SE8300 User Interface Guide

Commercial and Hotel/Lodging HVAC Fan Coil Applications

Version 8

2

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

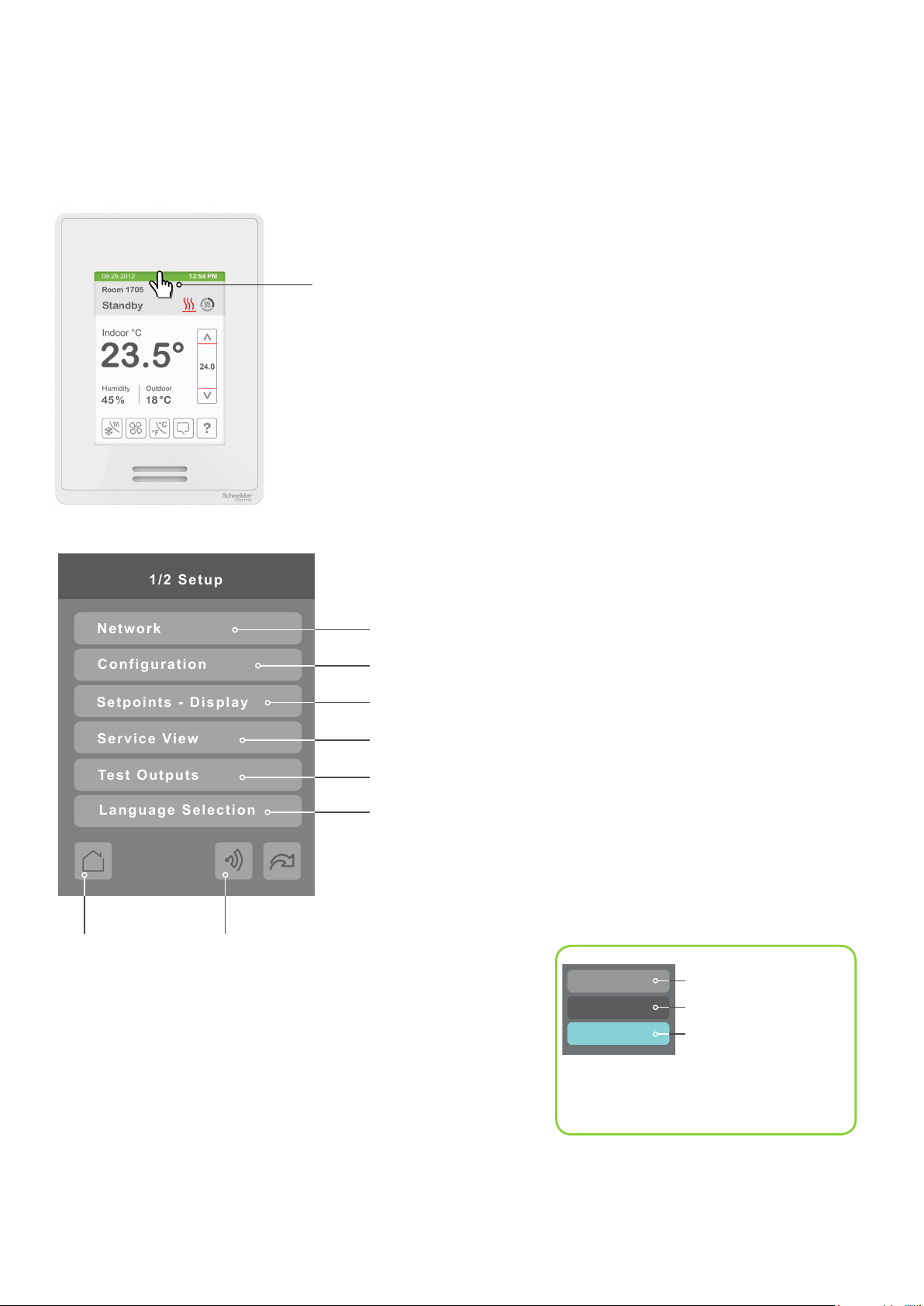

HMI Display

The below shows a typical user interface for the hospitality industry. The User HMI is congurable and allows display functions

such as Date, Time, Humidity, Outdoor Temperature, and Setpoint to be enabled or disabled by setting various parameters.

Short Network

Date

Message

Occupancy Status

Indoor Temperature

Indoor Humidity

Outdoor Temperature

System Mode

Time

System Status

Fan Status

Up Arrow

Increase Temperature Setpoint

Actual Setpoint

Down Arrow

Decrease Temperature

Setpoint

Help

Fan Mode

Temperature Units

Language Selection

General Notes

1. When any change is made to a parameter, the value is automatically saved in memory when the next

parameter is selected or another page is opened.

2. Arrows auto-increment/decrement at higher speed when holding button for more than 2.5 seconds.

3. All objects related to humidity do not display on HMI when Controller is ordered without built-in humidity sensor.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Enter Set-up Screen

1/2 Setup

Network

Configuration

Setpoints - Display

Service View

Test Outputs

Language Selection

Touch and hold this point

for 3 seconds to enter setup mode

Note: If a conguration/installer

password is activated to prevent

unauthorised access to the

conguration menu parameters, a

password entry prompt shows to

prevent access to device

conguration components.

3

SET-UP SCREEN DISPLAY

Enter BACnet® & ZigBee® network settings (only if ZigBee is detected)

Enter parameter conguration menu

Enter setpoint and display settings

Enter status and service view

Enter output testing mode

Enable selected language(s)*

Return to

home screen

Note: The following menus show according to context:

- ZigBee menu shows if ZigBee card detected.

- Network choice inside does not show if no network is available

Discover Mode The Controller

becomes discoverable on the wireless

ZigBee® network for 1 minute (this

button is hidden if ZigBee® settings are

not congured)

General Note:

Adjustable parameter

Nonadjustable parameter

Indicates invisible conditional

eld. Appears based only

on model, presence of a

ZigBee® wireless adapter

module or presence of a

Lua script, depending on the

eld.

*only available in recent versions of rmware

4

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

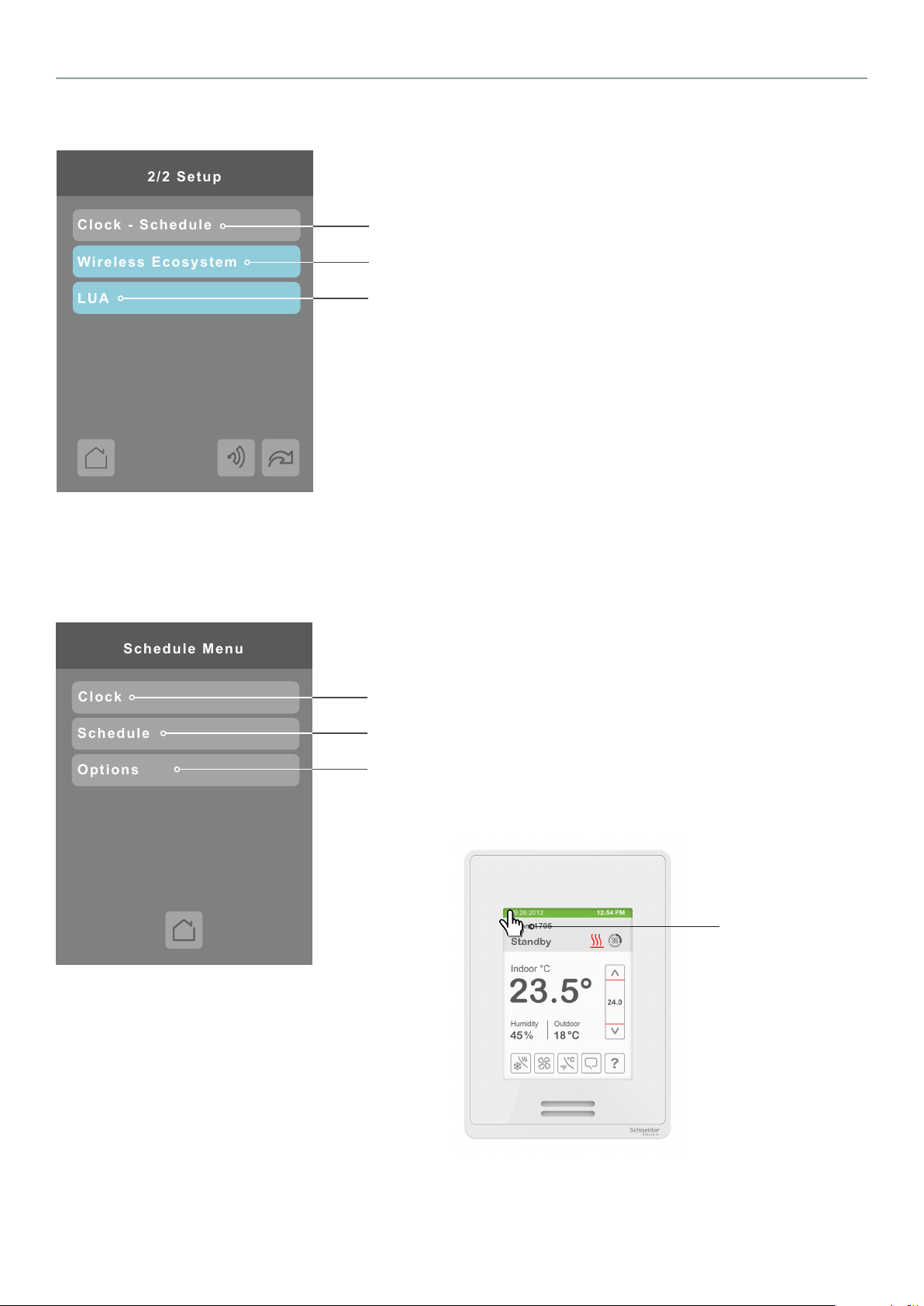

2/2 Setup

Clock - Schedule

LUA

Wireless Ecosystem

Options

Schedule Menu

Clock

Schedule

SET-UP SCREEN DISPLAY 2/2

Enter Schedule menu screen

Enter Wireless Ecosystem settings (ZigBee wireless adapter module required)

Enter LUA script settings (Lua script required)

SCHEDULE MENU SCREEN

Enter Clock settings

Enter Schedule settings

Enter Option settings

Note: The Schedule menu screen is directly

accessible from the main display if the Schedule

Menu conguration parameter is enabled. See

Conguration Parameters Screen 6/7 on page 26 for

more information.

