Scotsman Ice Machine MAR1400 Installation Manual

MAR1400 & MAR2000

Introduction

This is the manual for the SCOTSMAN MAR

SPLIT UNITS models MAR1400 and MAR2000.

They are designed to operate only with fresh

water.

Table of Contents

Specifications ·········································· 2

MAR1400 ············································· 4

MAR2000 ············································· 5

General information ······································· 6

Complete System Installation ································· 7

Condensing Unit Component Control Devices ························ 8

Location Consideration ····································· 9

Installation Diagrams ······································ 10

Water Circuit ··········································· 11

Installation ············································ 12

Bin Thermostat ·········································· 13

Component Assembly ······································ 14

Electrical Connection ······································ 15

Multiple Installations ······································· 16

Testing ·············································· 17

Start-Up ············································· 18

Electrical Sequence: ······································· 19

Water and Refrigeration Schematics ······························ 20

MAR Split - Electrical / Refrigeration ······························ 22

Adjustments ··········································· 24

Adjustment & Removal & Replacement Procedures ····················· 25

Adjustment & Removal & Replacement Procedures ····················· 29

Maintenance & Cleaning Instructions ····························· 30

Cleaning Instruction ······································· 31

Service Diagnosis ········································ 32

Service Diagnosis ········································ 33

December 2000

Page 1

MAR1400 & MAR2000

Specifications

The standard machine includes a stainless steel

cabinet, a 230 volt, 60 Hz, single phase drive

motor, automatic expansion valve, heat

exchanger, float reservoir, time delay switch, bin

thermostat, water pump, ice spout switch, liquid

line solenoid valve, EPR valve and low water

pressure cut out.

The condensing unit, interconnecting refrigerant

tubes and electrical system must be supplied by

the purchaser as per the instructions given in this

service manual.

Take time now and read this manual which

contains valuable information on the MAR Split

System. For any further questions regarding the

care or operation of the machine, please contact

your local Scotsman distributor or call

1-800-533-6006.

Basic Specifications

MAR Unit, shown without chute

Model Basic Electrical Maximum Fuse Size Minimum Circuit Ampacity

MAR1400RL-32A 208-230/60/1 15 2

MAR2000RL-32A 208-230/60/1 15 2

34 1/2"

Ice Machine Area

24 1/2"

Front

Chute Area

20 "

December 2000

Page 2

Top view of unit and chute.

10 "

