Harmony Hub

EIO0000001177 01/2020

Harmony Hub

ZBRN1/ZBRN2

User Manual

(Original Document)

01/2020

EIO0000001177.05

www.schneider-electric.com

The information provided in this documentation contains general descriptions and/or technical

characteristics of the performance of the products contained herein. This documentation is not

intended as a substitute for and is not to be used for determining suitability or reliability of these

products for specific user applications. It is the duty of any such user or integrator to perform the

appropriate and complete risk analysis, evaluation and testing of the products with respect to the

relevant specific application or use thereof. Neither Schneider Electric nor any of its affiliates or

subsidiaries shall be responsible or liable for misuse of the information contained herein. If you

have any suggestions for improvements or amendments or have found errors in this publication,

please notify us.

You agree not to reproduce, other than for your own personal, noncommercial use, all or part of

this document on any medium whatsoever without permission of Schneider Electric, given in

writing. You also agree not to establish any hypertext links to this document or its content.

Schneider Electric does not grant any right or license for the personal and noncommercial use of

the document or its content, except for a non-exclusive license to consult it on an "as is" basis, at

your own risk. All other rights are reserved.

All pertinent state, regional, and local safety regulations must be observed when installing and

using this product. For reasons of safety and to help ensure compliance with documented system

data, only the manufacturer should perform repairs to components.

When devices are used for applications with technical safety requirements, the relevant

instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may

result in injury, harm, or improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2020 Schneider Electric. All rights reserved.

2 EIO0000001177 01/2020

Table of Contents

Safety Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

About the Book . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Chapter 1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Offer Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Call To Action . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Product References. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 2 Physical Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

2.1 Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Hardware Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mechanical Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Environmental Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Housing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.3 Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Electrical Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.4 Data Management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compatibility Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Transmitter Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Monostable Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Set/Reset. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Receiver Types . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 3 First Installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

First Start Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Pairing Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Chapter 4 ZBRN1 Ethernet Communication . . . . . . . . . . . . . . . . . . 61

Communication on The Ethernet Network. . . . . . . . . . . . . . . . . . . . . .

Addressing Modes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication and Status Indicator. . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus TCP Settings and Supported Functions . . . . . . . . . . . . . . . .

Ethernet Cable. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

14

18

20

24

24

26

27

33

35

37

38

38

41

42

43

45

46

47

50

52

54

62

66

68

70

71

EIO0000001177 01/2020 3

Chapter 5 ZBRN2 Modbus Serial Line Communication . . . . . . . . . . 73

Communication on The Modbus Network . . . . . . . . . . . . . . . . . . . . . .

Communication and Status Indicator . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Serial Line Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modbus Settings and Supported Functions . . . . . . . . . . . . . . . . . . . . .

Modbus Serial Line Cables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

74

77

78

80

82

Chapter 6 ZBRRH Receiver for Harmony Hub . . . . . . . . . . . . . . . . . 85

Presentation of ZBRRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Installation Instruction for ZBRRH . . . . . . . . . . . . . . . . . . . . .

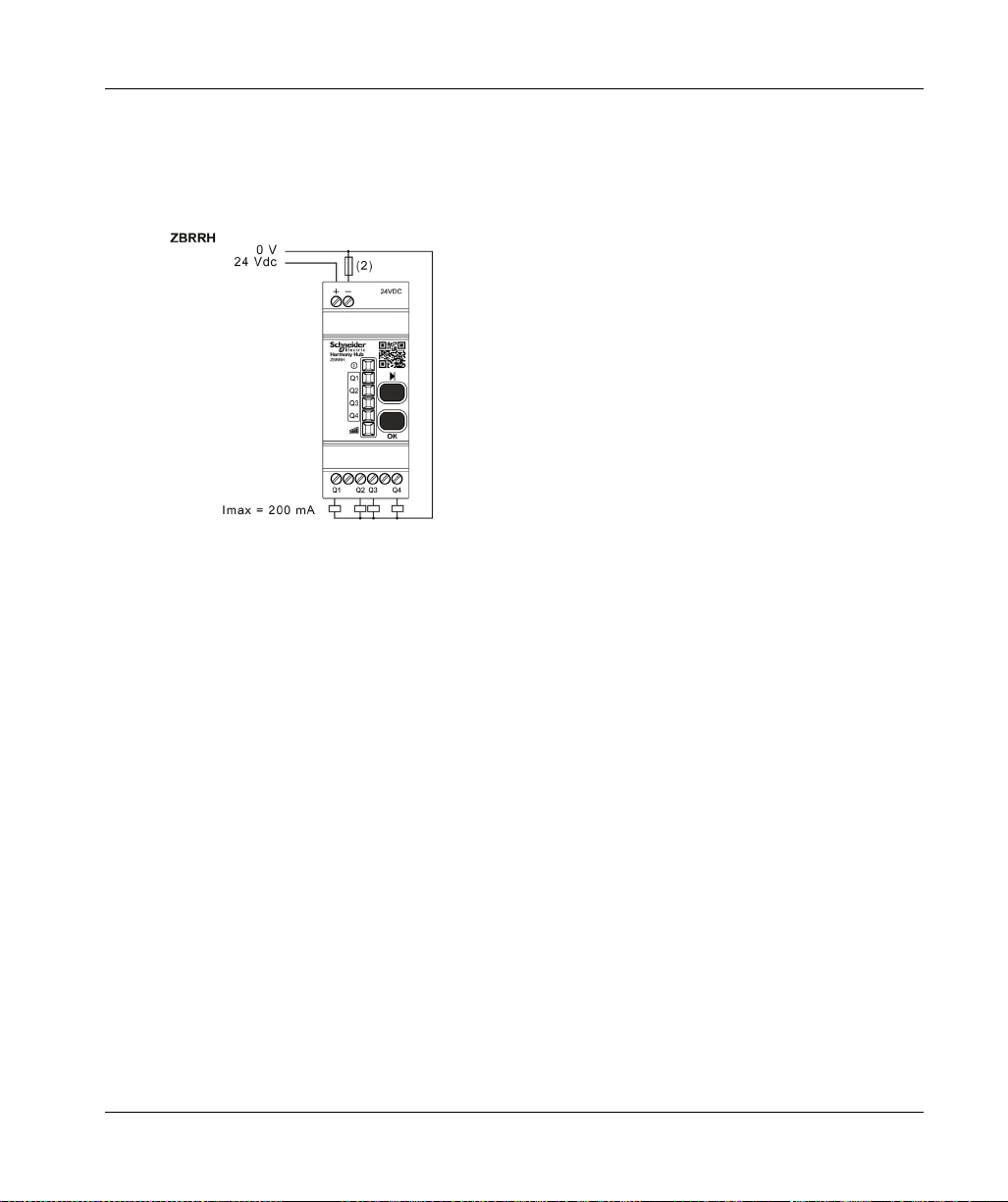

Receiver Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LED Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

How to Teach/Unteach ZBRRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lock/Unlock for ZBRRH . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Total Reset Function Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

86

87

91

92

93

96

99

Chapter 7 Modbus Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 101

7.1 Memory Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Memory Table . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Input Channels Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Channels Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type 1 Input Channels Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type 4 Input Channels Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type 5 Input Channels Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Type 6 Input Channels Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.4 Action Registers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Register. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Action Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.5 Diagnostic Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Diagnostics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.6 Configuration Registers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Device Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

102

102

103

104

106

107

108

109

112

112

114

115

116

126

127

133

136

140

141

146

Chapter 8 Radio . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Radio Communication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

149

4 EIO0000001177 01/2020

Chapter 9 User Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

9.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Principle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Menu Structure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Configuration Menu Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output Configuration Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Communication Menus . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Radio Frequency Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Factory Mode. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.3 Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagnostic Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 SD Card Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SD Card Menu. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

158

159

162

165

166

167

169

175

177

181

182

183

183

187

187

Chapter 10 SD Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 189

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Functions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

File Management and Diagnostics . . . . . . . . . . . . . . . . . . . . . . . . . . .

190

192

194

EIO0000001177 01/2020 5

6 EIO0000001177 01/2020

Safety Information

Important Information

NOTICE

Read these instructions carefully, and look at the equipment to become familiar with the device

before trying to install, operate, service, or maintain it. The following special messages may appear

throughout this documentation or on the equipment to warn of potential hazards or to call attention

to information that clarifies or simplifies a procedure.

EIO0000001177 01/2020 7

PLEASE NOTE

Electrical equipment should be installed, operated, serviced, and maintained only by qualified

personnel. No responsibility is assumed by Schneider Electric for any consequences arising out of

the use of this material.

A qualified person is one who has skills and knowledge related to the construction and operation

of electrical equipment and its installation, and has received safety training to recognize and avoid

the hazards involved.

8 EIO0000001177 01/2020

About the Book

At a Glance

Document Scope

This documentation is a reference for the wireless transmitters and receivers used with the

ZBRN1/ZBRN2 Harmony Hub.

The purpose of this document is to:

Show how to install and operate your Harmony Hub.

Show how to connect Harmony Hub with wireless transmitters, programmable logic controllers

(PLCs), and other devices.

Help become familiar with Harmony Hub features.

NOTE: Read and understand this document and all related documents

installing, operating, or maintaining your Harmony Hub.

The users must read through the entire document to understand all its features.

Validity Note

This documentation is valid for the ZBRN1/ZBRN2 Harmony Hub, firmware version ≥V3.31.

The technical characteristics of the devices described in the present document also appear online.

To access the information online:

Step Action

1 Go to the Schneider Electric home page

2 In the Search box type the reference of a product or the name of a product range.

3 If you entered a reference, go to the Product Datasheets search results and click on the

4 If more than one reference appears in the Products search results, click on the reference that

5 Depending on the size of your screen, you may need to scroll down to see the datasheet.

6 To save or print a datasheet as a .pdf file, click Download XXX product datasheet.

(see page 10)

www.schneider-electric.com

Do not include blank spaces in the reference or product range.

To get information on grouping similar modules, use asterisks (

reference that interests you.

If you entered the name of a product range, go to the Product Ranges search results and click

on the product range that interests you.

interests you.

.

*

).

before

The characteristics that are presented in the present document should be the same as those

characteristics that appear online. In line with our policy of constant improvement, we may revise

content over time to improve clarity and accuracy. If you see a difference between the document

and online information, use the online information as your reference.

