Scheidt and Bachmann NVP User Manual

Fare collection systems

Customer Documentation

State: December 2017

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Edit: Stevens |

-----Art.#.: 86 |

, Ver. 1.06 |

Date:13.12.2017 |

|

This manual, including all of its component parts, is copyright protected. Scheidt & Bachmann GmbH reserves all rights to its contents. Any use not expressly approved by copyright law is subject to prior approval by Scheidt & Bachmann GmbH. This applies particularly to copying, processing, translations and microfilming, as well as to storage and data processing in any electronic systems.

All contents of this manual shall be treated confidentially and shall not be transferred to any third party, either for their own commercial use or for any other client.

Since all information and facts are subject to technical changes, any liability for the data contained is hereby disclaimed. Modifications of technical details, in terms of information and illustrations are reserved. Make sure to follow the updating index. Scheidt & Bachmann GmbH cannot be held responsible for direct damage and/or possible consequential damage due to misuse by the customer or by third parties, unless the Product Liability Act (ProdHaftG) is concerned. In no event shall Scheidt & Bachmann GmbH be liable for any damage out of or in connection with the provision of the manual.

© 2017 Scheidt & Bachmann GmbH, Fare collection system (FCS)

Breite Straße 132 41238 Mönchengladbach

www.scheidt-bachmann.com

Subject to change.

History

Version |

Date |

Change |

Edit |

|

|

|

|

1.00 |

01.12.2016 |

Start Version |

Stevens |

|

|

|

|

1.01 |

31.03.2017 |

Reduced the contents of the manual to |

Stevens |

|

|

OV|41 relevant topics |

|

|

|

|

|

1.02 |

03.04.2017 |

Changes made according to specifications |

Stevens |

|

|

from the design department |

|

|

|

|

|

1.03 |

05.07.2017 |

Information on radio frequencies added |

Stevens |

|

|

|

|

1.04 |

21.08.2017 |

Changes made according to specifications |

Stevens |

|

|

from the design department (C.Gerspacher) |

|

|

|

|

|

1.05 |

15.09.2017 |

Changes made according to specifications |

Stevens |

|

|

from the design department (N.Huendgen.) |

|

|

|

|

|

1.06 |

13.12.2017 |

Changes made according to specifications |

Stevens |

|

|

from the design department |

|

|

|

(N. Huendgen. and I. Izler) |

|

|

|

|

|

Table 1-1

Edit: Stevens |

Art.#.: 86 ----- |

, Ver. 1.06 |

Date:13.12.2017 |

Chapter 1 Introduction and Safety Considerations

1.1 |

Overview ................................................................................................ |

1-7 |

1.2 |

Manual Organization............................................................................. |

1-7 |

1.3 |

Safety ..................................................................................................... |

1-8 |

1.4 |

General Safety Guide............................................................................ |

1-9 |

1.5 |

Protective Equipment ......................................................................... |

1-10 |

1.6 |

Special Tools ....................................................................................... |

1-10 |

1.7 |

Use of Symbols in Manual.................................................................. |

1-10 |

1.7.1 |

Warning Symbol ..................................................................................................... |

1-10 |

1.7.2 |

Caution Symbol ...................................................................................................... |

1-10 |

1.7.3 |

Information Symbol................................................................................................ |

1-10 |

1.7.4 |

Example Symbol..................................................................................................... |

1-10 |

1.7.5 |

Finger Tip Maintenance Symbol ........................................................................... |

1-11 |

1.7.6 |

Tools Symbol.......................................................................................................... |

1-11 |

1.7.7 |

Electrical Hazard Symbol....................................................................................... |

1-11 |

1.7.8 |

Electrostatic Discharge Symbol............................................................................ |

1-11 |

1.7.9 |

Hot Hazard Symbol................................................................................................. |

1-12 |

1.7.10 |

Maintenance Cycle Symbol ................................................................................... |

1-12 |

1.8 |

Device Safety Labels .......................................................................... |

1-12 |

1.8.1 |

Labels On the OV|41............................................................................................... |

1-13 |

1.8.1.1 |

Label Locations .............................................................................................. |

1-13 |

1.8.1.2 |

CE Label......................................................................................................... |

