SCHOTT FIBER OPTICS User Manual

FIBER OPTICS INDUSTRIAL E

Industrial fiber optic components

and LED solutions

Lighting, Sensing, Imaging

Content

2–3|Introduction

4–5|Physical principles and properties of optical fibers

6–13 | Manufacturing/Design of light guides

14–15 | Physical principles of LEDs

16–17 | Manufacturing/Design of image guides

18–23 | Applications

Creative new solutions

Generations of know-how as clear as glass

For more than 40 years, SCHOTT has

developed fiber optic products for a

diverse range of applications. Our name

stands for high quality and innovative

solutions in the field of fiber optic light-

ing, sensing and imaging.

The Fiber Optics Business Segment offers high-tech solutions in markets such

as automotive, lighting, medical, industrial and defense.

By mastering glass, fibers and processes for the production of fiber optic

components, we develop outstanding, market-oriented products. With our

leading technological know-how and innovative ideas we contribute to the

success of our customers – around the world, around the clock.

We work in partnership with you to develop new products:

New fiber optic compontents for widely

differing industrial applications are the

outcome of very close cooperation with

our customers. Customer ideas gener-

ated from knowledge of their product

and their industry coupled with

SCHOTT’s fiber optic know-how result

in new products with clear benefits to

the market.

We will continue to carry out further research and development in the future

to continuously improve our products. We can be your single source fiber

optic specialist to support development stages from basic research and proto-

typing to mass production with competent quality, creativity and support.

The earlier we are involved in your project, the more effectively we can help

to develop optimum solutions for your special requirement.

We are continuously striving to develop new technologies: latest develop-

ments include LEDs (Light Emitting Diodes) for illumination components.

32

A highway for light

The physical principles and properties of optical fibers

Optical fibers are the heart of all fiber optic components. Every optical fiber

consists of a core with a high refractive index and a cladding with a low refrac-

tive index. Light rays which enter the fiber at one end are guided along the

core by total internal reflection at the core/cladding interface. The light rays

follow the bends in the fiber and exit the fiber at its other end.

Spectral fiber transmission

Transmission of fiber bundles

The three most important characteristics

Cladding

of an individual fiber are its:

■

Diameter

■

Numerical Aperture

■

Spectral transmission

The principle of light transmission in an optical fiber

Core

Diameter

To ensure total internal reflection, the fiber cladding must have a minimum

thickness of 2 µm for the visible range of the spectrum. An improvement in the

optical efficiency can be achieved by increasing the diameter of the fiber with-

out increasing the thickness of the cladding. This, however, results in a loss of

mechanical flexibility. For the majority of applications an optimum relationship

between transmission and flexibility is achieved with a fiber diameter between

50 and 70 µm.

Cladding

Core

Fiber Ø 70 µm Hair Ø 200 µm

As light is transmitted through a fiber its intensity decreases. The relationship

between the input intensity and the output intensity defines the spectral

transmission T (λ). The spectral transmission depends on three factors:

■

Absorption losses in core glasses. These losses are mainly caused by un-

avoidable traces of coloring metal oxides. Rayleigh light scattering results

from a natural density fluctuation in the glass melt. These losses are pro-

portional to the length of the light guide.

■

Losses resulting from less than ideal total reflection at the core/cladding

interface depend greatly on the angle at which the light enters the fiber,

also impacting the total number of reflections accumulated over the whole

length of the fiber. The greater the number of reflections, the higher the

loss.

■

Fresnel reflection losses – at the input and output surface – amount to

approximately 11% combined.

In addition to the transmission of each

individual fiber, the transmission of fiber

bundles is influenced by another factor.

As a result of round fibers being bun-

dled together, interstitial gaps exist

between the fibers. These gaps – usually

filled with epoxy material – do not

transmit light as well as the glass

cladding.

The total amount of light which can be

transmitted through a single fiber is the

result of length dependent transmission,

numerical aperture and active fiber core

area. The spectral transmission of a

bundled fibers is essentially determined

by the type and quality of glass used for

the core and cladding, its absorption

properties, the packing density of the

fiber bundle and the quality of the end

terminations.

Numerical Aperture

The numerical aperture of an optical fiber depends on the refractive indices of

the two types of glass used for the core and the cladding.

2

The equation: NA = n

· sin α0= √ n

0

the optical axis of a fiber. For simplicity it can be used for a light guide where:

= Refractive index of the surrounding medium

n

0

= Refractive index of the fiber core

n

1

= Refractive index of the fiber cladding

n

2

= Critical angle to the optical axis.

α

0

4

2

- n

applies to light rays which intersect

1

2

All light rays which strike the perpendic-

ular polished end face of the light guide

at an angle of α ≤ α

are transmitted

0

along the fiber. This results in the fact,

that the amount of light which can be

transmitted through a fiber is propor-

2

tional to the NA

.

SCHOTT’s competencies …

Manufacturing/Design of light guides

From single fibers to light guides

Bundles of optical fibers are combined with appropriate end terminations and

protective sheathing to form light guides and image guides. Combining well-

proven

incorporates such fiber bundles into a multitude of engineered components

by modifying their properties to suit the particular application.