Touch and hold this

point for 3 seconds

to enter the Schedule

Menu screen.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

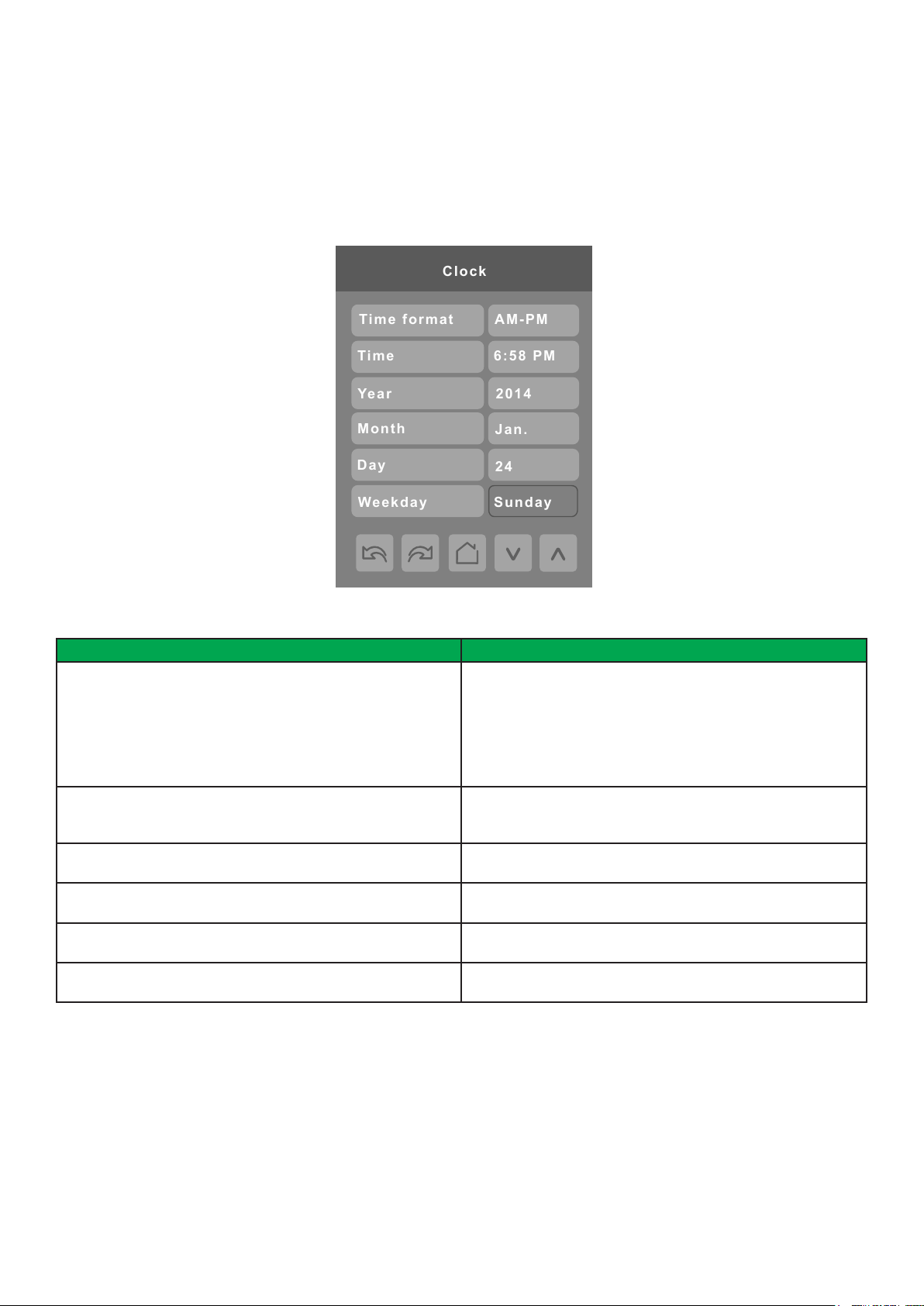

CLOCK SETTINGS

Clock

Time format

AM-PM

6:58 PM

Time

2014

Year

Month

Day

Weekday

24

Jan.

Sunday

The Clock settings screen allows the device’s internal time settings to be changed, including current time, standard day, month,

year and weekday options, as well as choice between a 12 hour AM / PM display or a 24 hour display.

5

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Time Format

Current time display format

Default value: AM-PM

Time

Current time display setting

Default value: Begins at 12:00 AM at initial power up.

Year

Default value: 2000

Month

Default value: Jan.

Day

Default value: 01

Weekday

Default value: Sunday

Choice between 12 hour AM - PM time format or 24 hour time

format.

AM-PM

24 Hours

Note: Changing the value of this parameter automatically

changes the format of the displayed value of the Time

parameter directly below.

Standard time display, 12 hour AM-PM or 24 hour; format is

determined by the Time Format parameter value.

Current year

Current month

Current day

Current day of the week

6

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

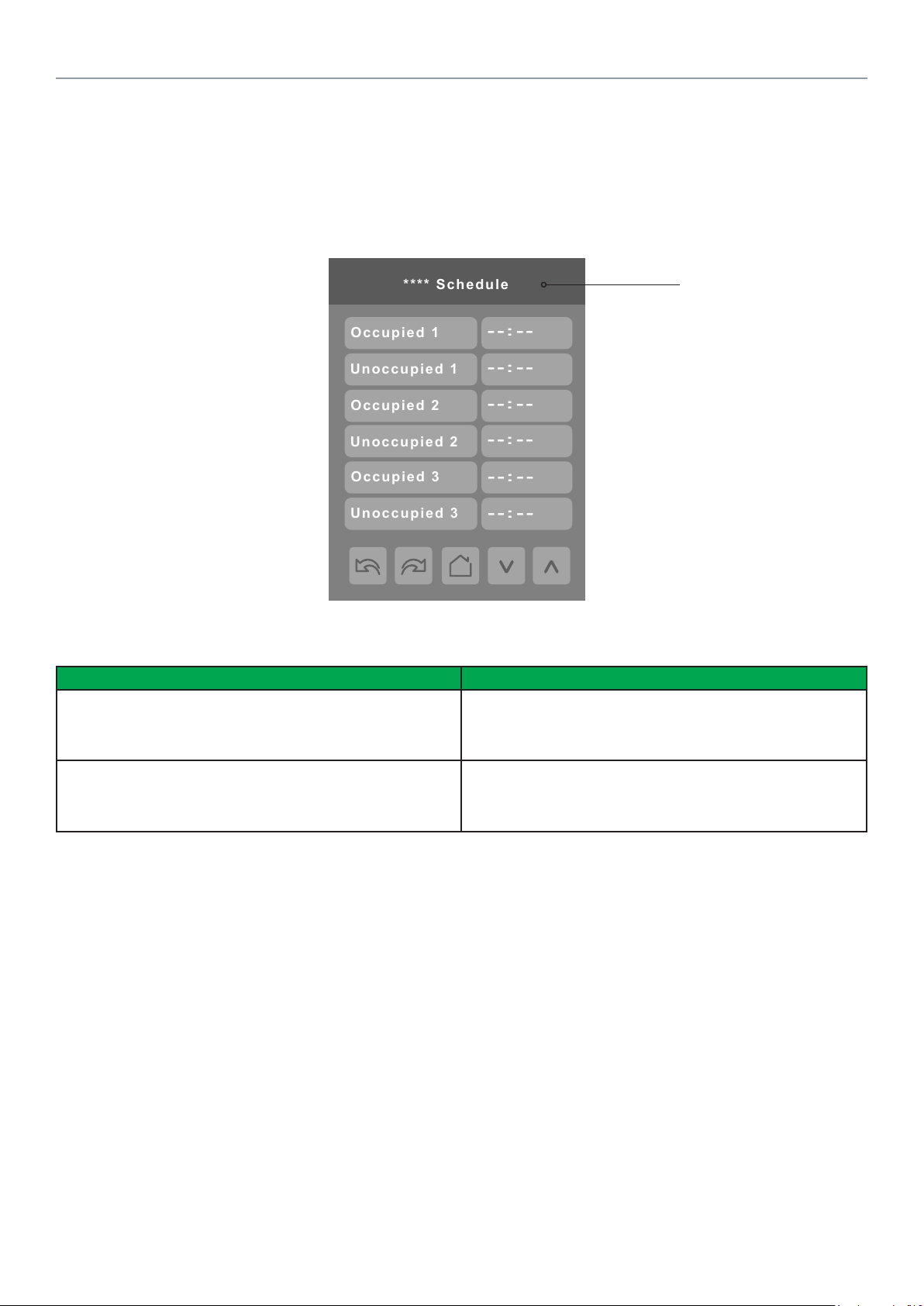

--:--

--:--

**** Schedule

Occupied 1

Unoccupied 1

--:--

--:--

Occupied 2

Unoccupied 2

--:--

--:--

Occupied 3

Unoccupied 3

SCHEDULE SETTINGS

There are 7 different schedule setting screens, one for each day of the week, titled accordingly. Each day can have different

scheduled events where the room controller is set to Occupied status or back to Unoccupied status and use the appropriate

setpoints, back and forth up to 3 times per day.

Screen title is identied by

day of the week (Sunday

through Saturday)

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Occupied

Default value: None

Unoccupied

Default value: None

Denes a time when the room controller is automatically set to

use the Occupied setpoint.

Note: There are 3 separate Occupied parameter entries.

Denes a time when the room controller is automatically set to

use the Unoccupied setpoint.

Note: There are 3 separate Unoccupied parameter entries.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

OPTIONS SETTINGS

The options settings screen allows you to determine how the Room Controller will determine whether it is functioning in Occupied

or Unoccupied mode and scheduling.

6/7 Configuration

Options

Language English

Occupancy cmd Loc occ.

Schedule type 7 days

Units °C

Low backlight 60 %

Night backlight 5 %

RH display Disable

7

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Occupancy cmd

Default value: Local occ

Schedule type

Default value: 7 days

Occupancy Command

Loc occ: occupancy is determined by local sequences (either PIR

or schedule, as congured under Occ. source).

Occupied: force occupied mode.

Unoccup: force unoccupied mode.

Schedule type Command

7 days: Independent scheduling; title is identied by day of the

week (Sunday through Saturday).

5+1+1 days: Weekdays scheduling and Independent Weekend

scheduling; title is identied as Weekdays, Saturday and Sunday.

5+2 days: Weekdays scheduling and Weekend scheduling; title is

identied as Weekdays and Weekend.

8

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Set function to

Status

1/10 Zone

Battery

Not paired

Comm. status

0x0000

IEEE addr.

None

Closed

Normal

Permit join

On

Set function to

Status

10/10 Zone

Battery

No

Comm. status

0x0000

IEEE addr.