1-14 |

1.8.1.3 |

FCC License Label......................................................................................... |

1-14 |

1.8.1.4 |

TÜV SÜD NRTL Label ................................................................................... |

1-14 |

Chapter 2 Glossary |

|

|

2.1 |

Glossary of Terms and Abbreviations .............................................. |

2-15 |

Chapter 3 Declaration of Conformity |

|

|

3.1 |

Europe.................................................................................................. |

3-27 |

3.2 |

USA/CANADA ...................................................................................... |

3-28 |

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Date:13.12.2017 |

|

1-3 |

|

|

|

|

|

|

|

|

|

|

Chapter 4 Troubleshooting and Module Removal

4.1 |

Troubleshooting Overview.................................................................. |

4-31 |

4.1.1 |

Out of Service ......................................................................................................... |

4-31 |

4.2 |

Error Identification............................................................................... |

4-32 |

4.2.1 |

Blocked Card .......................................................................................................... |

4-37 |

4.2.2 |

Card Error ............................................................................................................... |

4-38 |

4.2.3 |

Recovery Scenarios ............................................................................................... |

4-45 |

4.2.3.1 |

Recovery Scenario 1...................................................................................... |

4-45 |

4.2.3.2 |

Recovery Scenario 2...................................................................................... |

4-46 |

4.3 |

Verifying Software Versions ............................................................... |

4-47 |

4.4 |

Tools and Consumables ..................................................................... |

4-47 |

Chapter 5 Preventive Maintenance |

|

|

5.1 |

General Maintenance and Cleaning ................................................... |

5-49 |

5.2 |

Preventive Maintenance Schedule Summary.................................... |

5-50 |

5.3 |

Materials and Replacement Parts....................................................... |

5-50 |

Chapter 6 OV|41 Installation |

|

|

6.1 |

Overview ............................................................................................... |

6-51 |

6.2 |

Hardware............................................................................................... |

6-51 |

6.3 |

Dimension and Weight ........................................................................ |

6-51 |

6.4 |

Power Requirements ........................................................................... |

6-51 |

6.5 |

Operating Features .............................................................................. |

6-54 |

6.5.1 |

OV|41 Mounting and Environmental Considerations ......................................... |

6-54 |

6.6 |

Installation Requirements ................................................................... |

6-55 |

6.6.1 |

Materials.................................................................................................................. |

6-55 |

6.6.2 |

Standard Tools ....................................................................................................... |

6-55 |

6.6.3 |

Special Tools .......................................................................................................... |

6-55 |

6.7 |

Needs and Requirements for OV|41 Installation............................... |

6-55 |

6.8 |

Installation ............................................................................................ |

6-56 |

6.9 |

Post-Installation Checklist .................................................................. |

6-62 |

6.10 |

Disassembly and Removal.................................................................. |

6-62 |

1-4 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Date:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

Chapter 7 OV|41 Initialization

7.1 |

Initialization ......................................................................................... |

7-63 |

7.1.1 |

Initialize OV|41 With New System Software......................................................... |

7-63 |

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Date:13.12.2017 |

|

1-5 |

|

|

|

|

|

|

|

|

|

|

1-6 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Date:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

