Scholtes SDLE 129 EU, SDLE 129 MV User Manual

Instructions for use

WASHER DRYER

GB

English,1

I

Italiano,43

SDLE 129

! This symbol reminds you to read this instruction manual.

Español,29Français,15

ES

Contents

F

GB

Installation, 2-3-4-5

Unpacking and levelling

Connecting the electricity and water supplies

The first wash cycle

Technical data

Instructions for the fitter

Care and maintenance, 6

Cutting off the water or electricity supply

Cleaning the washer dryer

Cleaning the detergent dispenser drawer

Caring for the door and drum of your appliance

Cleaning the pump

Checking the water inlet hose

Precautions and tips, 7

General safety

Disposal

Opening the porthole door manually

Description of the washer dryer, 8-9

Control panel

Display

How to run a wash cycle or a drying cycle, 10

Wash cycles and functions, 11

Table of wash cycles

Wash functions

Detergents and laundry, 12

Detergent dispenser drawer

Preparing the laundry

Special wash cycles

Load balancing system

Troubleshooting, 13

Service, 14

1

Installation

GB

! This instruction manual should be kept in a safe

place for future reference. If the washer dryer is

sold, transferred or moved, make sure that the

instruction manual remains with the machine so

that the new owner is able to familiarise himself/

herself with its operation and features.

! Read these instructions carefully: they contain

vital information relating to the safe installation

and operation of the appliance.

Unpacking and levelling

Unpacking

1. Remove the washer dryer from its packaging.

2. Make sure that the washer dryer has not been

damaged during the transportation process. If it

has been damaged, contact the retailer and do not

proceed any further with the installation process.

3. Remove the 4 protective screws (used

during transportation)

and the rubber washer

with the corresponding

spacer, located on the

rear part of the appliance (see figure).

4. Close off the holes using the plastic plugs

provided.

5. Keep all the parts in a safe place: you will

need them again if the washer dryer needs to

be moved to another location.

! Packaging materials should not be used as

toys for children.

Levelling

Levelling the machine correctly will provide it with

stability, help to avoid vibrations and excessive

noise and prevent it from shifting while it is operating. If it is placed on carpet or a rug, adjust

the feet in such a way as to allow a sufficient

ventilation space underneath the washer dryer.

Connecting the electricity and water supplies

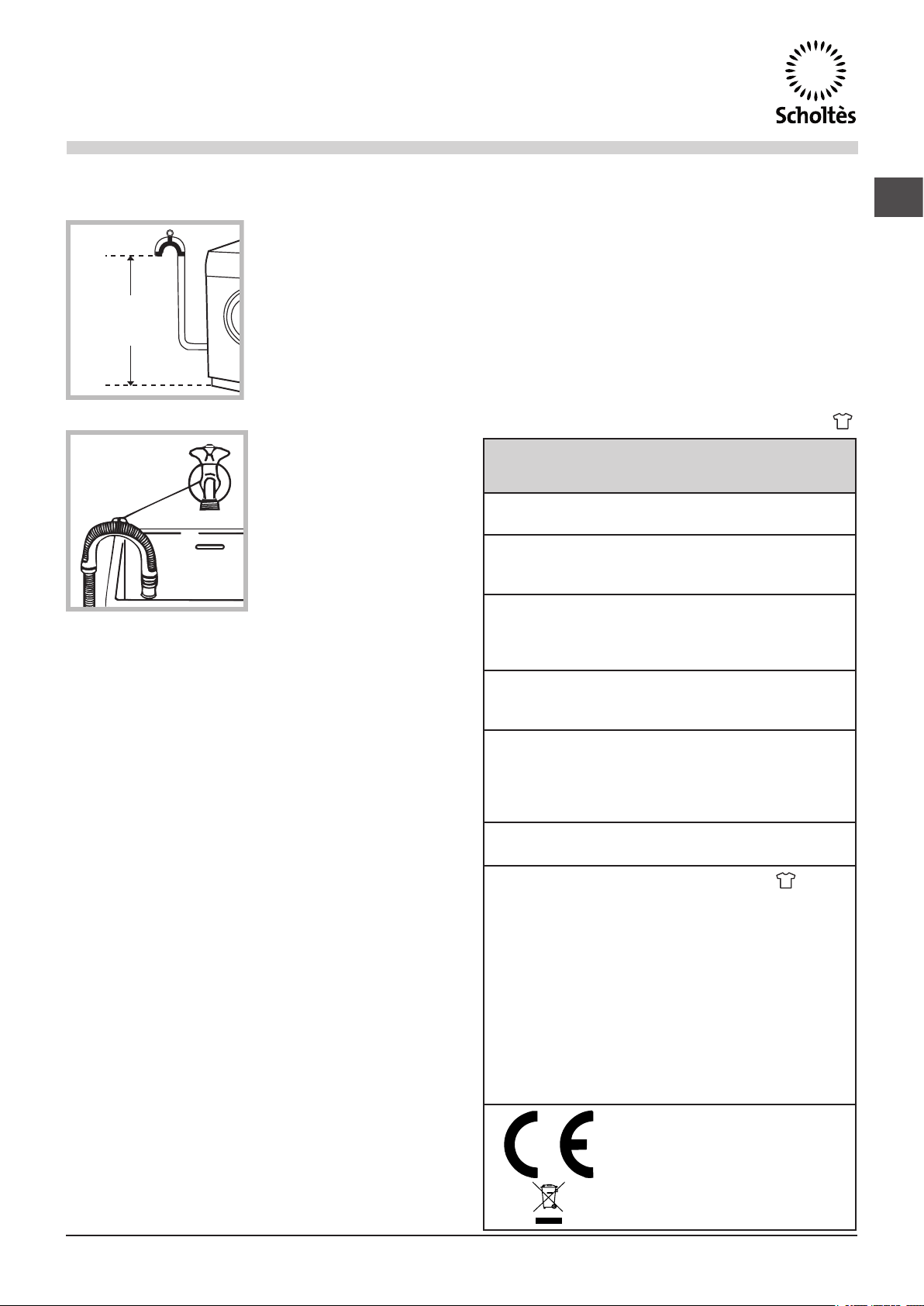

Connecting the water inlet hose

1. Connect the supply

pipe by screwing it to

a cold water tab using

a ¾ gas threaded connection (see figure).

Before performing the

connection, allow the

water to run freely until

it is perfectly clear.

2. Connect the inlet

hose to the washer dryer by screwing it onto

the corresponding water inlet of the appliance, which is situated on

the top right-hand side

of the rear part of the

appliance (see figure).

3. Make sure that the hose is not folded over

or bent.

! The water pressure at the tap must fall within

the values indicated in the Technical details table

(see next page).

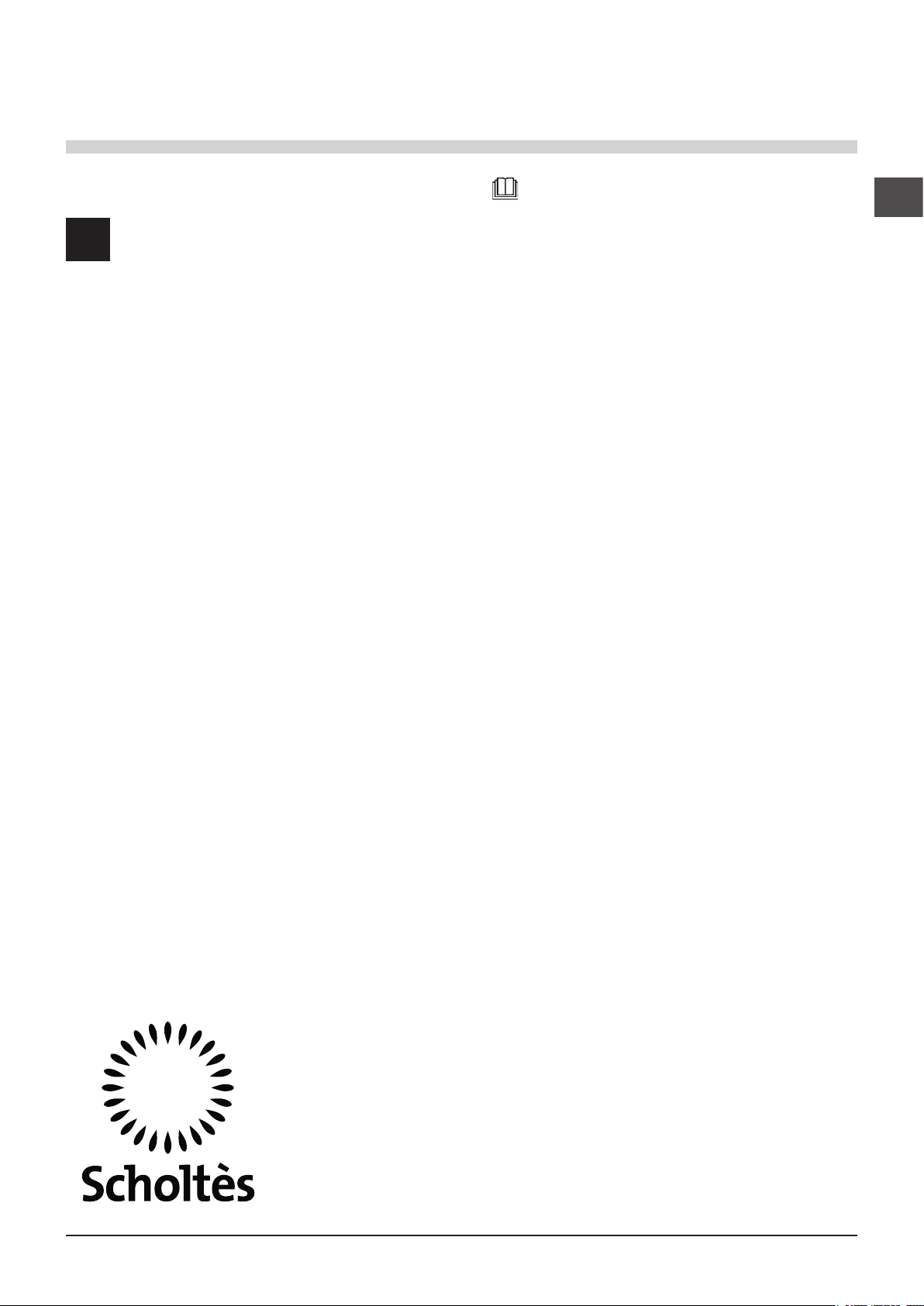

1. Install the washer dryer on a flat sturdy floor,

without resting it up against walls, furniture cabinets or anything else.

