EDMS xxxxxxxxx 03 2009

Zelio Control

Temperature controller

Quick start

04/2009

REG 24 ... REG 48 ... REG 96 ...

www.schneider-electric.com

Schneider Electric assumes no responsibility for any errors that may appear in this document. If you have any suggestions

for improvements or amendments or have found errors in this publication, please notify us.

No part of this document may be reproduced in any form or by any means, electronic or mechanical, including photocopying,

without express written permission of Schneider Electric.

All pertinent state, regional, and local safety regulations must be observed when installing and using this product. For

reasons of safety and to help ensure compliance with documented system data, only the manufacturer should perform

repairs to components.

When devices are used for applications with technical safety requirements, the relevant instructions must be followed.

Failure to use Schneider Electric software or approved software with our hardware products may result in injury, harm, or

improper operating results.

Failure to observe this information can result in injury or equipment damage.

© 2009 Schneider Electric. All rights reserved.

2

EIO0000000377 00 04/2009

SOMMAIRE

SOMMAIRE.........................................................................................................................................3

CHAPTER 1 INTRODUCTION............................................................................................................5

Fonctioning:...................................................................................................................................5

Application examples:...................................................................................................................5

Identification and functionnalities: Chapter 1 Introduction .....................................................6

CHAPTER 2 : TERMINOLOGY...........................................................................................................7

PID : Proportionnel Intégral Dérivé :.............................................................................................7

The outputs:...................................................................................................................................8

Regulation principle: .....................................................................................................................9

CHAPTER 3: EXAMPLES OF INTEGRATED FUNCTIONS INTO THE CONTROLLERS................11

Auto tunning: ...............................................................................................................................11

Fuzzy logic:..................................................................................................................................11

Self control :.................................................................................................................................11

Ramps: Chapter 3 Example of functions................................................................................12

Pid 2 :............................................................................................................................................12

Soft start :.....................................................................................................................................12

Alarms: .........................................................................................................................................12

CHAPTER 4 : WIRING AND SCHEMATICS :...................................................................................13

REG 24 (12 models) :..................................................................................................................13

REG 48 (14 models) :...................................................................................................................13

REG 96 (14 models): Chapter 4 wiring and shematics...........................................................14

CHAPTER 5: IMPLEMENTATION....................................................................................................15

Selection guide:...........................................................................................................................15

Front face description : Chapter 5 Implementation...............................................................16

CHAPTER 6: EXAMPLE OF IMPLEMENTATION............................................................................17

1 st step : Controller selection....................................................................................................17

2sd step : The cabling .................................................................................................................17

3 Rd step : Front face programming Chapter 6 Example of implementation .......................18

Probe type setting (PT100)..........................................................................................................18

Setting of the PT100 probe range (0 to 400°C)...... .....................................................................19

Setting of the minimum value for the PT100 probe Pvb = 0°C............................................ ......19

Setting of the maximum value for the PT100 probe PvF = 400°C.......................................... ...19

Chapter 6 Example of implementation ....................................................................................... 20

Setting of the choosen decimal value (Pvd) (to display the tenth)........................................... 20

Chapter 6 Example of implementation ....................................................................................... 21

Regulation mode selection = heating on channel 1 (rEv)..........................................................21

Alarms 1 and 2 parameters setting.............................................................................................21

Alarm 1 parameters setting at 32°C Chapter 6 Example of implementation.........................22

Alarm 2 setting at 38°C............................ ....................................................................................22

Parameter setting of the alarms on high overtaking (do1T) .....................................................22

4 Th step: Functional test............................................................................................................23

1 St step: install the software ZelioControl Soft (compatible with Windows XP and Vista) ...23

2 Nd step: installation of the TSXCUSB485 driver.....................................................................23

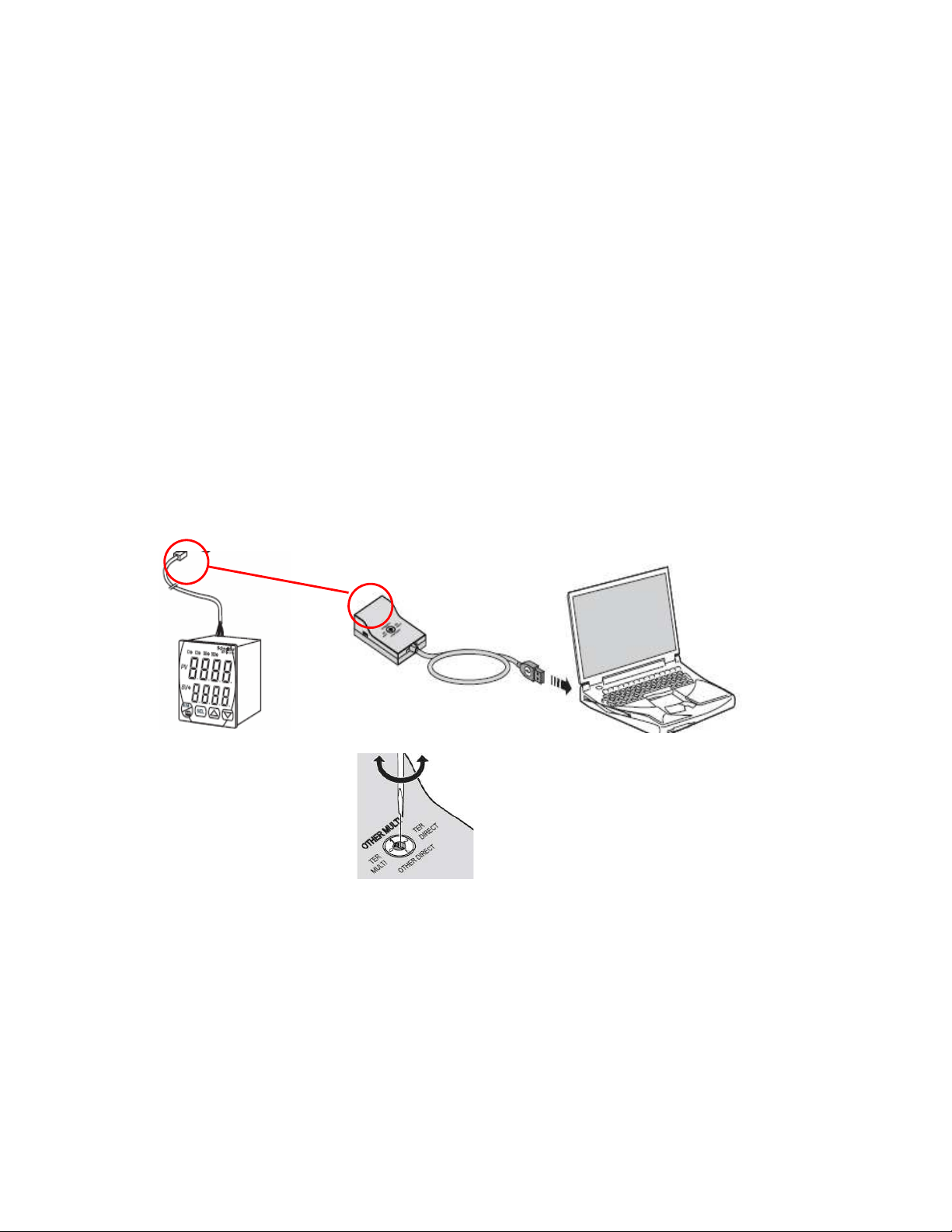

3 Rd step: connect the TSXUSB485 to your PC and the controller.......................................... 23

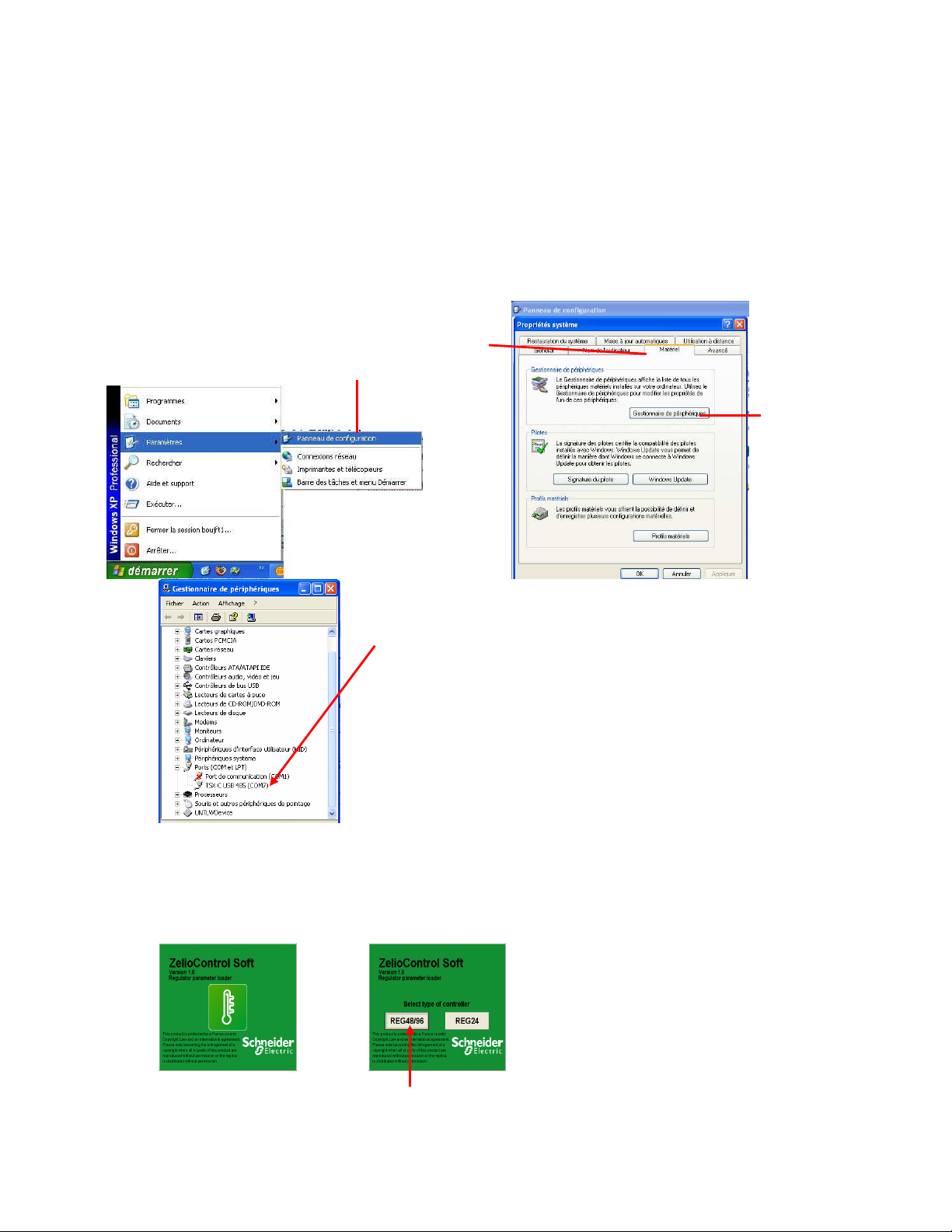

4 Th step : check the communication port parameters of the TSXCUSB485 driver................24

5 Th step: Discover the software ZelioControl Soft...................................................................24

Chapter 6 Example of implementation ....................................................................................... 25

6 Th step: check the communication parameters of the TSXCUSB485 driver.........................25

7 Th step: Communication parameters setting:.........................................................................25

Chapter 6 Setup example ............................................................................................................26

8 Th step: Connection to the régulator and application Upload...............................................26

9 Th step: Application display ....................................................................................................26

CHAPITRE 7: ZelioControl SOFT software....................................................................................27

