Page 1

Altivar 71

Network braking units

User’s manual

VW3 A7 201 ... 241

11/2010

1757361

www.schneider-electric.com

Page 2

Page 3

Contents

Before you begin______________________________________________________________________________________________ 4

Steps for setting up the braking unit_______________________________________________________________________________ 5

Checking the installation__________________________________________________________ ______________________________ 6

Recommendations ___________________________________________________________________________________________ 13

Characteristics ______________________________________________________________________________________________ 14

Sizing _____________________________________________________________________________________________________ 15

Dimensions________________________________________________________________________________ _________________ 19

Mounting and temperature conditions ____________________________________________________________________________ 21

Recommendations for the electrical installation_____________________________________________________________________ 22

Connection diagrams, fuses and associated cables__________________________________________________________________ 23

Operation on a neutral IT (isolated or impedance grounded neutral) system_______________________________________________ 28

Electromagnetic compatibility and wiring __________________________________________________________________________ 29

Starting tests________________________________________________________________________________________________ 33

Configuration _______________________________________________________________________________________________ 34

Troubleshooting _____________________________________________________________________________________________ 36

1757361 11/2010 3

Page 4

Before you begin

Read and understand these instructions before performing any procedure with this

braking unit.

DANGER

HAZARDOUS VOLTAGE

• Read and understand this User’s Manual before installing or operating the braking

unit. Installation, adjustment, repair, an d maintenance must be performed by qualifi ed

personnel.

• The user is responsible for compliance with all international and national electrical

standards in force concerning protective grounding of all equipment.

• Many parts in this equipment, including printe d circuit boards, o perate at line voltage .

DO NOT TOUCH.

Use only electrically insulated tools.

• DO NOT touch unshielded components or terminal strip screw connections with

voltage present.

• DO NOT short across terminals PA and PC or across the DC bus capacitors.

• Install and close all the covers before applying power or starting and stopping the

drive.

• Before servicing the braking unit

- Disconnect the power and the control power supply.

- Place a “DO NOT TURN ON” label on the disconnect at the head of the installation.

- Lock the disconnect in the open position.

• Disconnect the power supply, including the 230 V control power supply, before

working on the equipment. Wait for the charging LED to go of f. Then follow the DC bus

voltage measurement procedure described in the drive Installation Manual to verify

that the DC voltage is less than 45 VDC. The LEDs on the speed drive are not

accurate indicators of the absence of DC bus voltage.

Electric shock will result in death or serious injury.

4 1757361 11/2010

Page 5

Steps for setting up the braking unit

Steps 1 to 4 must

be performed with

the power off

b 1 Take delivery of the braking unit (see page 13)

v Check that the catalog number printed on the label is the same

as that on the purchase order.

v Remove the braking unit from its packaging and check that it has

not been damaged in transit.

b 2 Check the line voltage (see page 14)

v Check that the line voltage is compatible with the voltage

range of the braking unit

b 3 Install the braking unit (see page 21)

v Mount the braking unit in accordance with the

instructions in this document

v Install any internal and external options

b 4 Wire the braking unit (see page 23)

v Connect the braking unit to the 3-phase supply

(L1,L2,L3)

v Connect the braking unit to the drive DC bus

v

Connect the control cable

1757361 11/2010 5

Page 6

Checking the installation

L

max

CUΔ

GL

()

2

⋅

i

ˆ

2

------------------------------ -

=

I

max

CU

GL

2

Δ⋅

i

ˆ

2

L'⋅

------------------------- -

L

ZKD

L'

-------------

–=

Length of the DC bus

The maximum inductance of the DC bus connecting output PA/+, PC/- on the drive to the braking unit must not exceed a set level, as this

inductance results in an additional difference i n potential on the DC bus when the IGBTs are open. To avoid an overload on the components

of the braking unit, this difference in potential must not exceed 10 0 VDC. The maximu m inductan ce can be calcu lat ed us ing thi s and other

characteristics of the braking unit (value of the DC bus capacitors and absolute value of the grid current).

This inductance must always be greater than or equal to the sum of the inductance of the DC bus on the frequency inverter and the

inductance of the DC bus connection cables. The inductance of the DC bus on the frequency inverter must always be taken into

consideration. The inductance per unit of length of the cables generally used for the power supply is in the region of 0.6 µH/m.

The maximum length of the conductors l

max is calculated according to the following information:

• Values of the input capacities C

• Maximum DC voltage edge permitted during motor generator operation (ΔU

• Maximum AC current level for the equipment î (=2*Irms)

• Inductance per unit of length L'

• Inductance of the coil Lzkd of the DC bus

The equation below can be used to calculate l

max:

GL=100 VDC)

