Scotsman NSE654 Installation Manual

INTRODUCTION

NSE654

To the owner or user: The service manual you are

reading is intended to provide you, and the

maintenance or service technician, with the

information needed to install, start up, clean,

maintain, and service this ice system.

Table of Contents

FOR THE INSTALLER ······································ Page 2

FOR THE INSTALLER: Environmental Limitations ························ Page 3

FOR THE PLUMBER ······································· Page 4

FOR THE ELECTRICIAN ····································· Page 5

FOR THE INSTALLER ······································ Page 6

START UP ············································ Page 7

COMPONENT DESCRIPTION ·································· Page 8

COMPONENT DESCRIPTION ·································· Page 9

COMPONENT DESCRIPTION: Control Box ··························· Page 10

ELECTRICAL SEQUENCE ···································· Page 11

OPERATION: Water ······································· Page 12

OPERATION: Refrigeration ···································· Page 13

TECHNICAL CHARACTERISTICS ································ Page 14

MAINTENANCE AND CLEANING ································ Page 15

SENSOR MAINTENANCE ···································· Page 16

BEARING MAINTENANCE ···································· Page 17

MAINTENANCE AND CLEANING: Auger ···························· Page 18

SERVICE DIAGNOSIS ······································ Page 19

SERVICE DIAGNOSIS: ····································· Page 20

CONTROL SYSTEM DIAGNOSTICS ······························ Page 21

REMOVAL AND REPLACEMENT: Water Reservoir & Bin Controls ··············· Page 22

REMOVAL AND REPLACEMENT: Bearing And Breaker ···················· Page 23

REMOVAL AND REPLACEMENT: Auger ···························· Page 24

REMOVAL AND REPLACEMENT: Water Seal ·························· Page 25

REMOVAL AND REPLACEMENT: Evaporator ·························· Page 26

REMOVAL AND REPLACEMENT: Evaporator ·························· Page 27

REMOVAL AND REPLACEMENT: Gearmotor ·························· Page 28

REFRIGERATION SYSTEM SERVICE ····························· Page 29

The NSE654 is a complete ice system that

produces and stores nugget ice.

It features: front service for the condenser, control

box, and water reservoir; an electronic circuit for

monitoring ice and water level; a thermostatic

expansion valve; and HP62 as the refrigerant.

This manual was printed on recycled paper.

Keep it for future reference.

Note these symbols when they appear.

They mark a section that concerns potential hazards.

January 2000

Page 1

NSE654

FOR THE INSTALLER

Installation Limitations:

This ice system is designed to be installed indoors,

in a controlled environment:

Min. Max.

Air Temperature 50

Water Temperature 40

Water Pressure 20 PSI 80 PSI

Voltage 104 126

(Compared to the nameplate)

Operating the machine outside of the limitations is

misuse and can void the warranty.

When installing a new system, check to be sure

that you have everything you need before

beginning:

Correct Ice Machine (air or water cooled)

All kits, legs, and information required for

the specific job.

