Page 1

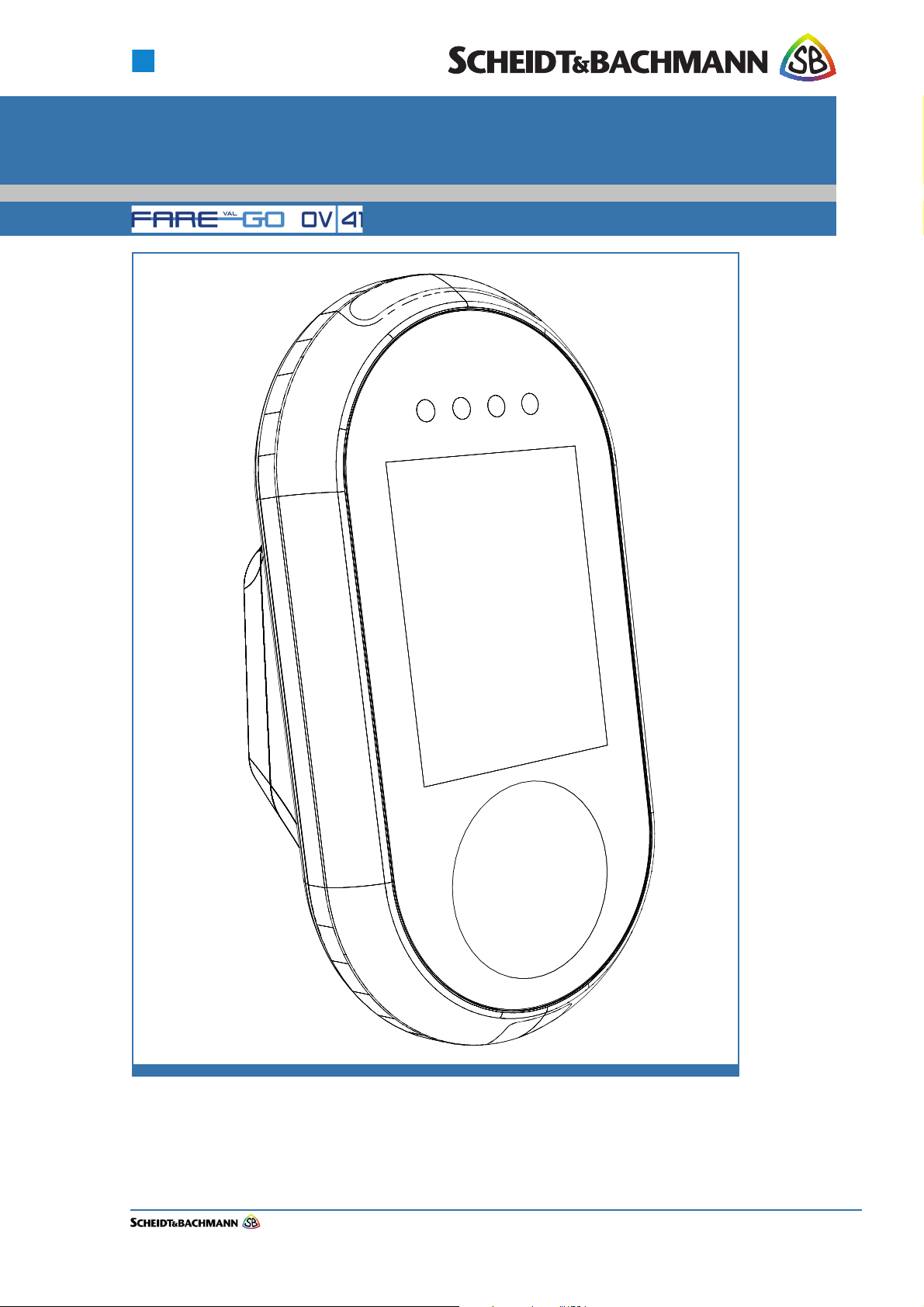

Fare collection

systems

Customer Documentation

State: December 2017

FareGo VAL OV|41

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

Page 2

This manual, including all of its component parts, is copyright protected. Scheidt & Bachmann GmbH

reserves all rights to its contents. Any use not expressly approved by copyright law is subject to prior

approval by Scheidt & Bachmann GmbH. This applies particularly to copying, processing, translations and

microfilming, as well as to storage and data processing in any electronic systems.

All contents of this manual shall be treated confidentially and shall not be transferred to any third party, either

for their own commercial use or for any other client.

Since all information and facts are subject to technical changes, any liability for the data contained is hereby

disclaimed. Modifications of technical details, in terms of information and illustrations are reserved. Make

sure to follow the updating index. Scheidt & Bachmann GmbH cannot be held responsible for direct damage

and/or possible consequential damage due to misuse by the customer or by third parties, unless the Product

Liability Act (ProdHaftG) is concerned. In no event shall Scheidt & Bachmann GmbH be liable for any damage out of or in connection with the provision of the manual.

© 2017 Scheidt & Bachmann GmbH, Fare collection system (FCS)

Breite Straße 132 41238 Mönchengladbach

www.scheidt-bachmann.com

Subject to change.