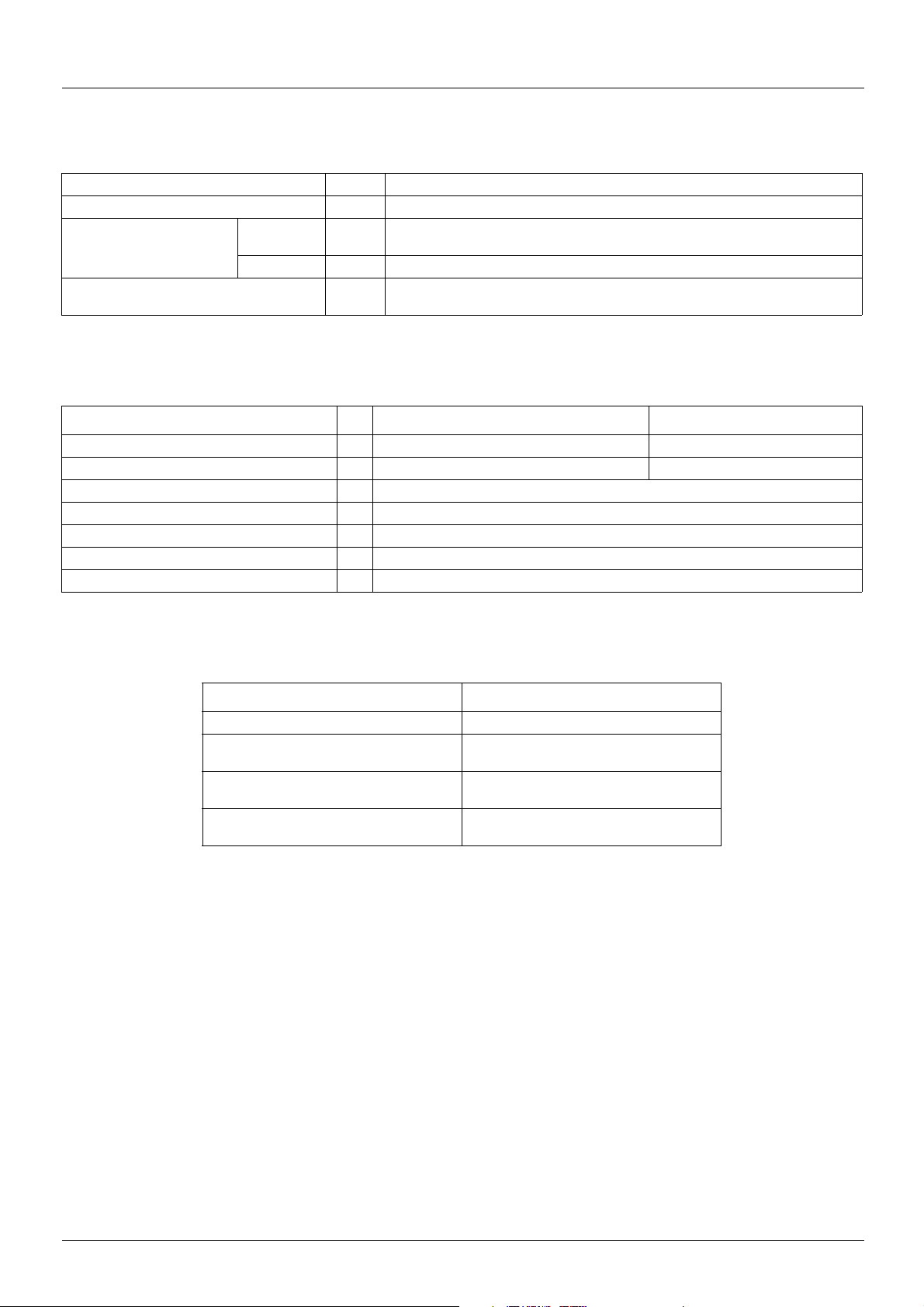

Typical capacity of the DC connection inside the braking unit

Braking unit Power

VW3 A7 ...

Example:

C = 200 μF,

For longer DC bus cables, additional capacitors must be installed (Please contact your local representative)

ΔU

= 100 V, i = 271 A, a = 80 mm, r = 8.5 mm, μ0=1.257.10-6H/m

GL

7 - 45 kW 100 μF

70 - 135 kW 200 μF

160 - 200 kW 420 μF

DC

capacity

6 1757361 11/2010

Page 7

Checking the installation

M

M

VW3A7...

R

0.4kV

100kVA

20kW

20kW

G

ATV71

Operation on a generator

It is possible to use a braking unit with an isolated line supply (for example: a diesel engine generating set), but there are restrictive rules

limiting the power.

With a line supply whose architecture is similar to that shown in the diagram above, there are 2 additional restrictions:

• The power of the motor connected to the inverter must be less than half the nominal power of the generator.

• The total power of the two other loads must be more than double the power returned on the line supply.

If these conditions are not verified, changing the motor to operation as a generator could result in a sudden overload. This overload is too

high for the voltage regulator of the generator. The regulator reacts with an overshoot which leads to an overvoltage with the isolated line

supply.

CAUTION

RISKS OF INTERFERENCE

Overvoltages can cause serious damage to the frequency inverter and/or the braking

unit and the other loads.

Failure to follow this precaution can result in equipment damage.

1757361 11/2010 7

Page 8

Checking the installation

M

M

R

Tr

10kV

0.4kV

100kVA

60kW

20kW

20kW

ATV71

VW3A7...

Operation on a transformer

If only some loads are operating on one section of the line supply, then the transformer that is connected must be capable of transporting

the unused generated power from this section to the next voltage level without exceeding the voltage edge permitted in the line supply

section. The nominal power of the transformer must therefore be one and a half times gr eater than the power generated outside the se ction,

so that the harmonic and reactive components of the current can be transmitted. In the line supply section shown in the diagram below,

these conditions are verified even if the other loads are disconnecte d.

If the power that is generated is in the region of the nominal power of the transformer, then the transformer short circuit voltage must be

fairly low (6% maximum) to limit the voltage increase in this section.

The operation of the braking unit used with a sized transformer (for example in the case of a slip ring induction motor) is only permitted if

the ratio of the power generated to the nominal power is considerably less than 1.

8 1757361 11/2010

Page 9

Checking the installation

ATV71

Prohibited

Position of the commutation reactor

If the frequency inverter is connected to an external commutation reactor, then the braking unit must be connected to the line supply

(diagram below). If the braking unit is connected downstream of the commutation reactor, then the inductance of the reactor prevents the

braking unit from synchronizing on the line supply and generates overvoltag es, which can result in damage to the components of the braking

unit.

CAUTION

RISKS OF INTERFERENCE

Overvoltages can cause serious damage to the frequency inverter and/or the braking

unit and the other loads.

Failure to follow this precaution can result in equipment damage.

VW3A7...

M

Same warning about the presence, also not permitted, of other commutation reactors upstream of the braking unit.

60kW

1757361 11/2010 9

Page 10

Checking the installation

M

ATV71

Δ

U

Δ

U

UU

Δ

U

U

Δ

U

I

Line supply

VW3A7...

Line resistances and contact resistances

The values of the capacitive currents of the cables depend on the conductive material. This is relevant for sizing. Aluminum conductors

must have a larger cross-section than copper conductors due to their high resistiv ity.

Whatever conductive material is used, the contact resistances of the connections must have a low impedance and the number of

connections must be kept to the absolute minimum.

Too many connections or contact resistances that are too high can result in overvoltages during power generation.

