Scotsman DCE33 Series,DCE33A-1WB,DCE33PA-1WB,DCE33A-1BB,DCE33PA-1BB,DCE33A-1SB,DCE33PA-1SB User Manual

INTRODUCTION

DCE33

The Scotsman DCE33 is a restaurant type ice

machine designed for home use. It produces the

same high quality ice as large Scotsman

commercial ice cube machines, and stores that ice

in a heavily insulated storage bin.

This service manual is intended as a resource for

people installing, using, and servicing the DCE33.

Because it contains information on safety and

maintenance, Scotsman strongly recommends that

this manual be kept where it is readily available.

Table of Contents

Page

Technical Information ............................. 2

Installation:

Water ................................... 3

Plumbing .................................. 4

Add On Kits:

Drain Pump ................................. 9

Door Kit .................................. 10

Reverse Door Swing ............................. 11

Initial Start Up ................................ 12

Operation .................................. 13

Component Location ............................. 14

Maintenance & Cleaning ............................ 15

Winterizing ................................. 15

Cleaning Ice Making System .......................... 16

Adjust Cube Size ............................... 17

Adjust Bin Ice Level .............................. 18

Adjust Timer ................................. 18

Service Diagnosis .............................. 19

Repair:

Curtain ................................... 21

Inlet Water Valve ............................... 21

Timer ................................... 22

Cube Size Control .............................. 23

Bin Thermostat ................................ 23

Water Pump ................................. 24

Parts lists and wiring diagrams are located in the center of the manual, printed on yellow paper.

This manual was printed on

August 1995 recycled paper.