MAR1400 & MAR2000

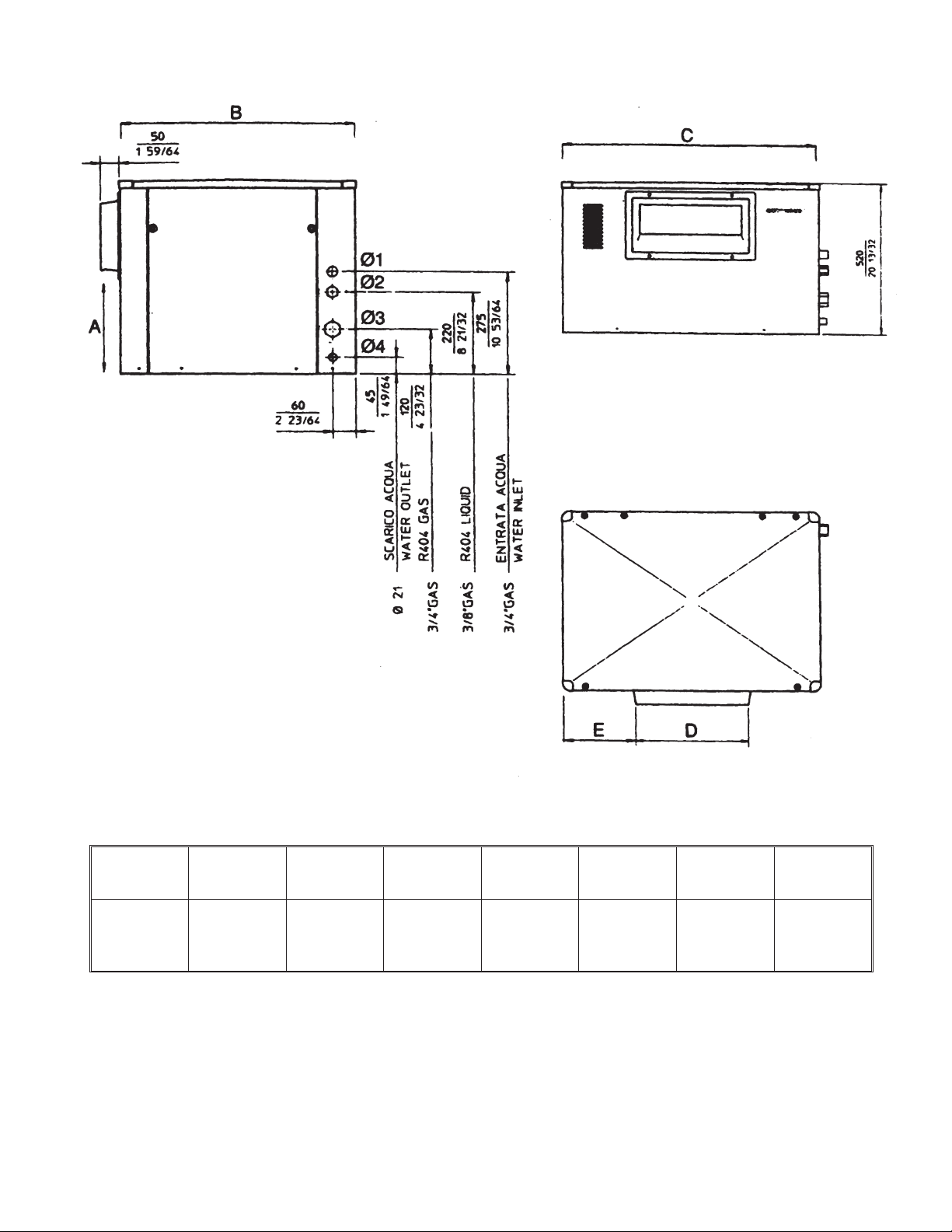

ABC

MAR1400

OR

MAR2000

876 mm

(34.49”)

621 mm

(24.49”)

876 mm

(34.49”)

* Adapter shipped inside unit to go to 3/8” male

flare.

** Line sizes may need to be larger, depending

upon length of run.

December 2000

Page 3

Ø1Water

Inlet Fitting

¾” Hose

Coupling

Thread*

Ø2 Liquid

Line

3/8” ** 5/8” ** 21 mm

Ø3 Suction

Line

Ø4 Drain

MAR1400 & MAR2000

MAR1400

Set for Fresh water Operation

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR

115-120 mm (4.5 to 4.75 inches)

•

DRUM ROTATING SPEED

1.5 RPM (thick ice)

•

2.3 RPM (thin ice)

•

REFRIGERANT:

R-404A

•

REQUIRED CONDENSING CAPACITY

4800 Kcal/h at -24EC Evap. Temp. (19,000

•

BTUH at -11

WATER PRESSURE CONTROL SETTING

0.8 Bar (11 PSIG)

•

MAX. WATER TEMPERATURE

35 °C (95oF)

•

MIN. WATER TEMPERATURE

5°C(41oF)

•

MIN. WATER PRESSURE

1 atm. (15 PSI)

•

MAX. WATER PRESSURE

•

5 atm. (75 PSI)

MIN. AMBIENT TEMPERATURE

•

5°C(41oF)

MAX. AMBIENT TEMPERATURE

•

40 °C (104oF)

MAX. VOLTAGE VARIATION

•

± 10%

o

F)

Suggested Condensing Unit Settings:

HEAD PRESSURE SETTING

15 Bar (218 PSIG) on air cooled and water

•

cooled units

LOW PRESSURE SETTING

1.6 Bar (23 PSIG) on air cooled units

•

HI-PRESSURE CONTROL SETTING

36 Bar (522 PSIG)

•

LO-PRESSURE CONTROL SETTING

0.2 Bar (3 PSIG)

•

December 2000

Page 4

MAR2000

MAR1400 & MAR2000

Set for Fresh water Operation

IMPORTANT OPERATING REQUIREMENTS:

WATER LEVEL IN DRUM RESERVOIR

115-120 mm (4.5 to 4.75 inches)

•

DRUM ROTATING SPEED

2.4 RPM (thick ice)

•

REFRIGERANT:

R-404A

•

REQUIRED CONDENSING CAPACITY

6500 Kcal/h at –24oC Evap. Temp (26,000

•

BTUH at –11

WATER PRESSURE CONTROL SETTING

0.8 Bar (11 PSIG)

•

MAX. WATER TEMPERATURE

35 °C (95oF)

•

MIN. WATER TEMPERATURE

5°C(41oF)

•

MIN. WATER PRESSURE

1 atm. (15 PSI)

•

MAX. WATER PRESSURE

•

5 atm. (75 PSI)

MIN. AMBIENT TEMPERATURE

•

5°C(41oF)

MAX. AMBIENT TEMPERATURE

•

40 °C (104oF)

MAX. VOLTAGE VARIATION

•

± 10%

o

F. )

Suggested Condensing Unit Settings

HEAD PRESSURE SETTING

15 Bar (218 PSIG) on air cooled and water

•

cooled units

LOW PRESSURE SETTING

1.6 Bar (23 PSIG) on air cooled units

•

HI-PRESSURE CONTROL SETTING

36 Bar (522 PSIG)

•

LO-PRESSURE CONTROL SETTING

0.2 Bar (3 PSIG)

•

December 2000

Page 5

MAR1400 & MAR2000

General information

Each MAR1400 or MAR2000 is an “Evaporating

Unit Section”, complete with driving mechanism

and control devices, encased in a stainless steel

cabinet. They only require a condensing unit to

make a complete scale-ice maker system.

Because they must be remotely connected to a

properly sized Condensing Unit, it is very important

that the right type and size of all the components

be used to complete the refrigerant system. It is

also very important that highly skilled refrigeration

technicians be used to complete the system by

making the refrigerant, water supply, drain and

electrical connections.

APPLICATIONS

The MAR units produce scale ice. Scale ice is a

dryer and colder form of the familiar flake ice. The

MAR split unit is a remote low side system. A

remote low side allows more flexibility in

placement of the ice machine section.

Some specific applications include:

a) Fishing Vessels

b) Fish Markets and Fish Processing Plants

c) Supermarkets

d) Meat packaging plants

Basically they can go in any place where there is a

limited space situation or where the condensing

unit (compressor/condenser) must be located in a

room where noise and heat is not objectionable.

MAR Split can be set to produce “THICK ICE”

generally used in the fishing industry or the

MAR1400 can be set to produce “THIN ICE”

generally used in the meat processing industry.

Standard versions are set for “THICK ICE”

production (about 2 mm or 5/64” thickness) and for

fresh water operation.