0

F 1000F

0

F 1000F

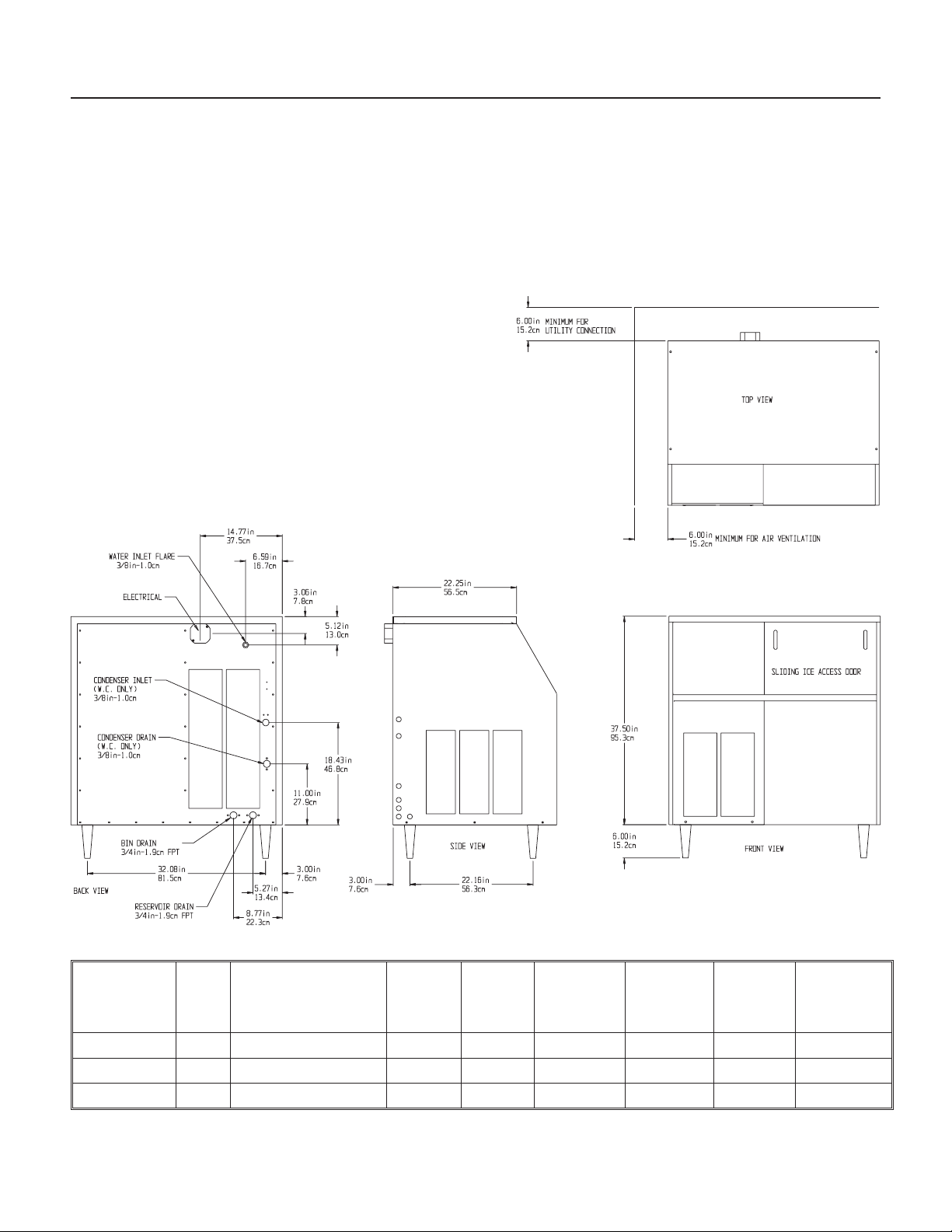

SPECIFICATIONS: ICE MAKER

Model

Number

NSE654AS-1 A or B 37.5" x 38.06" x 29.5" 115/60/1 NUGGET Air 20 35 25 ounces

NSE654WS-1 A same same NUGGET Water 20 30 20 ounces

NSE654WS-1 B same same same same same same 19 ounces

Model

Series

Dimensions

(w/o legs)

HxWxD

Basic

Electrical

Ice Type Condenser

Type

Minimum

Circuit

Ampacity

Maximum

Fuse Size

Refrigerant

Charge

(R-404A)

Note: Minimum Circuit Ampacity is used to determine wire size and type per national electric code.

June 2002

Page 2

FOR THE INSTALLER: Environmental Limitations

NSE654

Location

After uncrating the machine, and inspecting it for

freight damage, the unit is ready for installation.

It is important that the machine be installed in a

location where it has enough space for service

access. The unit will require removal of the top

panel for some service, so in under counter

applications, the unit will either have to be pulled

out, or the countertop will have to be removable.

Utility installation needs some space at the back of

the cabinet, the minimum is 6 inches.

On air cooled models, the air flow must be given

consideration: the unit takes in air from the front,

and exhausts it through the left and back panels.

These areas require at least 6 inches of air space

to exhaust the hot air.

Water Limitations

An ice machine is a food manufacturing plant; it

takes a raw material, water, and turns it into a food

product, ice. The purity of the water is very

important in obtaining pure ice and in maximizing

product life. This section is not intended as a

complete resource for water questions, but it does

offer these general recommendations:

1. Filter the water used to produce ice. That is the

water going to the "potable" water connection.

Water filters vary greatly in ability and function.

Install one that filters out suspended solids to a

dimension of 5 microns or smaller. The finer the

filter the better, but finer filters will clog sooner than

course ones. It may be necessary to add a course

filter ahead of the fine filter to prolong filter life.

2. Check with a water treatment specialist for a

water test, and recommendations regarding filters

and treatment.

