Page 1

SmartStruxure Lite

Solution

Smart Controllers (SEC-TE, SED-0)

Installation Instructions

Get Control. Get Efficient. Get Value

Page 2

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

SmartStruxure Building Peripherals User Guide

About this User Guide

This document contains the user guide for the SmartStruxure™ Lite Wireless Smart

building peripherals.

NOTE: The content of this document is applicable to the features of SmartStruxure

Lite Building Peripherals firmware version 1.4 and subsequent.

Who Should Read this Guide

This guide is for building automation professionals including engineers, contractors,

and electricians.

SmartStruxure Lite Wireless Smart building peripherals are programmable wireless

devices for the building automation industry. This document helps you understand,

install, operate, and maintain your SmartStruxure Lite peripherals.

Related Topics

2

To appreciate the full functionality of SmartStruxure Lite Wireless Building Peripherals,

a prior knowledge of the following topics and products is required:

• SmartStruxure Lite solution Multi-purpose Management Devices (MPM)

• ZigBee

• Lua script

Safety

Installation, operation, and maintenance of SmartStruxure Lite’s Wireless Building

Peripherals may require working with live electrical components. Only qualified

licensed electricians or other individuals who have been properly trained in handling

live electrical components should perform these operations.

Failure to follow electrical safety precautions when exposed to live electrical

components could result in death or serious injury. Always respect local codes and

regulations when installing SmartStruxure Lite products.

Page 3

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Overview

SmartStruxure Lite’s building peripherals are smart wireless devices that address

specific building applications with the added value of wireless communication, along

with local and distributed intelligence.

This document presents the following two SmartStruxure Lite Wireless Building

Peripherals:

• SED-0

• SEC-TE

IMPORTANT NOTE: SmartStruxure Lite Wireless Building Peripherals are NOT

stand-alone solutions. The SED-0 and SEC-TE require a section Manager, such as a

MPM-UN, to function correctly.

SED-0 Smart Wireless Actuator

The SED-0 is a locally programmable valve/damper actuator that communicates

wirelessly with SmartStruxure Lite Managers and gateways.

The SED-0 has an internal ZigBee transceiver and antenna, enabling it to

communicate with SmartStruxure Lite controllers and gateways.

The SED-0 internal memory contains a control engine that supports local scripting

programmability, enabling simple stand-alone control and/or a fail-safe mechanism.

The device has the following object properties:

• Damper setpoint

• Damper position

• 2 universal Inputs

• 1 feedback output signal

• 2 analog value objects

• 1 Lua script

3

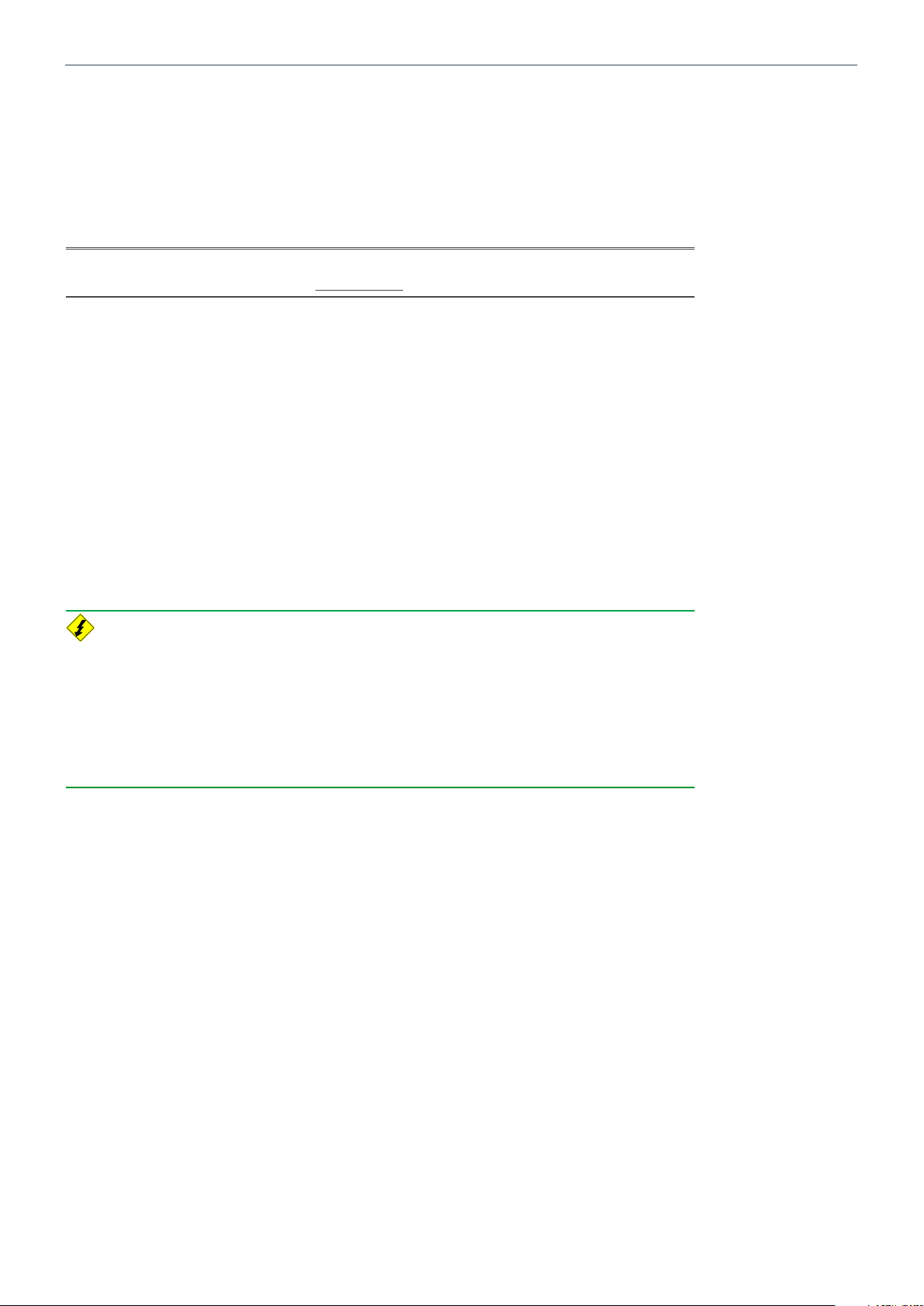

Physical Characteristics and Interactions

The figure shows the physical characteristics of the SED-0.

1. Actuator

2. 100% position of SED-0

3. LED

4. Network scan button

5. SED-0 body

6. Power supply and I/O connector

7. Manual override button

8. Label

9. 0% position of SED-0

1

9

8

7

2

3

4

5

6

Page 4

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

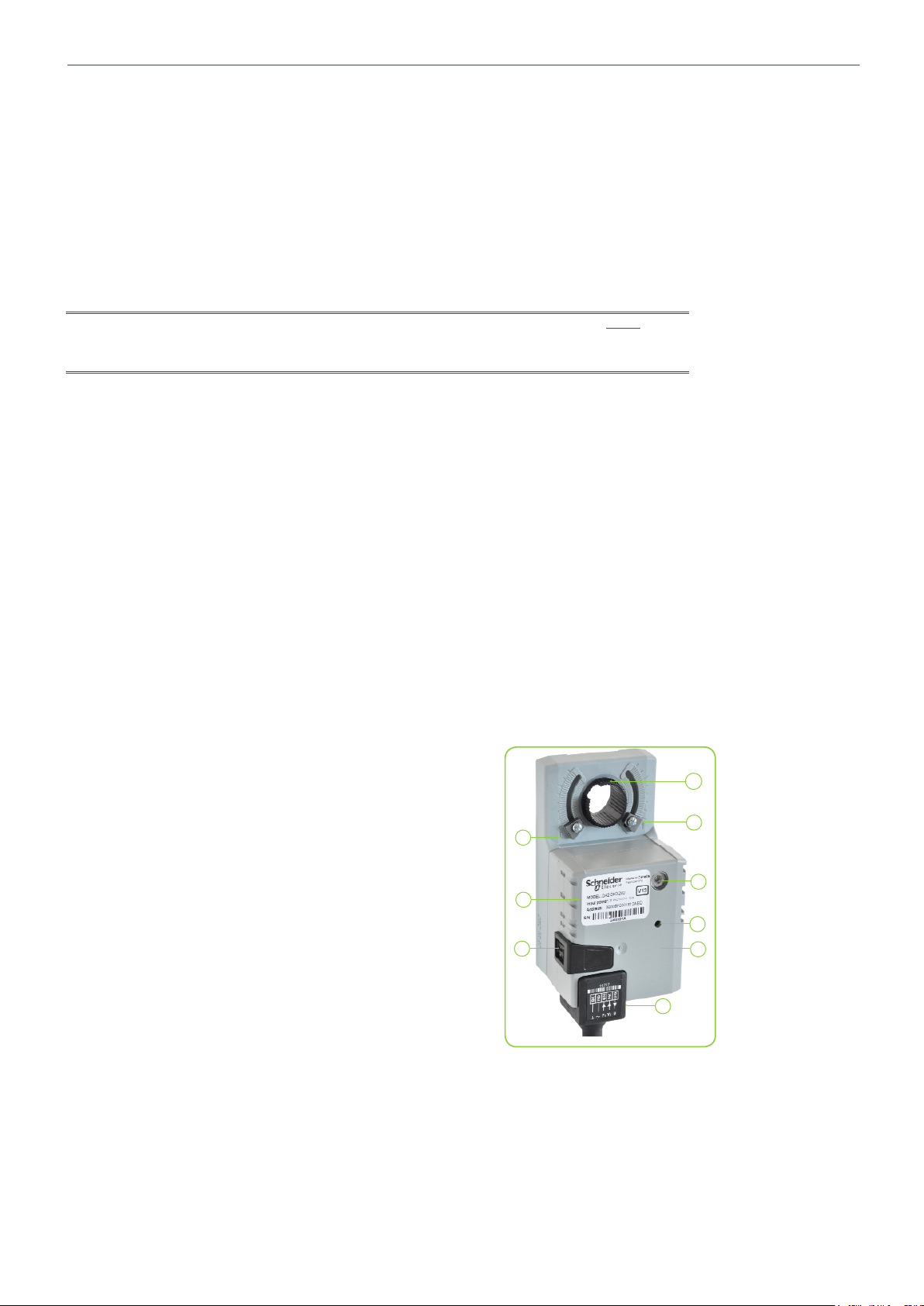

The below figure shows the wiring diagram for the SED-0.

