Page 1

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

PIR Ready SE7300F5x45X-ECM Series

Installation Guide for Commercial and Lodging FCU Applications

1

CONTENTS

Installation 2

Location 2

Installation 2

Features overview 3

Model Selection 3

Terminal, Identification and Function 3

Wiring 4

Screw terminal arrangement 4

Main outputs wiring 4

Remote mount temperature sensors 4

Configuring and Status Display Instructions 6

Status display 6

User Interface 7

Page 2

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

INSTALLATION

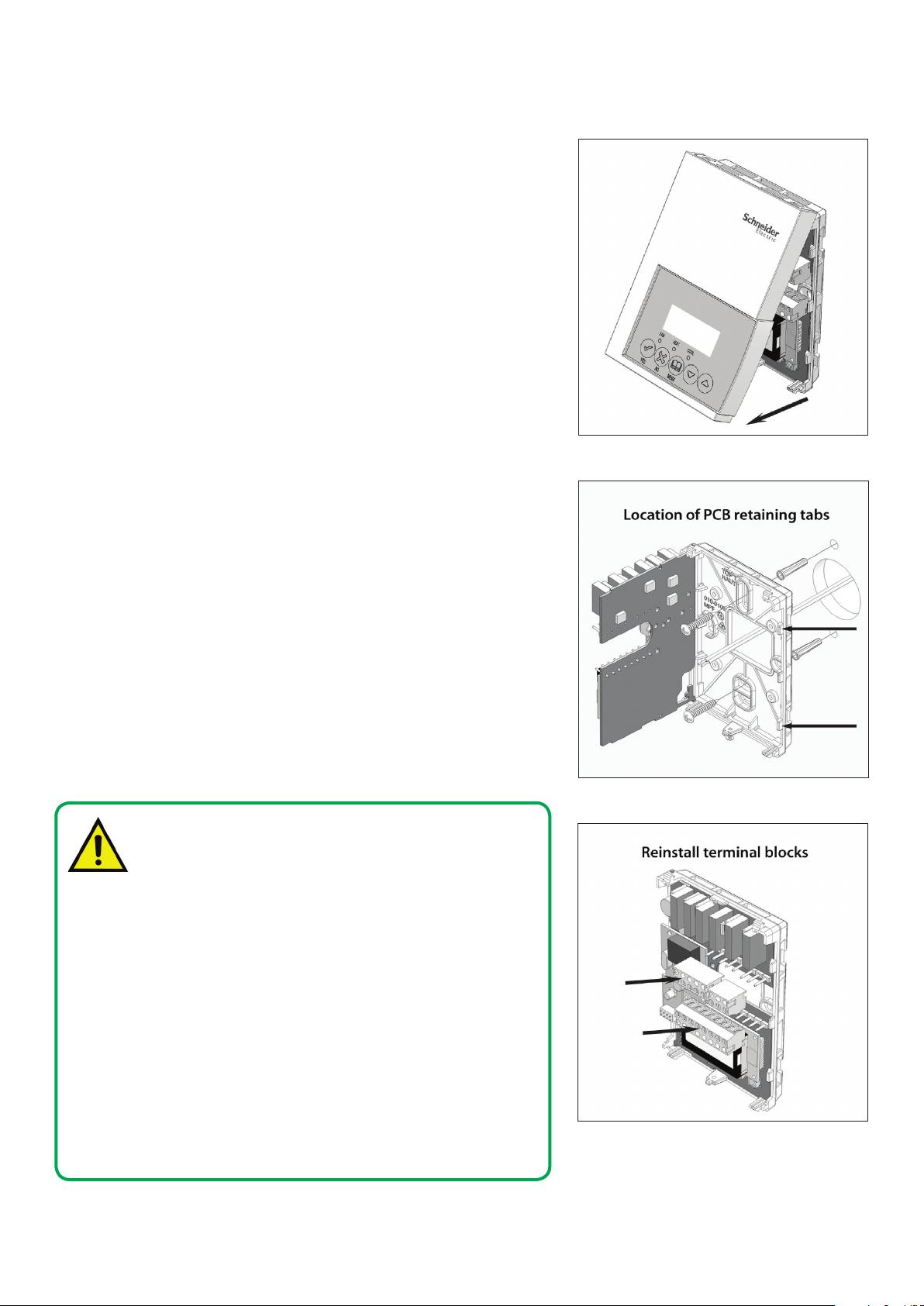

•

Remove security screw on bottom of Room Controller cover.