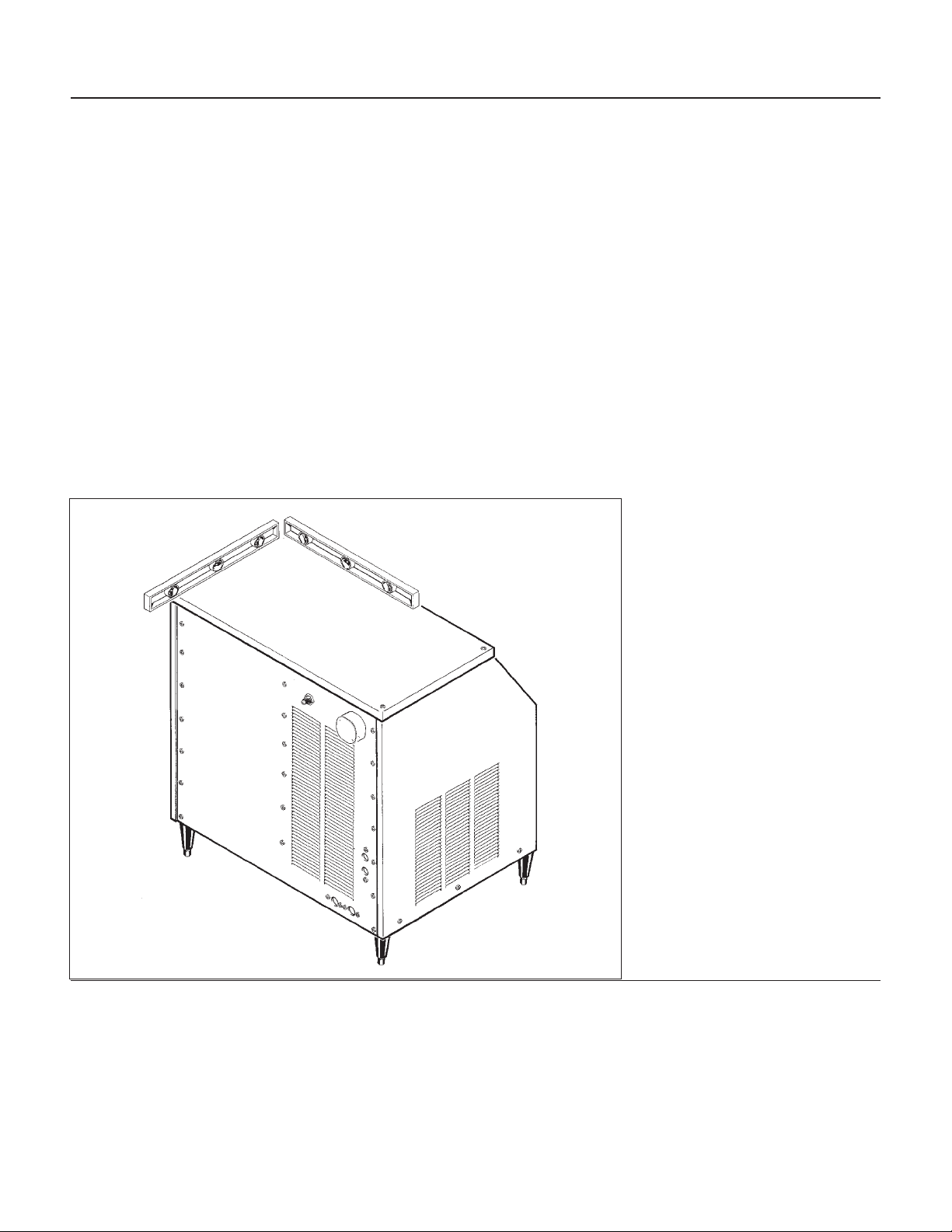

Legs

The legs (when used) may now

be installed. Either use a

mechanical lift to hoist the cabinet

high enough to screw in the legs,

or carefully lay the unit on its back

(using portions of the carton to

protect the back panel) and screw

the legs in. Note: the legs must be

threaded in all the way for

maximum strength.

Scotsman Ice Systems are designed and manufactured with the highest regard for safety and

performance. They meet or exceed the standards of UL, NSF, and CUL.

Scotsman assumes no liability or responsibility of any kind for products manufactured by Scotsman that

have been altered in any way, including the use of any part and/or other components not specifically

approved by Scotsman.

Scotsman reserves the right to make design changes and/or improvements at any time. Specifications and

design are subject to change without notice.

