Page 1

SE7600F Series

Installation Guide for RTU with Modulating Heat

CONTENTS

Installation 2

Location 2

Installation 2

Model Chart 3

Network ready 3

Terminal, Identification and Function 3

Screw terminal arrangement and wiring 3

Main outputs wiring 3

Typical Applications 4

Remote sensor accessories 4

Configuring and Status Display Instructions 6

Status display 6

User interface 7

User configuring instructions menu 7

Local keypad interface 7

Page 2

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

INSTALLATION

Inspection

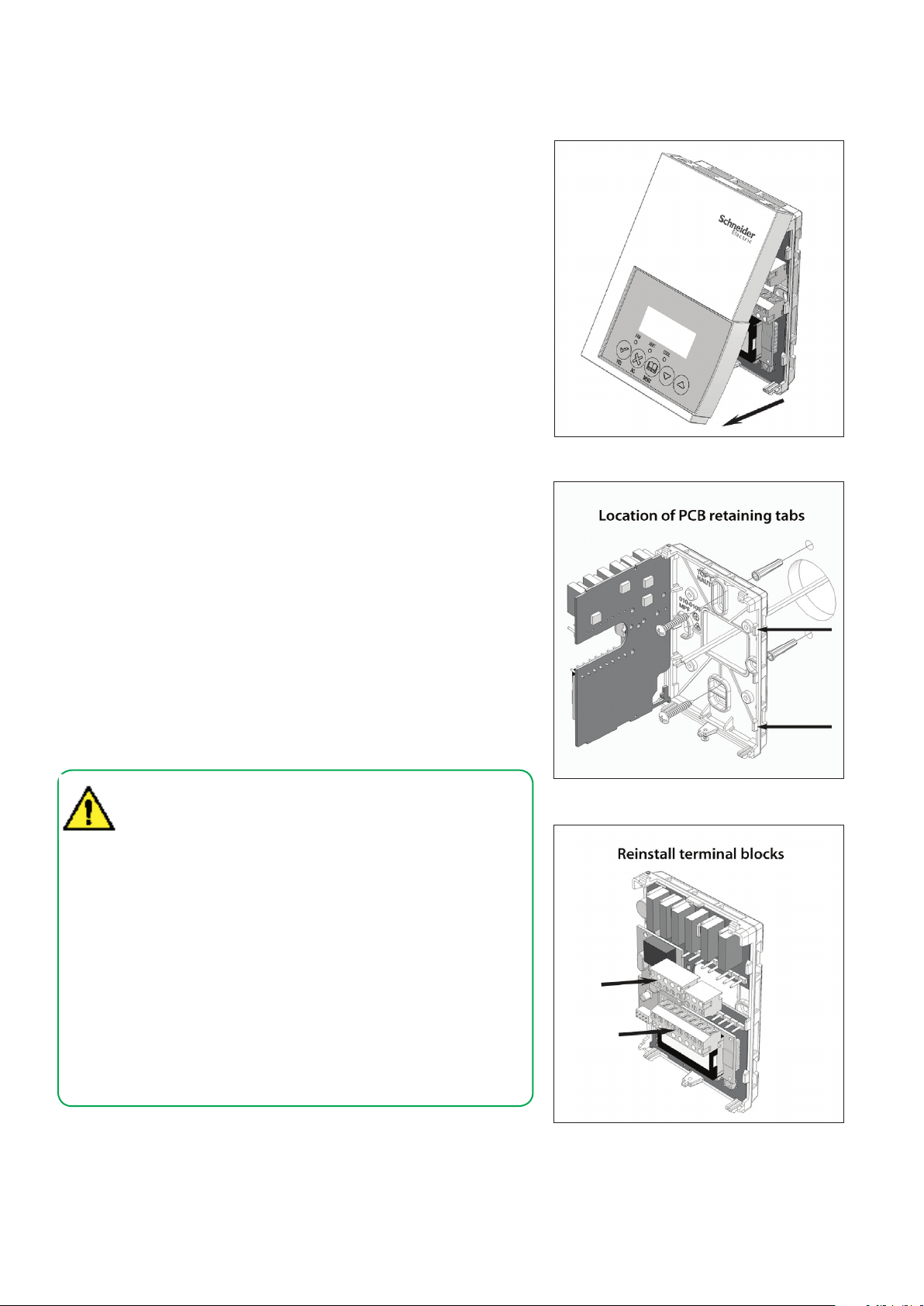

• Remove security screw on bottom of Room Controller cover.