History

Version Date Change Edit

1.00 01.12.2016 Start Version Stevens

1.01 31.03.2017 Reduced the contents of the manual to

OV|41 relevant topics

1.02 03.04.2017 Changes made according to specifications

from the design department

1.03 05.07.2017 Information on radio frequencies added Stevens

1.04 21.08.2017 Changes made according to specifications

from the design department (C.Gerspacher)

1.05 15.09.2017 Changes made according to specifications

from the design department (N.Huendgen.)

1.06 13.12.2017 Changes made according to specifications

from the design department

(N. Huendgen. and I. Izler)

Stevens

Stevens

Stevens

Stevens

Stevens

Table 1-1

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

Page 3

Chapter 1 Introduction and Safety Considerations

1.1 Overview ................................................................................................ 1-7

1.2 Manual Organization............................................................................. 1-7

1.3 Safety ..................................................................................................... 1-8

1.4 General Safety Guide............................................................................ 1-9

1.5 Protective Equipment ......................................................................... 1-10

1.6 Special Tools ....................................................................................... 1-10

1.7 Use of Symbols in Manual.................................................................. 1-10

1.7.1 Warning Symbol ..................................................................................................... 1-10

1.7.2 Caution Symbol ...................................................................................................... 1-10

1.7.3 Information Symbol................................................................................................1-10

1.7.4 Example Symbol..................................................................................................... 1-10

1.7.5 Finger Tip Maintenance Symbol ...........................................................................1-11

1.7.6 Tools Symbol..........................................................................................................1-11

1.7.7 Electrical Hazard Symbol....................................................................................... 1-11

1.7.8 Electrostatic Discharge Symbol............................................................................ 1-11

1.7.9 Hot Hazard Symbol................................................................................................. 1-12

1.7.10 Maintenance Cycle Symbol ................................................................................... 1-12

1.8 Device Safety Labels .......................................................................... 1-12

1.8.1 Labels On the OV|41............................................................................................... 1-13

1.8.1.1 Label Locations .............................................................................................. 1-13

1.8.1.2 CE Label......................................................................................................... 1-14

1.8.1.3 FCC License Label......................................................................................... 1-14

1.8.1.4 TÜV SÜD NRTL Label ...................................................................................1-14

Chapter 2 Glossary

2.1 Glossary of Terms and Abbreviations .............................................. 2-15

Chapter 3 Declaration of Conformity

3.1 Europe.................................................................................................. 3-27

3.2 USA/CANADA ...................................................................................... 3-28

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

1-3

Page 4

Chapter 4 Troubleshooting and Module Removal

4.1 Troubleshooting Overview..................................................................4-31

4.1.1 Out of Service ......................................................................................................... 4-31

4.2 Error Identification...............................................................................4-32

4.2.1 Blocked Card ..........................................................................................................4-37

4.2.2 Card Error ............................................................................................................... 4-38

4.2.3 Recovery Scenarios ............................................................................................... 4-45

4.2.3.1 Recovery Scenario 1......................................................................................4-45

4.2.3.2 Recovery Scenario 2......................................................................................4-46

4.3 Verifying Software Versions ...............................................................4-47

4.4 Tools and Consumables .....................................................................4-47

Chapter 5 Preventive Maintenance

5.1 General Maintenance and Cleaning ...................................................5-49

5.2 Preventive Maintenance Schedule Summary....................................5-50

5.3 Materials and Replacement Parts.......................................................5-50

Chapter 6 OV|41 Installation

6.1 Overview ...............................................................................................6-51

6.2 Hardware...............................................................................................6-51

6.3 Dimension and Weight ........................................................................6-51

6.4 Power Requirements ...........................................................................6-51

6.5 Operating Features ..............................................................................6-54

6.5.1 OV|41 Mounting and Environmental Considerations ......................................... 6-54

6.6 Installation Requirements ...................................................................6-55

6.6.1 Materials..................................................................................................................6-55

6.6.2 Standard Tools .......................................................................................................6-55

6.6.3 Special Tools ..........................................................................................................6-55

6.7 Needs and Requirements for OV|41 Installation...............................6-55

6.8 Installation ............................................................................................6-56

1-4

6.9 Post-Installation Checklist ..................................................................6-62

6.10 Disassembly and Removal..................................................................6-62

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

Page 5

Chapter 7 OV|41 Initialization

7.1 Initialization ......................................................................................... 7-63

7.1.1 Initialize OV|41 With New System Software.........................................................7-63

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

1-5

Page 6

1-6

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Date:13.12.2017

Page 7

Chapter 1 Introduction and Safety Considerations

1.1 Overview The OV|41 (On-Board Validator 41) Repair and Maintenance Manual provides

complete, detailed instructions for operating, maintaining, and troubleshooting

the OV|41. Comprehensive charts, tables, graphs, and other diagrams provide a

technical document that is easy to use and understand.

Full documentation that would be needed by maintenance personnel is available

through Scheidt & Bachmann. The manual assumes that comprehensive repair

procedures will be performed by fully trained contractor technicians.

This manual reflects Scheidt & Bachmann’s commitment to providing our customers with comprehensive technical documentation, along with training guidelines to augment our customer training program.

1.2 Manual Organization

The organizational structure of the OV|41 Repair and Maintenance Manual is

outlined below.