None

Closed

Normal

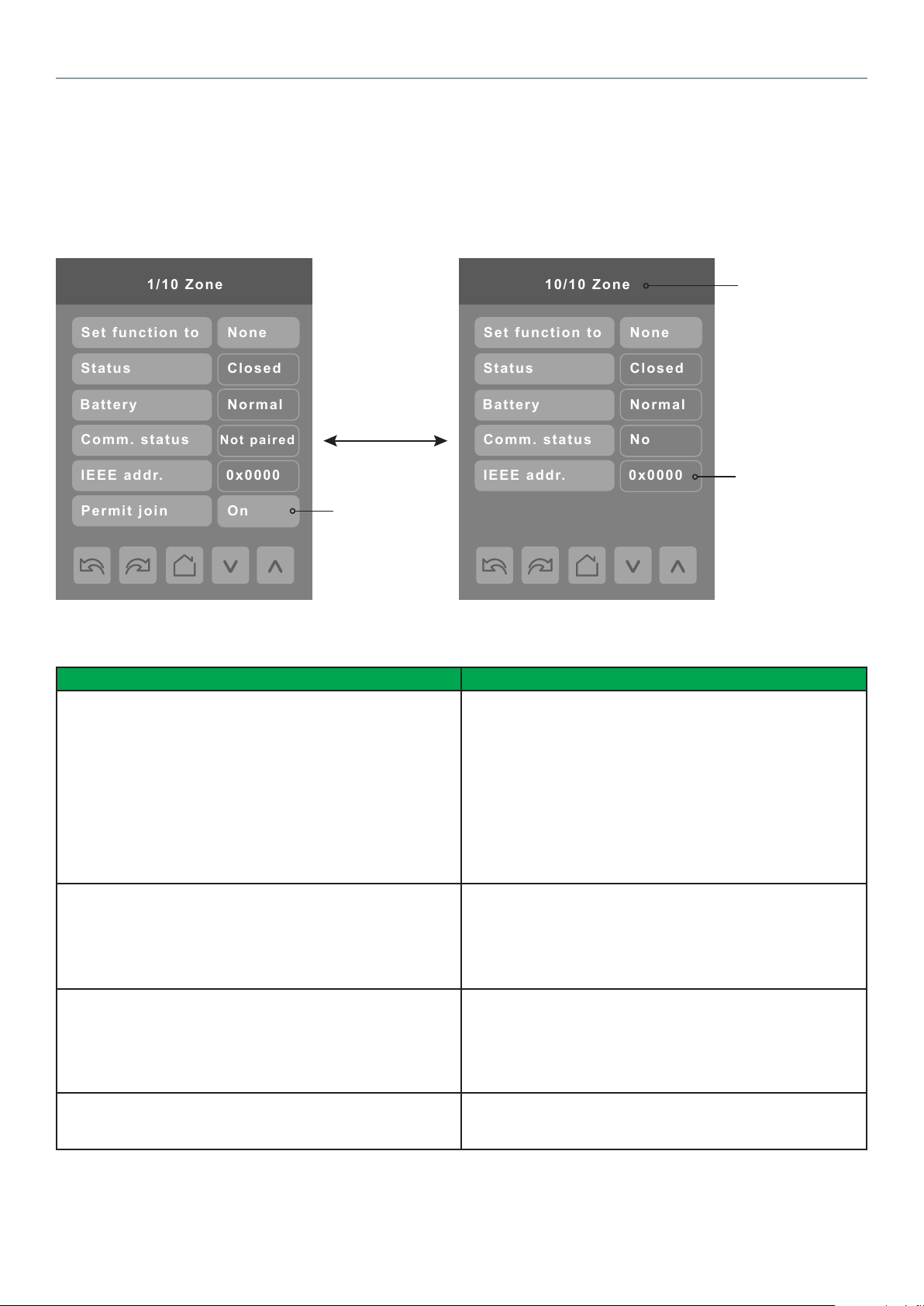

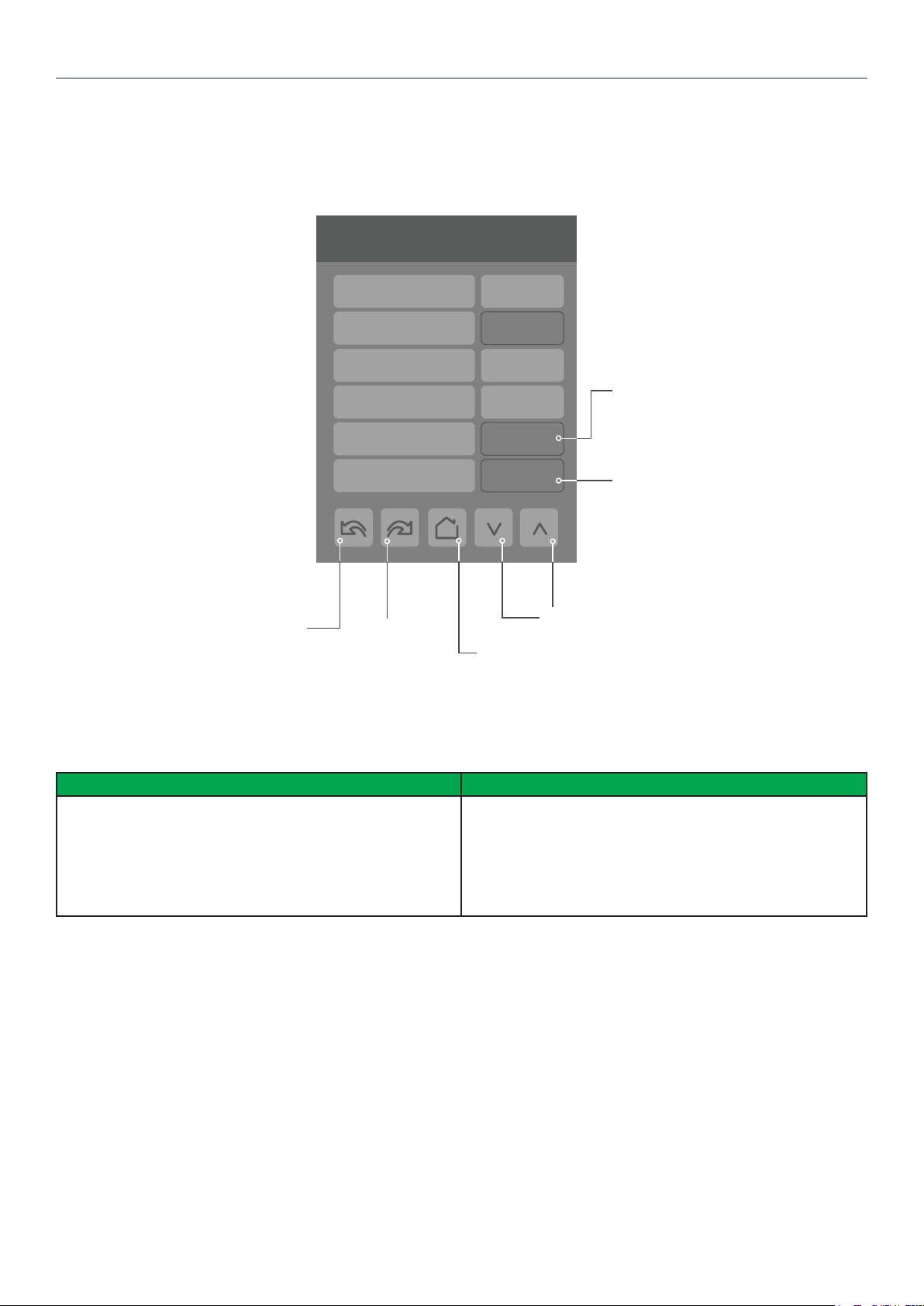

WIRELESS ECOSYSTEM

When ZigBee wireless sensors are set up to communicate with a Room Controller, the functioning of each such sensor is

described in a separate Zone screen, up to a maximum of 10 Zones. Select the appropriate type of sensor based on the required

functioning using the up and down arrow keys.

Up to 10 separate

wireless sensors

can be congured,

each with its own

Zone screen

Identical to ZigBee

settings display

parameter, see

page 11

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Set function to

Describe function of specied wireless sensor

Default value: None

Status

Current status of information received from the sensor

Read only

Battery

Current status of sensor battery, if any.

Read only

Comm. Status

Sensor pairing state

Read only

Only last 4 digits

in HEX shown

None: No sensor function congured for this zone

Door: Sensor is a door contact switch

Window: Sensor is a window contact switch

Motion: Sensor is a motion sensor

Status: Updates the BACnet status of the sensor, but no

action is taken by the internal logic of the controller.

Remove: Selecting this function clears the zone of the settings

for the attached sensor. However, the sensor will automatically

try to reconnect with the room controller unless it is manually

reset as well.

Close: Sensor in closed state (door/window only)

Open: Sensor in opened state (door/window only)

No motion: Sensor detects no motion (motion sensor only)

Motion: Sensor detects motion (motion sensor only)

None: No status information received from sensor.

Low: Battery power level is low, replacement or recharge will

be needed soon

Normal: Battery power level is in the normal range,

replacement or recharge is not currently needed.

None: Sensor does not use a battery

Default: Not paired

Choices: Not paired, Online, Invalid, Ofine

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

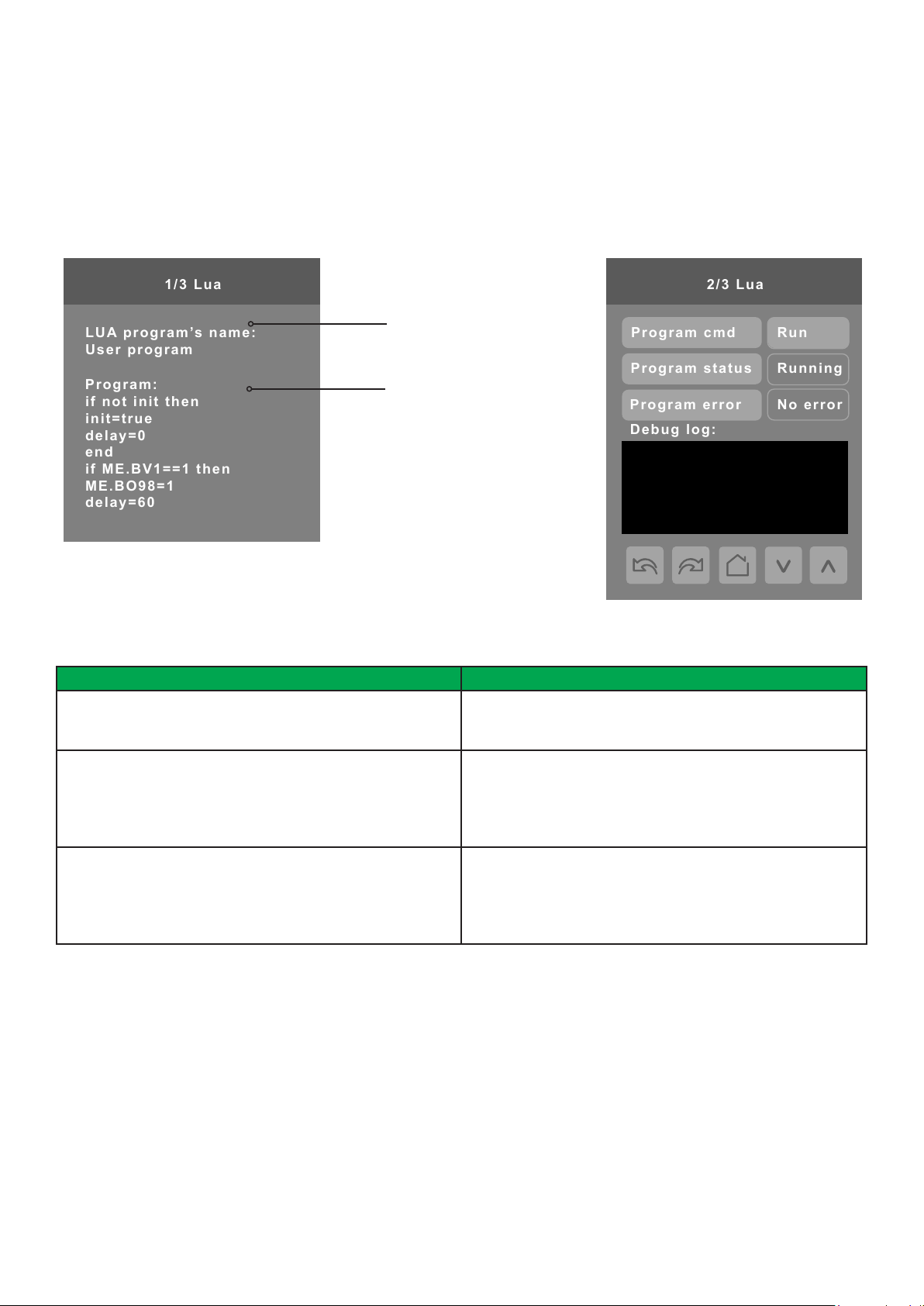

LUA SETTINGS

1/3 Lua

LUA program’s name:

User program

Program:

if not init then

init=true

delay=0

end

if ME.BV1==1 then

ME.BO98=1

delay=60

2/3 Lua

Debug log:

Program cmd

Program status

Program error

Run

Running

No error

The LUA settings screens show information about any custom LUA script uploaded to the controller. LUA scripts are not

programmable on the controllers, and so must be uploaded to the controllers.