•

Open unit by pulling on bottom side of Room Controller (Figure 1).

• Remove wiring terminals from sticker.

• Read FCC ID and IC label installed in cover.

Location

1. Should not be installed on outside wall.

2. Must be installed away from any direct heat source.

3. Should not be installed near air discharge grill.

4. Should not be affected by direct sun radiation.

5. Nothing should restrict vertical air circulation to Room Controller.

Installation

1. Swing open Room Controller PCB to left by pressing PCB locking tabs

(Figure 2).

2. Pull out cables 6” out from wall. Ensure wall surface is flat and clean.

4. Insert cable in central hole of base.

5. Align base and mark location of two mounting holes on wall ensuring

proper side of base is up.

6. Install anchors in wall.

7. Insert screws in mounting holes on each side of base (Figure 2).

8. Gently swing back circuit board on base and push until tabs lock.

9. Strip each wire 1/4 inch from end.

10. Insert each wire according to wiring diagram (page 3).

11. Gently push excess wiring back into hole (Figure 3).

12. Re-Install wiring terminals in correct locations (Figure 3).

13. Re-install cover (top side first) and gently push extra wire length back into

hole in wall.

14. Install security screw.

2

Figure-1 Ope ning the Cover

•

When replacing an existing Room Controller, label the wires

before removal of the Room Controller.

•

Electronic controls are static sensitive devices. Discharge

yourself properly before manipulating and installing the Room

Controller.

•

A short circuit or wrong wiring may permanently damage the

Room Controller or the equipment.

•

All SE7000 series Room Controllers are designed for use as

operating controls only and are not safety devices. These

instruments have undergone rigorous tests and verification

prior to shipping to ensure proper and reliable operation in

the field. Whenever a control failure could lead to personal

injury and or loss of property, it becomes the responsibility of

the user / installer / electrical system designer to incorporate

safety devices (such as relays, flow switch, thermal protections,

etc…) and or an alarm system to protect the entire system

against such catastrophic failures. Tampering with the devices

or unintended application of the devices will result in a void of

warranty.