• Open unit by pulling on bottom side of Room Controller (Figure-1).

• Remove wiring terminals from sticker.

• Read the FCC ID and IC label installed in the cover.

Location

• Do not install on an outside wall.

• Install away from any direct heat source.

• Do not install near air discharge grill.

• Do not locate in direct sun radiation.

• Nothing should restrict vertical air circulation to Room Controller.

Installation

1. Swing open Room Controller PCB to the left by pressing two PCB

retaining tabs (Figure-2).

2. Pull cables 6" out from wall.

Ensure wall surface is flat and clean.

3. Insert cable into central hole of base.

4. Align base and mark location of two mounting holes on wall ensuring

proper side of base is upward.

5. Install screw anchors in wall.

6. Insert screws in mounting holes on each side of base (Figure-2).

7. Gently swing back circuit board on base and push until tabs lock.

8. Strip each wire 1/4 inch from end.

9. Insert each wire according to wiring diagram.

10. Gently push excess wiring back into hole in base.

11. Reinstall wiring terminals in correct locations (Figure-3).

12. Reinstall cover (top side first) and gently push any extra wire length back

into hole in wall.

13. Install security screw.

2

Figure-1 Ope ning the Cover

• If replacing an existing Room Controller, label wires before

removal of Room Controller.

• Electronic controls are static sensitive devices. Discharge

yourself properly before manipulating and installing Room

Controller.

• A short circuit or wrong wiring may permanently damage the

Room Controller or the equipment.

• All SE7000 series Room Controllers are designed for use as

operating controls only and are not safety devices. These

instruments have undergone rigorous tests and verification

prior to shipping to ensure proper and reliable operation in

the field. Whenever a control failure could lead to personal

injury and/or loss of property, it becomes the responsibility

of the user / installer / electrical system designer to

incorporate safety devices (such as relays, flow switch,

thermal protections) and/or an alarm system to protect the

entire system against such catastrophic failures. Tampering

with the devices or unintended application of the devices will

result in a void of warranty.

Figure-2 Op ening the PCB

Figure-3 Terminal Block Reinstall

Page 3

3

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

NETWORK READY

• All Schneider Electric SE7600 series Room Controllers

(TEC) are designed for stand-alone (Network Ready) operation.

• They can be fully integrated into your choice of automation systems using

the available communication adapter options.

• If required, stand-alone (Network Ready) TECs can be field retrofitted with

the following communication adapters:

• VCM7000V5045W wireless Zigbee® communication adapter.

• VCM7600V5045B BACnet® MS-TP® communication adapter.

TERMINAL IDENTIFICATION

Terminal Use

1 – Y2 2nd cooling Y2 Second cooling stage output.

2 – Y1 1st cool Y1 First cooling stage output.

3 – G Fan G Fan output.

4 – RC 24VAC hot RC Power supply of thermostat, hot side.

5 – C 24VAC com C Power supply of thermostat, common side.

9 – AO analog heat AO Analog 0 – 10 VDC heating output.

10 – Auxiliary output AUX

11 – DI 1 DI 1

12 – DI 2 DI 2

13 – RS RS Remote temperature sensor input.

14 - Scom Scom Reference input for DI 1, RS, OS & DS.

15 - OS OS Outside air temperature sensor input.

16 - DS MS Discharge air temperature sensor input.

Terminal

Identification

Description

Auxiliary output used to disable economizer minimum

position or control lighting during unoccupied

periods.

Configurable extra digital input. See parameter

section for more information.

Configurable extra digital input. See parameter

section for more information.