January 2000

Page 3

NSE654

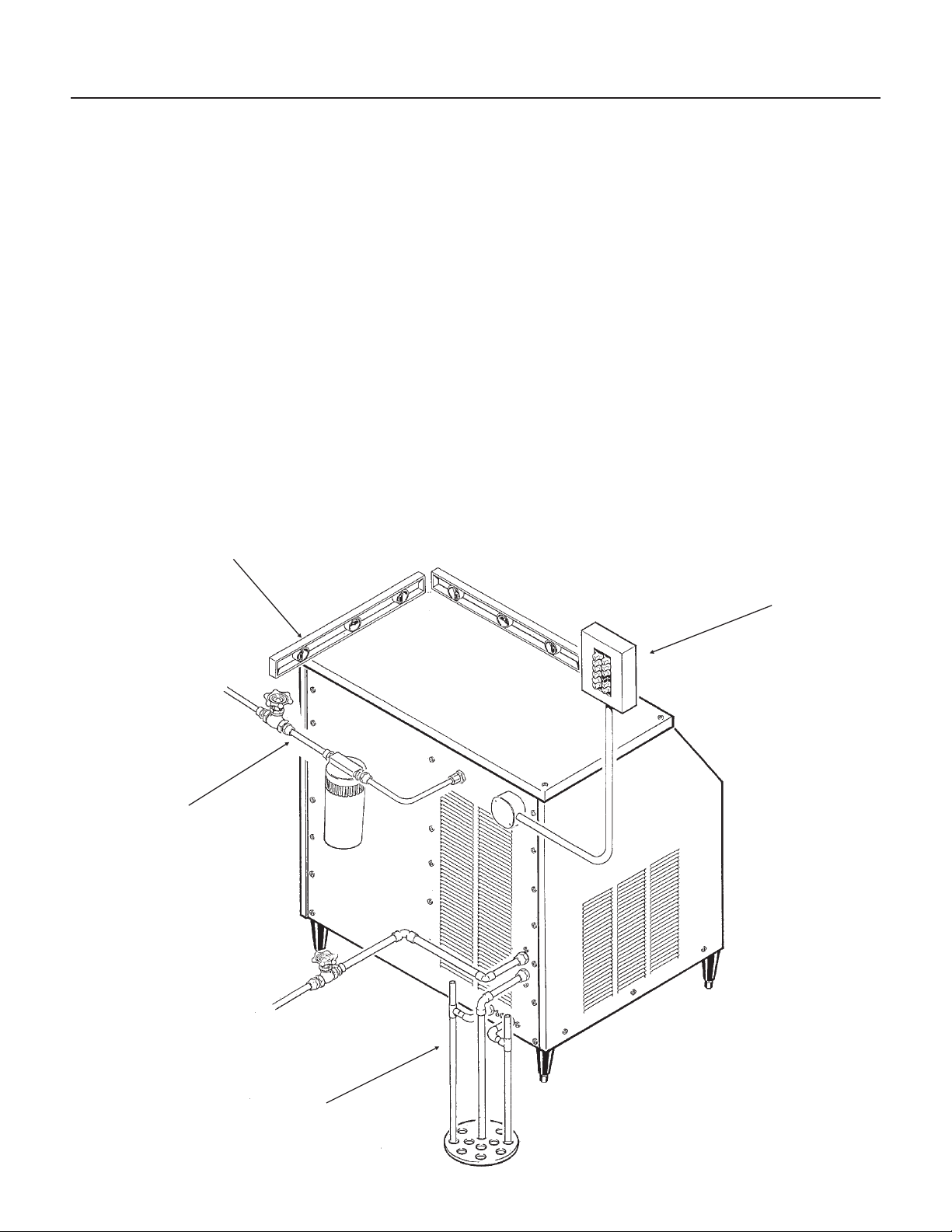

FOR THE PLUMBER

CONFORM TO ALL APPLICABLE CODES

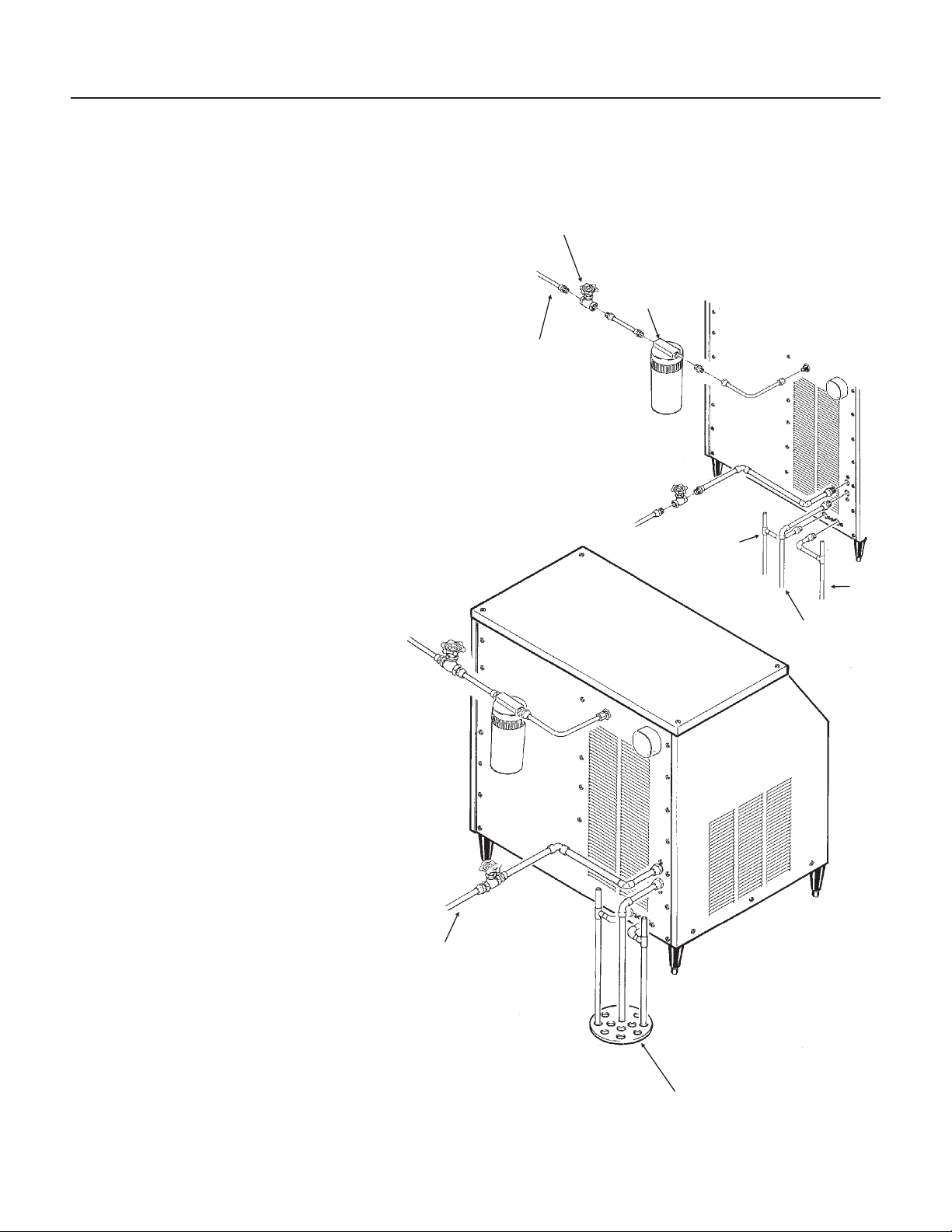

Water Inlet

Air Cooled Models: Connect a cold

potable water supply to the 3/8" male flare

fitting at the back of the cabinet. Install a

hand valve near the machine to control

the water supply.

Water Treatment: In most areas, a water

filter of some type will be useful. In areas

where the water is highly concentrated

with minerals the water should be tested

by a water treatment specialist, and the

recommendations of the specialist

regarding filtration and/or treatment

should be followed.

Water Cooled Models: Connect a

separate 3/8" O.D. copper line, with a

separate hand valve to control it, to the

3/8" FPT condenser inlet at the back of

the cabinet. The water pressure to all

lines must always be above 20 psig, and

below 80 psig.

Drains

HAND

VALVE

FIELD

SUPPLIED

FILTER

WATER

INLET

WATER

COOLED

MODEL

VENTED

DRAIN

VENTED

DRAIN

Air Cooled Models: There are two 3/4"

FPT drains at the back of the cabinet.

Connect a drain tube to each. These are

gravity type drains, and 1/4 inch per foot

fall is an acceptable pitch for the drain

tubing. Install a vent at the highest point

of each drain line, and the ideal drain

receptacle would be a trapped and vented

floor drain. Use only 3/4" rigid tubing.

Water Cooled Models: In addition to the

above mentioned drains, a separate

condenser drain must be installed.

Connect it to the 1/2" condenser drain

connection at the back of the cabinet.