The title of the LUA script

is shown here

The body of the LUA

script is shown here

9

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Program cmd

Default value: Run

Program status

Read only

Program error

Read only

Run: The LUA script is activated and will run continuously until

deactivated.

Stop: The LUA script is deactivated

Running: The LUA script is current active

Halted: The LUA script has been stopped and is not active.

Idle: The LUA script is running but is not currently taking any

actions

Waiting: The LUA script is running and waiting for a response.

No error: No errors in the LUA script are detected.

Syntax: A syntax error in the LUA script is detected

Runtime: A runtime error has occurred while running the LUA

script.

Memory: The device has run out of memory for the script

10

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

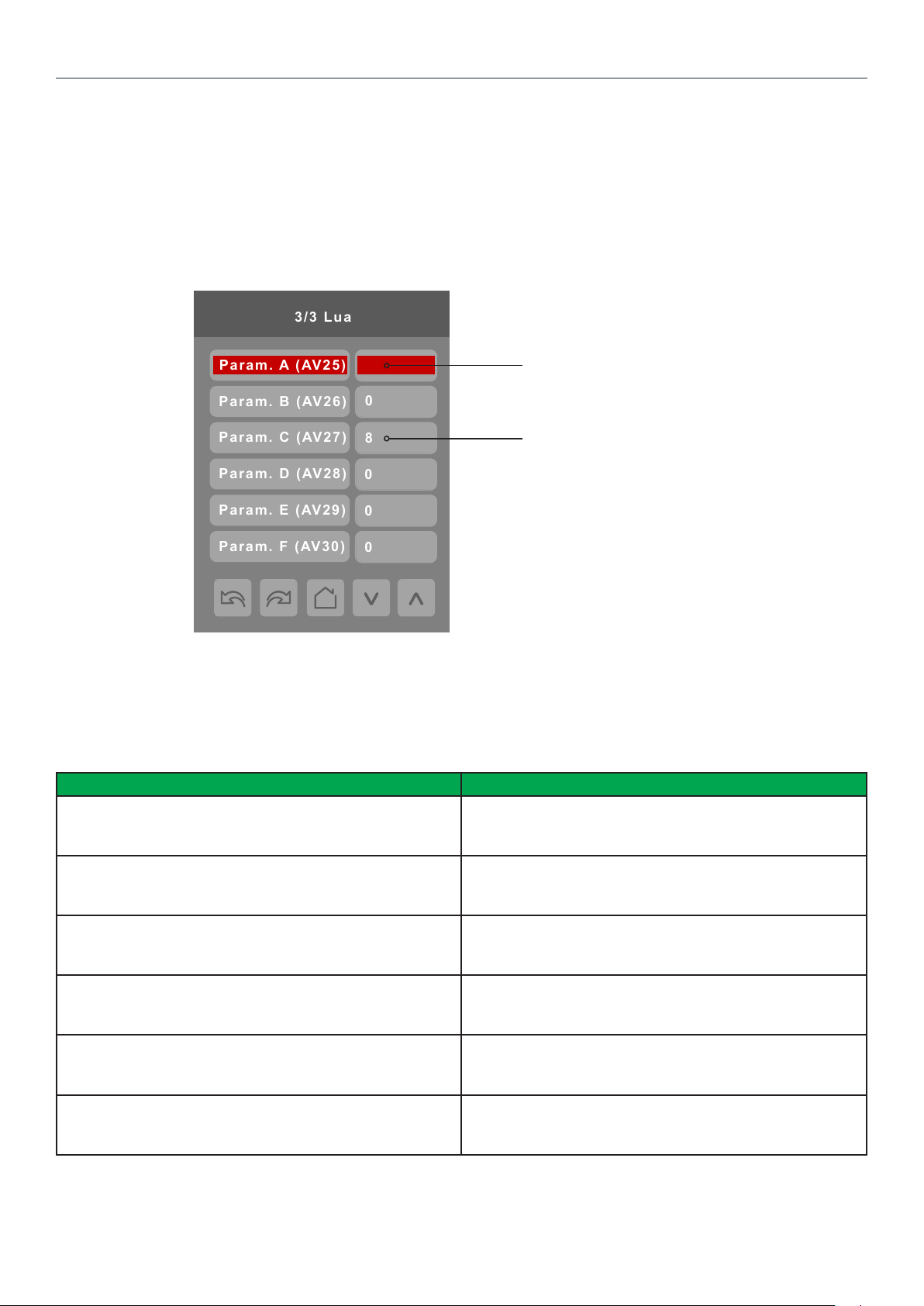

3/3 Lua

0

8

Param. B (AV26)

Param. C (AV27)

Param. D (AV28)

Param. E (AV29)

Param. F (AV30)

0

0

0

Param. A (AV25)

LUA GENERIC PARAMETERS

The LUA settings include six generic parameters that do not have predened values. These can be used to represent LUA script

variables. They are user congurable in their default state, but when they are assigned a value by a LUA script they become read

only, and the display colour of the parameter changes to red. These parameters are also modiable through BACnet as Analog

Values (AVs). These parameters can be congured to receive information from ZigBee sensors.

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Parameter A

Default value: 0

Default value can be changed by user

Parameter B

Default value: 0

Default value can be changed by user

Parameter C

Default value: 0

Default value can be changed by user

Parameter D

Default value: 0

Default value can be changed by user

Parameter E

Default value: 0

Default value can be changed by user

Parameter F

Default value: 0

Default value can be changed by user

5

A parameter dened by a LUA

script displays in red text.

The default value is normally 0,

but it can be user-congured to

use a different default value.

AV25

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

AV26

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

AV27

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

AV28

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

AV29

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

AV30

The value(s) of this parameter depends on what is assigned to

it using the LUA script function

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

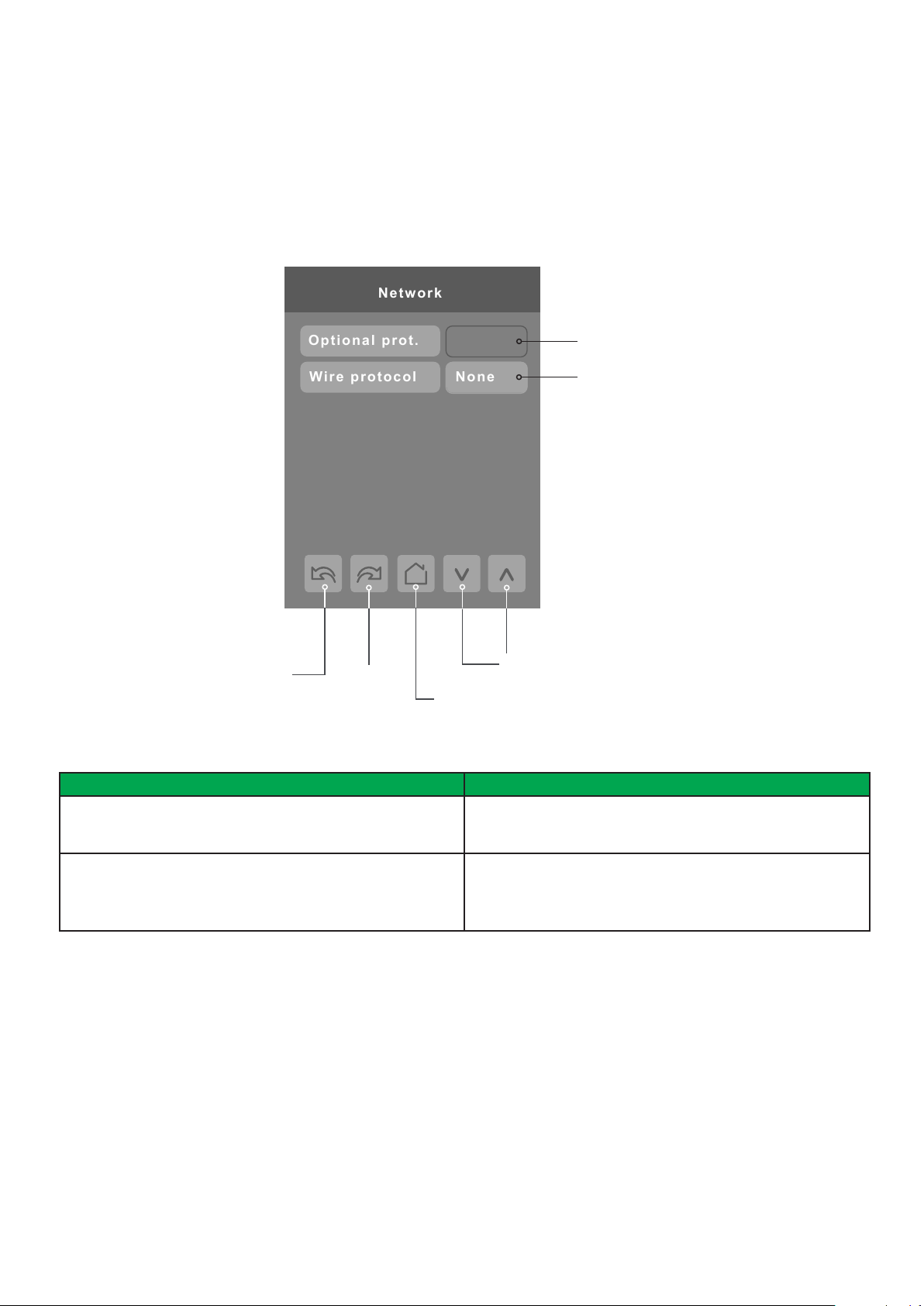

NETWORK SETTINGS

Network

None

Wire protocol

Optional prot.

Network screen shows if a ZigBee card is detected and selection between BACnet or Modbus network protocols.

11

Previous

Page

PARAMETER DETAILS

Conguration Parameters Default Value Signicance and Adjustments

Optional prot.

Default value: None

Default value can be changed by user

Wire protocol

Default value: None

Next

Page

None

ZigBee card detection

Wired network protocol selection

Change Value

( see note )

Back to

Setup Page

None: No ZigBee card detected

ZigBee: ZigBee card detected

None: No wired protocol congured

BACnet: Enable BACnet network protocol

Modbus: Enable Modbus network protocol

12

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

ZIGBEE PRO NETWORK SETTINGS

ZigBee Pro set-up screen shows when ZigBee card is detected in model. Select desired parameter and use up or down arrow to

set parameter to desired value.

1/3 Zigbee network

COM address 254

Node type Router

ZigBee PAN ID 25

ZigBee channel 15

ZigBee short 0x0000

ZigBee® Pro short

address. The address is

generated once device

joins a ZigBee® network

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Com address

Terminal Equipment

Controller networking address

Default value: 254

Range value: 0 - 254

Previous

Page

ZigBee status No NWK

Next

Page

Back to

Setup Page

Communication Address

For wireless models, the use of the COM address is not

mandatory.

The COM address is an optional way to identify a device on

the network.

Status of controller

detecting a ZigBee®

network. Shows Online

when connected

successfully to network

Change Value

( see note )

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

ZigBee Pan ID

Personal Area Network

Identication

Default value: 0

Range value: 1 - 1000

ZigBee channel

Channel selection

Default value: 10

Range value: 10 - 25

13

ZigBee Pro PAN ID

Links specic Terminal Equipment Controllers to

specic ZigBee® Pro coordinators. For every Terminal

Equipment Controller reporting to a coordinator. Ensure set

the SAME channel value both on the coordinator and the

Terminal Equipment Controller(s).

