Page 1

Catalog

August

05

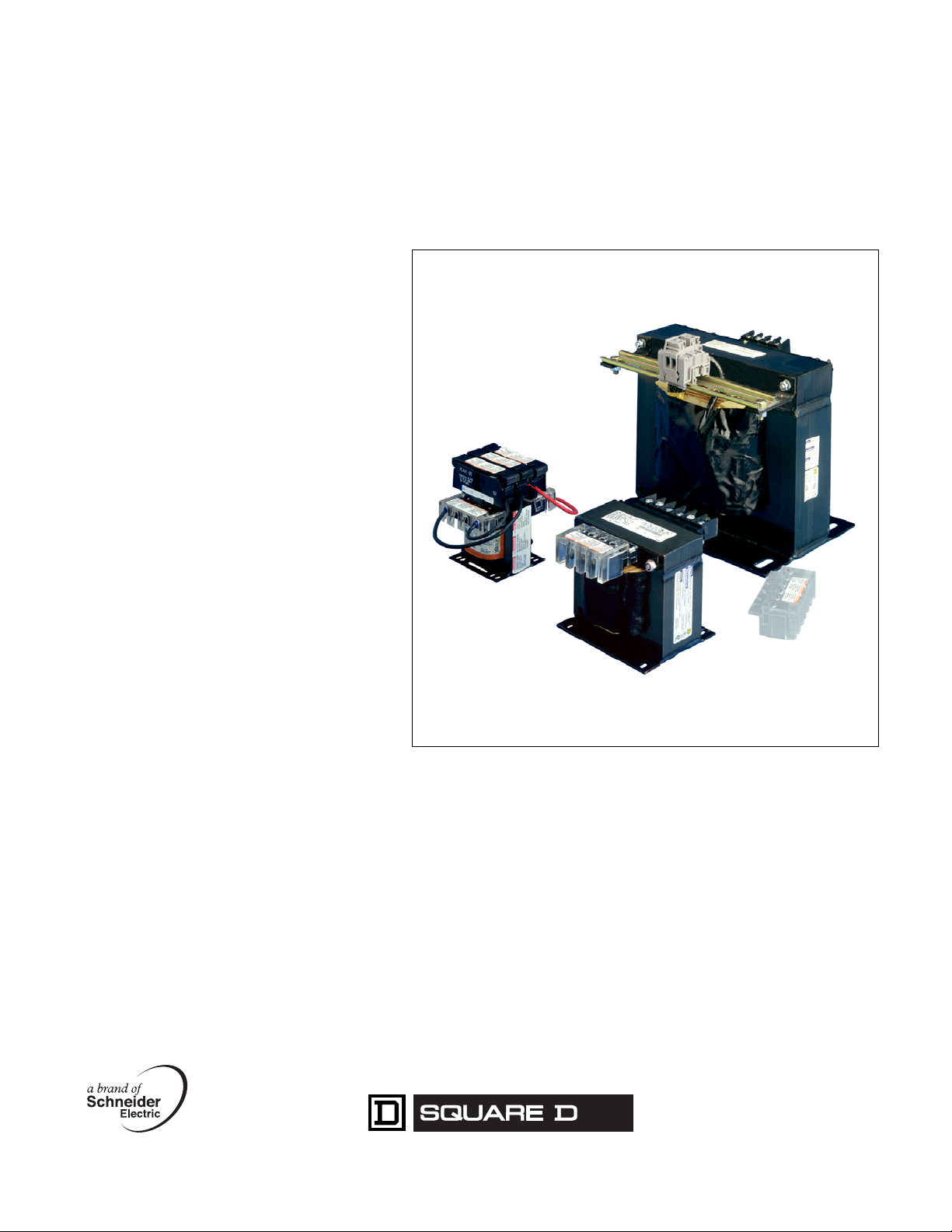

Industrial Control Transformers

Class 9070

CONTENTS

Description. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Page

Product Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Type T Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Type EO Transformers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Fuse Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Type TF Transformers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Field Installed Fuse Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Application . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

Frequently Asked Questions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Page 2

Page 3

Industrial Control Transformers

Product Description

PRODUCT DESCRIPTION

Control power transformers from Schneider Electric set the industry standard for design innovation and

performance. They are designed with low impedance windings for excellent voltage regulation, and

can accomodate the high inrush current associated with contactors, starters, solenoids, and relays.

A variety of designs are available to meet the diverse needs of panel builders and machinery OEMs.

The versatility of our control transformer line offers unparalleled options for design engineers. We also

have one of the most extensive offering of custom products with no minimum order requirements.

We have a national network of distributors to ensure prompt delivery, including industry leading

delivery on custom products. In most cases, we can design, manufacture, and ship a custom unit in

two weeks or less.

The Global Product Offering—Type T

Type T is our most popular and complete line of control transformers. It comes with unmatched design

innovations for top performance and is manufactured using the most advanced insulating materials.

The Type T control transformer is the best choice if size and cost are of concern.

The Exceptional Regulation Offering —Type EO

Constructed with traditional materials and manufacturing processes, Type EO transformers are UL and

CSA Component Recognized. Units are designed for 55°C rise. All units are 60HZ rated, with

de-rated VA levels for 50HZ.

Transformers with Fuse Block Protection—Types TF and EOF

We offer both product lines with factory installed overcurrent protection fuse blocks.

Type TF and EOF transformers consist of two primary fuse blocks and one secondary fuse block, a

configuration that meets the majority of overcurrent needs by panel builders and machinery OEMs.

Since the fuse blocks are pre-wired and mounted on top of the transformer, the Type TF and EOF

transformers have the same footprint as the Type T and Type EO units, respectively. This design frees

up space normally used for separate fuse blocks

We also have an extensive fuse block offering for custom applications. See the overcurrent section of

this catalog for full details.

Leaded Control Transformer Line

Schneider Electric offers transformers with internally pre-wired 24-inch primary and secondary leads,

instead of terminal boards, to make installation easier and faster for many applications. These are only

available for single voltage primary and single voltage secondary applications.

MultiTap

Schneider Electric offers Type T and Type EO transformers in the MultiTap version. The MultiTap

control transformer was designed to respond to the increased need for voltage and stock flexibility. It

combines multiple primary voltages with one or more secondary voltages, all in a single transfomer.

The most flexible MultiTap voltage is the Universal, available on the Type T product line only. It allows

for standard primary voltages of 208 to 600V and 110, 115, or 120V secondary voltages.

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

3

Page 4

Industrial Control Transformers

Type T Transformers

TYPE T TRANSFORMERS

Type T VA Ratings

UL, cUL, CSA and NOM VA

Rating

25 25

50 50

75 75

100 100

150 150

200 200

250 160

300 200

350 250

500 300

750 500

1000 630

1500 1000

2000 1500

3000 2000

5000 3000

CE

VA Rating

Type T Listings

Listing File VA Range

UL E61239, Guide XPTQ2 25–5000

cUL E61239 1500–5000

CSA LR37055, Guide 184-N-90 25–1000

947923, EN 61 558/01.89 (TUV

EN

ref: 00941-RAG/sg

E9371495E01)

9579078, EN 61 558/01.89 (TUV

ref: 00941-RAG/sg

E9471921E01)

9579078, EN 61 558/01.89 (TUV

ref: 00941-RAG/sg

E9471921.02E01)

25–200

250–1000

1500–3000

The Type T units are designed for the global market and are the best choice

when size and cost are of concern. This is our most popular and complete

offering of industrial control transformers. The following features are

included:

• 50/60 Hz rated

• Customer installed accessories (Finger-Safe covers, fuse blocks, fuse

clips)

• Type T transformers are designed with various temperature classes:

— 25–150 VA with a 55° C temperature rise, 105° C insulation

— 200–350 VA with a 80° C temperature rise, 130° C insulation

— 500–5000 VA with a 115° C temperature rise, 180° C insulation

Schneider Electric manufactures a wide variety of voltage combinations for

control transformers. The voltage combinations are expressed as “Voltage

Codes”, and are embedded within the catalog number of the transformer.

Standard codes are listed. If the voltage combination you need is not listed,

please call your Schneider Electric distributor for assistance.

CE Marking

Industrial control transformers (ICTs) entering the European Union (EU)

after January 1, 1997 are required by EU standards to have CE marking or

Declaration of Conformity to CE. EU documentation requires compliance

with specification EN 61 558 of the Low Voltage Directive. Type T ICTs from

Schneider Electric comply with this specification and are third party tested to

TÜV standards, which adhere to, and are accepted by, EU standards. A

Declaration of Conformity for all Type T units is available upon request.

Because of different overload criteria in the CE specification,

Schneider Elecric dual rates these transformers for UL VA, cUL VA, CSA

VA, NOM VA and CE VA ratings (see “Type T VA Ratings” table). Because

they are widely used with control circuit panels, ICTs are also required to

comply with EN 60 204 and EN 61 558 in these applications. The Type T

transformer line complies with EN 60 204 when Fingersafe

installed.

For more information regarding CE marking, please contact your local

Schneider Electric field sales office.

®

covers are

4

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 5

Selection Guide

Industrial Control Transformers

Type T Transformers

Example:

This example assumes the following:

• Two NEMA size 0 contactors do not start together, but one

could be ON when the other starts.

• One NEMA size 2 contactor can start with either of the

other contactors.

• One pilot light at 2 VA

1. VA and inrush are:

NEMA 0: sealed 27 VA; inrush 245 VA

NEMA 2: sealed 37 VA; inrush 311 VA; pilot light 2 VA

2. Total VA: 27 + 27 + 37 + 2 = 93 VA

3. Total inrush VA: 245 + 311 + 27 + 2 = 582 VA

4. From Regulation Chart for Type T at right below:

100 VA minimum unit; inrush 499 VA will not work at 90%

150 VA (next standard size); inrush 666 VA will work at 95%

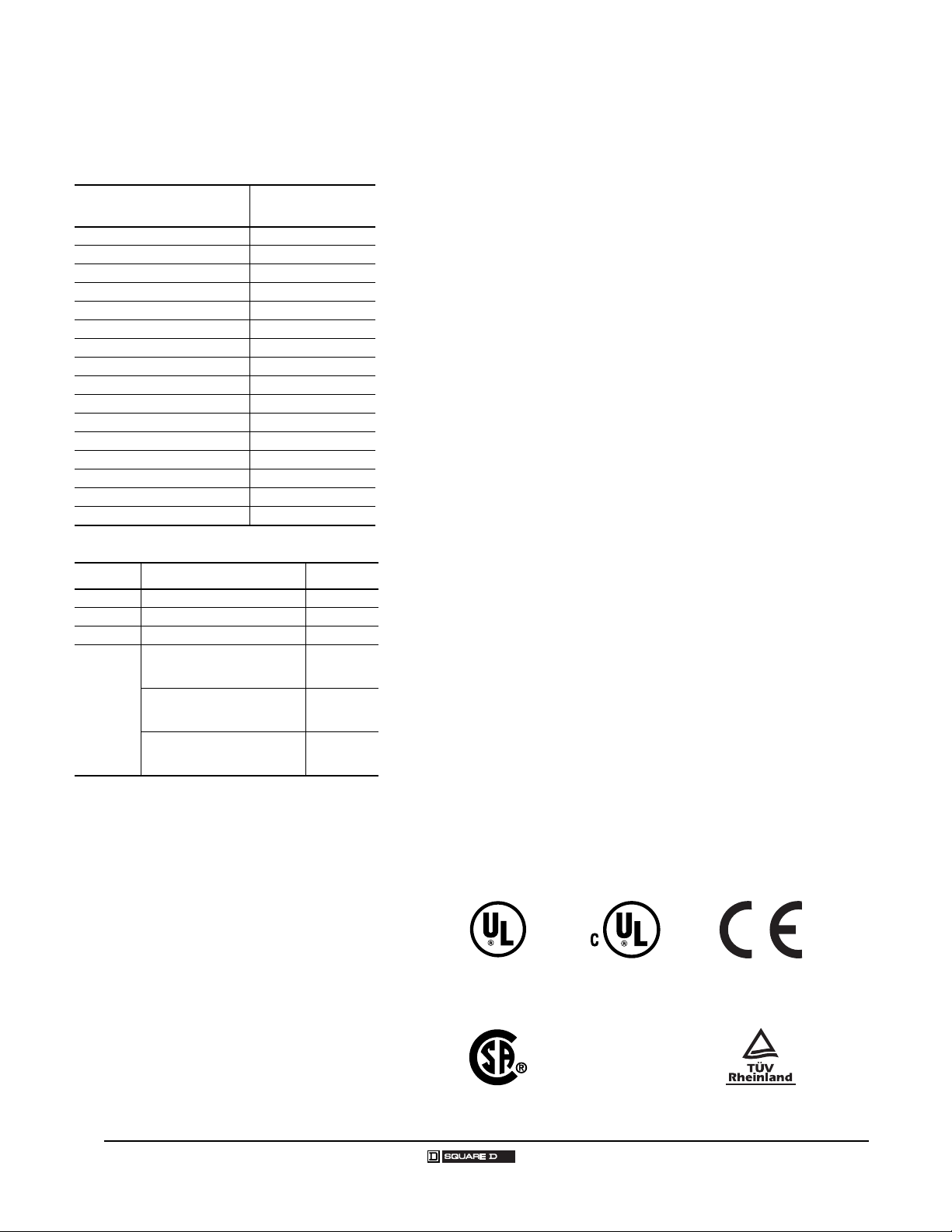

1. Determine inrush and sealed VA of each coil in the control circuit and VA

of all other components.

2. Total all sealed VA of all operating coils and other loads VA (determines

minimal VA size required for the circuit).

3. Total the inrush VA of all coils that are starting at the same time and all

loads and coils that are running (using the regulation chart to give

possible units to be used).

4. Take VA size from step 2, go to standard VA size in chart below. Make

sure inrush VA from chart is greater than total VA from step 3. If not, go

to next larger VA size and repeat.

If your supply voltage is stable and fluctuates less than 5%, we recommend

you use the 90% secondary voltage column. If your supply voltage is not

stable and fluctuates more than 10%, we recommend you use the 95%

secondary voltage column. We recommend that you never use the 85%

secondary voltage column since magnetic devices lose life expectancy if

they are continuously started at 85% of rated voltage.