Chapter 1 Introduction and Safety Considerations

1.1 Overview

1.2Manual Organization

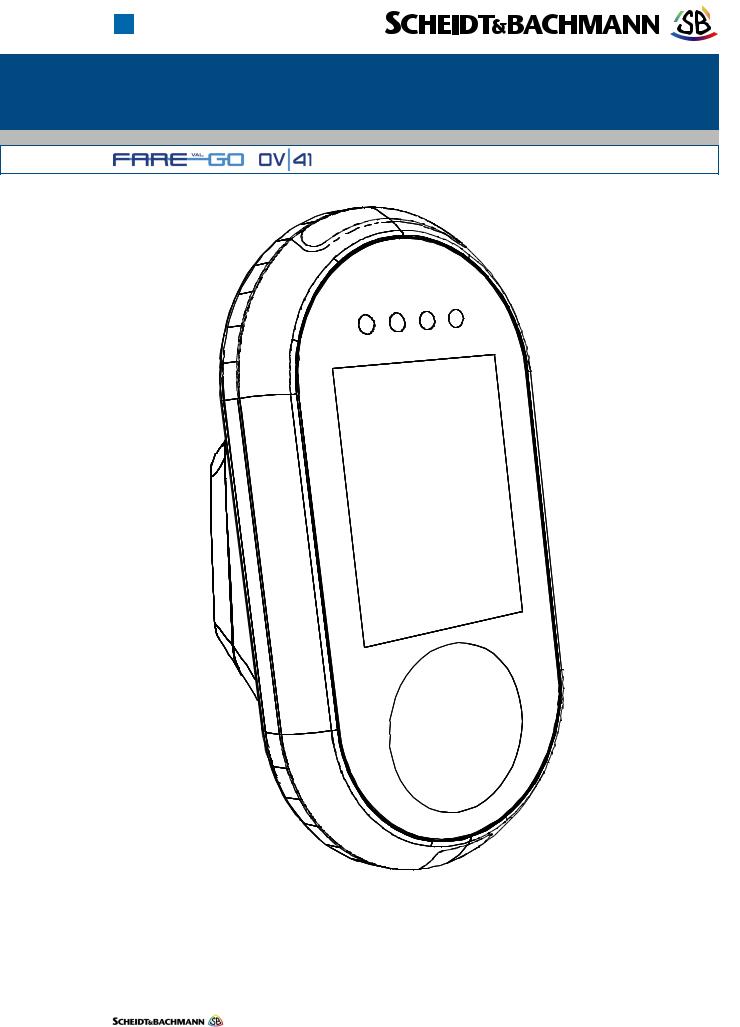

The OV|41 (On-Board Validator 41) Repair and Maintenance Manual provides complete, detailed instructions for operating, maintaining, and troubleshooting the OV|41. Comprehensive charts, tables, graphs, and other diagrams provide a technical document that is easy to use and understand.

Full documentation that would be needed by maintenance personnel is available through Scheidt & Bachmann. The manual assumes that comprehensive repair procedures will be performed by fully trained contractor technicians.

This manual reflects Scheidt & Bachmann’s commitment to providing our customers with comprehensive technical documentation, along with training guidelines to augment our customer training program.

The organizational structure of the OV|41 Repair and Maintenance Manual is outlined below.

Chapter 1 – Introduction

Chapter 2 – Glossary

Chapter 3 – Declaration of Conformity

Chapter 4 – Troubleshooting and Module Removal

Chapter 5 – Preventive Maintenance

Chapter 6 – OV|41 Installation

Chapter 7 – OV|41 Initialization

PLEASE READ THIS MANUAL AND ALL REFERENCED DOCUMENTS CAREFULLY BEFORE ATTEMPTING TO INSTALL THIS AFC EQUIPMENT. FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND THE INSTRUCTIONS OR NOTES IN THE INSTALLATION DRAWINGS MAY CAUSE INJURY TO YOURSELF OR DAMAGE TO THE EQUIPMENT AND MAY ULTIMATELY COMPROMISE THE OPERABILITY OF THE EQUIPMENT!

All Automated Fare Collection (AFC) equipment is TÜV-SÜD-NRTL listed. To continue to be compliant with TÜV-SÜD-NRTL requirements, please note that the following items need to be performed during installation:

The equipment will remain TÜV-SÜD-NRTL compliant only if the mounting and wiring are also TÜV-SÜD-NRTL compliant. Please take great care during installation to comply with TÜV-SÜD-NRTL and NEC requirements.

When measuring for position, always use the center of the device as the reference point.

Ensure compliance with all Safety Regulations and Safety Recommendations.

Although this manual has been prepared with great care, some information may seem unclear. If so, please feel free to contact us with your remarks or questions.

Scheidt & Bachmann GmbH

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

1-7 |

|

|

|

|

|

|

|

|

|

|

DISCLAIMER

1.3 Safety

Scheidt & Bachmann GmbH IS NOT LIABLE FOR INJURIES TO ANY PERSON OR DAMAGE TO THE EQUIPMENT RESULTING FROM FAILURE TO COMPLY WITH THE MANUFACTURER’S INSTRUCTIONS OR DOCUMENTATION. THIS DISCLAIMER INCLUDES ALL THIRD PARTY DOCUMENTATION PREPARED BY OEMS AND PROVIDED AS A COURTESY BY Scheidt & Bachmann GmbH. TO ITS CUSTOMERS.