Default value of 0 is NOT a valid PAN ID. The valid range of

available PAN IDs is from 1 to 1000.

Range 1 to 500 for centralized networked applications using

a ZigBee® Pro Coordinator.

Range 501 to 1000 is for stand-alone applications where

each controller is its own coordinator for stand alone

installation of wireless door and window switches.

ZigBee channel

This parameter links specic Terminal Equipment Controllers

to specic ZigBee® Pro coordinators. For every Terminal

Equipment Controller reporting to a coordinator, ensure you

set the SAME channel value both on the coordinator and the

Terminal Equipment Controller(s).

ZigBee status

Read only

Using channels 15 and 25 is recommended.

The default value of 10 is NOT a valid channel. The valid

range of available channels is from 11 to 25.

ZigBee status

The following read only messages show in this eld:

Not Det: ZigBee® Pro module not detected

Pwr On: ZigBee® Pro module detected but not congured

No NWK: ZigBee® Pro congured but no network joined

Joined: ZigBee® Pro network joined

Online: Communicating

14

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

2/3 Zigbee network

Door status

Closed

Door installed

No

Window status

Closed

Win. installed

No

Permit join

On

Low bat. alarm

Off

Door contact

status if installed

Window contact

status if installed

Battery status

of wireless switch

Note: Display returns to home screen

when no activity is detected for 1

minute.

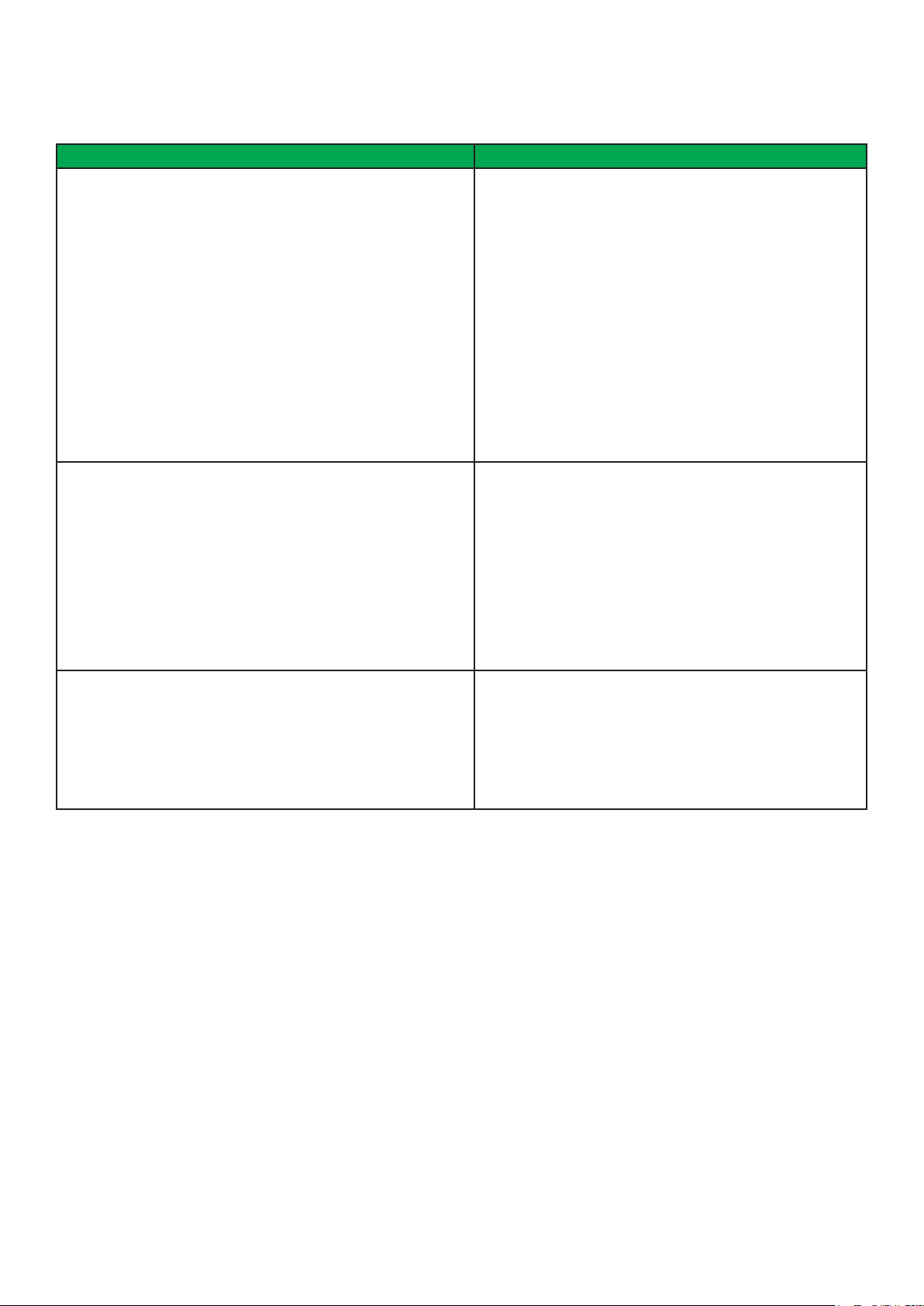

PARAMETER DETAILS

Indicates if door contact is

installed

Indicates if window contact

is installed

Automatically allows

ZigBee® Pro devices to

join the network through

this controller.

Conguration parameters default value Signicance and adjustments

Permit join

Default value: On

Permit Join

Changing this value to Off prevents any new ZigBee® Pro

devices from joining network through this controller.

3/3 Zigbee network

IEEE address 0x0000

Only last 4 digits in HEX

show

Note: The display will return to the home screen when no activity is detected for 1 minute.

PARAMETER DETAILS

Conguration parameters

default value

IEEE address

Default value = 0x0000

Signicance and adjustments

The extended IEEE ZigBee® node address is used to identify the device on the network.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

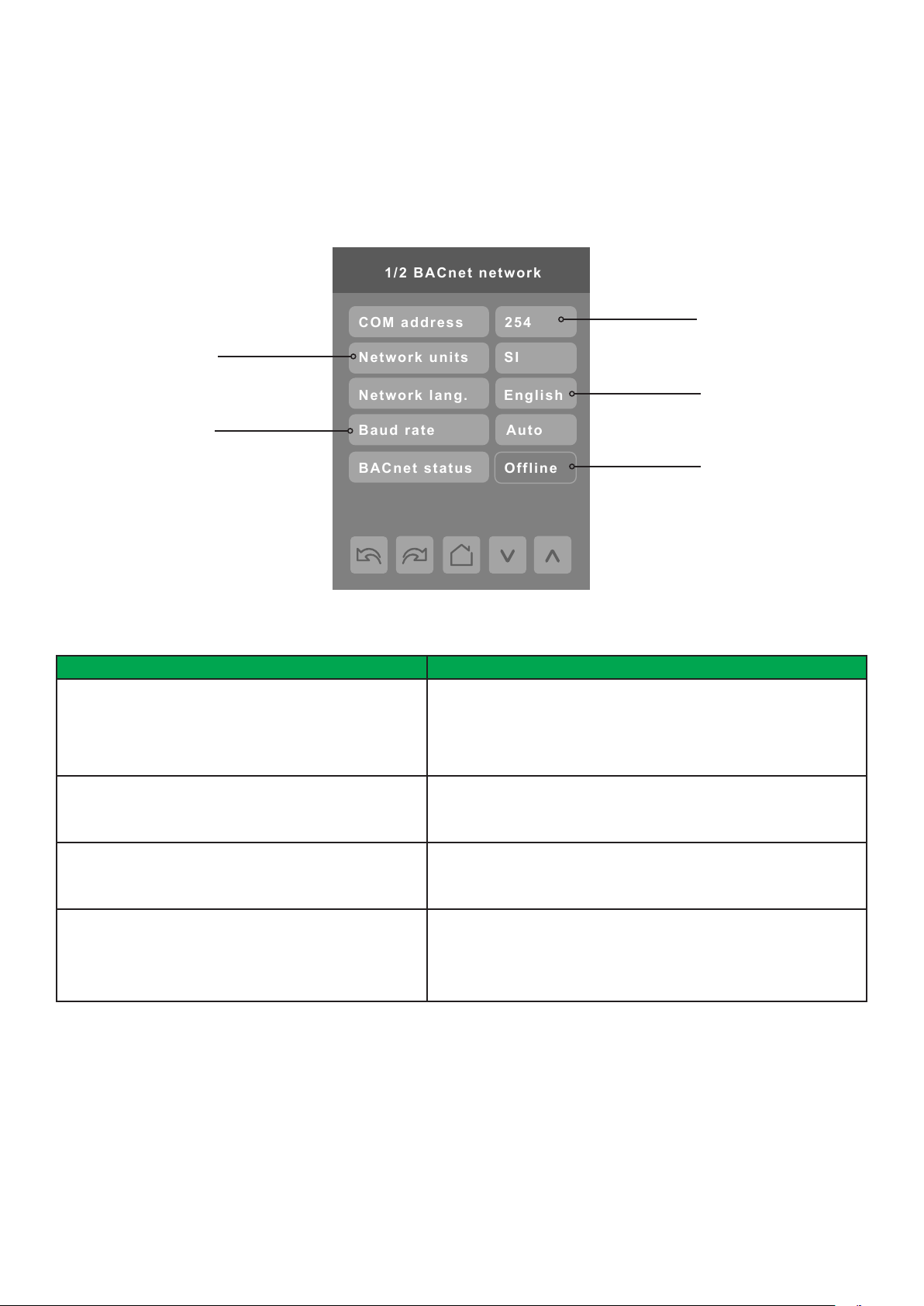

BACNET NETWORK SETTINGS

1/2 BACnet network

Baud rate

Auto

Network units

SI

Network lang.

English

BACnet status

Offline

COM address

254

BACnet network set-up screen shows when BACnet is detected in model. Select desired parameter and use up or down arrow to

set parameter to desired value.

15

Imperial or

Metric units

Baud rate

settings

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Comm address

Terminal Equipment Controller

networking address

Default value: 254

Range: 0 to 254

Network units

Default value: Imperial

Network lang

Default value: English

Baud rate

Default value: Auto

254 value sets BACnet

network Ofine. Choose

different value to activate

Online

Language setting

Displays BACnet status,

Ofine or Online

Communication Address

For BACnet® MS-TP models, the valid range is from 1 to 127.

Default value of 254 disables BACnet® communication for the Terminal Equipment Controller.

Measurement Units

Imperial: network units shown as Imperial units.

SI: network units shown as International Metric units.

Language Settings

Choice of network language/object names transmitted over network.

All available choices: (English, French, and Spanish).

Baud Rate

Auto: automatically detects BACnet® MS/TP baud rate.

Other choices: (115200, 76800, 57600, 38400, 19200, and 9600).

Leave the value at auto unless instructed otherwise.

®

16

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

0830057

2/2 BACnet instance

BACNET INSTANCE NUMBER

The default BACnet® instance number is generated by the model number and COM address of the controller. For example, the

instance number of a SE8300U5B00 with a COM address of 57 is generated as “83057”.

The default instance number appears rst. To change the instance number, use number pad and press Accept and save.