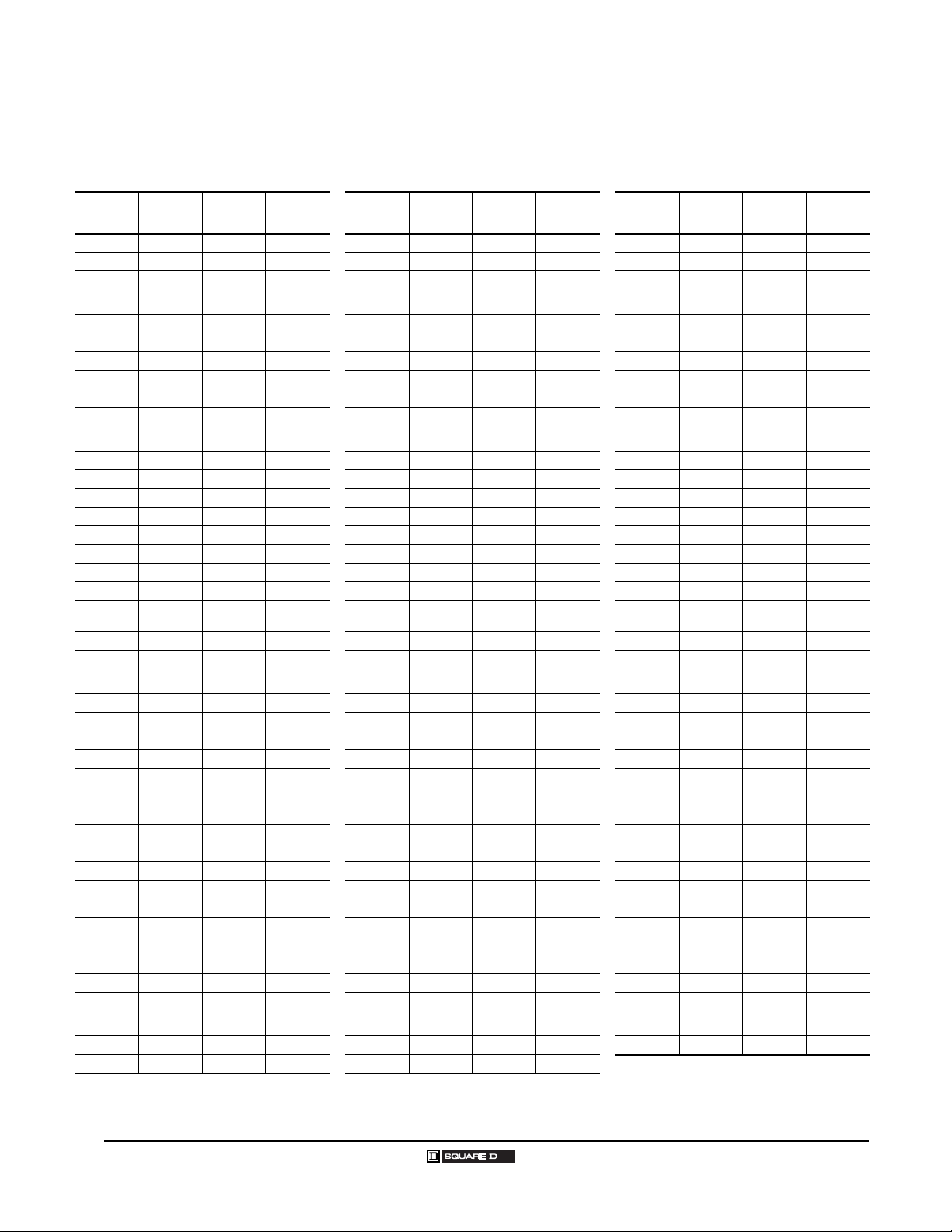

Regulation Chart for Type T

Secondary Voltage

VA

Inrush UL VA at 20% Power Factor Inrush UL VA at 40% Power Factor

95% 90% 85% 95% 90% 85%

50 193 266 339 151 215 282

75 271 396 520 210 318 430

100 339 499 659 266 404 549

150 666 893 1120 529 731 942

200 588 815 1041 459 659 866

250 1416 1910 2388 1057 1494 1936

300 1634 2184 2709 1194 1681 2169

350 1894 2592 3261 1392 2005 2621

500 3197 4104 4981 2374 3195 4019

750 3770 5515 7231 2887 4391 5945

1000 6587 9079 11430 4706 6886 9051

1500 19324 23983 28607 15066 19361 23756

2000 31384 38777 46161 24794 31630 38667

3000 26539 39934 52713 19355 30721 42216

5000 53111 85265 116277 39368 66309 93882

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

5

Page 6

Industrial Control Transformers

Type T Transformers

Use the following table to quickly find a Type T transformer for a 120 volt load for your specific application. First, find your source

and load voltages. Then, go to the indicated pages for details on the transformer(s) matching those voltages.

Type T Transformers for 120 Volt Loads

Source

Voltage

110 110 D24, D55 9, 13 277 115 D18 11 440 110/220 D31 13

110 220 D55 13 277 120 D4, D60 9, 14 460 95 D32, D50 11, 12

110 110/220 D55 13 277 240 D60 14 460 115

115 115 D24, D55 9, 13 277 120/240 D60 14 460 125 D50 12

115 230 D55 13 364 85 D50 12 460 230 D31 13

115 115/230 D55 13 364 100 D50 12 460 115/230 D31 13

120 120 D24, D55 9, 13 364 110 D50 12 480 99 D50 12

120 240 D55 13 380 91 D50 12 480 100 D32 11

120 120/240 D55 13 380 95 D18 11 480 120

190 110 D95 11 380 110 D6, D50 9, 12 480 130 D50 12

200 115 D93, D95 9, 11 380 115 D18, D33 11, 14 480 240 D31 13

208 85 D50 12 380 120 D40, D50 11, 12 480 120/240 D31 13

208 95 D18 11 380 230 D33 14 500 85 D50 12

208 100 D50 12 380 115/230 D33 14 500 100 D50 12

208 110 D50 12 400 95 D50 12 500 110 D50 12

208 115 D20, D18 10, 11 400 115 D33 14 550 90 D32 11

208 120 D3, D40 9, 11 400 120 D103, D50 9, 12 550 91 D50 12

220 90 D32 11 400 125 D50 12 550 110

220 91 D50 12 400 230 D33 14 550 120 D50 12

220 110

220 120 D50 12 415 110 D17 9 550 110/220 D37 14

220 220 D31, D55 13 415 115 D33 14 575 95 D32, D50 11, 12

220 110/220 D31, D55 13 415 230 D33 14 550 110/220 D37 14

230 95 D32, D50 11, 12 415 115/230 D33 14 575 95 D32, D50 11, 12

230 115

230 125 D50 12 416 120 D40, D50 11, 12 575 125 D50 12

230 230 D31, D55 13 416 130 D50 12 575 230 D37 14

230 115/230 D31, D55 13 420 85 D50 12 575 115/230 D37 14

240 99 D50 12 420 100 D50 12 600 99 D50 12

240 100 D32 11 420 110 D50 12 600 100 D32 11

240 120

240 130 D50 12 440 91 D50 12 600 130 D50 12

240 240 D31, D55 13 440 110

240 120/240 D31, D55 13 440 120 D50 12 600 120/240 D37 14

277 95 D18 11 440 220 D31 13

Load

Voltage

Voltage

Code(s)

D1, D32,

D95, D50,

D31, D55

D1, D20,

D32, D95,

D50, D31,

D55

D1, D32,

D40, D95,

D50, D31,

D55

Go To

Page(s)

8, 11, 12,

13

8, 10, 11,

12, 13

8, 11, 12,

13

Source

Voltage

400 115/230 D33 14 550 220 D37 14

416 99 D50 12 575 115

440 90 D32 11 600 120

Load

Voltage

Voltage

Code(s)

D1, D32,

D95, D50,

D31

Go To

Page(s)

8, 11, 12,

13

Source

Voltage

600 240 D37 14

Load

Voltage

Voltage

Code(s)

D1, D20,

D32, D95,

D50, D31

D1, D32,

D40, D95,

D50, D31

D5, D32,

D50, D37

D5, D32,

D50, D37

D5, D32,

D50, D37

Go To

Page(s)

8, 10, 11,

12, 13

8, 11, 12,

13

9, 11, 12,

14

9, 11, 12,

14

9, 11, 12,

14

6

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 7

Industrial Control Transformers

Type T Transformers

Use the following table to quickly find a Type T transformer for a 24 volt load for your specific

application. First, find your source and load voltages. Then, go to the indicated pages for details on the

transformer(s) matching those voltages.

Type T Transformers for 24 Volt Loads

Source

Voltage

115 24 D89 15

120 24 D23, D7 15, 16

208 24 D14, D19 16, 17

230 24 D89, D112 15, 16

240 24

277 24 D25, D19 16, 17

380 24 D88, D19 16, 17

460 24 D92 15

480 24 D2, D19 15, 17

600 24 D16 16

Load

Voltage

Voltage

Code(s)

D2, D23,

D19

Go To

Page(s)

15, 17

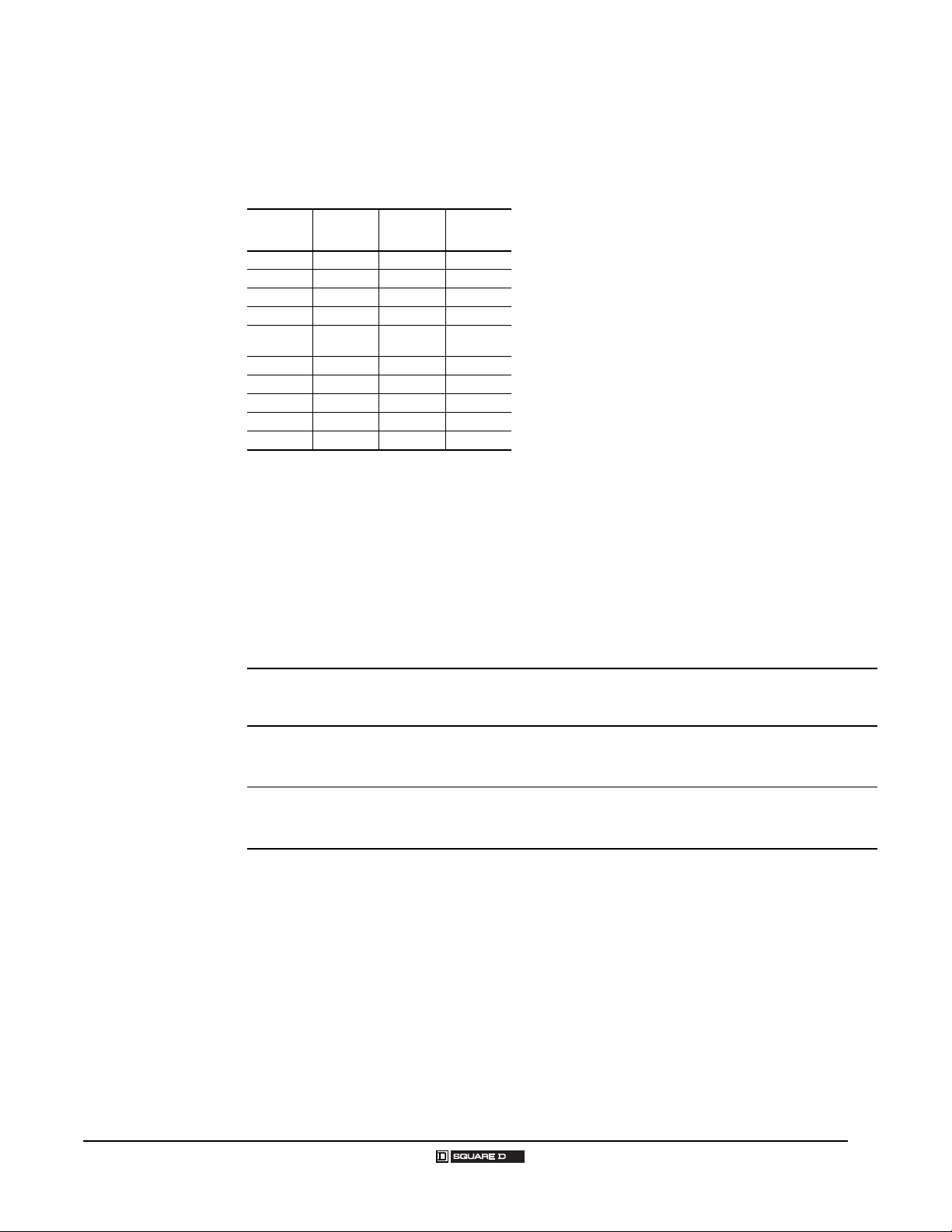

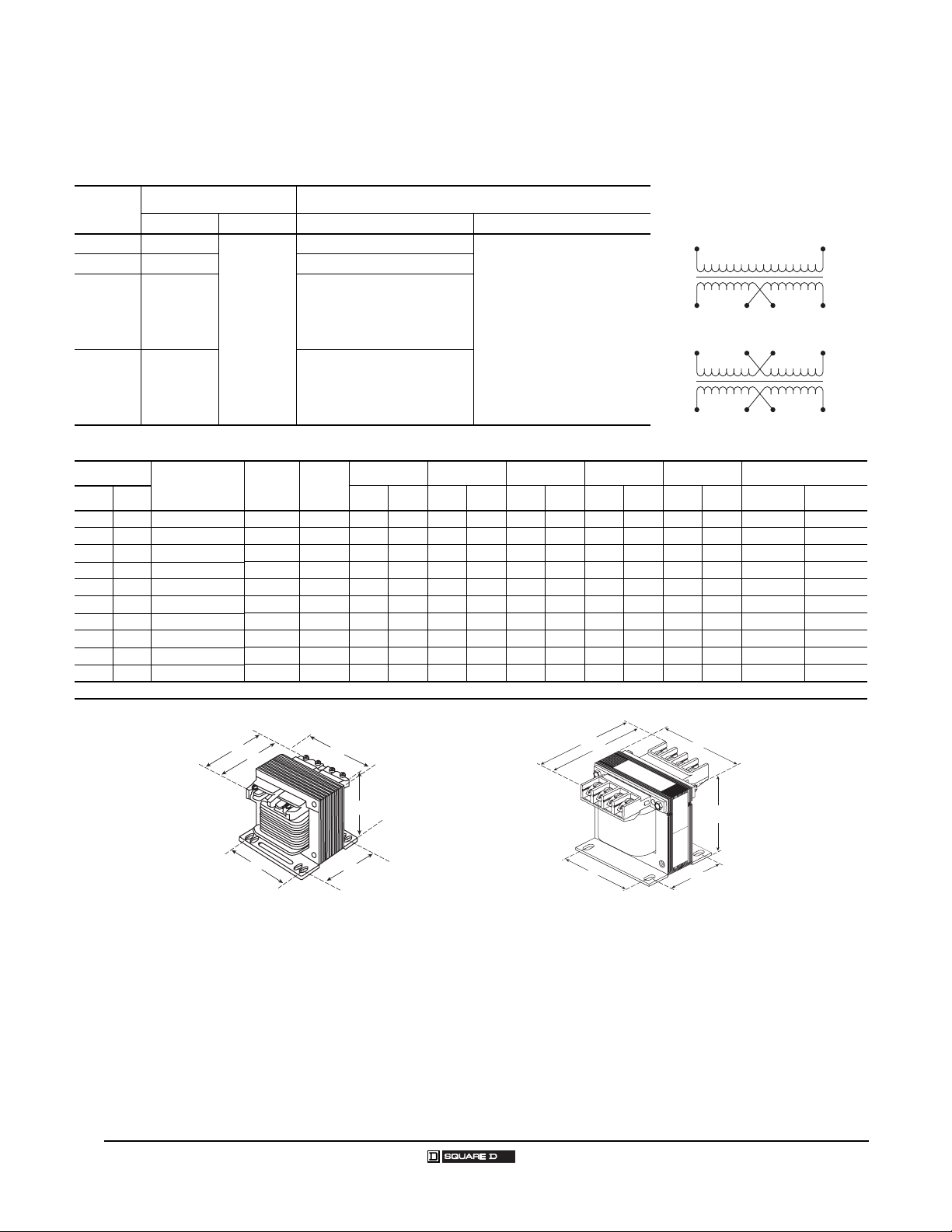

Custom-Built Type T Transformers

For voltage combinations not listed, Schneider Electric offers custom-built Type T transformers. Type T

units are limited to the following:

Primary Voltage Range: 120 to 600 Volts

Secondary Voltage Range: 12 to 277 Volts (25 to 1000VA)

12/24 to 277 Volts (25 to 2000VA)

24/48 to 277 Volts (25 to 5000VA)

Single

Dual

Single Dual

25VA to

5000VA

25VA to

5000VA

25VA to

5000VA

25VA to

5000VA

One Primary Tap

(two voltages)

Voltages with 20%

25VA to 5000VA

Voltages greater then

20% 25VA to 3000VA

Voltages with 20%

25VA to 5000VA

Voltages greater then

20% 25VA to 3000VA

Two Primary Taps

(three voltages

Voltages with 20%

25VA to 5000VA

Voltages greater then

20% 25VA to 3000VA

Voltages with 20%

25VA to 5000VA

Voltages greater then

20% 25VA to 3000VA

Three Primary

Taps

(four voltages)

25VA to 3000VA 25VA to 3000VA

25VA to 3000VA 25VA to 3000VA

Four Primary

Taps

(five Voltages)

Schneider Electric also offers Secondary Tapped units and Multiple Winding Secondary units. Since

the sizing of these units are determined by the secondary loading, they are limited to 3000VA total

secondary capacity in the 9070 Type T product.