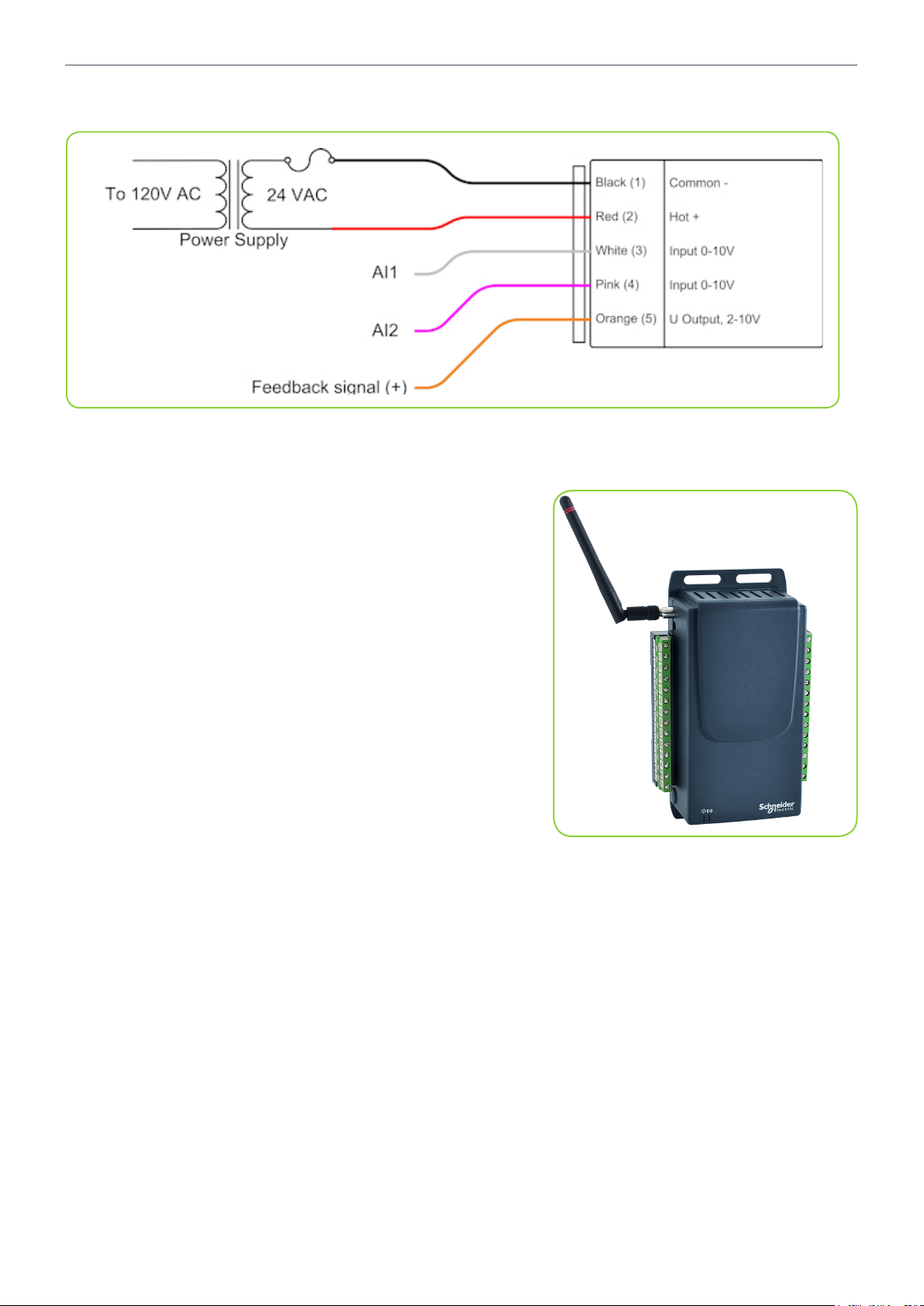

SEC-TE Terminal Equipment Controller

The SEC-TE is a programmable controller for terminal

equipment applications such as fan coil units. The SEC-TE

has an internal ZigBee transceiver and antenna, enabling it to

communicate with SmartStruxure Lite controllers and gateways

and other compliant devices.

The SEC-TE internal memory contains a control engine that

supports local scripting/programmability, which creates a

simple stand-alone control and/or fail-safe mechanism.