Press Reset to automatic instance addressing to reset to automatic instance addressing.

Instance number of controller

Reset to automatic

instance addressing

Accept and save

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

MODBUS NETWORK SETTINGS

1/1 Modbus network

Parity

None

Network units

SI

Baud rate

19200

COM address

254

Modbus network set-up screen shows when Modbus is detected in model. Select desired parameter and use up or down arrow to

set parameter to desired value.

254 value sets Modbus

network Ofine. Choose

Imperial or

Metric units

Baud rate

settings

different value to activate

Online

Parity checking

17

PARAMETER DETAILS

Conguration Parameters Default Value Signicance and Adjustments

Comm address

Terminal Equipment Controller

networking address

Default value: 254

Range: 0 to 254

Network units

Default value: Imperial

Baud rate

Default value: 19200 + Even Parity

Parity

Default value: None

Communication Address

Default value of 254 disables Modbus communication for the

Terminal Equipment Controller.

Measurement Units

Imperial: network units shown as Imperial units.

SI: network units shown as International Metric units.

Baud Rate

Auto: automatically detects baud rate.

Other choices: (115200, 76800, 57600, 38400, 19200, and

9600).

Leave the value at auto unless instructed otherwise.

Parity

Parity checking of the data character frame (Even, Odd, or no

parity (None)).

18

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

CONFIGURATION PARAMETERS SCREEN 1/8

1/8 Configuration

UI16 config None

UI17 config None

UI19 config None

Occupancy src Motion

Smart recovery Off

Setpoint func. Attach SP

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

UI 16

Universal input no.1 conguration

Dry contact to 24 Vac Com.

Default value: None

(MV46 = 1)

None: No function will be associated with the input. Input can be

used for remote network monitoring.

Rem NSB: Occupancy input via a dry contact to 24 Vac Com.

• Open contact = Occupied

• Closed contact = Unoccupied

Window: Disables instantly Heating and Cooling outputs if a

window and/or patio door is opened. The Fan output(s) remain

operational.

• Open contact = Window opened, disables Heat and Cool and

display “Window” alarm

• Closed contact = Normal operation

Motion NO: Remote Occupancy sensor with a Normally Opened

contact, contact closure = Motion.

Motion NC: Remote Occupancy sensor with a Normally Opened

contact, contact closure = Motion.

Fan lock: When (G) Fan output is activated, if this input is not

activated after 10 seconds, the thermostat will disable Heat and

Cool outputs and display “Fan Lock” alarm.

• Open contact = No airow alarm

• Closed contact = Airow present, normal operation

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

UI 17

Universal input no.2 conguration

Default value: None

UI 19

Universal input no.3 conguration

Default value: None

Occupancy src

Default value: Motion

Smart recovery

Smart recovery enabled

Default value: Off

Smart recovery is automatically disabled if UI 16 and / or

UI 17 are congured remote NSB

Setpoint func.

Local setpoint settings

Default value: Dual SP

19

Universal Input No. 2

None: no function associated with input.

Door Dry: door contact and motion detector.

Override: temporary occupancy remote override contact.

Filter: backlit ashing lter alarm shows on the Terminal

Equipment Controller LCD screen when the input is energized.

Service: backlit ashing Service alarm shows on Terminal

Equipment Controller LCD screen when input is energized.

Universal Input No. 3

None: no function associated with input though input can be used

for remote network monitoring.

COC/NH: change over dry contact; normally heat. Used for hot/

cold water or air change over switching in 2 pipe systems.

COC/NC: change over dry contact; normally cool. Used for hot/

cold water or air change over switching in 2 pipe systems.

COS: change over sensor. Used for hot/cold water or air

changeover switching in 2 pipe systems.

Occupancy Source

Local Motion: the local occupancy status is received from a

motion sensor.

Local Schedule: the local occupancy status is determined by the

schedule.

Note: Occ command in the schedule menu can be set to Local

Occ in which case Local occ points to Occ source.

Off = no smart recovery

The occupied schedule time is the time at which the system will

restart.

On = smart recovery active.

The occupied schedule time is the time at which the desired

occupied temperature will be attained. The controller will

automatically optimise the equipment start time.

In any case, the latest a system will restart is 10 minutes prior to

the occupied period time.

Setpoint function

Set the local setpoint interface for the user

Dual SP (Dual Occupied Setpoints Adjustment)

Attach SP (Two Occupied Setpoint Adjustment)

20

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

CONFIGURATION PARAMETERS SCREEN 2/8

2/8 Configuration

Mode button Normal

Auto mode Enabled

Fan menu On-Auto

Auto fan func. AS

Standby mode Absolute

Standby diff. 2.0 °C

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Mode button

Default value: Normal

Auto mode

Default value: On

Fan menu

Default value: On-Auto

Mode button

Normal: Displays temperature Setpoints on main screen

Off-auto: Hides or simplies temperature Setpoints on main screen

Auto Mode

Enables auto function for the mode button

For sequences 2, 4, and 5 only

On: auto active (Off-Cool-Heat-Auto)

Off: auto not active (Off-Cool-Heat)

Fan Speeds

User fan menu presented is dependent on selected fan sequence of

operation for the fan coil.

L-M-H: 3 Speed conguration using 3 fan relays.

L-H: 2 Speed conguration using 2 fan relays.

L-M-H-A: 3 Speed conguration with Auto fan speed mode using

3 fan relays. Auto Mode operation is dependent on Auto Fan

parameter.

L-H-A: 2 Speed conguration with Auto fan speed mode using 2 fan

relays. Auto Mode operation is dependent on Auto Fan parameter.

On-Auto: single Speed conguration. Auto is for Fan on demand/

On is On all the time.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Auto fan func.

Auto Fan Function

Default value: AS

Standby mode

Default value: Abs

Standby diff.

Default value: 2 °C ( 3 °F )

21

Automatic Fan Function

Auto Speed Fan Mode operation for Fan Menu (L-M-H-A) or

(L-H-A).

AS: In Occupied, Standby and Override modes, the Fan stays ON

at Low speed even if there is no demand for Heating or Cooling.

In Unoccupied mode the Fan turns Off all speeds when there is no

demand for Heating or Cooling.

AS/AD: In any Occupancy mode, the Fan turns Off all speeds when

there is no demand for Heating or Cooling.

Standby Mode

Choose which standby setpoints are used for control.

Abs: absolute; Standby entered values are used for standby mode.

Offset: offset; Occupied setpoints +/- Standby diff. used for standby

mode.

Standby Difference

When Standby mode is Relative, standby setpoints are calculated

as:

Standby cool: Cool setpoint + Standby diff.

Standby heat: Heat setpoint - Standby diff.

Adjustable from 0.5 a 2.5 °C ( 1 - 5 °F )

22

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

3/8 Configuration

Temp. occ. time

Unocc. time

Standby time

2.0 hrs

0.0 hrs

0.5 hrs

Deh. hysteresis

5.0% RH

Deh. max. cool

100%

Deh. lockout

Enabled

CONFIGURATION PARAMETERS SCREEN 3/8

These parameters are only displayed

on models with built in humidity sensor

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Standby time

Default value: 0.5 hours

Unocc. time

Default value: 0.0 hours

Standby Time

Time delay between the moment where the PIR cover detects last

movement in the area, and the time which the Terminal Equipment

Controller stand-by setpoints become active.

Range: 0.5 to 24.0 hours in 0.5 hours increments.

Unoccupied Time

Time delay between the moment where the Terminal Equipment

Controller toggles to stand-by mode, and the time which the Terminal

Equipment Controller unoccupied mode and setpoints become

active.

Factory value 0.0 hours: Setting this parameter to its default value of

0.0 hours disables the unoccupied timer. This prevents the Terminal

Equipment Controller to drift from stand-by mode to unoccupied

mode when PIR functions are used.

Range: 0.0 to 24.0 hours in 0.5 hours increments.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Temp. occ. time

Default value: 2 hours

Deh. hysteresis

Default value: 5% RH

Deh. max. cool

Default value: 100%

Deh. lockout

Default value: Enabled

Temporary Occupancy Time

Temporary occupancy time with occupied mode setpoints when

override function is enabled.

When Terminal Equipment Controller is in unoccupied mode, function

is enabled with either the menu or UI2 congured as remote override

input.

Range: 0 - 24 hours.

Humidity Control Hysteresis

Used only if dehumidication sequence is enabled:

Range: 2 to 20% RH

Models with humidity sensor only.

Maximum Dehumidication Cooling

Maximum cooling valve position when dehumidication is enabled. This

can be used to balance smaller reheat loads installed in regards to the

capacity of the cooling coil.

Range: 20 to 100 %

Models with humidity sensor only.

Dehumidication Lockout

Typically toggled through the network. This variable enables or

disables dehumidication based on central network requirements from

the BAS front end.

Enabled: Dehumidication Authorized

Disabled: Dehumidication Not Authorized

Models with humidity sensor only.

23

24

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

CONFIGURATION PARAMETERS SCREEN 4/8

4/8 Configuration

CPH 4

Control type Floating

BO8 out time 15 min.

BO8 aux. config Reheat

Floating time 1.5 min

Action DA

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

CPH

Default value: 4 CPH

Control Type

Control type for Triac models

Default: Floating

Cooling Output Cycles/Hr

Sets maximum number cycles per hour under normal control operation.

It represents the maximum number of cycles equipment turns ON and

OFF in one hour.

A higher CPH represents a higher accuracy of control at the expense

of wearing mechanical components faster.

Range: 3, 4, 5, 6,7 and 8 CPH.

Control Output for FCU Valves

Denes type of control output for type of valves installed for the FCU

application

On/Off: normally opened or normally closed 24 VAC 2 position valves

Floating: modulating 3 wires control of 24 VAC oating valves

Analog: analog modulating control of 2-10 Vdc valves

Refer to proper control diagram according to selected control type

outputs.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

BO8 out time

Default value: 0 = 15 minutes (4 CPH)

BO8 aux. cong

Aux contact function used for reheat if sequence is set

to use BO8 for reheat through network or local. Ignore

this parameter.

Default value: Reheat

Floating Time

Floating actuator stroke timing value

Default value: 1.5 minutes oating actuator timing

Reheat Output Time

Sets reheat output time base.

Valid only if reheat sequences are enabled.

0: 15 minutes

1: 10 seconds for solid state relays

Binary Output Terminal

Output directly follows occupancy of the Terminal Equipment

Controller.

1) Auxiliary NO: Occ or St-By = Contact Closed / Unoccupied =

Contact Opened

2) Auxiliary NC: Occ or St-By = Contact Opened / Unoccupied =

Contact Closed. Output to follow directly main occupancy and Fan on

command. Typically used for 2 position fresh air damper applications.

3) Auxiliary NO: Occ or St-By & Fan On = Contact Closed/

Unoccupied and Fan On or Off = Contact Opened

4) Auxiliary NC: Occ or St-By & Fan On = Contact Opened/

Unoccupied and Fan On or Off = Contact Closed

Floating Time

Maximum stroke time of oating valve actuator.

Range: 0.5 to 9.0 minutes in 0.5 minute increments

25

Action

For Analog Heating signals

Default value: DA signal

Direct Acting/Reverse Acting

Reverse Acting or Direct Acting signal for Analog Output signals

DA = 0 to 100 % = 0 to 10VDC

RA = 0 to 100 % = 10 to 0VDC

26

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

5/8 Configuration

Operation seq.