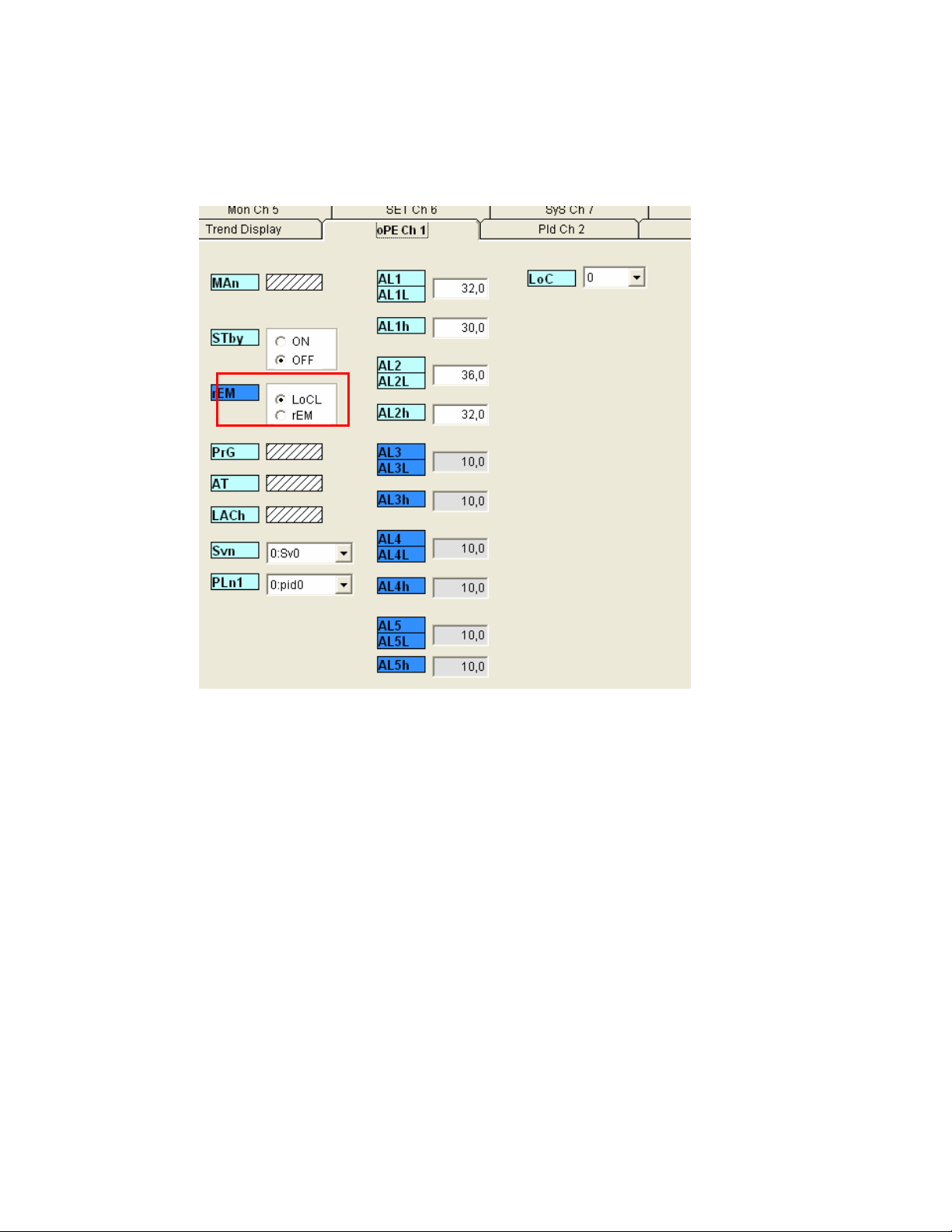

ZelioControl Soft screen - oPE CH1 ...........................................................................................27

EIO0000000377 00 04/2009

3

ZelioControl SOFT screen PID CH2............................................................................................27

ZelioControl SOFT screen PID CH2............................................................................................28

ZelioControl Soft screen - PLT CH3............................................................................................29

ZelioControl Soft screen - PRG CH4...........................................................................................30

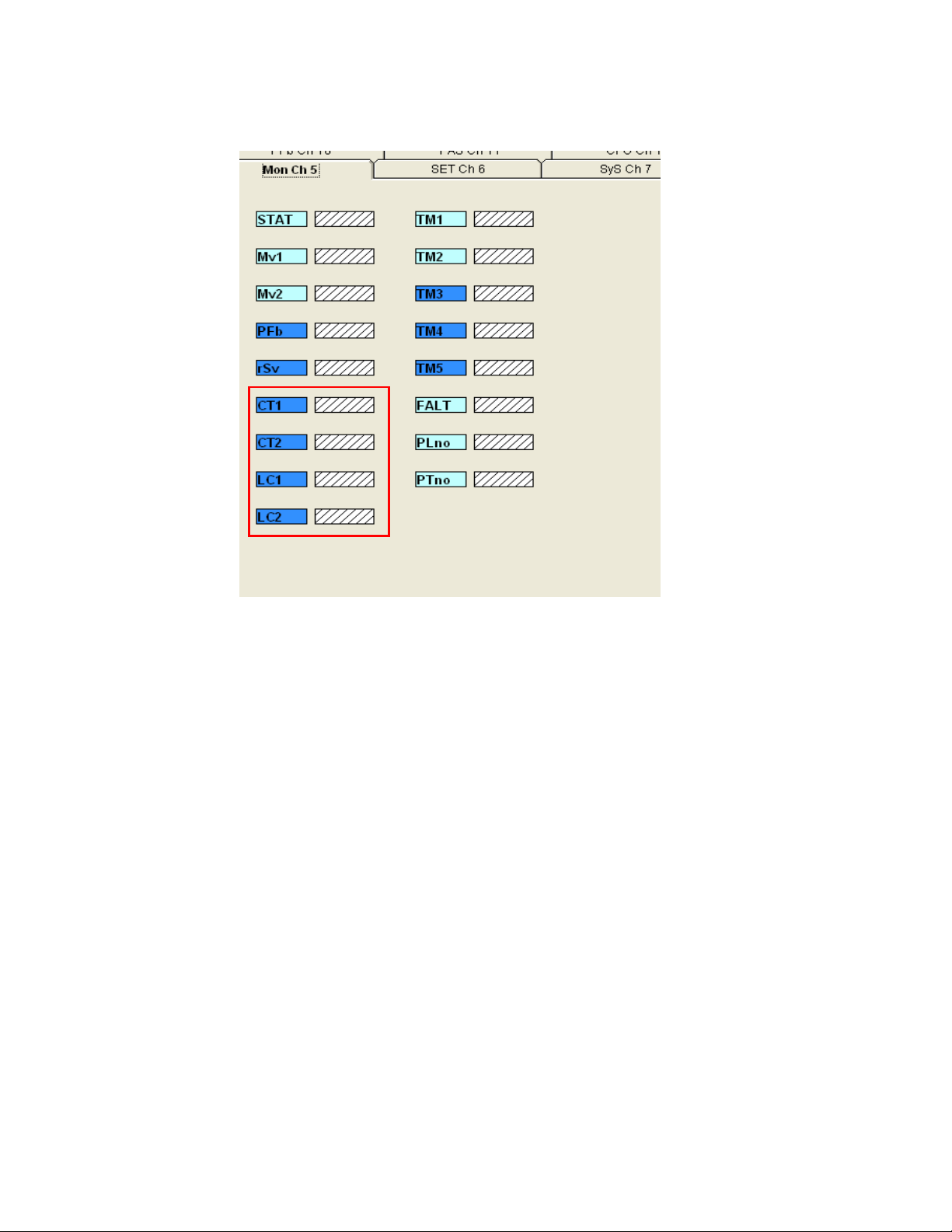

ZelioControl Soft screen - MON Ch5..........................................................................................31

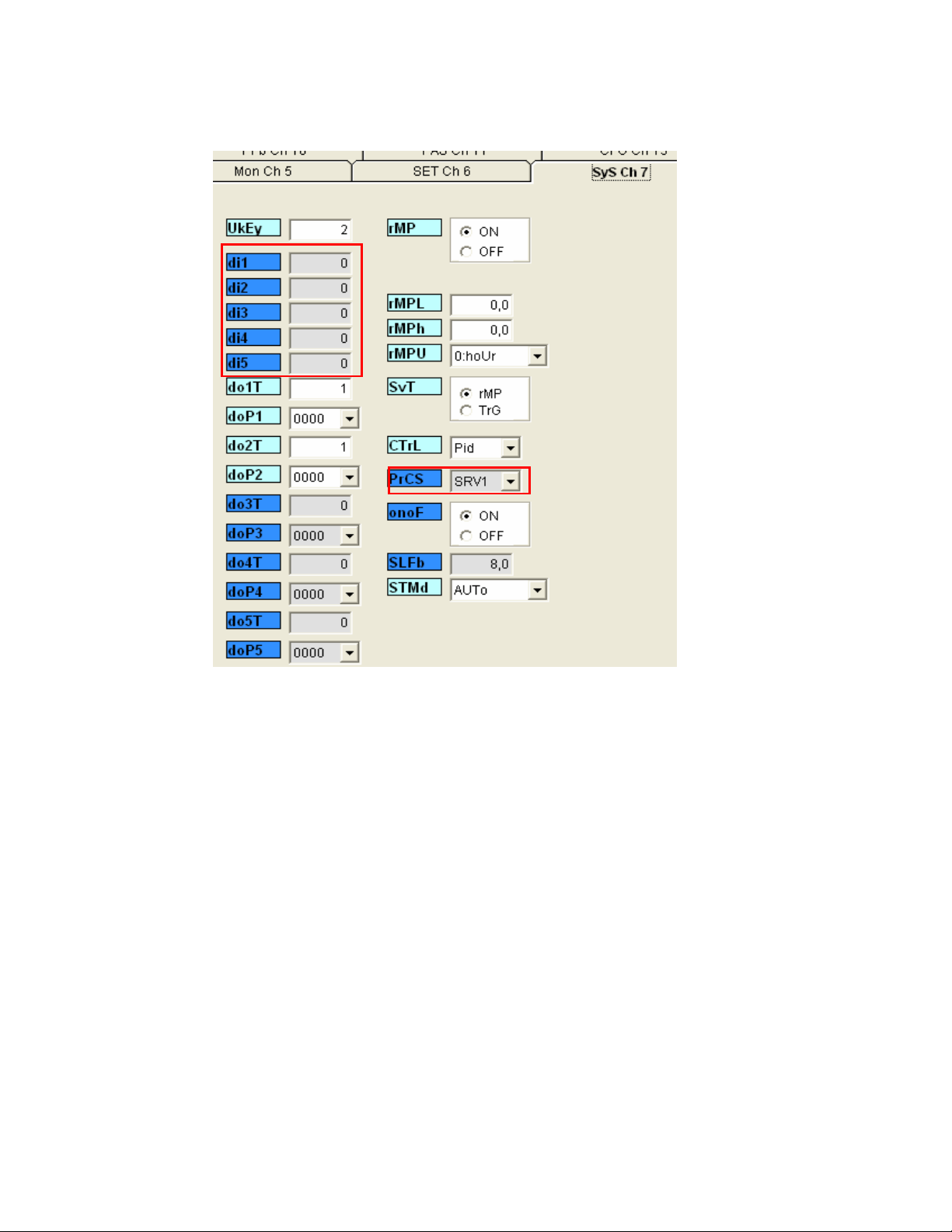

ZelioControl Soft screen – SET Ch6...........................................................................................32

ZelioControl Soft screen – SyS Ch7........................................................................................... 33

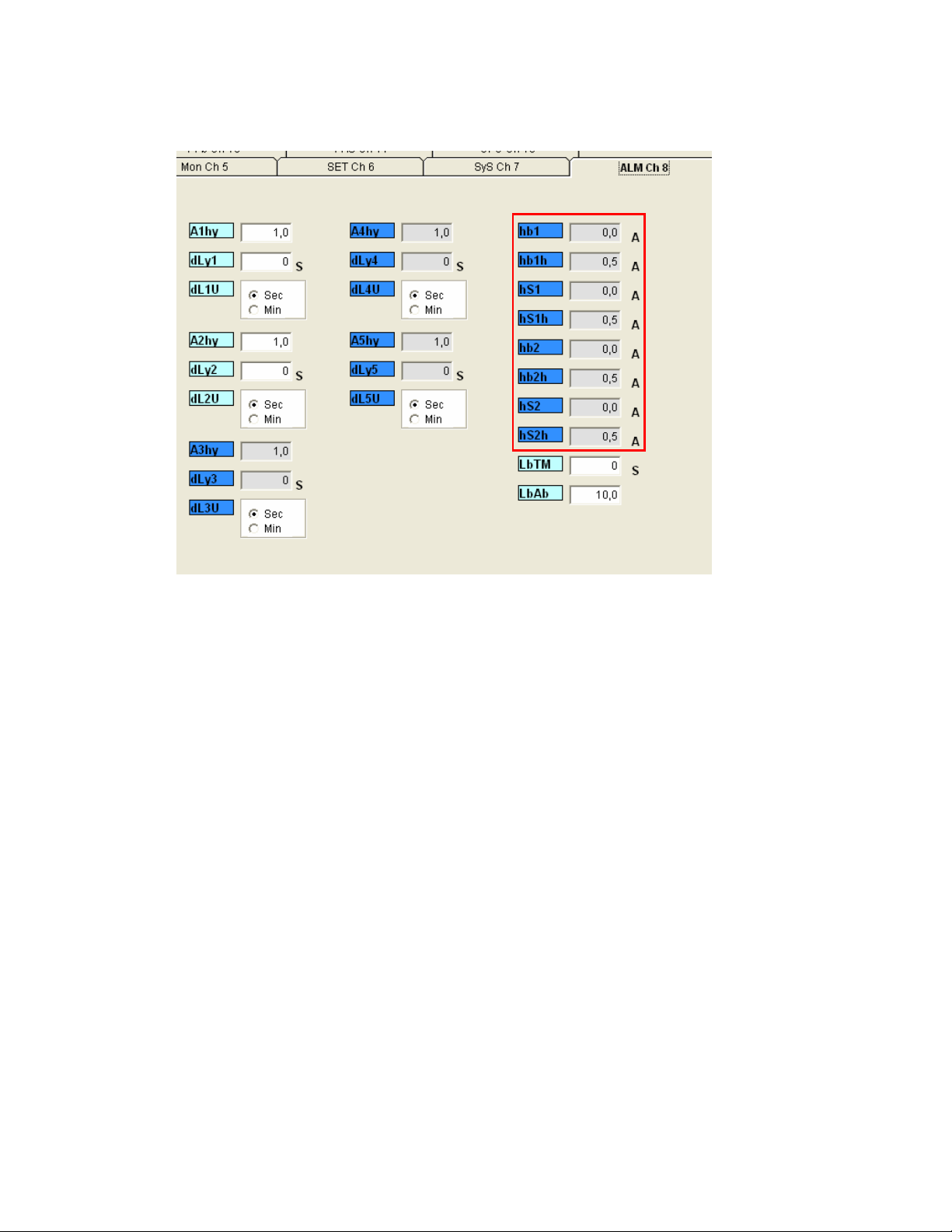

ZelioControl Soft screen – ALM Ch8.......................................................................................... 34