Based on a stable line supply with for example a nominal voltage of 400 V with a return current of 80 A, and a connection with a contact

resistance of 100 mΩ, a voltage dip of 8 V occurs (a correct connection has a contact resistance of approximately 1mΩ). During power

generation if there are 7 connection points to the line supply, this results in a total voltage of 456 V.

10 1757361 11/2010

Page 11

Checking the installation

M

60kW

ATV71

Line supply

M

VW3A7...

Prohibited

Correct

Connection of other loads

Connection of other loads (for example ventilation or air conditioning enclosure) in parallel on the frequency inverter and the braking unit

with a common circuit-breaker is not permitted (see diagram below). If this is nevertheless performed, then if the circuit-breaker trips, the

connection to the line supply will be absent (loss of power and synchronization information for the braking units). The IGBTs then transfer

the DC voltage directly to the other loads. The resulting quasi-rectangular supply voltage signal sends a current across the loads, whose

waveform and level depend on their impedance. If the power consumption of the loads is too low, then the DC vol tage and the output voltage

of the braking unit increase during generation. This overvoltage can damage all the components that are connected.

1757361 11/2010 11

RISKS OF INTERFERENCE

Overvoltages can cause serious damage to the frequency inverter and/or the braking

unit and the other loads.

Failure to follow this precaution can result in equipment damage.

CAUTION

Page 12

Checking the installation

M

ATV71

Line supply

M

ATV71

M

ATV71

VW3A7...

Connection of other loads (continued)

60kW

There are also risks of overvoltage for a structure such as that shown above. Even in this case, a circuit-breaker must be placed

in each current return circuit.

Correction circuit without reactor

Correction circuits are used at the center of the line supply of a company. Interference and damage on these circuits have consequences

on the line supply and can result in stoppage of the production process.

Although they are no longer currently made, many correction circuits without reactor are in use. A wide variety of problems arise from the

use of such correction equipment without reactor:

• Direct resonance

• Increase in resonance

• Switching transient

• Attenuation of central oscillations

The fact that a company returns energy to the line supply is not the only reason for the creation of a resonance phenomenon. The power

of the medium voltage transformer cos ϕ correction unit is the decisive element. The higher this power, the greater the risk of resonance.

The second important factor is the harmonic load of the medium voltage line supply.

This harmonic load is transmtted via the transformer and affects the low voltage level. More often than not the limits are exceeded by the

5th harmonic.

12 1757361 11/2010

Page 13

Recommendations

Receipt

Ensure that the equipment reference marked on the label conforms to the delivery note corresponding to the purchase order.

Open the packaging and check that the equipment has not been damaged in transit.

For successful setup, it is important to check that the braking unit, protection devices and mounting are correct. For more information, please

contact your local representative.

Capacitor discharge!

Before any operation on or in the braking unit, disconnect the power li ne supply and wait 15 minute s for the DC bus to discharge completely.

Measure the voltage on the DC bus before any intervention. This should be less than 60 V DC.

Automatic restart!

In certain cases, depending on its parameter setting, the drive may restart automatically when the power is restored. The safety of nearby

equipment and people must be assured.

General

As a motor slows down on a deceleration ramp, it is working as a generator. A drive uses a rectifier and cannot return electrical energy to

the distribution network.

During operation as a generator, the voltage at the DC bus terminal s increases d ue to the re storation of energy from the motor to the dri ve.

This locks out the drive on a DC bus overvoltage fault.

The restored power in the drive depends on the inertia of the load to be braked and the required braking time.

The drive protects itself against locking out due to DC bus overvolt age by auto-adapting its deceleration ramp. If a shorter decelerati on time

is required, a BRAKING UNIT must be used.

1757361 11/2010 13

Page 14

Characteristics

General characteristics

Degree of protection IP 20

Maximum relative humidity Class F humidity without condensation 5…85%

Ambient temperature

around the unit

Maximum operating altitude m 1000 without derating

Electrical characteristics

Type of module VW3 A7 201…212 VW3 A7 231…241

Supply voltage V a 400 a 460

Nominal voltage ± 10% V a 380…415 a 440…480

Operating frequency Hz 40…60 ± 10%

Overload capacity A 1.2 x maximum current (Irms)

Efficiency 97% (3% of thermal losses)

Power factor 1

Fundamental frequency component 0.7…0.95

Operation °C (°F) 5…+ 40 (41…+ 104) without derating

Up to 55°C (131°F) with current derating of 3% per °C (34°F) above 40°C (104°F)

Storage °C (°F) - 25…+ 55 (-77…+ 131)

1000…4000 derating the current by 5% per additional 1000 m

Connection characteristics

Type of module Maximum wire size

VW3 A7 201 25 mm

VW3 A7 202…205,

VW3 A7 231, 232

VW3 A7 206…209,

VW3 A7 233…238

VW3 A7 210…212,

VW3 A7 239…241

2

, connected on a bar, M5

2

35 mm

, connected on a bar, M6

2

, connected on a bar, M8

95 mm

2

150 mm

, connected on a bar, M10

14 1757361 11/2010

Page 15

Sizing

Line voltage: a 400 V

Maximum

current

Irms

a

AA kW AV kg

11 13 7 20 660 VW3 A7 201 20.000

20 24 13 30 690 VW3 A7 202 25.000

32 38 11 50 690 VW3 A7 203 26.000

48 58 21.5 80 690 VW3 A7 204 30.000

65 78 26 100 690 VW3 A7 205 32.000

102 123 32 160 660 VW3 A7 206 43.000

130 157 38 200 660 VW3 A7 207 48.000

195 236 38 315 660 VW3 A7 208 52.000

231 279 86 350 660 VW3 A7 209 90.000

289 350 120 400 1000 VW3 A7 210 100.000

360 433 135 500 1000 VW3 A7 211 115.000

500 600 200 630 1000 VW3 A7 212 125.000

Line voltage:

c

a 460 V

Continuous

braking

power

Fast-acting semi-

conductor fuses

aa

Catalog

number

Weight

Maximum

current

Irms

a

AA kW AV kg

28 33 – 50 690 VW3 A7 231 26.000

41 50 21.5 80 690 VW3 A7 232 30.000

57 69 26 100 690 VW3 A7 233 36.000

88 107 32 160 660 VW3 A7 234 43.000

113 137 38 200 660 VW3 A7 235 48.000

138 166 38 250 660 VW3 A7 236 48.000

157 189 38 250 660 VW3 A7 237 50.000

176 212 38 315 660 VW3 A7 238 90.000

201 243 86 315 660 VW3 A7 239 100.000

289 346 120 500 1000 VW3 A7 240 105.000

500 600 240 630 1000 VW3 A7 241 125.000

c

Continuous

braking

power

Fast-acting semi-

conductor fuses

aa

Catalog

number

Weight

1757361 11/2010 15

Page 16

Sizing

PU

rmsIrms

3 ϕcos⋅⋅⋅=

P400V65A 3×× 45033W==

P395V65A 3×× 44470W==

To calculate the correct value of the powe r that i s g enerat ed, t he f act t hat the a ctu al ins tan taneous power ge nerat ed d epen ds

on the actual voltage of the line supply at each moment must be take n into accou nt. Th e foll owing formula is used t o calcul ate

the power generated (during operation as a generator: cosϕ = 1):

The maximum power generated is calculated according to the instantaneous rms voltage of the line supply and according to

the maximum rms current of the device in question.

Example: The VW3 A7 205 has a maximum generated power of 45 KW and a maximum rms current of 65 A (refer to the

technical data). The nominal voltage of the line supply is, for example, 400 V. This gives:

That is, approximately 45.0 kW.

If the instantaneous rms voltage of the lin e supply is less than 395V for a moment, then the maximum power generated is also

reduced:

That is, approximately 44.5 kW.

16 1757361 11/2010

Page 17

Sizing

001

2

1

3

4

5

6

7

8

9

10

234 567891011

A

Time between braking operations (min.)

Braking time (min.)

27 kW

33 kW

001

2

1

3

4

5

6

7

8

9

10

234567891011

Time between braking operations (min.)

Braking time (min.)

27 kW

33 kW

0

2

1

3

4

5

6

7

8

9

10

01234567891011

Time between braking operations (min.)

Braking time (min.)

45 kW

33 kW

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

45 kW

70 kW

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

52 kW

90 kW

Example of how to use characteristic curves

Note: These curves are given for a voltage of 400 V or 460 V, depending on the model.

VW3 A7 204, A7 232

(Continuous braking power = 21.5 kW) (1)

Example of how to use the curves:

Required braking power of 27 kW.

The intersection point between the braking time and the time

between 2 braking operations must be on or below the relevant

curve.

A for a braking time of 2 minutes, there must be at least

Point

50 seconds between 2 braking operations.

VW3 A7 204, A7 232 (Continuous braking power = 21.5 kW) (1) VW3 A7 205, A7 233 (Continuous braking power = 26 kW) (1)

VW3 A7 206, A7 234 (Continuous braking power = 32 kW) (1) VW3 A7 207, A7 235 (Continuous braking power = 38 kW) (1)

(1) Power indicated for a temperature of 35°C (95°F).

1757361 11/2010 17

Page 18

Sizing

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Braking time (min.)

52 kW

135 kW

Time between braking operations (min.)

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

110 kW

Braking time (min.)

160 kW

Time between braking operations (min.)

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

135 kW

200 kW

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

170 kW

250 kW

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

230 kW

345 kW

001

1

0.5

1.5

2

2.5

3

3.5

4

4.5

5

234567891011

Time between braking operations (min.)

Braking time (min.)

260 kW

400 kW

VW3 A7 208 (Continuous braking power = 38 kW) (1) VW3 A7 209, A7 239 (Continuous braking power = 86 kW) (1)

VW3 A7 210, A7 240 (Continuous braking power = 120 kW) (1) VW3 A7 211 (Continuous braking power = 135 kW)

VW3 A7 212 (Continuous braking power = 200 kW) VW3 A7 241 (Continuous braking power = 240 kW)

(1) Power indicated for a temperature of 35°C (95°F).

18 1757361 11/2010

Page 19

Dimensions

H

G==

H1

b

a

c

4xØ

u 70

u 70

u 150u 150

H

G==

H1 H2

a

b

c

4xØ

u 70

u 70

u 150

VW3 A7 201…205, 231, 232

Mounting recommendations

VW3 a b c G H H1 Ø

A7 201, 202

A7 203…205

270 500 295 260 260 80 7

270 580 295 260 340 80 7

A7 231...232

VW3 A7 206…208, 233…237

VW3 a b c G H H1 H2 Ø

A7 206…208

A7 233…237

245 700 272 260 440 80 180 7

272 700 295 260 440 80 180 7

Mounting recommendations

1757361 11/2010 19

Page 20

Dimensions

320

350==

28080

837

380

395

2xØ8.5

4xØ8.5

u 70 u 70

u 150

H

G==

H2H1

b

a

c

2xØ

4xØ

937

u 70

u 70

u 150

VW3 A7 209, 210, 238, 239

VW3 A7 211, 212, 240, 241

Mounting recommendations

Mounting recommendations

VW3 a b c G H H1 H2 Ø

A7 211, 240

A7 212, 241

20 1757361 11/2010

380 937 395 350 320 80 280 8.5

380 1037 395 350 320 80 280 8.5

Page 21

Mounting and temperature conditions

Required mounting position

The braking unit has been designed to be mounted on a vertical wall only (+/- 15°). The unit can only be mounted on a smooth surface

without the use of any type of spacer. It must be mounted in this way to ensure correct circulation of the cooling air.

Important recommendations

• Leave sufficient free space!

- Leave a horizontal distance of at least 70 mm between the braking units and the other components, and between the braking uni ts and

the enclosure walls.

- Leave a vertical distance of at least 70 mm between the braking units and the other components, and between the braking units and

the enclosure walls.

• Check that there are no obstacles to the entry and exit of the cooling air. Leave a minimum distance of 15cm at the air intake and outlet

apertures.

• If the cooling air is polluted (dust, grease, corrosive gas) this may hamper some of the functions of the braking unit.

- Take appropriate measures, for example: Keep the cooling air separate, fit air filters, clean regularly.

• Do not exceed the acceptable ambient temperature during use.