Page 1

DCE33

TECHNICAL INFORMATION

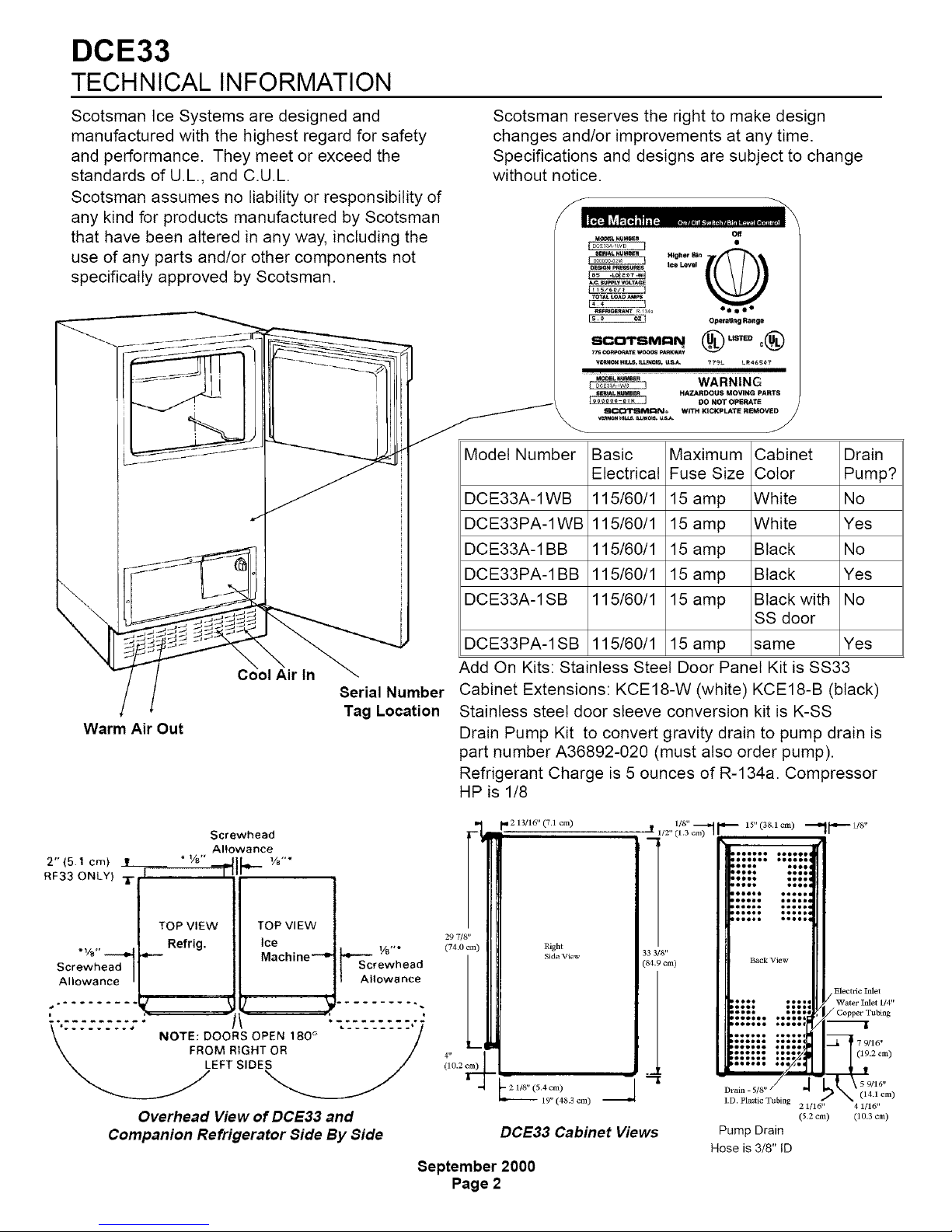

Scotsman Ice Systems are designed and

manufactured with the highest regard for safety

and performance. They meet or exceed the

standards of U.L., and C.U.L.

Scotsman assumes no liability or responsibility of

any kind for products manufactured by Scotsman

that have been altered in any way, including the

use of any parts and/or other components not

specifically approved by Scotsman.

C, el Air In

Serial Number

Tag Location

Warm Air Out

Scotsman reserves the right to make design

changes and/or improvements at any time.

Specifications and designs are subject to change

without notice.

Y

MOOeLHuMeea

seRIALmJ}Aeen Higher BIn

_ Ice Le'_l

TO_L _OAD_PS

_R_ R13_

_ Operating Ilange

VE_e_ 14tLt.&_laINO_, _1,_._ ?_L LR46Se7

SlS_AL tIUMeEn HAZARDOUS MOVING PARTS

J

Model Number

DCE33A-1WB

DCE33PA-1WB

DCE33A-1 BB

DCE33PA-1 BB

DCE33A-1 SB

DCE33PA-1 SB

SlI_I_IVN;;N_® WITH KICKPLATE RI_MOVED

Basic

Electrical

115/60/1

115/60/1

115/60/1

115/60/1

115/60/1

115/60/1

Maximum

Fuse Size

15 amp

15 amp

15 amp

15 amp

15 amp

15 amp

Add On Kits: Stainless Steel Door Panel Kit is SS33

Cabinet Extensions: KCE18-W (white) KCE18-B (black)

Stainless steel door sleeve conversion kit is K-SS

Drain Pump Kit to convert gravity drain to pump drain is

part number A36892-020 (must also order pump).

Refrigerant Charge is 5 ounces of R-134a. Compressor

HP is 1/8

Off

X

®°"°°°®

WARNING

DO NOT OPERATE

Cabinet Drain

Color Pump?

White No

White Yes

Black No

Black Yes

Black with No

SS door

same Yes

Screwhead

Allowance

2"(5.1 cm) _t__

RF33 ONLY)

* Vs" --,,_

Screwhead

Allowance

o

a

i

1/8"

-- q-IF-

TOP VIEW

Re!rig.

TOP VIEW

Ice

Machine --e

........ .OTE:OOO"SOPEN'80°" 7

\ FROM RIGHT OR /

Overhead View of DCE33 and

Companion Refrigerator Side By Side

213/16" (7.1 cm)