Chapter 1 – Introduction

Chapter 2 – Glossary

Chapter 3 – Declaration of Conformity

Chapter 4 – Troubleshooting and Module Removal

Chapter 5 – Preventive Maintenance

Chapter 6 – OV|41 Installation

Chapter 7 – OV|41 Initialization

PLEASE READ THIS MANUAL AND ALL REFERENCED DOCUMENTS

CAREFULLY BEFORE ATTEMPTING TO INSTALL THIS AFC EQUIPMENT.

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS MANUAL AND THE

INSTRUCTIONS OR NOTES IN THE INSTALLATION DRAWINGS MAY

CAUSE INJURY TO YOURSELF OR DAMAGE TO THE EQUIPMENT AND

MAY ULTIMATELY COMPROMISE THE OPERABILITY OF THE

EQUIPMENT!

All Automated Fare Collection (AFC) equipment is TÜV-SÜD-NRTL listed. To

continue to be compliant with TÜV-SÜD-NRTL requirements, please note that

the following items need to be performed during installation:

The equipment will remain TÜV-SÜD-NRTL compliant only if the mounting and

wiring are also TÜV-SÜD-NRTL compliant. Please take great care during installation to comply with TÜV-SÜD-NRTL and NEC requirements.

When measuring for position, always use the center of the device as the reference point.

Ensure compliance with all Safety Regulations and Safety

Recommendations.

Although this manual has been prepared with great care, some information may

seem unclear. If so, please feel free to contact us with your remarks or questions.

Scheidt & Bachmann GmbH

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

1-7

Page 8

DISCLAIMER

Scheidt & Bachmann GmbH IS NOT LIABLE FOR INJURIES TO ANY

PERSON OR DAMAGE TO THE EQUIPMENT RESULTING FROM FAILURE

TO COMPLY WITH THE MANUFACTURER’S INSTRUCTIONS OR

DOCUMENTATION. THIS DISCLAIMER INCLUDES ALL THIRD PARTY

DOCUMENTATION PREPARED BY OEMS AND PROVIDED AS A

COURTESY BY Scheidt & Bachmann GmbH. TO ITS CUSTOMERS.

1.3 Safety This section describes safety requirements for technicians who perform mainte-

nance or repair procedures for all AFC Systems. Information provided in this

chapter also includes a description of safety warnings and precautions.

PLEASE READ THIS MANUAL AND ALL REFERENCED DOCUMENTS

CAREFULLY BEFORE ATTEMPTING TO WORK WITH THIS EQUIPMENT.

FAILURE TO FOLLOW THE INSTRUCTIONS IN THIS ENTIRE MANUAL

MAY CAUSE INJURY TO YOURSELF OR DAMAGE TO THE EQUIPMENT

AND MAY ULTIMATELY COMPROMISE THE OPERABILITY OF THE

EQUIPMENT!

DISCLAIMER

Scheidt & Bachmann GmbH IS NOT LIABLE FOR INJURIES TO ANY

PERSON OR DAMAGE TO THE EQUIPMENT RESULTING FROM FAILURE

TO COMPLY WITH THE MANUFACTURER’S INSTRUCTIONS OR

DOCUMENTATION. THIS DISCLAIMER INCLUDES ALL THIRD PARTY

DOCUMENTATION PREPARED BY OEMS AND PROVIDED AS A

COURTESY BY Scheidt & Bachmann GmbH TO ITS CUSTOMERS.

FAILURE TO FOLLOW MANUFACTURER’S INSTRUCTIONS MAY

INVALIDATE ANY OR ALL WARRANTIES, EXPRESS OR IMPLIED.

NOTE: NOT ALL OF THESE WARNING LABELS OR HAZARDS MAY EXIST IN ALL

AFC DEVICES. ONLY THOSE LABELS THAT APPLY TO THE OV|41, AND

ARE REQUIRED TO MEET TÜV-SÜD-NRTL CERTIFICATION REQUIREMENTS, WILL BE FOUND IN THE OV|41. BE CAUTIOUS AND OBSERVANT,

AND LOOK FOR SUCH WARNING LABELS AND POTENTIAL HAZARDS.

ANY TECHNICIAN OR PERSON ACCESSING THE INTERIOR OF ANY AFC

DEVICE SHOULD USE COMMON SENSE AND EXERCISE EXTREME CAUTION.

Safety Features

Safety engineering is an integral part of Scheidt & Bachmann’s designs. Maintenance technicians must perform maintenance and repair in accordance with

industry safety standards including MSHA, OSHA, and other Federal, State, and

Local codes and regulations.

Close attention to proper safety precautions is of the utmost importance. Components should be installed, maintained, and repaired only by trained, qualified

personnel using reasonable care. Improper installation, maintenance, or repair

procedures may damage the device or cause serious personal injury or death.

The following pages provide detailed information on safety precautions that

must be observed when working on AFC Systems. This information should be

carefully read and thoroughly understood before performing routine maintenance or attempting to troubleshoot or repair the device.

1-8

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 9

It is the responsibility of the maintenance agency to ensure that the safety

instructions in this manual are read, understood, and implemented by properly

trained maintenance and service technicians. All other persons who work with

the internal systems of any AFC systems should also be trained in safety.

1.4 General Safety Guide

This chapter provides the technician with the safety information necessary to

avoid personal injury or equipment damage. Only qualified, trained technicians

using reasonable care should perform maintenance or repair. As with any

mechanical system, the AFC components can pose certain safety hazards. The

following guidelines must be followed when working on the mechanical systems

of any AFC Systems or Components.