The device has the following object properties:

• 4 universal inputs

• 4 analog outputs

• 5 binary outputs (dry contacts)

• 2 analog value objects

• 1 Lua script

The SEC-TE can also be used as a pulse counter with one

analog input configurable for this function.

4

Page 5

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Overview

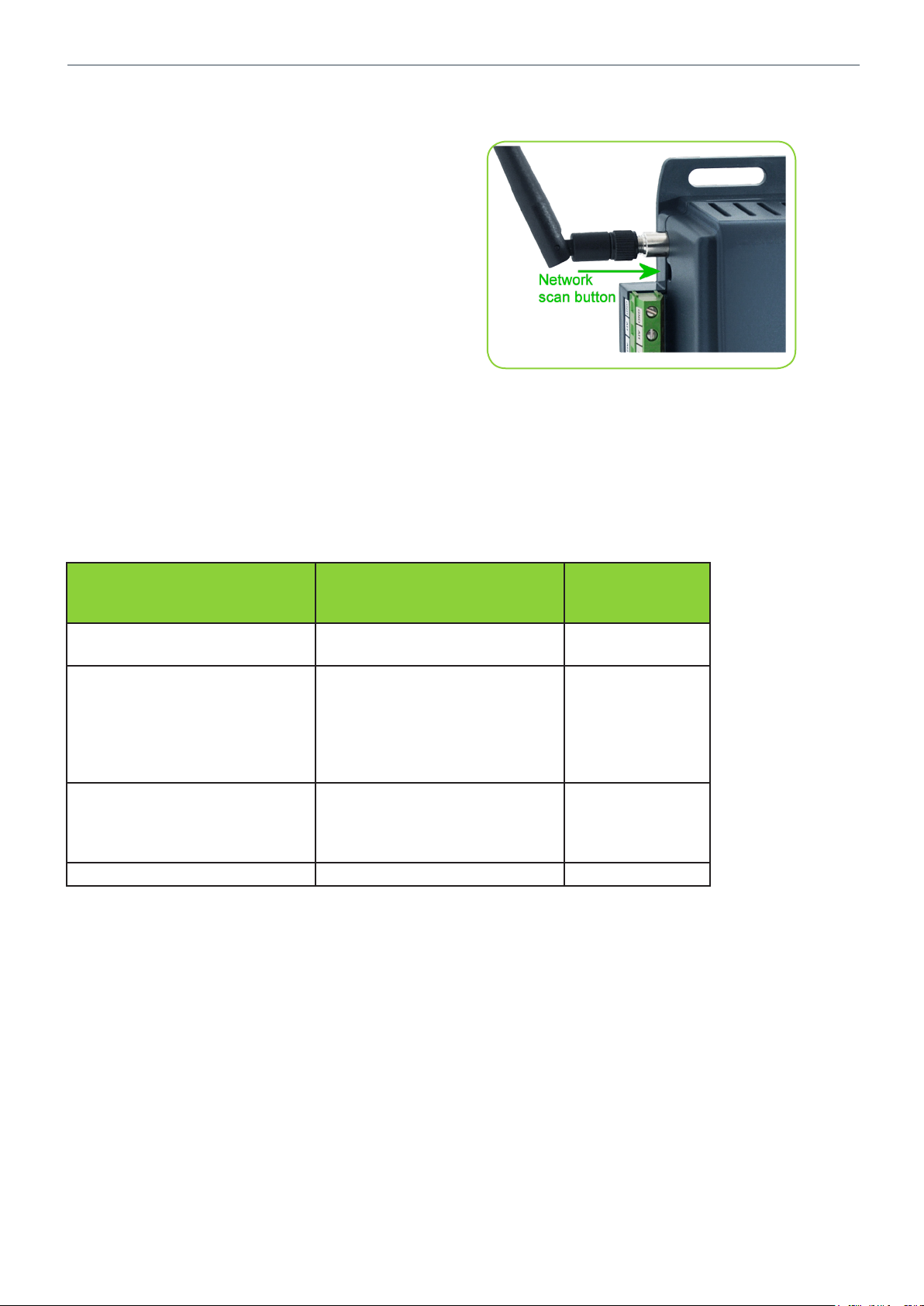

Network Scan Button Detail (all models)

The network scan button is recessed. Operation of the

button requires the use of a small, narrow tool such as

an Allen key.

Network Scan Button Action

Table 1 below shows the effects when pressing and

holding the network scan button on your Building

Peripheral.

5

Table 1

Actions applied to button by

user

Hold down between 1s and 5s Device tries to connect to the

Hold down between 6s and 30s Device scans for joinable

Hold down more than 30s Device clears all analog out-

Hold down less than 1s No action performed LED not affected

Actions performed on release of

button

next network on its list

networks (with user defined

extended pan id if applicable)

and compiles a list of networks

it finds, up to a maximum of 5

networks

puts, binary outputs, analog

values, and Lua script. It also

causes the device to reboot

Corresponding

Blue LED behavior

LED flashes

slowly (400ms)

LED flashes rapidly (200ms)

LED turns OFF

Page 6

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

LED Behavior

Each Building Peripheral has a blue LED and a green LED. During operation of the

devices, the green LED remains illuminated solid.