EIO0000001177 01/2020 9

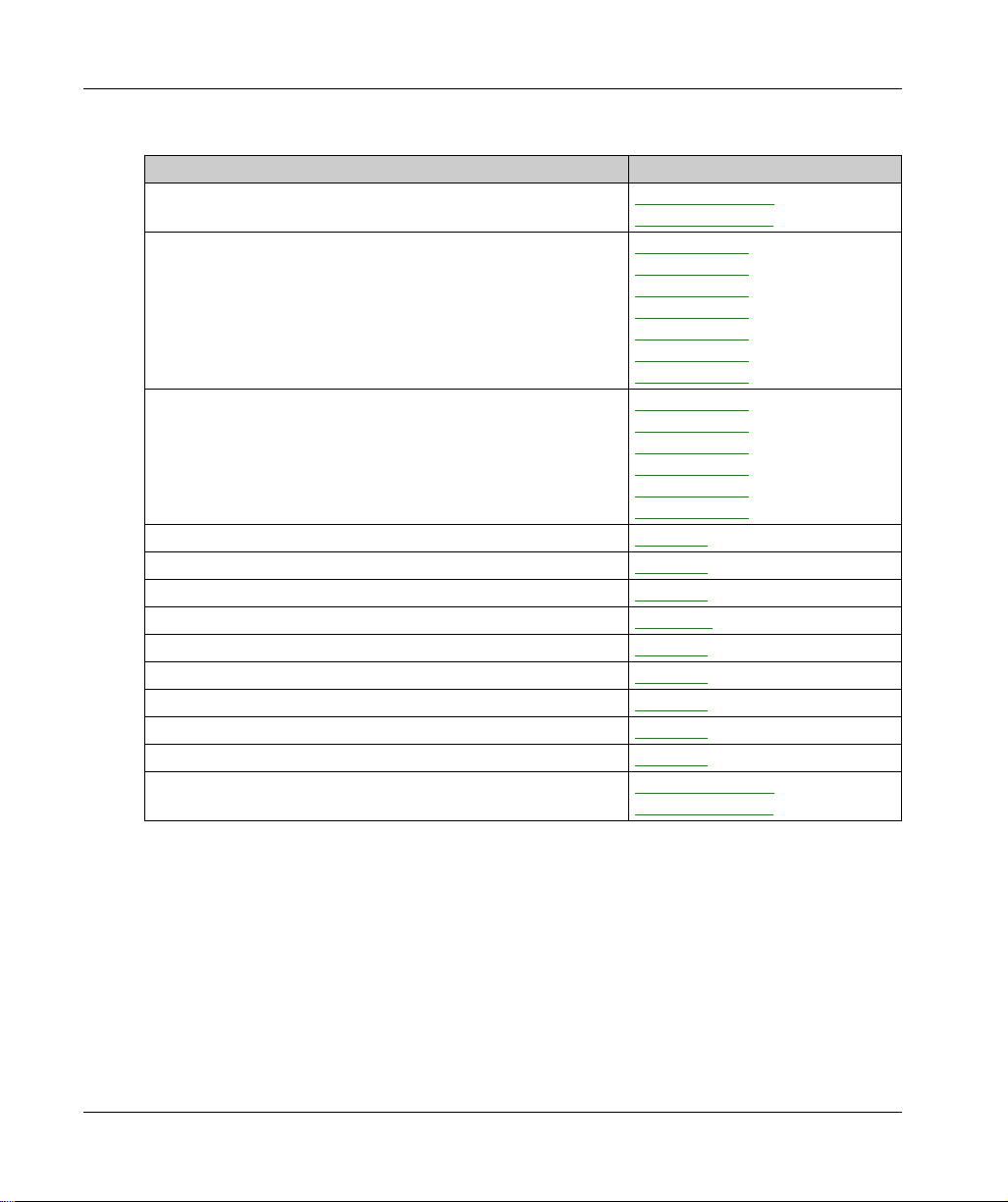

Related Documents

Title of Documentation Reference Number

Harmony XB5R Wireless and Battery-Less Push-Button Catalog

Harmony XB5R Expert Instruction Sheet

Magelis Box iPC Modular and Display Optimized, Universal and

Performance (HMIBMI, HMIBMO, HMIBMP, HMIBMU, HMIDM) User Manual

ZBRN1 Harmony Hub Instruction Sheet

ZBRN2 Harmony Hub Instruction Sheet

ZBRCETH Instruction Sheet

ZBRRH Receiver Instruction Sheet

ZBRRA/ZBRRC/ZBRRD Receivers Instruction Sheet

Packages Instruction Sheet

Transmitter with Metal or Plastic Head and Cap Instruction Sheet

Relay Antenna Instruction Sheet

Handy Box Instruction Sheet

Modbus Serial Modbus Serial Link for Machines

DIA5ED2121214EN

DIA5ED2121214FR

EIO0000000812

EIO0000000813

EIO0000000814

EIO0000000815

EIO0000000816

EIO0000000817

EIO0000000818

EIO0000003374

EIO0000003375

EIO0000003376

EIO0000003377

EIO0000003378

EIO0000003379

(Eng),

(Fre),

(Ger),

(Spa),

(Ita),

(Chs),

(Por)

(Eng),

(Fre),

(Ger),

(Spa),

(Ita),

(Chs),

S1B87888

S1B87941

S1B88209

GDE20645

S1A57202

S1A57199

S1A57198

S1A57194

S1A57210

DIA3ED2160106EN

DIA3ED2160106FR

(Eng),

(Fre)

(Eng)

(Fre)

You can download these technical publications and other technical information from our website

at https://www.se.com/ww/en/download/ .

10 EIO0000001177 01/2020

Product Related Information

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the equipment.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

UNINTENDED EQUIPMENT OPERATION

Only persons with expertise in the design and programming of control systems are allowed to

program, install, alter, and apply this product.

Follow all local and national safety codes and standards.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

DANGER

WARNING

EIO0000001177 01/2020 11

12 EIO0000001177 01/2020

Harmony Hub

Introduction

EIO0000001177 01/2020

Introduction

Chapter 1

Introduction

Purpose

This chapter provides an overview of the Harmony Hub and its wireless receiver.

What Is in This Chapter?

This chapter contains the following topics:

Offer Description 14

Call To Action 18

Product References 20

Topic Page

EIO0000001177 01/2020 13

Introduction

Offer Description

Overview

The Harmony XB5R offer using Harmony Hub allows more flexibility and simplicity in the

installation. Wireless transmitters technology reduces the wiring and the cost of installation.

Harmony Hub converts radio frequency inputs into various communication protocols and operates

as intermediate equipment between a transmitter and a PLC or industrial PCs (IT/OT box) that

support Modbus TCP protocols.

Harmony Hub can be used with transmitters such as XB4R and XB5R wireless and batteryless

push-buttons, rope pull switch, mushroom head push-buttons, emergency stop monitoring, XCKW

and XCMW wireless and batteryless limit switches, temperature sensors, and energy sensors.

It has a wide range of industrial and building applications. For example, in packing lines, automatic

doors in logistic centers, manufacturing of vehicles in automotive industries, for bag filling in

cement industries, and for efficient use of power in office lighting.

Harmony Hub can also control output especially receivers and communicate with a tower light for

example to make call for action. This use case will help the operator visually for the status of his

requested action.

14

EIO0000001177 01/2020

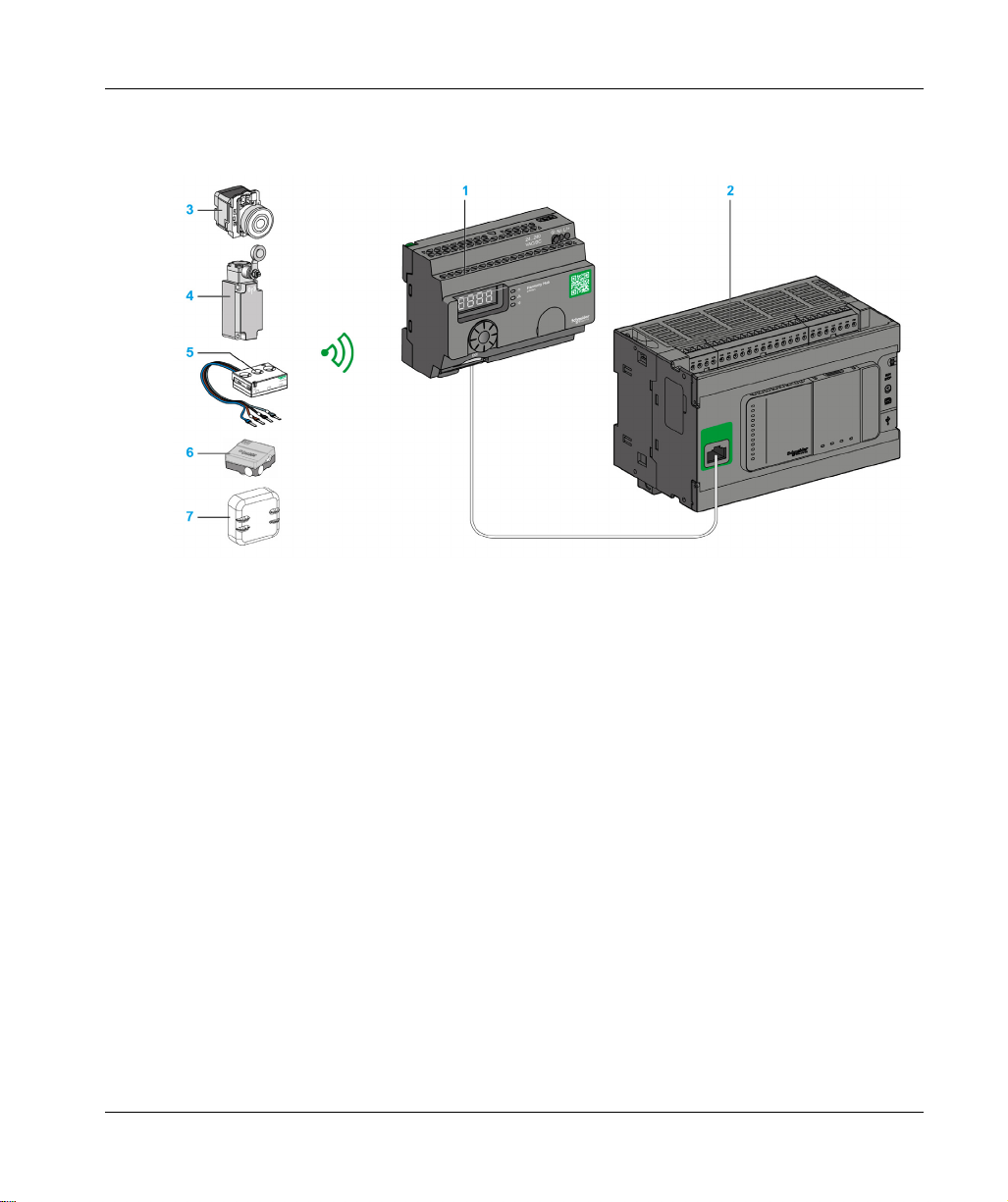

Basic Architecture with PLC

The following figure shows the transmission between transmitters and a ZBRN1 Harmony Hub:

1 Harmony Hub

2 PLC

3 Pushbutton

4 Limit switch

5 Energy sensor

6 Humidity and thermal sensor

7 Thermal sensor

Introduction

NOTE: You can associate 1 Harmony Hub with up to 60 transmitters. Each transmitter has a

unique ID (for example, 030079B1).

PowerTag energy monitoring sensor must be placed in a metal cabinet at a maximum distance of

3 meters to Harmony Hub.

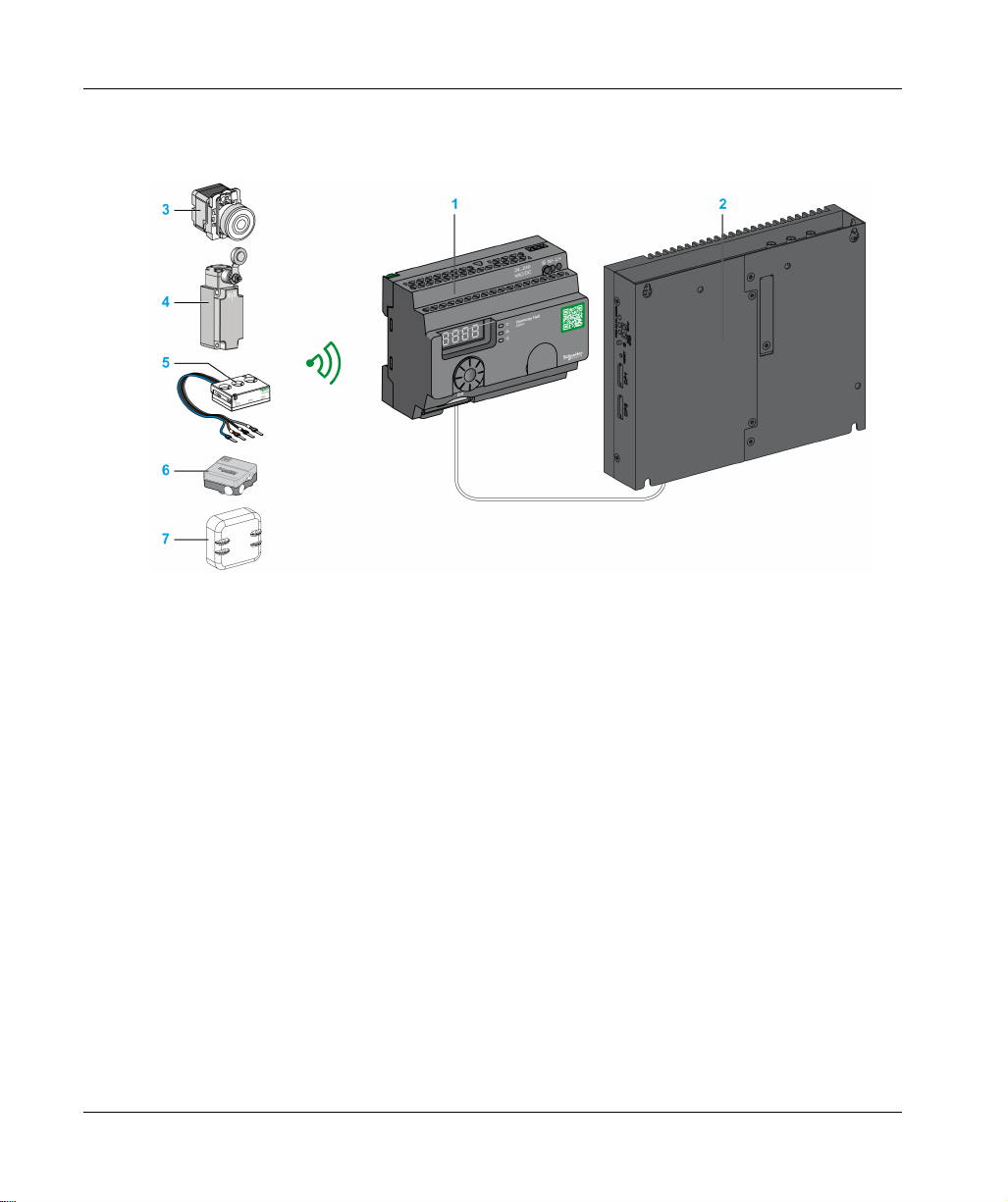

IT/OT Architecture

Harmony Hub provides network connectivity openness by operating as intermediate equipment

between the wireless devices and PLCs (Programmable Logic Controller) or all industrial PCs

(IT/OT box) that support Modbus TCP protocols.