To request a price quotation from Schneider Electric for a custom-built Type T transformer, use the

price quote sheet on page 26.

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

7

Page 8

Industrial Control Transformers

Type T Transformers

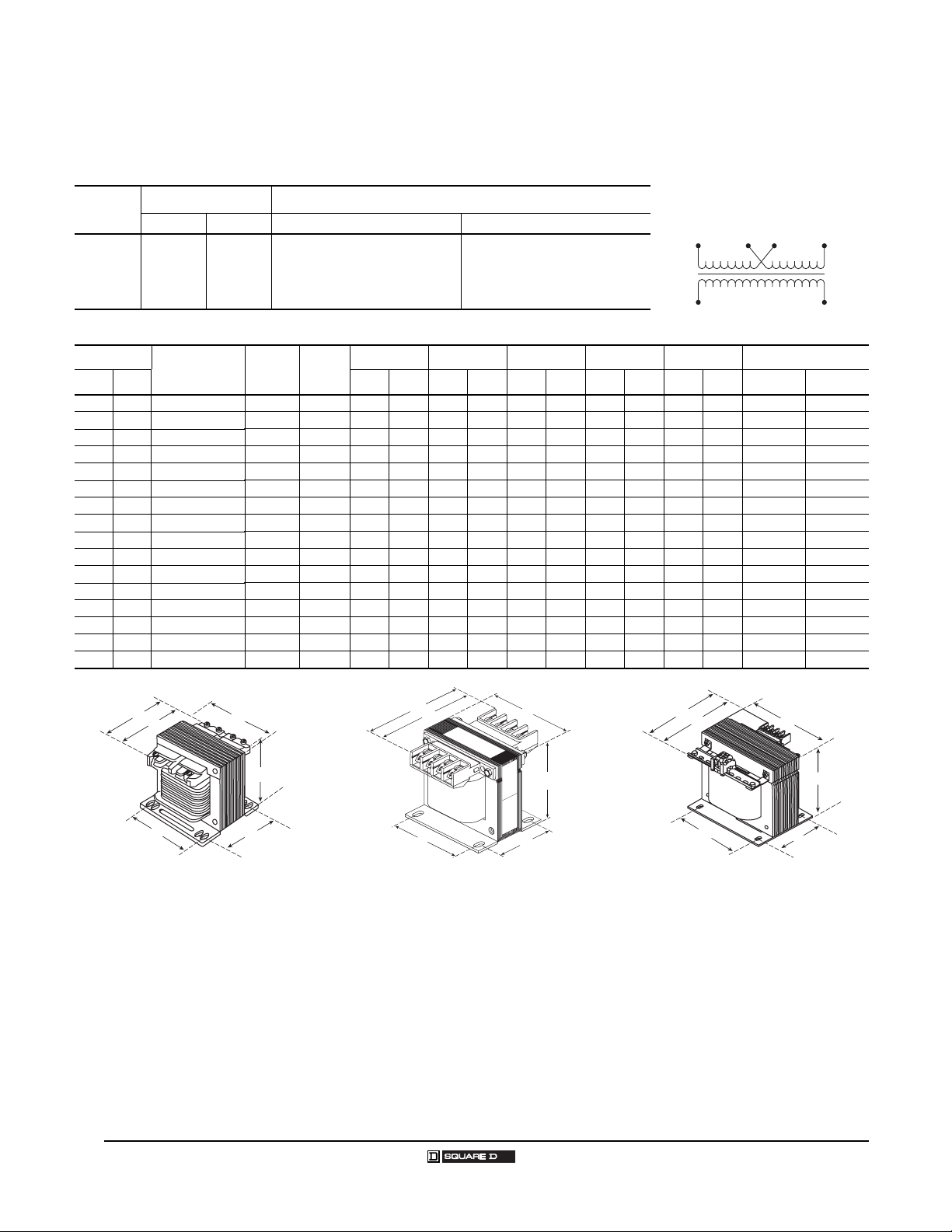

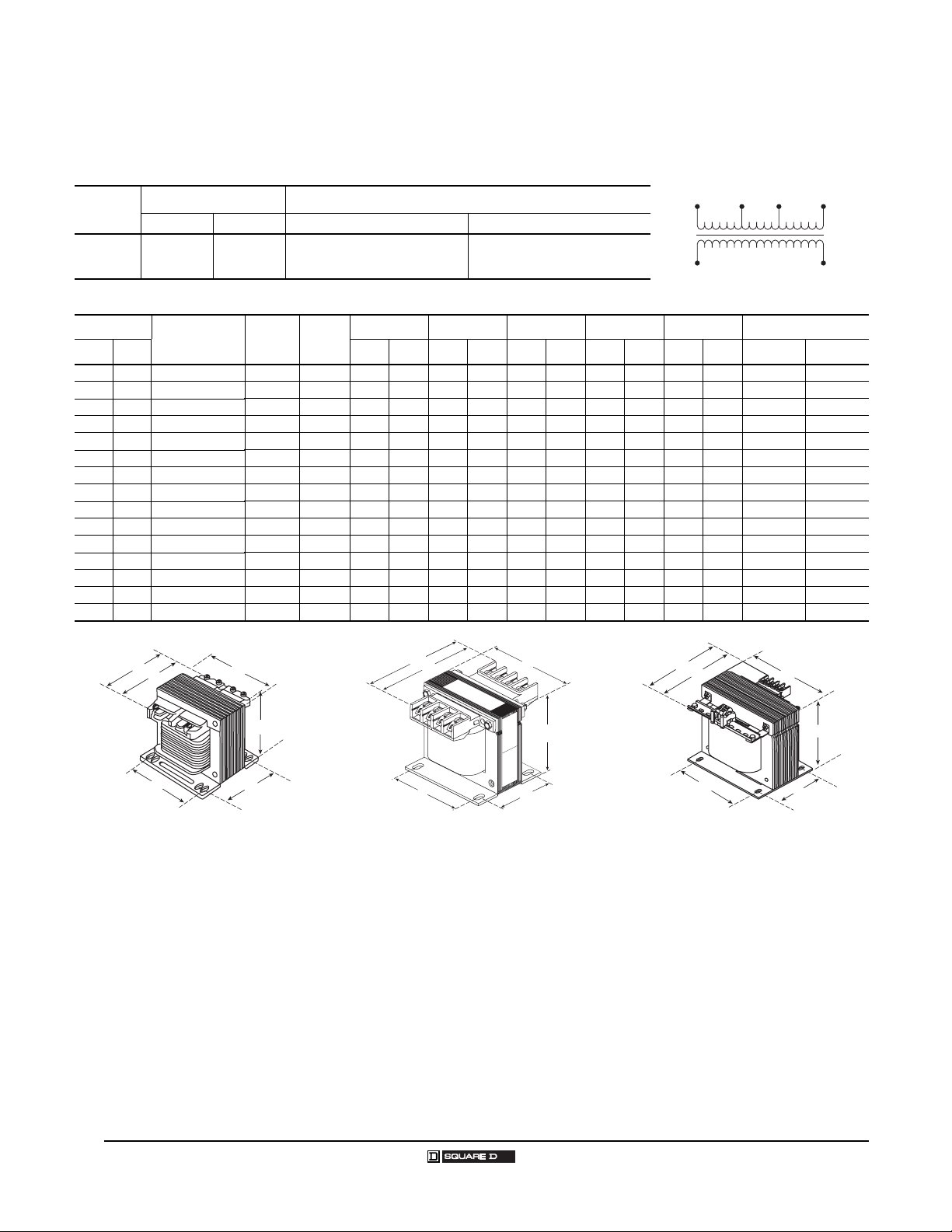

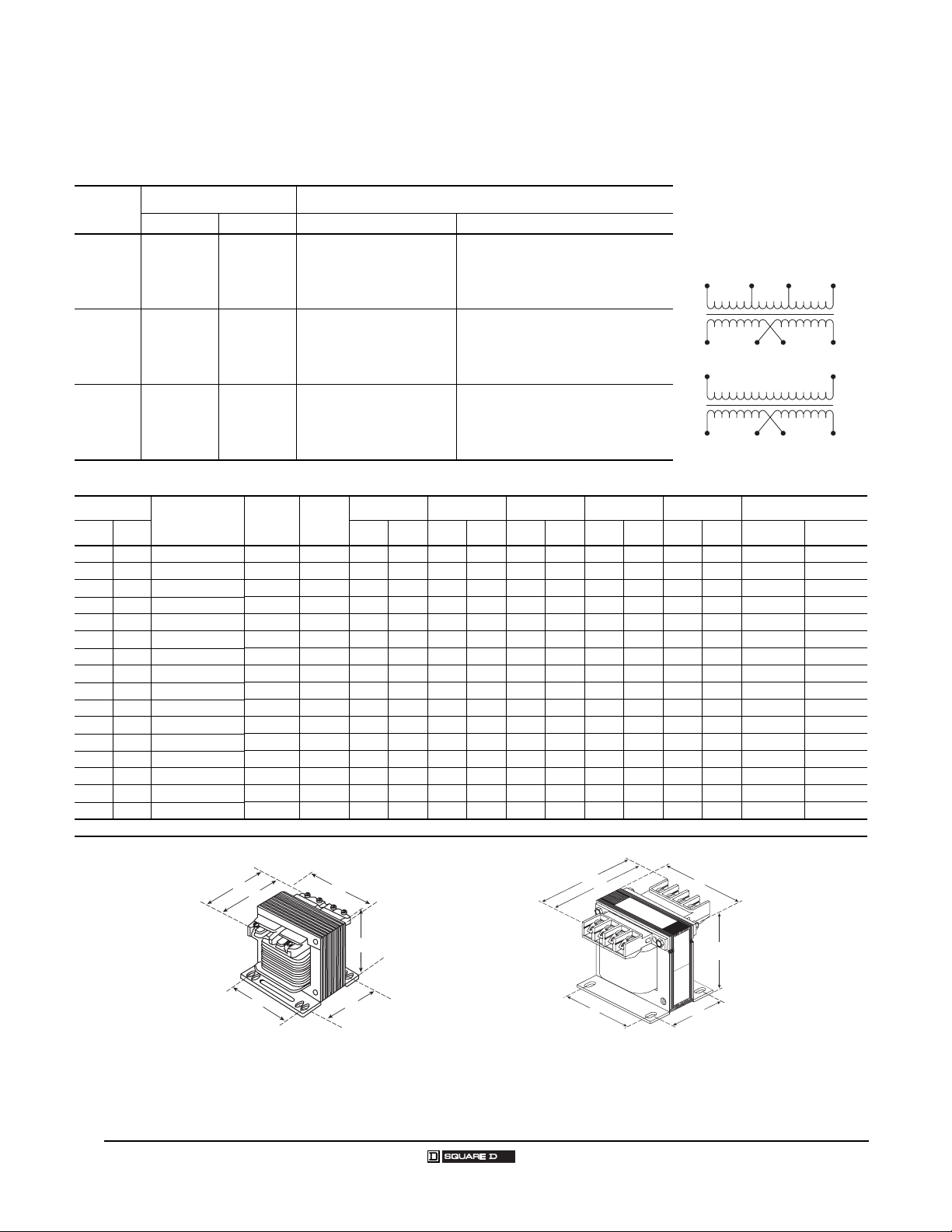

120 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D1

Dimensions

VA

UL CE IN

25 25 9070T25D1 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50D1 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75D1 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100D1 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150D1 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200D1 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250D1 2 I 5.30 135 3.75 95 3.21 82 2.88 73 3.13 80 0.20 x 0.38 5 x 10

300 200 9070T300D1 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350D1 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500D1 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

750 500 9070T750D1 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000D1 2 I 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1500 1000 9070T1500D1 2 I 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000D1 2 I 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

3000 2000 9070T3000D1 3 I 7.24 184 9.00 229 8.75 222 4.63 118 7.63 194 0.44 x 1.13 11 x 29

5000 3000 9070T5000D1 3 I 9.15 232 9.00 229 8.75 222 6.56 167 7.63 194 0.44 x 1.13 11 x 29

Voltages Connections

Primary Secondary Primary Secondary

220 x 440

230 x 460

240 x 480

Catalog

Number

220/230/240 V:Connect to H1 and H4

110

115

120

440/460/480 V:Connect to H1 and H4

Figure

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

Acc.

Key

Connect to X1 and X2

ABCE F Slots

mm

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

H2H3 H4

IN

mm

D

D

A

F

B

C

E

A

F

Figure 2Figure 1

B

C

E

D

A

F

B

E

Figure 3

8

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

C

Page 9

Industrial Control Transformers

Type T Transformers

120 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D3 208 120

D4 277 120

D5

D6 380 110

D17 415 110

D24

D93 200 115

D103 400 120

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.301353.75953.21822.88733.13800.20 x 0.385 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

750 500 9070T750t 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000t 2 I 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1500 1000 9070T1500t 2 I 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000t 2 I 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

3000 2000

5000 3000

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

2

Complete the catalog number by replacing the t with Voltage Code D3 or D4 from the “Voltage and Connection Options” table above.

3

Complete the catalog number by replacing the t with Voltage Code D5, D6, D17, D93, or D103 from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

550

575

600

110

115

120

Catalog

Number

9070T3000t

9070T3000t

9070T3000D24 3 N/A 8.08 205 9.00 229 8.75 222 4.63 118 7.63 194 0.44 x 1.13 11 x 29

9070T5000t 3 I 9.15 232 9.00 229 8.75 222 6.56 167 7.63 194 0.44 x 1.13 11 x 29

9070T5000D24 3 N/A 9.99 254 9.00 229 8.75 222 6.56 167 7.63 194 0.44 x 1.13 11 x 29

110

115

120

Connect to H1 and H2 Connect to X1 and X2

110

115

120

Figure

1

2

3

Acc.