The blue LED behavior characteristics are shown in Table 2 below.

Table 2

Blue LED Behavior Corresponding device behavior

LED ON 200ms every second Device is scanning for joinable Zigbee networks

LED ON 500ms every second Device is trying to join one of the networks it has

found during the scan

LED ON 800ms every second Device is trying to rejoin the network it was connect-

ed to after a loss of connection or a reboot

LED ON Device is connected to a network

LED flashes (400ms) Button is being held down between 1s and 5s

LED flashes (200ms) Button is being held down between 6s and 30s

LED OFF for 1s (pause) This pause in the LED pattern indicates the device

could not connect to a network. The device tries to

connect to the next network on its list.

LED OFF Button is being held for down more than 31s

NOTE: On the SED-0, both LEDs are viewed through the same circular glass. The

dominant color of the LED indicator is blue. You should not see a green LED indicator.

6

Page 7

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

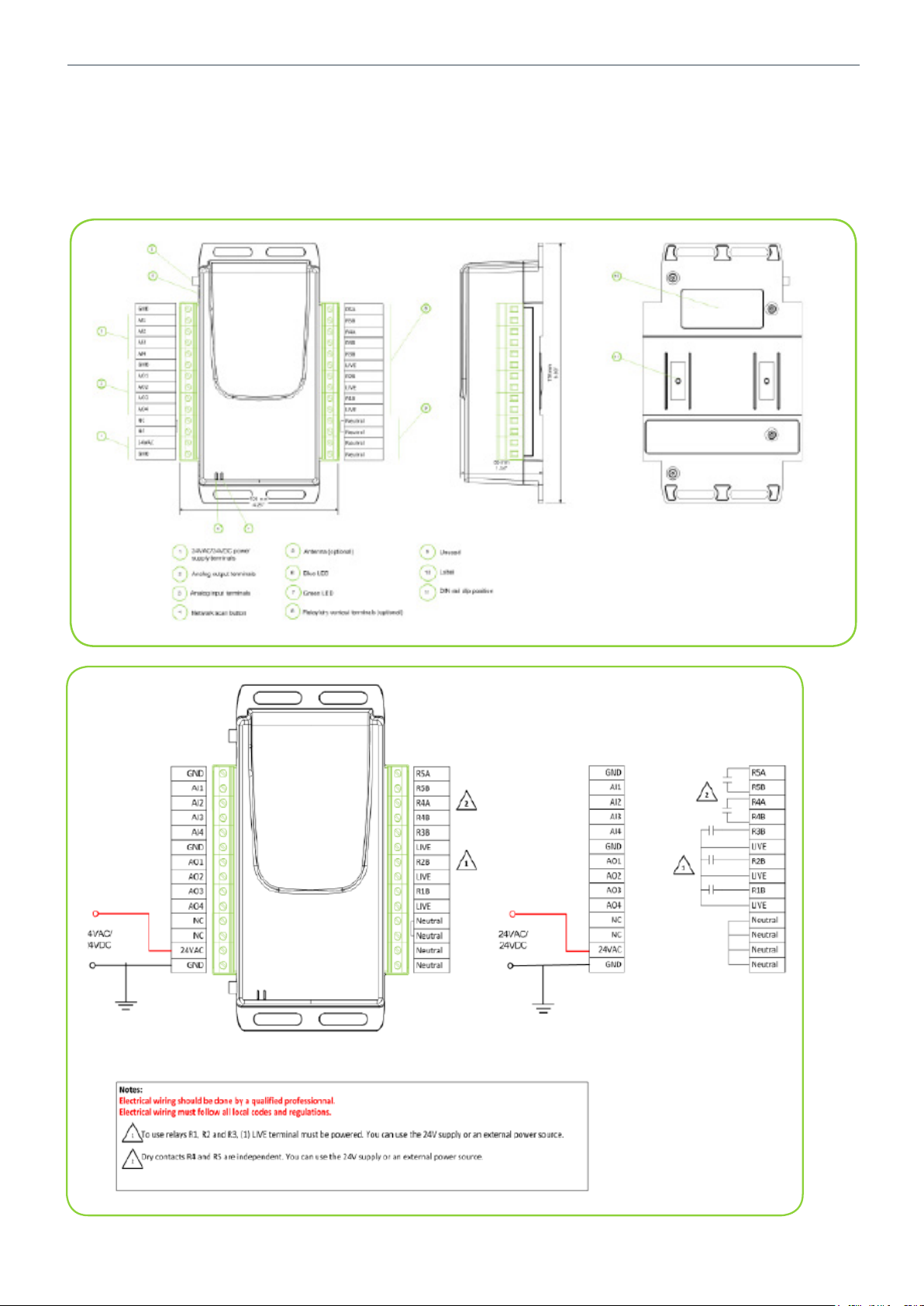

Wiring Diagram

The wiring diagrams for the 24VAC/24VDC SEC-TE smart wireless managers are

shown below.