Only competent, qualified technicians trained by Scheidt & Bachmann should

service this device.

Service technicians must read and understand all operating and service

instructions.

Turn electrical power off before opening any electrical enclosure.

Do not operate the device with the cover of any enclosure, or the guard or

covers over any mechanism, removed.

Due consideration should be given to any safety regulation applicable to the

particular location in which the device is operating.

Do not turn on power to the device when components are disconnected.

The device must not be used for any purpose other than that for which it was

designed and approved by Scheidt & Bachmann.

When servicing or repairing the device, all device control panels must be

tagged in compliance with OSHA Lockout/Tag out procedures to indicate that

the device should not be operated.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

1-9

Page 10

1.5 Protective Equipment

The technician should use care when working with solvents and other cleaning

agents that may be abrasive or have a tendency to cause irritation to the skin or

eyes. Read all labels carefully and follow instructions for the use of gloves when

working with chemical fluids.

When using cleaning agents such as fluids or pressurized air, safety glasses

must be worn to prevent eye damage.

1.6 Special Tools There are no special tools required to ensure the safety of the service techni-

cian. However, ESD (Electrostatic Discharge: see paragraph 1.7.8) protection is

required for all procedures involving contact with electrostatic sensitive printed

circuit boards. The use of a standard ESD Safety Wrist Strap is required when

working with electrostatic sensitive printed circuit boards.

1.7 Use of Symbols in Manual

1.7.1 Warning

Symbol

1.7.2 Caution Symbol The Caution Symbol indicates a potential for damage to a particular part or func-

Symbols for cautions and warnings are used frequently throughout this manual.

Each symbol appears on the left side of the page with the associated text printed

to the right.

There are several different types of symbols that indicate varying levels of safety

hazards. Detailed information on each symbol is provide in this chapter.

It is vital that the technician understand and follow all safety warnings, cautions

and information guidelines when working on AFC Systems.

The Warning Symbol indicates a potential for serious damage to the equipment

or serious injury to the maintenance or service technician. Extreme care should

be used when performing procedures that are preceded by this symbol.

This symbol indicates a WARNING. A detailed description of the particular

hazard will appear next to the symbol in bold, italic print.

tion of the device. Reasonable care should be used when performing procedures preceded by this symbol.

This symbol indicates a CAUTION. A detailed description of the particular

hazard will appear next to the symbol in bold, italic print.

1-10

1.7.3 Information

Symbol

1.7.4 Example

Symbol

The Information Symbol indicates special information that could be important for

protecting a particular part or function of the device. Reasonable care should be

used when performing procedures that are preceded by this symbol.

This symbol indicates that more INFORMATION follows. A detailed

description of the particular hazard will appear next to the symbol in bold,

italic print.

The Example Symbol precedes an example of a function. The text or illustration

explains one possible function. This explanation applies to all other functions of

the same kind.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 11

This symbol indicates that an EXAMPLE follows.

1.7.5 Finger Tip Maintenance Symbol

1.7.6 Tools Symbol The Tools Symbol indicates that tools are required to perform the task

1.7.7 Electrical Hazard Symbol

The Finger Tip Symbol indicates that no tools are required to perform the task

described. Reasonable care should be used when performing procedures that

are preceded by this symbol.

This symbol indicates a FINGER TIP MAINTENANCE action. A step-bystep description of the task will appear next to the symbol in bold, italic

print.

described. Reasonable care should be used when performing procedures that

are preceded by this symbol.

This symbol indicates a TOOL is required to perform the task described in

the text.

The Electrical Hazard Symbol indicates the potential for serious damage to the

device caused by electrical voltage surges or serious injury to the service technician caused by electrical shock. Extreme care should be used when performing procedures preceded by this symbol.

1.7.8 Electrostatic Discharge Symbol

This symbol indicates possibility of ELECTRICAL HAZARD. A detailed

description of the particular hazard will appear next to the symbol in bold,

italic print.

The Electrostatic Discharge Symbol indicates the potential for serious damage

to the printed circuit boards or other Electrostatic Discharge (ESD) sensitive

devices in the device. Extreme care should be used when performing procedures preceded by this symbol. The technician should wear a grounding strap

and use the proper techniques associated with handling printed circuit boards or

other ESD sensitive devices.

This symbol indicates an ESD HAZARD. A detailed description of the

particular hazard will appear next to the symbol in bold, italic print.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

1-11

Page 12

1.7.9 Hot Hazard Symbol

The Hot Hazard Symbol indicates the danger for serious burns caused by surfaces within the device that may be extremely HOT to the touch. Hot surfaces

can cause serious injury to the service technician. Extreme care should be used

when performing procedures preceded by this symbol.

This symbol indicates a RISK OF BURNS. A detailed description of the

particular hazard will appear next to the symbol in bold, italic print.

1.7.10 Maintenance Cycle Symbol

1.8 Device Safety

Labels

The maintenance cycle symbol indicates the required maintenance cycles

described in the subsequent part of the manual. An example is shown below.

Time is indicated by month or by quantities of coins or tickets.

Preventive maintenance cycle: Every 3 months

The typical AFC device has safety labels on some internal components to alert

service technicians and other personnel that a safety hazard may exist when

working on certain device subassemblies. Not all safety labels may apply to service operations on every subassemblies.