Key

2 I 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194 0.44 x 1.13 11 x 29

3 I 7.24 184 9.00 229 8.75 222 4.63 118 7.63 194 0.44 x 1.13 11 x 29

ABCEF Slots

mm

IN

mm

IN

mm

IN

mm

H1

X2 X1

IN

mm

H2

IN

mm

08/2005

D

D

A

F

B

C

E

A

F

Figure 2Figure 1

B

C

E

D

A

F

B

C

E

Figure 3

9

© 1999–2005 Schneider Electric All Rights Reserved

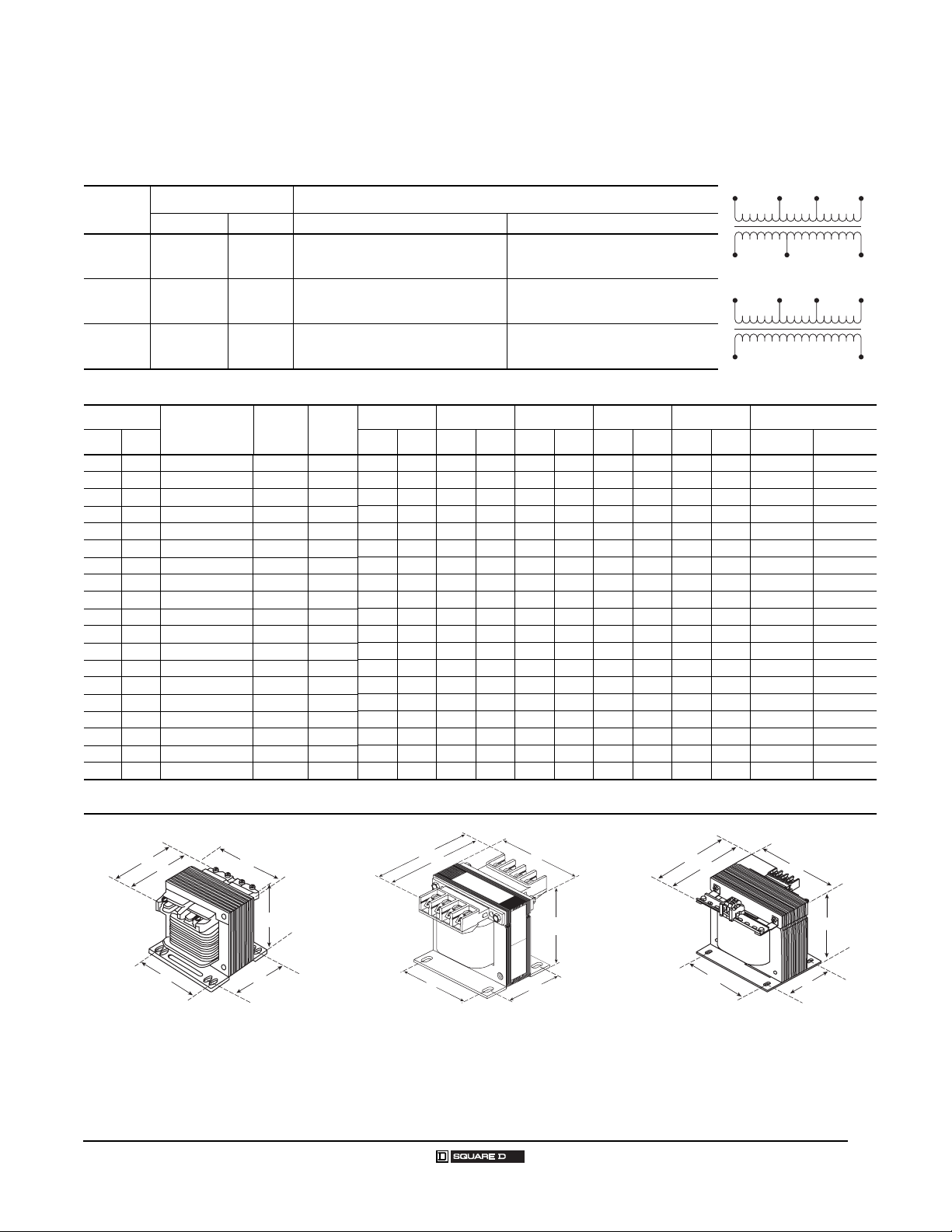

Page 10

Industrial Control Transformers

Type T MultiTap Transformers

120 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D20 208/230/460 115

Dimensions

VA

UL CE IN

25 25 9070T25D20 1 II 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50D20 1 II 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

75 75 9070T75D20 1 II 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100D20 1 II 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

150 150 9070T150D20 1 II 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200D20 2 II 4.70 119 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250D20 2 II 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

300 200 9070T300D20 2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350D20 2 II 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500D20 2 II 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

750 500 9070T750D20 2 II 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000D20 2 II 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

1500 1000 9070T1500D20 2 II 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000D20 2 II 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194 0.44 x 1.13 11 x 29

3000 2000 9070T3000D20 2 II 8.31 211 9.00 229 7.63 194 6.56 167 7.63 194 0.44 x 1.13 11 x 29

Voltages Connections

Primary Secondary Primary Secondary

208: Connect to H1 and H2

Catalog

Number

230: Connect to H1 and H3

460: Connect to H1 and H4

Figure

1

Acc.

Key

ABCE F Slots

mm

IN

Connect to X1 and X2

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

H3 H4H2

IN

mm

D

D

A

F

B

C

E

A

F

Figure 2Figure 1

B

C

E

D

A

F

B

C

E

Figure 3

10

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

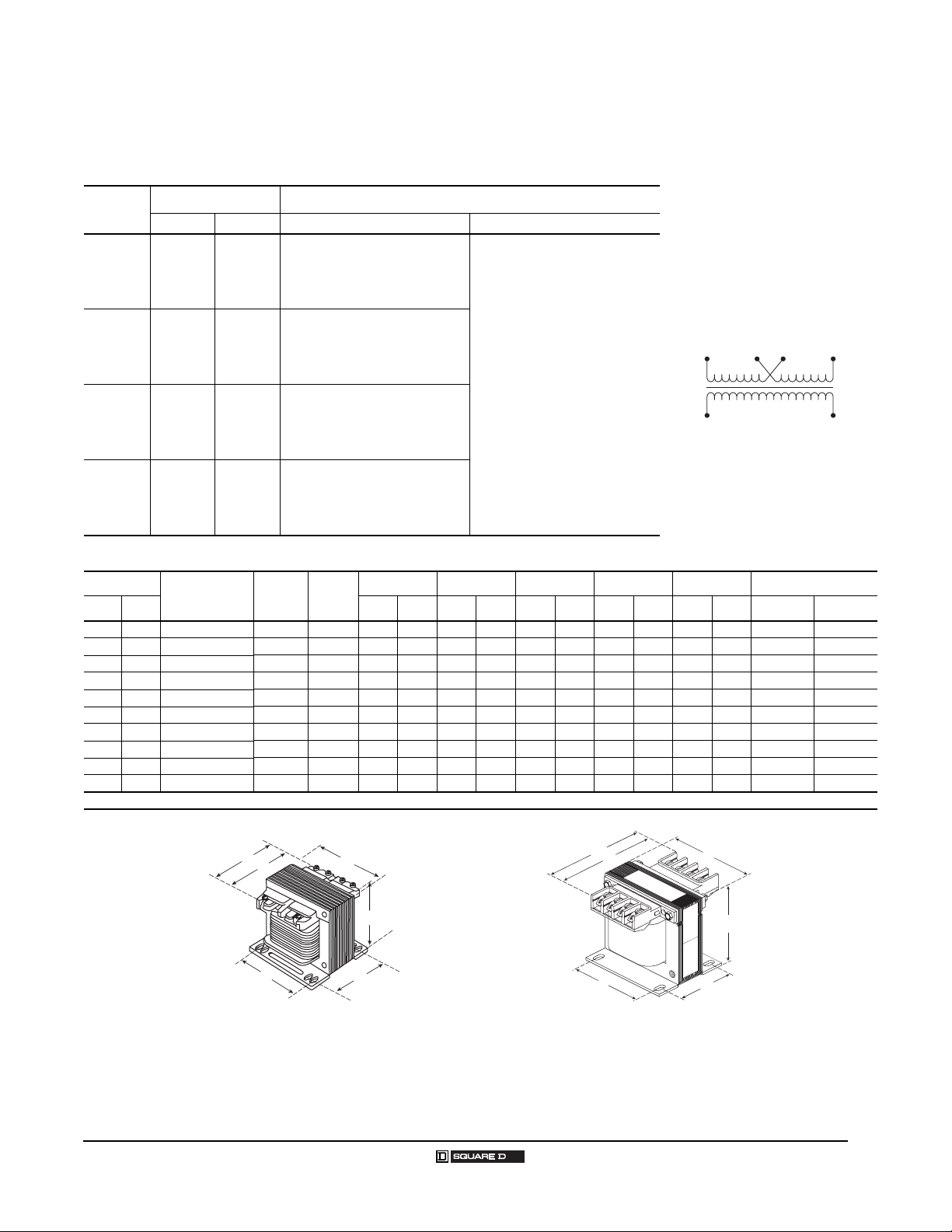

Page 11

Industrial Control Transformers

Type T MultiTap Transformers

120 Volt Secondary

Voltage and Connection Options

Voltage

Code

D18 208/277/380 95/115

D32

D95

Dimensions

VA

UL CE IN

25 25 9070T25t 1 II 3.09793.00762.58662.00512.50640.20 x 0.385 x 10

50 50 9070T50t 1 II 3.34853.38862.89732.38612.81710.20 x 0.485 x 12

75 75 9070T75D32 1 II 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

75 75 9070T75t

100 100 9070T100t 1 II 3.59913.75953.20812.88733.13800.20 x 0.385 x 10

150 150 9070T150D32 2 II 4.70 119 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

150 150 9070T150t

200 200 9070T200t 2 II 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

250 160 9070T250D32 2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

250 160 9070T250t

300 200 9070T300D32 2 II 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

300 200 9070T300t

350 250 9070T350t 2 II 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 II 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

750 500 9070T750t 2 II 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000t 2 II 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

1500 1000 9070T1500t 2 II 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000t 2 II 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194 0.44 x 1.13 11 x 29

3000 2000 9070T3000t 3 II 9.15 232 9.00 229 8.75 222 6.56 167 7.63 194 0.44 x 1.13 11 x 29

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

2

Complete the catalog number by replacing the t with Voltage Code D18 or D95 from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

220/440/550

230/460/575

240/480/600

190/220/440

200/230/460

208/240/480

Catalog

Number

2

1

2

2

2

208: Connect to H1 and H2

277: Connect to H1 and H3

380: Connect to H1 and H4

90/110

95/115

100/120

220 or 230 or 240: Connect to H1 and H2

440 or 460 or 480: Connect to H1 and H3

550 or 575 or 660: Connect to H1 and H4

110

190 or 200 or 208: Connect to H1 and H2

115

220 or 230 or 240: Connect to H1 and H3

120

440 or 460 or 480: Connect to H1 and H4

Figure

Acc.

Key

1 II 3.59913.75953.20812.88733.13800.20 x 0.385 x 10

1 II 3.59913.75953.20812.88733.13800.20 x 0.385 x 10

2 II 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

ABCEF Slots

mm

IN

95: Connect to X1 and X2

115: Connect to X1 and X3

90 or 95 or 100: Connect to X1 and X2

110 or 115 or 120: Connect to X1 and X3

110 or 115 or 120: Connect to X1 and X2

mm

IN

mm

IN

mm

H1

X3 X2 X1

H1

X2 X1

IN

mm

H3 H4H2

H3 H4H2

IN

mm

08/2005

D

D

A

F

B

C

E

A

F

Figure 2Figure 1

B

C

E

D

A

F

B

C

E

Figure 3

11

© 1999–2005 Schneider Electric All Rights Reserved

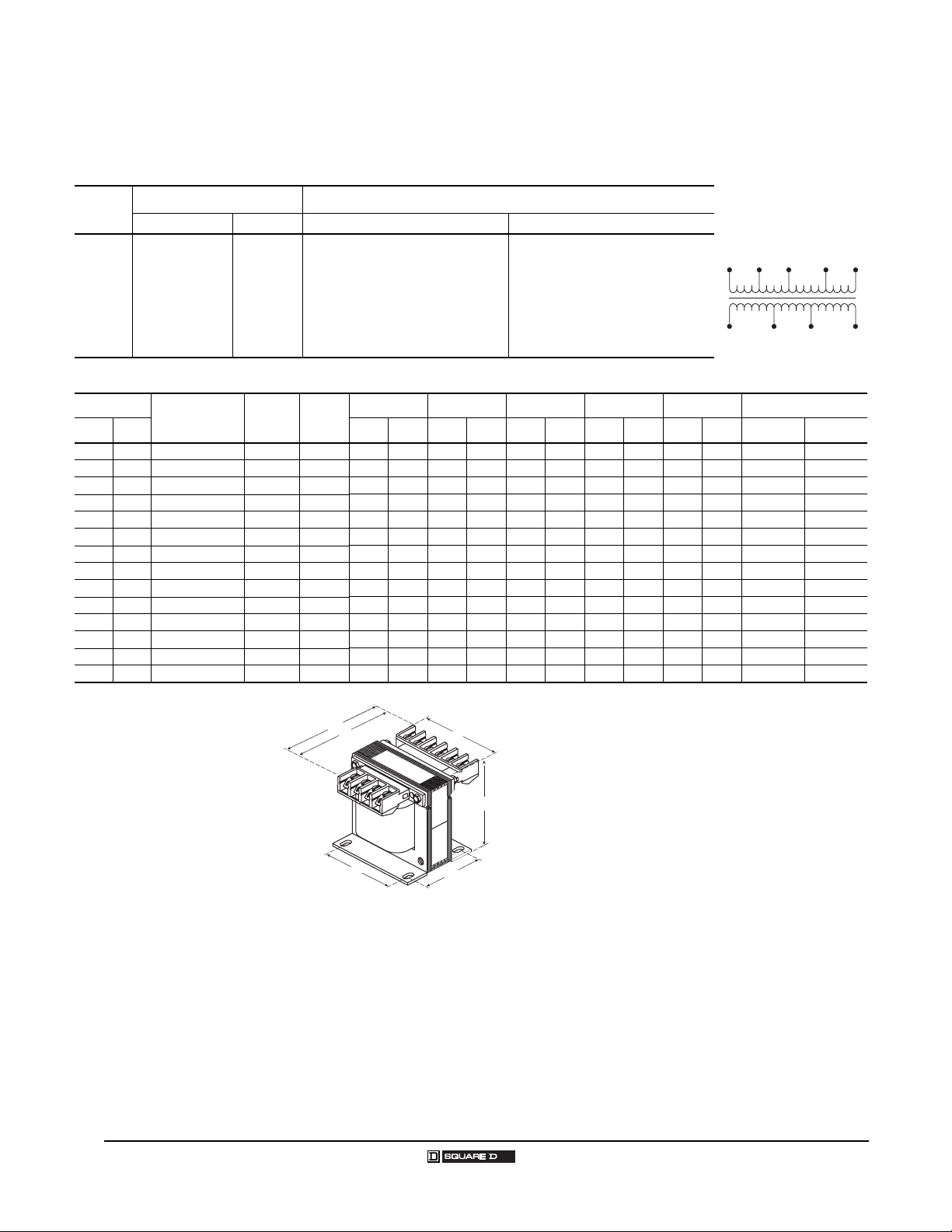

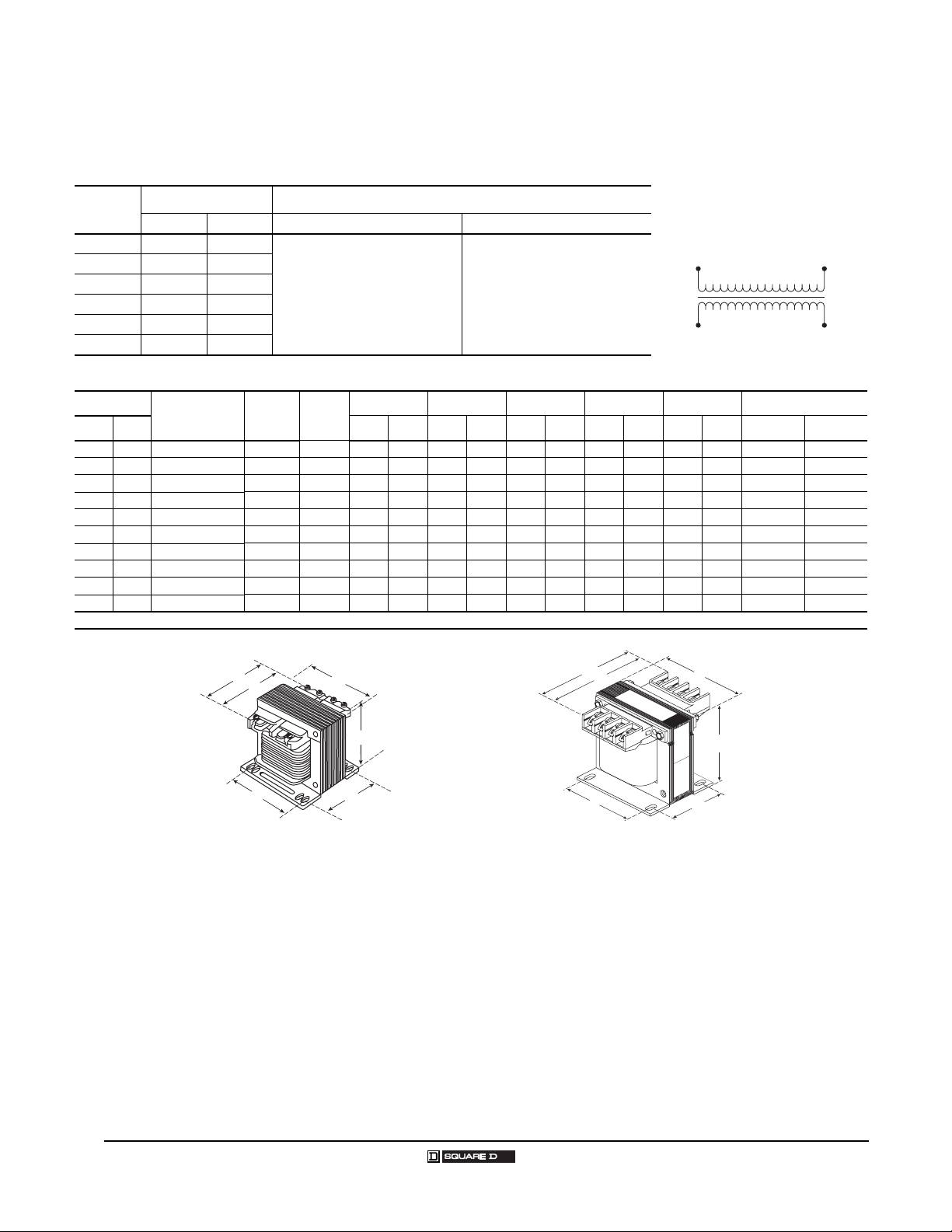

Page 12

Industrial Control Transformers

Type T MultiTap Transformers

Universal

Voltage and Connection Options

Voltage

Code

208/364/420/500

D50

220/380/440/550

230/400/460/575

240/416/480/600

Dimensions

VA

UL CE IN

25 25 9070T25D50 4 III 4.43 113.0 3.38 85.9 2.89 73.4 2.38 61.0 2.81 71.4 0.20 x 0.48 5 x 12