This section describes safety requirements for technicians who perform maintenance or repair procedures for all AFC Systems. Information provided in this chapter also includes a description of safety warnings and precautions.

PLEASE READ THIS MANUAL AND ALL REFERENCED DOCUMENTS CAREFULLY BEFORE ATTEMPTING TO WORK WITH THIS EQUIPMENT. FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS ENTIRE MANUAL MAY CAUSE INJURY TO YOURSELF OR DAMAGE TO THE EQUIPMENT AND MAY ULTIMATELY COMPROMISE THE OPERABILITY OF THE EQUIPMENT!

DISCLAIMER

|

Scheidt & Bachmann GmbH IS NOT LIABLE FOR INJURIES TO ANY |

|

PERSON OR DAMAGE TO THE EQUIPMENT RESULTING FROM FAILURE |

|

TO COMPLY WITH THE MANUFACTURER’S INSTRUCTIONS OR |

|

DOCUMENTATION. THIS DISCLAIMER INCLUDES ALL THIRD PARTY |

|

DOCUMENTATION PREPARED BY OEMS AND PROVIDED AS A |

|

COURTESY BY Scheidt & Bachmann GmbH TO ITS CUSTOMERS. |

|

FAILURE TO FOLLOW MANUFACTURER’S INSTRUCTIONS MAY |

|

INVALIDATE ANY OR ALL WARRANTIES, EXPRESS OR IMPLIED. |

NOTE: |

NOT ALL OF THESE WARNING LABELS OR HAZARDS MAY EXIST IN ALL |

|

AFC DEVICES. ONLY THOSE LABELS THAT APPLY TO THE OV|41, AND |

|

ARE REQUIRED TO MEET TÜV-SÜD-NRTL CERTIFICATION REQUIRE- |

|

MENTS, WILL BE FOUND IN THE OV|41. BE CAUTIOUS AND OBSERVANT, |

|

AND LOOK FOR SUCH WARNING LABELS AND POTENTIAL HAZARDS. |

|

ANY TECHNICIAN OR PERSON ACCESSING THE INTERIOR OF ANY AFC |

|

DEVICE SHOULD USE COMMON SENSE AND EXERCISE EXTREME CAU- |

|

TION. |

|

Safety Features |

|

Safety engineering is an integral part of Scheidt & Bachmann’s designs. Mainte- |

|

nance technicians must perform maintenance and repair in accordance with |

|

industry safety standards including MSHA, OSHA, and other Federal, State, and |

|

Local codes and regulations. |

|

Close attention to proper safety precautions is of the utmost importance. Com- |

|

ponents should be installed, maintained, and repaired only by trained, qualified |

|

personnel using reasonable care. Improper installation, maintenance, or repair |

|

procedures may damage the device or cause serious personal injury or death. |

|

The following pages provide detailed information on safety precautions that |

|

must be observed when working on AFC Systems. This information should be |

|

carefully read and thoroughly understood before performing routine mainte- |

|

nance or attempting to troubleshoot or repair the device. |

1-8 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

1.4General Safety Guide

It is the responsibility of the maintenance agency to ensure that the safety instructions in this manual are read, understood, and implemented by properly trained maintenance and service technicians. All other persons who work with the internal systems of any AFC systems should also be trained in safety.

This chapter provides the technician with the safety information necessary to avoid personal injury or equipment damage. Only qualified, trained technicians using reasonable care should perform maintenance or repair. As with any mechanical system, the AFC components can pose certain safety hazards. The following guidelines must be followed when working on the mechanical systems of any AFC Systems or Components.

Only competent, qualified technicians trained by Scheidt & Bachmann should service this device.

Service technicians must read and understand all operating and service instructions.

Turn electrical power off before opening any electrical enclosure.

Do not operate the device with the cover of any enclosure, or the guard or covers over any mechanism, removed.

Due consideration should be given to any safety regulation applicable to the particular location in which the device is operating.

Do not turn on power to the device when components are disconnected.

The device must not be used for any purpose other than that for which it was designed and approved by Scheidt & Bachmann.