2. If the floor is not perfectly level, compensate for any unevenness

by tightening or loosening the adjustable

front feet (see figure);

the angle of inclination,

measured in relation to

the worktop, must not

exceed 2°.

2

! If the inlet hose is not long enough, contact a

specialised shop or an authorised technician.

! Never use second-hand hoses.

! Use the ones supplied with the machine.

65 - 100 cm

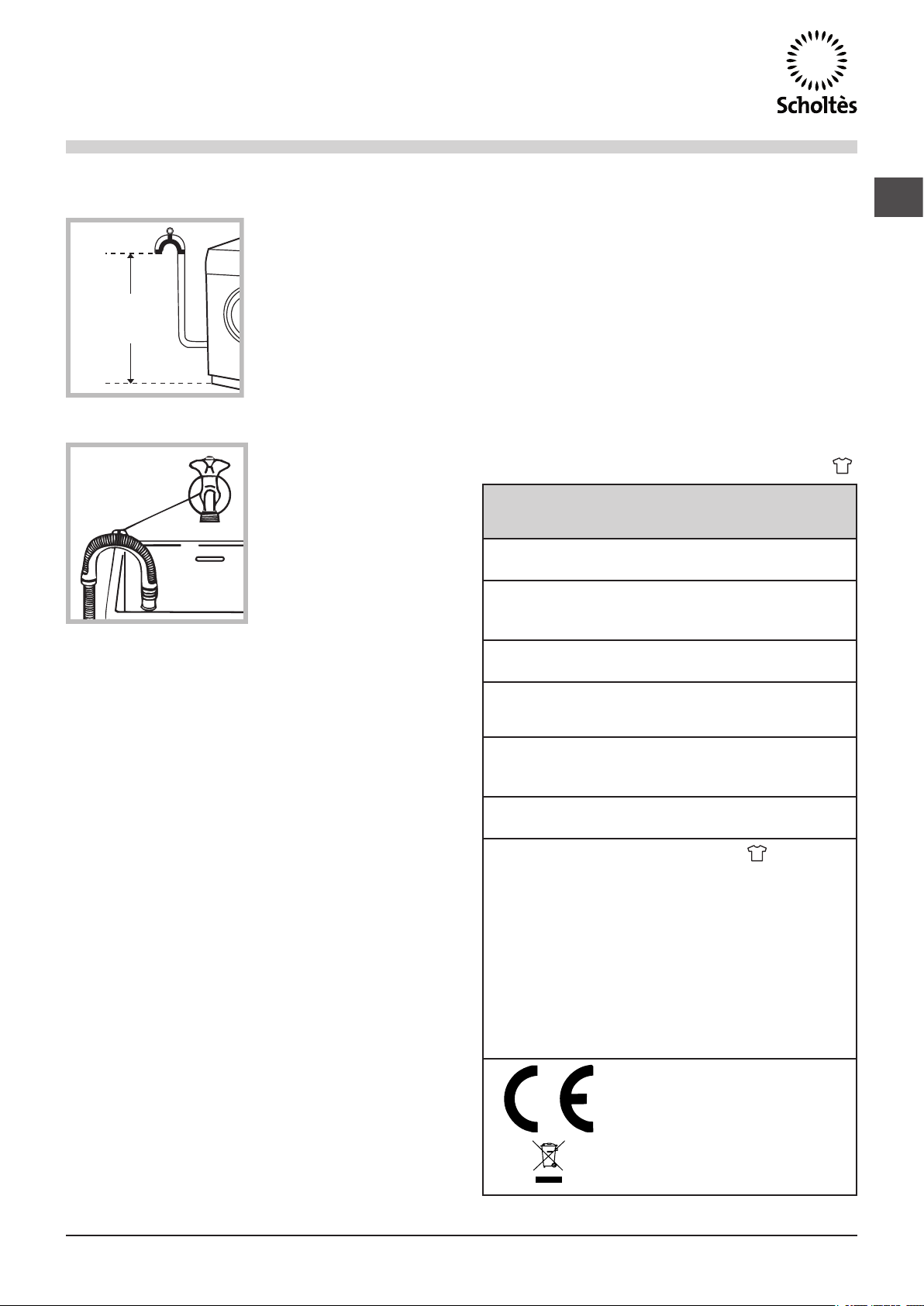

Connecting the drain hose

- 2004/108/EC (Electromagne-

Con nec t t h e d r ai n

hose, without bending

it, to a drainage duct or

a wall drain located at a

height between 65 and

100 cm from the floor;

alternatively, rest it on

the side of a washbasin or bathtub, fastening the duct supplied

to the tap (see figure).

The free end of the

hose should not be

underwater.

! We advise against the use of hose extensions;

if it is absolutely necessary, the extension must

have the same diameter as the original hose and

must not exceed 150 cm in length.

Electrical connections

Before plugging the appliance into the electricity

socket, make sure that:

• the socket is earthed and complies with all

applicable laws;

! Do not use extension cords or multiple sockets.

! The cable should not be bent or compressed.

! The power supply cable must only be replaced

by authorised technicians.

Warning! The company shall not be held responsible

in the event that these regulations are not respected.

The first wash cycle

Once the appliance has been installed, and before

you use it for the first time, run a wash cycle with

detergent and no laundry, using the wash cycle .

Technical data

Model

Dimensions

Capacity

Electrical

connections

Water connections

Spin speed

SDLE 129

width 59,5 cm

height 81,5 cm

depth 54,5 cm

from 1 to 7 kg for the wash

programme

from 1 to 5 kg for the drying

programme

please refer to the technical

data plate fixed to the machine

maximum pressure 1 MPa

(10 bar)

minimum pressure 0.05

MPa (0.5 bar)

drum capacity 52 litres

up to 1200 rotations per

minute

GB

• the socket is able to withstand the maximum

power load of the appliance as indicated in the

Technical data table (see opposite);

• the power supply voltage falls within the values

indicated in the Technical data table (see opposite);

• the socket is compatible with the plug of the

washer dryer. If this is not the case, replace the

socket or the plug.

! The washer dryer must not be installed outdoors, even in covered areas. It is extremely

dangerous to leave the appliance exposed to

rain, storms and other weather conditions.

! When the washer dryer has been installed, the

electricity socket must be within easy reach.

Energy rated

programmes

according to

regulation

EN 50229

Wash: programme

;

temperature 60°C (1st press

of the button); using a load of

7 kg.

Drying: the smaller load

must be dried by selecting

the “IRON DRY” dryness level. The load must consist of

2 sheets, 1 pillowcase and 1

hand towel;

the remainder of the load

must be dried by selecting

the “CUPBOARD DRY” dryness level.

This appliance conforms to

the following EC Directives:

tic Compatibility)

- 2006/95/EC (Low Voltage)