A dissipated thermal power of 3% of the maximum nominal power must be taken into account. The air temperature must not exceed 40°C

(104°F) in the vicinity of the braking unit. The air intake and outlet apertures at the top and bottom of the braking unit must not be covered

by installation equipment such as cable ducts or other equipment.

The required air flow rate depends on the size of the braking unit (nominal power and nominal voltage).

3

Braking module Required air flow rate (m

VW3A7 4-230, 7-230, 12-230, 18-230, 22-230, 25-230

VW3A7 7-400, 13-400, 22-400, 33-400, 45-400

VW3A7 22-460, 33-460, 45-460

VW3A7 18-500, 33-500, 45-500

VW3A7 38-230, 50-230, 75-230

VW3A7 70-400, 90-400, 135-400

VW3A7 70-460, 90-460, 110-460, 125-460

VW3A7 70-500, 90-500, 110-500, 125-500

VW3A7 75-230 (1)

VW3A7 135-400 (1)

VW3A7 125-460 (1)

VW3A7 125-500 (1)

VW3A7 70-690 (1)

VW3A7 90-230, 115-230

VW3A7 160-400, 200-400, 250-400

VW3A7 140-460, 160-460

VW3A7 140-500, 160-500

VW3A7 150-690, 250-690

200

350

450

700

/h)

(1) Some specific models have sli g ht ly di ffe re n t di m e ns i on s .

1757361 11/2010 21

Page 22

Recommendations for the electrical installation

Protection of the braking unit

CAUTION

RISKS OF INTERFERENCE

The braking unit contains components that are sensitive to electrostatic discharge.

During the installation and wiring phases, personnel must comply with the rules of

international standard IEC 747.1, section 9. Basically, before starting work, personnel

must discharge themselves of any electrostatic vol tage by touching the grou nding cable

screw located on the unit or a grounded surface of the enclosure.

Failure to follow these precautions can result in equipment damage.

22 1757361 11/2010

Page 23

Connection diagrams, fuses and associated cables

The connections can be accessed by removing the side screws and connection terminal cover f rom the unit. The cables must pass through

a cable gland located on the wiring plate.

CAUTION

RISKS OF INTERFERENCE

When you remove the cover, take care not to damage th e cables that lead to the displ ay.

Failure to follow this precaution can result in equipment damage.

Electrical power supply

Fuses

The braking unit is equipped with fuses for semi-conductors.

• The on-load voltage drop must be taken into consideration when choosing the cable cross-section (See section “Checking the

installation”, page 6

• Protection of the braking unit cables (L1,L2,L3) and the connections to the line supply:

- by commercially available cable protection fuses

- the fuses must comply with the appropriate standards for the site.

- the nominal voltage of the fuse must comply with the voltages for the site.

• Protection of the braking unit and the connections to the DC bus (+UG,-UG):

- The fuses are part of the braking unit

).

The installer/user of the circuit is responsible for compliance with the appropriate standards.

WARNING

• Overcurrent protective devices must be properly coordinated.

• Use the fuses recommended in this document.

Failure to follow these instructions can result in death or serious injury.

Connections

• All the connections must be a short as possible and have a low impedance.

• Shielded cables must be used in order to comply the EMC directives (in accordance with current standards such as EN 61800.3).

• Connect the line supply (line reactor) to terminals L1, L2 and L3 on the braking unit. Only a three-phase supply is permitted.

• A defined phase sequence (indirect rotation of the field) must be followed when connect ing the braking unit to the l ine supply. The braking

unit has a phase sequence check. If the rotating field is incorrect , an error mess age is display ed via an LED as follows: "in correct phase

rotation direction" or "phase loss". In this case, two phases connected to the braking unit must be inverted.

• Connect the ground of the power supply cables to the ground connection screw on the braking unit.

• The DC bus wires used to connect the drive and brak ing uni t must be connect ed to the DC fuse carrier. It is essen tial to compl y with th e

correct polarities.

The inversion of the + (PLUS) and the - (MINUS) will prevent correct operation of the braking unit.

1757361 11/2010 23

Page 24

Connection diagrams, fuses and associated cables

See Fan power supply page 25

Wiring diagram

L1

L2

L3

N

PE

1

3

2

4

1

3

2

4

(3) (3) (3)

S/L2

R/L1

5

6

5

6

(1)

F2

F3

F4

(2)

A2

L1L2L3

R1B

T/L3

R1A

R1C

R2A

R2C

PA/+

PC/–

+

–

Q1

KM1

A1

ATV 71Hppppp

L1

N

F1

N

L1

PE

W/T3

U/T1

V/T2

V1

U1

W1

M

3

LI1

+ 24

X2

1

2

3

4

Components for use with the unit (for a complete list of references, see our “Motor starter solutions. Power control and protection

components” specialist catalogue).

Ref. Description

A1 ATV 71 drive

A2 Network braking unit

F1 2 A fuse, a 230 V

F2…F4 For the fuses, refer to the reference tables on page 15

Q1 Residual curren t circuit breaker 300 mA. Provides protection against earth leakage faults.

(1) Optional additional EMC input filter

(2) Line reactor recommended

(3) For ATV 71HC40N4 drives combined with a 400 kW motor and ATV 71HC50N4, see the drive Installation Manual.

24 1757361 11/2010

Page 25

Connection diagrams, fuses and associated cables

Size of DC bus fuses (F1, F2, F3) depending on the drive rating

Fast-acting semi-conductor

For drives

ATV 71H037M3…HU15M3 25

ATV 71HU22M3…HU40M3 50

ATV 71HU55M3, HU75M3 100

ATV 71HD11M3X…HD18M3X 160

ATV 71HD22M3X, HD30M3X 250

ATV 71HD37M3X, HD45M3X 350

ATV 71HD55M3X 500

ATV 71HD75M3X 630

ATV 71H075N4…HU22N4 25

ATV 71H075N4…HU40N4 50

ATV 71HU55N4…HD11N4 80

ATV 71HD15N4…HD22N4 100

ATV 71HD30N4, HD37N4 160

ATV 71HD45N4 200

ATV 71HD55N4 250

ATV 71HD75N4 350

ATV 71HD90N4 315

ATV 71HC11N4, HC13N4 400

ATV 71HC16N4 500

ATV 71HC20N4 630

ATV 71HC25N4, HC28N4 800

ATV 71HC31N4 1000

ATV 71HC40N4, HC50N4 1250

(1) Nominal voltage of fast-acting semi-conductor fuse

fuses (1)

A

Line voltage

a VV

230 690

400 690

440 800

460 800

480 800

Nominal voltage of fast-acting

semi-conductor fuse

Fan power supply

Braking units (except for VW3A7201... 205, VW3A7231 and VW3A7232) have two terminals (blue terminal = neutral [N ], grey fuse terminal

= phase [L]) for supplying internal fan(s) (VW3A7206...7212 : 230 Vac, VW3A7233...7241 : 115 Vac). The fuse inside the fuse terminal is

installed in order to protect the internal wiring and is the following type: 2 A, 500 V, size: 5*30 mm

Control cable

Connect the control cable to the X2 terminals on the braking unit control panel.