Harmony Hub is providing an easy way to digitalize your production line to improve operation

efficiency by using a non-intrusive wireless system easy to connect to your IT system.

Harmony Hub collect physical signals from an operator interface or secondary sensing to generate

computed data information for computerized maintenance management system (CMMS) tools and

operation management tools.

EIO0000001177 01/2020 15

Introduction

Data can be analyzed through our dedicated EcoStruxure platform through AVEVA™ Software,

Maintenace Advisor software, and Augmented Operator Advisor application.

1 ZBRN1 Harmony Hub associated with ZBRCETH communication module

2 iPC

3 Pushbutton

4 Limit switch

5 Energy sensor

6 Humidity and thermal sensor

7 Thermal sensor

Compatible Transmitters

Harmony Hub is compatible with:

The Harmony batteryless and wireless push-buttons offer based on radio technology (ZBRT1,

ZBRT2)

The Harmony wireless and batteryless rope pull switch (ZBRP1)

The OsiSense wireless and batteryless radio limit switches (XCKW, XCMX)

Temperature sensors with battery (A9XST114, …)

Energy sensors (A9MEM1560, LV434020, …)

The following figures show some examples of transmitters:

16

EIO0000001177 01/2020

Example 1: Push-button with a plastic head

Example 2: Push-button with a metal head

Example 3: Push-button with a plastic head enclosed in a handy box

Introduction

EIO0000001177 01/2020 17

Introduction

Call To Action

Overview

Harmony Hub can communicate with up to 60 ZBRRH receivers.

If you connect a tower light to the ZBRRH receiver, you can make a call to action function.

Call to action:

When a problem occurs on the machine, the operator just pushes its wireless pushbutton.

The Harmony Hub can then control a device to solve the problem or at least to display it with a

tower light.

The following figure shows the transmission between a ZBRN• Harmony Hub and ZBRRH receiver

to command, for example, a tower light:

18

1 Harmony Hub

2 ZBRRH receiver

3 Pushbutton

4 Limit switch

5 Energy sensor

6 Humidity and thermal sensor

EIO0000001177 01/2020

7 Thermal sensor

8 XVU tower light

Call to action process:

Step Action

A If a problem occurs on the machine, the operator pushes its wireless pushbutton.

A message is sent to the Harmony Hub.

B The Harmony Hub send a message to the Maintenance Advisor.

C The Maintenance Advisor send a message to the Harmony Hub.

D The Harmony Hub send a message to a ZBRRH receiver.

E The ZBRRH receiver commands one lamp of the XVU tower light.

Compatible Receiver

Harmony Hub is compatible with the Harmony ZBRRH receiver:

Introduction

EIO0000001177 01/2020 19

Introduction

Product References

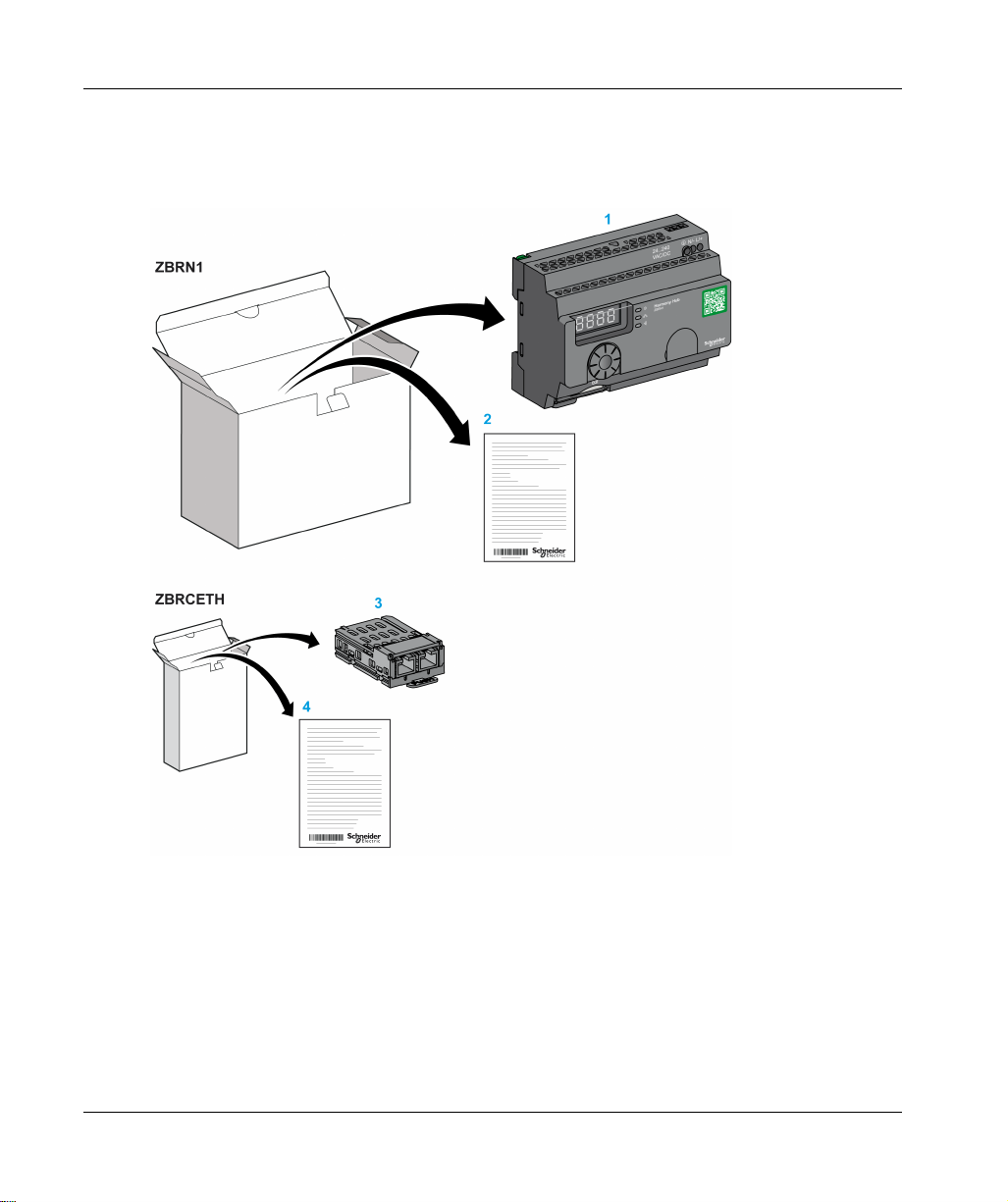

ZBRN1: Standard Harmony Hub with Communication Module

20

1 Harmony Hub

2 Instruction Sheet (ZBRN1)

3 Modbus TCP Communication module

4 Instruction Sheet (ZBRCETH)

NOTE: ZBRN1 must be associated with a communication module, reference ZBRCETH (Ethernet

protocol).

EIO0000001177 01/2020

ZBRN2: Harmony Hub for Modbus Serial Line Communication

1 Harmony Hub

2 Instruction Sheet

Introduction

Difference Between ZBRN1 and ZBRN2

ZBRN2 has an embedded communication port for a Modbus serial line, whereas ZBRN1 can

support Modbus TCP communication using ZBRCETH module.

EIO0000001177 01/2020 21

Introduction

22

EIO0000001177 01/2020

Harmony Hub

Physical Description

EIO0000001177 01/2020

Physical Description

Chapter 2

Physical Description

Purpose

This chapter provides an overview of Harmony Hub ZBRN1 and ZBRN2 hardware: description,

output connectors, installation, and power supply connections.

What Is in This Chapter?

This chapter contains the following sections:

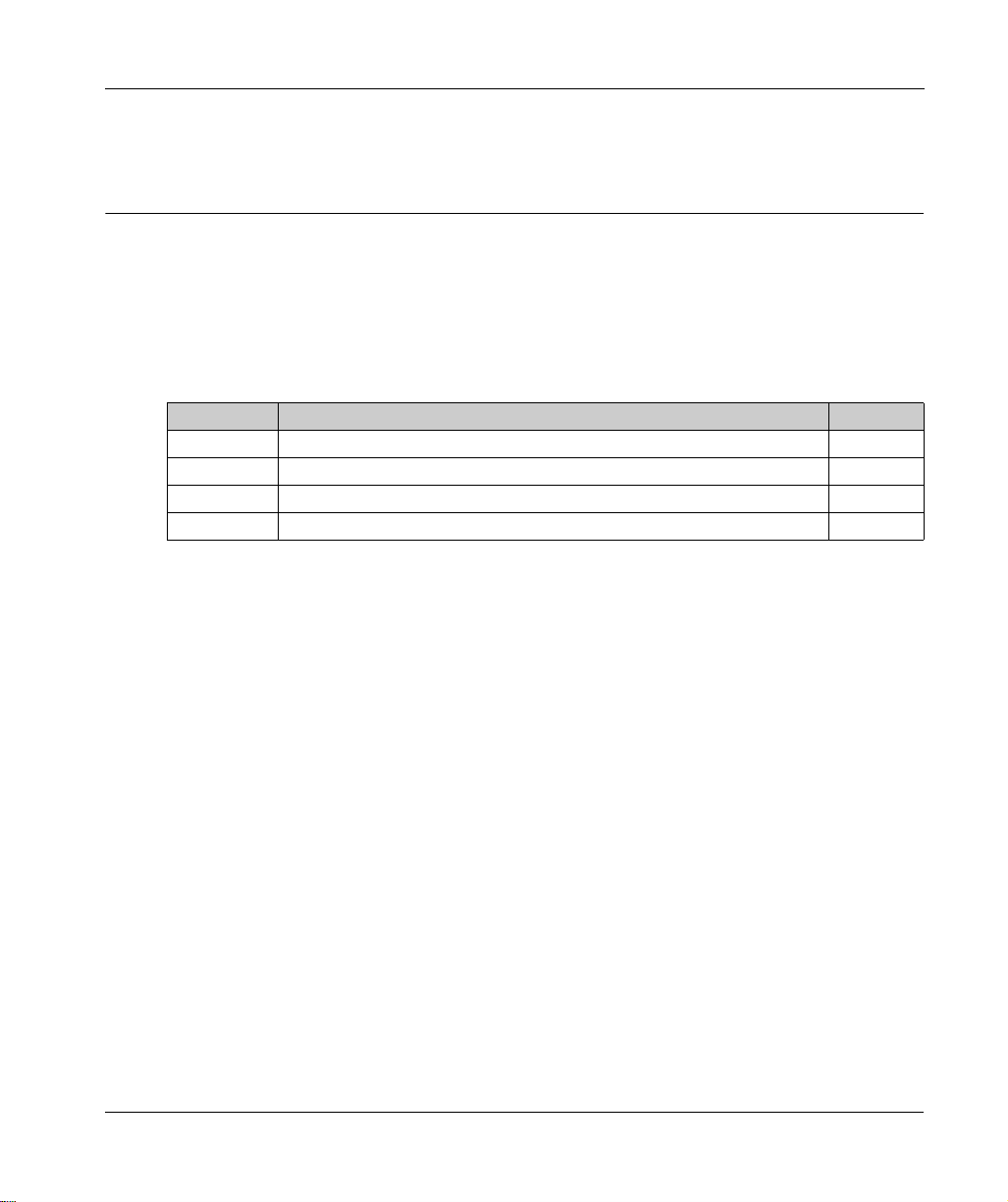

Section Topic Page

2.1 Product Overview 24

2.2 Installation 26

2.3 Specifications 38

2.4 Data Management 41

EIO0000001177 01/2020 23

Physical Description

Product Overview

Section 2.1

Product Overview

Hardware Description

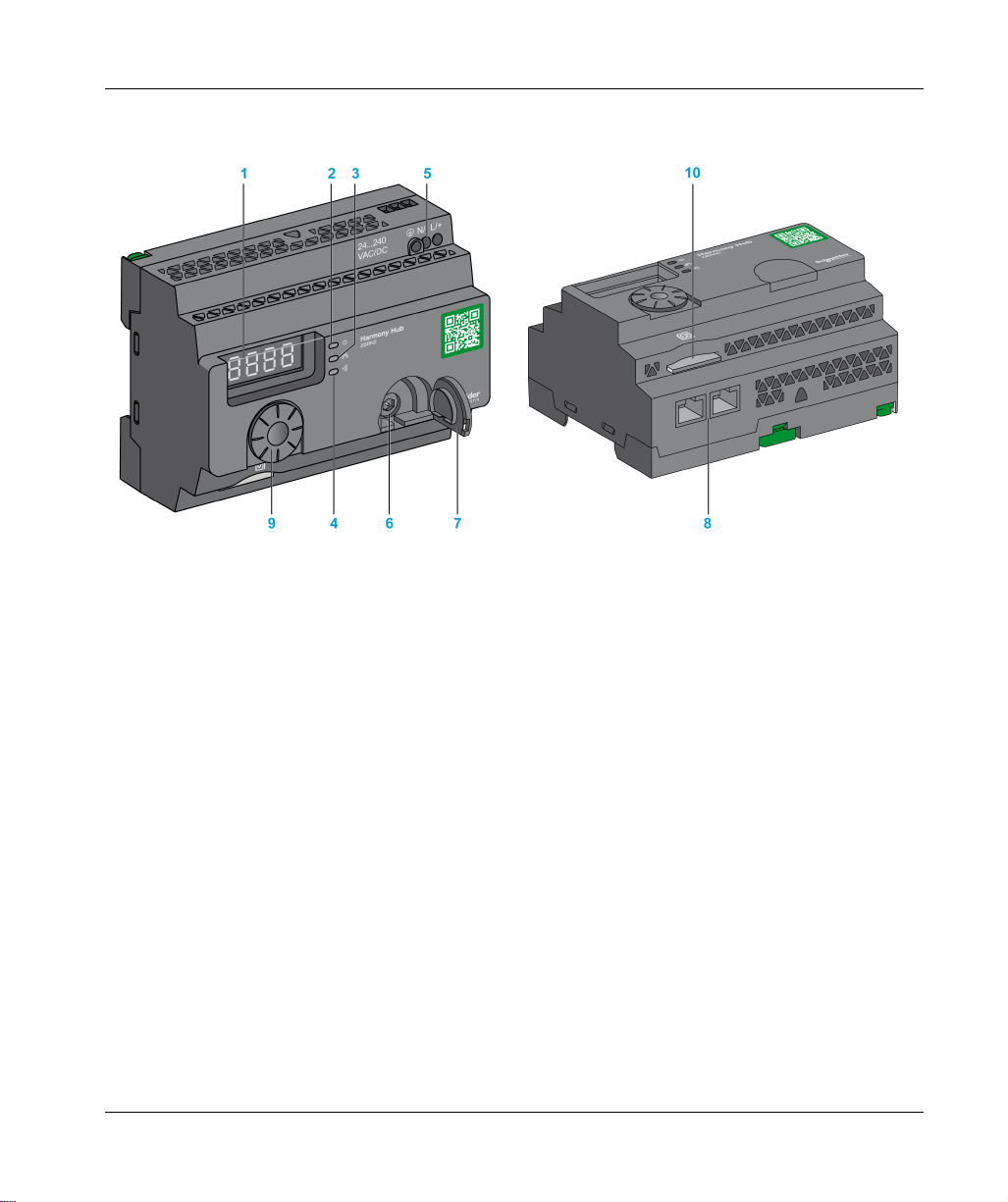

ZBRN1

24

1 Four 7-segments displays with 5 LEDs

2 Power LED

3 Communication LED

4 Radio signal strength LED

5 Power input terminal block

6 Connector for the optional external antenna

7 Protective plug for the connector for the optional external antenna

8 ZBRCETH Communication module inserted with 2 RJ45 Ethernet connectors

9 Jog dial

10 SD memory card slot

EIO0000001177 01/2020

ZBRN2

Physical Description

1 Four 7-segments displays with 5 LEDs

2 Power LED

3 Communication LED

4 Radio signal strength LED

5 Power input terminal block

6 Connector for the optional external antenna

7 Protective plug for the connector for the optional external antenna

8 2 RS-485 Modbus serial line connectors

9 Jog dial

10 SD memory card slot

EIO0000001177 01/2020 25

Physical Description

Installation

Section 2.2

Installation

What Is in This Section?

This section contains the following topics:

Installation Requirements 27

Mechanical Installation 33

Environmental Features 35

Housing 37

Topic Page

26

EIO0000001177 01/2020

Installation Requirements

Before Starting

Read and understand this chapter before beginning the installation of your Harmony Hub.

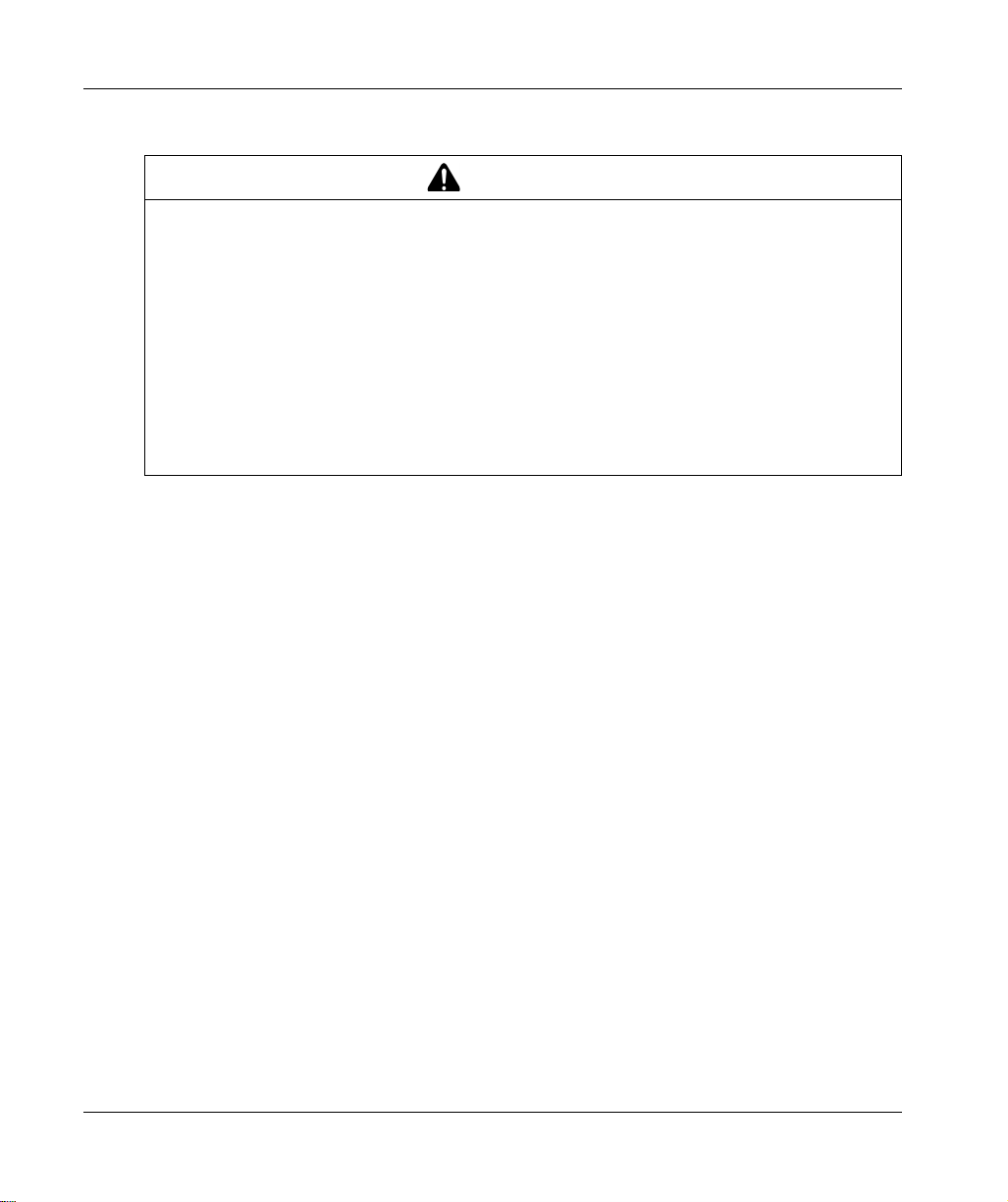

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Disconnect all power from all equipment including connected devices prior to removing any

covers or doors, or installing or removing any accessories, hardware, cables, or wires except

under the specific conditions specified in the appropriate hardware guide for this equipment.

Always use a properly rated voltage sensing device to confirm the power off where and when

indicated.

Replace and secure all covers, accessories, hardware, cables, and wires and confirm that a

proper ground connection exists before applying power to the equipment.

Use only the specified voltage when operating this equipment and any associated products.

Failure to follow these instructions will result in death or serious injury.

Operating Environment

UNINTENDED EQUIPMENT OPERATION

Install and operate this equipment according to the environmental conditions described in the

operating limits.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Physical Description

DANGER

WARNING

EIO0000001177 01/2020 27

Physical Description

Installation Considerations

UNINTENDED EQUIPMENT OPERATION

Use appropriate safety interlocks where personnel and/or equipment hazards exist.

Install and operate this equipment in an enclosure appropriately rated for its intended

environment.

Do not use this equipment in safety critical and hoisting machine functions due to:

No permanent communication

No acknowledge of the message from the receiver to the transmitters.

Do not disassemble, repair, or modify this equipment.

Do not connect any wiring to reserved, unused connections, or to connections designated as

