Schneider Electric SE8600 Series Installation Guide

SE8600 Series Installation Guide

Rooftop Unit, Heat Pump and Indoor Air Quality

Controller

CONTENTS

Installation 2

Terminal Identification & Function 3

Terminal identification 3

Typical Applications 4

2H / 2C 5

2C / Mod. heat 6

2C / Aux. Eco 6

Remote Sensor Accessories 7

Home Screen Display 8

How to Enter Setup Screen 9

Appendixes 10

Support 11

Version 5

2

Schneider Electric | II-SE860 0A4.EN.04.2016.v5 April 2016

INSTALLATION

Location

• Do not install on outside wall.

• Do not install in areas with direct heat source.

• Do no install near any air discharge grill.

• Do not install in areas exposed to direct sunlight.

• Ensure Room Controller has sufficient air circulation.

• Ensure wall surface is flat and clean.

Installation

1. Remove security screw (if any) on bottom of Room Controller cover.

2. Open unit by pulling on bottom side of Room Controller (Figure 1).

3. Read FCC ID and IC label installed in cover before installing any

wireless product.

4. Ensure correct side of base faces up.

5. Pull cables 6in (15cm) out from wall.

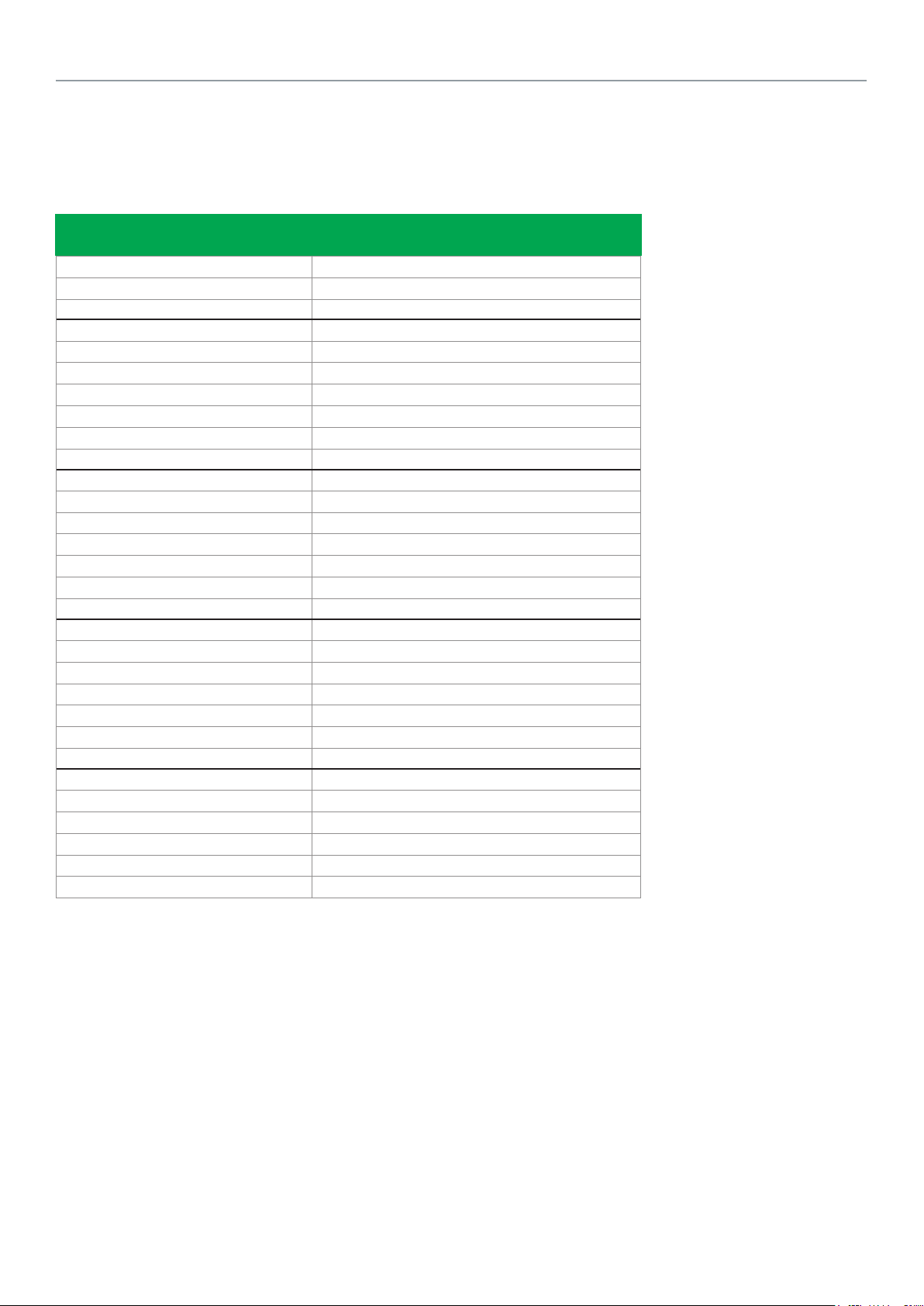

6. Align base and mark location of two mounting holes on wall (Figure 2).

7. Install anchors in wall.

8. Insert cable in central hole of base.

9. Insert screws in mounting holes on each side of base.

10. Strip each wire 1/4in (0.6cm) from end.

11. Insert each wire and screw according to wiring chart.

12. Gently push excess wiring back into hole.

13. Gently align cover to top of base and snap in place from bottom

(Figure 3).

14. Install security screw.

Figure-1 Open cover