CONDENSER

DRAIN

CONDENSER

INLET

January 2000

Page 4

FLOOR DRAIN

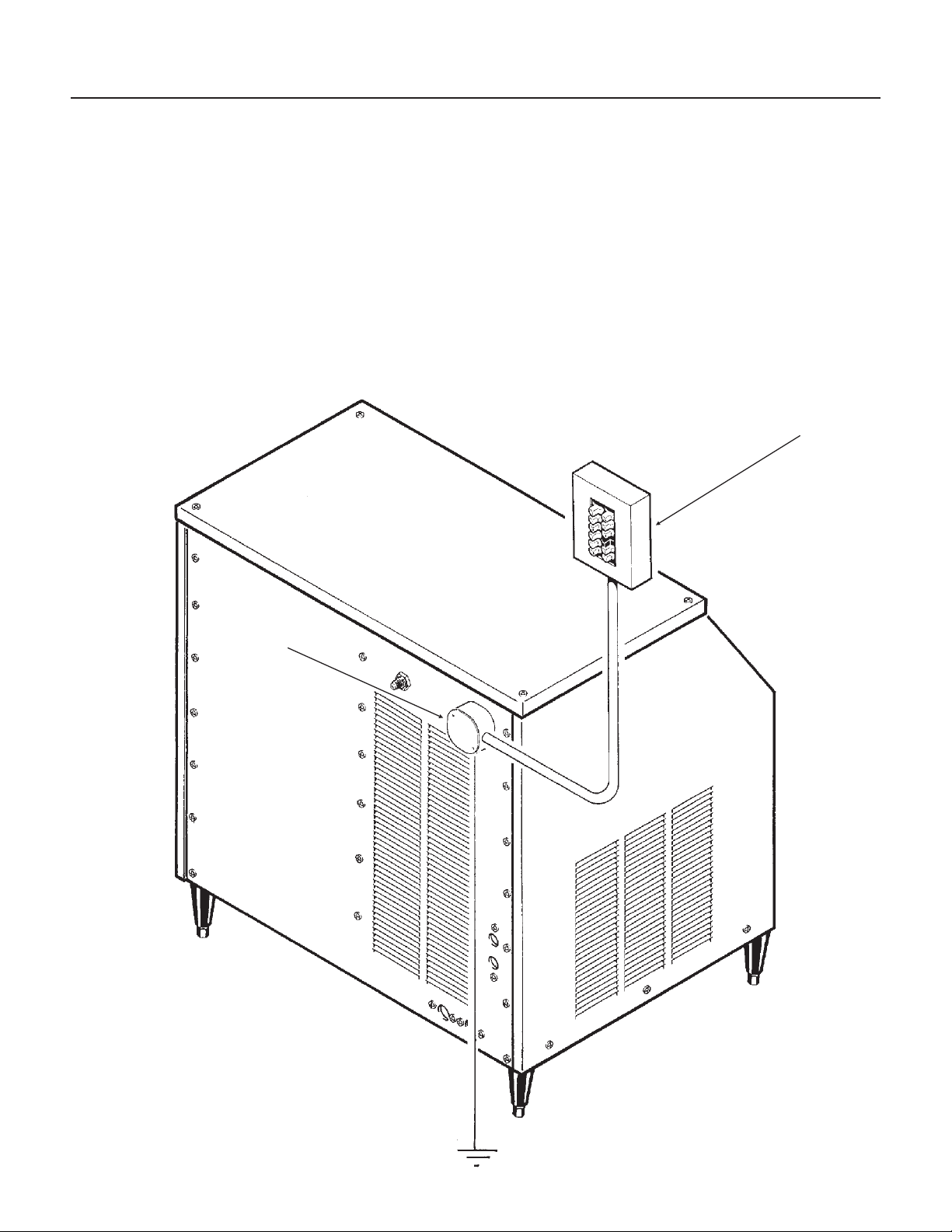

FOR THE ELECTRICIAN

CONFORM TO ALL APPLICABLE CODES

NSE654

The electrical power to the unit is supplied through

the junction box at the rear of the machine.

Check the nameplate (located on the back panel)

for the voltage requirements, and for the minimum

circuit ampacity. The machine requires a solid

chassis to earth ground wire.

The ice maker should be connected to its own

electrical circuit so it would be individually fused.

Voltage variation must remain within design

limitations, even under starting conditions.

All external wiring must conform to national,

state, and local electrical codes. The use of a

licensed electrician is required to perform the

electrical installation.

POWER

SUPPLY

JUNCTION

BOX

January 2000

Page 5

NSE654

FOR THE INSTALLER

Final Check List

1. Is the ice system installed indoors in a location

where the air and water temperatures are

controlled, and where they do not exceed the

design limitations?

2. Is there an electrical service disconnect within

sight of the installed machine? Has the voltage

been checked, and compared to nameplate

requirements?

3. Have all the plumbing connections been made

and checked for leaks?

4. Has the machine been leveled?

5. Is there a minimum of 6" clearance at the back

and left side of the machine for proper service

access and air circulation? (air cooled)

LEVELED?

6. Is the water pressure a minimum of 20 psig?

7. Is the unit grounded?

8. Is there clearance over the top of the machine

for service access?

9. Is there a water shut off valve installed near the

machine?

10. Have all of the shipping blocks been removed?

POWER

SUPPLY?

WATER

SUPPLY?

DRAINS?

January 2000

Page 6

START UP

Pre-Start Inspection

1. Remove the front panels.

2. Check that the styrofoam shipping blocks have

been removed.

3. Inspect the interior of the machine for loose

screws or wires. Check that no refrigerant lines

are rubbing each other. Check that the fan blade

turns freely (air cooled).

4. Check that the unit is installed correctly

according to the final check list (page 6).

Start Up

NSE654

1. Go through the prestart inspection.

2. Open the hand valve, observe that water enters

the water reservoir, fills the tube from the reservoir

to the evaporator, and then shuts off. Check for

leaks.

3. Switch the master switch on.

The electrical start up sequence is automatic.

A. There should be a short (15 second) delay

before the gearmotor starts.

B. After the gearmotor starts, the compressor will

start.

4. On air cooled models, the condenser will begin

to discharge warm air, on water cooled models, the

water regulating valve will open, and warm water

will be discharged into the drain.

5. The unit should soon be making ice, if desired,

the low side pressure can be checked: it should be

34 psig + or - 4 psig.

The suction line temperature at the compressor is

normally very cold, nearly to the point of frost up to

the compressor body, but not on it.

The air cooled discharge pressure will depend

upon air and water temperatures, but should be

between 220 psig and 300 psig.

The water cooled discharge pressure should be

constant at about 245 psig.

The above numbers are for new, clean machines,

you can expect to see some values higher, and

some lower between different units.

6. THERE ARE NO ADJUSTMENTS TO MAKE,

so replace the panels.

7. Clean and/or sanitize the storage bin interior,

wipe off the exterior with a clean, damp cloth.

8. Give the owner/user the service manual, instruct

him/her in the operation of the unit, and make sure

they know who to call for service.

9. Fill out the manufacturers registration card, and

mail it to the Scotsman Factory.

10. Fill out the Customer Evaluation & Warranty

Registration Form, and mail it to Scotsman.