8

rewhead

1 Allowance

INSTALLATION

DOE33

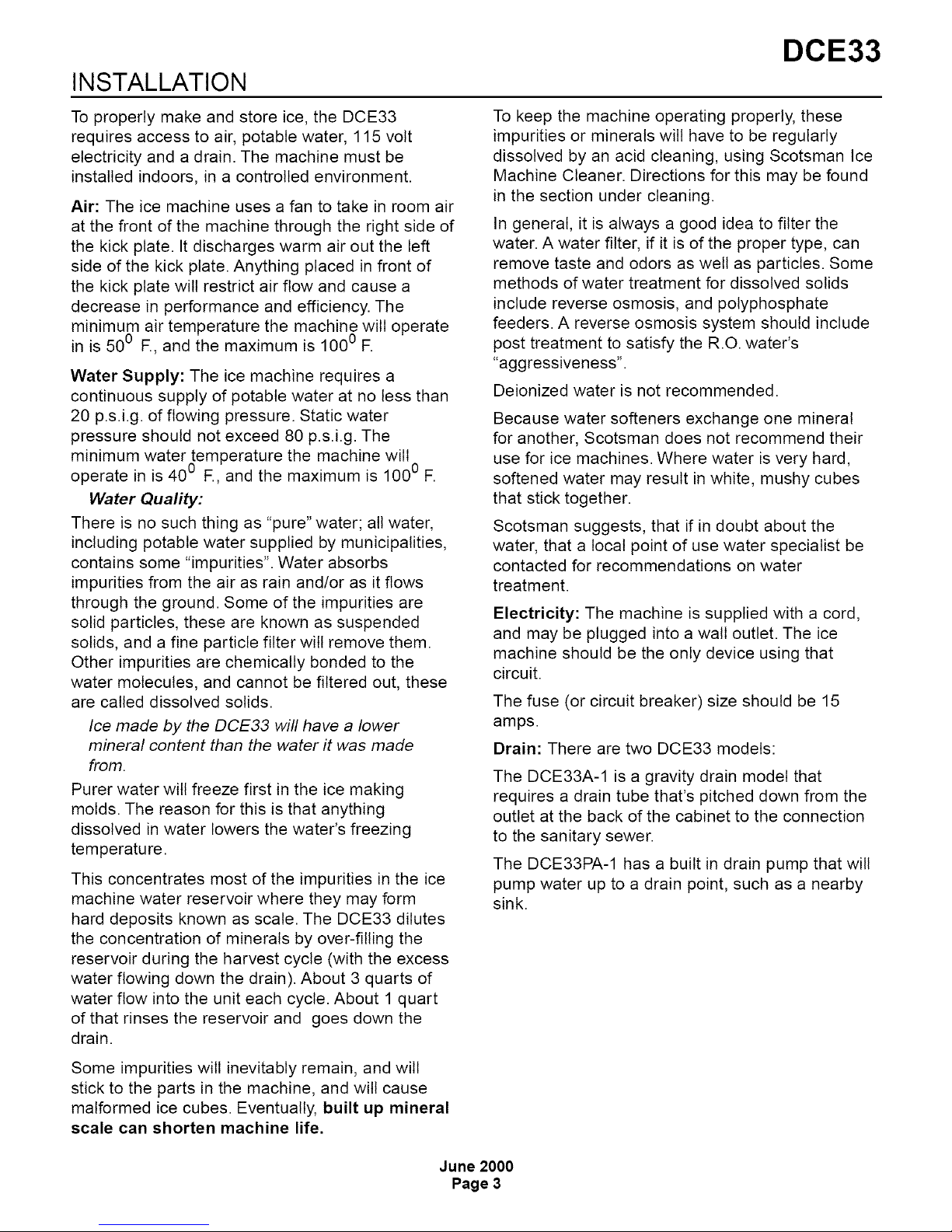

To properly make and store ice, the DCE33

requires access to air, potable water, 115 volt

electricity and a drain. The machine must be

installed indoors, in a controlled environment.

Air: The ice machine uses a fan to take in room air

at the front of the machine through the right side of

the kick plate. It discharges warm air out the left

side of the kick plate. Anything placed in front of

the kick plate will restrict air flow and cause a

decrease in performance and efficiency. The

minimum air temperature the machine will operate

in is 500 F., and the maximum is 100 ° F.

Water Supply: The ice machine requires a

continuous supply of potable water at no less than

20 p.s.i.g, of flowing pressure. Static water

pressure should not exceed 80 p.s.i.g. The

minimum water temperature the machine will

operate in is 400 F., and the maximum is 100 ° F.

Water Quality:

There is no such thing as "pure" water; all water,

including potable water supplied by municipalities,

contains some "impurities". Water absorbs

impurities from the air as rain and/or as it flows

through the ground. Some of the impurities are

solid particles, these are known as suspended

solids, and a fine particle filter witl remove them.

Other impurities are chemically bonded to the

water molecules, and cannot be filtered out, these

are called dissolved solids.

Ice made by the DCE33 will have a lower

mineral content than the water it was made

from.