Do not place the control cables near the power supply cables as the power supply cables cause interf erence.

Connect the shielding of the control cables with the metal connector on the guide, over as large an area as possible.

Control functions

The control terminals are on the braking unit control card and are indicated by X2. These terminals can be removed easily using a simple

operation. (see diagram “Use of the terminals”, page27

The control card must always be configured for the voltage of the line supply.

The contacts of the fault relay on the X2 terminals can be connected to the outside. It is also possible to perform an external reset or

switching functions by connecting them to the drive or the PLC.

)

1757361 11/2010 25

Page 26

Connection diagrams, fuses and associated cables

!" #

$!

!

%%

&

' ()*

+ ()*

+ ,-&.$*

% %*

!# %

/ %

Layout of the control panel

26 1757361 11/2010

Page 27

Connection diagrams, fuses and associated cables

12

X2

General error relay

Terminals 5 and 6

connected internally to

temperature supervision

External OFF

External

ON/RESET

ON/RESET

Use of the terminals

1

2

3

4

5

6

7

8

9

10

11

Terminals 1 to 4 (refer to the diagram above)

These terminals are connected to two volt-free relays (one is normally open, the other is normally closed) with a maximum load current of

5AAC or 3ADC.

Maximum voltage V DC, V AC.

The relay is shown in open position in the above diagram.

The relay closes if:

1 The line supply is OK

2 There is no fault

and possibly after an ON/RESET pulse.

After an OFF pulse, a general fault is displayed while the relay opens.

Terminals 5 and 6

These terminals are already used for supervision of the i nternal temperature of the heatsink.

Terminals 7 and 8

(use shielded cables only, maximum length: 1.5 m)

OFF signal

These terminals can be used for an external OFF signal (normally open contact) to stop the braking unit.

The OFF signal stops the braking immediately. If this is performed in generator mode, the drive trips immediately afterwards,

due to the excessively high voltage of the DC bus.

+

-

Terminals 9 and 10

(use shielded cables only, maximum length 1.5 m)

ON / RESET signal

These connections can be used for an external ON signal (normally open contact) to start/reinitialize the braking unit.

CAUTION

RISKS OF INTERFERENCE

Do not use external voltage in the co nnecti ons of t erminals 5 to 10: unexpe cted action s

and damage can occur.

Failure to follow these precautions can result in equipment damage.

Terminals 11 and 12

(use shielded cables only )

These connections can be used for an external ON si gnal (external volt age of 12- 24 V DC, for example from a PLC, short duration pulse)

to start or reinitialize the braking unit.

(Connect the "Plus" to terminal 11 and the "Minus" to terminal 12)

1757361 11/2010 27

Page 28

Operation on a neutral IT (isolated or impedance grounded neutral) system

Types of electrical network and their main characteristics

Comply with the restrictions relating to each type of network.

If you want to use braking units on types of network that are not listed in the table below, please contact our technical experts.

Network type Use of the braking unit Note

Star connection with

grounded neutral

Star connection with

isolated or impedance

grounded neutral

With grounded active

neutral

Specification of the cables used

• The cables used must comply with the specifications for the site (for example UL or UL-c)

• The restrictions concerning the minimum cross-section of the grounding cables must be adhered to!

• The efficiency of a shielded cable is dependent on:

- A correctly shielded connection

- The quality of the connection of the shielding

- Low impedance of the shielding (only use tinned copper or nickel-plated copper shielding!).

Permitted Comply with the technical

data for the unit

Permitted after consultation

with the manufacturer and

possible modification of the

unit

Permitted after checking

with the manufacturer

28 1757361 11/2010

Page 29

Electromagnetic compatibility and wiring

To install a braking unit in an EC approved control system, the following measures and warnings must be taken into account:

General • The user is responsible for compliance of the application with EC directives.

• Connect the braking unit and the EMC filter to the grounded mounting plate with a cable whose cross-section is as

large as possible:

Assembly

- Mounting plates with conductive surfaces (coated zinc or stainless steel) provide a permanent contact .

- Varnished cards must not be used for installations that are to comply with EMC standards.

• If you use several mounting plates:

- Connect as large an area as possible of the mounting plate (for example with copper strips).

• Check that the power supply cables and control cables are separated.

Filters

Shielding

Grounding

Braking units are electrical units for use in industrial and commercial equipment. In accordance with the EMC directive, 2004/108/EC, it is

not compulsory to mark these braking units, although in the sense of the directive and the EMC law these components are designed for

installation by an electromechanical engineer and cannot be used autonomously. Compliance with the protection objectives of the EMC

directive must be proved by the installer or the user of the machine or the equipment. If EMC filters provid ed by Schneider-Electric are used,

and if the conditions below and the installation directives are followed, then the compliance of the measures is assured.

Conditions

The braking unit, combined with the connected EMC filters, has been designed for use under the conditions defined by class "A" ("B" on

request).

Definition conforming to the basic standards:

• EN50081-2 for emission

• EN50082-2 for immunity

• Use the EMC filters that are assigned to the braking unit. EMC filters reduce high frequency interference from a

prohibited value to a permitted value.

• Metal cable connectors provide a connection between the shielding and the unit over a large area.

• If there are breaks in the shielding at all the ends in the cable route:

- Connect the cable shielding to the mounting plate over a large area

• If the power supply cables between the EMC filter and the braking unit are longer than 300 mm:

- Use shielded power supply cables

- Connect the shielding directly to the drive/braking unit mounting plate and to the EMC filter mounting plate.