A series of different labels is used within the device. The following paragraphs

describe these labels and note the location within the device where they will be

found. It is important to read and understand this information thoroughly.

1-12

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 13

1.8.1 Labels On the OV|41

There are several labels used on the OV|41. These labels and their meanings

are described below.

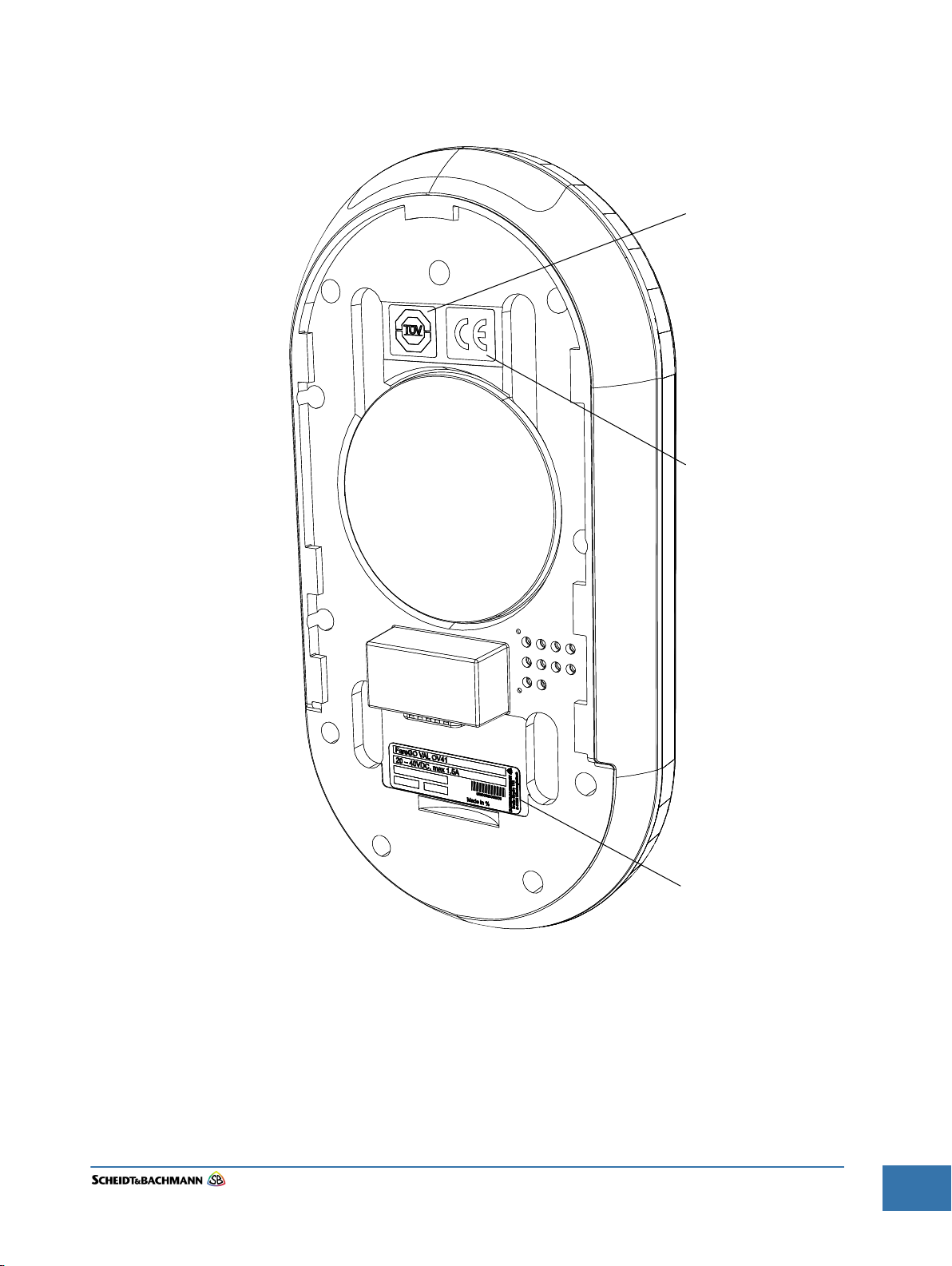

1.8.1.1 Label

Locations

The Labels shown in Figure 1-1 are found inside the device as shown.

TÜV-NRTL Label

CE Label

Serial Number Label

Figure 1-1 Label Locations

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

1-13

Page 14

1.0.0.1 Type Label The type label shown in Figure 1-2 appears at the back of the enclosure as

shown in Figure 1-1. This label indicates the voltage range, maximum amperes,

year of manufacture, and manufacturing location as well as the name of the

device and serial number.

Figure 1-2 The Type Label

1.8.1.2 CE Label The CE label shown in Figure 1-3 appears on the backside of the device as

shown in Figure 1-1

1.8.1.3 FCC License

Label

1.8.1.4 TÜV SÜD

NRTL Label

Figure 1-3CE Label

The FCC License label shown in Figure 1-4 appears on the backside of the

device.

HVIN: OV41

FCC ID: O5K-NVP

IC: 8312A-NVP

Figure 1-4FCC-License

The TÜV-SÜD-NRTL label shown in Figure 1-4 appears on the backside of the

device as shown in Figure 1-1.