Figure-2 Op ening the PCB

Figure-3 Terminal Block Reinstall

Page 3

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

3

Wa

osition

t

Hot/Cold

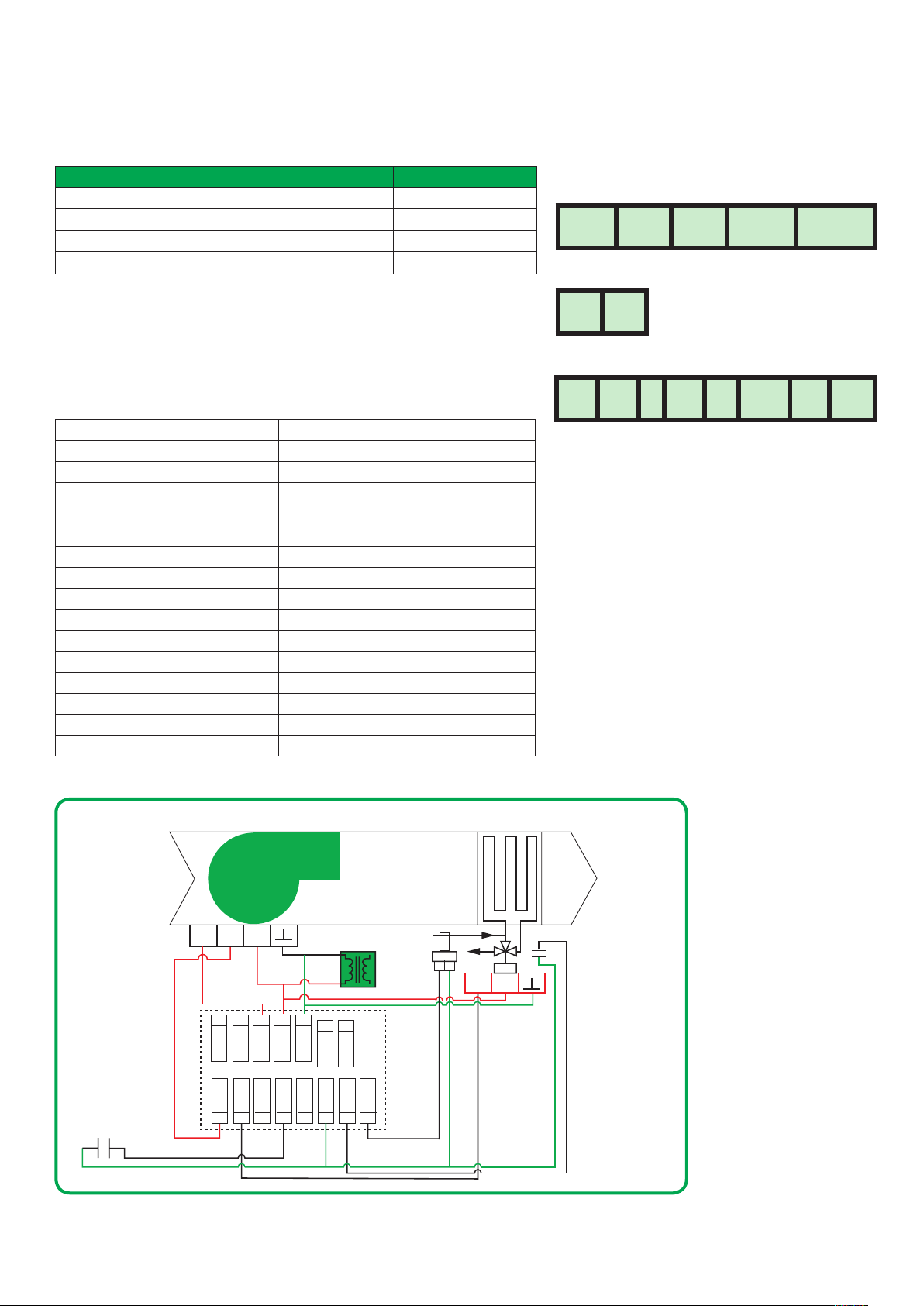

MODEL SELECTION

Part number Description Communication Options

SE7300F5x45-ECM Commercial Applications with Override Communication Ready

SE7300F5x45B-ECM Commercial Applications with Override BACnet MS/TP

SE7305F5x45-ECM °C/°F Hotel/Lodging Applications Communication Ready

SE7305F5x45B-ECM °C/°F Hotel/Lodging Applications BACnet MS/TP

• Controllers can be ordered with a factory installed PIR cover. Please use (5545)

extension instead of the (5045) only extension. Ex. SE7300F5545B-ECM.

• Controllers ordered without a PIR cover can be retrofitted with a separate

PIR accessory cover afterwards when required

TERMINAL, IDENTIFICATION AND FUNCTION

1- Not used

2- Not used

3- Fan Enable/disable

4- 24 V~ Hot

5- 24 V~ Com

6- Aux BO 5

7- Aux BO 5

8- Blank

9- ECM Output

10-Valve Output

11- Not used

12- BI #1

13- RS

14- Scom

15- BI # 2

16- UI # 3 COS / COC /SS

Fan H

Fan M

Fan L

24 V~ Hot

24 V~ Com

BO 5-Aux

BO 5-Aux

Blank

AO 2

AO 1

Blank

BI 1

RS

Scom

BI 2

UI 3

Screw terminal arrangement and wiring

5 pole left top connector

FAN H FAN M FAN L 24V~Hot 24V-Com

3 pole right top connector

BO5 BO5

8 pole left top connector

AO2 AO1 BI1 RS Scom B12 UI3

Main outputs wiring

Wiring notes:

Note 1

Electromechanical contacts are to be used with the

digital inputs. Electronic triacs cannot be used as

mean of switching for the input. The switched leg

to the input for the input to activate is terminal C

(common).

Note 2

The transformer of the unit provides power to the

Room Controller and the additional loads that will be

wired to the Room Controller.

