up of ice in the spout will occur.

To Vend Ice and Water.

Switch the Water Switch to ON. Place a container

in front of the Touch Free sensor and below the ice

spout. Water and ice will be dispensed into the

container below the spout. Note: The water is NOT

cooled, it is the same temperature as the building

supply water.

Daily Maintenance: Pour hot water into the sink to

flush out any debris or build up. Wipe the cabinet

off, wash the sink and grill to keep minerals from

accumulating.

Caution:

Unless the touch free sensor is

de-activated by pushing the

Cleaning Switch in, ice and/or water

may be dispensed during cleaning.

The Cleaning Switch is a button,

located to the left of the ice chute,

that temporarily shuts off the sensor

for cleanup of the splash panel.

Pushing the button in will disable the

sensor for 2 minutes, pushing the

button in again will return the sensor

to normal operation.

Water

Switch

Glass

Sensor

Touch Free

Disable

Switch

November 2008

Page 8

Page 10

MDT3F & MDT4F User Manual

Mechanical Operation

General:

The machine makes, stores and dispenses ice. It

also dispenses water. The ice making portion of

the machine produces flaked ice at about 32

The ice falls thru a chute into the dispensing bin.

Above the cylindrical bin is a dispense drive motor

and electric eyes. The drive motor is connected to

an ice vane in the bin. When the user holds a

container in front of the glass sensor and below the

ice chute, the dispense drive motor rotates the

vane and the ice. There is a slot in the base of the

bin, located just above the vend spout and glass

filler lever. When the ice moves over that slot,

some of the ice on the bottom of the bin falls thru

the slot, into the chute and fills the container.

ON/OFF Control:

Flaked ice is produced by the ice maker until ice

builds up between the electric eyes. When the

electric eyes can no longer “see” each other, they

send a signal to the control board to shut the

machine off. The refrigeration compressor stops

but the auger drive motor will continue to operate

for about 2 minutes to clear the evaporator of ice.

o

F.

Ice Vending

Dispensing takes place when the touch free

sensor’s infrared beam bounces back to the

sensor from a container placed directly in front of

the sensor and under the ice chute.

When the beam is reflected back, it signals the

circuit board to connect power to the dispense

drive motor, and ice is then moved over the slot in

the base of the bin, where it falls by gravity thru the

chute into the container.

If the Water switch is On, water is also dispensed

at the same time.

Dispensing continues until the beam is no longer

reflected back to the sensor.

Water Control:

Because water is such an important requirement

for making ice, a water level sensor has been

placed in the reservoir. If the water supply to the

machine should fail, the water level sensor will

send a signal to the control board to shut down

the machine.

Refrigeration:

The refrigeration system uses a hermetic

compressor (specifically designed for R-134a),

forced draft air cooled condenser, capillary tube

and vertical flaked ice evaporator. Inside the

evaporator is a slowly rotating auger. The auger is

supported by bearings at each end, and there is a

face-type water seal above the bottom bearing.

The auger is driven by a 1/10 HP direct drive gear

reducer. The auger drive motor has a speed

operated switch on it that will keep the compressor

from operating if the auger motor is not turning at

full speed.

Water System

Water flows from the building supply to the

reservoir and to the electric solenoid valve. Water

from the reservoir is used to make ice. Water the

flows thru the solenoid is dispensed.

Touch Free Sensor

The bin, sink and reservoir overflow all have

drains.

November 2008

Page 9

Page 11

MDT3F & MDT4F User Manual

Maintenance:

Although the ice in this dispenser is completely

untouched, the water and ice vending systems will

need to be periodically sanitized and

de-mineralized. The air cooled condenser will also

need to be kept clean.

Schedule the sanitation, cleaning and

de-mineralization on a regular basis to keep the ice

clean and the machine operating efficiently. Twice

per year is the standard recommendation.

Sanitation and Cleaning

Water System:

This ice machine requires periodic sanitation and

de-mineralization.

1. Vend all ice from the machine.

2. Remove top and right side panels.

3. Unplug or disconnect electrical power.

4. Shut off water supply.

5. Drain reservoir.

6. Mix 8 ounces of Scotsman Ice Machine Scale

Remover and 3 quarts of hot (95

potable water.

Scotsman Ice Machine

Cleaner contains acids.

These compounds may

cause burns. If

swallowed, DO NOT

induce vomiting. Give

large amounts of water

or milk. Call Physician

immediately. In case of

external contact, flush

with water. Keep out of

the reach of children.

7. Pour the water into the reservoir.

8. Wait 15 minutes for the cleaner to dissolve the

minerals inside the evaporator.

9. Plug in the machine or reconnect electrical

power.

10. As the machine operates, pour in the balance

of the cleaning solution.

o

F. -115oF.)

possible sanitizing solution may be obtained by

mixing 1 ounce of household bleach with 2 gallons

of clean, warm (95

13. Unplug or disconnect electrical power.

14. Remove bin top, pour in warm potable water to

melt out any ice.

15. Pull out the vane and bin bottom from the bin.

16. Thoroughly wash the bin’s interior, bin top

interior, spout, ice vane and bin bottom with the

sanitizing solution. Pour some down the bin drain.

17. Reassemble the bin bottom, vane and bin

cover.

18. Wash the sink area with the sanitizing solution

and pour sanitizing solution down the sink drain.

19. Replace all panels and reconnect water and

electrical power.

Air Cooled Condenser:

1. Disconnect electrical power.

2. Remove top panel

3. Remove right and left side panels.

4. Use pressurized air to blow the lint from the

outside of the condenser in towards the fan motor.