not connected (N.C.).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

28

EIO0000001177 01/2020

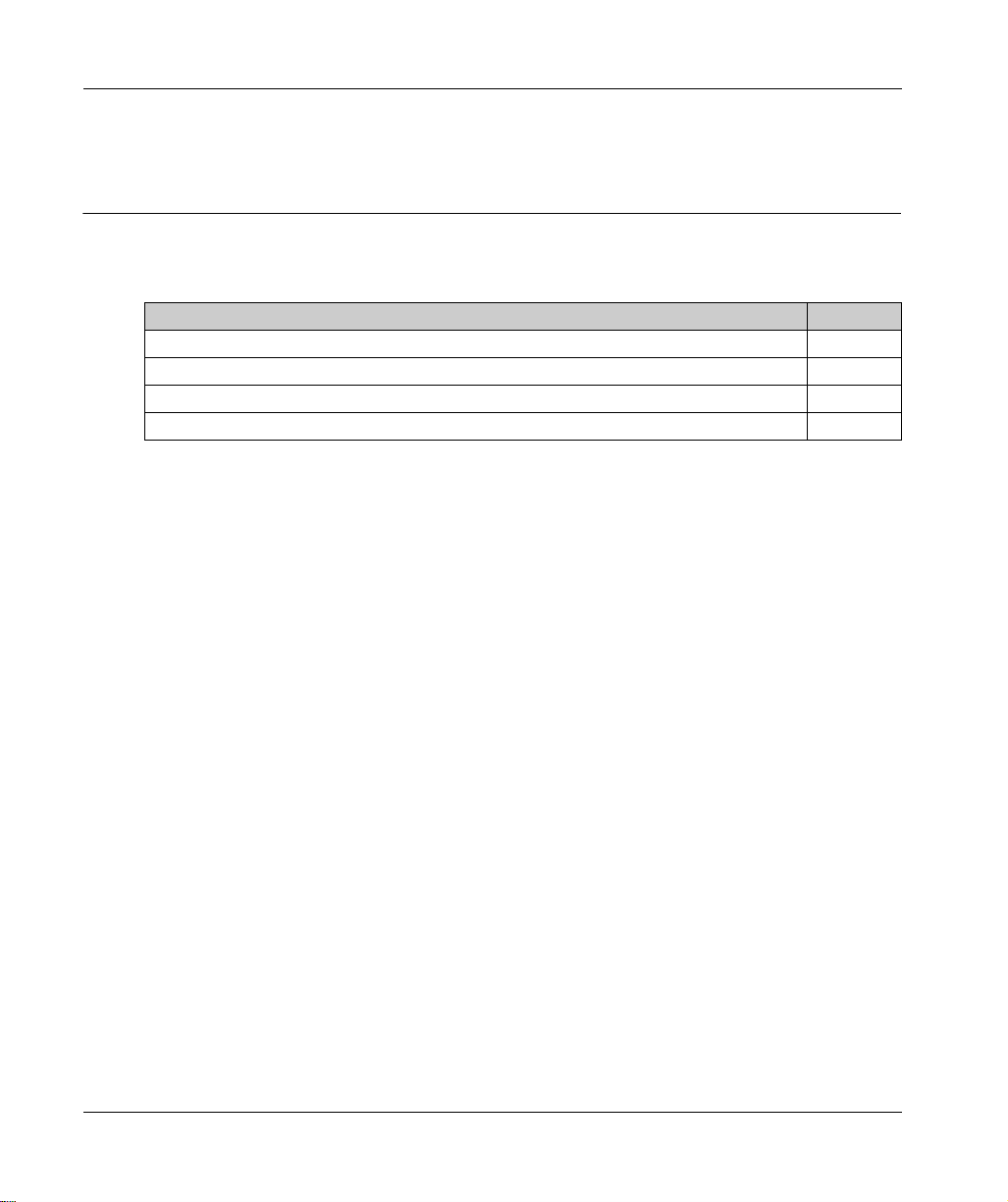

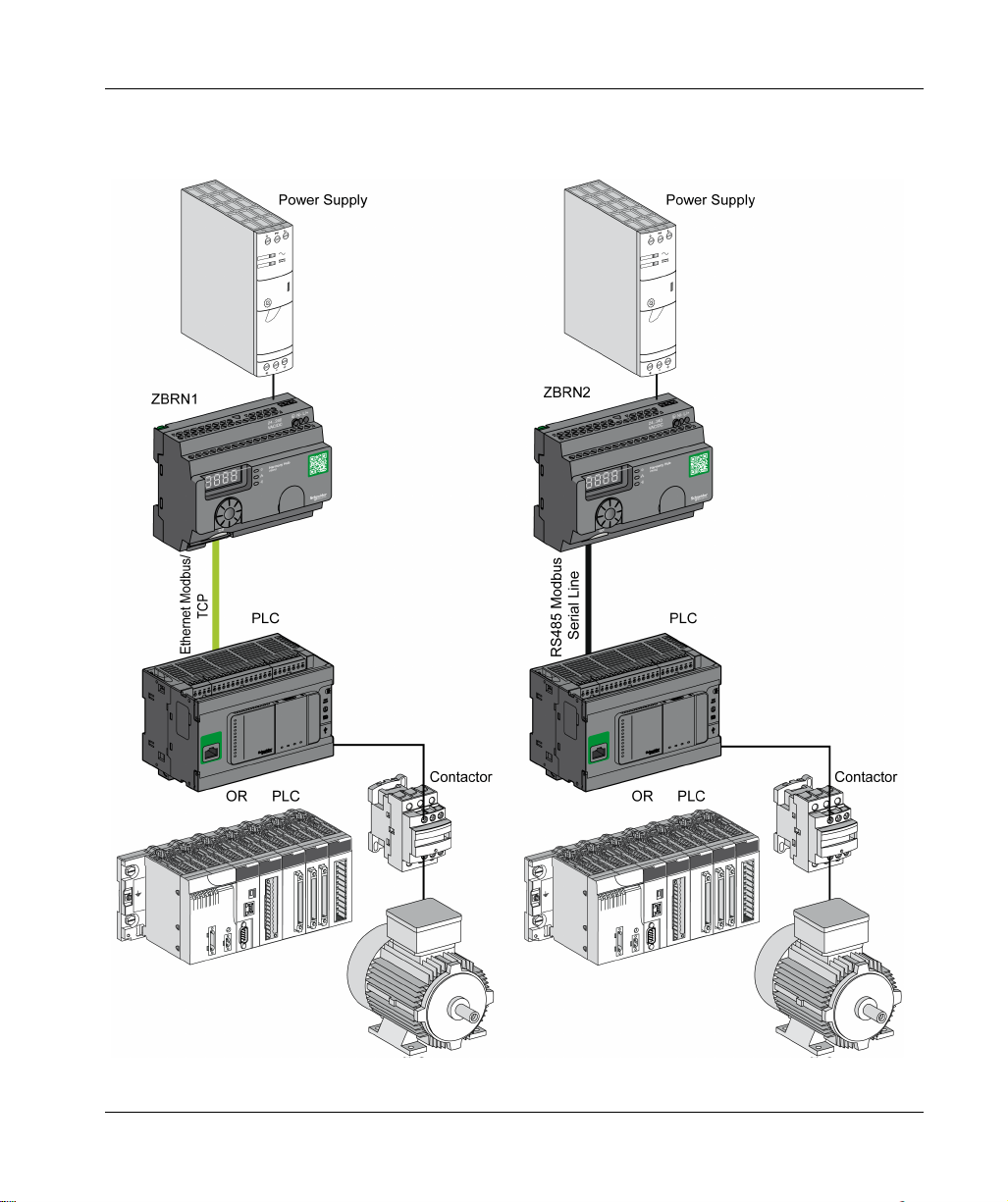

Architecture

The following figures shows the general principle of Harmony Hub architecture:

Physical Description

EIO0000001177 01/2020 29

Physical Description

NOTE:

The previous figure is not exhaustive. It shows only the general principle of the architecture.

Refer to the specifications section

Harmony Hubs.

Refer to the user manual of your associated products for detailed wiring diagrams and

instructions.

Harmony Hub can be connected to any PLC supporting the network buses listed in this

document.

Connection Requirements

Power Supply Connection

24...240 Vac/Vdc

Network connection

RS-485 Modbus serial line network

Ethernet Modbus TCP network

(see page 38)

for detailed wiring diagram and instructions for

30

EIO0000001177 01/2020

Maximum Distances

The following figure shows the maximum distance between the transmitters and the

ZBRN1/ZBRN2 Harmony Hubs:

Physical Description

(*) The application environment can modify the typical values.

(**) Free field (unobstructed and without electromagnetic perturbations).

The level of signal attenuation depends on the material through which the signal passes:

Material Attenuation

Glass window

Plaster wall

Brick wall

Concrete wall

10...20 %

30...45 %

60 %

70...80 %

(*) Values for indication purpose only. Actual values depend on the thickness and nature of the material.

EIO0000001177 01/2020 31

(*)

(*)

(*)

(*)

Physical Description

Material Attenuation

Metal structure

(*) Values for indication purpose only. Actual values depend on the thickness and nature of the material.

NOTE: You can add ZBRA1 or ZBRA2 antenna or both to increase the range.

The reception is reduced if Harmony Hub is placed in a metal cabinet.

For further information on the use of ZBRA1 and ZBRA2 antennas, refer to the Radio chapter

(seepage149)

Impact of the radio performances in the environment:

For any environment, the radio performances are subjected to be instable due to perturbations

made by any kind of industrial machines, processes, or electronic devices.

As a consequence at any time, it is possible that the radio frames sent by a transmitter will not

be caught by the receiver during the perturbation.

With Harmony XB5R offer, only one radio frame is sent to the receiver, there is no permanent

radio communication. This reason prevents the use of Harmony XB5R offer for applications

where permanent reliability and/or permanent precisions are needed.

(*)

60...100 %

.

32

EIO0000001177 01/2020

Mechanical Installation

Mounted on DIN Rail

Harmony Hub must be installed on DIN rails complying with EN/IEC 60715.

To install Harmony Hub, use a tool to press down the D lock for inserting the DIN rail.

The following figure shows the position of Harmony Hub on the DIN rail:

Physical Description

Mounted on a Grid or Plate

Harmony Hub can be installed on a grid or a plate.

The following steps explain how to install the module:

Step Action

1 Pull out the panel mounting hooks.

2 Mount Harmony Hub on the grid or plate using the screws as shown in the

following figure.

EIO0000001177 01/2020 33

Physical Description

34

EIO0000001177 01/2020

Environmental Features

Specifications

The following table shows the general environmental specifications:

Characteristics Specifications

Standards Conformity to

standards

Conformity to

standards

Conformity to

standards

Radio

certifications

Agencies

UL USA UL508, 17th edition

CSA Canada CSA C22.2, No. 142-M2000

C-Tick Australia –

GOST Russia –

ANATEL Brazil –

FCC USA –

SRRC China –

CCC China –

MIC Japan –

RSS Canada –

Ambient operating

temperature

Storage temperature –40...+70 °C (–40...+158 °F)

Relative humidity 95% RH at 55 °C (131 °F)

Degree of pollution 2 (IEC60664-1)

Degree of protection IP20

Shock resistance Half sine wave acceleration: 11 ms 30 gn (IEC 60068-2 27)

Resistance to vibration ±3.5 mm (±0.13 in.): 5...8.14 Hz

Physical Description

R&TTE 1999/5/EC, LVD 2006/95/EC, EMC2004/108/EC

EN/IEC 60947-1, EN/IEC 60947-5-1, EN/IEC60950-1, IEC61131-2, EN

300440-2, EN300489-3, EN300328, EN62311

UL 508 (USA), CSA C22-2 n° 14 (Canada), CCC (China), Gost (Russia)

FCC (USA), CSA, RSS (Canada), C-Tick (Australia), ANATEL (Brazil),

SRRC (China), MIC (Japan)

–25...+55 °C (–13...+131 °F)

1 gn: 8.14...150 Hz when mounted on a panel

2 gn: 8.45...150 Hz when mounted on a DIN rail (IEC 60068-2-6)

EIO0000001177 01/2020 35

Physical Description

Characteristics Specifications

Altitude requirement Operation: 0...2000 m (6561.66 ft)

Storage: 0...3000 m (9842.49 ft)

Only used at altitude not exceeding 2000 m (6561.66 ft).

Only used in non-tropical climate regions.

36

EIO0000001177 01/2020

Housing

Clearances and Mounting Position

(1) To enhance the signal reception, observe the above positioning.

(2) In a metal cabinet, the optimum place for Harmony Hub is on the top. This position avoids obstacles and

enhances the signal reception.

Physical Description

EIO0000001177 01/2020 37

Physical Description

Specifications

Section 2.3

Specifications

Electrical Specifications

Power Supply Specifications

Harmony Hub complies with the following power requirements:

Electrical Features Description

Rated voltage 24...240 Vac 24...240 Vdc

Voltage range 21...264 Vac 21...264 Vdc

Rated frequency 50/60 Hz –

Frequency range 47...63 Hz –

Under voltage protection No

Terminal blocks 3-pin terminal with a pitch of 7.62 mm (0.3 in.) on the output terminal block

Immunity to short interruptions

(Conforming to IEC 61000-4-

11)

Dielectric strength with others 3000 Vac / 4250 Vdc (input-output)

Short-circuit protection Yes (internal fuse 2 A, 250 V)

* PE = protective earth ground

AC Power Supply DC Power Supply

10 ms

1500 Vac / 2150 Vdc (input-PE*)

Power Supply Connections

You can connect the power supply to any common supply from 24...240 Vac/Vdc.

HAZARD OF ELECTRIC SHOCK, EXPLOSION OR ARC FLASH

Comply with the wiring diagram shown immediately after this message.

Failure to follow these instructions will result in death or serious injury.

38

DANGER

EIO0000001177 01/2020

Physical Description

The following table shows the recommended wire sizes for the L/+ and N/- terminals:

The following table shows the recommended wire sizes for the PE terminal (protective earth

ground):

The following table shows the recommend torque for the 3 terminals:

EIO0000001177 01/2020 39

Physical Description

UNINTENDED EQUIPMENT OPERATION

For the protective earth ground (PE) wiring, use a cable not longer than 300 mm (11.8 in.).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

The following table shows the input power consumption:

Reference Input Power

ZBRN1 9 W

ZBRN2 3.3 W

UNINTENDED EQUIPMENT OPERATION

Supply this product with a power line protected by a circuit breaker rated 16 A maximum and

a ground fault circuit breaker.

A readily accessible disconnect device shall be incorporated external to the equipment.

Install this product in an electrical cabinet and lock the cabinet using a key.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

WARNING

40

EIO0000001177 01/2020

Data Management

Section 2.4

Data Management

What Is in This Section?

This section contains the following topics:

Compatibility Rules 42

Transmitter Types 43

Monostable Input 45

Set/Reset 46

Receiver Types 47

Physical Description

Topic Page

EIO0000001177 01/2020 41

Physical Description

Compatibility Rules

Transmitter Compatibility

ZBRT2 transmitter is compatible with the following only:

ZBRRA, ZBRRC, and ZBRRD receivers with firmware version 2.0 and higher

ZBRA1 relay antenna with firmware version 2.0 and higher

ZBRN1 /ZBRN2 Harmony Hubs with firmware version higher than 1.2

ZBRN• Harmony Hubs Compatibility

ZBRN• Harmony Hub transmitters are compatible with the following only:

ZBRRH receiver with firmware version 1.03 and higher

42

EIO0000001177 01/2020

Transmitter Types

ZBRT1 and ZBRTP Transmitters

The radio message is sent when the button is pressed, signaled by a click. If the button is held

down, the message is not transmitted continuously. The message is not sent when the button is

released.