50 50 9070T50D50 4 III 4.43 113.0 3.38 85.9 2.89 73.4 2.38 61.0 2.81 71.4 0.20 x 0.48 5 x 12

75 75 9070T75D50 4 III 4.70 119.4 3.75 95.3 3.20 81.3 2.88 73.2 3.13 80.0 0.20 x 0.38 5 x 10

100 100 9070T100D50 4 III 4.70 119.4 3.75 95.3 3.20 81.3 2.88 73.2 3.13 80.0 0.20 x 0.38 5 x 10

150 150 9070T150D50 4 III 4.74 120.4 4.50 114.3 3.84 98.0 2.56 65.0 3.75 95.3 0.20 x 0.38 5 x 10

200 200 9070T200D50 4 III 5.11 129.8 4.50 114.3 3.84 98.0 3.00 76.2 3.75 95.3 0.20 x 0.38 5 x 10

250 160 9070T250D50 4 III 5.11 129.8 4.50 114.3 3.84 98.0 3.00 76.2 3.75 95.3 0.20 x 0.38 5 x 10

300 200 9070T300D50 4 III 5.49 139.4 4.50 114.3 3.84 98.0 3.56 90.4 3.75 95.3 0.20 x 0.38 5 x 10

350 250 9070T350D50 4 III 5.61 142.5 5.25 133.4 4.51 114.6 3.43 87.1 4.38 111.3 0.28 x 0.56 7 x 14

500 300 9070T500D50 4 III 5.61 142.5 5.25 133.4 4.51 114.6 3.43 87.1 4.38 111.3 0.28 x 0.56 7 x 14

750 500 9070T750D50 4 III 6.30 160.0 5.25 133.4 4.51 114.6 4.31 110.0 4.38 111.3 0.28 x 0.56 7 x 14

1000 630 9070T1000D50 4 III 5.92 150.4 7.06 179.3 6.17 156.7 4.13 104.9 5.81 147.6 0.28 x 0.56 7 x 14

1500 1000 9070T1500D50 4 III 7.17 182.1 7.06 179.3 6.17 156.7 4.56 115.8 5.81 147.6 0.28 x 0.56 7 x 14

2000 1500 9070T2000D50 4 III 6.38 162.1 9.00 228.6 7.63 193.8 4.63 117.6 7.63 193.8 0.44 x 1.13 11 x 29

Voltages Connections

Primary Secondary Primary Secondary

Catalog

Number

85/100/110

91/110/120

95/115/125

99/120/130

Figure

208 or 220 or 230 or 240:Connect to H1

364 or 380 or 400 or 416:Connect to H1

420 or 440 or 460 or 480:Connect to H1

500 or 550 or 575 or 600:Connect to H1

Acc.

Key

and H2

and H3

and H4

and H5

85 or 91 or 95 or 99: Connect to X1

100 or 110 or 115 or 120:Connect to X1

110 or 120 or 125 or 130:Connect to X1

ABCEF Slots

mm

IN

mm

IN

mm

IN

and X2

and X3

and X4

mm

H1

X4 X3 X2 X1

IN

mm

H3 H5H4H2

IN

mm

D

A

F

B

C

E

Figure 4

12

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

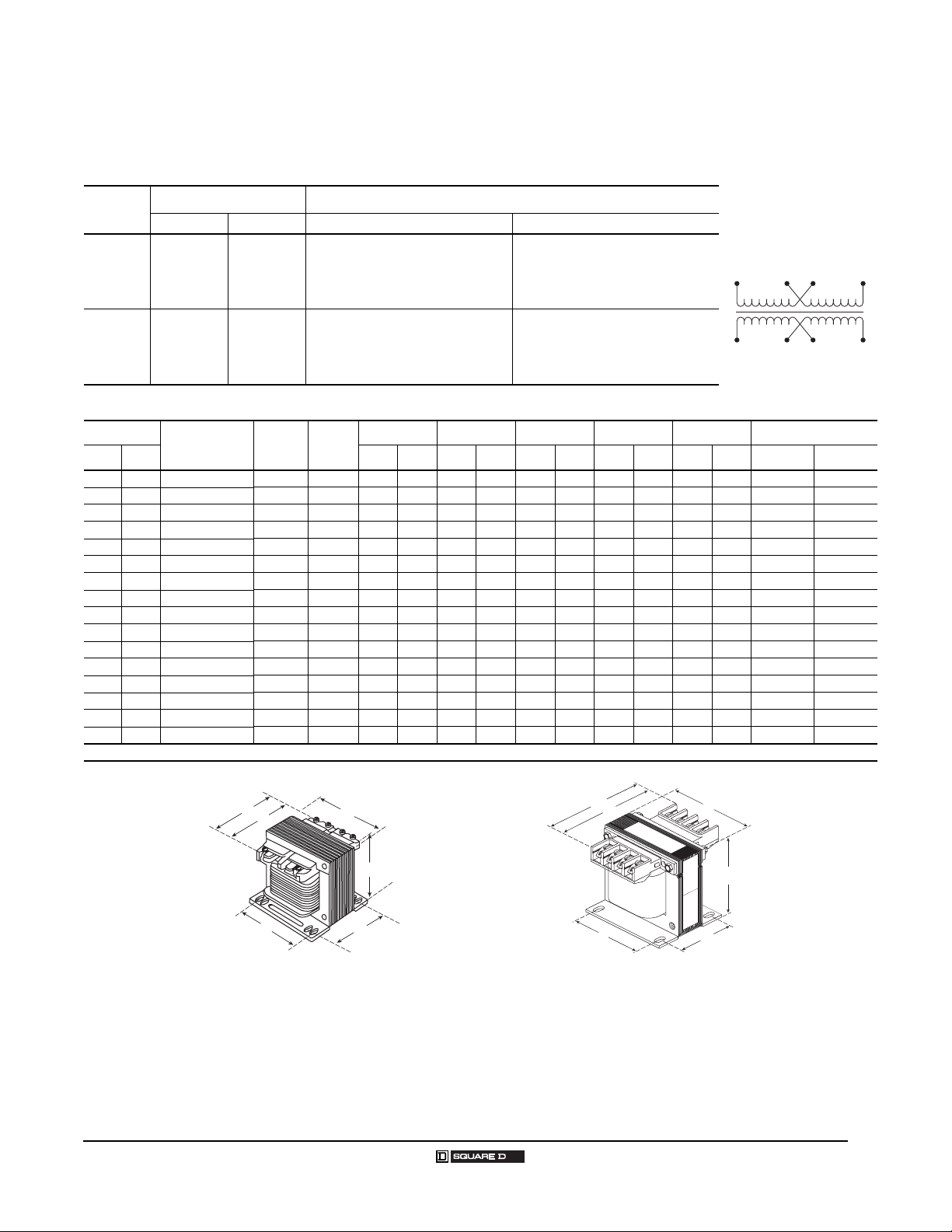

Page 13

Industrial Control Transformers

Type T Transformers with Dual Secondary

120/240 Volt Secondary

Voltage and Connection Options

Voltage

Code

D31

D55

-

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.301353.75953.21822.88733.13800.20 x 0.385 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

750 500 9070T750t 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000t 2 I 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1500 1000 9070T1500t 2 I 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000t 2 I 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

3000 2000 9070T3000t 2 I 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194 0.44 x 1.13 11 x 29

5000 3000 9070T5000t 2 I 8.31 211 9.00 229 7.63 194 6.56 167 7.63 194 0.44 x 1.13 11 x 29

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

220 x 440

230 x 460

240 x 480

110 x 220

115 x 230

120 x 240

Catalog

Number

110/220

115/230

120/240

110 x 220

115 x 230

120 x 240

1

Figure

220 or 230 or 240:Connect to H1 and H4

440 or 460 or 480:Connect to H1 and H4

110 or 115 or 120:Connect to H1 and H4

220 or 230 or 240:Connect to H1 and H4

Acc.

Key

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

ABCEF Slots

mm

IN

110 or 115 or 120:Connect to X1 and X4

220 or 230 or 240:Connect to X1 and X4

110 or 115 or 120:Connect to X1 and X4

220 or 230 or 240:Connect to X1 and X4

mm

IN

mm

Jumper X1 with X3

Jumper X2 with X4

Jumper X2 with X3

Jumper X1 with X3

Jumper X2 with X4

Jumper X2 with X3

IN

mm

IN

H3 H2

H1

X4 X2 X3

mm

IN

mm

H4

X1

08/2005

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

© 1999–2005 Schneider Electric All Rights Reserved

13

Page 14

Industrial Control Transformers

Type T Transformers with Dual Secondary

120/240 Volt Secondary

Voltage and Connection Options

Voltage

Code

D33 380/400/415 115/230

D37 550/575/600

D60 277 120/240 277: Connect to H1 and H2

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.30 135 3.75 95 3.21 82 2.88 73 3.13 80 0.20 x 0.38 5 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

750 500 9070T750t 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 0.28 x 0.56 7 x 14

1000 630 9070T1000t 2 I 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 0.28 x 0.56 7 x 14

1500 1000 9070T1500t 2 I 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 0.28 x 0.56 7 x 14

2000 1500 9070T2000t 2 I 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 0.28 x 0.56 7 x 14

3000 2000 9070T3000t 2 I 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194 0.44 x 1.13 11 x 29

5000 3000 9070T5000t 2 I 8.31 211 9.00 229 7.63 194 6.56 167 7.63 194 0.44 x 1.13 11 x 29

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

Catalog

Number

1

110/220

115/230

120/240

Figure

380: Connect to H1 and H2

400: Connect to H1 and H3

415: Connect to H1 and H4

550 or 575 or 600: Connect to

Acc.

Key

H1 and H2

ABCEF Slots

mm

115: Connect to X1 and X4

230: Connect to X1 and X4

110 or 115 or 120:Connect to X1 and X4

220 or 230 or 240:Connect to X1 and X4

120: Connect to X1 and X4

240: Connect to X1 and X4

IN

mm

Jumper X1 with X3

Jumper X2 with X4

Jumper X2 with X3

Jumper X1 with X3

Jumper X2 with X4

Jumper X2 with X3

Jumper X1 with X3

Jumper X2 with X4

Jumper X2 with X3

IN

mm

H1 H3 H4H2

X4 X2 X3 X1

H1

X4 X2 X3 X1

IN

mm

IN

mm

IN

H2

mm

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

14

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 15

24 Volt Secondary

Voltage and Connection Options

Voltage

Code

D2 240 x 480 24

D23 120 x 240 24

D89 115 x 230 24

D92 230 x 460 24

Voltages Connections

Primary Secondary Primary Secondary

240: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

480: Connect to H1 and H4

Jumper H2 with H3

120: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

240: Connect to H1 and H4

Jumper H2 with H3

115: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

230: Connect to H1 and H4

Jumper H2 with H3

230: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

460: Connect to H1 and H4

Jumper H2 with H3

Industrial Control Transformers

Type T Transformers with 24 Volt Secondary

H1

Connect to X1 and X2

X2 X1

H2H3 H4

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.301353.75953.21822.88733.13800.20 x 0.385 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Catalog

Number

Figure

1

D

A

F

Acc.

Key

B

ABCEF Slots

mm

IN

mm

IN

mm

IN

mm

IN

mm

D

A

C

E

F

B

C

E

IN

mm

Figure 2Figure 1

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

15

Page 16

Industrial Control Transformers

Type T Transformers with 24 Volt Secondary

24 Volt Secondary

Voltage and Connection Options

Voltage

Code

D7 120 24

D14 208 24

D16 600 24

D25 277 24

D88 380 24

D112 230 24

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.30 135 3.75 95 3.21 82 2.88 73 3.13 80 0.20 x 0.38 5 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

Connect to H1 and H2 Connect to X1 and X2

Catalog

Number

Fig.

1

Acc.