24VAC/24VDC

7

Page 8

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

115VAC/230VDC

The wiring diagrams for the 115VAC/230VAC SEC-TE smart wireless managers are

shown below.

8

Page 9

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Software Interaction

This section presents general operation of SmartStruxure Lite Building Peripherals, as

well as an overview of the different states of a Building Peripheral. This information

should be read in conjunction with the Device Behavior section to gain a full

understanding of the behavior of your Building Peripheral in different stages of

operation.

Scanning for Zigbee Networks

Wireless communication with your Building Peripheral requires the device join a

ZigBee network previously formed by one or more SmartStruxure Lite Managers.

A SmartStruxure Lite Building Peripheral can store in its memory the information

to connect to five different Zigbee networks. Your device discovers the available

networks in its communication range by doing a network scan.

The network scan occurs under one of the following two conditions:

• Automatic scan: when a SmartStruxure Lite Building Peripheral is powered up

and its internal memory contains no network information such as a new Building

Peripheral or device that was never connected to a Zigbee network.

• Manual scan: when the Building Peripheral network scan button is pressed for

more than five seconds and less than 30 seconds to initiate the scan.

If the network scan is unsuccessful and the device cannot find an available Zigbee

network, the device remains disconnected and stays in that state until a manual

network is initiated and a joinable network is found.

9

Joining a Zigbee network

After a successful scan, the Building Peripheral automatically joins the first Zigbee

network stored on its list. When the blue LED on the Building Peripheral stops flashing,

the Building Peripheral has joined a network.

If for some reason it cannot join the first network on the list before reaching a

programmed timeout, the device automatically tries to join the next network. The

device repeats this sequence until it joins a network on its list, or a manual network

scan is initiated to refresh its network list.

Refer to the following two sections for more details:

• “Procedure - Configure Zigbee” on page 10

• “Using Com Log” on page 14

Page 10

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Procedure - Configure Zigbee

NOTE: This procedure assumes you have already wired electrical power to your

device as per the wiring diagrams. For the purpose of this procedure, a SED-0

Building Peripheral is used. The procedure is identical for the SEC-TE except where

otherwise indicated. Also, ensure Devices tab on left side of Building Expert is

expanded before you start the procedure.

Configure ZigBee

10

1. In Devices tab, select your Multi-purpose Manager.

2. In Object tab, select ZigBee Configuration (ZBC1) object.

3. Set following parameters accordingly:

• In Stack Profile, select 2-ZigBee Pro.

• In Security Profile, select Home Automation.

4. Click Save button.

5. In Devices tab, select your Multi-purpose Manager again.

6. In Explorer tab, click Add Devices button.

A new window opens.

Page 11

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Add Device

11

1. In Add Devices tab, select DA2.

2. Click Add Devices button.

3. In Devices tab, select your newly added device.

4. In Explorer tab, select ZigBee Peripheral Configuration.

Page 12

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Configure Device

1. In Extended Node ID (hex) text field, enter your Building Peripheral`s 16-digit MAC

address specified on device`s label.

12

NOTE: For SED-0, the label is affixed to top of device. For SEC-TE, the label may be

affixed to rear panel. The value must be a non-zero hexadecimal with a maximum of 16

characters.

2. Click Save button.

3. Using a narrow tool such as an Allen key, press Network Scan button on Building

Peripheral for 6 to 30 seconds until LED begins flashing rapidly, Then release

Network Scan button.

The device begins scanning for all Zigbee networks within range and the LED flashes

slowly. When the LED stops blinking and illuminates solid, the Building Peripheral has

joined a network

Page 13

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Verify Configuration

1. Allow up to 30 seconds to pass, and verify device has joined correct network:

• Case 1: If device has joined correct network, Status field shows Online. Click

Save button.

• Case 2: If device has not joined correct network where more than one ZigBee

network is present, Status field shows Communication Error followed by

numeric error code.

NOTE: In Case 2, you must press network scan button again for approximately 2

seconds to skip to next network in list of stored networks. For each attempt, allow up

to 30 seconds for ZPC object’s status field to update. Once the device is online, click

Save button.

Block Diagram

The block diagram below shows a graphical representation of how a SmartStruxure

Lite Building Peripheral joins a ZigBee network.

13

Page 14

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Using Com Log

In large installations where multiple ZigBee networks may be present, the Building

Expert’s Com Log is a useful, time-saving tool for determining whether your Building

Peripheral has joined the correct network.

To verify whether the Building Peripheral has joined the desired Zigbee network, you

must monitor the Zigbee activity on the Com Log window of the section Manager

where the Building Peripheral should be joining.

The Com Log should be accessed before starting the joining process to ensure you

see the Com Log entry of the device joining the network.

Access Com Log

1. In Devices tab, right-click on your section Manager.

2. Select Show Com Log.

The Com Log shows in a separate window, and the figure below shows a typical

message appearing on Com Log when a Building Peripheral joins the network.