No. of pipes

Prop. band

Heat only

2

3.0

Purge sample

0.0 hrs

Purge open

1 min

Temp. sensor

Remote

CONFIGURATION PARAMETERS SCREEN 5/8

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Prop. band

Default value: 3

Proportional Band Setting

Adjusts proportional band used by the Terminal Equipment Controller

PI control loop.

Note: default value of 3.0 gives satisfactory operation in most normal

installation cases. The use of a superior proportional band different

than the factory one is normally warranted in applications where

Terminal Equipment Controller location is problematic and leads to

unwanted cycling of the unit. A typical example is a wall mounted unit

where Terminal Equipment Controller is installed between return and

supply air feeds and is directly inuenced by the supply air stream of

unit.

Value Effective Proportional Band

Fahrenheit Celsius

3 3 1.2

4 4 1.7

5 5 2.2

6 6 2.8

7 7 3.3

8 8 3.9

9 9 5.0

10 10 5.6

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

No. of pipes

Default value: 4 pipes

Operation seq.

Default value: Sequence #1

Pipe Setting Type Installed

Denes type of system installed.

2 Pipes: limits number of sequences of operation available from

0 - 4. It also enables heat/cool operation from the same output.

4 Pipes: can access all sequences of operation from 0 - 2. Also

enables heat/cool operation from different output.

Sequence Operation

Selects initial sequence of operation required by installation type and

application.

System Modes System = 2 Pipes System = 4 Pipes

Off - Cool Cooling Only Cooling Only

Off - Heat Heating Only Heating Only

Off - Auto - Heat -

Cool

Cooling With Electric

Reheat

Off - Heat Heating With Electric

Reheat

Off - Auto - Heat -

Cool N/A

Off - Auto - Heat -

Cool N/A

For 2 Pipe output applications, the system

is limited if congured for local changeover

COS, COC/NC or COC/NC. The current

water temperature detected by the RU1 then

limits the system mode available for the local

conguration or network write.

27

Cooling With Electric

Reheat

Heating With Electric

Reheat

4 = Cooling and

Heating (2 modulat-

ing outputs)

5 = Cooling/Heating

(2 modulating out-

puts) with reheat

Purge sample

Default value: 2 hours

Purge open

Default value: 2 minutes

Temp. sensor

Default Value: Remote

Time interval between valve samples. Opens valve for a short period

adjusted by Purge open parameter to sample pipe temperature to

decide between heating or cooling mode.

Adjustable for 0 to 4 hours (0 = disable).

Time valve opens to sample pipe temperature to decide between heating or cooling mode.

Adjustable for 1 to 3 minutes.

Selection of room temperature sensor

• Remote: Room Controller uses internal temperature sensor only if

UI20 terminal is empty. If a valid temperature sensor is connected

on UI20 terminal, Room Controller will automatically disable its

internal sensor and use the remote sensor as control point. Disconnecting the sensor, or, if the sensor value is out-of-range, the

room controller will automatically re-enable its internal temperature sensor.

• Local: Room Controller uses internal temperature sensor even

if UI20 terminal is used. Typical use for return air temperature or

other temperature monitoring via BACnet point UI20. It can also

be used for average internal sensor with remote sensor using a

simple Lua4RC script.

28

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

6/8 Configuration

User password

Main password

0

0

Schedule menu

Enabled

CONFIGURATION PARAMETERS SCREEN 6/8

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Main password

Default value: 0

User Password

Default value: 0

Schedule menu

Default value: Enabled

Toggles activation of schedule menu direct access

Main Password

Installer password. This parameter sets a protective access

password to prevent unauthorised access to conguration menu

parameters.

Default value of 0 does not prompt a password or lock access

conguration menu.

Range: 0 - 9999.

User Password

End user password. This parameter sets a protective access password

to prevent user unauthorised access to main screen adjustments.

Default value of 0 does not prompt a password.

Range: 0 - 9999.

Enabled: The Schedule Menu is directly accessible from the main

screen via a touch in the upper corner (see page 4).

Disabled: The Schedule Menu can only be accessed through the

Setup Menu screens.

Dis.no.clk: Clock function disabled.

En.no.clk: Clock function enabled.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

7/8 Configuration

Calib. temp.

0.0 °C

Calib. humid.

0.0 %RH

CO2 autocal.

Enabled

CONFIGURATION PARAMETERS SCREEN 7/7

Parameter only displayed on

models with built in humidity

sensor.

29

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Calib. temp.

Default value: 0.0 °C or °F

Calib. humid.

Default value: 0% RH

CO2 autocal.

Default value: Enabled

Calibration Temperature

Room temperature sensor calibration. Offset can be added or

subtracted to actual displayed room temperature.

Range: ± 2.5 °C, 0.5 °C increments ( ± 5.0 °F, 1.0 °F increments ).

Humidity Calibration

Humidity sensor calibration. Offset can be added or subtracted to

actual displayed humidity.

Range: ± 15.0 %RH (models with humidity sensor only).

Enable or Disable CO2 sensor auto calibration.

30

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

8/8 Reinitialization

Push to accept:

Are you sure?

Erase all?

No

No

CONFIGURATION PARAMETERS SCREEN 8/8

PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Erase all?

Default value: No

Are you sure?

Default value: No

Erase All

Answering Yes on both and pressing Accept button erases all values

and changes to factory default values except the following network

related values:

• COM address

• ZigBee® Pro Pan ID

• ZigBee® Pro channel

• Network units

• Network language

• Baud rate

• BACnet® instance

• Device name

• Screen Contrast

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

PASSWORD SETTINGS

Installer Password

01234

56789

Enter the code

The following shows you how to enter the password for the Installer and User

Installer Password

31

1. Installer password prompt shows only if password value is greater than 0000. A password value of 0000 disables installer

password but does not restrict access to conguration options.

2. Installer password prompt automatically disappears after 10 seconds if no value is entered.

3. An error code is automatically generated if incorrect password is entered.

4. Installer is permitted access to all Installer functions and menus when correct password is entered.

NOTE: when the schedule menu is enabled OR when the 5th button is set to schedule or custom, the clock, occupancy

command, schedule or custom pages are NOT password-protected. Always use a system password when the Room Controller is

in regular use to avoid inadvertent changes of the Room Controller logic.

32

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

User Password

01234

56789

Wrong code

User Password

1. User password prompt shows only if password value is greater than 0000. A password value of 0000 disables user password but

does not restrict access to local user functions.

2. User password prompt automatically disappears after 10 seconds if no value is entered.

3. User is permitted access to controller interface to change any allowed settings when correct password is entered.

4. Password lock resumes after 1 minute of non activity.

PASSWORD PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Main password

Default value: 0

User password

Default value: No

Installers Password

Parameter sets a protective access password to prevent unauthorised

access to the conguration menu parameters. A default value of 0

does not prompt a password or lock access to conguration menu.

Range: 0 to 9999.

Are You Sure?

Parameter sets a protective access password to prevent User

unauthorised access to main screen adjustments. A default value of 0

does not prompt for a password.

Range: 0 to 9999.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

1/2 Setpoints

Occ. cool

Standby cool

Unocc. cool

25.5 °C

24.0 °C

22.0 °C

20.5 °C

16.5 °C

26.5 °C

Occ. heat

Standby heat

Unocc. heat

SETPOINT SETTINGS 1/2

33

SETPOINT PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Unocc. cool

Default value: 26.5 °C (80 °F)

Standby cool

Default value: 25.5 °C (78 °F)

Occ. cool

Default value: 24.0 °C (74 °F)

Occ. heat

Default value: 22.0 °C (72 °F)

Standby heat

Default value: 20.5 °C (69 °F)

Unocc. heat

Default value: 16.5 °C (62 °F)

Unoccupied Cooling

Unoccupied cooling setpoint range: 2.0 to 37.5 °C (54 to 100 °F).

Standby Cooling

The value of this parameter should be set between occupied and

unoccupied cooling setpoints. Ensure difference between standby and

occupied value can be recovered in a timely fashion when movement

is detected in the zone.

Stand-by cooling setpoint range: 12.0 to 37.5 °C (54 to 100 °F).

Occupied Cooling

Cooling setpoint range: 12.0 to 37.5 °C (54 to 100 °F).

Occupied Heating

Heating setpoint range: 12.0 to 37.5 °C (54 to 100 °F).

Standby Heating

The value of this parameter should be set between occupied and

unoccupied heating setpoints. Ensure difference between standby and

occupied value can be recovered in a timely fashion when movement

is detected in the zone.

Stand-by heating setpoint range: 4.5 to 32.0 °C (40 to 90 °F).

Unoccupied Heating

Unoccupied heating setpoint range: 4.5 to 32.0 °C (40 to 90 °F).

34

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

2/2 Setpoints

Max. heating

Min. deadband

Default heat

1.5 °C

32.0 °C

12.0 °C

13.0 °C

22.0 °C

Min. cooling

Supply air SP

50.0 %RH

Dehum. SP

SETPOINT SETTINGS 2/2

Parameter only displayed on

models with built in humidity

sensor.

SETPOINT PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Default heat

Default value: 22.0 °C (73 °F)

Min. deadband

Default value: 1.5 °C (3 °F)

Max heating

Default value: 32 °C (90 °F)

Min. cooling

Default value: 12.0 °C (54 °F)

Dehum. SP

Default value: 50% RH

Default Heat

Used for hospitality applications in stand-alone mode only. When

devices are in deep unoccupied mode, any movement detected by PIR

resets actual occupied set points to fresh room default setting.

Default setpoint is used to write to Heating setpoint when thermostat

goes to Unoccupied mode.

Cooling setpoint is set according to Min. deadband; 18.5 to 26.5 °C (65

to 80 °F).

Parameter is only used when Stand-by mode = Offset.

Minimum Deadband

Minimum deadband value between heating and cooling setpoints

applied only when any setpoints are modied.

Range: 1.0 to 2.5 °C, 0.5 °C increments (2, 3, 4 or 5 °F,

1.0 °F increments).

Maximum Heating

Maximum occupied and unoccupied heating setpoint adjustment.

Range: 4.5 to 32.0 °C (40 to 90 °F).

Minimum Cooling

Minimum occupied and unoccupied cooling setpoint adjustment.

Range: 12.0 to 37.5 °C (54 to 100 °F).

Dehumidication Setpoint

Used only if dehumidication sequence is enabled:

Range is: 30-95% RH (models with humidity sensor only).

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Contrast

1/2 Display

Colour

White

User HMI

0

Main display

Temp.

Standby screen

No

0

DISPLAY SETTINGS 1/2

35

SETPOINT PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

User HMI

Default value: 0

Colour

Default value: White

Main display

Default value: Temp.

Standby screen

Default value: No

Contrast

Default value: 0

User HMI

Select user HMI type.

Range: 0 to 11.

White

Change background colors according to set font colors.

Main Display

Shows room temperature or setpoint

Standby Screen

When the device is left unattended for 2 minutes background

backlight dims.

Installers can load a custom image for brand identication.

Controls the screen contrast and brightness.

-5 is least bright, most contrast; 5 is most bright, least contrast.

Range: -5 to 5

36

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

User HMI for hospitality

Hospitality 0 Hospitality 1 Hospitality 2 Hospitality 3

• Setpoint adjustment

• System mode setting

• Fan mode setting

• Local unit scale

adjustment

• Local user language

• User help menu

Parameters are model dependent and may not appear on certain models.