Purer water witl freeze first in the ice making

molds. The reason for this is that anything

dissolved in water lowers the water's freezing

temperature.

This concentrates most of the impurities in the ice

machine water reservoir where they may form

hard deposits known as scale. The DCE33 dilutes

the concentration of minerals by over-filling the

reservoir during the harvest cycle (with the excess

water flowing down the drain). About 3 quarts of

water flow into the unit each cycle. About 1 quart

of that rinses the reservoir and goes down the

drain.

To keep the machine operating properly, these

impurities or minerals will have to be regularly

dissolved by an acid cleaning, using Scotsman Ice

Machine Cleaner. Directions for this may be found

in the section under cleaning.

In general, it is always a good idea to filter the

water. A water filter, if it is of the proper type, can

remove taste and odors as well as particles. Some

methods of water treatment for dissolved solids

include reverse osmosis, and polyphosphate

feeders. A reverse osmosis system should include

post treatment to satisfy the R.O. water's

"aggressiveness".

Deionized water is not recommended.

Because water softeners exchange one mineral

for another, Scotsman does not recommend their

use for ice machines. Where water is very hard,

softened water may result in white, mushy cubes

that stick together.

Scotsman suggests, that if in doubt about the

water, that a local point of use water specialist be

contacted for recommendations on water

treatment.

Electricity: The machine is supplied with a cord,

and may be plugged into a wall outlet. The ice

machine should be the only device using that

circuit.

The fuse (or circuit breaker) size should be 15

amps.

Drain: There are two DCE33 models:

The DCE33A-1 is a gravity drain model that

requires a drain tube that's pitched down from the

outlet at the back of the cabinet to the connection

to the sanitary sewer.

The DCE33PA-1 has a built in drain pump that will

pump water up to a drain point, such as a nearby

sink.

Some impurities will inevitably remain, and will

stick to the parts in the machine, and will cause

malformed ice cubes. Eventually, built up mineral

scale can shorten machine life.