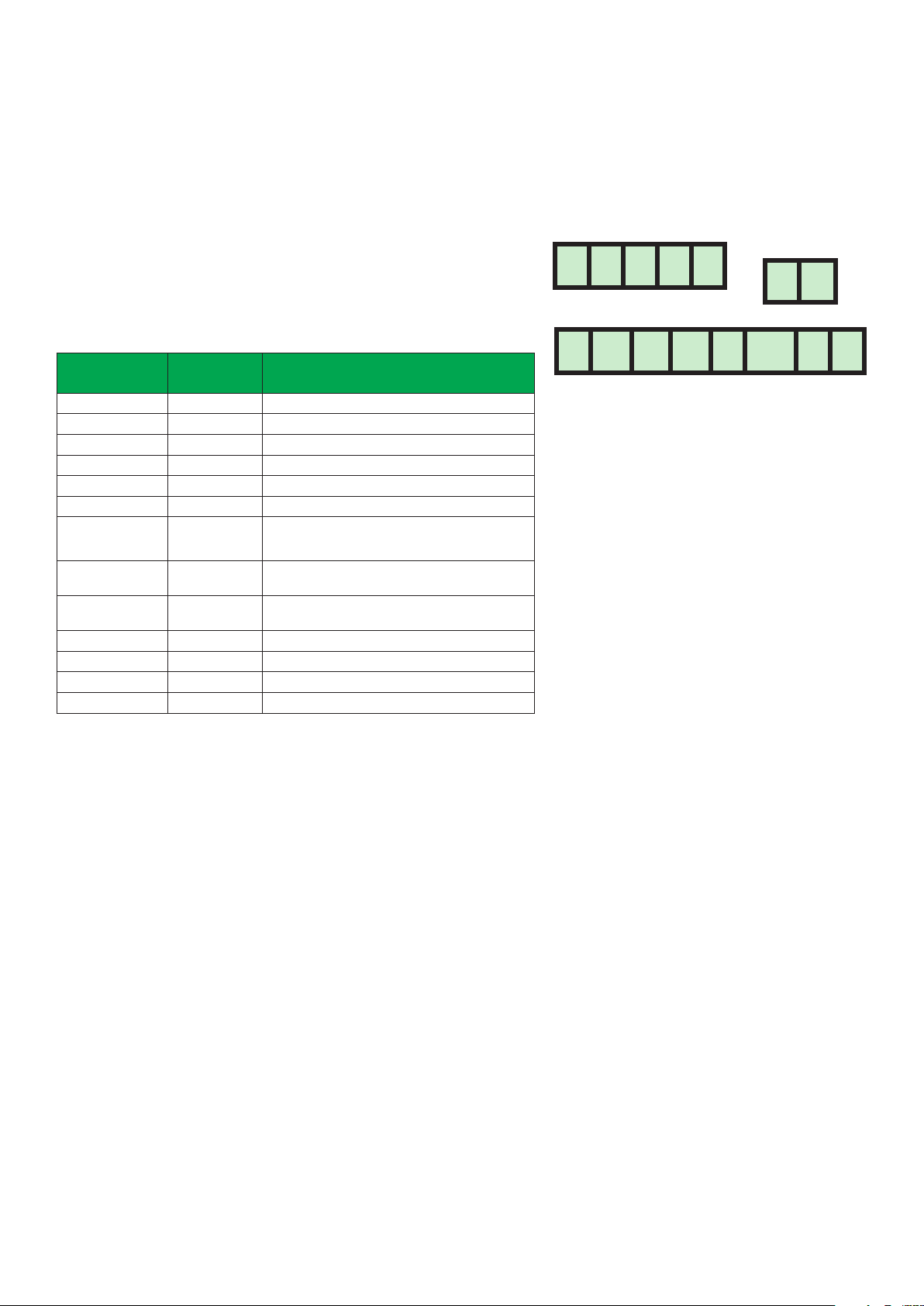

MAIN OUTPUTS WIRING

Screw Terminal Arrangement

SE76XXF Controller Terminals

Y2 Y1 G RC C

AO Aux DI1 DI2 RS Scom OS MS

Wiring Notes

Note 1

If the same power source is used for the heating

stages, install a jumper across terminals RC and RH.

The maximum current is 2.0 amps.

Note 2

If the auxiliary output is used to toggle occupancy

of the electronic control card inside the equipment,

configure the relay parameter (Aux cont) to the N.O.

setting. A second relay can be added for additional

functionality of the occupancy output.