December 2000

Page 6

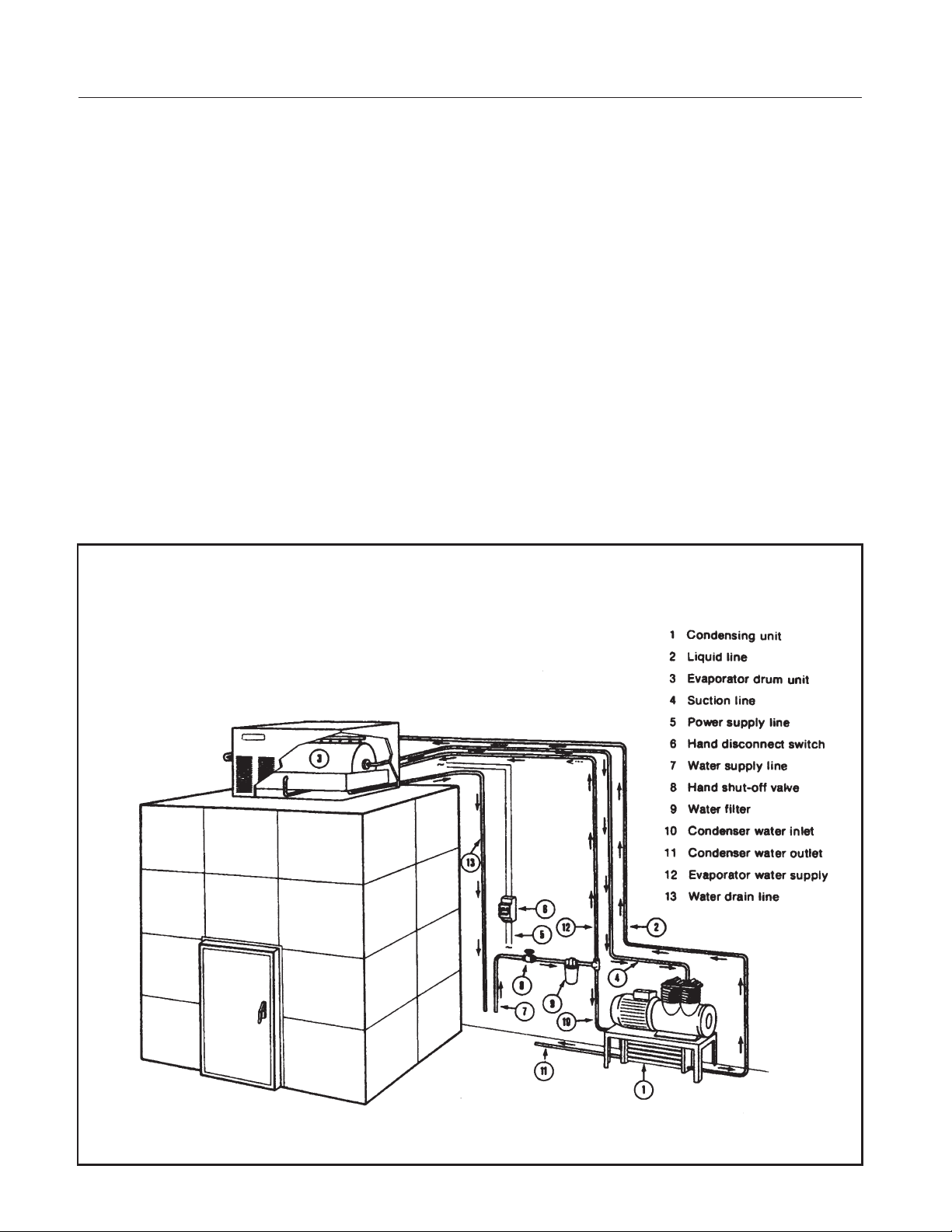

Complete System Installation

MAR1400 & MAR2000

How it is made

The complete scale-ice making system can be

divided in three major groups, they are:

a) the condensing unit or rack system

b) the evaporator drum unit (MAR1400 or

MAR2000) complete with drive mechanism, drive

motor, refrigerant and water lines fittings,

refrigerants expansion valve and electric wire

junction box.

c) control panel and box with compressor ON/OFF

switch, relay, timer, warning lights, pressure

switches and electrical wire terminal block,

connected to and controlling the condensing unit.

CONDENSING UNIT COMPONENTS - For

Reference Only

The condensing unit is not part of the MAR1400 or

MAR2000. They must either be connected to an

existing rack system or a separate condensing

unit.

Dedicated Condensing Units: Suggested

Models

MAR1400: Use MAR1400-RHS-A/C (air cooled) or

MAR1400-RHS-W/C (water cooled)

MAR2000: Use MAR2000-RHS-A/C (air cooled) or

MAR2000-RHS-W/C (water cooled)

Condensing Unit Component Guidelines

The condenser is basically a heat exchanger

where the heat absorbed by the refrigerant during

the evaporating process is discharged to the

condensing medium, which could be air or water.

Water cooled condensers require the use of a

water regulating valve. When using a marine type

condenser a marine type water regulating valve is

required. The required capacity of the condenser

about 30,000 BTUH for the MAR1400 and 39,000

for the MAR2000.

Particular care must be deserved to the selection

of the water cooled condenser especially the

marine type for fishing vessels installation. They

must be marine type (cupro-nickel).

is

The selection of proper type and size of

compressor together with the proper type and size

of condenser, their components and controls, is

critical for proper system operation.