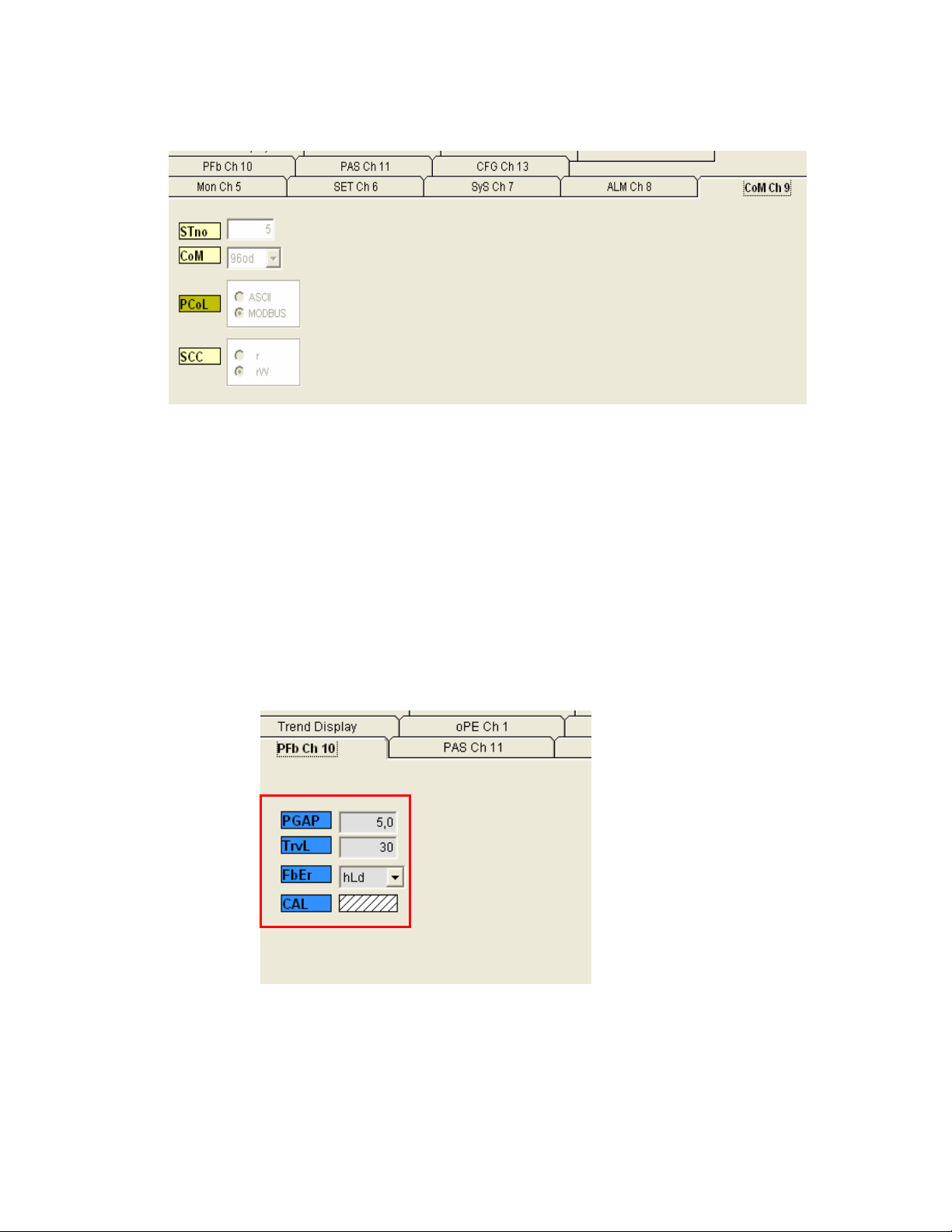

ZelioControl Soft screen - CoM CH9...........................................................................................35

ZelioControl Soft screen - PFb CH10..........................................................................................35

ZelioControl Soft screen - PAS CH11.........................................................................................36

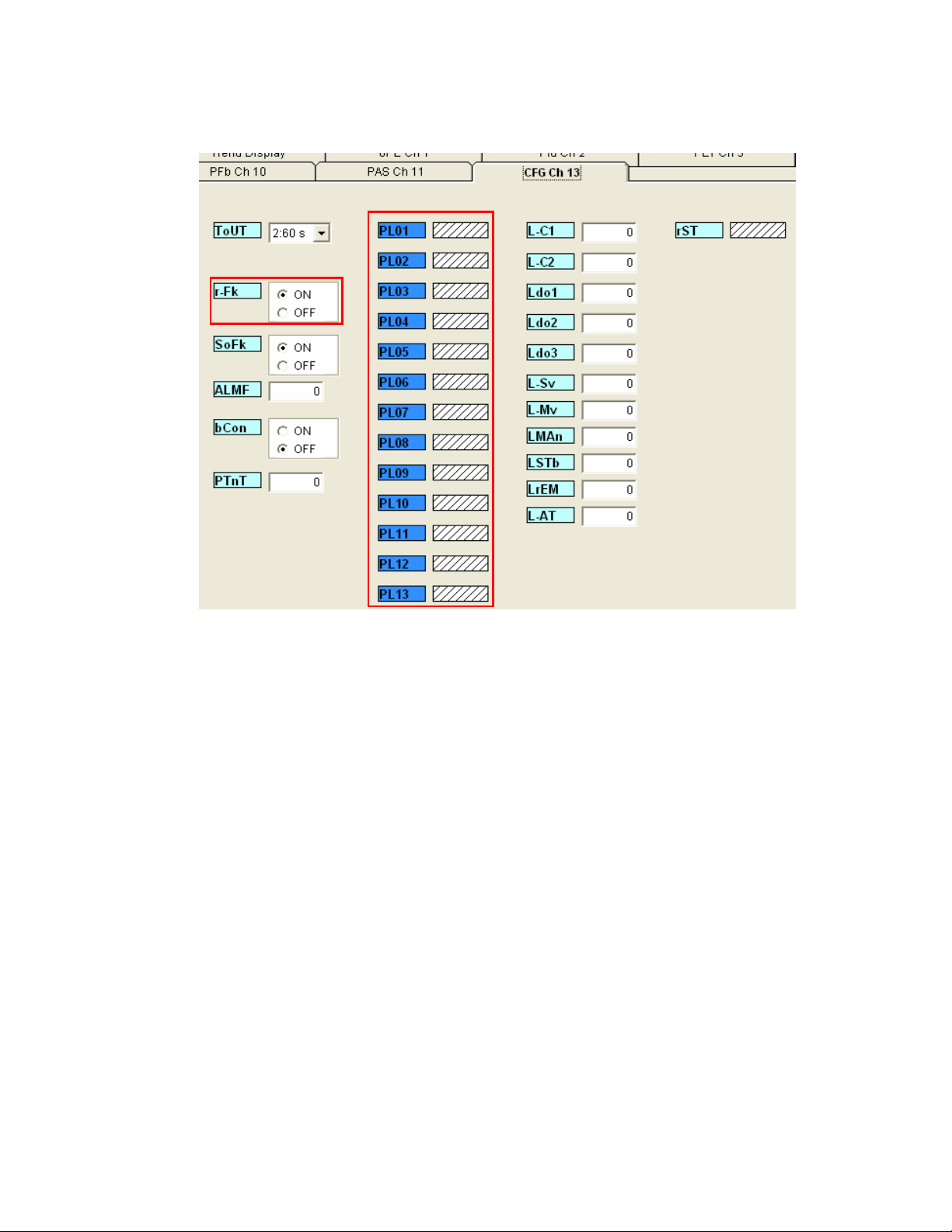

ZelioControl Soft screen - CFG CH13.........................................................................................37

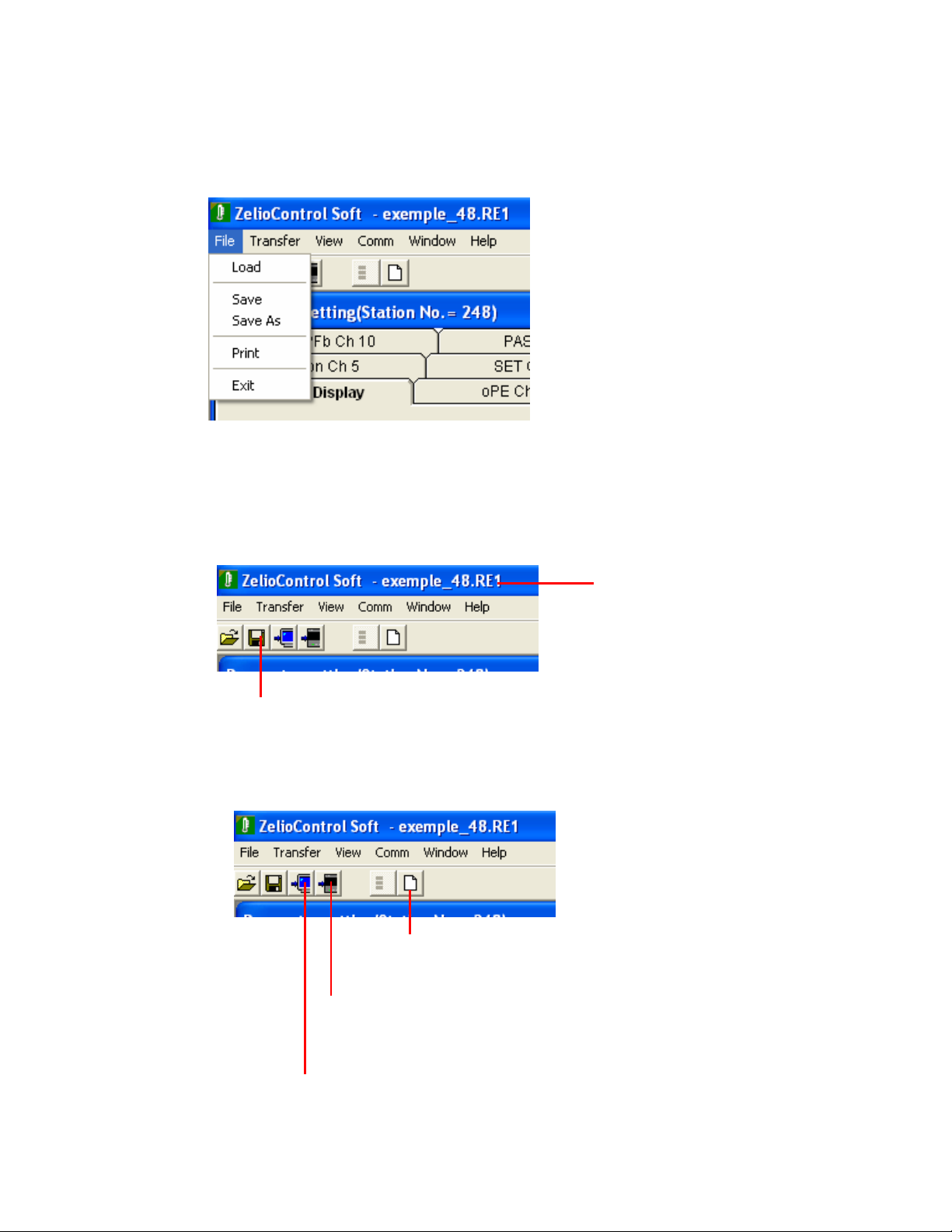

Application file saving under ZelioControl SOFT......................................................................38

4

EIO0000000377 00 04/2009

CHAPTER 1 INTRODUCTION

Fonctioning:

The temperature control relays are equiped with a sensor input that permits to use multiple types of

sensors (PT100 probe, thermocouple, current or voltage sensors depending the model), one or two

process outputs (relay, solid state relay interface or analog) for heating, cooling or heating and

cooling regulation based on PID algorithm.