materials with in-house developed technologies SCHOTT

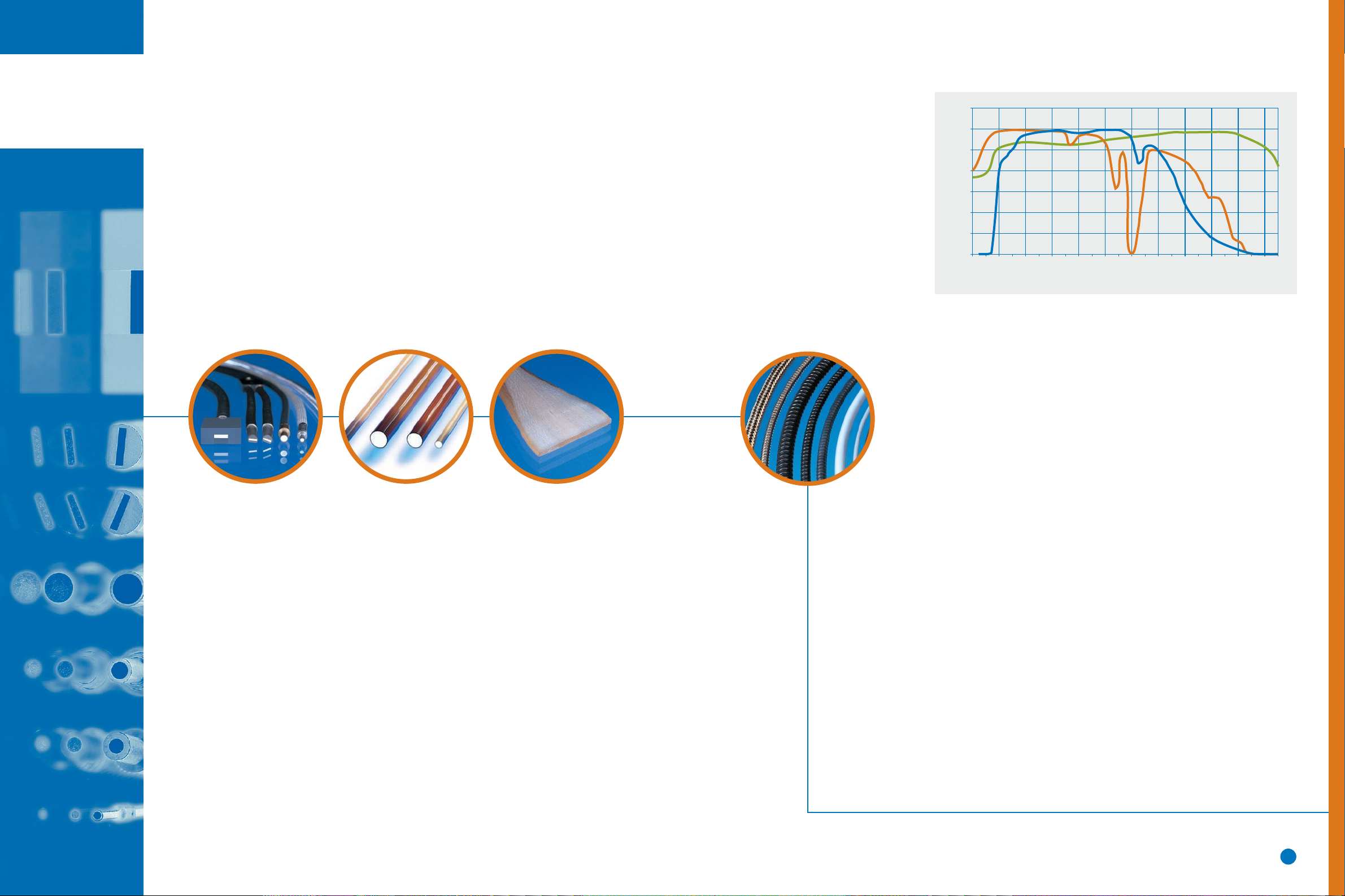

Fiber types

The selected fiber type is dependent on

the demands of the application.

flexible fibers as well as rigid fiber optic

rods cover a variety of diameters and

optical characteristics like Numerical

Aperture and Transmission. Fiber types

for the visible and UV spectral range,

plus several types to accommodate near

IR enable manufacturing of fiber optic

components best suited for a variety of

different applications. For further details

please refer to the actual datasheets.

SCHOTT

70

60

50

40

30

Transmission (%)

20

10

0

200 400 600 800 1000 1200 1400 1600 1800 2000 2200 2400

■ UV fiber ■ IR fiber ■ VIS fiber

Spectral Transmission – Different fiber types (fiber Ø 70 µm, length 1000 mm) – Typical values

Wavelength (nm)

Mechanical Protection

Materials

Flexible or rigid? The first step in designing a fiber optic light guide is the

decision if it needs to be flexible or rigid. Rigid fiber optic rods also referred to

as light conducting rods are solid fiber optic elements which can be used to

transmit light, image or signals over short distances whenever flexibility is not

required. Their advantages over flexible light guides are:

■

No packing losses in interstitial gaps and therefore higher transmission

■

Excellent temperature resistance because epoxied end ferrules and

protective sheathings are not required

■

Vacuum or pressure seals are possible

In addition,

conical light guides for reducing or increasing the effective optical cross-

section and aperture angle (“Light magnification”). Please contact your local

sales person for further details.

SCHOTT can also manufacture fiber optic cones respective

Sheathing

Clearly

fiber bundles; sheathing is an integral structural component used to meet

specific applications.

If, and for how long, a light guide operates reliably depends to a large extent

on the protective sheathing used.

sheathing, so that fiber bundles can be protected in various mechanical,

physical and chemical environments.

A standard range of protective sheathing to suit particular applications is

available (i.e. metal, polymer, compound). Details see separate datasheet.

Ferrules

End ferrules for bonded/epoxied light guides are made out of aluminum,

brass, stainless steel, nickel silver or other materials. For end ferrules in hot

fused components stainless steel is used.

Housings

If requested we can manufacture housings to your specifications. Typical

housing materials are: nickel, silver aluminum, stainless steel and various

plastics.

SCHOTT believes that sheathing is more than simply packaging for

SCHOTT offers many different types of

7

Loading...

Loading...