1-14

Figure 1-5FCC-License

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 15

Chapter 2 Glossary

2.1 Glossary of

Terms and

Abbreviations

Many terms and abbreviations are used to describe Fare Collection Equipment.

Some are Automated Fare Collection (AFC) industry standard terms, some are

application-specific, such as networking and telecommunications terms, and

some are unique to the customer’s system.

A

A See “Ampere”.

AC See “Alternating Current”.

Access Level Individual users of a computer system have

specific access rights that regulate what they

can view or modify. Access rights are organized

into groups, which are called Access Levels.

ADA See “Americans with Disabilities Act”.

Alarm Event

Alternating Current An electrical current that continuously changes

An alarm event is generally defined as the

unauthorized opening of an AFC device.

polarity or direction of flow, usually 50 or 60

times per second

Americans with Disabilities

Act (ADA)

Ampere A unit of measure of electrical current, the cur-

ANSI American National Standards Institute

Application Server NT-based server which runs the Central Data

APTA American Public Transportation Association

ASCII American Standard Code for Information Inter-

Audio Speaker A speaker that broadcasts messages in the lan-

AWG American Wire Gauge, a measure of the cross

The federal law mandating facility and equipment accessibility requirements for persons

with disabilities.

rent produced by applying one volt to a circuit

with a resistance of one ohm.

Collection System Application processes

change

guage of choice with content similar to the message on the customer display.

section of a wire.

B

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-15

Page 16

Barcode A barcode is used to encrypt data into a series

of vertical bars (universal product code [UPC]).

It identifies various modules within an AFC

device such as a ticket roll.

Barcode Scanner The Barcode Scanner is a handheld scanner

used to read barcodes (e.g. on replacement

components).

Bitmap Bit-oriented graphics

Blower Also referred to as a “fan,” the blower cools the

Central Processing Unit (CPU) in the ECU.

Boot Loading of the operating system into the RAM

Byte 1 Byte = 8 Bit

C

Card A credit, debit, stored value, or “smart” card

CDCS See “Central Data Collection and Information

System”.

Central Data Collection

System (CDCS)

Command Instruction to initiate a special transaction

Command Codes See “Service Command”.

CPU Central Processing Unit

CRC Cyclic Redundancy Check. Check sum of the

Customer Display The Customer Display is a part of the user

Customer Specific Value A data field in which the customer is able to

Centralized company file server that collects

and distributes operating and system fare collection data. The CDCS serves all connected

machines and devices.

content of the file.

interface. In some devices, it may include a

touch screen.

store individualized information.

D

Database A database is an accumulation of individual

pieces of information that are related to each

other.

2-16

Database Server The Database Server is the CDCS hardware

and software system on which the database is

located.

DC Direct Current

DCM Data Control Module; a flash card used to

update equipment in the field.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 17

Device Type Device type is a term that refers to categories of

AFC equipment, such as TVMs, TOMs, Fare

Gates, MEMs, etc.

Distance Based Fares Fares that vary in cost with the length of the

trip.

DK Derivation key; the derivation key is used within

the data encryption process.

Download The process of sending information from a host

to a client, enabling client data to be updated.

Driver Software interface which connects devices to

the operating system.

DTE Diagnostic and Test Equipment

E

Electrostatic Discharge

(ESD)

Element.h The element.h file defines elements in service/

EPF Ethernet Power Feed; S&B power supply sys-

Error Codes Also called an error message, which is gener-

Error Message See “Error Code”.

ESD See “Electrostatic Discharge”.

Ethernet Card The Ethernet Card is installed in the ECU main

The Electrostatic Discharge symbol indicates

the potential for serious damage to the printed

circuit boards or other Electrostatic Discharge

(ESD) sensitive devices in the device. Grounding precautions must be followed whenever this

symbol appears.

statistic printouts.

tem

ated automatically when a particular set of

abnormal conditions occurs. Error information

concerning a system fault or equipment malfunction can be viewed on the Customer Display, Service Terminal Display, or on a printed

report.

computer. It provides a communications interface between the device and an Ethernet Local

Area Network (LAN).

Event Every action that occurs at or in the TSM is

defined as event.

F

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-17

Page 18

FCC Labels Federal Communications Commission (FCC)

labels that identify the license for the transponder identification system. These labels are

located near each transponder, such as on the

Additional Coin Magazine connection board, in

the Coin Magazine Drawer and beside the Coin

Vault.

File Transfer Protocol

(FTP)

Filter A Filter selects data under special criterion.

Firmware Computer programs and data loaded into read-

Flash Card The Flash Card is a memory storage module

FTP See “File Transfer Protocol”.

The Internet's file transfer protocol. FTP, which

has been used for more than two decades, is a

standard protocol for accessing files on servers

all over the world.

only memory that cannot be modified by the

computer during normal operation and that is

not erased by loss of power.

(PCMCIA) used for device initialization and

backup storage.

G

GHz GigaHertz - a unit of measure of electrical fre-

quency equal to one thousand million (1012)

Hertz (cycles per second).

Graphical User Interface The panel and components through which the

customer interacts with the device.

2-18

GUI See “Graphical User Interface”.

H

Hexadecimal Numeric system with base 16 (figures from 0 to

15).

Hz A unit of measure of electrical frequency, equal

to one cycle per second.