To avoid any conflict of multiple transmission from different transmitters, a minimum of 10 ms is

required between each radio transmission.

Physical Description

ZBRT1 is used for applications where single pulse is required (for example, remote start of

machine and reset after machine fault detection).

EIO0000001177 01/2020 43

Physical Description

ZBRT2 Transmitter

The radio message is sent when the button is pressed, signaled by a click.

If the button is held down, the message is not transmitted continuously.

A second radio message is sent when the button is released. This message is not transmitted

continuously. It is transmitted once, at the release of the push-button.

This transmitter is used only for the set/reset output mode.

44

EIO0000001177 01/2020

Monostable Input

Principle

The battery-less transmitter is equipped with a dynamo generator that converts mechanical energy

(produced by pressing the push-button) into electrical energy. A radio-coded message with a

unique ID code is sent in single pulse form.

The radio signal is transmitted when the push-button is pressed. This action is indicated by a click

in the example shown below. If the button is held, the signal is not transmitted continuously. No

signal is sent when the button is released.

The corresponding input channel of Harmony Hub stays active, depending on the input holding

time range, from 100 ms...1 s.

The input holding time is set for all the input channels.

Example

The following figure shows an example of a monostable channel with the input holding time of

500 ms:

Physical Description

EIO0000001177 01/2020 45

Physical Description

Set/Reset

Push-button Set/Reset

NOTE:

1. Release and push again to resynchronize

2. Push and release again to resynchronize

46

EIO0000001177 01/2020

Receiver Types

ZBRN Transmitter / ZBRRH Receiver

Harmony Hub can communicate with up to 60 ZBRRH receivers

Physical Description

EIO0000001177 01/2020 47

Physical Description

48

EIO0000001177 01/2020

Harmony Hub

First Installation

EIO0000001177 01/2020

First Installation

Chapter 3

First Installation

What Is in This Chapter?

This chapter contains the following topics:

First Start Up 50

Configuration 52

Pairing Procedures 54

Topic Page

EIO0000001177 01/2020 49

First Installation

First Start Up

Overview

Follow this procedure when installing and starting up Harmony Hub.

ZBRN1 Startup Procedure

The following table shows the startup procedure for ZBRN1 Harmony Hub:

Step Action Comments

1 Unpack your Harmony Hub (ZBRN1), the

Ethernet communication Module (ZBRCETH),

and check the contents of the packages.

2 Insert the communication module in

Harmony Hub.

3 Choose an appropriate cabinet. Refer to Mechanical Installation

4 Install Harmony Hub on a DIN rail, a grid, or a

plate.

5 If needed, connect the external antenna to

Harmony Hub.

6 Ensure that upstream power is off. Connect the

external 24...240 Vac/Vdc power supply.

7 Turn on the power. –

8 Configure Harmony Hub through the user

interface.

9 Connect Ethernet communication buses and

network.

10 Verify all the connections. –

11 Run the application. –

Refer to package content

Refer to ZBRCETH Communication Module

(see page 62)

.

(see page 20)

.

(see page 33)

Refer to Mounting Tips for ZBRA2 External

Antenna

Refer to Power Supply Connections

(see page 38)

Refer to User Interface

Refer to the Ethernet Cable

.

(see page 151)

.

.

(see page 167)

(see page 71)

.

.

NOTE: If you want to access to call to action features

firmware update (3.29 and higher)

ZBRN2 Startup Procedure

The following table shows the startup procedure for the ZBRN2 Harmony Hub:

Step Action Comments

1 Unpack your Harmony Hub (ZBRN2) and check

the contents of the package.

50

(seepage192)

(see page 18)

.

Refer to package content

, you have to proceed to the

(see page 21)

EIO0000001177 01/2020

.

Step Action Comments

2 Choose an appropriate cabinet. Refer to Mechanical Installation

3 Install Harmony Hub on a DIN rail, a grid, or a

plate.

4 If needed, connect the external antenna to

Harmony Hub.

5 Ensure that upstream power is off. Connect the

external 24...240 Vac/Vdc power supply.

6 Turn on the power. –

7 Configure Harmony Hub through the user

interface.

8 Connect the serial line communication buses and

network.

9 Connect line termination devices to Harmony Hub

(optional).

10 Verify all the connections. –

11 Run the application. –

(see page 33)

Refer to Mounting Tips for the ZBRA2

External Antenna

Refer to Power Supply Connections

(see page 38)

Refer to User Interface

Refer to Modbus Serial Line Cables

(see page 82)

Refer to Modbus Serial Line Cabling

(see page 78)

.

(see page 151)

.

(see page 167)

.

.

First Installation

.

.

NOTE: If you want to access to call to action features

firmware update (3.29 and higher)

EIO0000001177 01/2020 51

(seepage192)

(see page 18)

.

, you have to proceed to the

First Installation

Configuration

Mandatory Settings

Configure the following 2 types of parameters:

Communication protocol

Wireless devices association

Configure Harmony Hubs through the user interface. Refer to Configuration Menu

Transmitters Association Definition

For each input channel of Harmony Hub, the following states are possible:

Empty: No transmitter associated with the input.

Associated off-line: The input parameters are configured but no radio exchanges have been

performed.

Associated on-line: The input parameters are configured and radio exchanges have been

performed.

HMI display for the input states:

I02 means that the input 2 is free

I-02 means that the input 2 is associated off-line

I_02 means that the input 2 is associated on-line

ZigBee Over the Air

The transmitter may be:

Static: Data are only sent by the transmitter to Harmony Hub during pairing.

There is no encryption key or the encryption key is hard-coded in the transmitter and sent to

Harmony Hub.

OTA (Over the Air): The transmitter and Harmony Hub exchange data while pairing.

The encryption key is generated by Harmony Hub and sent to the transmitter.

(see page 167)

.

Supported Transmitter Types

The following transmitter types are supported:

Type

number

1

52

HMI label Related transmitters

So

Push buttons, limit switches, …

EIO0000001177 01/2020

First Installation

Type

number

Pairing Modes

Depending on the type of transmitter associated, three pairing modes are available:

Menu Description Compatible

Id

t

tId

(1) The pairing request must be received by Harmony Hub within 2 minutes after the pairing mode has

been selected.

HMI label Related transmitters

2

3

4

5

6

E3

th

CL

Et

S1

Reserved

Reserved

Humidity and thermal monitoring sensors

Thermal monitoring sensors

Generic ZigBee, PowerTag sensors

Transmitter Types

transmitters

Manual pairing. The ID of the transmitter is

set manually.

Teach pairing

(1)

The first transmitter emitting a pairing

request is paired to this input.

Teach pairing with ID

(1)

Only the transmitter emitting a pairing

request with the correct ID is paired to this

input.

Static transmitters

So

S1

OTA transmitters

So

CL

Et

S1

OTA transmitters

So

CL

Et

S1

Transmitters type

1

6

Transmitters type

1

4

5

6

Transmitters type

1

4

5

6

EIO0000001177 01/2020 53

First Installation

Pairing Procedures

Overview

The steps to follow to add and pair a transmitter to an input of Harmony Hub depends on the type

of transmitter to add.

In the following examples, consider that four inputs are already configured and that the new

transmitter is paired to the free input 2.

Procedure examples:

Adding a Type 1 Transmitter Through the User Interface

Adding a Type 4 Transmitter Through the User Interface

Adding a Type 5 Transmitter Through the User Interface

Adding a Type 6 Transmitter Through the User Interface

Teach an Associated Off-line Transmitter Through the User Interface

Adding a ZBRRH Receiver Through the User Interface

Refer to Supported Transmitter Types

Adding a Type 1 Transmitter Through the User Interface

NOTE: Type 1 transmitters can be paired with several Harmony Hubs.

Steps to follow to add a type 1 transmitter using the Id pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.So: push-buttons or limit switches

3 Select the pairing mode. Id: Manual pairing

4 Enter the first two digits of the transmitter ID. -

5 Enter the last two digits of the transmitter ID. I_02 is displayed (associated on-line)

(seepage52)

(see page 54)

(see page 55)

(see page 56)

(see page 57)

(see page 58)

(see page 59)

.

rdY > ConF > In.04 > I02

54

Steps to follow to add a type 1 transmitter using the t pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.So: push-buttons or limit switches

3 Select the pairing mode. t: Teach pairing

4 Harmony Hub is waiting for a paring request. t is blinking

rdY > ConF > In.04 > I02

If the commissioning request is not received within

2 minutes I02 is displayed, the input is free.

EIO0000001177 01/2020

Step Action Comment

5 Press the transmitter button 3 times. t1 is displayed at first press

t2 is displayed at second press

t3 is displayed quickly at third press

I_02 is displayed (associated on-line)

Steps to follow to add a type 1 transmitter using the tId pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.So: push-buttons or limit switches

3 Select the pairing mode. tId: Teach pairing with ID

4 Enter the first two digits of the transmitter ID. -

5 Enter the last two digits of the transmitter ID. -

6 Harmony Hub is waiting for a paring request. t is blinking

7 Press the transmitter button once. I_02 is displayed (associated on-line)

rdY > ConF > In.04 > I02

If the commissioning request is not received within

2minutes, I-02 is displayed (associated off-

line), refer to Teach an Associated Off-line

Transmitter

(see page 58)

.

First Installation

Adding a Type 4 Transmitter Through the User Interface

NOTE: Type 4 transmitters can be paired with only one Harmony Hub.

The transmitter must be unpaired before to pair it to Harmony Hub.

To unpair the humidity and thermal monitoring sensor, press and maintain the transmitter button

until its embedded led flashes three times, and wait 15 s before to start the new pairing.

Steps to follow to add a type 4 transmitter using the t Id pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.CL: Humidity and thermal monitoring

3 Select the pairing mode. tId: Teach pairing with ID

4 Enter the first two digits of the transmitter ID. -

5 Enter the last two digits of the transmitter ID. -

EIO0000001177 01/2020 55

rdY > ConF > In.04 > I02

sensors

First Installation

Step Action Comment

6 Harmony Hub is waiting for a paring request. t is blinking

7 Press and maintain the transmitter button

until its embedded led flashes two times to

set it on commissioning mode

Adding a Type 5 Transmitter Through the User Interface

NOTE: Type 5 transmitters can be paired with only one Harmony Hub. The transmitter must be

unpaired before to pair it to Harmony Hub.

To unpair the thermal monitoring sensor, press and maintain the transmitter button until its

embedded led flashes three times, and wait 15 s before to start the new pairing.

Steps to follow to add a type 5 transmitter using the t Id pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.Et: Thermal monitoring sensors

3 Select the pairing mode. tId: Teach pairing with ID

4 Enter the first two digits of the transmitter ID. -

5 Enter the last two digits of the transmitter ID. -

6 Harmony Hub is waiting for a paring request. t is blinking

7 Press and maintain the transmitter button

until its embedded led flashes two times to

set it on commissioning mode

If the commissioning request is not received within

2 minutes, I-02 is displayed (associated off-

line), refer to Teach an Associated Off-line

Transmitter

t1 is displayed at first frame received

t2 is displayed at second frame received

t3 is displayed quickly at third frame received

I_02 is displayed (associated on-line)

rdY > ConF > In.04 > I02

If the commissioning request is not received within

2 minutes, I-02 is displayed (associated off-

line), refer to Teach an Associated Off-line

Transmitter

t1 is displayed at first frame received

t2 is displayed at second frame received

t3 is displayed quickly at third frame received

I_02 is displayed (associated on-line)

(see page 58)

(see page 58)

.

.

56

EIO0000001177 01/2020

Adding a Type 6 Transmitter Through the User Interface

NOTE: Type 6 transmitters can be paired with only one Harmony Hub. A type 6 transmitter must

be unpaired before to pair it to Harmony Hub. For more detailsabout type 6 transmitter unpairing

procedure, refer to the transmitter documentation.

Steps to follow to add a type 6 transmitter using the t Id pairing mode:

Step Action Comment

1 Go on a free input of Harmony Hub (input 2

in this example).

2 Select the type of transmitter. tY.S1: Generic transmitter, PowerTag

3 Select the pairing mode. tId: Teach pairing with ID

4 Enter the first two digits of the transmitter ID. -

5 Enter the last two digits of the transmitter ID. -

6 Harmony Hub is waiting for a paring request. t is blinking

7 The self-powered PowerTag transmitter

sends frame periodically.