The measured temperature and the setpoint can be displayed in °Celsius or °Fahrenheit.

Advanced functions are embedded: Ramps (up to 16), hysteresis, fuzzy logic, auto tuning, soft

start, alarms.

The temperature controllers can be setup using the front face interface or through a common

software by a communication port and the integrated Modbus.

This communication port provides intergartion capability in an itelligente architecture supervised by

Magelis terminal or controled by PLCs(Twido, M340 or Premium) to exchange setpoints, process

values and alarms.

Application examples:

The temperature controllers Zélio control REG provide a solution for temperature control in the

following applications:

- Ovens and furnaces,

- Extrusion lines,

- UV &laser technologies,

- Cabin of painting,

- Cold rooms,

- Horticultural and livestock farms,

- Maintening the temperature of a colour bath…

- Plastic and rubber presses,

- thermo-forming,

- Production of synthetic fibres an polymerisation,

- Food and drink processing lines,

- Moulding presses,

- Environmental chambers, overhead furnaces and test benches,

EIO0000000377 00 04/2009

5

Identification and functionnalities:

The product part number allows identification of the embedded functions:

Chapter 1 Introduction

24 controllers :

REG

24 P TP 1 A R HU

P UJ L LU

J

Regulator

P = PID

Input type: TP = Thermocouples and PT100

UJ = Analog signal

Modbus function: A = no modbus available

Output type: R = relay

L = solid state relay interface

J = analog (4/20mA)

Power supply: HU = 110/220 VAC

LU = 24 V AC/DC

Size

PID Input Output Without Output power

type

number modbus type supply

48/96 controllers :

REG

48 P UN 1 L R HU

96 2 L LU

J

Regulator

Input type: UN = universal input thermocouple / PT100 / analog

Output type: R = relay

L = solid state relay interface

J = analog (4/20mA)

Modbus function: L = no modbus available

Power supply : HU = 110/220 VAC

LU = 24 V AC/DC

Note : When 2 outputs possible combination between 1 relay and 1 solid state relay interface or 1

solid state relay and one current (for detail see doc 24480-EN page 6)

Size

P = PID

PID Input

type

Output Without Output Power

number modbus type supply

6

EIO0000000377 00 04/2009

CHAPTER 2 : TERMINOLOGY

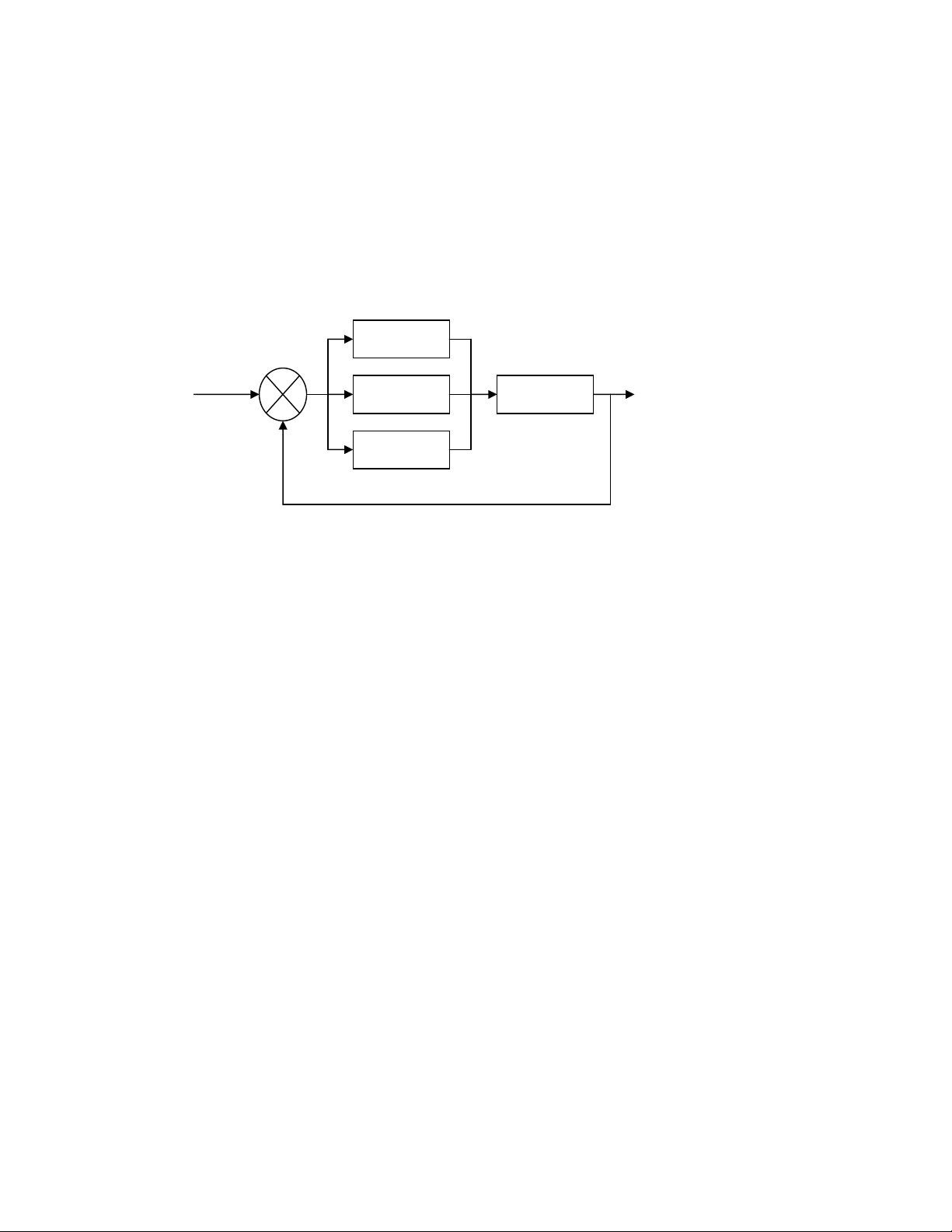

PID : Proportionnel Intégral Dérivé :

The principle of the PID algorithm consists on 3 actions that are dependant to the difference

between the setpoint (SV) and the measured process value (PV).

- A proportional action ne action proportionnelle, the error is multiplied by a gain GR

- A complete action, the error is integrated on an interval of time TI

- Derivated action, the error is derivated according to time TD

Consigne

SetPoint (SP)

+

-

Gr

1/Ti

Process

Td

Mesure

Process value (PV)

PID principle schematic

The parameters of the PID influence the answer of the system in the following way:

- When the proportional gain GR increases, the time of rise is shorter but there is a more

important overshoot of the setpoint. The time of stabilization varies little and the static error is

improved.

- When 1 / TI increase, the time of rise is shorter, but there is a more important overtaking of the

setpoint. The time of stabilization stretches out but we assure a static no error.

- When TD increases, the time of rise changes little, but the overshoot decreases. The time of

stabilization is better and there is no influence on the static error.

Introduction

EDMS xxxxxxxxx 03 2009

The use of 24/48/96 controllers is going to allow through a parameter setting of variables to appeal

to automatic functions or manual regulations.

These variables are going to allow:

- To choose the type of sensor used (probe thermocouple or PT100, analogical sensor),

- To choose the type of output used according to the actuator(s) (relay, solid state relay,

analogical),

- To choose the function of regulation (heating or cooling or heating and cooling),

- To reduce the time of establishment (the value of measure reaches as quickly as possible the

setpoint),

- Avoid overshoot (fuzzy logic and PID2),

- To maintain the temperature very close to the setpoint (réduction of the hysteresis and the dead

band),

- Avoid influence of perturbation,

- To activate alarms (high, low, delayed…),

- Setup ramps (up to 16 depending the model) to chain cycles of regulations,

- To have information of defects (overflowing measures, defect sensors),

- To lock or authorize the modification of the parameters from the front face of the product.

EIO0000000377 00 04/2009

7

Chapter 2 Terminology

The outputs:

- Relay : Output type mostly used

- Solid state relay interface: Used to contrôle actuator with no noise or frequent switching.

-

Courant : used to drive analog actuator such as speed drives

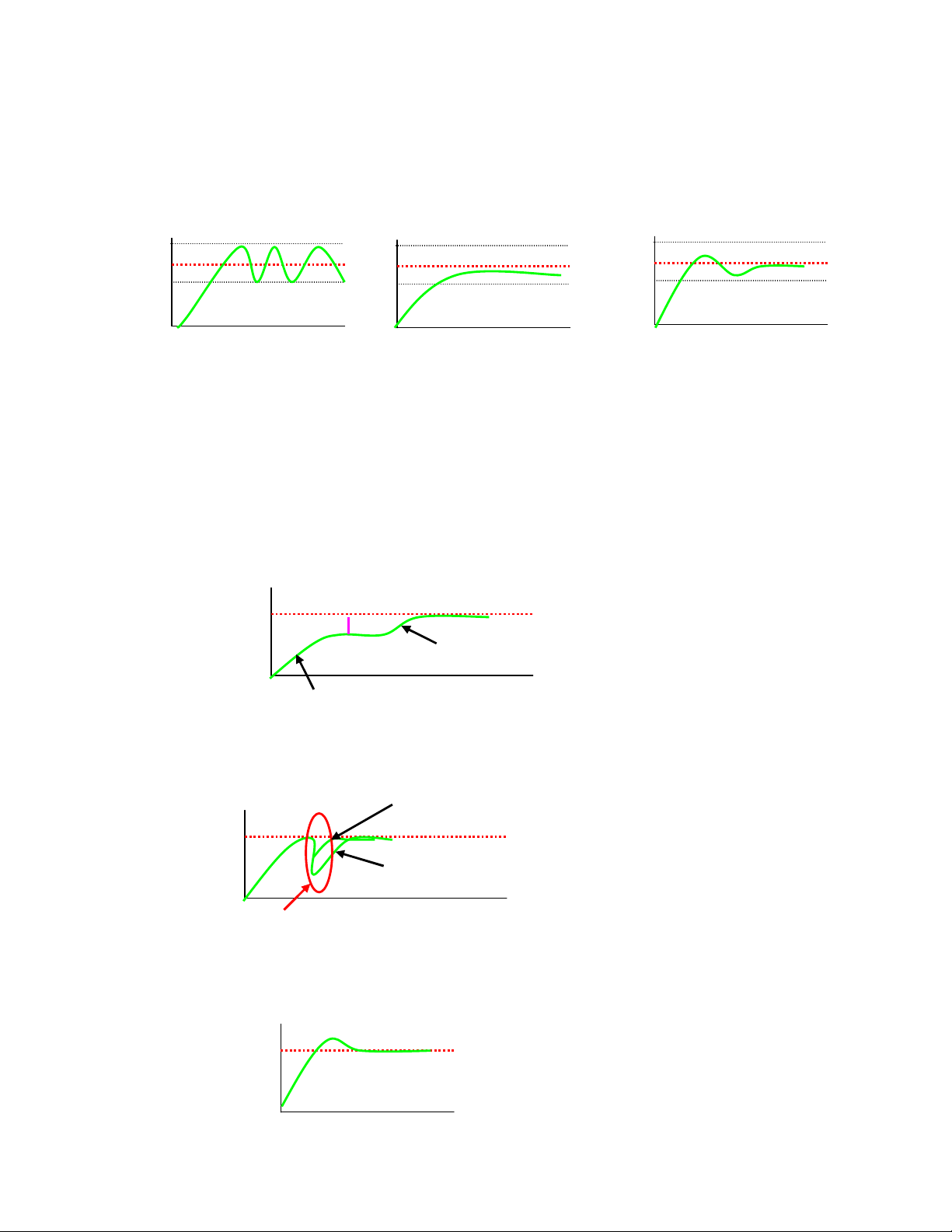

On and OFF control: Most simple algorithm, no anticipation of the setpoint, not precized, we notice

a lot of oscillations.

Proportional control: The process output is proportional to the derivation from the. The

proportional band allows overshoots anticipation.

Proportional control

SV

PV

Proportional band

8

EIO0000000377 00 04/2009

:

Regulation principle

Chapter 2 Terminology

Proportional

SV

PV

P too low =

oscillations

Intégrale

SV

PV

Derivative

SV

PV

External perturbation

PID

Offset

P

SV

PV

P too high = slow rise

and important gap

PI

Proportional + derivative

Proportional only

The integral allow catching up the

setpoint when there is an offset with

the process value.