June 2000

Page 3

DCE33

TO INSTALL: Plumbing

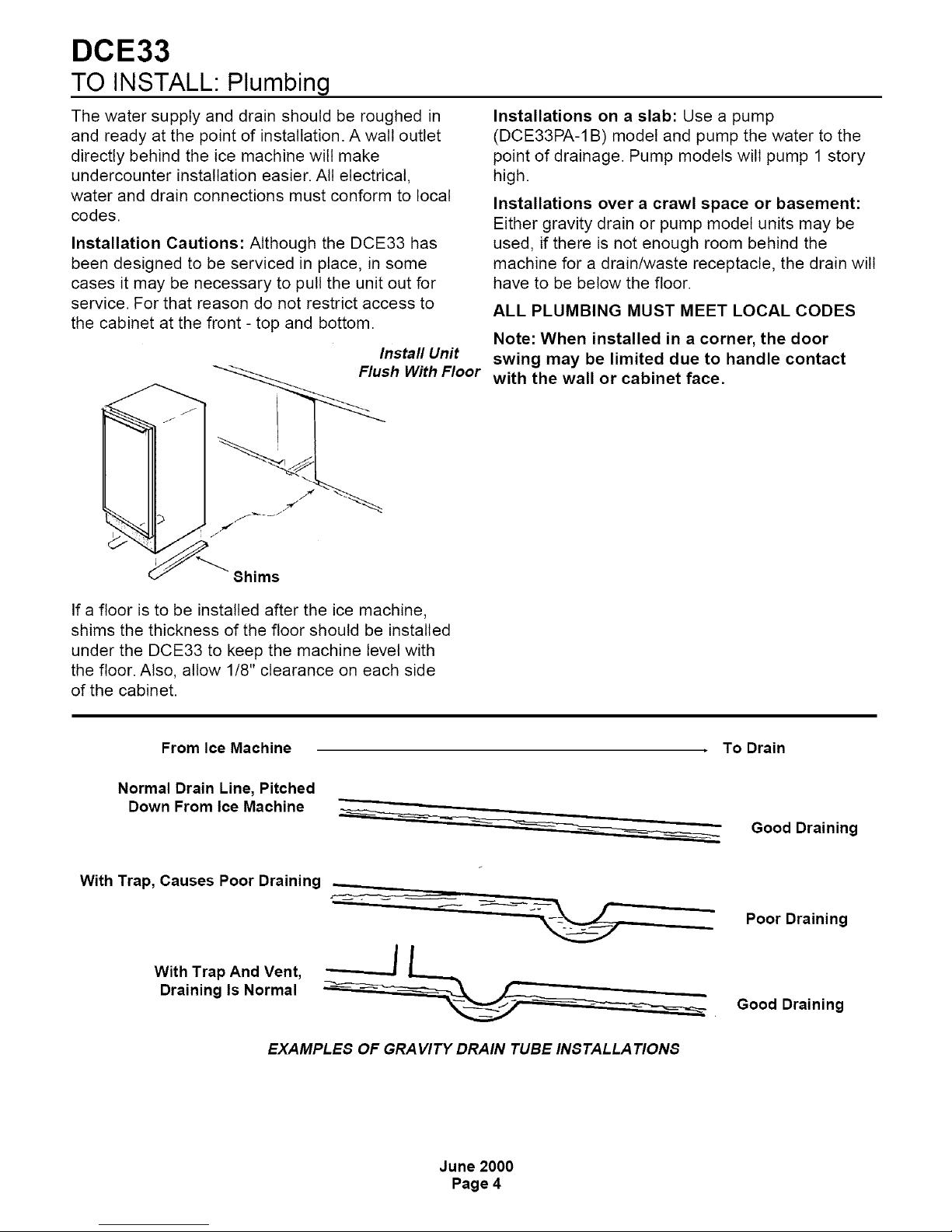

The water supply and drain should be roughed in

and ready at the point of installation. A walt outlet

directly behind the ice machine will make

undercounter installation easier. All electrical,

water and drain connections must conform to local

codes.

Installation Cautions: Although the DCE33 has

been designed to be serviced in place, in some

cases it may be necessary to pull the unit out for

service. For that reason do not restrict access to

the cabinet at the front - top and bottom.

Install Unit

lush With Floor

Installations on a slab: Use a pump

(DCE33PA-1 B) model and pump the water to the

point of drainage. Pump models wilt pump 1 story

high.

Installations over a crawl space or basement:

Either gravity drain or pump model units may be

used, if there is not enough room behind the

machine for a drain/waste receptacle, the drain will

have to be below the floor.

ALL PLUMBING MUST MEET LOCAL CODES

Note: When installed in a corner, the door

swing may be limited due to handle contact

with the wall or cabinet face.

Shims

If a floor is to be installed after the ice machine,

shims the thickness of the floor should be installed

under the DCE33 to keep the machine level with

the floor. Also, allow 1/8" clearance on each side

of the cabinet.

From Ice Machine

Normal Drain Line, Pitched

Down From Ice Machine

With Trap, Causes Poor Draining --

o __ .