• Shield the control cables:

- Connect the shielding to their terminals via the shortest possible route.

• All metal parts (braking unit, drive, EMC filter) must be connected to a common grou nd (PE).

• Comply with the minimum cable cross-sections defined in the safety directives:

- From an EMC point of view, it is the area of the cable and the contact with the mounting plate that is important for

operation, rather than the cable cross-section.

:

1757361 11/2010 29

Page 30

Electromagnetic compatibility and wiring

Connected protective cable

Busbar connected to the

mounting plate over a large area

Mounting plate

Ground attachment

Power supply cable

Connection of RFI filter to

mounting plate over a large area

Equalization of the potential

to the building ground

Filtered cable to drive

Installation

To avoid coupling interference, the following cables must be at least 15 cm apart:

a) Network/power supply cables

b) Motor and drive cables

c) Control and data cables (low voltage range < 48 V)

To obtain a low impedance HF connection, the grounding cables, the shielding and other metal connections (for example: mounting plate/

mounted units) must be made using as large an area as possible with the metal conductive part. Use grounding cables and a grounding

network with as large a cross-section as possible (minimum 10 mm2) or metal strips.

Use shielded copper or tinned copper cables. Shielded s te el cabl es a re not su itabl e f or h igh fre quenc y ap plic atio ns. Connect th e shielding

using metal clips or connectors to the grounding connections. Do not extend the shielding with a single wire!

If external EMC filters are used, they must be installed no more than 30 cm away from the noise source, and must have low impedance

connections and contacts.

Relays, magnetic contactors, etc, must always be fitted with varistors, RC circuits or diode filters.

All connections must be as short as possible and must be positioned as close as possible to the ground. Unconnected wires act like

antennae.

Avoid current loops in all cables. Connect unused cables to the ground at both ends.

If unshielded cables are used, twist the pairs to attenuate the non asymmetric noise.

Connection of an EMC filter

30 1757361 11/2010

Page 31

Electromagnetic compatibility and wiring

8

3

6

Design of EMC compliant enclosure

1

7

14

14

12

15

2

5

6

1 Enclosure

2 Wiring betwe en th e EM C filter and the drive

3 EMC filter

4 Line supply cable

5 Wiring betwe en th e EM C filter and the braking unit: cable cross-section conforming to the short circuit protection

6 Motor wiring

7 Control wiring

8 Wiring from the DC bus to the braking unit (DC)

9 Common central point mounting plate (Star connection)

10 Equipotential link

11 Additional grounding cable

12 Braking unit

13 Connection to the power supply

14 PLC

15 Drive

16 Power supply fuses

17 Magnetic power supply switch

9 10

16

7

11

9

17

4

13

4

1757361 11/2010 31

Page 32

Electromagnetic compatibility and wiring

Comments

A system is generally divided into one zone for the power electronics and one zone for the control electronics. This is important, whether

the system is installed in one enclosure or spread over several enclosures. It is recommended that a shielding screen is fitted, due to the

high noise emission of the power supply cables. This screen must have a low contact resistance with the frame or the mounting

plate (remove the varnish!).

The installed braking unit and the connected EMC filter must form one unit, that is, they must be connected via a mounting plate with no

insulating varnish.

The connection between the braking unit and the EMC filt er must be shield ed. The shielding must be connected to ground at each e nd. The

cable must not exceed 300 mm.

The braking unit mounting plate must be the connection point for the grounding and the shielding of the machine or the equipment. If the

drive or another component of the equipment cause s interf erence, th e HF connecti on of thi s component will be poor. It can b e improved by

an additional grounding network.

The leakage currents increase when EMC filters are used. When the leakage cu rrent is greater th an 3.5 mA, one of the following conditions

must be met:

- Copper protective cable whose cross-section is greater than 10 mm

- Supervision of the protective cable by a module that trips in the event of a fault.

- Second cable connected in parallel with the protective cabl e via separate terminals. This cable must be VDE0100 / part 540 compliant.

Installation of the control cables

2

The shielding of the digital signal cables, which are connected to the terminals, must be connected to the shielding strips or directly to the

grounded plate, in order to reduce the impedance.

The shielding of the digital signal cables, which are connected to the terminals, must be connected over as large a surface area as possible.

If the screen is grounded via a single wire, there is a 70% increase in the noise.

Commercially available cable clips are suitable for connecting the shielding.

If unshielded signal cables are used, use twisted pairs only.

32 1757361 11/2010

Page 33

Starting tests

CAUTION

RISKS OF INTERFERENCE

• Check the wiring of the braking unit (short circuits and ground faults) before it is

turned on for the first time

• If the wiring is not correct, unexpected operation of the dri ve and/or t he braking unit

is possible.

Failure to follow these precautions can result in equipment damage.

Initial power-up

• Step 1: Connect the line supply.

- The braking unit is ready to operate after approximately 1 s.

• Step 2: Check that the braking unit is ready to be used.

- If the green LED only is on, the braking unit is ready to be used.

- If all the other LEDs are also on, as well as the green LED, there is interference. Eliminate the interference before starting up

(See section: “Troubleshooting”, page 36

• Step 3: Check that the drive is ready to be started up.

- Proceed in accordance with the drive manual.

).

1757361 11/2010 33

Page 34

Configuration

The configuration of the jumpers provides various control possibilities and different internal functions in accordance with the specific error

messages.

Various definitions resulting from the specific configuration possibilities of the jumpers are explained in the following parag raphs.

"Autostart"

Jumper J1 closed: Autostart.

Autostart means that the device starts automatically one second after being connected to the line supply ("automatic power-up").

Configuration of the jumpers, see the table below.

If the braking unit must not start up automatically , even if the phase control i s deactivat ed, terminals 7 and 8 must be linked unt il 4 seconds

after power-up. Then, to activate braking there must be a short pulse on the RESET input.

"Power-up" - "Stop"

"Stop" means that the control of the semi-conductors and the braking unit wi ll be int errupted. It is no longer possible to brak e the frequen cy

inverter with the braking unit.