• Setpoint adjustment

• System mode setting

• Fan mode setting

• User help menu

• Local unit scale

adjustment

• Local user language

• User help menu

• Setpoint adjustment

• User help menu

Hospitality 4 Hospitality 5 Hospitality 6 Commercial 7

• Fully locked interface

with no user settings

• Setpoint adjustment

• System mode setting

• User help menu

• Setpoint adjustment

• System mode setting

• Fan mode setting

• Local unit scale

adjustment

• User help menu

• Setpoint adjustment

• System mode setting

• Fan mode setting

• unoccupied mode

overdrive

• User help menu

37

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Commercial 8

• Setpoint adjustment

• Unoccupied mode

override

• Local user language

• User help menu

Note:

The day/night setback button appears only in unoccupied mode from 7 to 11 in HMI Commercial.

If UI17 input is congured as “override”, the day/night setback button does not show.

Commercial 9 Commercial 10 Commercial 11

• Setpoint adjustment

• Unoccupied mode

override

• User help menu

• Unoccupied mode

override

• Setpoint adjustment

• System mode setting

• Unoccupied mode

override

• User help menu

Parameters are model dependent and may not appear on certain models.

Other Functions

Local humidity only shows on models with the humidity sensor present and when enabled by conguration property RH Display.

Outdoor temperature display is dependent on receiving a valid networked outdoor temperature value.

38

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Heating only conguration

Setpoint value shows if main

display parameter is set to

Setpoint.

On/Off icon is used instead

of system mode icon when

sequence of operation is set

to either heating on or

cooling only.

Time and Date show only when a

network time synchronisation command is

received.

Setpoint adjustment for cooling mode

In Cooling mode, the setpoint displayed in the bar is the current occupied cooling setpoint.

During occupied setpoint adjustment, the large digits are temporarily used to show occupied cooling setpoint

while it is adjusted.

Normal temperature display resumes after setpoint is adjusted and actual occupied cooling setpoint shows in

setpoint bar.

Cooling mode or cooling only sequence of

operation.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Setpoint adjustment for heating mode

In automatic mode, setpoint showing at the top of the set point bar located directly under the blue line

represents the actual occupied cooling setpoint.

During occupied setpoints adjustment, large digits are temporarily used to display the occupied Cooling

Setpoint or occupied Heating Setpoint. The actual setpoint is dependent on the last effective demand (heating

or cooling). The setpoint on top of the red line represents the actual occupied heating setpoint. The

differential between the occupied heating and cooling setpoint is dened by the minimum deadband

conguration parameter.

Normal temperature display resumes after setpoints are adjusted and the actual occupied heating and cooling

setpoints show in the setpoint bar.

39

Automatic Heating/Cooling Mode

40

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

CUSTOMIZABLE COLOR OPTIONS

White Green Blue

Dark Grey Grey

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Language

Night backlight

Units

Low backlight

English

5%

°C

60%

RH display

Disabled

2/2 Display

CO2 display

Enabled

DISPLAY SETTINGS 2/2

Parameter only displayed on

models with built in humidity

sensor.

41

SETPOINT PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Language

Default value: English

Only EN, FR and SP available for BACnet models.

Units

Default value: °C

Low backlight

Default value: 60%

Language

Select language for main display.

Choices: English, French, Spanish, Chinese, Russian, Arabic,

Bulgarian, Czech, Danish, Dutch, Finnish, German, Hungarian,

Indonesian, Italian, Norwegian, Polish, Portuguese, Slovak,

Swedish, Turkish

Temperature Units

Sets default local scale value when Terminal Equipment Controller powers up.

°C for Celsius.

°F for Fahrenheit.

Backlight Display

Set display backlight intensity after 2 minutes of keyboard

inactivity.

Adjustable: 0 to 100%.

42

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

SETPOINT PARAMETER DETAILS

Conguration parameters default value Signicance and adjustments

Night backlight

Default value: 5%

RH display

Default value: Disabled

CO2 display

Default value: Disabled

Night Backlight Display

Set display backlight intensity after 2 minutes of keyboard

inactivity.

Adjustable: 0 to 100%.

Parameter only available for models with motion/light detectors. The screen backlight progressively decreases down to

this setting when room is dark. This feature is used mostly in

hospitality applications when a darker non obtrusive lighting

level is desired when room is dark.

Relative Humidity Display

Enables display of humidity below room temperature on the

display

(On): Display %RH.

(Off): Do not display %RH.

Models with humidity sensor only

CO2 Levels Display

Enables display of carbon dioxide (CO2) below room temperature

on the display

(On): Display %CO2.

(Off): Do not display %CO2

.

Models with CO2 sensor only.

43

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

1/8 Service view

Room temp.

xx.x °C

Room humidity

xx.x %RH

Firmware rev.

1.0

xx.x °C

UI20 temp.

xx.x °C

UI1 9 changover

xx.x °C

Outdoor temp.

2/8 Service view

PI heat demand

0%

0%

PI cool demand

Heat dem. limit

0.0%

0.0%

Cool dem. limit

Effective occ.

Occupied

Supply temp.

xx.x °C

SERVICE VIEW SCREENS

The service view screens show the current status of certain points locally at the controller. These points can also be viewed through

the network. Service view allows service contractor to visualize the status of key functionality to correctly diagnose operational system

issues.

Firmware Revision

Room Temperature

Changeover Temperature

Remote Temperature

Outdoor Temperature

Room Humidity

Parameter only displayed on

models with built in humidity

sensor.

Effective Occupancy

PI Cooling Demand

PI Heating Demand

Cooling Demand Limit

Heating Demand Limit

Supply Temperature

44

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

3/8 Service view

UI16 binary

UI19 binary

UI17 binary

Activated

Not activ.

Zigb. sens. mot.

Zigb. PIR inst.

No motion

Off

Not activ.

Filter alarm

Window alarm

Off

Off

Off

Service alarm

Local motion

4/8 Service view

Deh. status

Off

Recovery status

Off

Local motionLocal motion

Motion

Deh. status

Off

Universal Input Status

Universal Input Status

Universal Input Status

External PIR Install Status

Local Motion Status

Window Alarm Status

Service Alarm Status

Filter Alarm Status

Recovery Status

Local Motion Status

Dehumidication Status

Parameter only displayed on

models with built in humidity

sensor.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

UO9 config

Binary

Binary

5/8 Service view

UO10 config

UO11 config

UO12 config

Binary

Binary

Term.24 10V

0.0 Vdc

Universal Output Conguration

UI19 type

Sensor

Sensor

6/8 Service view

UI20 type

UI22 type

UI23 type

Sensor

Sensor

UI24 type

Voltage

Universal Output Conguration

Universal Output Conguration

Universal Output Conguration

0-10Vdc Universal Input

45

Universal Input Conguration

Universal Input Conguration

Universal Input Conguration

Universal Input Conguration

Universal Input (Voltage)

46

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

8/8 Service view

Device name:

Graphic Library Revision:

2.0.0

SE83xxUxx-xxx

CO2 module

0x0000

None

7/8 Service View

CO2 err. code

CO2 level

CO2 FW rev.

CO2 S/N

0 PPM

CO2 Sensor module

CO2 Sensor error code

CO2 Remote Sensor Level

CO2 Sensor rmware revision

CO2 Sensor serial number

Device Name / Model Number

The Model Number is the BACnet® device name automatically assigned when using the current BACnet®

addressing scheme based on the MAC address. The network can update and change the device BACnet® name. If changed, the

new updated BACnet® device name shows on the screen.

For example, when a SE8300U5B00 thermostat with a MAC address of 41 is connected to a network, its default Device Name is

SE8300UxB00-41 and its default BACnet Device ID is 83041.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

BO2 fan low

BO4 fan high

Off

Off

Off

BO3 fan med

BO8 aux. out

Off

1/2 Test Outputs

TEST OUTPUTS

47

Note 1: Cooling output can also be used for heating on two pipes systems.

Note 2: The test output screen allows manual override of specied outputs. When any BACnet® network priority array includes a

value, the status background shows in red. After any output state is overridden, the command is cancelled after 1 minute of screen

inactivity (auto exit to main screen) or when page is exited. Refer to the BACnet® integration guide for more details.

Note 3: Use high caution when manually enabling outputs so as to not cause damage to equipment. It is the responsibility of the

Installer or Service Contractor to insure safe operation during usage.

48

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

UO11 binary

UO9 binary

Off

Off

Off

UO10 binary

UO12 binary

Off

2/2 Test outputs

UO11 analog

0 Vdc

0 Vdc

UO12 analog

2/2 Test outputs

TEST OUTPUTS

CASE A

CASE B

Note: screen Test outputs are LIVE. Any output gets displayed immediately for any value change according to the following:

1. If any BACnet priority array (1 - 16) includes a value, the displayed state background shows in red.

2. When toggling a value on the screen, the output directly energizes according to the selected value.

3. You can override any output if you bypass the BACnet array (1 - 16).

4. It is not possible to modify the set BACnet array values.

5. After any output state gets modied, all overrides get cancelled after 1 minute of button inactivity, or if you scroll from one

screen to another screen.

CASE A: screen 2/2 display is dependent on Control type conguration. If mode is set to Floating or On/Off, binary options show.

CASE B: screen 2/2 display is dependent on Control type conguration. If mode is set to Analog, analog options show.

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

LANGUAGE SELECTION

1/4 Language selection

Chinese

Spanish

French

Enabled

Enabled

Enabled

Russian

Enabled

Arabic

Disabled

2/4 Language selection

Danish

Czech

Bulgarian

Disabled

Disabled

Disabled

Dutch

Disabled

Finnish

Disabled

3/4 Language selection

Indonesian

Hungarian

German

Disabled

Disabled

Disabled

Italian

Disabled

Norwegian

Disabled

4/4 Language selection

Slovak

Portuguese

Polish

Disabled

Disabled

Disabled

Swedish

Disabled

Turkish

Disabled

49

Only English, French, Spanish, Chinese, and Russian are enabled by default and are accessible to users cycling through

languages on the display settings menu screen. To change the language selection settings, touch a language on the screen and

then use the arrow buttons to disable or enable it. The English language is always enabled.

50

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

APPENDIX A: TERMINAL CORRESPONDENCE

The terminals of an SE8300 are identied differently and have a wider range of possible functions compared to those of any of the

SE7000 series Room Controllers. Nonetheless, there is a direct correspondence of functions between the terminals of the SE7000

series and the SE8300 series. Consult the table below to verify the appropriate terminal when replacing a SE7000 Room Control-

ler with a SE8300 Room Controller.

SE7000 SE8300

Terminal name Terminal ID Terminal name Terminal ID

Binary Input 1 BI1 Universal Input 16 UI16

Binary Input 2 BI2 Universal Input 17 UI17

Universal Input 3 UI3 Universal Input 19 UI19

Sensor Common Scom Terminal 18 Common COM

Remote Sensor RS Universal Input 20 UI20 - RS

Sensor Common Scom Terminal 21 Common COM

Mix/Supply Sensor MS Universal Input 22 UI22 - SS

Schneider Electric | UI-SE8 300 -HMI- A4.EN.01.2017.v8 January 2017

Schneider Electric is the global specialist in energy management and automation. With revenues of

25 billion in FY2014, our 170,000 employees serve customers in over 100 countries, helping them

to manage their energy and process in ways that are safe, reliable, efficient and sustainable. From

the simplest of switches to complex operational systems, our technology, software and services

improve the way our customers manage and automate their operations. Our connected technolo-

gies will reshape industries, transform cities and enrich lives.

At Schneider Electric, we call this Life Is On.

Loading...

Loading...