With Trap And Vent,

Draining Is Normal

To Drain

Good Draining

Poor Draining

Good Draining

EXAMPLES OF GRAVITY DRAIN TUBE INSTALLATIONS

June 2000

Page 4

TO INSTALL: Plumbing

DCE33

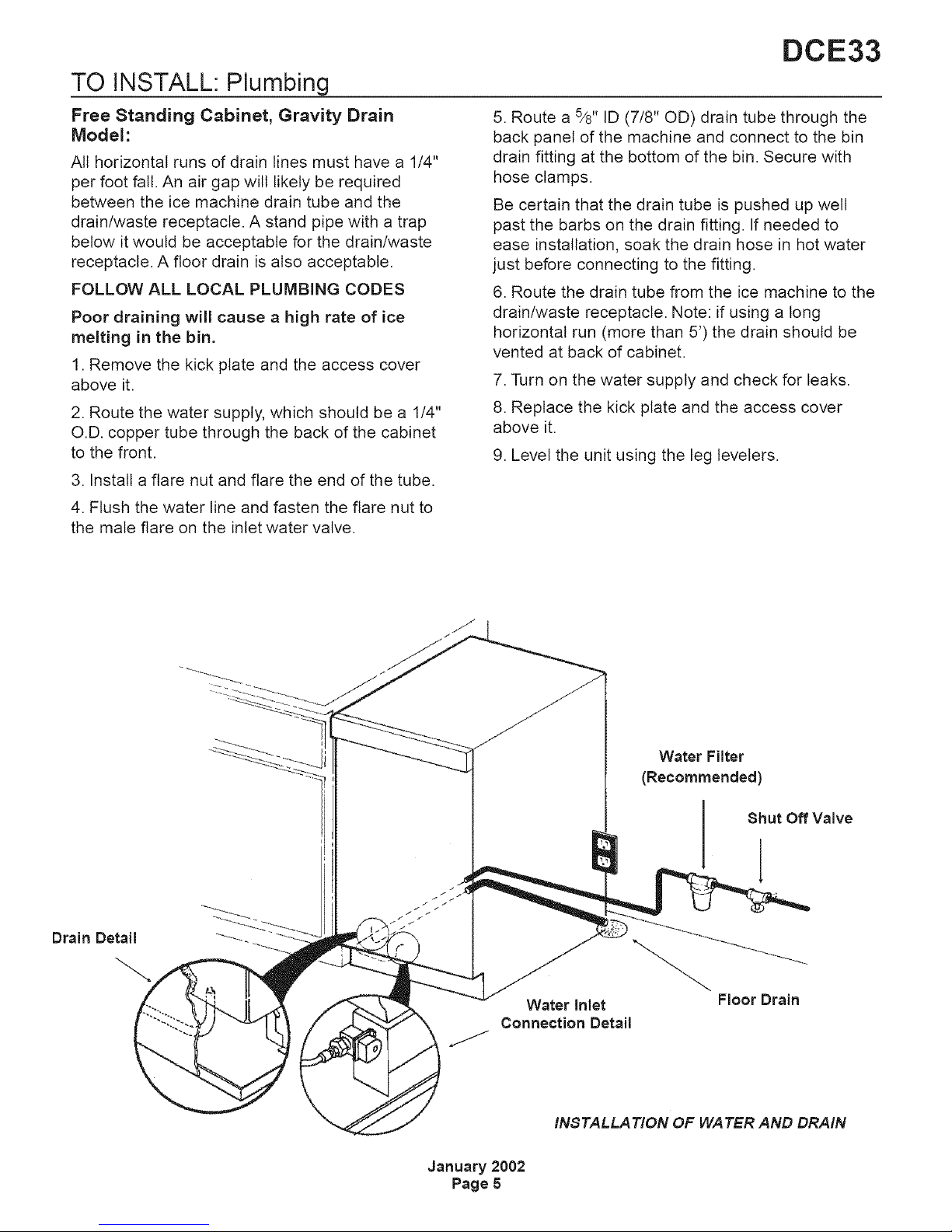

Free Standing Cabinet, Gravity Drain

Model:

All horizontal runs of drain lines must have a 1/4"

per foot fall. An air gap wilt likely be required

between the ice machine drain tube and the

drain/waste receptacle. A stand pipe with a trap

below it would be acceptable for the drain/waste

receptacle. A floor drain is also acceptable.

FOLLOW ALL LOCAL PLUMBING CODES

Poor draining will cause a high rate of ice

melting in the bin.

1. Remove the kick plate and the access cover

above it.

2. Route the water supply, which should be a 1/4"

O.D. copper tube through the back of the cabinet

to the front.

3. Install a flare nut and flare the end of the tube.

4. Flush the water line and fasten the flare nut to

the male flare on the inlet water valve.

5. Route a 5/8" ID (7/8" OD) drain tube through the

back panel of the machine and connect to the bin

drain fitting at the bottom of the bin. Secure with

hose clamps.

Be certain that the drain tube is pushed up well

past the barbs on the drain fitting. If needed to

ease installation, soak the drain hose in hot water

just before connecting to the fitting.

6. Route the drain tube from the ice machine to the

drain/waste receptacle. Note: if using a long

horizontal run (more than 5') the drain should be

vented at back of cabinet.

7. Turn on the water supply and check for leaks.

8. Replace the kick plate and the access cover

above it.

9. Level the unit using the leg levelers.

Connection Detail

January 2002

Page 5

Water Filter

(Recommended)

Shut Off Valve

Water Inlet

INSTALLATION OF WATER AND DRAIN

Floor Drain

DCE33

TO INSTALL: Plumbing

Free Standing Cabinet, Pump Model:

1. Remove the kickptate and control box cover.

2. Route the water supply, which should be a 1/4"

O.D. copper tube through the back of the cabinet

to the front.