- 2002/96/EC

3

GB

Tur seite

Instructions for the fitter

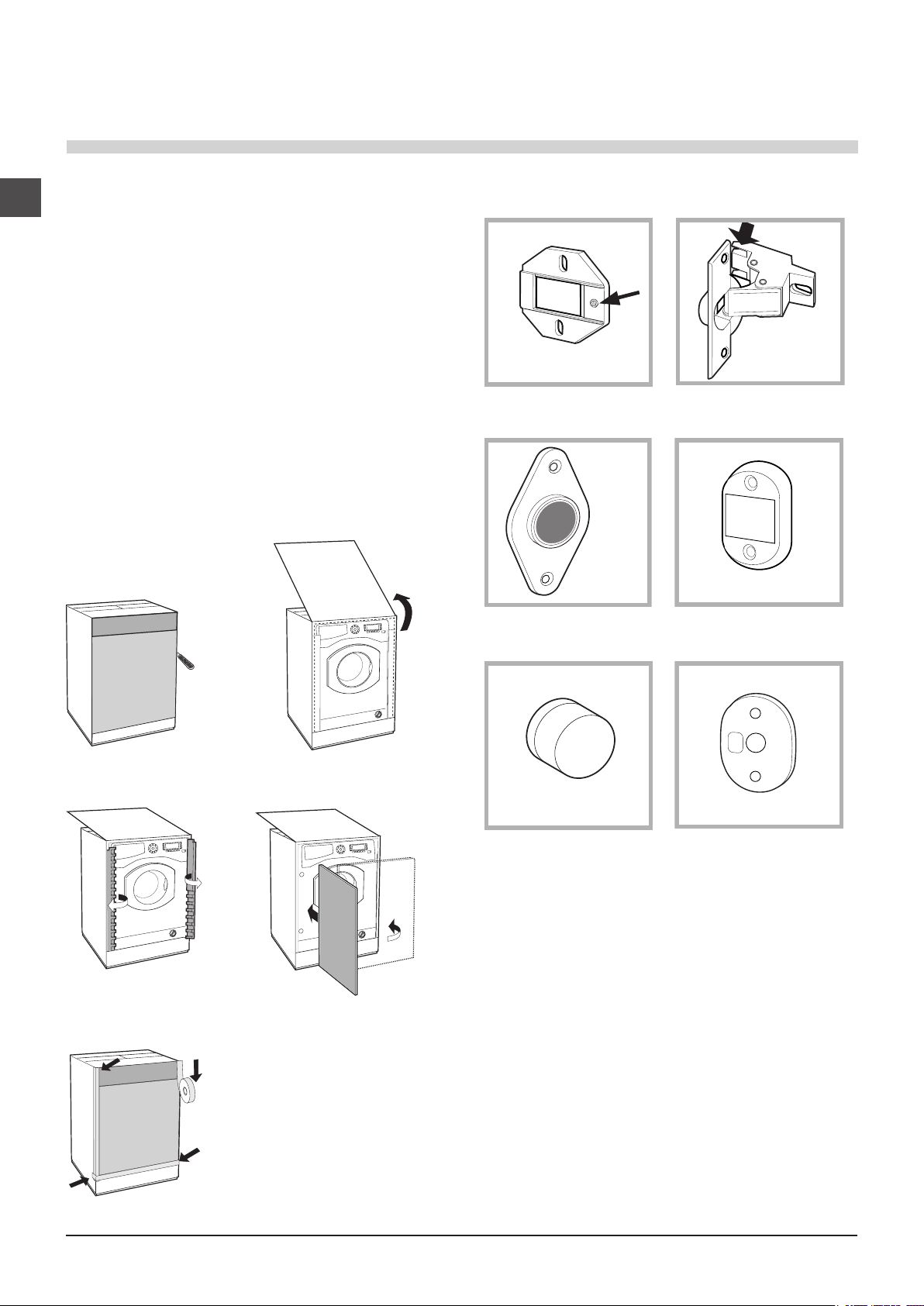

Mounting the wooden panel onto the door

and inserting the machine into cabinets:

In the case where the machine must be shipped

for final installation after the wooden panel has

been mounted, we suggest leaving it in its original packaging. The packaging was designed

to make it possible to mount the wooden panel

onto the machine without removing it completely

(see figures below).

The wooden panel that covers the face of

the machine must not be less than 18 mm in

thickness and can be hinged on either the right

or left. For the sake of practicality when using

the machine, we recommend that the panel be

hinged on the same side as the door for the

machine itself - the left.

Door Mounting Accessories (Fig. 1-2-3-4-5).

N° 2 Hinge Supports

Fig. 1

N° 1 Magnet N° 1 Magnet plate

Fig. 3 Fig. 4

Fig. 2

N° 2 Hinges

A

C

E

B

D

N° 1 Rubber plug

Fig. 5

Fig. 4/B

N° 4 Spacers

- No. 6 type A self-threading screws, l =13 mm.

- No. 2 type B metric, countersunk screws, l =25;

for fastening the magnet plate to the cabinet.

- No. 4 type C metric screws, l =15 mm; for

mounting the hinge supports to the cabinet.

- No. 4 type D metric screws, l =7 mm; for

mounting the hinges on the supports.

Mounting the Parts onto the Face of the

Machine.

- Fit the hinge supports to the appliance front

panel, positioning the hole marked with an arrow

in fig. 1 so that it is on the inner side of the front

panel. Fit a spacer (fig. 4/B) between the surfa-

ces using type C screws.

- Fit the magnet plate at the top of the opposite

side, using type B screws to fix two spacers (fig.

4/B) between the plate and the surface.

4

Using the Drilling Template.

570

min

815

540

595

820 ÷ 900

600 min

L

I

H

G

- To trace the positions of the holes on the lefthand side of the panel, align the drilling template

to the top left side of the panel using the lines

traced on the extremities as a reference.

- To trace the positions of the holes on the righthand side of the panel, align the drilling template

to the top right side of the panel.

- Use an appropriately sized router to mill the holes

for the two hinges, the rubber plug and the magnet.

Mounding the Parts onto the Wooden Panel

(Door).

- Insert the hinges into the holes (the movable part of

the hinge must be positioned facing away from the

panel) and fasten them with the 4 type A screws.

- Insert the magnet into the top hole on the opposite side of the hinges and fasten it with the

two type B screws.

- Insert the rubber plug into the bottom hole.

The panel is now ready to be mounted onto the

machine.

Mounting the Panel into the machine.

Insert the nib of the hinge (indicated by the arrow

in fig. 2) into the hole for the hinge and push the

panel towards the front of the machine. Fasten

the two hinges with the type D screws.

Fastening the plinth guide.

If the machine is installed at the end of a set of

modular cabinets, mount either one or both of

the guides for the base molding (as shown in fig.

8). Adjust them for depth based on the position

of the base molding, and, if necessary, fasten

the base to the guides (fig. 9).

This is how to assemble the plinth guide (fig. 8):

Fasten angle P using screw R, insert plinth guide

Q into the special slot and once it is in the desired

position, lock it in place using angle P and screw R.

Inserting the machine into the Cabinet.

- Push the machine into the opening, aligning it

with the cabinets (fig. 6).

- Regulate the adjustable feet to raise the machine to the appropriate height.

- To adjust the position of the wooden panel in

both the vertical and horizontal directions, use

the C and D screws, as shown in fig. 7.

Important: close the lower part of the appliance

front by ensuring that the plinth rests against the floor.

C

GB

Fig. 8 Fig. 9

Accessories provided for the height

adjustment.

The following can be found inside the polystyrene

lid (fig. 10): 2 crossbars (G), 1 strip (M)

the following can be found

inside the appliance drum:

4 additional feet (H),

4 screws (I),

4 screws (R),

4 nuts (L),

2 plinth guides (Q)

Fig. 10

Adjusting the appliance height.

The height of the appliance can be adjusted (from

815 mm to 835 mm), by turning the 4 feet.

Should you require the appliance to be placed

higher than the above height, you need to use the

following accessories to raise it to up to 870 mm:

The two crossbars (G); the 4 feet (H); the 4 screws (I); the

4 nuts (L) then perform the following operations (fig. 11):

remove the 4 original feet, place a crossbar G at

the front of the appliance, fastening it in place

using screws I (screwing them in where the original feet were) then insert the new feet H.

Repeat the same operation at the back of the appliance.

Now adjust feet H to raise or lower the appliance

from 835 mm to 870 mm.

Once you have reached the desired height, lock

nuts L onto crossbar G.

To adjust the appliance to a height between 870

mm and 900 mm, you need to mount strip M,

adjusting feet H to the required height.

Insert the strip as follows:

loosen the three screws N situated at the front of

the Top cover of the appliance, insert strip M as

shown in fig. 12, then fasten screws N.

M

D

Fig. 6 Fig. 7

C

Fig. 11 Fig. 12

5

Care and maintenance

1

2

GB

Cutting off the water and electricity supplies

• Turn off the water tap after every wash cycle.

This will limit wear on the hydraulic system

inside the washer dryer and help to prevent

leaks.

• Unplug the washer dryer when cleaning it

and during all maintenance work.

Cleaning the washer dryer

The outer parts and rubber components of the

appliance can be cleaned using a soft cloth

soaked in lukewarm soapy water. Do not use

solvents or abrasives.