14

The device is identified on the Com Log with an extended_id corresponding to its

MAC address. This address is unique and permanent for each device.

Note: When the device joins the network, the Device Announce message shows on

the Com Log several seconds before its status field on the ZPC object updates. Allow

the status field sufficient time to update to “Online” before clicking the ZPC object’s

Save button.

Page 15

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Joining Other Networks on the List

If the device joins a network (LED is ON) but does not appear on the Com Log, this

means the device joined a network from a list not detected on the desired network.

The list can contain up to 5 Zigbee networks.

To change the network, press the button on the device and hold it between 1 and

5 seconds. The blue LED flashes until the device joins the next network, and then

remains solid.

Each time you press the button, the device joins the next network on its list and cycles

continuously. If there is only one network available, it constantly attempts to rejoin the

same network.

Other Operation Scenarios

1. SmartStruxure Lite Building Peripheral loses power:

If a Building Peripheral joins a network at least once, it tries to reconnect to the

same network it was last connected to if it loses power and is powered back on.

If you want the device to join another network, you must do a new manual network

scan, since stored networks get deleted on power loss, with the exception of the

last joined network.

2. ZigBee Network goes down:

If the network to which a device is connected is temporarily unavailable, the

device tries to rejoin this network indefinitely. Once the network is back up, the

device rejoins it.

15

Perform one of the following if you want the device to connect to another network:

• Press the button on the device and hold it between 1 and 5 seconds to search for

another network on the list of discovered networks.

• Initiate a network discovery to find available networks.

Page 16

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Endpoint Descriptions

Analog Inputs (AI)

Each analog input is configurable via the ZPC1 object used with devices supplying a

signal in Ohms (thermistor, potentiometer, dry contact) or in Volts (analog temperature

or humidity sensors). By default, all analog inputs are set to Volts.

16

Analog Outputs (AO) – SEC-TE Only

• SEC-TE offers 4 analog outputs.

• Value assigned to the output can be between 0V and 12V. The output value has a

resolution of 12 bits.

Binary Outputs (BO) – SEC-TE Only

• SEC-TE offers (as an option) 5 relays/binary outputs.

• Each relay is rated for 5A at 24VAC.

Page 17

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Valve Digital Position (AI5) – SED-0 Only

• Current position of the SED-0 valve actuator is stored in AI5.

• Position is stored as a percentage, where 0% represents the valve physically in

position 0, and 100% represents the valve physically in position 1.

You cannot physically reverse polarity of the SED-0 actuator. If required, reversing the

polarity must be done inside your control script.

Valve Set Position (AO1) – SED-0 Only

• Desired valve actuator position is stored and can be edited in object AO1.

• Position must be defined in percentage, where 0% represents the valve physically

in position 0, and 100% represents the valve physically in position 1.

• You cannot physically reverse polarity of the SED-0 actuator. If required, reversing

the polarity must be done inside your control script, AV1 and AV2.

• Objects AV1 and AV2 allow you to store analog values in the SED-0 actuator

memory. These objects are used mainly in the Lua script embedded in the SED-0

valve actuator.

17

Lua Script

The SED-0 and SEC-TE can run a simple Lua script. This script can have a maximum

of 225 characters (including spaces) and is used mostly to create a fail-safe control

sequence when the ZigBee communication with the network is lost, or, to execute

simple control tasks.

Tip: Optimization is the key! Do not hesitate to contact our Support Team to assist you

in the development of an embedded script.

Page 18

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Pulse Counting– SEC-TE Only

Universal input AI3 of a SEC-TE can be configured as a pulse counter. In this

configuration, pulses from a dry contact pulse source are counted, and the total gets

stored in endpoint AI3 of the device firmware.

To activate particle counting, access the SEC-TE’s ZigBee Peripheral Configuration

(ZPC1) object in Building Expert and select Pulse Counting from Analog Input

Mode 3.

18

Page 19

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Technical Specifications

SED-0

Power

Voltage 24 VAC; +/-15%; 50/60Hz; Class 2

Typical Consumption 5 VA

Enclosure

Material Rigid ABS

Dimensions 130mm (5.12in) X 73mm (2.87in)

Rating UL94 -5 VA

Environmental

Operating Temperature 0 °C (32 °F) to 60 °C (140 °F)

Storage Temperature -20 °C (-4 °F) to 60 °C (140 °F)

Relative Humidity 0 to 90% non-condensing

Agency Approvals UL 61010-1 (2007/12/17, 4th edition), CSA C2 2.2 # 61010-1 (1983/0 6/01, R20 09),

IEC 61010-1 (2001/02/01 Corrigendum#2 20 03/04), CENELEC EN 61326 -1 (2006/05/01),