First Installation

rdY > ConF > In.04 >I02

If the commissioning request is not received within

2minutes, I-02 is displayed (associated off-

line), refer to Teach an Associated Off-line

Transmitter

t1 is displayed at first frame received

t2 is displayed at second frame received

t3 is displayed quickly at third frame received

I_02 is displayed (associated on-line)

(see page 58)

.

EIO0000001177 01/2020 57

First Installation

Teach an Associated Off-line Transmitter Through the User Interface

A transmitter is associated off-line if the transmitter ID is already configured but no radio exchanges

have been performed.

Steps to follow to teach a transmitter that is associated off-line:

Step Action Comment

1 Go on an associated off-line input of

Harmony Hub (input 2 in this example).

2 Select the pairing mode. t: Teach pairing

3 Harmony Hub is waiting for a paring request. t is blinking

4 According to the transmitter type:

Type 1: Press the transmitter button 3

times.

Type4: Press and maintain the

transmitter button until its embedded led

flashes two times to set it on

commissioning mode.

Type5: Press and maintain the

transmitter button until its embedded led

flashes two times to set it on

commissioning mode.

Type 6: The self-powered PowerTag

transmitter sends frame periodically.

rdY > ConF > In.04 > I-02

If the commissioning request is not received within

2 minutes, I-02 is displayed (associated off-

line).

t1 is displayed at first frame received

t2 is displayed at second frame received

t3 is displayed quickly at third frame received

I_02 is displayed (associated on-line)

58

EIO0000001177 01/2020

Adding a ZBRRH Receiver Through the User Interface

As a prerequisite, the Harmony Hub must have a MAC/ID. For more details, refer to Factory Mode

(seepage182)

.

Steps to follow to teach an Output (ZBRRH receiver) through the user interface:

Step Action Comment

1 On the ZBRRH:

Start Teach mode

2 On the Harmony Hub:

Go on Output configuration menu (input 2 in

this example)

3 Select the pairing mode. t > YES

4 Harmony Hub sends Pairing request -

5 On the ZBRRH:

ZBRRH is commissioned

ZBRRH Receiver turns-on one time (around 1 second) when commissioning and decommissioning with the Harmony Hub.

WARNING

UNINTENDED EQUIPMENT OPERATION

Before performing the ZBRRH commissioning or decommissioning with the Harmony Hub,

consider the effect on all equipment connected to the ZBRRH.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

First Installation

Select button Choice during 3 s.

Then led 1 to 4 blink.

Press button Ok once

rdY > ConF > OU.04 > OU 02

t: Teach pairing

The Q1…Q4 outputs are active during 1 s after the

teaching procedure.

For a graphical explanation, refer to the teach ZBRRH procedure

EIO0000001177 01/2020 59

(see page 93)

.

First Installation

60

EIO0000001177 01/2020

Harmony Hub

Ethernet Communicati on

EIO0000001177 01/2020

ZBRN1 Ethernet Communication

Chapter 4

ZBRN1 Ethernet Communication

What Is in This Chapter?

This chapter contains the following topics:

Communication on The Ethernet Network 62

Addressing Modes 66

Communication and Status Indicator 68

Modbus TCP Settings and Supported Functions 70

Ethernet Cable 71

Topic Page

EIO0000001177 01/2020 61

Ethernet Communication

Communication on The Ethernet Network

Introduction

Ethernet is a widely used, low-cost technology for local area networks. This technology is used to

exchange data between several devices connected together on a network.

Network Connection

1 ZBRN1 Harmony Hub associated with ZBRCETH communication module

2 iPC

3 Pushbutton

4 Limit switch

5 Energy sensor

6 Humidity and thermal sensor

7 Thermal sensor

ZBRCETH Communication Module

ZBRCETH is a communication module that supports Ethernet Modbus TCP protocol.

The following procedure describes the insertion of the communication module:

Step Action

1 Disconnect all power from the ZBRN1 Harmony Hub.

62

EIO0000001177 01/2020

Step Action

2 Place the module in ZBRN1 Harmony Hub.

Ethernet Communication

1 ZBRN1 Harmony Hub

2 ZBRCETH communication module

3 Press firmly into place.

EIO0000001177 01/2020 63

Ethernet Communication

The following procedure describes the removal of the communication module:

Step Action

1 Disconnect all power from the ZBRN1 Harmony Hub.

2 Push down the release tab.

3 Pull out the module.

64

ZBRCETH offers one Ethernet communication port equipped with two RJ45 plugs. It enables daisy

chain wiring between devices without using a switch.

EIO0000001177 01/2020

The following table shows the specifications of the communication module:

Feature Specifications

Plug Two RJ45 connectors

Driver

Type of cable Shielded

Topology Daisy chain

Automatic polarity correction Yes

RJ45 Layout Description

ZBRCETH communication module has two RJ45 connectors for Ethernet connectivity as shown in

the following figure:

Ethernet Communication

10/100 MB/s

Auto negotiation

Half/Full duplex

The following table shows the pin details of the RJ45 connector:

RJ45 pins Signal Description

1 TX+ Transmission signal

2 TX- Transmission signal

3 RX+ Reception signal

4 Unused –

5 Unused –

6 RX- Reception signal

7 Unused –

8 Unused –

EIO0000001177 01/2020 65

Ethernet Communication

Addressing Modes

Address Assignment

Assign the IP address to Harmony Hub using one of the following methods:

By a DHCP (dynamic host control protocol) server.

By a BOOTP (bootstrap protocol) server (BOOTP zone).

Using the IP address stored in the flash memory.

NOTE: If Harmony Hub detects a duplicate address, it does not start until a unique address is

assigned to the transmitter.

Address Assignment by a DHCP Server

The IP address assigned by a DHCP server is stored in a table of DHCP server.

Step Action Comments

1 Select DHCP mode from the Ethernet menu

using the jog dial on Harmony Hub.

2 Select the DHCP value between 0–159 using

the jog dial.

3 Wait 10 s. When the display stops flashing after 10 s,

For further information, refer to the IP setting

menu

(see page 179)

This action defines the device name.

Harmony Hub triggers a request for an IP

address.

.

Address Assignment by BOOTP Server

The BOOTP server contains a MAC address table for the device connected to network with its IP

address. The following steps explain how to assign the address to Harmony Hub from the BOOTP

server:

Step Action Comments

1 Select the BOOTP mode from the Ethernet

menu using the jog dial on Harmony Hub.

2 Wait 10 s. When the display stops flashing after 10 s,

66

For further information, refer to the IP setting

menu

(see page 179)

Harmony Hub triggers a request for an IP

address.

.

EIO0000001177 01/2020

Assignment of Stored IP Addresses

Harmony Hub uses the IP address stored in its flash memory. The following steps explain how to

assign the address to Harmony Hub from the flash memory:

Step Action Comments

1 Select the Static IP mode from the Ethernet

menu using the jog dial on Harmony Hub.

2 Wait 10 s. When the display stops flashing after 10 s,

Modbus Unit ID Parameter

Use the PLC with the following UIDs to access the device communication details:

Use UID 247 to access the Ethernet diagnostics information (ZBRCETH communication

module server).

Use UID to access the Modbus TCP registers, such as input registers and holding time (ZBRN1

Harmony Hub server):

For firmware version ≤ V1.5, use UID 248 or 255 to access the Modbus TCP registers

For firmware version = V3.26, use UID 248 to access the Modbus TCP registers

For firmware version ≥ V3.31, use UID 248 or 255 to access the Modbus TCP registers

Ethernet Communication

Harmony Hub uses the IP address stored in

the flash memory. For further information, refer

to the IP setting menu

Harmony Hub triggers a request for an IP

address.

(see page 179)

.

EIO0000001177 01/2020 67

Ethernet Communication

Communication and Status Indicator

Status LED on The ZBRN1 Harmony Hub

1 Power LED

2 Communication LED

3 Radio signal strength LED

The yellow Ethernet communication LED shows the following status:

On/flashing: Data is being exchanged (depends on the quantity of information).

Off: No data is being exchanged.

Status LED on The ZBRCETH Communication Module

The following table shows the Ethernet Modbus TCP LED status:

Item Name LED State Description Module State

1 Link/Activity port 1 Solid green Ethernet link is present at

100 Mbit/s.

Flashing green Ethernet link is present with

Ethernet traffic at

100 Mbit/s.

Solid yellow Ethernet link is present at

10 Mbit/s.

Flashing yellow Ethernet link is present with

Ethernet traffic at 10 Mbit/s.

68

The module is detecting an

Ethernet link.

The module is detecting Ethernet

traffic.

The module is detecting an

Ethernet link.

The module is detecting Ethernet

traffic.

EIO0000001177 01/2020

Ethernet Communication

Item Name LED State Description Module State

2 Module status Green On. The module is turned on.

Off. The module is off.

3 Network status Red Harmony Hub is being

The module is being turned on.

turned on.

Solid green The network is operating

The module is operating normally.

normally.

4 flashes A duplicate IP condition

The module is offline.

exists.

5 flashes The module is attempting to

get an IP configuration from

BootP server.

6 flashes The operation is normal with

default IP addressing

settings.

4 Link/Activity port 2 Solid green Ethernet link is present at

100 Mbit/s.

Flashing green Ethernet link is present with

Ethernet traffic at

The module is sending

BOOTP/DHCP requests to a

BootP server and awaiting a reply.

The BootP request timed out. The

module applies the default IP

address (85.16.x.y).

The module is detecting an

Ethernet link.

The module is detecting Ethernet

traffic.

100 Mbit/s.

Solid yellow Ethernet link is present at

10 Mbit/s.

Flashing yellow Ethernet link is present with

Ethernet traffic at 10 Mbit/s.

The module is detecting an

Ethernet link.

The module is detecting Ethernet

traffic.

EIO0000001177 01/2020 69

Ethernet Communication

Modbus TCP Settings and Supported Functions

For further information on Modbus TCP settings, refer to the Modbus Settings and Supported

Functions

(seepage80)

.

70

EIO0000001177 01/2020

Ethernet Cable

Ethernet Cable for ZBRN1 Harmony Hub

The following figure shows the Ethernet cable used to connect to the terminal equipment:

Item Description Reference Length

1 Ethernet cable (2 x RJ45

connectors, one at each

end)

Ethernet Communication

490NTW00002U 2 m (6.6 ft)

490NTW00005U 5 m (16.4 ft)

490NTW00012U 12 m (39.4 ft)

EIO0000001177 01/2020 71

Ethernet Communication

72

EIO0000001177 01/2020

Harmony Hub

Modbus Serial Line Communication

EIO0000001177 01/2020

ZBRN2 Modbus Serial Line Communication

Chapter 5

ZBRN2 Modbus Serial Line Communication

Purpose

This chapter provides an overview of the Modbus layout description, communication and status

indicator, line termination mode, settings, and the supported functions.

For more details, refer to Modbus Serial Modbus Serial Link for Machines documentation

(seepage10)

What Is in This Chapter?

This chapter contains the following topics:

Communication on The Modbus Network 74

Communication and Status Indicator 77

Modbus Serial Line Wiring 78

Modbus Settings and Supported Functions 80

Modbus Serial Line Cables 82

.

Topic Page

EIO0000001177 01/2020 73

Modbus Serial Line Communication

Communication on The Modbus Network

Introduction

The Modbus protocol is a master/slave protocol. It allows a single master to request responses

from the slaves, or to act based on the request. The master can address individual slaves, or can

send a broadcast message to all slaves. The slaves return a message (response) to requests

addressed to them individually. The slaves do not return responses to broadcast requests from the

master.

UNINTENDED EQUIPMENT OPERATION

Do not use more than one master on the Modbus network. Unintended I/O behavior can result if

more than one master is able to communicate on the network at the same time.

Failure to follow these instructions can result in death, serious injury, or equipment damage.

Network Connection

WARNING

74

1 PLC as master

2 Modbus Advantys OTB network interface module

3 ZBRN2 Harmony Hub

4 ATV12 drive

5 Modbus serial line

EIO0000001177 01/2020

Modbus Serial Ports

The following figure shows the serial line connectors in ZBRN2 :

1 Serial line connectors

ZBRN2 offers 1 Modbus serial line communication port equipped with 2 RJ45 plugs. It enables

wiring between the devices without using a hub.

The following table shows the specifications of ZBRN2 :

Features Specification

Function Modbus slave and Modbus RTU

Plug 2 RJ45 connectors

Isolated Yes

Maximum cable length 1000 m (3280.83 ft)

Polarization No

Supported baud rates Auto/1200/2400/4800/19200/38400/115200

Parity Even/Odd/No/Auto

Stop bit 1 bit (even and odd)

Modbus Serial Line Communication

2 bits (no parity)

EIO0000001177 01/2020 75

Modbus Serial Line Communication

RJ45 Layout Description

Modbus serial port is an RS-485, 2-wire and common Modbus serial line using a RJ45 connector.