Cleaning the detergent dispenser

drawer

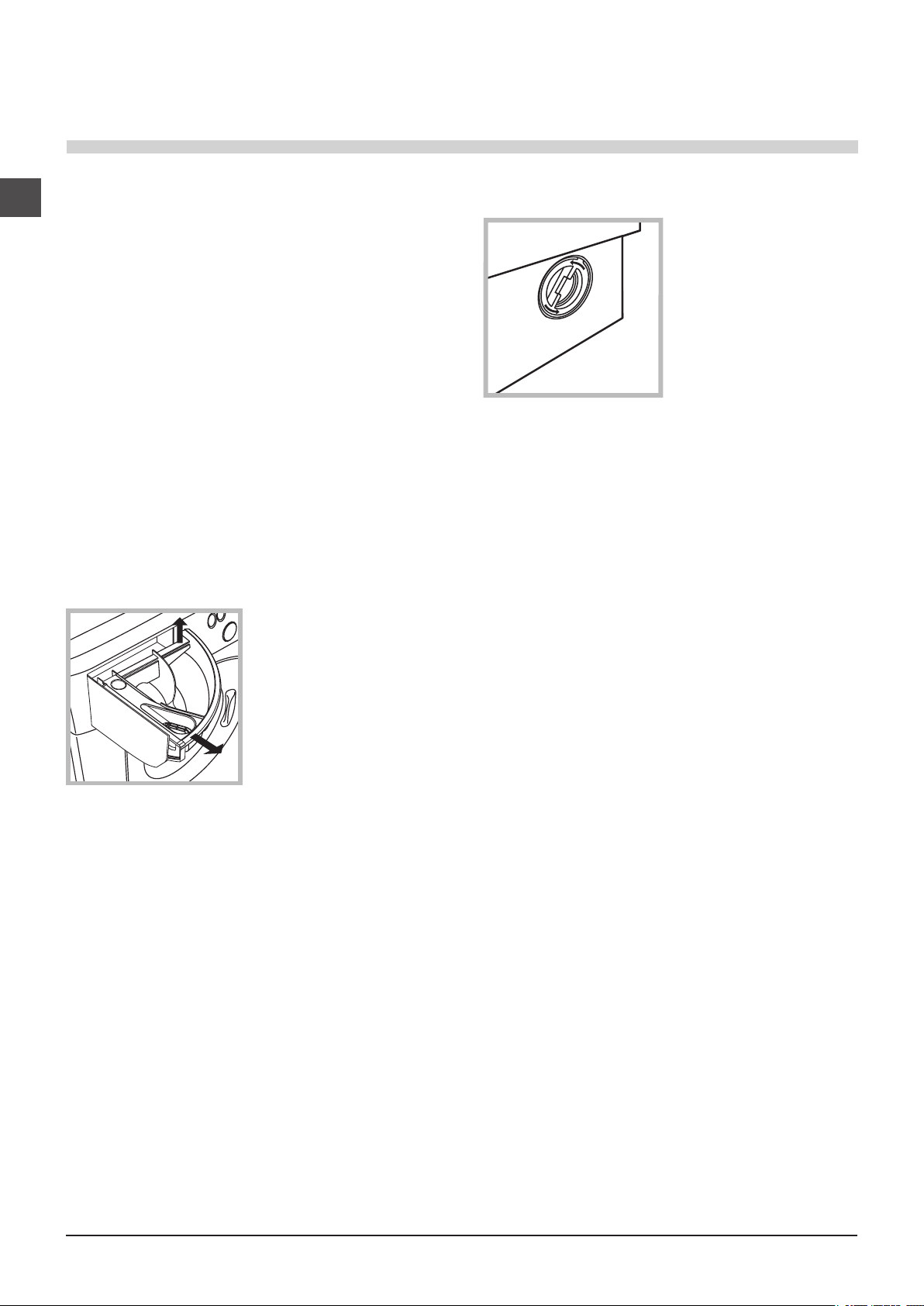

Remove the dispenser

by raising it and pulling it out (see figure).

Wash it under running

water; this operation

should be repeated

frequently.

To access the pre-chamber:

1. unscrew the lid

by rotating it anticlockwise (see figu-

re): a little water may

trickle out. This is

perfectly normal;

2. clean the inside thoroughly;

3. screw the lid back on;

Checking the water inlet hose

Check the inlet hose at least once a year. If

there are any cracks, it should be replaced

immediately: during the wash cycles, water

pressure is very strong and a cracked hose

could easily split open.

! Never use second-hand hoses.

Caring for the door and drum of

your appliance

• Always leave the porthole door ajar in order

to prevent unpleasant odours from forming.

Cleaning the pump

The washer dryer is fitted with a self-cleaning

pump which does not require any maintenance. Sometimes, small items (such as coins or

buttons) may fall into the pre-chamber which

protects the pump, situated in its bottom part.

! Make sure the wash cycle has finished and

unplug the appliance.

6

Precautions and tips

! This washer dryer was designed and constructed in ac-

cordance with international safety regulations. The following

information is provided for safety reasons and must therefore

be read carefully.

General safety

• This appliance was designed for domestic use only.

• This appliance can be used by children aged

from 8 years and above and persons with reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

- Do not dry unwashed items in the tumble dryer.

- Items that have been soiled with substances such as cooking

oil, acetone, alcohol, petrol, kerosene, spot removers, turpentine,

waxes and wax removers should be washed in hot water with

an extra amount of detergent before being dried in the tumble

dryer.

- Items such as foam rubber (latex foam), shower caps, waterproof textiles, rubber backed articles and clothes or pillows fitted

with foam rubber pads should not be dried in the tumble dryer.

- Fabric softeners, or similar products, should be used as specified by the fabric softener instructions.

- The final part of a tumble dryer cycle occurs without heat

(cool down cycle) to ensure that the items are left at a temperature that ensures that the items will not be damaged.

WARNING: Never stop a tumble dryer before the end of the

drying cycle unless all items are quickly removed and spread

out so that the heat is dissipated.

• Do not touch the machine when barefoot or with wet or

damp hands or feet.

• Do not pull on the power supply cable when unplugging

the appliance from the electricity socket. Hold the plug and

pull.

• Do not open the detergent dispenser drawer while the

machine is in operation.

• Do not touch the drained water as it may reach extremely

high temperatures.

• Never force the porthole door. This could damage the safety

lock mechanism designed to prevent accidental opening.

• If the appliance breaks down, do not under any circumstances access the internal mechanisms in an attempt to

repair it yourself.

• Always keep children well away from the appliance while

it is operating.

• The door can become quite hot during the wash cycle.

• If the appliance has to be moved, work in a group of two

or three people and handle it with the utmost care. Never

try to do this alone, because the appliance is very heavy.

• Before loading laundry into the washer dryer, make sure

the drum is empty.

• During the drying phase, the door tends to get quite hot.

• Do not use the appliance to dry clothes that have been

washed with flammable solvents (e.g. trichlorethylene).

• Do not use the appliance to dry foam rubber or similar

elastomers.

• Make sure that the water tap is turned on during the drying

cycles.

Disposal

• Disposing of the packaging materials: observe local regu-

lations so that the packaging may be re-used.

• The European Directive 2002/96/EC on Waste Electrical

and Electronic Equipment, requires that old household electrical appliances must not be disposed of in the normal unsorted

municipal waste stream. Old appliances must be collected

separately in order to optimise the recovery and recycling of

the materials they contain and reduce the impact on human

health and the environment. The crossed out “wheeled bin”

symbol on the product reminds you of your obligation, that

when you dispose of the appliance it must be separately

collected. Consumers should contact their local authority or

retailer for information concerning the correct disposal of their

old appliance.

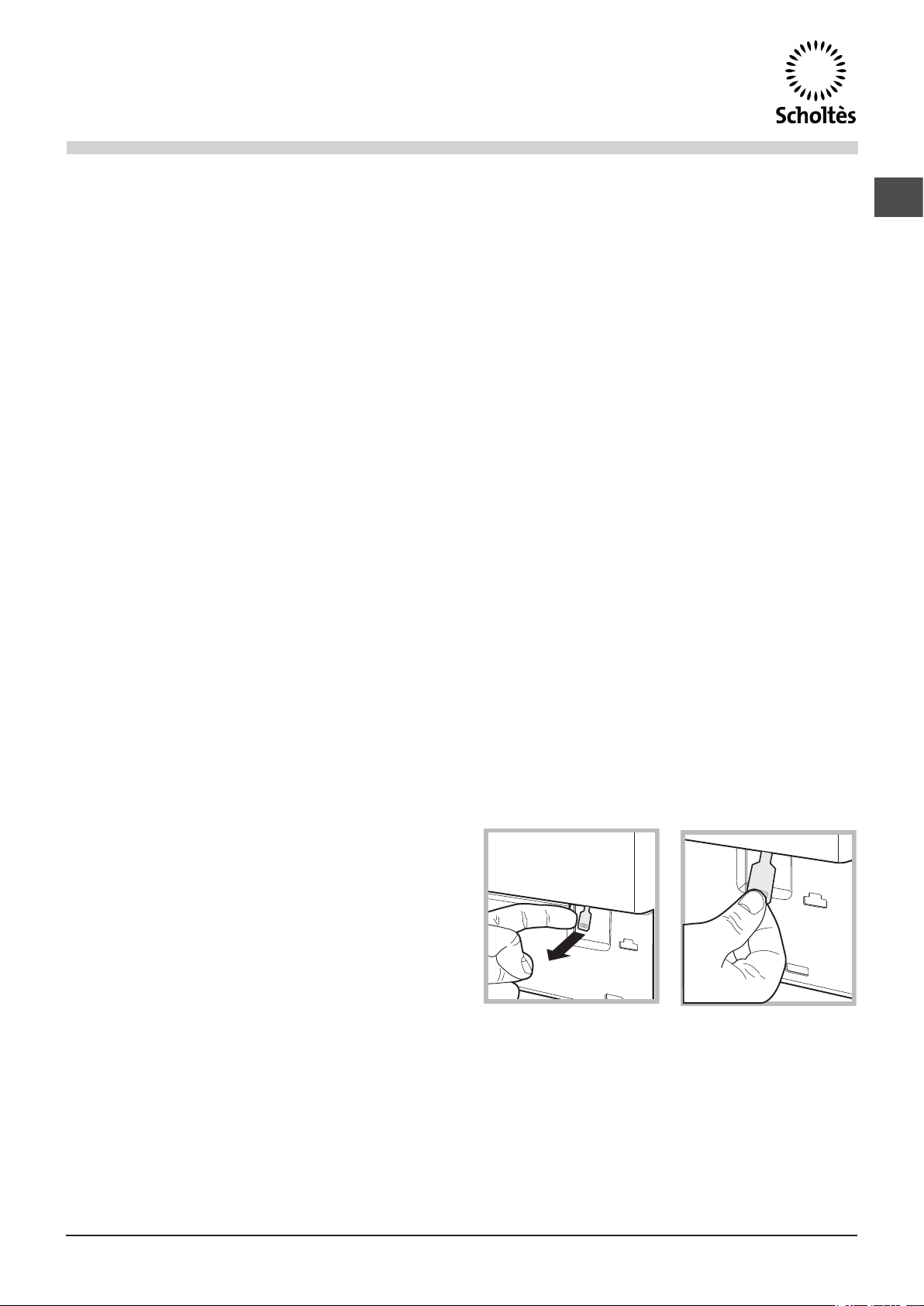

Opening the porthole door manually

In the event that it is not possible to open the porthole door

due to a powercut, and if you wish to remove the laundry,

proceed as follows:

1. remove the plug from the electrical socket.