Key

ABCEF Slots

mm

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

H2

IN

mm

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

16

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

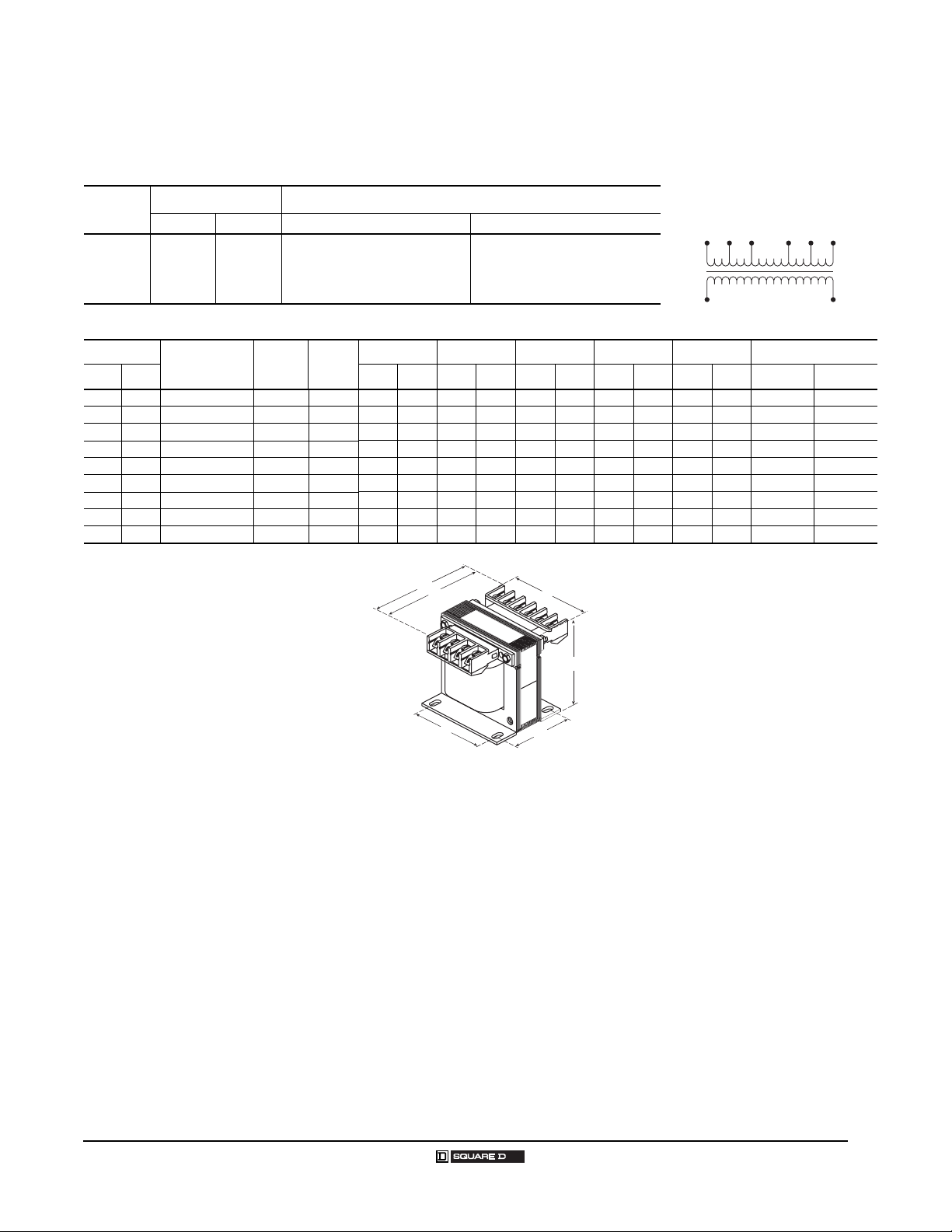

Page 17

Industrial Control Transformers

Type T Transformers with 24 Volt Secondary

24 Volt Secondary

Voltage and Connection Options

Voltage

Code

D19

Dimensions

VA

UL CE IN

50 50 9070T50D19 4 III 4.43 113.0 3.38 85.9 2.89 73.4 2.38 61.0 2.81 71.4 0.20 x 0.48 5 x 12

75 75 9070T75D19 4 III 4.70 119.4 3.75 95.3 3.20 81.3 2.88 73.2 3.13 80.0 0.20 x 0.38 5 x 10

100 100 9070T100D19 4 III 4.70 119.4 3.75 95.3 3.20 81.3 2.88 73.2 3.13 80.0 0.20 x 0.38 5 x 10

150 150 9070T150D19 4 III 4.70 119.4 3.75 95.3 3.20 81.3 2.88 73.2 3.13 80.0 0.20 x 0.38 5 x 10

200 200 9070T200D19 4 III 4.74 120.4 4.50 114.3 3.84 98.0 2.56 65.0 3.75 95.3 0.20 x 0.38 5 x 10

250 160 9070T250D19 4 III 5.11 129.8 4.50 114.3 3.84 98.0 3.00 76.2 3.75 95.3 0.20 x 0.38 5 x 10

300 200 9070T300D19 4 III 5.11 129.8 4.50 114.3 3.84 98.0 3.00 76.2 3.75 95.3 0.20 x 0.38 5 x 10

350 250 9070T350D19 4 III 5.49 139.4 4.50 114.3 3.84 98.0 3.56 90.4 3.75 95.3 0.20 x 0.38 5 x 10

500 300 9070T500D19 4 III 5.61 142.5 5.25 133.4 4.51 114.6 3.43 87.1 4.38 111.3 0.28 x 0.56 7 x 14

Voltages Connections

Primary Secondary Primary Secondary

208

240

277

380

480

Catalog

Number

24

1

208: Connect to H1 and H2

240: Connect to H1 and H3

277: Connect to H1 and H4

380: Connect to H1 and H5

480: Connect to H1 and H6

Figure

Acc.

Key

Connect to X1 and X2

ABCEF Slots

mm

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

H4 H6H5H2 H3

IN

mm

Figure 4

D

A

F

B

C

E

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

17

Page 18

Industrial Control Transformers

Type T Transformers with 24 Volt Secondary

Type T Units with Dual 12/24 Volt Secondary

Voltage and Connection Options

Voltage

Code

D13 120

D36 600 Connect to H1 and H2

D54 120 x 240

D59 240 x 480

Dimensions

VA

UL CE IN

25 25 9070T25t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

50 50 9070T50t 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 75 9070T75t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

100 100 9070T100t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 0.20 x 0.48 5 x 12

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 200 9070T200t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 0.20 x 0.38 5 x 10

250 160 9070T250t 2 I 5.30 135 3.75 95 3.21 82 2.88 73 3.13 80 0.20 x 0.38 5 x 10

300 200 9070T300t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 0.20 x 0.38 5 x 10

350 250 9070T350t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 0.20 x 0.38 5 x 10

500 300 9070T500t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 0.20 x 0.38 5 x 10

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

Connect to H1 and H2

120: Connect to H1 and H4

Catalog

Number

Jumper H1 with H3

Jumper H2 with H4

12/24

Fig.

1

240: Connect to H1 and H4

Jumper H2 with H3

240: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

480: Connect to H1 and H4

Jumper H2 with H3

Acc.

Key

ABCEF Slots

mm

IN

12: Connect to X1 and X4

Jumper X1 with X3

Jumper X2 with X4

24: Connect to X1 and X4

Jumper X2 with X3

mm

IN

mm

H1

X4 X2 X3 X1

H3 H2

H1

X4 X2 X3

IN

mm

IN

mm

H2

H4

X1

IN

mm

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

18

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 19

Industrial Control Transformers

Multiple Secondary

MULTIPLE SECONDARY

Designed to meet the needs for both 24 V control and 120 V control. Available in the 9070 Type T

product line, with all the type T features.

Tapped Secondary D15: 24 V rated for 20% capacity and 120 V rated for 80% capacity when

simultaneous loading, or 100% loading when 120 V only.

20% rating at 24 V or 100% rating at 120 V gives equal output current from the device.

VA 24 V amps 120 V amps

50 .416 .416

75 .625 .625

100 .833 .833

150 1.25 1.25

200 1.67 1.67

250 2.08 2.08

300 2.5 2.5

350 2.9 2.9

500 4.17 4.17

750 6.25 6.25

1000 8.3 8.3

1500 12.5 12.5

2000 16.7 16.7

3000 25 25

5000 41.7 41.7

Tapped Secondary D65: Both outputs fully rated for non-simultaneous loading, and simultaneous rated

for any combination that does not exceed the nameplate VA rating.

Separate Windings Options: All voltage codes offer fully rated non-simultaneous loading, and

simultaneous rated for any combination that does not exceed the nameplate VA rating.

Features of separate windings:

1. Allows two isolated control circuits, 24 V and 120 V, from the same device

2. Wire sizing for circuits for each voltage not highest current for common when simultaneous loading.

(no common)

3. If a common is required, it can be obtained with a jumper kit.

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

19

Page 20

Industrial Control Transformers

Multiple Secondary

Type T Units with Dual 24/120 Volt Secondary (Tapped Units)

Voltage and Connection Options

Voltage

Code

D15 240 x 480

Dimensions

VA

UL CE IN

50 50 9070T50D15 1 I 3.09 79 3.00 76 2.58 66 2.00 51 2.50 64 .20 x .38 5 x 10 50 10 40 10

75 75 9070T75D15 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 .20 x .48 5 x 12 75 15 60 10

100 100 9070T100D15 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 .20 x .48 5 x 12 100 20 80 20

150 150 9070T150D15 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 150 30 120 30

200 200 9070T200D15 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 200 40 160 40

250 160 9070T250D15 2 I 5.30 135 3.75 95 3.21 82 2.88 73 3.13 80 .20 x .38 5 x 10 250 50 200 50

300 200 9070T300D15 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 300 60 240 60

350 250 9070T350D15 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 350 70 280 70

500 300 9070T500D15 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 .20 x .38 5 x 10 500 100 400 100

750 500 9070T750D15 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 750 150 600 150

1000 630 9070T1000D15 2 I 6.30 160 5.25 133 4.51 115 4.31 109 4.38 111 .28 x .56 7 x 14 1000 200 800 200

1500 1000 9070T1500D15 2 I 5.92 150 7.06 179 6.17 157 4.13 105 5.81 148 .28 x .56 7 x 14 1500 300 1200 300

2000 1500 9070T2000D15 2 I 7.17 182 7.06 179 6.17 157 4.56 116 5.81 148 .28 x .56 7 x 14 2000 400 1600 400

3000 2000 9070T3000D15 2 I 6.38 162 9.00 229 7.63 194 4.63 118 7.63 194

5000 3000 9070T5000D15 3 I 9.15 232 9.00 229 8.75 222 6.56 167 7.63 194

Voltages Connections

Primary Secondary Primary Secondary

240: Connect to H1 and H4

Jumper H1 with H3

Jumper H2 with H4

480: Connect to H1 and H4

Jumper H2 with H3

23 or 24 or 25: Connect to X1 and X2

110 or 115 or 120: Connect to X1 and X3

ABCEF Slots

mm

IN

mm

IN

mm

IN

mm

IN

mm

Catalog

Number

23/110

24/115

25/120

Fig.

Acc.

Key

IN

.44 x 1.13

.44 x 1.13

H3 H2

H1

X3 X2

120

24

Only

Only

Max

Max

VA

VA

mm

UL UL 120V 24V

11 x 29 3000 600 2400 600

11 x 29 5000 1000 4000 1000

H4

X1

Simultaneous

Loading Max

UL VA

D

D

A

F

B

C

E

A

F

Figure 2Figure 1

B

C

E

D

A

F

B

E

Figure 3

20

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

C

Page 21

Industrial Control Transformers

Multiple Secondary

Type T Units with Dual 24/120 Volt Secondary (Tapped Units)

Voltage and Connection Options

Voltage

Code

D65

Dimensions

VA

UL CE IN

50 50 9070T50D65 1 II 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 .20 x .48 5 x 12 50 50

75 75 9070T75D65 1 II 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 75 75

100 100 9070T100D65 1 II 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 100 100

150 150 9070T150D65 1 II 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 150 150

200 200 9070T200D65 2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 200 200

250 160 9070T250D65 2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 250 250

300 200 9070T300D65 2 II 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 .20 x .38 5 x 10 300 300

350 250 9070T350D65 2 II 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 350 350

500 300 9070T500D65 2 II 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 500 500

Voltages Connections

Primary Secondary Primary Secondary

200/220/440

208/230/460

217/240/480

Catalog

Number

23/110

24/115

25/120

Fig.

200 or 208 or 217:Connect to H1 and H2

220 or 230 or 240:Connect to H1 and H3

440 or 460 or 480:Connect to H1 and H4

Acc.

ABCEF Slots

Key

mm

IN

mm

23 or 24 or 25: Connect to X1 and X2

110 or 115 or 120:Connect to X1 and X3

IN

mm

IN

mm

IN

mm

H1 H3 H4H2

X3 X2 X1

115

Only

Max

VA

IN

mm

UL UL 115V 24V

24

Only

Max

VA

Simultaneous

Loading Max

UL VA

Any

combination

that does not

exceed

Primary Max

VA

For example,

T350

200VA (120V)

150VA (24V)

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

21

Page 22

Industrial Control Transformers

Multiple Secondary

Type T Units with Dual 24/120 Volt Secondary (Separate Windings)

Voltage and Connection Options

Voltage

Code

D114

Dimensions

VA

UL CE IN

50 50 9070T50D114 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 .20 x .48 5 x 12 50 50

75 75 9070T75D114 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 75 75

100 100 9070T100D114 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 100 100

150 150 9070T150D114 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 150 150

200 200 9070T200D114 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 200 200

250 160 9070T250D114 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 250 250

300 200 9070T300D114 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 300 300

350 250 9070T350D114 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 .20 x .38 5 x 10 350 350

500 300 9070T500D114 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 500 500

Voltages Connections

Primary Secondary Primary Secondary

220 x 440

230 x 460

240 x 480

Catalog

Number

23/110

24/115

25/120

Fig.

220/230/240: Connect to H1 and H4

440/460/480: Connect to H1 and H4

Acc.

Key

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

23/24/25: Connect to X1 and X2

110/115/120: Connect to X3 and X4

ABCEF Slots

mm

IN

mm

IN

mm

IN

mm

IN

mm

IN

H3 H2

H1

X4 X3 X2 X1

115

Only

Max

VA

mm

UL UL 115V 24V

24

Only

Max

VA

H4

Simultaneous

Loading Max

UL VA

Any

combination

that does not

exceed

Primary Max

VA

For example,

T350

200VA (120V)

150VA (24V)

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

22

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 23

Type T Units with Dual 24/120 Volt Secondary (Separate Windings)

Industrial Control Transformers

Multiple Secondary

Voltage and Connection Options

Voltage

Code

D115 208/277 24/115

D116

D119 380/400/415 24/115

Voltages Connections

Primary Secondary Primary Secondary

550

575

600

23/110

24/115

25/120

208: Connect to H1 and H2

277: Connect to H1 and H3

Connect to H1 and H2

380: Connect to H1 and H2

400: Connect to H1 and H3

415: Connect to H1 and H4

24: Connect to X1 and X2

115: Connect to X3 and X4

23/24/25: Connect to X1 and X2

110/115/120: Connect to X3 and X4

24: Connect to X1 and X2

115: Connect to X3 and X4

H1 H2 H3

X4 X3 X2 X1

H1 H2

X4 X3 X2 X1

H1 H3 H4H2

X4 X3 X2 X1

Dimensions

115

VA

Catalog

Number

1

Key

Acc.

Fig.

UL CE IN

50 50 9070T50t 1 I 3.34 85 3.38 86 2.89 73 2.38 61 2.81 71 .20 x .48 5 x 12 50 50

75 75 9070T75t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 75 75

100 100 9070T100t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 100 100

150 150 9070T150t 1 I 3.59 91 3.75 95 3.20 81 2.88 73 3.13 80 .20 x .38 5 x 10 150 150

200 200 9070T200t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 200 200

250 160 9070T250t 2 I 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 250 250

300 200 9070T300t 2 I 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 300 300

350 250 9070T350t 2 I 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 .20 x .38 5 x 10 350 350

500 300 9070T500t 2 I 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 500 500

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

ABCEF Slots

mm

IN

mm

IN

mm

IN

mm

IN

mm

IN

Only

Max

VA

mm

UL UL 115V 24V

24

Only

Max

VA

Simultaneous

Loading Max

UL VA

Any

combination

that does not

exceed

Primary Max

VA

For example,

T350

200VA (120V)

150VA (24V)

08/2005

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

© 1999–2005 Schneider Electric All Rights Reserved

23

Page 24

Industrial Control Transformers

Multiple Secondary

Type T Units with Dual 24/120 Volt Secondary (Separate Windings)

Voltage and Connection Options

Voltage

Code

D117

D118

Dimensions

VA

UL CE IN

50 50 9070T50t 1 II 3.34853.38862.89732.38612.8171.20 x .485 x 12 50 50

75 75 9070T75t 1 II 3.59913.75953.20812.88733.1380.20 x .385 x 10 75 75

100 100 9070T100t 1 II 3.59913.75953.20812.88733.1380.20 x .385 x 10 100 100

150 150 9070T150t 1 II 3.59913.75953.20812.88733.1380.20 x .385 x 10 150 150

200 200 9070T200t 2 II 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 200 200

250 160 9070T250t 2 II 4.74 120 4.50 114 3.84 98 2.56 65 3.75 95 .20 x .38 5 x 10 250 250

300 200 9070T300t 2 II 5.11 130 4.50 114 3.84 98 3.00 76 3.75 95 .20 x .38 5 x 10 300 300

350 250 9070T350t 2 II 5.49 139 4.50 114 3.84 98 3.56 90 3.75 95 .20 x .38 5 x 10 350 350

500 300 9070T500t 2 II 5.61 143 5.25 133 4.51 115 3.43 87 4.38 111 .28 x .56 7 x 14 500 500

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Voltages Connections

Primary Secondary Primary Secondary

200/220/400

208/230/460

217/240/480

220/440/550

230/460/575

240/480/600

Catalog

Number

23/110

24/115

25/120

23/110

24/115

25/120

Fig.