In combination with the proportional,

the integrale function reaches the

setpoint.

The derived control allows countering

any distance created by an external

perturbation.

SV

PV

P correct = correct

rise and minor gap

SV

PV

EIO0000000377 00 04/2009

The combination of proportional,

derivative and integrale optimized

the regulation

9

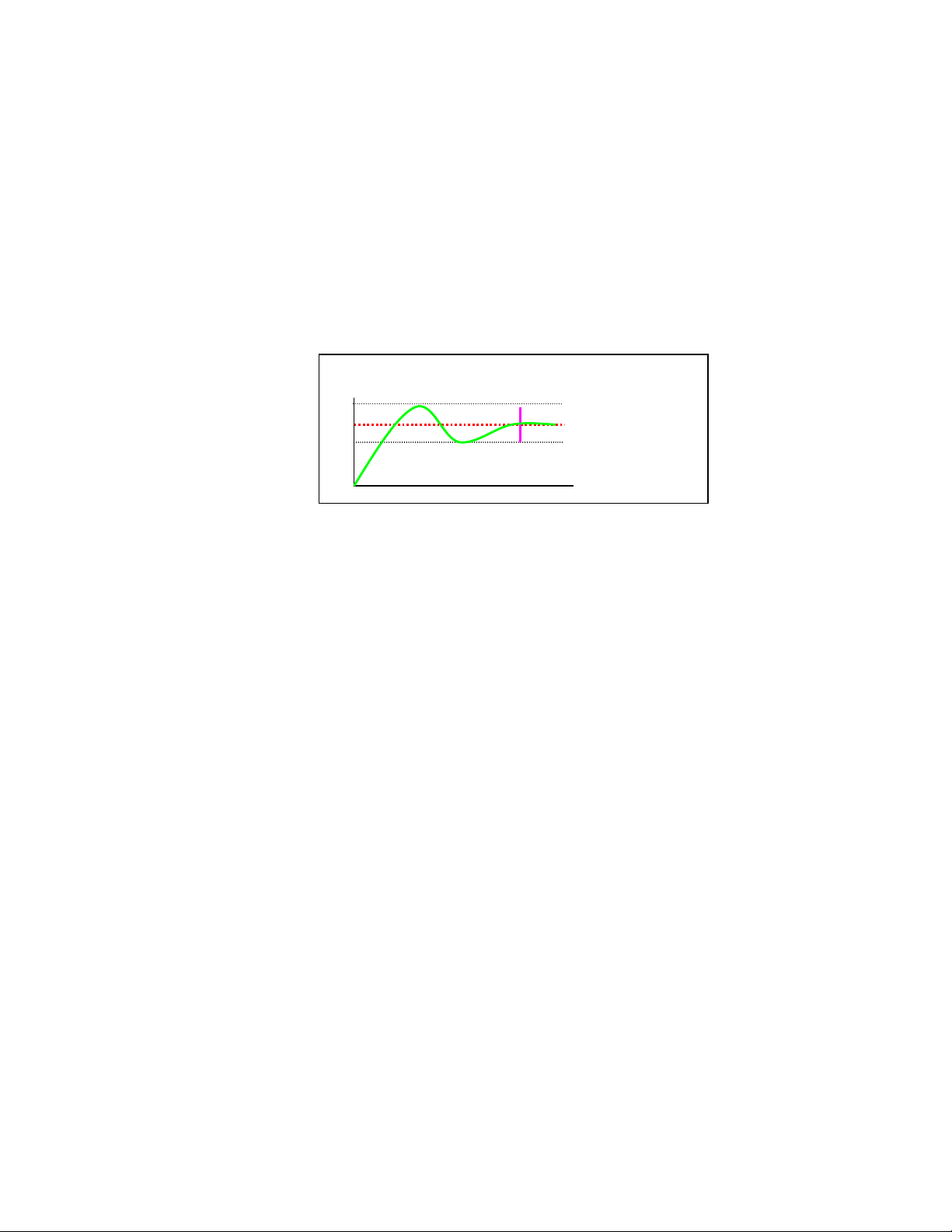

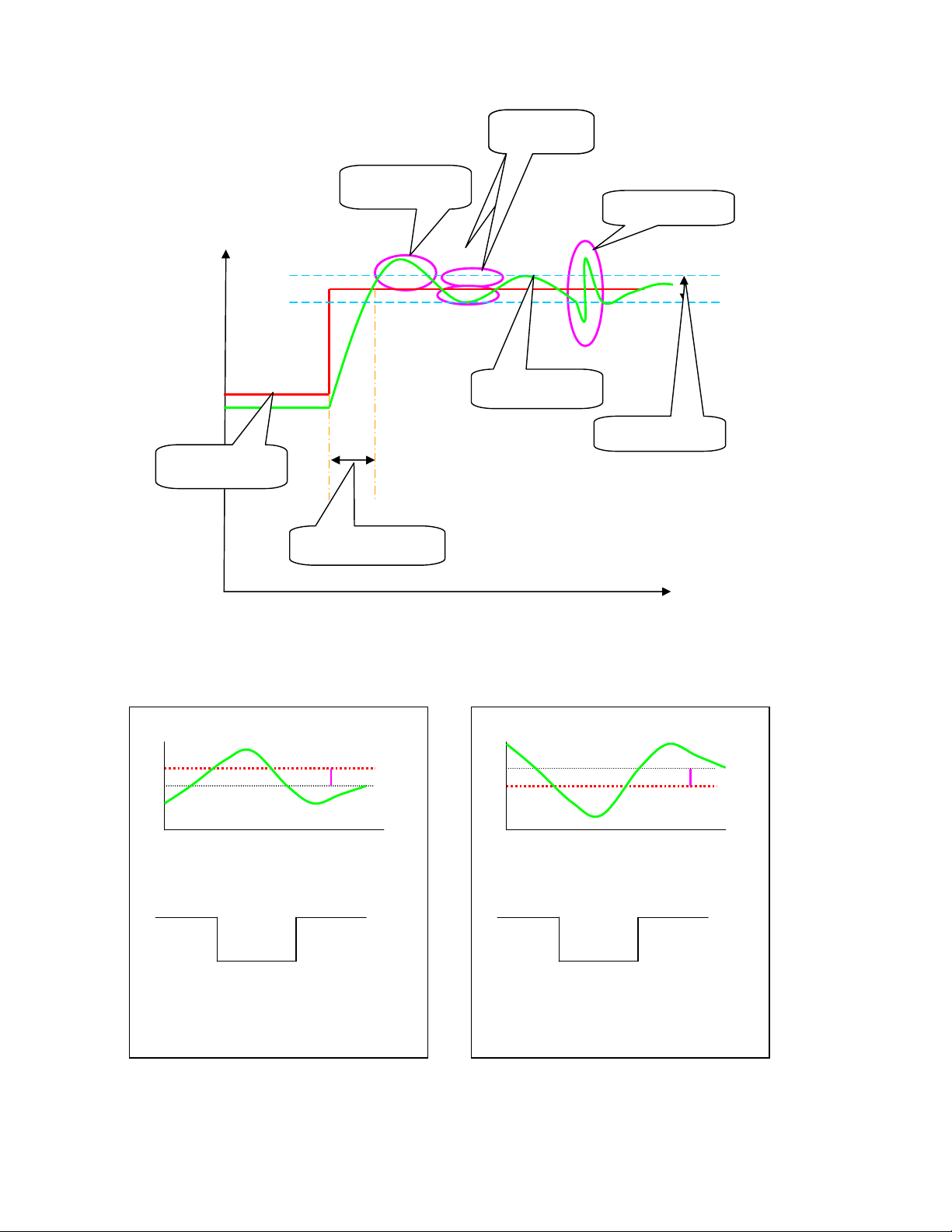

Visualization of PID structure:

Chapter 2 Terminology

Hystérésis Hysteresis

Overshoot

Perturbation

Values

PV (measure)

SP (setpoint)

Dead band

Response time

Visualization of PID structure Time

Reverse operation (heat control)

SV

PV

hys

Normal operation (cooling control)

PV

SV

hys

ON

PV<SV

ON

PV>SV

OFF

PV>SV

OFF

PV<SV

Output state

Output state

Choice of regulation type

10

EIO0000000377 00 04/2009

CHAPTER 3: EXAMPLES OF INTEGRATED FUNCTIONS INTO THE

CONTROLLERS

Auto tunning:

This function calculates automatically the proportional, derivative and integrale factors of the PID

function. This calculation is done during 2 regulation cycles.

Fuzzy logic:

The fuzzy logic manages the command of the process in a range of 0 to 100% of the measure

scale. This logic applies a command to the process to optimize the switching between heating and

cooling outputs depending the setpoint and avoid overshoot.

.

100%

Fuzzy logic principle

Heating Cooling

0%

Setpoint

Temperature

Self control :

This function restarts the calculation of the PID parameters at each setpoint change or after a

power on.

Remark: This command will generate temporarly a perturbation of the regulation close to the

setpoint value. Some applications might be sensitive to this function.

EIO0000000377 00 04/2009

11

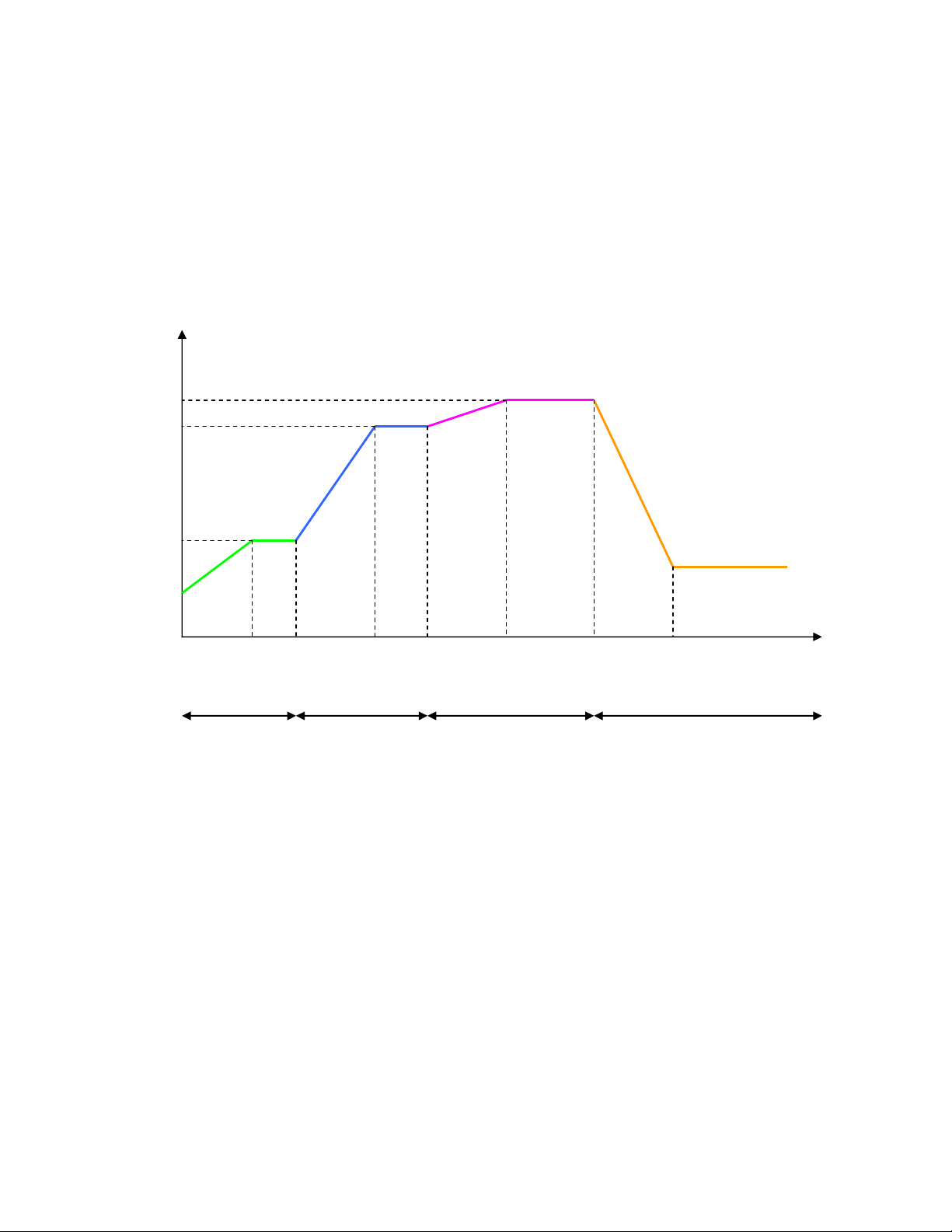

Ramps:

Chapter 3 Example of functions

This function allows a sequence of setpoints (up to 16 ramps for REG48 and REG96) during a

certain period of time. For each setpoint, a response time and the duration of the level can be

setup.