2. make sure the water level inside the machine is lower than

the door opening; if it is not, remove excess water using the

drain hose, collecting it in a bucket.

3. pull outwards using the tab as indicated in the figure, until

the plastic tie-rod is freed from its stop position; pull downwards and open the door at the same time.

GB

7

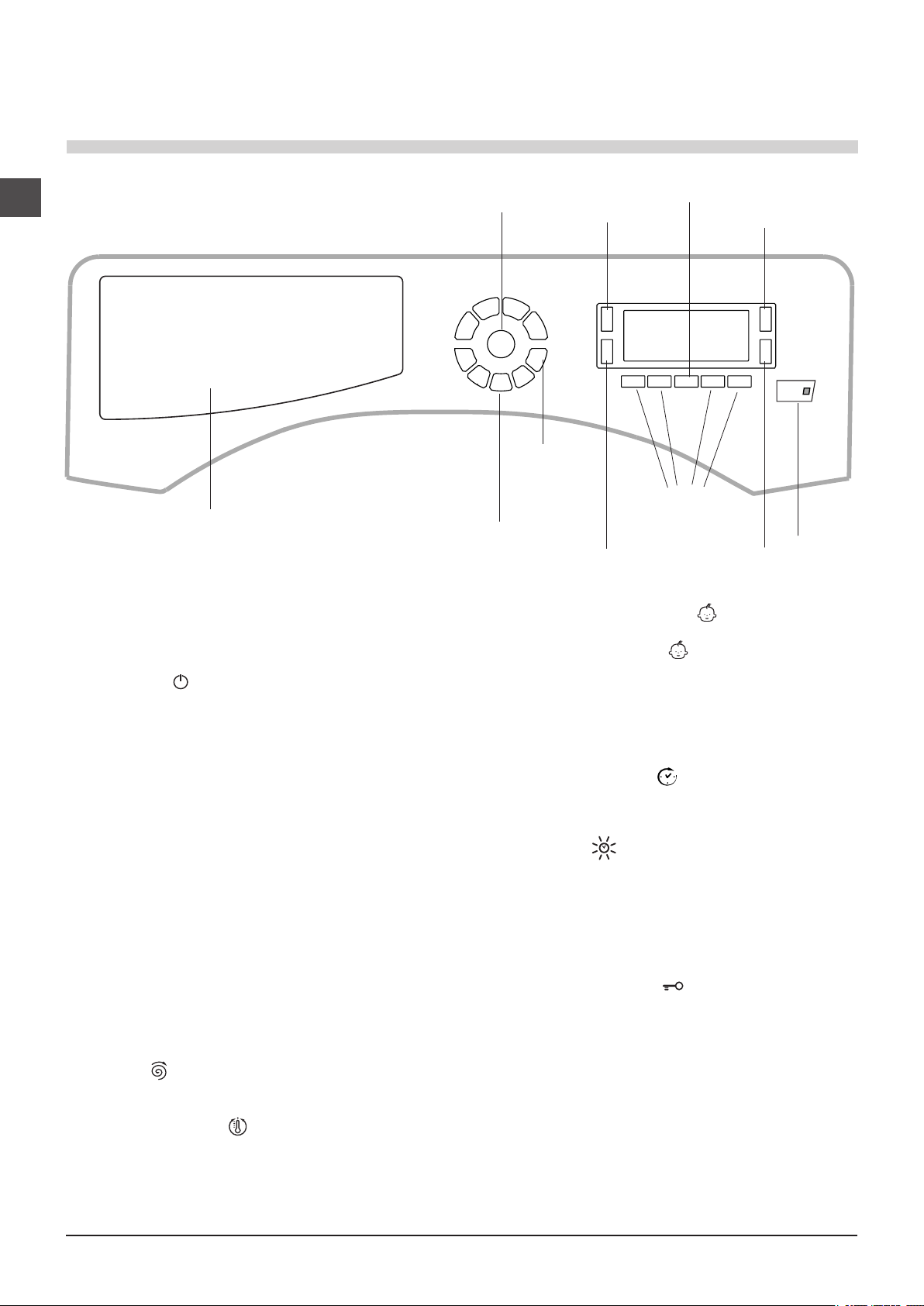

Description of the washer dryer

GB

Control panel

SELECTOR

Detergent dispenser drawer

Detergent dispenser drawer: used to dispense

detergents and washing additives (see “Detergents and

laundry”).

ON/OFF button : press this briefly to switch the machine on or off. The START/PAUSE indicator light, which

flashes slowly in a green colour shows that the machine

is switched on. To switch off the washer dryer during the

wash cycle, press and hold the button for approximately 2

seconds; if the button is pressed briefly or accidentally the

machine will not switch off. If the machine is switched off

during a wash cycle, this wash cycle will be cancelled.

CONTROL PANEL

LOCK button

ON/OFF

button

MEMORY

WASH

CYCLE

Buttons

Button

DELAYED

START

Button

CONTROL PANEL LOCK button : to activate the control

panel lock, press and hold the button for approximately 2

seconds. When the symbol is illuminated, the control

panel is locked (apart from the ON/OFF key). This means

it is possible to prevent wash cycles from being modified

accidentally, especially where there are children in the home.

To deactivate the control panel lock, press and hold the

button for approximately 2 seconds.

DELAYED START button : press to set a delayed start

time for the selected wash cycle. The delay time will be

shown on the display.

DRYING

Button

DISPLAY

FUNCTION

buttons

TEMPERATURE

Button

SPIN SPEED

Button

START/PAUSE

button with indicator

light

WASH CYCLE SELECTOR buttons: used to set the

desired wash cycle (see “Table of wash cycles”).

MEMORY button: press and hold the button to store a

cycle with your own set of preferences in the memory of

the machine. To recall a previously stored cycle, press the

MEMO button.

FUNCTION buttons: press the button to select the

desired function. The corresponding indicator light on the

display will switch on.

SPIN button : press to reduce or completely exclude

the spin cycle - the value is indicated on the display.

TEMPERATURE button : press to decrease the temperature: the value will be shown on the display.

8

DRYING button : press to set a drying cycle.

START/PAUSE button with indicator light: when the gre-

en indicator light flashes slowly, press the button to start a

wash cycle. Once the cycle has begun the indicator light

will remain lit in a fixed manner. To pause the wash cycle,

press the button again; the indicator light will flash in an

orange colour. If the symbol is not illuminated, the door

may be opened. To start the wash cycle from the point at

which it was interrupted, press the button again.

Standby mode

This washing machine, in compliance with new energy saving regulations, is fitted with an automatic standby system

which is enabled after about 30 minutes if no activity is

detected. Press the ON-OFF button briefly and wait for the

machine to start up again.

Consumption in off-mode: 0,5 W

Consumption in Left-on: 0,5 W

Display

GB

F

Z

B

A

C

F

L

The display is useful when programming the machine and provides a great deal of information.

X

D

E

Y

F

The upper two strings A and B are used to display the selected wash cycle or the type of drying selected, the current wash

cycle phase (the selected dryness level or drying time) and all the indications relating to the progress status of the cycle.

String C shows the time remaining until the end of the wash cycle in progress and, if a DELAYED START has been set, the

time remaining until the start of the selected wash cycle.

String D shows the maximum spin speed value (this depends on the selected wash cycle); if the wash cycle does not include

a spin cycle, the string remains unused.

String E shows the maximum temperature value which may be selected (this depends on the wash cycle used); if the temperature of the wash cycle cannot be modified, the string remains unused.

Indicator lights F correspond to the functions and light up when the selected function is compatible with the set wash cycle.

Door locked symbol

If the symbol is lit, this indicates that the washer dryer door is blocked to prevent it from being opened accidentally. To prevent any damage from occurring, wait for the symbol to switch itself off before opening the appliance door.

N.B.: if the DELAYED START function has been activated, the door cannot be opened; pauses the machine by pressing the

START/PAUSE button if you wish to open it.

! The first time the machine is switched on, you will be asked to select the language and the display will automatically show

the language selection menu.

To select the desired language press the X and Y buttons; to confirm the selection press the Z button.

If you wish to change the selected language, simultaneously press and hold all the three buttons marked with an L in the

figure, until you hear a beep. Switch the machine on again; the language selection menu will be displayed.

9

How to run a wash cycle or a

drying cycle

GB

1. SWITCH THE MACHINE ON. Press the button; the

text WELCOME will appear on the display and the START/

PAUSE indicator light will flash slowly in a green colour.

2. LOAD THE LAUNDRY. Open the porthole door. Load the

laundry, making sure you do not exceed the maximum load

value indicated in the table of programmes on the following

page.

3. MEASURE OUT THE DETERGENT. Pull out the

detergent dispenser drawer and pour the detergent into

the relevant compartments as described in “Detergents

and laundry”.

4. CLOSE THE DOOR.

5. SELECT THE WASH CYCLE. Press one of the WASH

CYCLE SELECTOR buttons to select the required wash

cycle; the name of the wash cycle will appear on the

display. A temperature and spin speed is set for each wash

cycle; these may be adjusted. The duration of the cycle will

appear on the display.