When servicing or repairing the device, all device control panels must be tagged in compliance with OSHA Lockout/Tag out procedures to indicate that the device should not be operated.

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

1-9 |

|

|

|

|

|

|

|

|

|

|

1.5Protective Equipment

1.6Special Tools

The technician should use care when working with solvents and other cleaning agents that may be abrasive or have a tendency to cause irritation to the skin or eyes. Read all labels carefully and follow instructions for the use of gloves when working with chemical fluids.

When using cleaning agents such as fluids or pressurized air, safety glasses must be worn to prevent eye damage.

There are no special tools required to ensure the safety of the service technician. However, ESD (Electrostatic Discharge: see paragraph 1.7.8) protection is required for all procedures involving contact with electrostatic sensitive printed circuit boards. The use of a standard ESD Safety Wrist Strap is required when working with electrostatic sensitive printed circuit boards.

1.7Use of Symbols in Manual

1.7.1Warning Symbol

Symbols for cautions and warnings are used frequently throughout this manual. Each symbol appears on the left side of the page with the associated text printed to the right.

There are several different types of symbols that indicate varying levels of safety hazards. Detailed information on each symbol is provide in this chapter.

It is vital that the technician understand and follow all safety warnings, cautions and information guidelines when working on AFC Systems.

The Warning Symbol indicates a potential for serious damage to the equipment or serious injury to the maintenance or service technician. Extreme care should be used when performing procedures that are preceded by this symbol.

This symbol indicates a WARNING. A detailed description of the particular hazard will appear next to the symbol in bold, italic print.

1.7.2Caution Symbol The Caution Symbol indicates a potential for damage to a particular part or func-

tion of the device. Reasonable care should be used when performing procedures preceded by this symbol.

This symbol indicates a CAUTION. A detailed description of the particular hazard will appear next to the symbol in bold, italic print.

1.7.3Information The Information Symbol indicates special information that could be important for

Symbol |

protecting a particular part or function of the device. Reasonable care should be |

|

used when performing procedures that are preceded by this symbol. |

|

This symbol indicates that more INFORMATION follows. A detailed |

|

description of the particular hazard will appear next to the symbol in bold, |

|

italic print. |

1.7.4 Example |

The Example Symbol precedes an example of a function. The text or illustration |

Symbol |

explains one possible function. This explanation applies to all other functions of |

|

the same kind. |

1-10 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

This symbol indicates that an EXAMPLE follows.

1.7.5Finger Tip The Finger Tip Symbol indicates that no tools are required to perform the task Maintenance described. Reasonable care should be used when performing procedures that

Symbol |

are preceded by this symbol. |

|

This symbol indicates a FINGER TIP MAINTENANCE action. A step-by- |

|

step description of the task will appear next to the symbol in bold, italic |

|

print. |

1.7.6Tools Symbol The Tools Symbol indicates that tools are required to perform the task

|

described. Reasonable care should be used when performing procedures that |

|

are preceded by this symbol. |

|

This symbol indicates a TOOL is required to perform the task described in |

|

the text. |

1.7.7 Electrical |

The Electrical Hazard Symbol indicates the potential for serious damage to the |

Hazard Symbol |

device caused by electrical voltage surges or serious injury to the service tech- |

|

nician caused by electrical shock. Extreme care should be used when perform- |

|

ing procedures preceded by this symbol. |

|

This symbol indicates possibility of ELECTRICAL HAZARD. A detailed |

|

description of the particular hazard will appear next to the symbol in bold, |

|

italic print. |

1.7.8Electrostatic The Electrostatic Discharge Symbol indicates the potential for serious damage Discharge to the printed circuit boards or other Electrostatic Discharge (ESD) sensitive

Symbol |

devices in the device. Extreme care should be used when performing proce- |

|

dures preceded by this symbol. The technician should wear a grounding strap |

|

and use the proper techniques associated with handling printed circuit boards or |

|

other ESD sensitive devices. |

|

This symbol indicates an ESD HAZARD. A detailed description of the |

|

particular hazard will appear next to the symbol in bold, italic print. |

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

1-11 |

|

|

|

|

|

|

|

|

|

|

1.7.9Hot Hazard The Hot Hazard Symbol indicates the danger for serious burns caused by sur-

Symbol |

faces within the device that may be extremely HOT to the touch. Hot surfaces |

|

can cause serious injury to the service technician. Extreme care should be used |

|

when performing procedures preceded by this symbol. |

|

This symbol indicates a RISK OF BURNS. A detailed description of the |

|

particular hazard will appear next to the symbol in bold, italic print. |

1.7.10Maintenance The maintenance cycle symbol indicates the required maintenance cycles Cycle Symbol described in the subsequent part of the manual. An example is shown below.