• If replacing an existing device, label wires before removal of

Room Controller.

• Electronic controls are static sensitive devices. Discharge

yourself correctly before manipulating and installing Room

Controller.

• A short circuit or wrong wiring may permanently damage

Room Controller or equipment.

• All SE8600 series controls are designed for use as operating

controls only and are not safety devices. Tampering with the

devices or unintended application of the devices will result

in a void of warranty.

• This device must be installed to provide a separation

distance of at least 8in (20cm) from all persons and must

not be located or operating in conjunction with any other

antenna or transmitter.

Figure-2 Install base

Figure-3 Reinstall cover

Schneider Electric | II-SE860 0A4.EN.04.2016.v5 April 2016

TERMINAL IDENTIFICATION AND FUNCTION

Terminal identification

3

SE86xxU

Description / Application

Internal Temperature X

1- BO1

2- BO2 Y2

3- BO3 Y1

4- BO4 G

5- RC RC (24 Vac)

6- C Common

7- RH

8- BO8 W1

9- UO9 W2 / OB

10- UO10 Econo (0-10 Vdc)

11- UO 11 Heat (0-10 Vdc), set "Heat Stages" to 0 to enable

12- U O12 Dehumidification output (24 Vac On/Of f)

13- RS485 + BACnet (+)

14- RS485 - BACnet (-)

15- RS485 Ref BACnet Ref. (do not sire shield in this terminal)

16- UI16 UI16 (multifunction input)

17- U I17 UI17 (multifunction input)

18 Scom Common

Used in applications

IAQ, HP & RTU

Aux

RH

19- UI19 CO2 (0-10 Vdc input)

20- UI20 RS (Remote sensor input 10K, type 2 thermistor)

21 Scom Common

22- UI22 SS (Supply sensor input 10K, type 2 thermistor)

23- UI23 OS (Outside sensor input 10K, type 2 thermistor)

24- UI24 Airflow (0-10 Vdc input)