1

200/208/217: Connect to H1 and H2

220/230/240: Connect to H1 and H3

400/460/480: Connect to H1 and H4

220/230/240: Connect to H1 and H2

440/460/480: Connect to H1 and H3

550/575/600: Connect to H1 and H4

Acc.

ABCEF Slots

Key

mm

IN

mm

23/24/25: Connect to X1 and X2

110/115/120: Connect to X3 and X4

IN

mm

IN

mm

IN

mm

IN

H1 H3 H4H2

X4 X3 X2 X1

115

Only

Only

Max

Max

VA

mm

UL UL 115V 24V

24

VA

Simultaneous

Loading Max

UL VA

Any

combination

that does not

exceed

Primary Max

VA

For example,

T350

200VA (120V)

150VA (24V)

D

D

A

F

B

C

E

A

F

B

C

E

Figure 2Figure 1

24

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 25

TYPE T PERFORMANCE DATA

Industrial Control Transformers

Type T Transformers

Catalog

Number

9070T25D1 4.5 3.7 8.2 3.81 75.3 3.84 10.9 28 22 19 16 15 25.0 30.0

9070T50D1 4.5 7.1 11.6 7.97 81.1 8.01 10.5 40 29 21 17 15 24.1 28.9

9070T75D1 7.3 6.8 14.1 4.94 84.2 5.00 15.9 48 38 31 26 25 28.0 33.6

9070T100D1 7.3 10.2 17.5 6.82 85.1 6.9 15.4 60 45 34 27 25 26.8 32.2

9070T150D1 10.5 10.8 21.3 4.77 87.6 5.25 20.2 73 57 45 38 36 31.2 37.4

9070T200D1 10.5 19.5 30.0 7.70 86.9 7.83 18.0 102 73 53 40 36 19.7 23.7

9070T250D1 14.1 17.8 31.9 5.73 88.7 5.73 3.5 109 82 63 52 48 22.9 27.5

9070T300D1 13.3 18.8 32.1 5.60 90.3 5.62 6.0 110 82 61 49 45 11.0 13.2

9070T350D1 16.4 19.9 36.3 5.07 90.6 5.08 4.9 124 94 73 60 56 16.0 19.2

9070T500D1 20.7 30.6 51.3 5.47 90.7 5.48 5.3 175 129 97 77 71 12.9 15.5

9070T750D1 30.8 37.9 68.7 4.57 91.6 4.58 5.7 235 178 138 113 105 17.4 20.9

9070T1000D1 35.4 51.3 86.7 4.83 92.0 4.84 6.0 296 219 165 132 121 10.3 12.3

9070T1500D1 51.5 51.3 102.8 3.25 93.6 3.30 8.0 351 274 220 187 176 10.5 12.6

9070T2000D1 81.8 50.0 131.8 2.31 93.8 2.31 6.3 450 375 322 290 279 15.6 18.8

9070T3000D1 81.9 67.2 149.1 2.24 96.1 2.04 9.3 532 415 338 294 285 7.7 9.3

9070T5000D1 143.3 83.7 227.0 1.67 95.6 1.52 7.2 781 648 558 507 495 8.5 10.2

9070T50D3 4.5 7.1 11.6 7.97 81.1 8.01 10.5 40 29 21 17 15 24.1 28.9

9070T75D3 7.3 6.8 14.1 4.94 84.2 5.00 15.9 48 38 31 26 25 28.0 33.6

9070T100D3 7.3 10.2 17.5 6.82 85.1 6.90 15.4 60 45 34 27 25 26.8 32.2

9070T150D3 10.5 10.8 21.3 4.77 87.6 5.25 20.2 73 57 45 38 36 31.2 37.4

9070T200D3 10.5 19.5 30.0 7.70 86.9 7.83 18.0 102 73 53 40 36 19.7 23.7

9070T250D3 14.1 17.8 31.9 5.73 88.7 5.73 3.5 109 82 63 52 48 22.9 27.5

9070T300D3 13.3 18.8 32.1 5.60 90.3 5.62 6.0 110 82 61 49 45 11.0 13.2

9070T350D3 16.4 19.9 36.3 5.07 90.6 5.08 4.9 124 94 73 60 56 16.0 19.2

9070T500D3 20.7 30.6 51.3 5.47 90.7 5.48 5.3 175 129 97 77 71 12.9 15.5

9070T750D3 30.8 37.9 68.7 4.57 91.6 4.58 5.7 235 178 138 113 105 17.4 20.9

9070T1000D3 35.4 51.3 86.7 4.83 92.0 4.84 6.0 296 219 165 132 121 10.3 12.3

9070T1500D3 51.5 51.3 102.8 3.25 93.6 3.30 8.0 351 274 220 187 176 10.5 12.6

9070T2000D3 81.8 50.0 131.8 2.31 93.8 2.31 6.3 450 375 322 290 279 15.6 18.8

9070T3000D3 81.9 74.5 156.4 2.37 95 2.39 11.9 534 423 343 296 280 7.7 9.3

9070T5000D3

Core

Watts

Coil

Watts

FL Total

Watts

Reg

1.0PF

Eff

100%

%IZ X/R

100% 75% 50% 25%

No

Load

60HZ 50HZ

BTU/hr Inrush (x FL RMS)

9070T50D20 7.3 6.8 14.1 4.94 84.2 5.00 15.9 48 38 31 26 25 28.0 33.6

9070T75D20 7.3 10.2 17.5 6.82 85.1 6.90 15.4 60 45 34 27 25 26.8 32.2

9070T100D20 10.5 10.8 21.3 4.77 87.6 5.25 20.2 73 57 45 38 36 31.2 37.4

9070T150D20 10.5 19.5 30.0 7.70 86.9 7.83 18.0 102 73 53 40 36 19.7 23.7

9070T200D20 14.1 17.8 31.9 5.73 88.7 5.73 3.5 109 82 63 52 48 22.9 27.5

9070T250D20 13.3 18.8 32.1 5.60 90.3 5.62 6.0 110 82 61 49 45 11.0 13.2

9070T300D20 16.4 19.9 36.3 5.07 90.6 5.08 4.9 124 94 73 60 56 16.0 19.2

9070T350D20 20.7 30.6 51.3 5.47 90.7 5.48 5.3 175 129 97 77 71 12.9 15.5

9070T500D20 30.8 37.9 68.7 4.57 91.6 4.58 5.7 235 178 138 113 105 17.4 20.9

9070T750D20 35.4 51.3 86.7 4.83 92.0 4.84 6.0 296 219 165 132 121 10.3 12.3

9070T1000D20 51.5 51.3 102.8 3.25 93.6 3.30 8.0 351 274 220 187 176 10.5 12.6

9070T1500D20 81.8 50.0 131.8 2.31 93.8 2.31 6.3 450 375 322 290 279 15.6 18.8

9070T2000D20 81.9 74.5 156.4 2.37 95.0 2.39 11.9 534 423 343 296 280 7.7 9.3

9070T3000D20 143.3 84.8 228.1 1.63 95.6 1.64 11.8 779 652 562 507 489 8.5 10.2

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

25

Page 26

Industrial Control Transformers

Type T Transformers

TYPE T - SPECIAL QUOTE REQUEST SHEET

Determine VA by Load Requirements

Dual or CT Secondary

Secondary Voltages: ____ x ____ or ____ CT

Amps at higher of the two voltages ________

Tapped Unit Separate Windings

Secondary 1: ______ Volts ______ Amps Secondary 1: ______ Volts ______ Amps

Secondary 2: ______ Volts ______ Amps Secondary 2: ______ Volts ______ Amps

Secondary 3: ______ Volts ______ Amps Secondary 3: ______ Volts ______ Amps

Secondary 4: ______ Volts ______ Amps

Secondary 5: ______ Volts ______ Amps

Secondary Simultaneous Loading?

If Yes: VA Sizing ______

S1: V x A + S2: V x A + S3: V x A + S4: V x A + S5: V x A

If No: VA Sizing ______

Largest VA of the secondary listed above: V x A

Dual Primary _____ x _____ Volts

Tapped Unit

Primary 1: _____ Volts

Primary 2: _____ Volts

Primary 3: _____ Volts

Primary 4: _____ Volts

Primary 5: _____ Volts

Technical Data

Regulation Requirements: ______ VA @ ______ PF for ______% Voltage Drop

BTU Requirements: ______ No Load Max ______ Total Full Load Max

Dimensions

If dimensions are critical, provide them below (or supply a drawing with dimensions clearly marked):

Maximum size in inches: _____ H ____ W _____ D

All units will have standard Type T features:

Temperature Rise, Insulation Material, Terminal Board, cULus and CE Marked,

Footprints for VA frame created above.

26

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 27

Industrial Control Transformers

TYPE EO TRANSFORMERS

Type EO Transformers

Type EO VA Ratings

Type

60 Hz 50 Hz

EO17 25 25

EO1 50 35

EO18 75 75

EO2 100

EO3 150 120

EO19 200 200

EO15 250 200

EO4 300 240

EO16 350 280

EO51 500 400

EO61 750 500

EO71 1000 900

EO81 1500 1300

EO91 2000 1800

EO10 3000 3000

EO11 5000 5000

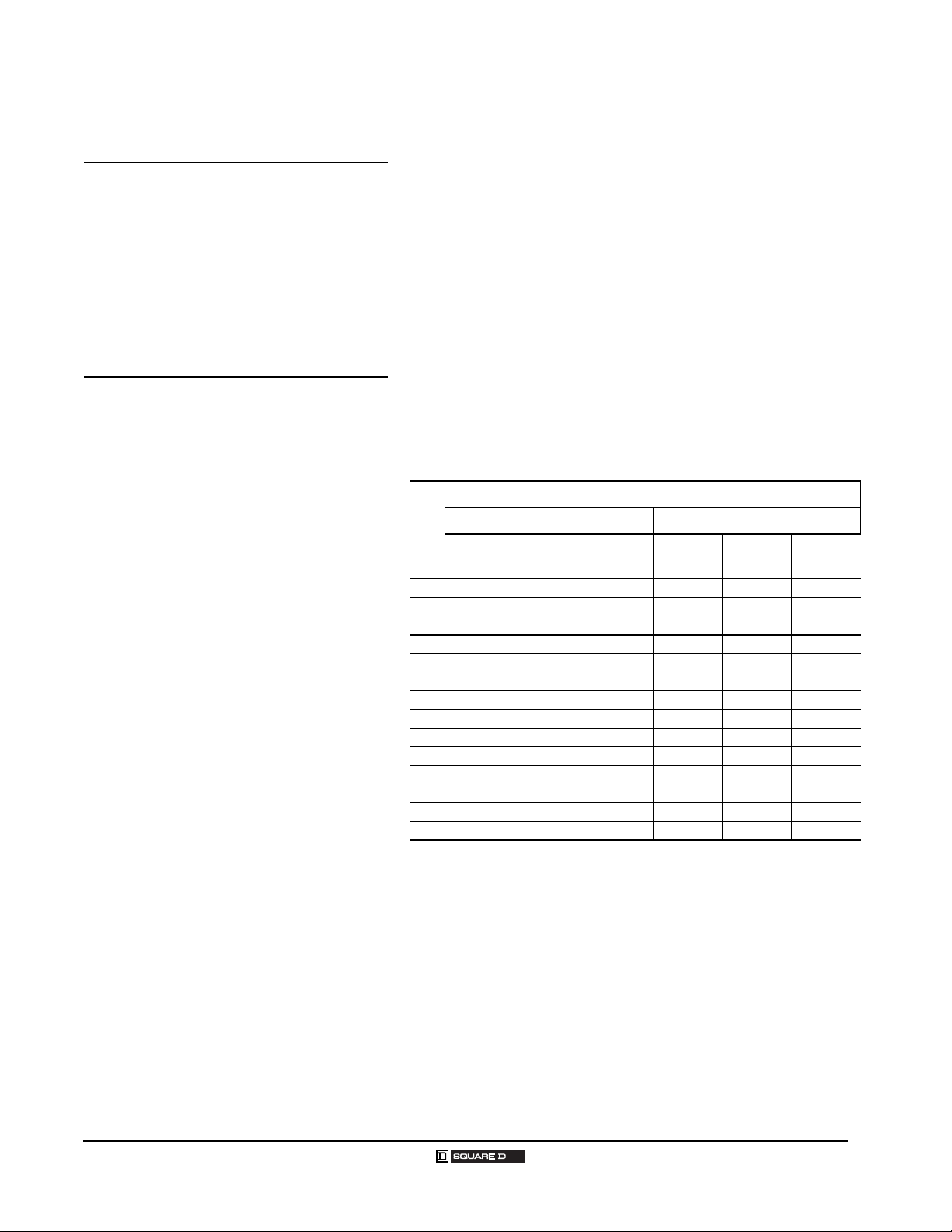

Example:

This example assumes the following:

• Two NEMA size 0 contactors do not start together, but one

could be ON when the other starts.

• One NEMA size 2 contactor can start with either of the

other contactors.

• One pilot light at 2 VA

1. VA and inrush are:

NEMA 0: sealed 27 VA; inrush 245 VA

NEMA 2: sealed 37 VA; inrush 311 VA; pilot light 2 VA

2. Total VA: 27 + 27 + 37 + 2 = 93 VA

3. Total inrush VA: 245 + 311 + 27 + 2 = 582 VA

4. From Regulation Chart for Type EO at right below:

100 VA minimum unit; inrush 606 VA will not work at 90%

150 VA (next standard size); inrush 755 VA will work at 95%

VA

70

The Type EO units are designed with exceptional voltage regulation. These

control transformers are constructed using traditional materials and

manufacturing techniques, and are designed for 25 VA to 5000 VA with a

55° C temperature rise. When exceptional regulation and very low

temperature rise are an absolute necessity, choose the Type EO units.

Type EO Listings

Listing File VA Range

UL E61239 25–5000

CSA LR37055, Guide 184-N-90 25–5000

Selection Guide

1. Determine inrush and sealed VA of each coil in the control circuit and VA

of all other components.

2. Total all sealed VA of all operating coils and other loads VA (determines

minimal VA size required for the circuit).

3. Total the inrush VA of all coils that are starting at the same time and all

loads and coils that are running (using the regulation chart to give

possible units to be used).

4. Take VA size from step 2, go to standard VA size in chart below. Make

sure inrush VA from chart is greater than total VA from step 3. If not, go

to next larger VA size and repeat.

If your supply voltage is stable and fluctuates less than 5%, we recommend

you use the 90% secondary voltage column. If your supply voltage is not

stable and fluctuates more than 10%, we recommend you use the 95%

secondary voltage column. We recommend that you never use the 85%

secondary voltage column since magnetic devices lose life expectancy if

they are continuously started at 85% of rated voltage.