Note 3

Economizer output uses a half-bridge rectifier.

Reference of the control signal is the Common

(Terminal C) of the power supply of the Room

Controller.

Note 4

Electromechanical contacts are to be used with the

digital inputs. Electronic triacs cannot be used as a

means of switching for the input. The switched leg

to the input for the input to activate is the Common

(Terminal C).

Note 5

The transformer of the unit provides power to the

Room Controller and the additional loads that will be

wired to the Room Controller.

Page 4

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

TYPICAL APPLICATIONS

Digital Input #1

Main Outputs Wiring

4

Digital Input #2

Y2 Y1 GAOAU DI1 DI2 RS OS MSScom

Cool

Stage

2

Cool

Stage

1

RC C

Fan

T1

24V AC

REMOTE SENSOR ACCESSORIES

0-10 VDC

24V Com

Controller Wiring

System Wiring

Auxiliary

Output

Field

Contacts

Remote

Room

Sensor

Remote

Outdoor

Sensor

Remote

Mixed Air

Sensor

Applicable Models

Model Description Application Picture

• Remote room sensing

SE3010W1045 Room sensor

Room sensor

with temporary

SE3020W1045

override

key and

occupancy

LED

• 3 thermistors with 2 dip

switches are provided with

each sensor for various

averaging combinations

• Remote room sensing

with override key and

occupancy LED

• 3 thermistors with 2 dip

switches are provided with

each sensor for various

averaging combinations

Page 5

5

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

D2 D1

One Sensor:

Two Sensors,

REMOTE TEMPERATURE SENSORS

Single Sensor

Scom

RS

AU

C

Two Sensor Averaging Application

Scom

RS

AU

C

D2 D1

Scom

RS

AU

C

D2 D1

Scom

RS

Three Sensor Application

Scom

RS

AU

C

D2 D1

Scom

RS

AU

C

D2 D1

SENSOR

SE3020W1045

Scom

RS

Aux

C

DI

SE3020W1045 SE3010W1045

Scom

RS

Aux

C

DI

SE3020W1045

Scom

RS

Aux

C

DI

SE3010W1045

Scom

RS

SE3020W1045 SE3010W1045

Scom

RS

Aux

C

DI

SE3020W1045 SE3020W1045 SE3010W1045

Scom

RS

Aux

C

DI

SE3010W1045

OR

Scom

RS

SE3020W1045

Scom

RS

Aux

C

DI

SE3010W1045

Scom

SE3010W1045

RS

Scom

RS

Scom

RS

Aux

C

DI

SENSOR

Scom

RS

SE3010W1045

Scom

RS

Scom

RS

Temp. Sensor DIP Switch Settings

ON

1

ON

1

SE3020W1045

Remote temperature sensor DIP switch location

S2-1 = ON

S2-2 = ON

2

Three Sensors:

S2-1 = OFF

S2-2 = OFF

2

ON

1

2

Temperature vs. resistance chart

for 10 Kohm NTC thermistor

ºC ºF Kohm

-40 -40 324.3197

-35 -31 234.4009

-30 -22 171.3474

-25 -13 126.6109

-20 -4 94.5149

-15 5 71.2430

-10 14 54.1988

-5 23 41.5956

0 32 32.1910

5 41 25.1119

10 50 19.7390

15 59 15.6286

20 68 12.4601

25 77 10.0000

30 86 8.0694

35 95 6.5499

40 104 5.3467

45 113 4.3881

50 122 3.6202

55 131 3.0016

(R

= 10KΩ±3%, B25/85°C = 3975K±1.5%)

25°C

averaging:

S2-1 = OFF

S2-2 = ON

Page 6

6

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

CONFIGURING / STATUS DISPLAY

INSTRUCTIONS

Status Display

The Room Controller features a two-line, eightcharacter display. A low-level, always-active backlight can be seen only at night.

Left unattended, the Room Controller shows an

auto scrolling display that indicates the status of the

system. Each item is scrolled one by one with the

back lighting in low level mode. Pressing any key

will cause the back light to increase to high level.

Manual scrolling of each menu item is achieved by

pressing the YES (scroll) key repetitively. The last

item viewed will be shown on the display for 30

seconds before returning to automatic scrolling.