The following figure shows the layout of RJ45 connector:

RJ45 pin Signal Description

1 Unused –

2 Unused –

3 Unused –

4 D1 Transmission signal.

5 D0 Reception signal.

6 Unused Reserved.

7 Unused Reserved (5...24 Vdc).

8 Common Common of signal and supply.

76

EIO0000001177 01/2020

Communication and Status Indicator

Modbus Communication and Status LED

1 Power LED

2 Communication LED

3 Radio signal strength LED

The yellow Modbus communication LED shows the following status:

On/flashing: Data is being exchanged (depends on the quantity of information).

Off: No data is being exchanged.

Modbus Serial Line Communication

EIO0000001177 01/2020 77

Modbus Serial Line Communication

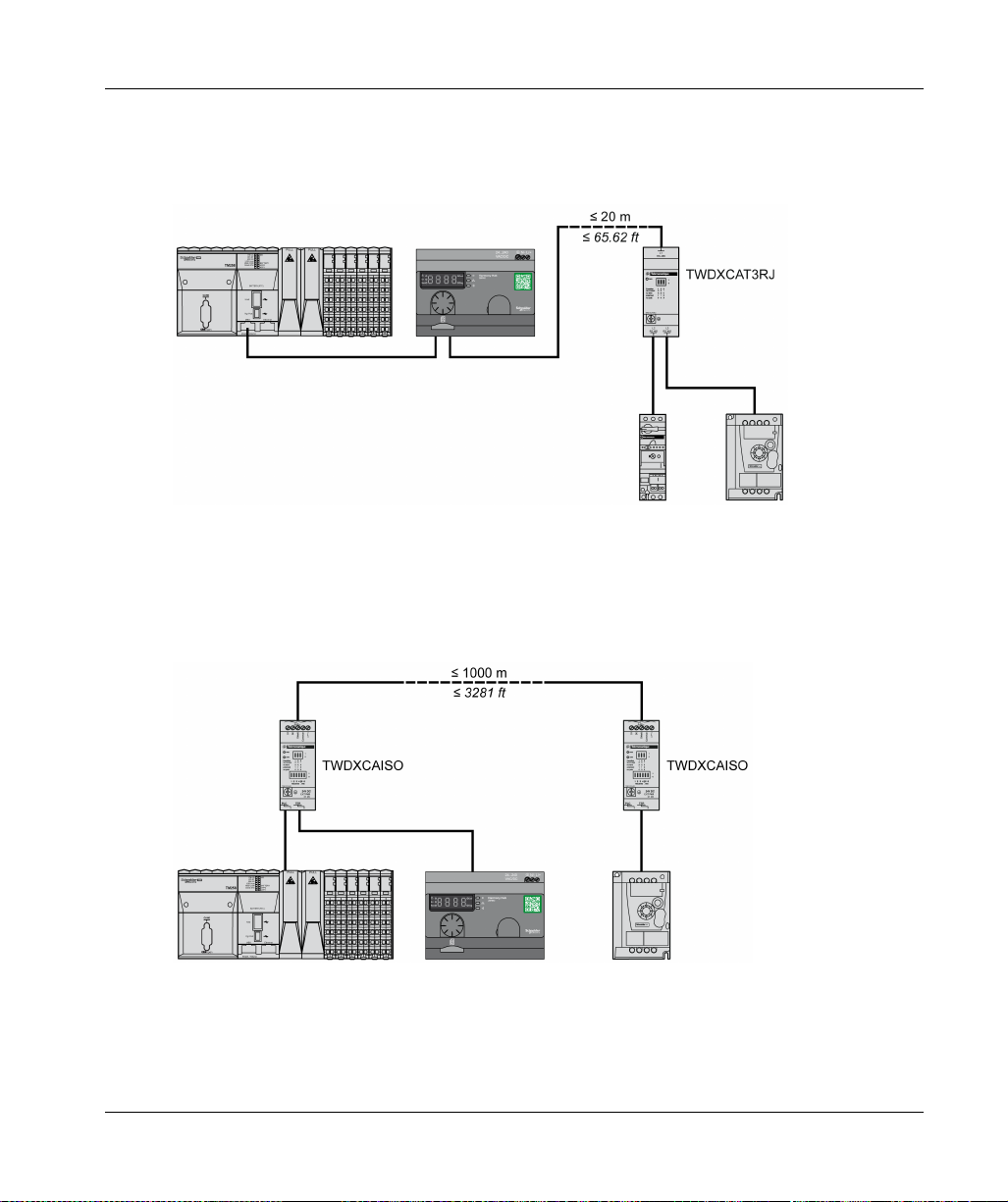

Modbus Serial Line Wiring

Network Connection

You can directly connect Harmony Hub to a PLC for a distance up to 20 m (65.62 ft) as shown in

the following figure:

UNINTENDED EQUIPMENT OPERATION

Use a Modbus serial line cable not longer than 20 m (65.62 ft).

Add a 120 ohm termination line when Harmony Hub is located at the end of the Modbus serial

line (reference VW3A8306RC).

Failure to follow these instructions can result in death, serious injury, or equipment damage.

WARNING

78

EIO0000001177 01/2020

Using TWDXCAT3RJ

TWDXCAT3RJ is used for three connections, polarization, and line termination.

The following figure shows the connection of the device on the bus using TWDXCAT3RJ:

Using TWDXCAISO

TWDXCAISO is used for isolation and line termination.

The following figure shows the connection of the device on the bus using TWDXCAISO

(even if Harmony Hub is already isolated):

Modbus Serial Line Communication

For distances longer than 20 m (65.62 ft), verify that the other devices connected to the bus are

isolated. If other devices are not isolated, use the TWDXCAISO module.

EIO0000001177 01/2020 79

Modbus Serial Line Communication

Modbus Settings and Supported Functions

Modbus Message Structure

The Modbus protocol uses 16-bit words (registers) divided into 2 bytes of 8 bits each.

A Modbus message starts with a header followed by a 1-byte address. A Modbus message uses

a Modbus function as its first byte.

The following table shows the full structure of a Modbus RTU message:

Address Modbus Messages CRC

Function Code Data

1 byte 1 byte n-byte field 2 bytes

List of Supported Commands

The following table shows the list of Modbus commands:

Modbus Function

Code:

Dec Index (Hex)

01 (0001 H) – Read coils. This function code is used to read the

03 (0003 H) – Read holding registers. This function code is used to read the

06 (0006 H) – Write single register. This function code is used to write the

16 (0010 H) – Write n registers. This function code is used to write the

43 (002B H) 14 (000E H) Read device identification. This function code is used to read the

Sub-Function:

Modbus

Encapsulated

Interface

Command Description

content of one or more contiguous coil

statuses in a slave.

content of one or more adjacent

registers in a slave.

content of a register in a slave.

content of one or more contiguous

registers in the slave.

identification and other information

relating to the physical description of a

slave.

NOTE: Registers can be read or written only if the registers are adjacent.

80

EIO0000001177 01/2020

List of Identification Registers

The following table lists the Modbus identification registers:

Identifier Register Name Value Data Type

0 (0000 H)

1 (0001 H)

2 (0002 H)

3 (0003 H)

4 (0004 H)

5 (0005 H)

VendorName

ProductCode

MajorMinorRevision

VendorUrl

ProductName

ModelName

Abort Code

Function Code Abort Code Description

03 H 02 H One of the registers does not exist.

03 H Incorrect register number.

04 H Unavailable value.

06 H 02 H The register does not exist.

04 H Invalid value or register in read only.

10 H 02 H The register does not exist.

03 H Incorrect register number.

04 H Invalid value or register in read only.

2B H 01 H Modbus encapsulated interface different from 14.

02 H Identifier does not exist.

03 H Identifier > 4 or = 0

Modbus Serial Line Communication

Schneider Electric ASCII string

ZBRN1: 052848

ZBRN2: 052849

1.0 for the first official version

https://www.schneider-electric.com

Harmony

ZBRN1

ZBRN2

EIO0000001177 01/2020 81

Modbus Serial Line Communication

Modbus Serial Line Cables

Modbus Serial Line Cables for ZBRN2 Harmony Hub

The following figure shows the Modbus serial line cable with 2 RJ45 connectors to connect to any

device supporting the protocol:

Item Description Reference Length

1 Modbus serial line cable VW3A8306R03 0.3 m (0.9 ft)

VW3A8306R10 1 m (3.2 ft)

VW3A8306R30 3 m (9.8 ft)

82

The following figure shows the Modbus serial line cable with 1 RJ45 connector and 1 mini DIN

connector to connect to a Twido PLC:

EIO0000001177 01/2020

Modbus Serial Line Communication

Item Description Reference Length

2 Modbus serial line cable for Twido PLC TWDXCARJ003 0.3 m (0.9 ft)

TWDXCARJ010 1 m (3.2 ft)

TWDXCARJ030 3 m (9.8 ft)

The following figure shows the Modbus serial line cable with 1 RJ45 connector and one USB

connector to connect to a PC:

Item Description Reference Length

3 Modbus serial line cable TCSMCNAM3M002P 2.5 m (8.2 ft)

The following figures show USB to RS-485 converter and Modbus serial line cable to connect to a

PC:

EIO0000001177 01/2020 83

Modbus Serial Line Communication

Item Description Reference Length

4a USB to RS-485 converter TSXCUSB485 –

4b Modbus serial line cable VW3A8306R03 –

The following figures show USB to RS-485 converter and Modbus serial line cable to connect to a

Twido PLC.

Item Description Reference Length

5a USB to RS-485 converter TSXCUSB485 –

5b Modbus serial line cable for Twido PLC TWDXCARJP03P –

84

EIO0000001177 01/2020

Harmony Hub

ZBRRH Receiver for Harmony Hub

EIO0000001177 01/2020

ZBRRH Receiver for Harmony Hub

Chapter 6

ZBRRH Receiver for Harmony Hub

Purpose

This chapter provides an overview of the Harmony ZBRRH receiver, hardware description, output

connectors, installation, power supply connections, and main procedures.

What Is in This Chapter?

This chapter contains the following topics:

Presentation of ZBRRH 86

General Installation Instruction for ZBRRH 87

Receiver Wiring Diagram 91

LED Status 92

How to Teach/Unteach ZBRRH 93

Lock/Unlock for ZBRRH 96

Total Reset Function Description 99

Topic Page

EIO0000001177 01/2020 85

ZBRRH Receiver for Harmony Hub

Presentation of ZBRRH

Programmable Receiver

The following figure shows the Harmony ZBRRH receiver:

(1): Selection button

(2): Validation button

The following table describes the characteristics of the receiver:

86

Designation Ouputs Receiver Voltage Reference Mass

Receiver with indicator light

LED and teach button

4PNP

200 mA

24 Vdc ZBRRH 0.130 kg

(0.287 lb)

EIO0000001177 01/2020

General Installation Instruction for ZBRRH

Overview

The general installation instructions for ZBRRH are the same as the ZBRN ones:

Maximum distances transmitter/receiver,

The installation conditions,

The mounting tips,

The mounting tips for antenna,

…

For more details, refer to the ZBRRH Instruction Sheet.

Maximum Distances

ZBRRH Receiver for Harmony Hub

(*) Typical values that may be modified by the application environment.

(**) Free field (unobstructed).

NOTE:

The range may be increased by adding antenna ZBRA1.

The range is reduced if the transmitter is placed in a metal box (reduction factor: approx. 10%).

Once wiring is complete, test the product in all possible active areas (while remaining within

range).

NOTE: The relay antenna must have a firmware version ≥V3.2.

EIO0000001177 01/2020 87

ZBRRH Receiver for Harmony Hub

The level of signal attenuation depends on the materials through which the signal will pass:

Material Attenuation

Glass window 10...20 % (*)

Plaster wall 30...45 % (*)

Brick wall 60 % (*)

Concrete wall 70...80 % (*)

Metal structure 60...100 % (*)

(*) Values for indication purposes only. Actual values depend on the thickness and nature of the material.

Installation Conditions

Receiver operating temperature -25...+55°C (-13...+131°F)

Receiver protection level IP20

88

EIO0000001177 01/2020

Mounting Tips for Antenna

The ZBRA1 relay antenna is installed with regard to its vertical axis as shown in the following figure

The antenna and the receiver are installed following their vertical axis.

The relay antenna is used to bypass the obstacle as shown in the following figure:

ZBRRH Receiver for Harmony Hub

EIO0000001177 01/2020 89