The available capacity of the system must equal at

least

•

4800 Kcal/h at -24EC Evap. Temp. (19,000

BTUH at -11

MAR1400

•

6500 Kcal/h at –24oC Evap. Temp (26,000

BTUH at –11

the MAR2000

Length of Tubing Run Suction Line Liquid Line

4 to 15 meters (11 to 50 feet) 18 mm ID (3/4” OD) 12 mm ID (1/2” OD)

Less than 3 meters (10 feet) 14 mm ID (5/8” OD) 14 mm ID (3/8” OD)

o

F) refrigerating capacity for the

o

F.) refrigerating capacity for

The Liquid receiver is a storage tank for liquid

refrigerant. It is a common component used in

refrigeration and should be large enough to hold all

the refrigerant in the system.

A suggested component for some installations an

oil separator. When the compressor operates

small amount of oil is pumped out along with the

hot compressed vapor and to prevent it from going

any further in the system, the oil separator traps it

to return, upon opening of its float valve, to the

crankcase of the compressor.

December 2000

Page 7

MAR1400 & MAR2000

Condensing Unit Component Control Devices

The scale-ice maker refrigeration system must

have certain safety devices and controls in order to

fully protect it, however an excess of automatic

controls and protections may complicate the

situation.

In order to help the installer to decide with which

controls to use, a description of typical controls

and their positive and negative points is listed

below.

High Pressure Control

Strongly recommended for a condensing unit. Set

to values shown on tech. spec.

Lo Pressure Control

Recommended for a condensing unit. Very

important because in case of refrigerant leaks at

the evaporator, it prevents the operation of the

machine when the evaporator is in a vacuum.

Operating the evaporator in a vacuum could draw

into the system water from the drum reservoir.

Vacuum could also cause air inflow through the

compressor crank-shaft seal.

However, it may trip-out at system start-up and if

the suction operating pressure is very close to the

cut out point, it may trip out then as well.

December 2000

Page 8

Location Consideration

MAR1400 & MAR2000

WARNING - MAR SCALE ICE MAKERS are not

designed for outdoor installations where air

temperature falls below 5EC (40EF) or may

exceed 40EC (100EF)

Operating a machine with an unacceptable

configuration will void the refrigeration system

warranty.

For installation on board of fishing vessels, the

location for the condensing unit is generally the

engine room, while the evaporator unit can be

permanently placed in some area of the

deck-house or, if it is not too cold (not below 5EC

o

or 40

F.), inside the fish and ice hold.

If the MAR unit will be mounted to a fabricated

stand, it must be adequately fastened to it.

The stand must also be sturdy so it does not cause

excessive vibration and must be able to be

securely fastened to the wall or to the floor.

Placement of the MAR unit must take into

consideration where the ice is discharged and

what type of container (ice storage bin or walk-in)

will be used.

REFRIGERANT LINES

The diameter of refrigerant lines going from

condensing unit to evaporator unit and back must

be of adequate size in relation to tubing length.

Insulate any lines that will be exposed to

temperatures that will be below freezing for

extended periods of time.

Follow straight line routing, when possible,

however pitch the suction line 2 cm per meter or

¾” per yard.

Do not restrict the liquid line. Bends and fittings

should be the minimum necessary as they can

increase the resistance to the fluid flow.

If using a semi-hermetic compressor, the use of

vibration absorbers near the condensing unit will

help to reduce condensing unit vibration traveling

into the lines.

Because the appearance of an installation is

important, the piping should be put-in as neatly as

possible.

For best sound absorption, it is best to put-in two

absorbers in each line, one vertically and one

horizontally.

For evacuation and charging operations two

service valves must be provided. One on the liquid

line and one on the suction line.

A drier and a sight glass should be installed in the

liquid line at the condensing unit.

The table below show the recommended sizes of

refrigerant lines:

Note: The tubing connections at the MAR unit are

3/8” liquid and 5/8” suction.