6. CUSTOMISE THE WASH CYCLE. Use the relevant

buttons:

Modifying the temperature and/or spin

speed. The machine automatically selects the maximum

temperature and spin speed set for the selected wash

cycle; these values cannot therefore be increased. The

temperature can be decreased by pressing the button,

until the cold wash “OFF” setting is reached. The spin

speed may be progressively reduced by pressing the

button, until it is completely excluded (the “OFF” setting). If

these buttons are pressed again, the maximum values are

restored.

Setting a delayed start.

To set a delayed start for the selected programme, press

the corresponding button repeatedly until the required

delay period has been reached. When this option is

enabled, the symbol lights up on the display. To remove

the delayed start function press the button until the text

“OFF” appears on the display.

Setting the drying cycle.

The desired drying cycle type may be set by pressing the

DRYING button once or several times. Two options are

available:

A - Based on the how damp the clothes are once they

have been dried:

Iron dry: slightly damp clothes, easy to iron.

Hanger dry: dry clothes to put away.

Cupboard dry: very dry clothes, recommended for

towelling and bathrobes.

B - Based on time: from 40 minutes to 180.

To exclude the drying phase press the relevant button until

the text OFF appears on the display.

If your laundry load to be washed and dried is much greater

than the maximum stated load (see adjacent table), perform

the wash cycle, and when the cycle is complete, divide

the garments into groups and put some of them back in

the drum. At this point, follow the instructions provided

for a “Drying only” cycle. Repeat this procedure for the

remainder of the load.

N.B: a cooling-down period is always added to the end of

each drying cycle.

Drying only

Select a drying setting ( - - ) using the WASH

CYCLE selector in accordance with the type of fabric, then

select the desired drying type using the DRYING button.

Table of Drying times (guideline values)

Max.

Fabric

type

Cotton

Synthetics

Wool

Load type

Clothing of

different sizes,

Terry towels

Sheets, Shirts,

Pyjamas,

socks, etc.

Knitwear, Pullovers, etc.

Modifying the cycle settings.

• Press the button to enable the function; the indicator

light corresponding to the button will switch on.

• Press the button again to disable the function; the

indicator light will switch off.

Cupboard

load

(kg)

5 180 170 160

3 180 170 160

1,5 150 140 130

dry

Henger

dry

Iron

dry

! If the selected function is not compatible with the

programmed wash cycle, the indicator light will flash and

the function will not be activated.

! If the selected function is not compatible with another

function which has been selected previously, the indicator

light corresponding to the first function selected will flash

and only the second function will be activated; the indicator

light corresponding to the enabled function will remain lit.

! The functions may affect the recommended load value

and/or the duration of the cycle.

7. START THE PROGRAMME. Press the START/PAUSE

button. The corresponding indicator light will become

green, remaining lit in a fixed manner, and the door will be

locked (the DOOR LOCKED symbol will be on). During

the wash cycle, the name of the phase in progress will

appear on the display. To change a wash cycle while it is

in progress, pause the washer dryer using the START/

PAUSE button (the START/PAUSE indicator light will flash

slowly in an orange colour); then select the desired cycle

and press the START/PAUSE button again.

To open the door while a cycle is in progress, press the

START/PAUSE button; if the DOOR LOCKED symbol

is switched off the door may be opened. Press the START/

PAUSE button again to restart the wash cycle from the

point at which it was interrupted.

8. THE END OF THE WASH CYCLE. This will be indicated

by the text “END OF CYCLE” on the display; when the

DOOR LOCKED symbol switches off the door may be

opened. Open the door, unload the laundry and switch off

the machine.

! If you wish to cancel a cycle which has already begun, press

and hold the button. The cycle will be stopped and the

machine will switch off.

10

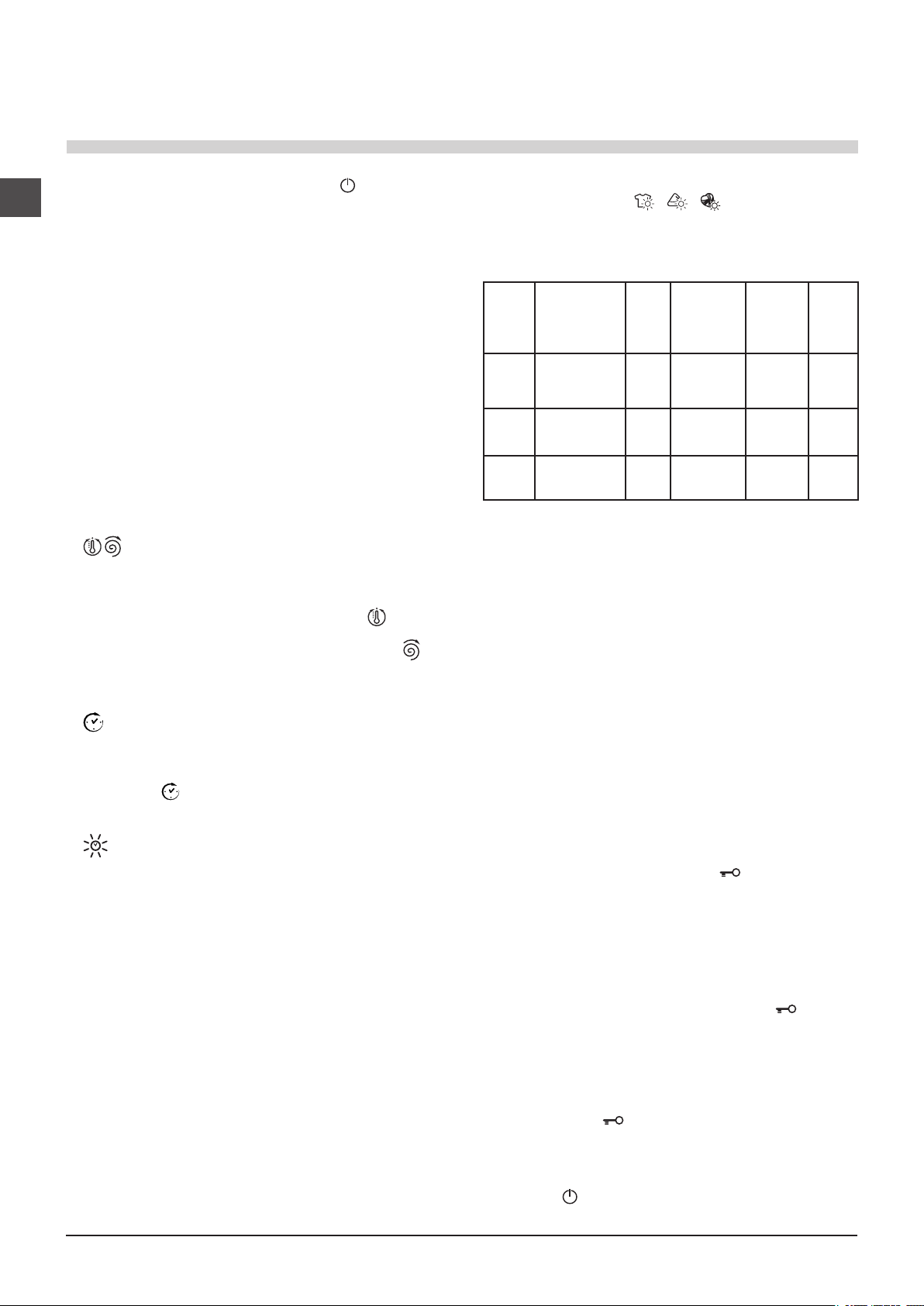

Wash cycles and functions

M

AX

1

3

2

Table of wash cycles

Max.

Max.

Description of the wash cycle

Wash cycles

Everyday wash cycles (Daily)

Cottons (*) (1st press of the button): extremely soiled whites. 90° 1200

Cottons (2nd press of the button): heavily soiled whites and resistant colours. 60° 1200

Cottons (3rd press of the button): heavily soiled whites and delicate colours. 40° 1200

Synthetics (1st press of the button): heavily soiled resistant colours. 60° 800

Synthetics (2nd press of the button): lightly soiled resistant colours. 40° 800

Mix 30' (1st press of the button): to refresh lightly soiled garments quickly

(not suitable for wool, silk and clothes which require washing by hand).

Mix 15' (2nd press of the button) : to refresh lightly soiled garments quickly

(not suitable for wool, silk and clothes which require washing by hand).

Silk/Curtains: for garments in silk and viscose, lingerie. 30° 0 - -

Memory: allows for any wash cycle to be stored.

M

Wool: for wool, cashmere, etc. 40° 800

Drying Programmes

Cotton dry (1st press of the button):

Synthetics dry (2nd press of the button)

Wool dry (3rd press of the button)

Partials wash cycles

Spin - 1200

Rinse (1st press of the button): - 1200

Pump out (2nd press of the button) - 0 - - - - 7

For all Test Institutes:

speed

temp.

(°C)

30° 800

30° 800

- -

- -

- -

(rpm)

Dry-

ing

* Test wash cycle in compliance with regulation EN 50229: set wash cycle with a temperature of 60°C.

Wash functions

Detergents

Ble-

Wash

ach

-

-

-

- - - 5

- - - 3

- - - 1,5

- - - 7

softener

-

Fabric

Max.

load

(kg)

7

7

7

3

3

3

1,5

1

1,5

7

GB

Cycle

duration

The duration of the wash cycles can be checked

on the display.