I

I/O Abbreviation for input/output

ID Abbreviation for “Identification Number”

IEC International Electrotechnical Commission

IEEE Institute of Electrical and Electronic Engineers

ISDN See “Integrated Services Digital Network”.

ISO International Standards Organization

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 19

K

KB Kilobyte (one thousand bytes, where 1 byte

equals 8 bits)

Keyboard The keyboard is used by the user to enter data

into the system.

kHz KiloHertz – a measure of frequency equal to

one thousand Hertz (cycles per second)

L

LAN See “Local Area Network”.

Language Marker Displays the language the device is equipped

with.

LCD Liquid Crystal Display; see “LCD Display” .

LED Light Emitting Diode

LLRC See “Lowest Level Replaceable Component”.

LLRU See “Lowest Level Replaceable Unit”.

Lmk Check Value The Lmk Check Value images the check sum of

the host security module internal data.

Local Area Network (LAN) A group of interconnected computers located

within the same physical or geographical area

(e.g. within the same building or campus.) See

Wide Area Network.

Login To get access the system, a login with ID and

password has to be completed.

Lowest Level Replaceable

Component (LLRC)

Lowest Level Replaceable

Unit (LLRU)

The most basic component that is normally

replaced in the field

The most basic unit or assembly that is normally replaced in the field

M

mA Milliampere – a unit of measure of electrical

current equal to one thousandth of an ampere.

An ampere is the current that flows through a

circuit of 1 ohm resistance with a voltage of 1

Volt applied.

MAC Abbreviation for Message Authentication

Codes.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-19

Page 20

mAh An mAh is a milliampere-hour. It is one thou-

sandth of an ampere-hour and is commonly

used as a measure of charge in batteries. An

ampere-hour is the amount of energy charge in

a battery that will allow one ampere of current

to flow for one hour. The HCR battery is rated at

1200 mAh.

Main Circuit Breaker The Main Circuit Breaker, which is located in

the Power Connection Box, protects the system

against high current overload.

Main Module Main Application which controls the Central

Server Application.

Maintenance The action performed to prevent equipment

performance degradation or failure (preventive

maintenance) or restore the device to an in-service condition following a failure (corrective

maintenance).

MB Megabyte – one million bytes, where one byte

equals 8 bits.

Mbps Megabits per second – one million bits per sec-

ond

MDT Abbreviation for Mobile Data Transporter.

MSHA Mine Safety and Health Administration

Multimedia Multimedia includes texts, pictures and audio

data.

N

NEMA National Electrical Manufacturers Association

Noise Extraneous or interfering signals present on a

system caused by undesirable voltages or currents.

NRTL National Registered Test Laboratory

NWC Abbreviation for Network Controller

O

Occupational Safety and

Health Administration

(OSHA)

The United States Government regulatory and

oversight agency responsible for safety in the

workplace.

2-20

ODBC Open Data Base Connectivity

OEM Original Equipment Manufacturer

Oersted [Oe] 1 Oersted = 2.021268 Ampere per inch

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 21

Online/Offline If the TSM is connected to the Network, the net-

work state of the TSM is online, if the TSM is

disconnected, the state is offline.

Oracle Manufacturer of database software.

OSHA See “Occupational Safety and Health Adminis-

tration”.

P

Packet A unit of data routed between an origin and a

destination on any packet switching network.

These “chunks” of data are an efficient size for

routing.

Pass A magnetically encoded document that pro-

vides access to designated portions of the system for a specified time period.

Password Every user has his own individual, classified

password that provides access to equipment.

Path The path describes the location of a data file.

PC Personal Computer – a mass-market class of

computer.

PCB Printed Circuit Board

PDU See “Portable Data Unit”.

Permit A fare media element issued to a specific per-

son that identifies that person as authorized for

a reduced fare or adjustment. It is presented

when the person purchases a ticket or pays for

a ride.

PIN Personal Identification Number.

Polling Data transmission initiated by inquiry.

Portable Data Unit A device used to extract data from a farebox for

uploading to the Garage Computer System.

Powerfail Control A possible power failure is monitored by the

system

Primary Key Unique number (index) for a row in the data-

base

Process System Interface The Process System Interface (PSI) is a soft-

ware process that both controls a hardware

component and interprets its state. This process is specific to each hardware component.

The PSI, which is responsible for communication between separate software modules, operates independently of the operating system.

PROM Programmable Read-Only Memory

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-21

Page 22

PSI See “Process System Interface”.

PSI number Address number of the device

Psiboot.bat Helpfile that starts different processes.

Q

QA/QC Quality Assurance/Quality Control

2-22

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 23

R

RAM Random Access Memory

RF Radio Frequency – a high frequency electrical

signal

RGB Video display color standard (Red, Green,

Blue)

ROM Read-Only Memory

RR Abbreviation for railroad

RTTE Radio and Telecommunications Terminal

Equipment Directive = RL 1999/EG) label identifies the radio license which is used for the

transponder reading transactions. The label is

located on the ACM (Additional Coin Magazine)

connection board.

S

S&B Scheidt & Bachmann

SCR See “Smart Card Reader”.

Service Command The Service Commands are entered into the

service terminal to initiate actions (e.g. prints

error codes, test tickets).

Service Text Service Text appears on the display inside of

the device (TVM) or on the agent display

(TOM).

Smart Card Reader A device that reads the encoded value stored

on a smart card.

Speaker See “Audio Speaker”.