Time is indicated by month or by quantities of coins or tickets.

1.8Device Safety Labels

Preventive maintenance cycle: Every 3 months

The typical AFC device has safety labels on some internal components to alert service technicians and other personnel that a safety hazard may exist when working on certain device subassemblies. Not all safety labels may apply to service operations on every subassemblies.

A series of different labels is used within the device. The following paragraphs describe these labels and note the location within the device where they will be found. It is important to read and understand this information thoroughly.

1-12 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

1.8.1Labels On the There are several labels used on the OV|41. These labels and their meanings

OV|41 |

are described below. |

|

1.8.1.1 Label |

The Labels shown in |

Figure 1-1 are found inside the device as shown. |

Locations |

|

|

TÜV-NRTL Label

CE Label

Serial Number Label

Figure 1-1 Label Locations

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

1-13 |

|

|

|

|

|

|

|

|

|

|

1.0.0.1Type Label The type label shown in Figure 1-2 appears at the back of the enclosure as

shown in Figure 1-1. This label indicates the voltage range, maximum amperes, year of manufacture, and manufacturing location as well as the name of the device and serial number.

Figure 1-2 The Type Label

1.8.1.2CE Label The CE label shown in Figure 1-3 appears on the backside of the device as

shown in Figure 1-1

Figure 1-3CE Label

1.8.1.3FCC License The FCC License label shown in Figure 1-4 appears on the backside of the

Label device.

HVIN: OV41

FCC ID: O5K-NVP

IC: 8312A-NVP

Figure 1-4FCC-License

1.8.1.4TÜV SÜD The TÜV-SÜD-NRTL label shown in Figure 1-4 appears on the backside of the

NRTL Label device as shown in Figure 1-1.

Figure 1-5FCC-License

1-14 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

Chapter 2 |

Glossary |

2.1Glossary of Terms and Abbreviations

Many terms and abbreviations are used to describe Fare Collection Equipment. Some are Automated Fare Collection (AFC) industry standard terms, some are application-specific, such as networking and telecommunications terms, and some are unique to the customer’s system.

A

A |

See “Ampere”. |

AC |

See “Alternating Current”. |

Access Level |

Individual users of a computer system have |

|

specific access rights that regulate what they |

|

can view or modify. Access rights are organized |

|

into groups, which are called Access Levels. |

ADA

Alarm Event

Alternating Current

See “Americans with Disabilities Act”.

An alarm event is generally defined as the unauthorized opening of an AFC device.

An electrical current that continuously changes polarity or direction of flow, usually 50 or 60 times per second