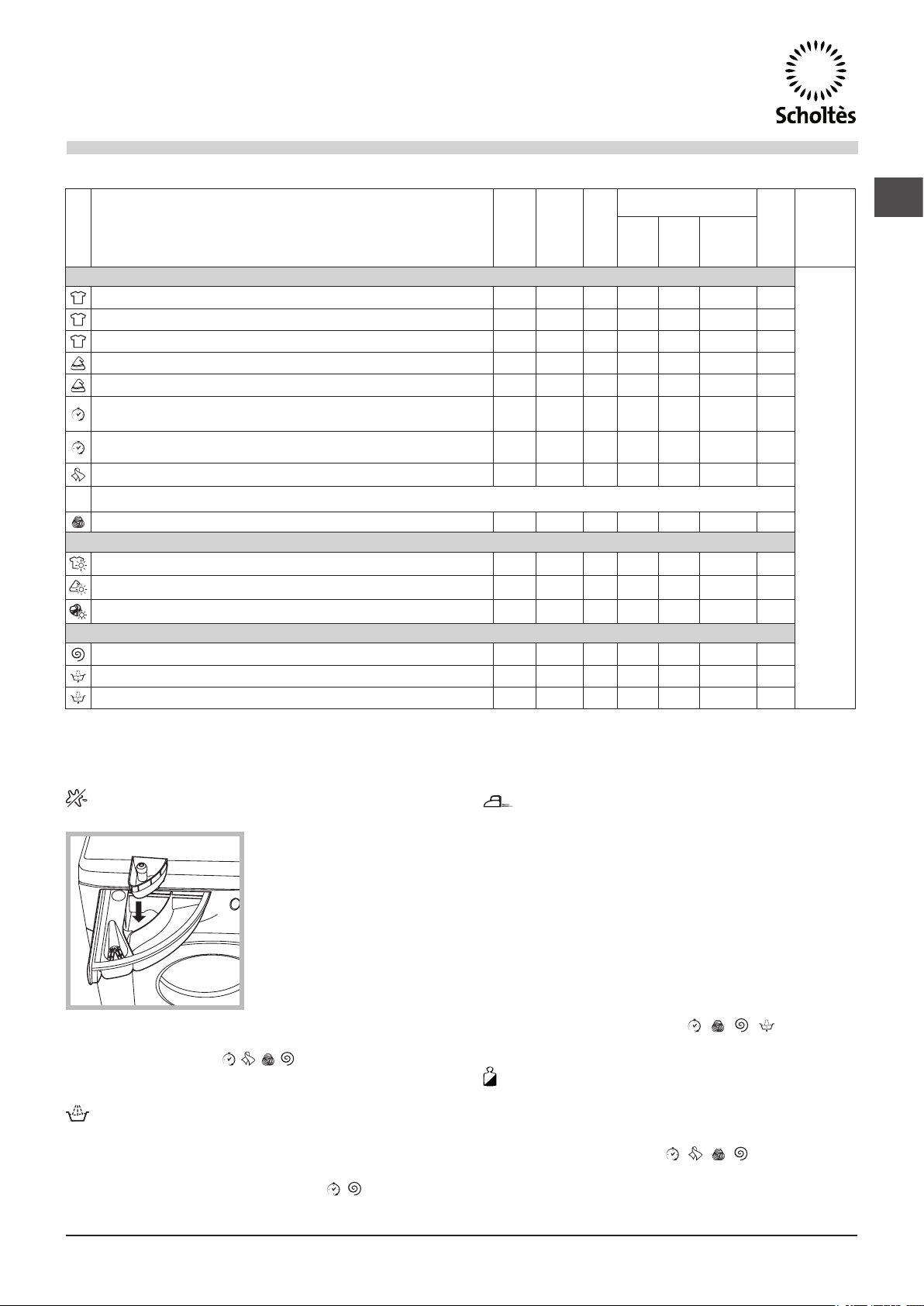

Stain removal

This function is particularly useful for the removal of stubborn stains.

Place extra compartment 3

(supplied). When pouring in

the bleach, be careful not to

exceed the “max” level marked

on the central pivot (see figure).

To run the bleach cycle on its

own, pour the bleach into extra

compartment 3, set the “Rinse”

programme and activate the

“Stain removal” programme.

To bleach during a wash cycle,

pour in the detergent and any fabric softener you wish to use, set

the desired wash cycle and enable the “Stain removal” function.

! It cannot be used with the , , , , “Pump out” and “Drying

programmes”.

Extra rinse

By selecting this option, the efficiency of the rinse is increased

and optimal detergent removal is guaranteed. It is particularly

useful for sensitive skin.

! It cannot be used in conjunction with the , , “Pump out”

and “Drying programmes”.

Easy iron

By selecting this function, the wash and spin cycles will be modified

in order to reduce the formation of creases. At the end of the cycle

the washer dryer will perform slow rotations of the drum; the EASY

IRON indicator light will switch on, the START/PAUSE indicator light

will flash in an orange colour and the text “END OF CYCLE” will

appear on the display. To end the cycle, press the START/PAUSE

button or the EASY IRON button. For the Silk/Curtains cycle, the

machine will end the cycle while the laundry is soaking; the EASY

IRON indicator light will switch on, the START/PAUSE indicator light

will flash in an orange colour and the text “STOP WITH WATER” will

appear on the display. To drain the water so that the laundry may be

removed, press the START/PAUSE button or the EASY IRON button.

! It may not be used with the , , , and “Drying

programmes”.

Mini load

This function is recommended for when the load of laundry is

equal to half, or less than half, of the maximum recommended

load (see Table of wash cycles).

! It cannot be used with the , , , , “Pump out” and

“Drying programmes”.

11

Detergents and laundry

M

AX

1

3

2

GB

Detergent dispenser drawer

Good washing results also depend on the correct dose of

detergent: adding too much detergent will not necessarily result in a more efficient wash, and may in fact cause

build up on the inside of your appliance and contribute to

environmental pollution.

! Do not use hand washing detergents because these

create too much foam.

Open the detergent dispenser drawer and pour

in the detergent or washing

additive, as follows.

compartment 1: Detergent for the wash cycle

(powder or liquid)

Liquid detergent should only be poured in immediately

prior to the start of the wash cycle.

compartment 2: Additives (fabric softeners, etc.)

The fabric softener should not overflow the grid.

extra compartment 3: Bleach

Silk: use special wash cycle to wash all silk garments.

We recommend the use of special detergent which has been

designed to wash delicate clothes.

Curtains: fold curtains and place them in a pillow case or

mesh bag. Use wash cycle .

Wool: the wool wash cycle of this machine has been

approved by The Woolmark Company for the washing of

wool garments labelled as “hand wash” provided that the

products are washed according to the instructions on the

garment label and those issued by the manufacturer of this

washing machine (M1126)

Load balancing system

Before every spin cycle, to avoid excessive vibrations and

to distribute the load in a uniform manner, the drum rotates

continuously at a speed which is slightly greater than the

washing rotation speed. If, after several attempts, the load

is not balanced correctly, the machine spins at a reduced

spin speed. If the load is excessively unbalanced, the washer

dryer performs the distribution process instead of spinning.

To encourage improved load distribution and balance, we

recommend small and large garments are mixed in the load.

Preparing the laundry

• Divide the laundry according to:

- the type of fabric/the symbol on the label

- the colours: separate coloured garments from whites

• Empty all garment pockets and check the buttons.

• Do not exceed the listed values, which refer to the weight

of the laundry when dry: see “Table of wash cycles”.

How much does your laundry weigh?

1 sheet 400-500 g

1 pillow case 150-200 g

1 tablecloth 400-500 g

1 bathrobe 900-1200 g

1 towel 150-250 g

Special wash cycles

Mix 30’: this wash cycle was designed to wash lightly soi-

led garments quickly: it lasts just 30 minutes and therefore

saves both energy and time. By selecting this wash cycle (

at 30°C), it is possible to wash different fabrics together

(except for wool and silk items), with a maximum load of 3 kg.

Mix 15’: this wash cycle was designed to wash lightly soiled

garments quickly: it lasts just 15 minutes and therefore saves

both energy and time. By selecting this wash cycle ( at

30°C), it is possible to wash different fabrics together (except

for wool and silk items), with a maximum load of 1.5 kg.

12

Troubleshooting

Your washer dryer could fail to work. Before contacting the Technical Assistance Centre (see “Assistance”), make sure that

the problem cannot be solved easily using the following list.

Problem:

The washer dryer does not switch

on.

The wash cycle does not start.

The washer dryer does not take in

water (the text “NO WATER, CHECK

SUPPLY” appears

on the display).

The washer dryer continuously

takes in and

drains water.

Possible causes / Solutions:

• The appliance is not plugged into the socket fully, or is not making contact.

• There is no power in the house.

• The washer dryer door is not closed properly.

• The ON/OFF button has not been pressed.

• The START/PAUSE button has not been pressed.

• The water tap has not been opened.

• A delayed start has been set (see “How to run a wash cycle or a drying cycle”).

• The water inlet hose is not connected to the tap.

• The hose is bent.

• The water tap has not been opened.

• There is no water supply in the house.

• The pressure is too low.

• The START/PAUSE button has not been pressed.

• The drain hose is not fitted at a height between 65 and 100 cm from the floor

(see “Installation”).

• The free end of the hose is under water (see “Installation”).

• The wall drainage system is not fitted with a breather pipe.