3. Install a flare nut and flare the end of the tube.

4. Flush the water line and fasten the flare nut to

the male flare on the inlet water valve.

5. Locate the coil of 3/8" ID plastic drain tubing

secured to the back of the cabinet.

6. Route the plastic drain tubing to the drain point

connection. Do not connect to a drain/waste line

below a trap. Connect the discharge line to the

drain, per local codes. An air gap will likely be

required between the ice machine drain tube and

the drain/waste receptacle.

7. Turn on the water and plug in the ice machine.

Pour a couple quarts of water in the bin, the drain

pump should start. Check for water leaks.

8. Replace the kickptate and control box cover.

9. Level the unit using the leg levelers.

ALL PLUMBING MUST MEET LOCAL CODES

THE DCE33 WILL FIT IN A SPACE

151/4"WIDE X 333/4" HIGH.

THE DEPTH OF THE CABINET IS 22" TO

THE FRONT EDGE OF THE HANDLE.

Drain

Connection

Water Sh ut

Off Valve

Water Filter

(Recommended)

Air Gap Device

(Where Required)

WATER AND DRAIN

INS TALLA TION

Drain Tube

From Back Of

Machine

Water Inlet Connection

June 2000

Page 6

TO INSTALL: Plumbing

Built In, Gravity Drain Model:

The drain and inlet water tubes must be plumbed

before connecting to the ice machine. All horizontal

runs of drain lines must have a 1/4" per foot fall. An

air gap will likely be required between the ice

machine drain tube and the drain/waste

receptacle. A stand pipe with a trap below it would

be acceptable for the drain/waste receptacle.

Note: Poor draining will cause a high rate of ice

melting in the bin,

1. Place ice machine in front of installed location.

Adjust leg levelers to approximately correct

position.

2. Remove kickptate and the access cover above it.

3. Route water inlet line, which should be a 1/4"

O.D. copper tube, from walt through ice machine to

the front.

4. Route drain line from wall position through ice

machine. Note: if using a tong horizontal run (more

than 5') the drain should be vented at back of

cabinet.

DCE33

6. Push ice machine into installed position.

7. Cut off water inlet line at required length.

8. Flush water line. Place flare nut on inlet water

line and flare the end of the copper tube.

9. Attach flare nut to the male flare on the inlet

water valve.

10. Cut off the drain tube to the required length.

11. Route a 5/8"drain tube through the back panel

of the machine and connect to the bin drain fitting

at the bottom of the bin. Secure with hose clamps.

Be certain that the drain tube is pushed up well

past the barbs on the drain fitting. If needed to

ease installation, soak the drain hose in hot water

just before connecting to the fitting.

12. Turn on the water supply and check for leaks.

13. Replace the kickptate and the access cover

above it. Level as needed.

ALL PLUMBING MUST MEET LOCAL CODES

5. If electrical outlet for ice machine is behind the

cabinet, plug in the ice machine now.

INSTALLATION OF WATER

AND DRAIN _

I

Drain

Connection

Water Filter

(Recommended)