A vacuum cleaner hose placed on near the fan

motor should pick up most of the dust. Check for

interior dirt. If needed, use coil cleaner to

de-grease the condenser.

5. Replace all panels and reconnect electrical

power.

o

F.-115oF.) water.

11. Reconnect water supply, operate the machine

for 15 more minutes, then switch it off.

12. Repeat steps 3-11, except substitute a locally

approved sanitizing solution for the cleaner. A

November 2008

Page 10

Page 12

MDT3F & MDT4F User Manual

Inspection:

Photo-Electric Eyes

The photo electric eyes used to “see” the ice build

up in the top of the bin cover must be clean to get

a good “look” at the ice. If clouded by mineral

scale, the eyes will cause the ice machine to shut

off and stay off.

To clean the photo-electric eyes.

1. Remove the top panel.

2. Pull both of the photo-electric eyes out of their

rubber grommets.

3. Wash both eyes with a clean cloth dipped in

Scotsman Ice Machine Scale Remover.

4. Wash the eyes off with clean water.

5. Replace the eyes in the grommets

6. Replace the top panel

Water Level Sensor

The water level sensor may not shut the ice

machine off when the reservoir goes dry if there is

a film of mineral scale on the probe tip.

Clean Photo-Electric

Eyes

1. Remove the top panel.

2. Remove the reservoir cover.

3. Pull the water level probe up and out of the

reservoir.

4. Carefully wipe the tip of the probe with a clean

cloth. Ice machine cleaner may be needed.

Note: The tip is made of glass.

5. Reinsert the water level sensor in the reservoir.

6. Replace the reservoir cover and the top panel.

Coupling

Use the grease zerk on the side of the coupling to

add grease once per year.

Bearing and Water Seal

The top bearing should be checked every time the

machine is cleaned. Unscrew the cap and check. A

visual check can determine if corrosion is

occurring. If worn or corroded, have the bearings

and water seal changed.

Also check for water leaks from the bottom of the

evaporator. If there is a leak, the bearings and

water seal must be replaced. The gear reducer will

also need to be checked for water infiltration.

Clean Water Level

Sensor

Water

Reservoir

April 2010

Page 11

Page 13

MDT3F & MDT4F User Manual

Dispense Area Sanitation

1. The spout may be removed by taking out the

two mounting screws. Wash and sanitize it.

2. The sink grill may be removed for washing and

sanitizing.

3. The sink should be flushed with hot water and

wiped clean with sanitizer.

4. The splash panel requires special attention to

clean it.

Push and release the Cleaning Switch located

·

to the left of the ice spout. This disables the

Touch Free Sensor so the splash panel may be

cleaned without vending ice or water.

Wash the splash panel and wipe with sanitizer.

·

Re-push the clean switch or allow 2 minutes to

·

pass for the Touch Free system to reset.

November 2008

Page 12

Push Touch Free Sensor

Disable Button Before

Wiping Splash Panel

Pour Hot Water Into Sink

Regularly To Keep Drain

Line Open

Page 14

MDT3F & MDT4F User Manual

Service Diagnosis

PROBLEM POSSIBLE CAUSE PROBABLE CORRECTION

No ice is dispensed. No ice in bin due to:

No electrical power

·

Overuse

·

Water supply turned off

·

Bin controls dirty

·

Water sensor dirty

·

Control system malfunction

·

Auger drive motor open

·

Centrifugal switch open

·

Auger does not turn

·

No refrigeration

·

Ice in bin, but will not dispense:

Drive motor does not turn

Vend system does not work

·

·

Dispense motor open

·

Dispense output shaft broken

Ice in bin, motor turns vane.

Ice jammed up

·

Users held cup against

dispense spout and jammed

unit.

·

Bin bottom slot not over spout

·

Ice will not slide down bin wall,

bin out of round.

·

Wet ice in the bin from high

water level or high suction

pressure

Check/restore power

Recheck ice needs vs. machine

capacity.

Check water filter/hand valve/float

valve

Check & clean bin control (electric

eyes)

Check & clean water sensor

Check control system

Check auger drive motor

Check centrifugal switch

Check coupling & gear reducer

Check refrigeration system

Check/replace vend system

Check that cleaning switch has

been released.

Check/replace dispense motor

Check/replace output shaft

Advise owner/manager to instruct

users.

Check bin bottom position

Check bin interior wall for rough

texture or out of round.

Check water level, check suction

and discharge pressures

November 2008

Page 13

Page 15

MDT3F & MDT4F User Manual

Service Diagnosis: Circuit Board

1

2

3

Explanation of Indicator Light Position On

Board

On at all times when the master switch is ON and machine is

connected to electrical power.

On when ice level is low (unit making ice).

Normal 6 minute off/delay start. To prevent short cycling, the

machine will not restart after any shut off (except power to the

board) until 6 minutes have passed.

On when water level is low in the reservoir.

To check the electrical system, first check the lights on the circuit board.

1. Remove the top panel.

1 Power,

2 Bin Empty,

3 Off Timer,

4 No Water,

4

Name and Meaning of

Light or Reset

ON = Normal

ON = Needs Ice

ON = Unit cycling off

ON = Trouble

2. Remove the left side panel.

3. Remove the control box cover.

November 2008

Page 14

Page 16

SCOTSMAN ICE SYSTEMS

775 Corporate Woods Parkway, Vernon Hills, IL 60061

800-533-6006

www.scotsman-ice.com

17-3281-01 Revised April 2010

Loading...

Loading...