Wiring

ter Detector

(NO contact)

On/

O

2-10

Vdc24Vac

2

1

Fan-H

Fan-M3Fan-L

AO210AO1

9

4

24V-Hot

BI1

12

5

24V-Com

13RS14

Transformer

6

B05

Scom

24Vac

7

B05

BI2

15

UI3

16

Water

Supply

Sensor

Water Coil

0-10

Vdc24Vac

(Valve Open P

Detector) NO Contac

Page 4

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

4

BI 2

One Sensor:

Two Sensors,

Remote mount temperature sensors use 10K type 2 NTC thermistors

• Each sensor can be configured for various averaging combinations

• Optional occupancy led

• Optional override key

Single Sensor Averaging Application

Scom

RS

BO5

24 Vac Com

BI 2

SE3020W1045

Scom

RS

Aux

C

DI

Two Sensor Averaging Application

Scom

SE3010W1045 SE3020W1045

Scom

RS

BO5

24 Vac Com

BI 2

OR

RS

Aux

C

DI

SE3010W1045

Scom

RS

Scom

RS

Temp. Sensor DIP Switch Settings

ON

1

ON

1

SE3020W1045

Remote temperature sensor DIP switch location

S2-1 = ON

S2-2 = ON

2

Three Sensors:

S2-1 = OFF

S2-2 = OFF

2

ON

averaging:

S2-1 = OFF

S2-2 = ON

1

2

Scom

RS

BO5

24 Vac Com

SE3020W1045

Scom

RS

Aux

DI

BI 2

Scom

RS

SE3010W1045

Scom

RS

Three Sensor Averaging Application

Scom

RS

BO5

24 Vac Com

Scom

RS

SE3010W1045 SE3010W1045

Scom

RS

Aux

C

DI

SE3010W1045 SE3010W1045 SE3010W1045

Scom

RS

SE3020W1045

Scom

Notes for averaging applications:

RS

Aux

C

C

DI

• SE3010W1045 and SE3020W1045 can be mixed

matched.

• SE3010W1045 and SE3020W1045 are to be

wired in parallel.

• Respect the dip switch setting in each remote

sensor.

SE3010W1045

Scom

S3010W1045

RS

SE3020W1045

Scom

RS

Scom

RS

Scom

RS

Scom

RS

Page 5

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

Temperature vs. Resistance Chart for 10K Type 2 NTC Thermistor

(R

= 10KΩ±3% - B

25°C

25/85°C

5

= 3975K±1.5%)