Water inlet Connection

Detail

January 2002

Page 7

DCE33

TO INSTALL: Plumbing

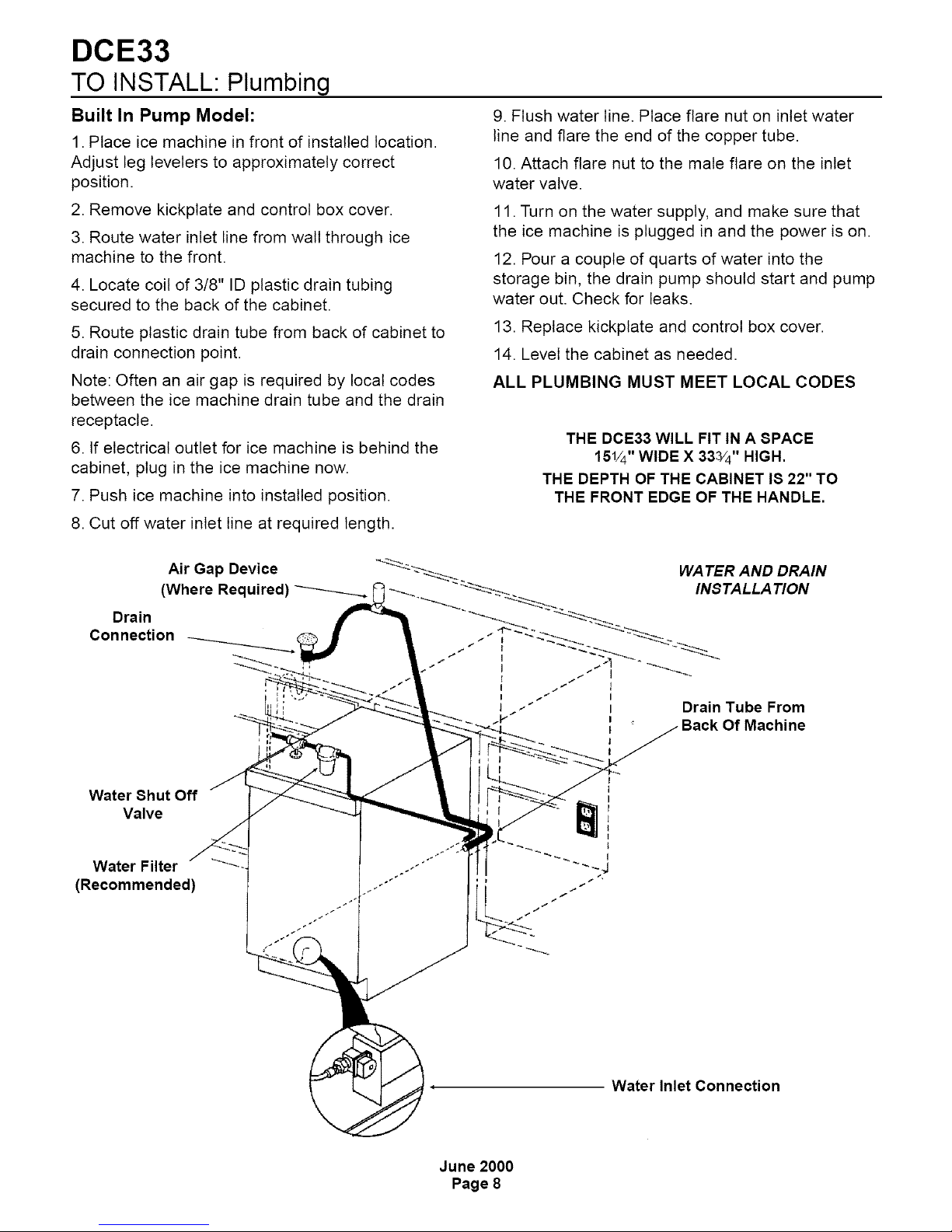

Built In Pump Model:

1. Place ice machine in front of installed location.

Adjust leg levelers to approximately correct

position.

2. Remove kickplate and control box cover.

3. Route water inlet line from walt through ice

machine to the front.

4. Locate coil of 3/8" ID plastic drain tubing

secured to the back of the cabinet.

5. Route plastic drain tube from back of cabinet to

drain connection point.

Note: Often an air gap is required by local codes

between the ice machine drain tube and the drain

receptacle.

6. If electrical outlet for ice machine is behind the

cabinet, plug in the ice machine now.

7. Push ice machine into installed position.

8. Cut off water inlet line at required length.

9. Flush water line. Place flare nut on inlet water

line and flare the end of the copper tube.

10. Attach flare nut to the male flare on the inlet

water valve.

11. Turn on the water supply, and make sure that

the ice machine is plugged in and the power is on.

12. Pour a couple of quarts of water into the

storage bin, the drain pump should start and pump

water out. Check for leaks.

13. Replace kickplate and control box cover.

14. Level the cabinet as needed.

ALL PLUMBING MUST MEET LOCAL CODES

THE DCE33 WILL FIT IN A SPACE

151/4"WIDE X 333/4" HIGH.

THE DEPTH OF THE CABINET 18 22" TO

THE FRONT EDGE OF THE HANDLE.

Air Gap Device

(Where Required)

Drain

Con nection

Water Shut Off

Valve

Water Filter

(Recommended)

WATER AND DRAIN

INS TALLA TION

I /_" l

I / _ I

l i" I Drain Tube From

t . Back Of Machine

I

I

I

I

r

I

t

I

Water Inlet Connection

June 2000

Page 8

Loading...

Loading...