Length of Tubing Run Suction Line Liquid Line

4 to 15 meters (11 to 50 feet) 18 mm ID (3/4” OD) 12 mm ID (1/2” OD)

Less than 3 meters (10 feet) 14 mm ID (5/8” OD) 14 mm ID (3/8” OD)

December 2000

Page 9

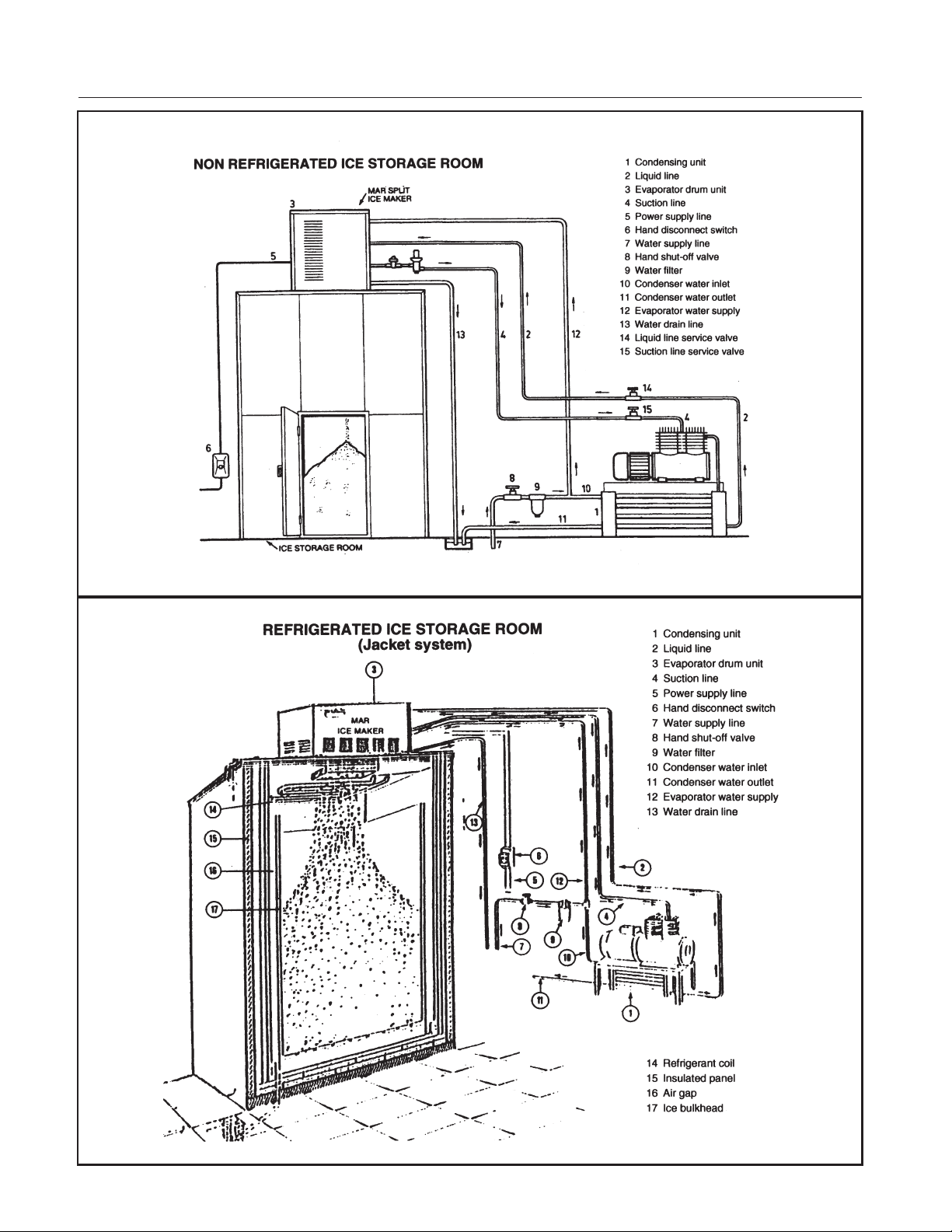

MAR1400 & MAR2000

Installation Diagrams

December 2000

Page 10

Loading...

Loading...