If the problem persists even after these checks, turn off the water tap, switch

the appliance off and contact the Assistance Service. If the dwelling is on one of

the upper floors of a building, there may be problems relating to water drainage,

causing the washer dryer to fill with water and drain continuously. Special antidraining valves are available in shops and help to avoid this inconvenience.

GB

The washer dryer does not drain or

spin.

The washer dryer vibrates a lot

during the spin cycle.

The washer dryer leaks.

The machine is locked and the display

flashes, indicating an

error code (e.g. F-01, F-..).

There is too much foam.

The washer-dryer does not dry.

• The wash cycle does not include draining: some wash cycles require the drain

phase to be started manually (see “Wash cycles and functions”).

• The EASY IRON function has been activated: To complete the wash cycle,

press the START/PAUSE button (see “Wash cycles and functions”).

• The drain hose is bent (see “Installation”).

• The drainage duct is clogged.

• The drum was not unlocked correctly during installation (see “Installation”).

• The washer dryer is not level (see “Installation”).

• The washer dryer is trapped between cabinets and walls (see “Installation”).

• The water inlet hose is not screwed on properly (see “Installation”).

• The detergent dispenser drawer is blocked (for cleaning instructions, see

“Care and maintenance”).

• The drain hose is not fixed properly (see “Installation”).

• Switch off the machine and unplug it, wait for approximately 1 minute and

then switch it back on again.

If the problem persists, contact the Technical Assistance Service.

• The detergent is not suitable for machine washing (it should display the text

“for washer dryers” or “hand and machine wash”, or the like).

• Too much detergent was used.

• The appliance is not plugged into the socket, or not enough to make contact.

• There has been a power failure.

• The appliance door is not shut properly.

• A delayed start has been set.

• DRYING is in the OFF position.

13

Service

GB

Before calling for Assistance:

• Check whether you can solve the problem alone (see “Troubleshooting”);

• Restart the programme to check whether the problem has been solved;

• If this is not the case, contact an authorised Technical Assistance Centre using the telephone number provided on the

guarantee certificate.

! Always request the assistance of authorised technicians.

Have the following information to hand:

• the type of problem;

• the appliance model (Mod.);

• the serial number (S/N).

This information can be found on the data plate applied to the rear of the washer dryer, and can also be found on the

front of the appliance by opening the door.

14

Mode d’emploi

LAVANTE-SÉCHANTE

FR

Français

SDLE 129

! Ce symbole vous rappelle de lire ce mode d’emploi.

Sommaire

Installation, 16-17-18-19

Déballage et mise à niveau

Raccordements eau et électricité

Premier cycle de lavage

Caractéristiques techniques

Instructions pour l’installateur

Entretien et soin, 20

Coupure de l’arrivée d’eau et du courant

Nettoyage du lavante-séchante

Nettoyage du tiroir à produits lessiviels.

Entretien du hublot et du tambour

Nettoyage de la pompe

Contrôle du tuyau d’arrivée de l’eau

Précautions et conseils, 21

Sécurité générale

Mise au rebut

Ouverture manuelle de la porte hublot

FR

Description du lavante-séchante, 22-23

Bandeau de commandes

Écran

Comment effectuer un cycle de lavage

ou un séchage, 24

Programmes et fonctions, 25

Tableau des programmes

Fonctions de lavage

Produits lessiviels et linge, 26

Tiroir à produits lessiviels

Triage du linge

Programmes spéciaux

Système d’équilibrage de la charge

Anomalies et remèdes, 27

Assistance, 28

15

Installation

FR

! Conserver ce mode d’emploi pour pouvoir le consulter à tout moment. En cas de vente, de cession ou

de déménagement, veiller à ce qu’il suive toujours le

lavante-séchante pour que son nouveau propriétaire

soit informé sur son mode de fonctionnement et

puisse profiter des conseils correspondants.

! Lire attentivement les instructions: elles fournissent des conseils importants sur l’installation,

l’utilisation et la sécurité de l’appareil.

Déballage et mise à niveau

Déballage

1. Déballer le lavante-séchante.

2. Contrôler que le lavante-séchante n’a pas été

endommagé pendant le transport. S’il est abîmé,

ne pas le raccorder et contacter le vendeur.

3. Enlever les 4 vis

de protection servant

au transport, le caoutchouc et la cale,

placés dans la partie

arrière (voir figure).

Une bonne mise à niveau garantit la stabilité

de l’appareil et évite qu’il y ait des vibrations,

du bruit et des déplacements en cours de

fonctionnement. Si la machine est posée sur

de la moquette ou un tapis, régler les pieds de

manière à ce qu’il y ait suffisamment d’espace

pour assurer une bonne ventilation.

Raccordements eau et électricité

Raccordement du tuyau d’arrivée de l’eau

1. Reliez le tuyau d’alimentation en le vissant

à un robinet d’eau froide à embout fileté 3/4

gaz (voir figure).

Faire couler l’eau jusqu’à ce qu’elle soit

limpide et sans impuretés avant de raccorder.

2. Raccorder le tuyau

d’arrivée de l’eau au

lavante-séchante en le

vissant à la prise d’eau

prévue, dans la partie

arrière en haut à droite

(voir figure).

4. Boucher les trous à l’aide des bouchons

plastique fournis.

5. Conserver toutes ces pièces: il faudra les re-

monter en cas de transport du lavante-séchante.

! Les pièces d’emballage ne sont pas des jouets

pour enfants.

Mise à niveau

1. Installer le lavante-séchante sur un sol plat

et rigide, sans l’appuyer contre des murs, des

meubles ou autre.

2. Si le sol n’est pas

parfaitement horizontal, visser ou dévisser

les pieds de réglage

avant (voir figure) pour

niveler l’appareil; son

angle d’inclinaison,

mesuré sur le plan

de travail, ne doit pas

dépasser 2°.

3. Attention à ce que le tuyau ne soit pas plié

ou écrasé.

! La pression de l’eau doit être comprise entre

les valeurs indiquées dans le tableau des Caractéristiques techniques (voir page ci-contre).

! Si la longueur du tuyau d’alimentation ne suffit

pas, s’adresser à un magasin spécialisé ou à un

technicien agréé.

! N’utiliser que des tuyaux neufs.

! Utiliser ceux qui sont fournis avec l’appareil.

16

65 - 100 cm

Raccordement du tuyau de vidange

Raccorder le tuyau

d’évacuation, sans

le plier, à un conduit

d’évacuation ou à une

évacuation murale placés à une distance du

sol comprise entre 65

et 100 cm;

ou bien l’accrocher à

un évier ou à une baignoire, dans ce cas,

fixer le support en plastique fourni avec l’appareil au robinet (voir

figure). L’extrémité libre

du tuyau d’évacuation

ne doit pas être plongée dans l’eau.

! L’utilisation d’un tuyau de rallonge est absolument déconseillée mais si on ne peut faire

autrement, il faut absolument qu’il ait le même

diamètre que le tuyau original et sa longueur ne

doit pas dépasser 150 cm.

! N’utiliser ni rallonges ni prises multiples.

! Le câble ne doit être ni plié ni trop écrasé.

! Le câble d’alimentation ne doit être remplacé

que par des techniciens agréés.

Attention! Nous déclinons toute responsabilité en cas

de non-respect des normes énumérées ci-dessus.

Premier cycle de lavage

Avant la première mise en service de l’appareil, effectuer un cycle de lavage avec un produit lessiviel

mais sans linge et sélectionner le programme .

Caractéristiques techniques

Modèle

Dimensions

Capacité

Raccordements

électriques

SDLE 129

largeur 59,5 cm

hauteur 81,5 m

profondeur 54,5 cm

de 1 à 7 kg pour le lavage

de 1 à 5 kg pour le séchage

Voir la plaque signalétique appliquée

sur la machine

FR

Branchement électrique

Avant de brancher la fiche dans la prise de courant, s’assurer que:

• la prise est bien reliée à la terre et est conforme

aux réglementations en vigueur;

• la prise est bien apte à supporter la puissance

maximale de l’appareil indiquée dans le tableau

des Caractéristiques techniques (voir ci-contre);

• la tension d’alimentation est bien comprise

entre les valeurs figurant dans le tableau des

Caractéristiques techniques (voir ci-contre);

• la prise est bien compatible avec la fiche du

lavante-séchante. Autrement, remplacer la

prise ou la fiche.

! Le lavante-séchante ne doit pas être installé

dehors, même à l’abri, car il est très dangereux

de le laisser exposé à la pluie et aux orages.

! Après installation du lavante-séchante, la prise

de courant doit être facilement accessible.

Raccordements

hydrauliques

Vitesse d’essorage

Programmes de

contrôle selon

la norme

EN 50229

pression maximale 1 MPa (10 bar)

pression minimale 0,05 MPa (0,5

bar) capacité du tambour 52 litres

jusqu’à 1200 tours minute

avage: programme

de la touche); température 60°C;

effectué avec une charge de 7 kg.

séchage: pour le séchage de la

charge de linge réduite, sélectionner

le niveau de séchage «A REPASSER», le linge doit comprendre: 2

draps, 1 taie d’oreiller et 1 serviette

de toilette;

pour le séchage de la charge de

linge restante, sélectionner le niveau

de séchage «A RANGER».

Cet appareil est conforme aux Directives Communautaires suivantes:

- 2004/108/CE (Compatibilité électromagnétique)

- 2006/95/CE (Basse Tension)

- 2002/96/CE

(1° pression

17

Loading...

Loading...