These times can be defined in hour and minutes or in minutes and seconds.

Example:

TM1r TM1s TM2r TM2s TM3r TM3s TM4r TM4s

Ramp 1 Ramp 2 Ramp 3 Ramp 4

Pid 2 :

Choice of a PID that avoid overshoot during the regulation phase.

Soft start :

Moderate starting up, the time of establishment (the process value reaches the setpoint) is

adjustable. This function can be used in the case of machines sensitive to the abrupt variations of

temperature.

Alarms:

One to 3 alarms are available depending the models. Each alarm is based on an output relay

(1 to 3A depending the model). Two more alarms are available through Modbus on REG96 and one

on the REG48 models.

The alarms can be configured for a low or high level and can also be delayed.

12

EIO0000000377 00 04/2009

Modbus

Power supply

Output

1

actuator

Input temperature

Contact alarm

Modbus

Output 1

actuator

Input

Power supply

Output

2

actuator

Contacts for 2

CHAPTER 4 : WIRING AND SCHEMATICS :

REG 24 (12 models) :

probe 2 or 3 wires

or voltage / current

sensor depending

model

REG 48 (14 models) :

alarm outputs

3 A

for heating or

cooling :

relay / solid state

relay, analog

depending model

output 1 A

24 V (AC/DC)

or

100/240 VAC

Depending model

for heating:

relay / solid state

relay /

analog depending

the model

24 V (AC/DC)

or

100/240 V AC

Depending model

EIO0000000377 00 04/2009

for cooling:

relay / solid state

relay /

analog depending

the model

temperature

probe 2 / 3 or 4

wires or voltage

current sensor

13

Power supply

Contacts for 3

Output 1

actuator

Input

Output

2

actuator

REG 96 (14 models):

Chapter 4 wiring and shematics

Modbus

for cooling:

relay / solid state

relay /

analog depending

the model

for heating:

relay / solid state

relay /

analog depending

the model

alarm outputs

3 A

24 V (AC/DC)

or

100/240 V AC

Depending model

temperature

probe 2 / 3 or 4

wires or voltage

current sensor

Note :

The alarms D4 and D5 are only available through Modbus

The output(s) type depends on the product (see page 6 of the document).

Remark:

The wiring of the solid sate relays or analog actuators and input probe must follow the wiring

shematics, especially the polarity..

For the modbus connection avalability check carrefully the part number and the table

described page 6.

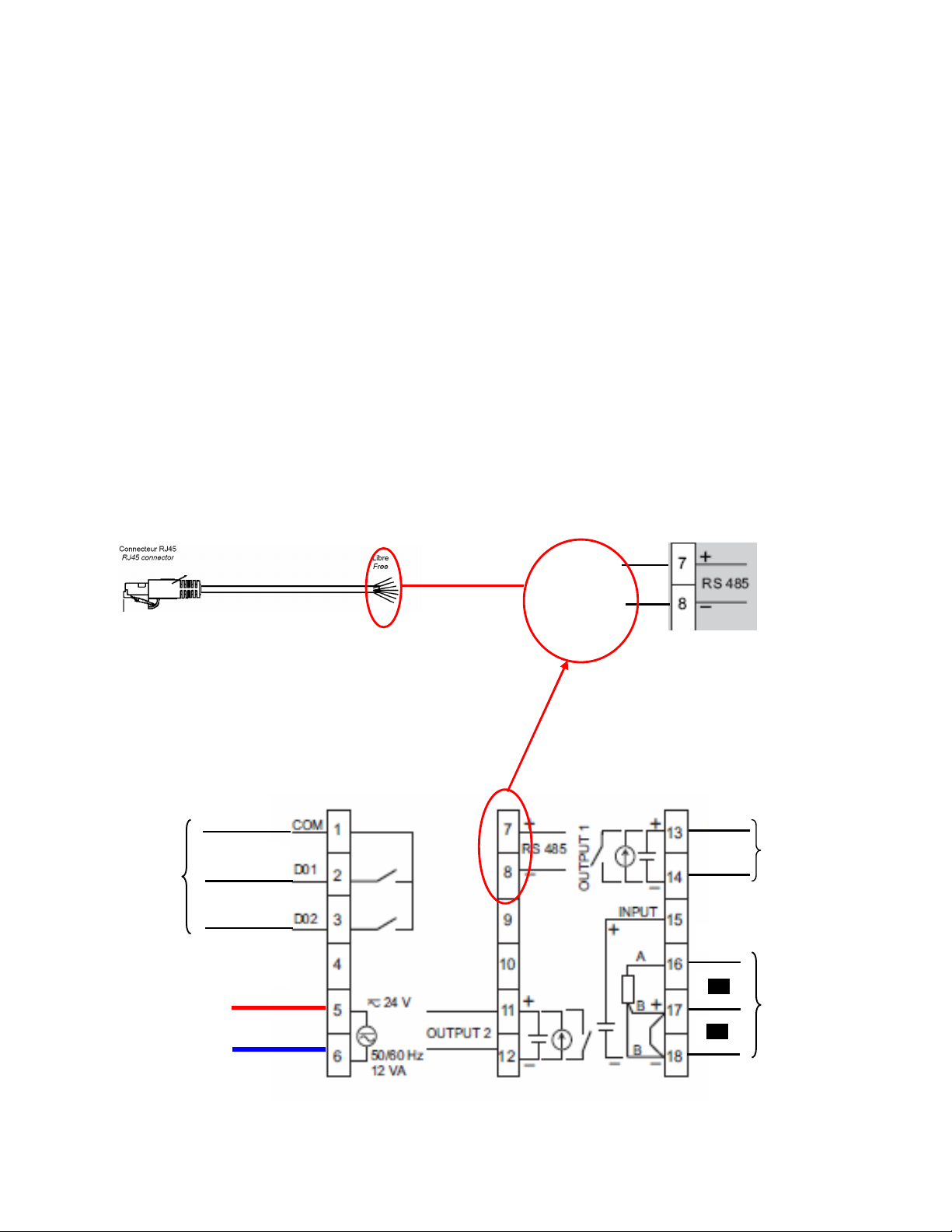

The modbus connection is connected to the screw termials:

- 14/15 for REG 24

- 7/8 for REG 48

- 1 /2 for REG 96

14

EIO0000000377 00 04/2009

CHAPTER 5: IMPLEMENTATION

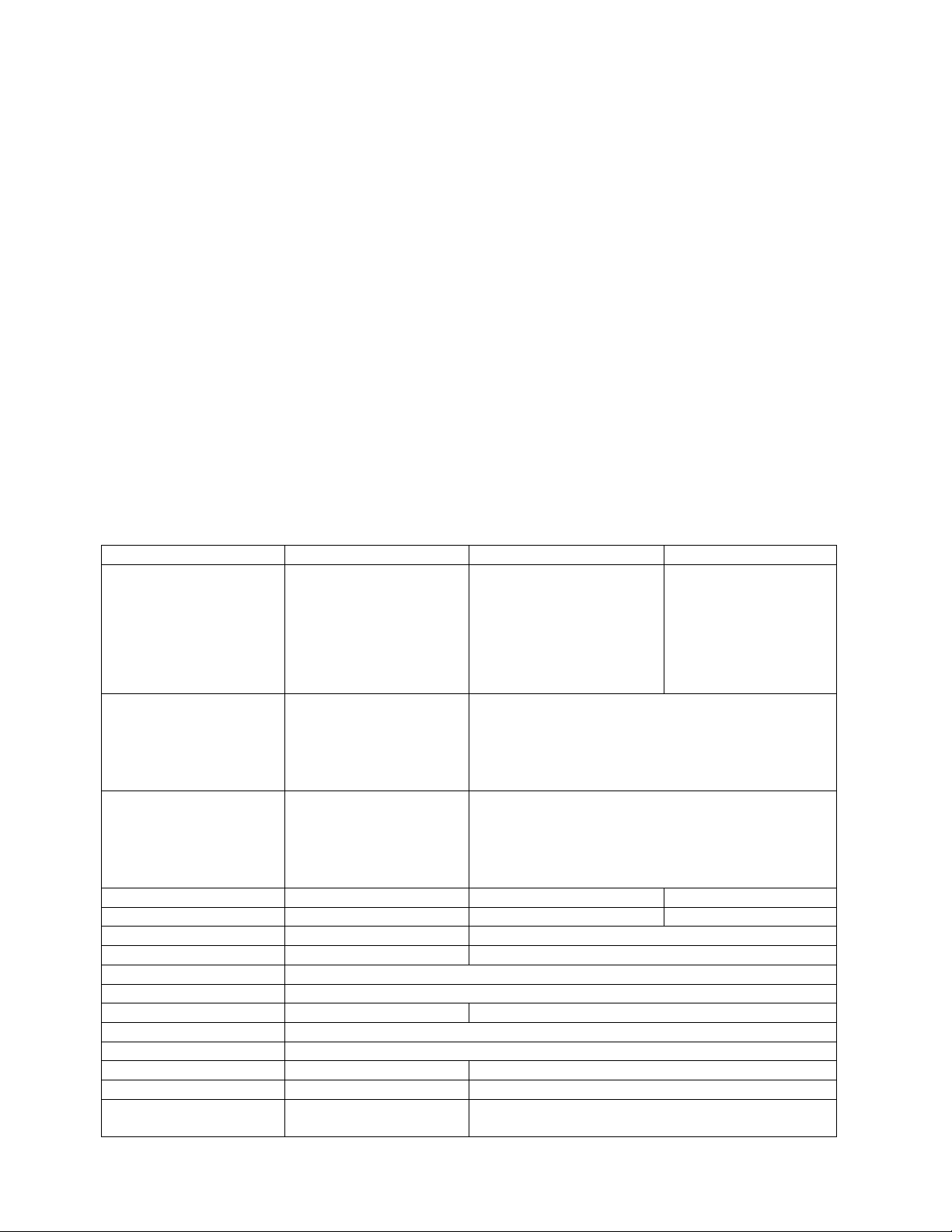

Selection guide:

To choose the most adapted controller the characteristics that must be take into account

are (functional analysis):

- The sensor type connected to the input (PT100, thermocouple, analog, current or voltage);

- The number and type of the outputs: need to manage one or 2 actuators for heating, cooling or

heating and cooling regulation (relay or solid state relay interface or analog (proportional valve,

speed drive) ;

- The number of alarms;

- The number of ramps;

- Operation mode (automatic or automatic and manual);

- Modbus communication available (need of multiple controllers, communication with a Magelis,

a PLC such as TWIDO, M340 or Premium);

Advanced function easy to use and to setup embedded on controllers:

- hysteresis

- auto tuning

- fuzzy logic (see page 8)

- soft start (on REG48 and REG96)

REG 24 REG 48 REG 96

Input type

Process output type

Number of process

outputs

Alarms

Sampling time

Precision

Number of ramps

Hysteresis

PID

PID2

Auto tuning

Fuzzy logic

Soft start

Operating mode

Modbus

communication

-PT100

-Themocouple

J,K,R,B,S,T,E,N,PLII

-Voltage

1....5V

-Current

4...20mA

-SPDT Relay 220VAC,

30VAC/DC 3A

-Solid state interface 24VDC,

20 mA, 850Ω

- analog

4....20mA (600Ω maxi)

1relay

ou 1 solid sate relay interface

ou 1 analog current

1 physical or 1Modbus 2 + 1Modbus 3 + 2 Modbus

500ms 200ms 200ms

0,5% FS 0,3% FS

8 16

NON OUI

NO Yes

AUTOMATIC AUTOMATIC and MANUAL

NO if A letter in the part

number

-PT100

-Themocouple

J,K,R,B,S,T,E,N,PLII

-Voltage

0….5V,1....5V,0….10V,

2…10V,

-Current

0...20mA, 4….20mA

-SPST Relay 220VAC, 30VAC/DC 3A

-Solid state interface 24VDC, 20 mA, 850Ω

- analog 4....20mA (600Ω maxi)

0….5V, 1….5V, 0….10V (10KΩ mini)