Americans with Disabilities |

The federal law mandating facility and equip- |

Act (ADA) |

ment accessibility requirements for persons |

|

with disabilities. |

Ampere |

A unit of measure of electrical current, the cur- |

|

rent produced by applying one volt to a circuit |

|

with a resistance of one ohm. |

ANSI |

American National Standards Institute |

Application Server |

NT-based server which runs the Central Data |

|

Collection System Application processes |

APTA |

American Public Transportation Association |

ASCII |

American Standard Code for Information Inter- |

|

change |

Audio Speaker |

A speaker that broadcasts messages in the lan- |

|

guage of choice with content similar to the mes- |

|

sage on the customer display. |

AWG |

American Wire Gauge, a measure of the cross |

|

section of a wire. |

B

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

2-15 |

|

|

|

|

|

|

|

|

|

|

Barcode |

A barcode is used to encrypt data into a series |

|

of vertical bars (universal product code [UPC]). |

|

It identifies various modules within an AFC |

|

device such as a ticket roll. |

Barcode Scanner |

The Barcode Scanner is a handheld scanner |

|

used to read barcodes (e.g. on replacement |

|

components). |

Bitmap |

Bit-oriented graphics |

Blower |

Also referred to as a “fan,” the blower cools the |

|

Central Processing Unit (CPU) in the ECU. |

Boot |

Loading of the operating system into the RAM |

Byte |

1 Byte = 8 Bit |

C |

|

Card |

A credit, debit, stored value, or “smart” card |

CDCS |

See “Central Data Collection and Information |

|

System”. |

Central Data Collection |

Centralized company file server that collects |

System (CDCS) |

and distributes operating and system fare col- |

|

lection data. The CDCS serves all connected |

|

machines and devices. |

Command |

Instruction to initiate a special transaction |

Command Codes |

See “Service Command”. |

CPU |

Central Processing Unit |

CRC |

Cyclic Redundancy Check. Check sum of the |

|

content of the file. |

Customer Display |

The Customer Display is a part of the user |

|

interface. In some devices, it may include a |

|

touch screen. |

Customer Specific Value |

A data field in which the customer is able to |

|

store individualized information. |

D |

|

Database |

A database is an accumulation of individual |

|

pieces of information that are related to each |

|

other. |

Database Server |

The Database Server is the CDCS hardware |

|

and software system on which the database is |

|

located. |

DC |

Direct Current |

DCM |

Data Control Module; a flash card used to |

|

update equipment in the field. |

2-16 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

Device Type |

Device type is a term that refers to categories of |

|

AFC equipment, such as TVMs, TOMs, Fare |

|

Gates, MEMs, etc. |

Distance Based Fares |

Fares that vary in cost with the length of the |

|

trip. |

DK |

Derivation key; the derivation key is used within |

|

the data encryption process. |

Download |

The process of sending information from a host |

|

to a client, enabling client data to be updated. |

Driver |

Software interface which connects devices to |

|

the operating system. |

DTE |

Diagnostic and Test Equipment |

E |

|

Electrostatic Discharge |

The Electrostatic Discharge symbol indicates |

(ESD) |

the potential for serious damage to the printed |

|

circuit boards or other Electrostatic Discharge |

|

(ESD) sensitive devices in the device. Ground- |

|

ing precautions must be followed whenever this |

|

symbol appears. |

Element.h |

The element.h file defines elements in service/ |

|

statistic printouts. |

EPF |

Ethernet Power Feed; S&B power supply sys- |

|

tem |

Error Codes |

Also called an error message, which is gener- |

|

ated automatically when a particular set of |

|

abnormal conditions occurs. Error information |

|

concerning a system fault or equipment mal- |

|

function can be viewed on the Customer Dis- |

|

play, Service Terminal Display, or on a printed |

|

report. |

Error Message |

See “Error Code”. |

ESD |

See “Electrostatic Discharge”. |

Ethernet Card |

The Ethernet Card is installed in the ECU main |

|

computer. It provides a communications inter- |

|

face between the device and an Ethernet Local |

|

Area Network (LAN). |

Event |

Every action that occurs at or in the TSM is |

|

defined as event. |

F |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

2-17 |

|

|

|

|

|

|

|

|

|

|

FCC Labels |

Federal Communications Commission (FCC) |

|

labels that identify the license for the transpon- |

|

der identification system. These labels are |

|

located near each transponder, such as on the |

|

Additional Coin Magazine connection board, in |

|

the Coin Magazine Drawer and beside the Coin |

|

Vault. |

File Transfer Protocol |