"Power-up" is the activation of the control of the semi-conductors.

"Memorize"

The braking unit has a fault memo ry i n which speci al faul t s can be ass ign ed. Memorize d error me ssage s mu st be d ele ted u sing RESET or

by breaking the line supply. "Memorize" always results in a stop and tripping of the general fault relay.

"RESET"

When a fault has been deleted, if it was memorized, it must be reset to zero:

• Either by pressing the RESET button

• Or by disconnecting and reconnecting the line supply (three phase).

CAUTION

RISKS OF INTERFERENCE

Resetting to zero in the case of excessive DC bus voltage during generation is not

recommended. If this is performed, the power semi-conductors are exposed to

increased stress, which can result in accelerated aging.

Failure to follow this precaution can result in equipment damage.

"Phase loss"

Phase loss supervision monitors the 3 phases of the line supply.

If one phase fails, the braking unit continues to operate, but with reduced generated power.

The braking unit reacts in different ways when there is a phase loss. One possibility is "two phase operation". The other is to allow the

system to exit operation and the general fault relay indicates the fault.

Configuration using the jumpers, see the table below:

J3 J5 J6 J7 Phase loss supervision

⎯00 ⎯ Sensitive, fault memory ON

⎯⎯⎯⎯Not sensitive, fault memory ON

0XX⎯ Stop, fault memory ON

0 X X 0 Sto p , fault memory OFF

0 Jumper open

⎯ Jumper closed

X Jumper in either position

Note: Fault memory "ON" means that the "phase loss" fault is indicated by an LED until it is cl eared, if the fault no lon ger exists . Fault

memory "OFF" means that the "phase loss" fault is indicated by an LED only as long as the fault exists.

34 1757361 11/2010

Page 35

Configuration

RISKS OF INTERFERENCE

• Jumper J3 can only be removed after the frequ ency i nverter o r t he braki ng uni t has

been turned off if the line supply has been cut-off by opening the series switches

(contactors, line supply switch, etc).

• To avoid a dangerous voltage rise in the devices located in the section that is not

powered up: power generation must be stopped.

• Jumper J3 must always be removed before removing jumper J7. I f not, if phase loss

supervision is active, the "phase loss" fault rema ins di splayed as long as it exist s (it

is not memorized in the fault memory).

Failure to follow these precautions can result in equipment damage.

"Overvoltage supervision"

CAUTION

The braking module has overvoltage supervision for the line supply, which stops the device if the voltage level is greater than 1.15 x UN.

Fault code 3 will be shown as the error message (See the "LED messages", “Troubleshooting”, page 36

loss and overvoltage error messages you can deactivate phase loss supervision by removing jumper 3 from the con trol card. If, after doing

so, there is a stop with indication via the red and yellow LEDs (fault code 3), this will then be due to an overvoltage.

J3 J5 J6 J7 J8 LED message Assessment (overvoltage)

_ X X _ _ Green 1.Red Yellow Overvoltage and/or phase loss/switching fault

_ X X 0 _ Green _ Yellow Overvoltage

0 X X _ _ Green 1.Red Yellow Overvoltage and/or phase loss/switching fault

0 X X 0 _ Green _ Yellow Overvoltage

0 X X 0 _ Green 1.Red Yellow Constant phase loss

0 Jumper open

⎯ Jumper closed

X Jumper in either position

Standard adjustment of the device:

Autostart and no stop in the case of phase loss

). To differentiate between phase

1757361 11/2010 35

Page 36

Troubleshooting

The 4 LEDs on the cover of the braking unit display the operating conditions. For simplified display during operation and the first time the

unit is turned on, similar LEDs are pl aced on the control card. The orange and green LEDs are separate on the control card, while there is

a two-color LED (green/orange) on the cover.

CAUTION

RISKS OF INTERFERENCE

If the braking unit trips during a slow-down, it must not be reset to zero before the end

of the slow-down, or before the DC bus voltage has fallen to a normal value.

To avoid any problems, you can block the release of the inverter pulse by connecting

the general fault relay contact on the braking unit to the corresponding connection on

the frequency inverter.

Failure to follow these precautions can result in equipment damage.

Tripping on VCE:

The braking unit trips via the VCE protection circui t, if the specific maximum current of the d evice is exceeded. The principle o f this protection

circuit means that for a short time (less than a millisecond), the IGBT is subjected to stress beyond its specifications for normal operation.

In an exceptional case this is no problem for the braking unit. However, if there are frequent or periodic current surges at braking voltage,

the high power semi-conductors will age rapidly and become prematurely faulty.

The cause of periodic tripping on VCE may be an overload, a fall in line voltage, an oscillating or faulty dri v e, an oscillating input reference

or poor design of the equipment.

LED messages

LED display Assessment

LED display

fault code

1 X Ready to operate System in operation

2 X Ready to operate, but no power generated ⇒ check the DC fuse

3 X X X Heatsink overheating ⇒ error message

4 X X Fault code 3 ⇒ the heatsink temperature

5 X X The system has stopped, (external OFF) ⇒

6 X X An overvoltage has been detected (J8 closed) => a reset to zero is required when the grid

7 X X X Incorrect phase rotation direction or a phase

8 X X X Overcurrent detected => reset required

9 X X X X Faults 7 and 8 Overcurrent and phase loss detected

10 X X X X X Several faults have been detected

11 System stopped, at least 2 phases missing System stopped, at least 2 phases

12 X X Trip-I2t => reset required

13 X X Voltage drop during switching but no trip,

OperationPhase

green red red orange yellow

loss

VCE OverheatingFault First start (after approx. 1 s) During operation

reset to zero required

voltage falls to its nominal value

missing.

simultaneously

cannot be reset to zero while overheating

continues

has fallen to normal and the fault can be

reset to zero

The system has stopped, (external OFF)

⇒ reset to zero required

Phase loss detected => reset required

simultaneously

Several faults have been detected

simultaneously

missing

while jumpers 3 and 7 are open (See the

“Configuration”, page

possible, improvement of the line voltage

recommended.

34) => operation

36 1757361 11/2010

Page 37

1757361 11/2010 37

Page 38

AT V71_regen_units_EN_1757361_03

1757361 11/2010

Loading...

Loading...