4

Schneider Electric | II-SE860 0A4.EN.04.2016.v5 April 2016

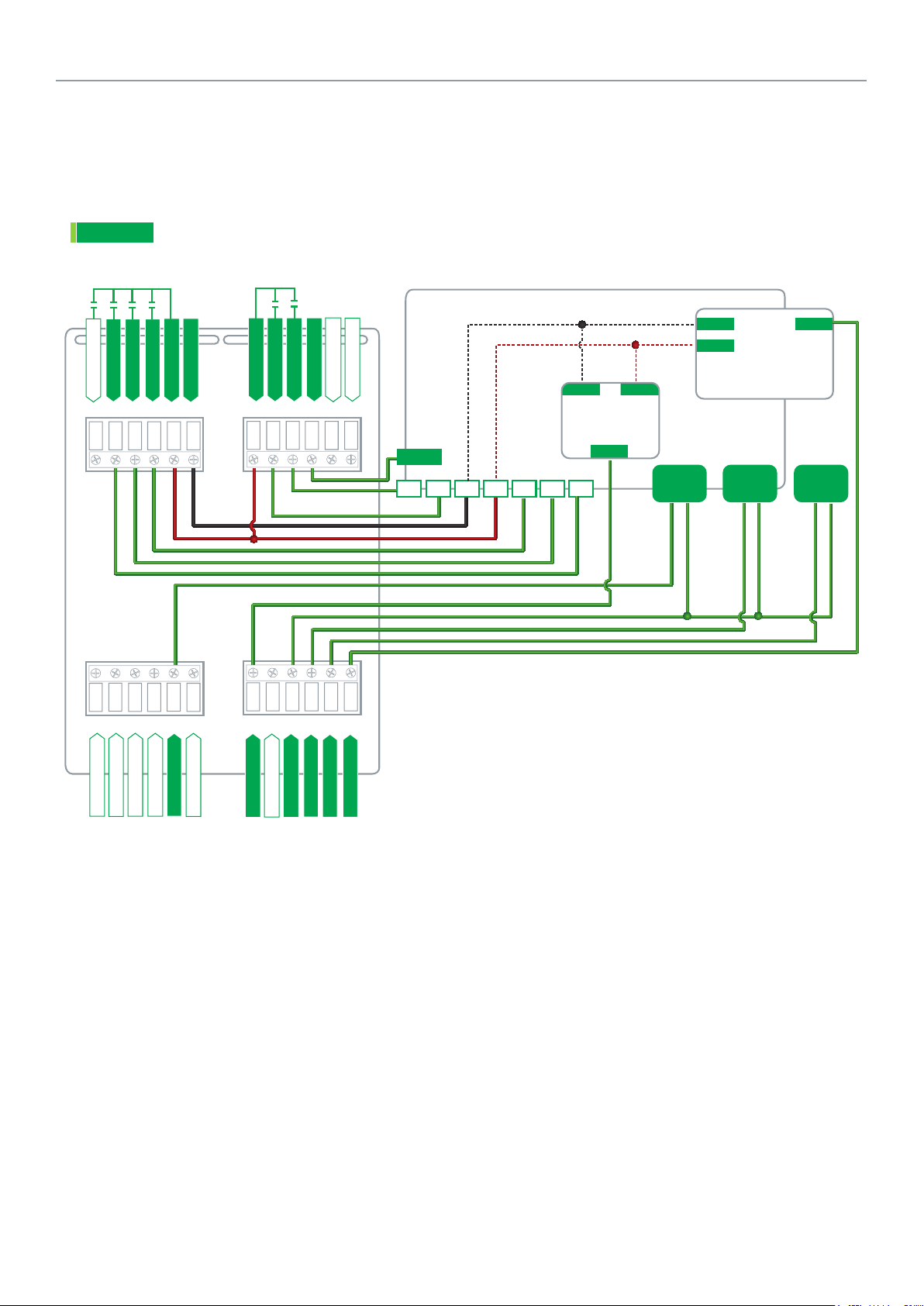

TYPICAL APPLICATIONS

SE8600

BO 2 - Y2

BO 1 - Aux

RTU: 2 Heating / 2 Cooling

BO 4 - G

BO 3 - Y1

RC (24 Vac)

C (Common)

1 2 3 4 5 6

RH

BO 8 - W1

UO 9 - W2

UO 10 - Econo

- Heat

UO 11

UO 12

7 8 9 10 11 12

TRANSMITTER

ECONO

W2 W1 C R G Y1 Y2

C R

CO2

(0-10 VDC)

OUT

C OUT

R

MEASURING STATION

FILTER

DPS

SENSOR

AIR FLOW

(0-10 VDC)

SAT

OAT

SENSOR

13 14 15 16 17 18

BACnet +

BACnet -

BACnet REF

UI 16

UI 17

Common

19 20 21 22 23 24

UI 19 - CO2

UI 20 - RS

Common

UI 22 - SS

UI 23 - OS

UI 24 - Airflow

Loading...

Loading...