1 relay

ou 2 relays

ou 1 solide state relay interface

ou 1 relay + 1 solid state relay interface

ou 1 analog current

ou 1 solid state relay interface + 1 analog current

OUI

OUI

OUI

Yes

NO if L letter in the part number befor the number of output

-PT100

-Themocouple

J,K,R,B,S,T,E,N,PLII

-Voltage

0….5V,1....5V,0….10V,

2…10V,

-Current

0...20mA, 4….20mA

EIO0000000377 00 04/2009

15

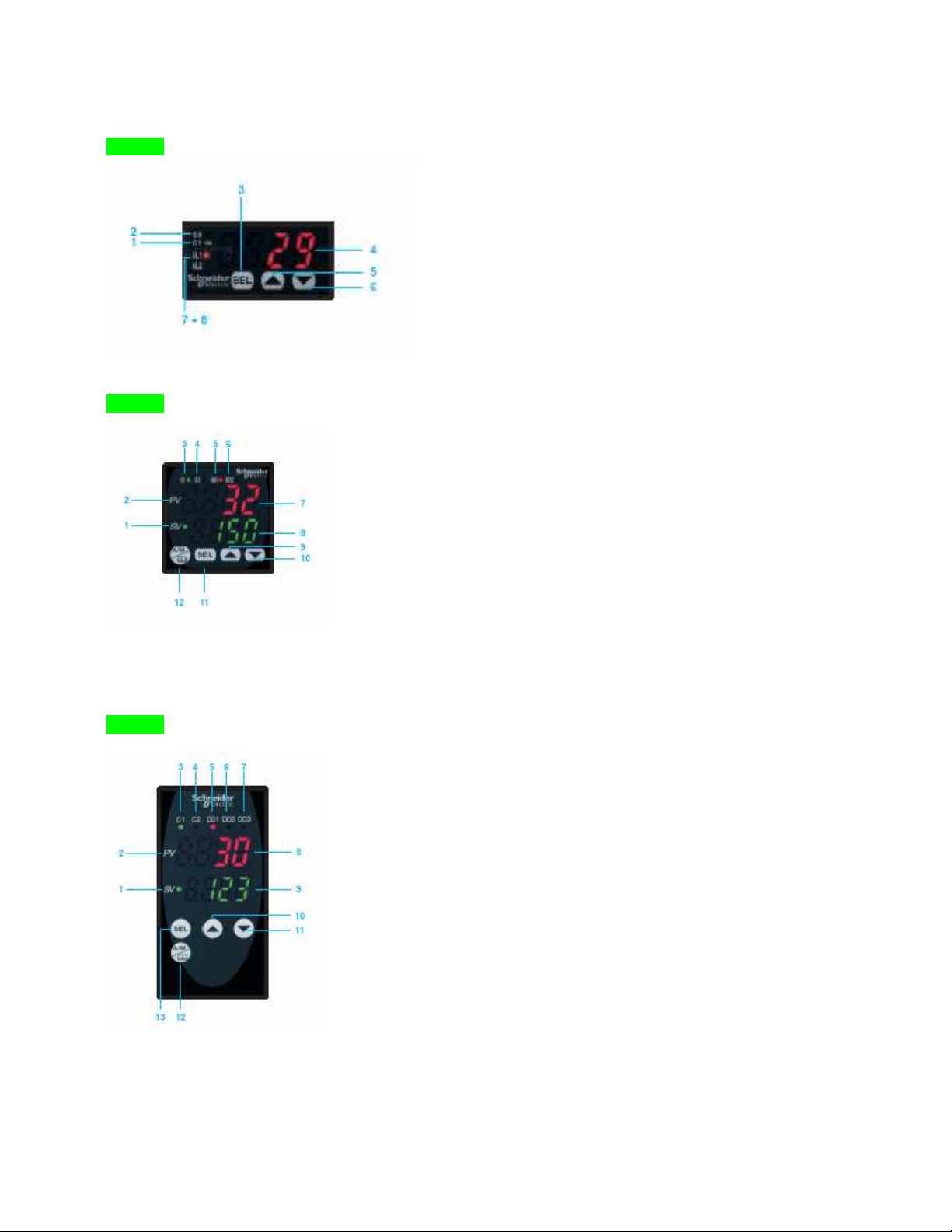

Front face description :

REG 24

REG 48

REG 96

Chapter 5 Implementation

1 C1 : indicator showing output 1 ON

2 SV : set-point value indicator; on = SV, off=PV present value

indicator, if parameter entry

3 SEL : selector button

4 Display of parameter value entered, 4 red digits, 10mm high

5 UP (increment) arrow.

6 DOWN (decrement) arrow

7 AL1 : relay output alarm on REG24PTP1A•HU only.

8 AL2 : Modbus alarm.

1 C1 : set-point value indicator.

2 PV : process value indicator

3 C1 : indicator showing output 1 ON.

4 C2 : indicator showing output 2 ON.

5 D01 : Alarm 1 output ON

6 D02 : Alarm 2 output ON

7 Display of process value, 4 red digits, 12 mm high

8 Display of parameter value entered, 4 green digits, 10mm high

9 UP (increment) arrow

10 DOWN (decrement) arrow.

11 SEL : selector button.

12 A/M : automatic / manual mode or configuration key.

1 SV : set-point value indicator

2 PV : process value indicator

3 C1 : indicator showing output 1 ON

4 C2 : indicator showing output 2 ON

5 D01 : alarm 1 output ON

6 D02 : alarm 2 output ON

7 D03 : alarm 3 output ON

8 Display of process value, 4 red digits, 12 mm high

9 Display of parameter value entered, 4 green digits, 10mm high

10 UP (increment) arrow

11 DOWN (decrement) arrow.

12 SEL : selector button.

13 A/M : automatic / manual mode or configuration key.

16

EIO0000000377 00 04/2009

White

Red

Red

Alarm 1

Alarm 2

Alarms

Blue

Raccordement liaison Modbus REG/PC

CHAPTER 6: EXAMPLE OF IMPLEMENTATION

The function to be done is the piloting of a system of heating. The actuator is managed by a

relayand the temeprature probe is a PT100, range from 0 to 400 °Celsius.

The temperature setpoint is 28°C. It can be adjusted by the operator from 24 to 30°C.

One alarm must turn on when the temperature reaches 32°C and a second alarm when the

temperature reaches 36°C.

The controller power supply is 220VAC.

At first no particular function is needed, just a regulation closer of to the setpoint.

1 st step : Controller selection

The demand of two alarms imposes at least a regulator of type 48, Modbus communication to use

the software ZelioControl soft.

The selected model is:

REG 48 PUN 1 R HU: 1 universal input, 1 relay output, 220VAC power supply,

Modbus communication to allow parameter setting using the software

2sd step : The cabling

CABLE TWDXCAFJ010

Power

supply

Ph

N

White/Blue

Process

output 1

Probe

PT100

EIO0000000377 00 04/2009

17

this screen appears

3 Rd step

:

Front face programming

Power on the controller,

Probe type setting (PT100)

From the main screen push on the key until

Ch 1 functions, for detail see the user guide

Push on the key until this screen appears

Ch 6 functions, for detail see the user guide

Chapter 6 Example of implementation

Push on key until this screen appears

PvT choice of the probe type

Push on the key, the green figure is blinking

PvT = 1 (PT100 probe)

Impulsion sur jusqu’à l’apparition du chiffre 1

Choice validation by pushing the key

18

EIO0000000377 00 04/2009

Chapter 6 Example of implementation

Setting of the PT100 probe range (0 to 400°C)

Push on key to get this screen

Setting of the minimum value for the PT100 probe Pvb = 0°C

Push on the key, the green figure is blinking

Push on the key to get 0

Choice validation by pushing the key

Setting of the maximum value for the PT100 probe PvF = 400°C

Push on key until this screen appears

Push on key, the green figure is blinking

Push on key to reach 400

Choice validation by pushing the key

EIO0000000377 00 04/2009

Push on key to get this screen

19

Push the

key to get the figure

1

Chapter 6 Example of implementation

Setting of the choosen decimal value (Pvd) (to display the tenth)

Push the key, the green figure is blinking

Choice validation by pushing the key

Back to the main screen by pushing

Push the key until this screen appears

Push the key until this screen appears

Ch 2 functions, for details see the user guide

Push the key until this screen appears

Push the key until this screen appears

20

EIO0000000377 00 04/2009

Chapter 6 Example of implementation

Regulation mode selection = heating on channel 1 (rEv)

see details of the

choices

page 8

Push the key, the line no- - is blinking

One push on to get rv --

Choice validation by the key

Back to the main screen by pushing

Alarms 1 and 2 parameters setting

Push the key key until this screen appears

Push the key until this screen appears

Push the key key until this screen appears

EIO0000000377 00 04/2009

21

Alarm 1 parameters setting at 32°C

Push the key the green figure is blinking

Push the key until 32.0 value di sdisplayed

Choice validation by pushing the key

One push on to adjust alarm 2

Alarm 2 setting at 38°C

Same operation as for alarm 1, adjust at 38.0°C

Validation of the choice by pushing the key

Chapter 6 Example of implementation

Back to the main screen by pushing

Parameter setting of the alarms on high overtaking (do1T)

Push the key the green

figure is blinking

1 push on the key to display the number 1

Validation using the key

Back to the main screen by pushing

22

EIO0000000377 00 04/2009

Chapter 6 Example of implementation

4 Th step: Functional test

The controller has been configured as for the example. Real tests can be made.

(Status of the alarm 1 and 2 compare to the temperature displayed on the front face….)

Following the same method it’s possible to modify through the front face the other parameters

(Auto Tunning, PID2, etc…)

Use of the ZelioControl SOFT software

1 St step: install the software ZelioControl Soft (compatible with Windows

XP and Vista)

2 Nd step: installation of the TSXCUSB485 driver

3 Rd step: connect the TSXUSB485 to your PC and the controller

Check the rotary swith is positionned to OTHER MULTI

EIO0000000377 00 04/2009

23

4 Th step : check the communication port parameters of the

TSXCUSB485

Open the Windows configuration panel (1), then “System”, then “Hardware” (2) and “peripheral

management” (3):

driver

Chapter 6 Example of implementation

2

1

3

Communication port

assigned to the driver : in

If the communication port number is higher than 10 you must

reassign the communication port to a lower number.

Open the port property window, click on the advance button,

in the field « Number » of the COM port, you must choose a

number less or equal to 10. Validate the change using the

“OK” button.

5 Th step: Discover the software ZelioControl Soft

After the installation of ZelioControl Soft done, start ZelioControl Soft :

24

Select the controllers 48/96

EIO0000000377 00 04/2009

Chapter 6 Example of implementation

6 Th step: check the communication parameters of the

Select the same communication port than for

Chapter 6 Example of implementation

7 Th step: Communication parameters setting:

Baudrate, parity, station number:

These parameters must be the same than the controller’s one. You can check this value using

the controller front face interface and the screen CH9:

TSXCUSB485

driver

In this example: baudrate 9600, parity odd, stantion number 5

Communication setting using ZelioControl Soft

(Communication default values are : 19200 bauds, parity Even, station n°248)

Baudrate 9600 bds Parity odd

Station n° 5

EIO0000000377 00 04/2009

25

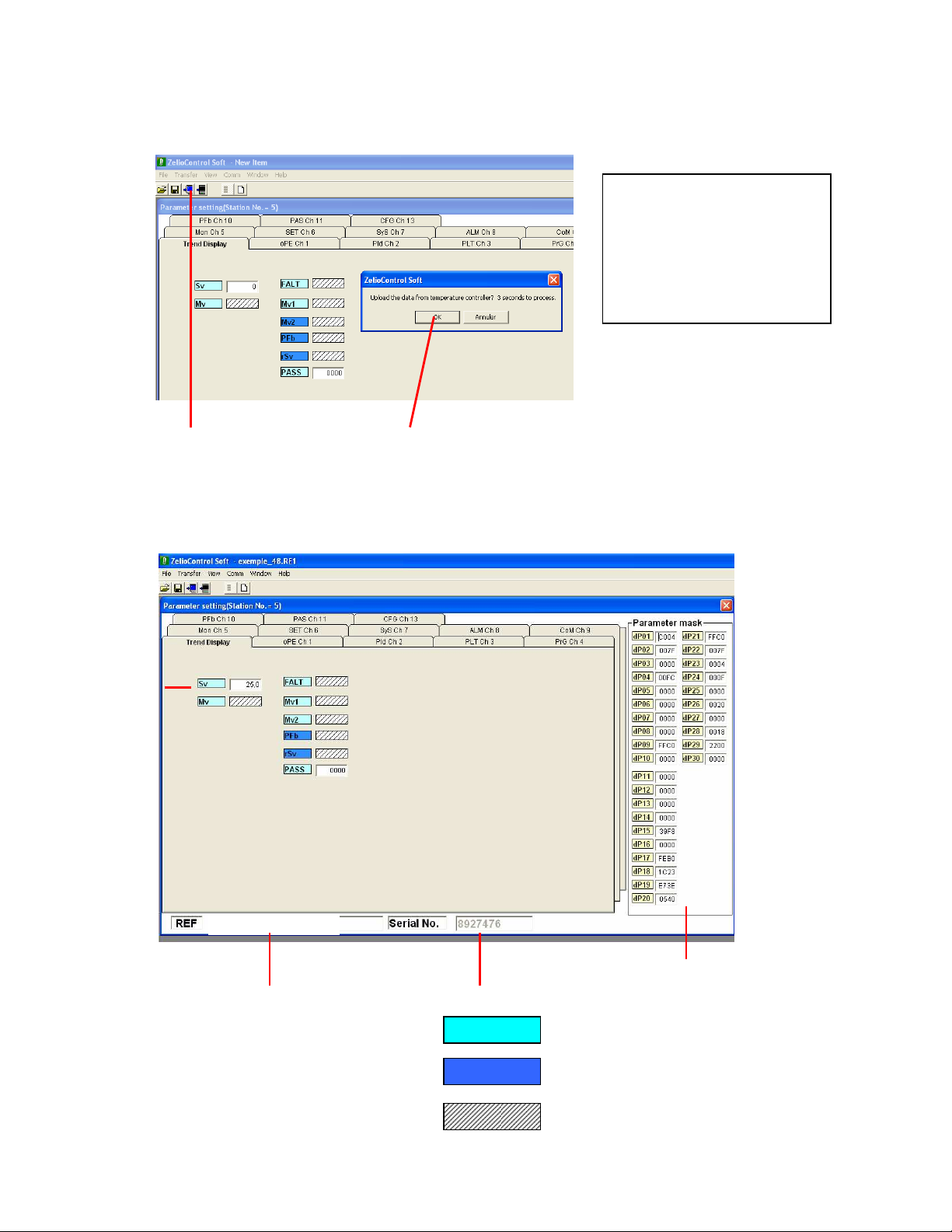

Sv

(setpoint) = 25,0

Hidden parameter on the product

Hidden parameters

Chapter 6 Setup example

8 Th step: Connection to the régulator and application Upload

Important :

Before exit of ZelioControl

Soft, don’t forget to save

your application.