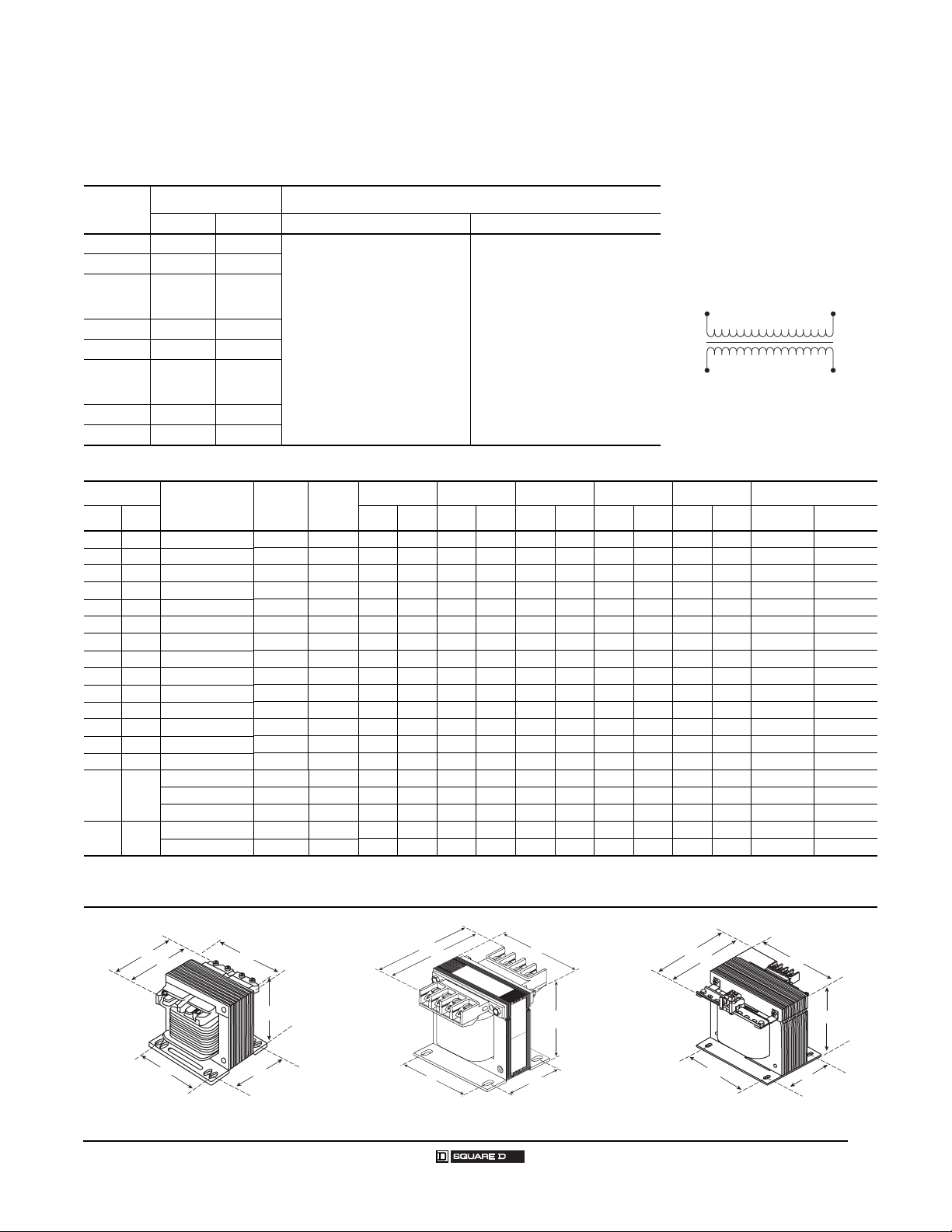

Regulation Chart for Type EO

Secondary Voltage

VA

Inrush UL VA at 20% Power Factor Inrush UL VA at 40% Power Factor

95% 90% 85% 95% 90% 85%

25 95 ... 146 60 ... 119

50 164 213 277 123 168 225

75 387 487 622 284 375 798

100 479 606 770 346 463 613

150 755 1177 1532 567 930 1252

200 1260 1883 2419 910 1462 1950

250 1530 2327 2995 1115 1811 2419

300 2030 2981 3800 1455 2290 3038

350 2920 4586 5981 2180 3637 4903

500 4230 5984 7707 3120 4661 6229

750 7430 11460 14736 5380 8907 11891

1000 10300 16873 21734 7450 13145 17571

1500 19200 30042 39217 14500 23859 32179

2000 27750 45194 60022 21750 36901 50994

3000 31800 82333 108205 26750 66072 89509

5000 86100 148768 202077 72600 126887 175552

08/2005

© 1999–2005 Schneider Electric All Rights Reserved

27

Page 28

Industrial Control Transformers

Type EO Transformers

Use the following tables to quickly find a Type EO transformer for your specific application. First, find

your source and load voltages in either the 120 or 24 Volt table below. Then, go to the indicated pages

for details on the transformer(s) matching those voltages.

Type EO Transformers for 120 Volt Loads

Source

Voltage

110 110 D24 30

115 115 D24 30

120 120 D24 30

200 115 D93 30

208 120 D3 30

220 110 D1 29

230 115 D1 29

240 120 D1 29

277 120 D4 30

380 110 D6 30

400 120 D103 30

415 110 D17 30

440 110 D1 29

460 115 D1 29

480 120 D1 29

550 110 D5 30

575 115 D5 30

600 120 D5 30

Load

Voltage

Voltage

Code(s)

Go To

Page(s)

Type EO Transformers for 24 Volt Loads

Source

Voltage

115 24 D89 31

120 24 D23, D7 31, 32

208 24 D14 20

230 24 D89, D112 31, 32

240 24 D2, D23 31, 31

277 24 D25 32

380 24 D88 32

460 24 D92 31

480 24 D2 31

600 24 D16 32

Load

Voltage

Voltage

Code(s)

Go To

Page(s)

28

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 29

Industrial Control Transformers

Type EO Transformers

120 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D1

1

Jumper kit (two jumpers) supplied with unit.

Dimensions

VA

25 9070EO17D1 6 3.31 84 3.00 76 2.50 64 1.75 44 2.50 64 0.20 x 0.38 5 x 10

50 9070EO1D1 6 3.31 84 3.00 76 2.50 64 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 9070EO18D1 6 3.78 96 3.38 86 2.81 71 2.19 56 2.81 71 0.20 x 0.38 5 x 10

100 9070EO2D1 6 3.78 96 3.38 86 2.81 71 2.38 60 2.81 71 0.20 x 0.38 5 x 10

150 9070EO3D1 6 4.44 113 3.75 95 3.13 80 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 9070EO19D1 6 4.81 122 4.50 114 3.75 95 2.5 63 3.75 95 0.20 x 0.38 5 x 10

250 9070EO15D1 6 5.19 132 4.50 114 3.75 95 2.88 73 3.75 95 0.20 x 0.38 5 x 10

300 9070EO04D1 6 5.56 141 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

350 9070EO16D1 6 6.19 157 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

500 9070EO51D1 6 6.56 167 5.25 133 4.38 111 3.81 97 4.38 111 0.28 x 0.56 7 x 14

750 9070EO61D1 6 7.94 202 5.25 133 4.38 111 5.13 130 4.38 111 0.28 x 0.56 7 x 14

1000 9070EO71D1 6 7.94 202 6.00 152 5.00 127 4.75 121 5.00 127 0.28 x 0.56 7 x 14

1500 9070EO81D1 6 8.59 218 7.06 179 6.03 153 5.88 149 5.81 148 0.44 x 0.69 11 x 18

2000 9070EO91D1 6 9.22 234 7.06 179 6.03 153 6.50 165 5.81 148 0.44 x 0.69 11 x 18

3000 9070EO10D1 6 9.44 239 9.00 229 7.50 191 5.88 149 7.63 194 0.44 x 0.69 11 x 18

5000 9070EO11D1 6 12.06 306 9.00 229 7.50 191 8.50 216 7.63 194 0.44 x 0.69 11 x 18

Number

Voltages Connections

Primary Secondary Primary Secondary

220 x 440

230 x 460

240 x 480

Catalog

110

115

120

Figure

220/230/240: Connect to H1 and H4

440/460/480: Connect to H1 and H4

ABCEF Slots

IN

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

mm

IN

mm

Connect to X1 and X2

1

IN

mm

H1

X2 X1

IN

mm

IN

mm

IN

H2H3 H4

mm

08/2005

Figure 6

29

© 1999–2005 Schneider Electric All Rights Reserved

Page 30

Industrial Control Transformers

Type EO Transformers

120 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D3 208 120

D4 277 120

D5

D6 380 110

D17 415 110

D24

D93 200 115

D103 400 120

Dimensions

VA

25 9070EO17t 6 3.31 84 3.00 76 2.50 64 1.75 44 2.50 64 0.20 x 0.38 5 x 10

50 9070EO1t 6 3.31 84 3.00 76 2.50 64 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 9070EO18t 6 3.78 96 3.38 86 2.81 71 2.19 56 2.81 71 0.20 x 0.38 5 x 10

100 9070EO2t 6 3.78 96 3.38 86 2.81 71 2.38 60 2.81 71 0.20 x 0.38 5 x 10

150 9070EO3t 6 4.44 113 3.75 95 3.13 80 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 9070EO19t 6 4.81 122 4.50 114 3.75 95 2.5 63 3.75 95 0.20 x 0.38 5 x 10

250 9070EO15t 6 5.19 132 4.50 114 3.75 95 2.88 73 3.75 95 0.20 x 0.38 5 x 10

300 9070EO04t 6 5.56 141 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

350 9070EO16t 6 6.19 157 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

500 9070EO51t 6 6.56 167 5.25 133 4.38 111 3.81 97 4.38 111 0.28 x 0.56 7 x 14

750 9070EO61t 6 7.94 202 5.25 133 4.38 111 5.13 130 4.38 111 0.28 x 0.56 7 x 14

1000 9070EO71t 6 7.94 202 6.00 152 5.00 127 4.75 121 5.00 127 0.28 x 0.56 7 x 14

1500 9070EO81t 6 8.59 218 7.06 179 6.03 153 5.88 149 5.81 148 0.44 x 0.69 11 x 18

2000 9070EO91t 6 9.22 234 7.06 179 6.03 153 6.50 165 5.81 148 0.44 x 0.69 11 x 18

3000 9070EO10t 6 9.44 239 9.00 229 7.50 191 5.88 149 7.63 194 0.44 x 0.69 11 x 18

5000 9070EO11t 6 12.06 306 9.00 229 7.50 191 8.50 216 7.63 194 0.44 x 0.69 11 x 18

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Number

Voltages Connections

Primary Secondary Primary Secondary

550

575

600

110

115

120

Catalog

1

110

115

120

110

115

120

Figure

Connect to H1 and H2 Connect to X1 and X2

ABCEF Slots

mm

IN

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

IN

H2

mm

Figure 6

30

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 31

Industrial Control Transformers

Type EO Transformers

24 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D2 240 x 480

D23 120 x 240

D89 115 x 230

D92 230 x 460

Dimensions

VA

25 9070EO17t 6 3.31 84 3.00 76 2.50 64 1.75 44 2.50 64 0.20 x 0.38 5 x 10

50 9070EO1t 6 3.31 84 3.00 76 2.50 64 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 9070EO18t 6 3.78 96 3.38 86 2.81 71 2.19 56 2.81 71 0.20 x 0.38 5 x 10

100 9070EO2t 6 3.78 96 3.38 86 2.81 71 2.38 60 2.81 71 0.20 x 0.38 5 x 10

150 9070EO3t 6 4.44 113 3.75 95 3.13 80 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 9070EO19t 6 4.81 122 4.50 114 3.75 95 2.5 63 3.75 95 0.20 x 0.38 5 x 10

250 9070EO15t 6 5.19 132 4.50 114 3.75 95 2.88 73 3.75 95 0.20 x 0.38 5 x 10

300 9070EO04t 6 5.56 141 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

350 9070EO16t 6 6.19 157 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

500 9070EO51t 6 6.56 167 5.25 133 4.38 111 3.81 97 4.38 111 0.28 x 0.56 7 x 14

750 9070EO61t 6 7.94 202 5.25 133 4.38 111 5.13 130 4.38 111 0.28 x 0.56 7 x 14

1000 9070EO71t 6 7.94 202 6.00 152 5.00 127 4.75 121 5.00 127 0.28 x 0.56 7 x 14

1500 9070EO81t 6 8.59 218 7.06 179 6.03 153 5.88 149 5.81 148 0.44 x 0.69 11 x 18

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Number

Voltages Connections

Primary Secondary Primary Secondary

Catalog

240 or 120 or 115 or 230:Connect to H1 and H4

24

480 or 240 or 230 or 460:Connect to H1 and H4

ABCEF Slots

1

Fig.

mm

IN

Jumper H1 with H3

Jumper H2 with H4

Jumper H2 with H3

IN

mm

Connect to X1 and X2

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

H2H3 H4

mm

08/2005

Figure 6

31

© 1999–2005 Schneider Electric All Rights Reserved

Page 32

Industrial Control Transformers

Type EO Transformers

24 Volt Control Secondary

Voltage and Connection Options

Voltage

Code

D7 120

D14 208

D16 600

D25 277

D88 380

D112 230

Dimensions

VA

25 9070EO17t 6 3.31 84 3.00 76 2.50 64 1.75 44 2.50 64 0.20 x 0.38 5 x 10

50 9070EO1t 6 3.31 84 3.00 76 2.50 64 2.00 51 2.50 64 0.20 x 0.38 5 x 10

75 9070EO18t 6 3.78963.38 862.81712.19562.81 710.20 x 0.38 5 x 10

100 9070EO2t 6 3.78963.38 862.81712.38602.81 710.20 x 0.38 5 x 10

150 9070EO3t 6 4.44 113 3.75 95 3.13 80 2.88 73 3.13 80 0.20 x 0.38 5 x 10

200 9070EO19t 6 4.81 122 4.50 114 3.75 95 2.5 63 3.75 95 0.20 x 0.38 5 x 10

250 9070EO15t 6 5.19 132 4.50 114 3.75 95 2.88 73 3.75 95 0.20 x 0.38 5 x 10

300 9070EO04t 6 5.56 141 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

350 9070EO16t 6 6.19 157 4.50 114 3.75 95 3.81 97 3.75 95 0.20 x 0.38 5 x 10

500 9070EO51t 6 6.56 167 5.25 133 4.38 111 3.81 97 4.38 111 0.28 x 0.56 7 x 14

750 9070EO61t 6 7.94 202 5.25 133 4.38 111 5.13 130 4.38 111 0.28 x 0.56 7 x 14

1000 9070EO71t 6 7.94 202 6.00 152 5.00 127 4.75 121 5.00 127 0.28 x 0.56 7 x 14

1500 9070EO81t 6 8.59 218 7.06 179 6.03 153 5.88 149 5.81 148 0.44 x 0.69 11 x 18

1

Complete the catalog number by replacing the t with the correct Voltage Code from the “Voltage and Connection Options” table above.

Number

Voltages Connections

Primary Secondary Primary Secondary

24 Connect to H1 and H2 Connect to X1 and X2

Catalog

1

Fig.

ABCEF Slots

IN

mm

IN

mm

IN

mm

H1

X2 X1

IN

mm

IN

mm

IN

H2

mm

Figure 6

32

© 1999–2005 Schneider Electric All Rights Reserved 08/2005

Page 33

TYPE EO PERFORMANCE DATA

Industrial Control Transformers

Type EO Transformers

Catalog

Number

9070EO17D1 2.25 2.25 4.50 6.37% 84.75% 7.38 0.151 15.35 10.84 9.16 8.32 7.68 44.70

9070EO1D1 3.50 4.20 7.70 7.35% 86.66% 7.69 0.158 26.27 20.66 16.20 13.19 11.94 44.70

9070EO18D1 4.25 4.85 9.10 5.63% 89.18% 5.62 0.079 31.05 25.45 20.79 17.45 14.50 32.30