January 2000

Page 7

NSE654

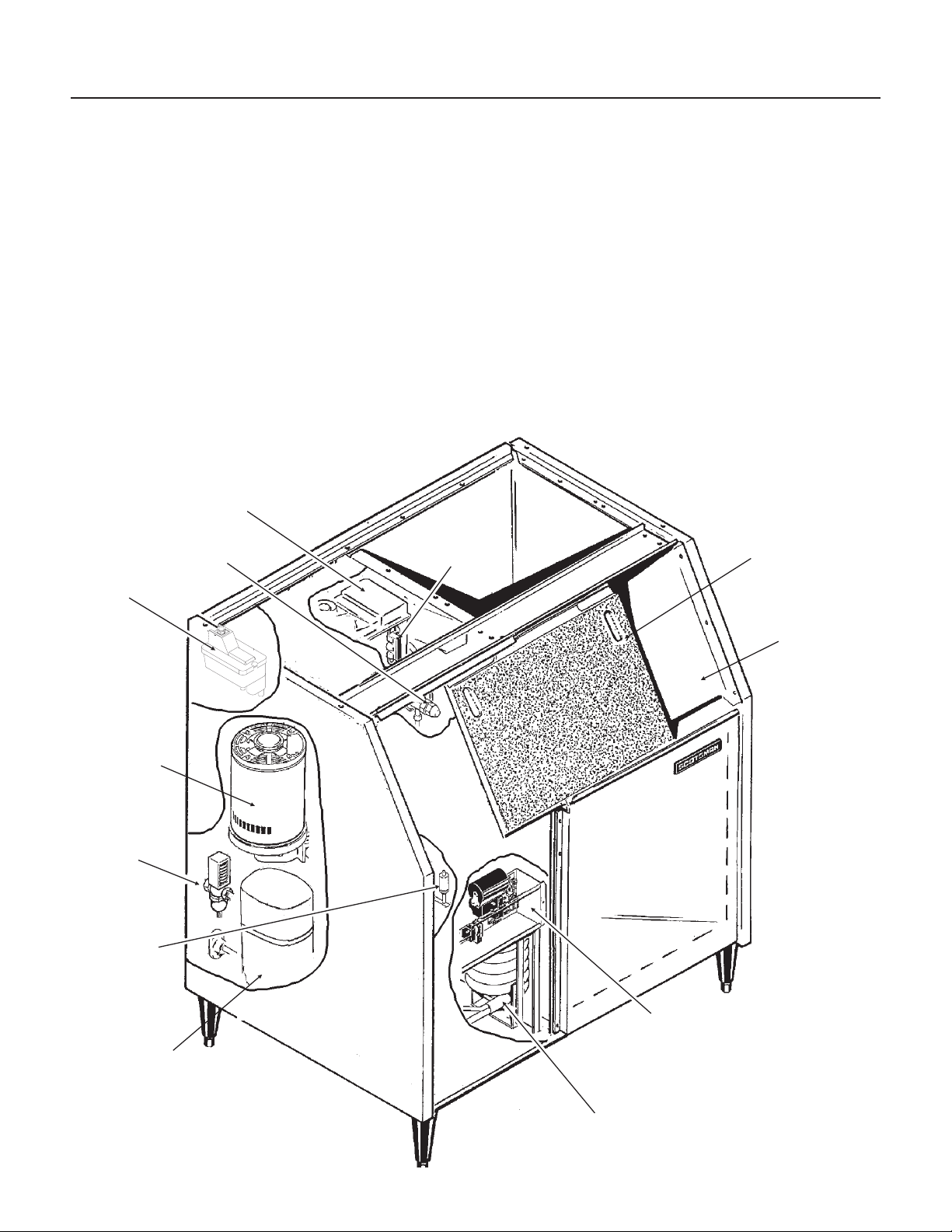

COMPONENT DESCRIPTION

Control Box: Contains the electrical controls that

operate the machine.

High Pressure Cut Out Switch: An automatic

reset switch sensing the high side refrigeration

pressure. It is set to shut the machine off if the

discharge pressure should ever exceed 450 psig.

Compressor: The refrigerant vapor pump.

Reservoir: Float operated, it maintains the water

level in the evaporator at a constant level, it also

contains the water level sensor.

Water Level Sensor: Senses if there is water in

the reservoir to make ice out of. Will shut the

machine off it there is none.

Ice Discharge Chute: Directs the ice produced by

the evaporator into the storage bin.

RESERVOIR

AND WATER

LEVEL SENSOR

ICE CHUTE

EXPANSION

VALVE

Ice Level Sensor: An electronic “eye”, it senses

the presence of ice in the bottom of the ice

discharge chute. Operates to turn the ice machine

on and off automatically as the level of ice in the

bin changes.

Gear Motor: An oil filled, speed reduction

gearbox, driving the auger.

Condenser: Air or water cooled, where the heat

removed in ice making is discharged.

Expansion valve: The refrigerant metering

device.