The software closes

without an automatic save

of the file. (see page 36)

1

Upload choice

2

Confirmation

9 Th step: Application display

ZelioControl Soft principal screen

1

Controller identification Serial Number

1

2

for details see user guide

2

Visible parameter on the product

(Settable through the software)

No display through ZelioControl Soft

26

EIO0000000377 00 04/2009

CHAPITRE 7: ZelioControl SOFT software

ZelioControl Soft screen - oPE CH1

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

Operations :

1 Man switches to manual mode

2 Stby Control RUN/STANDBY

3 NOT USED

4 PrG Ramp soak operation command (Off/Run/hold)

5 AT Auto Tuning Command (Off/ON/Low)

6 LACh Output alarm retain

7 Svn Preselection setpoint (0:Sv0 default value)

8 PLn1 Preselection PID (0:pid0 default value)

9 AL1 AL1L Alarm 1 low limit (example : 32°C )

a AL1h Alarm 1 high limit

b AL2 AL2L Alarm 2 low limit ( example : 36°C )

AL2h Alarm 2 high limit

c AL3 AL3L Alarm 3 low limit

AL3h Alarm 3 high limit

d AL4 AL4L Alarm 4 low limit

AL4h Alarm 4 high limit

e AL5 AL5L Alarm 5 low limit

AL5h Alarm 5 high limit

f LoC Front face keys locked

Note : the REG48 includes 2 alarms, the REG96 3 alarms. The alarms 4 and

5 are acsessible through Modbus only

Note : if auto tuning then the setting of P/I/D/hys/bal/ar is automatic

EIO0000000377 00 04/2009

27

ZelioControl SOFT screen PID CH2

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

g

h

i

j

k

PID parameters:

1 Sv0 Setpoint

2 P proportional factor

3 i integrale factor

4 d derivation factor

5 hyS hysteresis (0 to 50% FS)

6 CoL cooling proportional band

7 db dead band

8 bAL output convergence value

9 Ar anti reset windup – ovoid overshoot if PID inactive

a rEv normal/reverse – selection type (example : rEv - see page 8)

b SvL SV low limit - (example : 0°C )

c Svh SV high limit - (example: 400°C )

d TC1 OUT 1 proportionnal cycle (if solid state interface type : max frequency swithing)

e TC2 OUT 1 proportionnal cycle (if solid state interface type : max frequency switching)

f PLC1 OUT 1 lower limit - (if analog)

g PhC1 OUT 1 upper limit - (if analog)

h PLC2 OUT 2 lower limit - (if analog)

i PhC2 OUT 2 upper limit - (if analog)

i PCUT Select ouput limiter type - (PLC1/2 – PHC1/2)

K NOT USED

Remind: if auto tuning then the setting of P/I/D/hys/bal/ar is automatic

28

EIO0000000377 00 04/2009

ZelioControl Soft screen - PLT CH3

8

9

1

2

3

4 6

5

7

Setpoints and PID settings:

1 Sv1 setpoint 1

P1 Proportional 1

i1 Integrale 1

d1 Derivative 1

hyS1 hysteresis 1

CoL1 Cooling proportional band 1

db1 dead band 1

bAL1 output convergence 1

Ar1 anti reset windup 1

rEv1 Normal/reverse function selection

2 Same for PID 2

3 Same for PID 3

4 Same for PID 4

5 Same for PID 5

6 Same for PID 6

7 Same for PID 7

8 SvMX Selectable Sv numbers

9 PL1M Currently select PID

EIO0000000377 00 04/2009

29

ZelioControl Soft screen - PRG CH4

1

2

3

4

5

6

Ramp parameters:

1 PTn ramp soak patern – ramp number selection

2 TiMU ramp soak time unit (hhmm or mmss)

3 Sv1 setpoint ramp 1

TM1r ramp soak 1 ramp time

TM1s ramp soak 1 seg soak

4 Same for ramp 2

5 Same for ramp 3

6 Same for ramp 4

7 Same for ramp 5

8 Same for ramp 6

9 Same for ramp 7

a Same for ramp 8

b Same for ramp 9

c Same for ramp 10

d Same for ramp 11

e Same for ramp 12

f Same for ramp 13

g Same for ramp 14

h Same for ramp 15

i Same for ramp 16

j MoD ramp soak mod (0 to 15)

k GsoK garanty soak (ON/OFF)

l GS-L garanty soak lower limit

m GS-h garanty soak upper limit

n PvST Consideration of the global nature of the programmed curve (OFF)

Consideration of the real value measured for starting up (ON)

o ConT 3 choices rES/CON/INI

p PTnM sets the max pattern selection

q Pmin sets the min pattern selection

j

7

8

9

a

b

c

d

e

f

g

h

i

k

l

m

n

o

p

q

30

EIO0000000377 00 04/2009

ZelioControl Soft screen - MON Ch5

1 7

2

3

4

5

6

Monitoring functions:

1 STAT ramp soaks progress

2 Mv1 output 1

3 Mv2 output 2

4 PFb PFB intput value display

5 rSv RSV input value display

6 NOT USED

7 TM1 remaining time on timer 1

8 TM2 remaining time on timer 2

9 TM3 remaining time on timer 3

a TM4 remaining time on timer 4

b TM5 remaining time on timer 5

c FALT Fault status error source display

d Plno PID in progress

e Ptno ramp in progress

Note: Data used only with the Software. Updated only after

the upload.

8

9

a

b

c

d

e

EIO0000000377 00 04/2009

31

ZelioControl Soft screen – SET Ch6

1

2

3

4

5

6

7

8

9

a

b

c

d

f

g

h

i

j

k

l

m

n

o

p

q

r

Setup :

1 PvT Sensor type selection (example: 1 PT100 )

2 Pvb Pv input lower limit - (example: 0,0°C )

3 PvF Pv input upper limit - (example: 400,0°C )

4 Pvd decimal position - (example: 1)

5 PvU unit selection °Celsius or °Fahrenheit ( example: °C )

6 CUT

7 PvoF PV input shift offset

8 SvoF SV shift offset

9 TF PV input filter

a AdJO user zero adjustement

b AdJS user span adjustement

c rCJ Compensation weld for thermocouple probe

d NOT USED

f C1r OUT1 range (if OUT 1 is analog)

g C2r OUT2 range (if OUT 2 is analog)

h Flo1 OUTPUT 1 set value during fault

i Flo2 OUTPUT 2 set value during fault

j SFo1 Soft start OUT 1 set value (if Output 1 digital –3% =0 , 103% =1)

k SFo2 Soft start OUT 2 set value (if Output 2 digital –3% =0 , 103% =1)

l SFTM Soft start set time

m Sbo1 during standby OUT 1 set value

n Sbo2 during standby OUT 2 set value

o SbMd standby mode setting – alarms output state in standby mode

p AoT type off output retransmission (Modbus only)

q AoL AO lower limit scaling (Modbus only)

r Aoh AO upper limit scaling (Modbus only)

32

EIO0000000377 00 04/2009

ZelioControl Soft screen – SyS Ch7

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

g

h

i

j

k

l

m

System parameters:

1 UkEy User key assignement setting

2 NOT USED

3 do1T DO1 output event setting - alarm 1 type configuration

4 doP1 DO1 option function setting - hold alarm 1

5 do2T DO2 output event setting - alarm 1 type configuration

6 doP2 DO2 option function setting - hold alarm 2

7 do3T DO3 output event setting - alarm 1 type configuration

8 doP3 DO3 option function setting - hold alarm 3

9 do4T DO4 output event setting - alarm 1 type configuration

a doP4 DO4 option function setting - hold alarm 4

b do5T DO5 output event setting - alarm 1 type configuration

c doP5 DO5 option function setting - hold alarm 5

d rMP ramp use on setpoint change

e rMPL ramp SV decline

f rMPh ramp SV incline

g rMPU ramp SV slipe time unit

h SvT ramp SV-SV display mode selection

i CTrL select PID/FUZZY/SELF function

j NOT USED

k onoF hysteresis mode setting

l SLFb pv stable range

m STMd start mode selection

EIO0000000377 00 04/2009

33

ZelioControl Soft screen – ALM Ch8

1

2

3

4

5

6

7

8

9

a

b

c

d

e

f

g

h

i

Alarms setting:

1 A1hy alarm 1 hysteresis (0 to 50% FS)

2 dLy1 alarm 1 delay – alarm 1 depending the selected unit

3 dL1U alarm 1 time unit – alarm time unit (0=second – 1=minute)

4 A2hy alarm 2 hysteresis

5 dLy2 alarm 2 delay délai - alarm 2 depending the selected unit

6 dL2U alarm 2 time unit - alarm time unit (0=second – 1=minute)

7 A3hy alarm 3 hysteresis

8 dLy3 alarm 3 delay - alarm 3 depending the selected unit

9 dL3U alarm 3 time unit - alarm time unit (0=second – 1=minute)

a A4hy alarm 4 hysteresis

b dLy4 alarm 4 delay - alarm 4 depending the selected unit

c dL4U alarm 4 time unit - alarm time unit (0=second – 1=minute)

d A5hy alarm 5 hysteresis

e dLy5 alarm 5 delay - alarm 5 depending the selected unit

f dL5U alarm 5 time unit - alarm time unit (0=second – 1=minute)

g NOT USED

h NOT USED

i NOT USED

34

EIO0000000377 00 04/2009

ZelioControl Soft screen - CoM CH9

1

2

3

4

Note: For communication parameters setting see page 23

Modbus communication parameters display :

1 Stno station number (5 in the example )

2 CoM baudrate and parity (96 = 9600 bauds, odd parity (as for the example)

3 PcoL Communication type (Modbus fixed value)

4 SCC read/write possible (up load/down load (fixed value)

ZelioControl Soft screen - PFb CH10

1

Feedback position:

1 NOT USED

EIO0000000377 00 04/2009

35

ZelioControl Soft screen - PAS CH11

1

2

3

Passwords setting:

1 PAS1 Password 1 (default value = 0000)

2 PAS2 Password 2 (default value = 0000)

3 PAS3 Password 3 (default value = 0000)

36

EIO0000000377 00 04/2009

ZelioControl Soft screen - CFG CH13

1

2

3

8

9

a

b

c

j

4

5

6

7

d

e

f

g

h

i

Environment parameters configuration:

1 ToUT Time delay to principal screen return after key action

2 NOT USED

3 SoFK

4 ALMF Blinking or fix state of front face alarm leds

5 bCon

6 PTnT Ramps execution order modification

7 NOT USED

8 L-C1 Led function selection

9 L-C2

a Ldo1

b Ldo2

c Ldo3

d L-Sv

e L-Mv

f LMAn

g LSTB

h LrEM

i L-AT

j rST controller reset

EIO0000000377 00 04/2009

37

Application file saving under ZelioControl SOFT

Application file saving :

1

EDMS xxxxxxxxx 03 2009

2

1 File selection

2 Save As and then indicates the path

for the file

Current file saving

Other functions :

Download (Application transfert from PC to

controller using Modbus)

File name

Report function: all parameters display

(printing possibility)

Upload (Application tranfert from controller

to PC using Modbus)

38

EIO0000000377 00 04/2009

Loading...

Loading...