Temperature is automatically updated when scrolling is held.

Sequence of auto-scroll status display

CLOCK

STATUS

Monday

12:00 AM

SYSTEM

MODE

Sys Mode

Off

Sys Mode

Auto

Sys Mode

Cool

Sys Mode

Heat

SCHEDULE

STATUS

Occupied

OUTDOOR

TEMP.

Outdoor

x.x °C or °F

ALARMS

Service

Unoccupied DAS Alrm

Override SetClock

Filter

Fan lock

Frost ON

Alarms

• If alarms are detected, they will be displayed automatically at the end of the

status display scroll.

• During an alarm message display, the back lit screen will light up at the

same time as the message and shut off during the rest of the status display.

• Two alarms maximum can appear at any given time. The priority for the

alarms is as follows:

When any of the fan speeds are ON,

the FAN LED will illuminate.

When heating & reheat is ON, the

HEAT LED will illuminate.

When cooling is ON, the COOL LED

will illuminate.

Outdoor air temperature

• The outdoor air temperature display is only enabled when the outdoor air temperature sensor is

connected.

• A maximum range status display of 50 °C (122

°F) indicates a shorted sensor. Associated functions, such as mode lockouts and economizer

function are automatically disabled.

• A minimum range status -40 °C (-40 °F)

indicates an open-circuited sensor or a sensor

not connected. Associated functions, such as

mode lockouts and economizer function are

automatically disabled.

Frost ON

SetClock

Service

Filter

Fan lock

DAS

Alarm

Indicates that the heating is energized by the low limit frost

protection room temperature setpoint 5.6 °C (42 °F).

Indicates that the clock needs to be reset. There has been a power

failure which has lasted longer than 6 hours.

Indicates that there is a service alarm as per one of the configurable

digital inputs (DI1 or DI2).

Indicates that the filters are dirty as per one of the configurable

digital inputs (DI1 or DI2).

Indicates that the heating and cooling action are locked out due to a

fan malfunction.

Indicates that the discharge air temperature is either too low or too

high.

Page 7

7

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 December 2015

USER INTERFACE

User Configuring Instructions Menu

The SE76X6 series of Room Controller feature an

intuitive, menu-driven, back-lit LCD display that

walks users through the configuring steps, making the configuring process extremely simple. This

menu is typically accessed by the user to set the

parameters such as temperature and time events,

system mode, fan mode, etc...

It is possible to bring up the user menu at any time

by pressing the MENU key. The status display automatically resumes after exiting the user-configuring

menu.

If the user pauses at any given time during configuring, Auto Help text is displayed to help and guide

the user through the usage and configuring of the

Room Controller.

Local Keypad Interface

The YES key is used to confirm a selection, to move onto the

next menu item and to manually scroll through the displayed

information.

The NO key is used when you do not desire a parameter change,

and to advance to the next menu item. May also be used to

toggle between heating and cooling setpoints.

The MENU key is used to access the Main User Menu or

to exit the menu.

The DOWN ARROW key is used to decrease a temperature

setpoint and to adjust the desired values when configuring the

Room Controller.

The UP ARROW key is used to increase a temperature setpoint

and to adjust the desired values when configuring the Room

Controller.

Sequence of User Menu

OVERRIDE

RESUME

Override

schd? Y/N

(Appears only in

unoccupied mode)

Cancel

ovrd? Y/N

(Appears only in

override mode)

SYSTEM MODE

SETTING

Sys mode

set? Y/N

SCHEDULE

SETTING

Schedule

set? Y/N

CLOCK SETTING

Clock

set? Y/N

Example: Press the YES key to change the cooling

temperature setpoint. Use the Up/Down Arrow keys

to adjust the cooling setpoint.

Each of the sections in the menu is accessed and

configured using 5 keys on the Room Controller

cover.

When left unattended for 45 seconds, the display

will resume automatic status display scrolling.

To turn on the back light, press any key on the front

panel. The back light will turn off when the Room

Controller is left unattended for 45 seconds.

Page 8

8

Schneider Electric | II-SE7600F-A4.EN.12.2015.v2 www.schneider-electric.com/buildings December 2015

Loading...

Loading...