ICE LEVEL

SENSORS

WATER COOLED

ICE ACCESS

DOOR

GEARMOTOR

WATER

REGULATING

VALVE

HIGH

PRESSURE

CUT OUT

COMPRESSOR

ICE

STORAGE

BIN

CONTROL BOX

January 2000

Page 8

CONDENSER

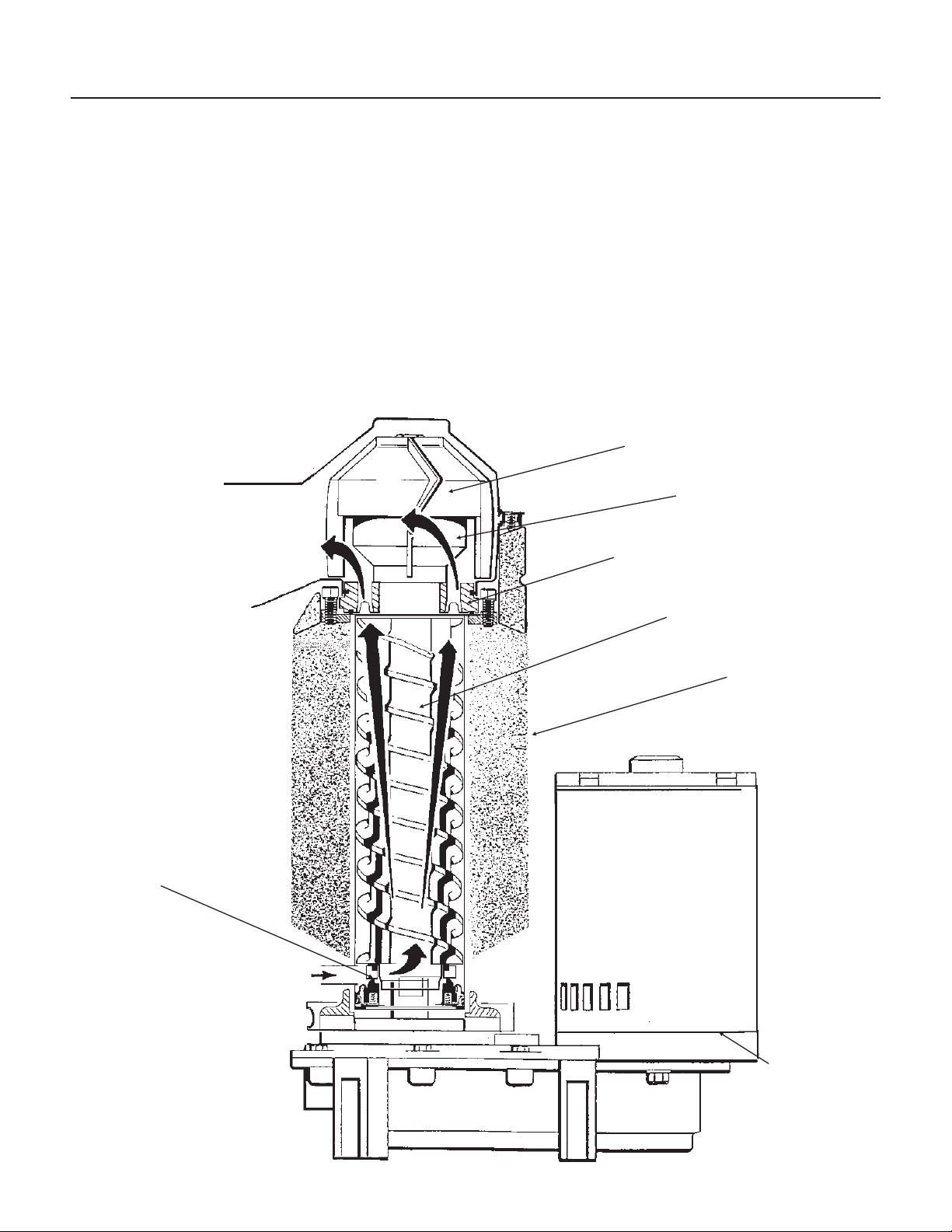

COMPONENT DESCRIPTION

NSE654

Evaporator: A refrigerated vertical tube filled with

water and containing a water seal and auger.

Auger: A solid stainless steel double spiral auger,

it pushes the ice crystals up to the top of the

evaporator.

Water Seal: A two part “face” seal, the top half

rotating with the auger, the bottom half stationary,

the sealing action being where the two seal “faces”

meet.

Ice Sweep: A plastic cap with “fingers”. It revolves

with the auger to “sweep” the ice into the ice chute.

Breaker: Where the ice is compressed and much

of the extra water is squeezed out of it before it is

discharged into the bin.

Motor: A split phase motor that drives the gear

reducer.

Thrust Bearing: As the ice is pushed up the

evaporator, the auger is thrust down, and pressure

from the auger thrust is taken up by this bearing.

ICE SWEEP

BEARING

BREAKER

WATER

SEAL

AUGER

EVAPORATOR

January 2000

Page 9

MOTOR

Loading...

Loading...