FCC 47CFR 15B cIB (2011/04/21), ICES-003 Issue 4 (20 04), CE, RoHS

Inputs

Quantity 2

Voltage 0-1 0 Vo lt s

Current 4-20 mA with 249 Ohms external resistor

Resistance 1 kOhms to 100 kOhms

Resolution 14- b it

ZigBee Transceiver

Communication Zigbee Pro

Frequency 2400 – 2483.5 MHz, 16 RF channels

Data rate / Mod. t ype 250 kbps

Receiver Sensitivity -101dBm / -105dBm (amplified)

Nominal Output Power 8dBm / 18dBm (amplified)

Range Up to 300m open air , Up to 100m in building

Antenna Internal

Actuator Technical Data

Communication Zigbee Pro

Frequency 2400 – 2483.5 MHz, 16 RF channels

Data rate / Mod. t ype 250 kbps

Receiver Sensitivity -101dBm / -105dBm (amplified)

Nominal Output Power 8dBm / 18dBm (amplified)

Range Up to 300m open air , Up to 100m in building

Antenna Internal

19

Page 20

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

SEC-TE

Power

Voltage 24 VAC; +/-15%; 50/60Hz; Class 2 / 24 VDC +/-10%

115 VAC; 230 VAC;

Typical Consumption 10 VA (Unloaded)

Enclosure

Material Rigid ABS

Dimensions 176mm (6.93in) X 108mm (4.25in)

Rating UL94 -5 VA

Mounting Din-rail, wall or ceiling mount

Environmental

Operating Temperature 0 °C (32 °F) to 60 °C (140 °F)

Storage Temperature -20 °C (-4 °F) to 60 °C (140 °F)

Relative Humidity 0 to 90% non-condensing

Agency Approvals UL 61010-1 (2007/12/17, rev 2010/06/04), CSA C22. 2 # 205 (1983/06/01, R2009), IEC 61010-

1 (2001/02/01 Corr igendum#2 20 03/04), CENELEC EN 61326 -1 (2006/05/01), FCC 47CFR

15B cIB (2011/04/21), ICES-003 Issue 4 (2004), CE, RoHS

Inputs

Quantity 4

Voltage 0-1 0 Vo lt s

Current 4-20 mA with 249 Ohms external resistor

Resistance 1 kOhms to 100 kOhms

Resolution 14 bits

Outputs

Analog (x4) 0-12V nominal 50 mA max each

12 bit resolution

Relay (x5) 24VAC, 5A per relay

Pulse Counting

Inputs 1 (AI3)

Pulse source Dry Contact

Period minimum 5 ms (200 Hz)

Duty Cycle 10%-50%

Count resolution 1 pulse

Accuracy 99.9% @ 200 Hz

ZigBee Transceiver

Communication Zigbee Pro

Frequency 2400 – 2483.5 MHz, 16 RF channels

Data rate / Mod. Type 250 kbps

Receiver Sensitivity -101dBm / -105dBm (amplified)

Nominal Output Power 8dBm / 18dBm (amplified)

Range Up to 300m open air ; Up to 100m in building

Antenna Internal or (Optimal) External Whip, RP SMA 2.5 dBi

20

Page 21

Schneider Electric | II-SSL-SEC-TE-SED-0 -A4.EN.08.2016.v2 August 2016

Compliance

ZigBee radio module: ETRX357 / ETRX357HR

• Contain FCC ID:S4GEM35XA

• Contain IC ID: 8735A-EM35XA

ZigBee long range radio module: ETRX357LRS / ETRX357HRLRS

• Contain FCC ID: S4GEM35X2

These enclosed devices comply with Part 15 of the FCC Rules. Operation is subject to

the following two conditions:

• Device may not cause harmful interference.

• Device must accept any interference received, including interference that may

cause undesired operation.

Any changes or modifications not expressly approved by Schneider Electric could

void the user’s authority to operate the equipment.

RoHS & WEEE

The European Union has issued directives on the Restriction of Hazardous

Substances (RoHS), Directive 2002/95/EC and Waste Electrical, and Electronic

Equipment (WEEE), Directive 2002/96EC.

Schneider Electric is committed to comply with applicable requirements stated in

the RoHS Directive which presently restricts the use of lead, mercury, cadmium,

hexavalent chromium and two bromine-containing flame retardants, PBB

(polybrominated biphenyls) and PBDE (polybrominated diphenyl ethers), in certain

electrical and electronic products.

Additionally, Schneider Electric is dedicated to minimizing the impact our products

have on the environment. The WEEE Directive aims to reduce waste arising from

electrical and electronic equipment, and to improve the environmental performance of

all those involved in the life cycle of these products.

21

Waste Electrical and Electronic Equipment (WEEE) Returns

In the European Union (EU) the processing of waste electrical and electronic

equipment (WEEE) is now subject to legislation to encourage treatment and recycling

measures to minimise the amount of such waste ultimately disposed to landfills.

The objective of the EU WEEE Directive is to protect and improve the quality of the

environment. In particular, the EU WEEE Directive 2002/96/EC (the WEEE Directive)

requires the Producer or Importer of electronic equipment be held responsible for the

collection, recycling and treatment of WEEE which the Producer has placed on the EU

market effective 13 August, 2005.

Loading...

Loading...