ºC ºF Kohm

-40 -40 324.3197

-39 -38 303.6427

-38 -36 2 8 4.418 9

-37 -35 266.5373

-36 -33 249.8958

-35 -31 234.4009

-34 -29 219.9666

-33 -27 206.5140

-32 -26 19 3.9703

-31 -24 182.2686

-30 -22 171. 3474

-29 -20 16 1.14 9 9

-28 -18 151. 623 9

-27 -17 142.7 2 11

-26 -15 134.3971

-25 -13 126 .610 9

-24 -11 119.324 4

-23 -9 112. 50 2 8

-22 -8 10 6.113 5

-21 -6 10 0 .12 6 8

ºC ºF Kohm

-20 -4 9 4. 514 9

-19 -2 89.2521

-18 0 84.3147

-17 1 79.6808

-16 3 75.3299

-15 5 71. 24 3 0

-14 7 6 7. 4 02 8

-13 9 63.7928

-12 10 60.3980

-11 12 5 7. 20 4 4

-10 14 5 4 .1 9 8 8

-9 16 51. 3 692

-8 18 48.70 42

-7 19 46.1933

-6 21 43.8268

-5 23 41.5 956

-4 25 39.4921

-3 27 3 7. 5 0 5 6

-2 28 35.6 316

-1 30 33.8622

ºC ºF Kohm

0 32 3 2 .191 0

1 34 30. 612 0

2 36 2 9 .1197

3 37 2 7. 7 0 8 8

4 39 2 6 . 3 74 4

5 41 2 5 .1119

6 43 2 3.9172

7 45 22.7861

8 46 21.7151

9 48 20.700 4

10 50 19.7390

11 52 18.8277

12 54 17. 9 63 6

13 55 17.14 4 0

14 57 16 .36 65

15 59 15.6 28 6

16 61 14. 928 0

17 63 14 .26 2 9

18 64 13.6 310

19 66 13.0307

ºC ºF Kohm

20 68 12.4 601

21 70 11.9177

22 72 11. 4 0 18

23 73 10 . 9112

24 75 10.4443

25 77 10.0000

26 79 9.5754

27 81 9 .1711

28 82 8.786 0

29 84 8.4190

30 86 8.0694

31 88 7.7 3 6 0

32 90 7. 41 8 2

33 91 7.115 0

34 93 6.8259

35 95 6.5499

36 97 6.2866

37 99 6.0 3 51

38 10 0 5.7950

39 102 5.5657

ºC ºF Kohm

40 10 4 5.3467

41 10 6 5.1373

42 108 4.9373

43 10 9 4 .746 0

44 111 4.5631

45 113 4.3881

46 115 4.2208

47 117 4.0607

48 118 3 .9 074

49 120 3.7607

50 12 2 3.6202

51 124 3.4857

52 126 3.3568

53 127 3.2333

54 12 9 3 .115 0

55 131 3.0016

56 13 3 2.8928

57 135 2.788 6

58 13 6 2.6886

59 138 2.5926

Page 6

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

6

CONFIGURING AND STATUS DISPLAY INSTRUCTIONS

Status display

The Room Controller features a two-line, eight-character display. There is a low

level backlight that is always active and can only be seen at night.

When left unattended, the Room Controller has an auto scrolling display that

shows the current status of the system.

Each item is scrolled sequentially with the back lighting in low level mode.

Pressing any key will cause the back light to come on to high level.

Manual scrolling of each menu item is achieved by pressing the Yes (scroll) key

repetitively. The last item viewed will be shown on the display for 30 seconds

before returning to automatic scrolling. Temperature is automatically updated

when scrolling is held.

Sequence of auto-scroll status display

CLOCK

STAT U S

Monday

12: 00 AM

SYSTEM

MODE

Sys Mode

Auto

Sys Mode

Cool

Sys Mode

Heat

Sys Mode

Off

SCHEDULE

STAT U S

Occupied

Stand-by

OUTDOOR

TEMP.

Outdoor

x.x °C or °F

Network

value only

ALARMS

Service

Filter

Unoccup Window

Overrride

Three status LED’s on the Room Controller cover are

used to indicate the status of the fan (any speed), a

call for heat, or a call for cooling.

Fan coil models

When any of the fan speeds are ON,

the FAN LED will illuminate.

When heating is ON, the HEAT LED

will illuminate.

When cooling is ON, the COOL LED

will illuminate.

Outdoor air temperature

• Display is only enabled when outdoor air temperature network variable is

received.

Occupancy status

• Occupied, Stand-By, Unoccupied and Override status are displayed on the

scrolling display.

Alarms

• If alarms are detected, they will automatically be displayed at the end of the

scrolling status display.

• When an alarm message is displayed, the backlit screen will illuminate at the

same time as the message and shut off during the rest of the status display.

• A maximum of two alarms can appear at any given time. The priority for the

alarms are as follows:

Service

Filter

Window

Indicates that there is a service alarm as per one of the configurable

digital input.

Indicates that the filters are dirty as per one of the configurable

digital input.

Indicates that the outside window or door is opened and that the

Room controller has cancelled any cooling or heating action.

Page 7

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

USER INTERFACE

Hotel/Lodging Models Commercial Models

Unoccupied mode override

An Override can be made on commercial models during an unoccupied

period. If the Override option is enabled in the lockout configuration, pressing

the middle override button will resume occupied setpoints for a time specified

by the parameter “ToccTime”.

7

Local Keypad Interface

Each of the sections in the menu is accessed and configured using 5 keys on

the Room Controller cover.

MODE Is used to toggle between the different system modes

available as per sequence and menu selected.

• Repetitively pressing the button will toggle between all the

available modes.

•

Available menus are dependent on selected sequence of

operation

FAN Is used to toggle between the different fan modes available

as per the sequence and menu selected

• Repetitively pressing the button will toggle between all the

available modes

• Available menus are dependent on selected sequence of

operation and menu selected for Fan

Hotel and lodging applications. Toggles the local user

temperature scale between °F and °C

Commercial and institutional applications. Set a local unoccupied

timed OVERRIDE to occupied mode

• In cooling mode only the cooling setpoint is displayed,

• In heating mode only the heating setpoint is displayed

• In auto mode, (See below)

• In cooling mode only the cooling setpoint is displayed,

• In heating mode only the heating setpoint is displayed

• In auto mode, (See below)

• Any setpoint change can be permanent or temporary based on

configuration parameter (Setpoint Type)

• Any setpoint written through the network, will be permanent and cancel any

active temporary setpoints

• Lockouts of access to certain functions is made with configuration

parameter (lockout)

Page 8

Schneider Electric | II-SE730 0F-A4.EN.12.2015.v2 December 2015

Loading...

Loading...