The Internet's file transfer protocol. FTP, which |

(FTP) |

has been used for more than two decades, is a |

|

standard protocol for accessing files on servers |

|

all over the world. |

Filter |

A Filter selects data under special criterion. |

Firmware |

Computer programs and data loaded into read- |

|

only memory that cannot be modified by the |

|

computer during normal operation and that is |

|

not erased by loss of power. |

Flash Card |

The Flash Card is a memory storage module |

|

(PCMCIA) used for device initialization and |

|

backup storage. |

FTP |

See “File Transfer Protocol”. |

G |

|

GHz |

GigaHertz - a unit of measure of electrical fre- |

|

quency equal to one thousand million (1012) |

|

Hertz (cycles per second). |

Graphical User Interface |

The panel and components through which the |

|

customer interacts with the device. |

GUI |

See “Graphical User Interface”. |

H |

|

Hexadecimal |

Numeric system with base 16 (figures from 0 to |

|

15). |

Hz |

A unit of measure of electrical frequency, equal |

|

to one cycle per second. |

I |

|

I/O |

Abbreviation for input/output |

ID |

Abbreviation for “Identification Number” |

IEC |

International Electrotechnical Commission |

IEEE |

Institute of Electrical and Electronic Engineers |

ISDN |

See “Integrated Services Digital Network”. |

ISO |

International Standards Organization |

2-18 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

K

KB |

Kilobyte (one thousand bytes, where 1 byte |

|

equals 8 bits) |

Keyboard |

The keyboard is used by the user to enter data |

|

into the system. |

kHz |

KiloHertz – a measure of frequency equal to |

|

one thousand Hertz (cycles per second) |

L |

|

LAN |

See “Local Area Network”. |

Language Marker |

Displays the language the device is equipped |

|

with. |

LCD |

Liquid Crystal Display; see “LCD Display” . |

LED |

Light Emitting Diode |

LLRC |

See “Lowest Level Replaceable Component”. |

LLRU |

See “Lowest Level Replaceable Unit”. |

Lmk Check Value |

The Lmk Check Value images the check sum of |

|

the host security module internal data. |

Local Area Network (LAN) |

A group of interconnected computers located |

|

within the same physical or geographical area |

|

(e.g. within the same building or campus.) See |

|

Wide Area Network. |

Login |

To get access the system, a login with ID and |

|

password has to be completed. |

Lowest Level Replaceable |

The most basic component that is normally |

Component (LLRC) |

replaced in the field |

Lowest Level Replaceable |

The most basic unit or assembly that is nor- |

Unit (LLRU) |

mally replaced in the field |

M |

|

mA |

Milliampere – a unit of measure of electrical |

|

current equal to one thousandth of an ampere. |

|

An ampere is the current that flows through a |

|

circuit of 1 ohm resistance with a voltage of 1 |

|

Volt applied. |

MAC |

Abbreviation for Message Authentication |

|

Codes. |

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

2-19 |

|

|

|

|

|

|

|

|

|

|

mAh |

An mAh is a milliampere-hour. It is one thou- |

|

sandth of an ampere-hour and is commonly |

|

used as a measure of charge in batteries. An |

|

ampere-hour is the amount of energy charge in |

|

a battery that will allow one ampere of current |

|

to flow for one hour. The HCR battery is rated at |

|

1200 mAh. |

Main Circuit Breaker |

The Main Circuit Breaker, which is located in |

|

the Power Connection Box, protects the system |

|

against high current overload. |

Main Module |

Main Application which controls the Central |

|

Server Application. |

Maintenance |

The action performed to prevent equipment |

|

performance degradation or failure (preventive |

|

maintenance) or restore the device to an in-ser- |

|

vice condition following a failure (corrective |

|

maintenance). |

MB |

Megabyte – one million bytes, where one byte |

|

equals 8 bits. |

Mbps |

Megabits per second – one million bits per sec- |

|

ond |

MDT |

Abbreviation for Mobile Data Transporter. |

MSHA |

Mine Safety and Health Administration |

Multimedia |

Multimedia includes texts, pictures and audio |

|

data. |

N |

|

NEMA |

National Electrical Manufacturers Association |

Noise |

Extraneous or interfering signals present on a |

|

system caused by undesirable voltages or cur- |

|

rents. |

NRTL |

National Registered Test Laboratory |

NWC |

Abbreviation for Network Controller |

O |

|

Occupational Safety and |

The United States Government regulatory and |

Health Administration |

oversight agency responsible for safety in the |

(OSHA) |

workplace. |

ODBC |

Open Data Base Connectivity |

OEM |

Original Equipment Manufacturer |

Oersted [Oe] |

1 Oersted = 2.021268 Ampere per inch |

2-20 |

|

Edit: Stevens |

Art.#.: 86 -----, Ver. 1.06 |

Datum:13.12.2017 |

|

|

|

|

|

|

|

|

|

|

Loading...

Loading...