Stored Value Card A magnetically encoded ticket or smart card

with a specified dollar value that provides

access to designated portions of the system.

The value on the card is reduced with each

use.

System Devices that are integrated to perform a spe-

cific function, such as the Coin Processing System, Bank Note System, and so on.

T

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-23

Page 24

TCP/IP Transmission Control Protocol/Internet Proto-

col. The TCP is a reliable, connection-oriented

protocol that delivers, with virtually no error, a

byte stream originating on one device to

another device anywhere on the Internet. The

IP facilitates this transfer of data by placing the

bytes into packets that are easily transmitted.

Ticket A magnetically encoded plastic or paper docu-

ment used for entrance to the system and for

verification of payment. In general, this term

refers to the physical media, which can be

encoded as a stored value card or a time based

pass.

Ticket Validator A Ticket Validator is a complete, replaceable

module designed to verify the authenticity of a

properly inserted magnetic ticket. Paper tickets

without magnetic strips may not be validated.

The printing components of a Ticket Validator

interface with the CDCS through an device.

Touch Controller Monitors the device Customer Display touch

screen panel. Reports the results of data input

(screen touches) to the Application Software.

(Applies only to systems equipped with Touch

Screen devices.)

Touch Screen A Touch Screen is the component part of the

Customer/Agent Display that detects user input

by sensing a touch (or tap) on specific areas of

a surface wave-sensitive touch panel.

Transponder The Transponder Chip stores the individual ID-

numbers of the Money Modules.

Transponder Reader The Transponder Reader is located in such a

way that it will read and/or recognize the chip

only when the corresponding money module is

correctly positioned.

U

UNIX Operating System.

Upload The process of sending data from the Client to

the Host Computer.

Username Every individual has a unique username that

identifies that person within the system.

V

2-24

VAC Volts Alternating Current

Variableelement.vel Fixes the organization and the position of the

components of the freetext record.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 25

VDC Volts Direct Current

Version Group of data downloaded to the devices.

VGA Abbreviation for video graphics array

VGA Controller The VGA Controller, located in the ECU Main

Computer, provides the synchronization and

control signals required to generate the video

for the color VGA Customer Display.

W

WAN See “Wide Area Network”.

Watchdog Timer The Watchdog Timer monitors the ECU CPU.

Should the CPU fall into a “dead” processor

loop, the Watchdog Timer instructs the CPU to

re-initialize the ECU and to reboot.

WAV-File File containing audio data.

Wide Area Network (WAN) Spanning a country or continent, a Wide Area

Network is a communication network that

serves geographically separated areas and

locations.

Workstation PC within a network serving as a control, input,

or monitoring device.

Z

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

2-25

Page 26

THIS PAGE INTENTIONALLY BLANK.

2-26

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 27

Fare collection

systems

Declaration of Conformity

Chapter 3 Declaration of Conformity

3.1 Europe The device complies to the European Directive RED 2014/53/EU

The OV41 use the following radio frequencies in Europe

Characteristic Specification

Chapter 3

Radio frequency:

Transmission power:

radio frequency:

Transmission power:

radio frequency:

Transmission power:

Table 3-2 Operating Characteristics

2400 - 2483.5 MHz

49 mW

5150-5775 MHz

45 mW

13.56 MHz

1.18 μW

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

3-27

Page 28

Chapter 3

Declaration of Conformity

3.2 USA/ CANADA

NOTICE:

This device complies with Part 15 of the FCC Rules and with Industry Canada

licence-exempt RSS standard(s).

Operation is subject to the following two conditions:

1. this device may not cause harmful interference, and

2. this device must accept any interference received, including interference that

may cause undesired operation.

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux

appareils radio exempts de licence. L'exploitation est autorisée aux deux

conditions suivantes:

(1) l'appareil ne doit pas produire de brouillage, et

(2) l'utilisateur de l'appareil doit accepter tout brouillage radioélectrique subi,

même si le brouillage est susceptible d'en compromettre le fonctionnement.

NOTICE:

Changes or modifications made to this equipment not expressly approved by

(Scheidt&Bachmann) may void the FCC authorization to operate this equipment.

Radiofrequency radiation exposure Information:

This equipment complies with FCC radiation exposure limits set forth for an

uncontrolled environment. It also complies with Industry Canada licence-exempt

RSS standard(s).

The radiated output power of the device is far below the FCC radio frequency

exposure limits. Nevertheless, the device shall be used in such a manner that

the potential for human contact during normal operation is minimized.

NOTE: This equipment has been tested and found to comply with the limits for

a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause harmful interference to radio or television

reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures:

3-28

Reorient or relocate the receiving antenna.

Increase the separation between the equipment and receiver.

Connect the equipment into an outlet on a circuit different from that to which

the receiver is connected.

Consult the dealer or an experienced radio/TV technician for help.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 29

Fare collection

systems

Chapter 3

Declaration of Conformity

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

3-29

Page 30

Chapter 3

Declaration of Conformity

3-30

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 31

Chapter 4 Troubleshooting and Module Removal

4.1 Troubleshooting

Overview

4.1.1 Out of Service Shown in Figure 4-6, the ‘Out of Service’ screen is displayed when the OV|41

This chapter provides information about OV|41 error and failure identification.

The first indication of a problem is usually a message displayed on the LCD

screen. Responding to an error involves identifying the nature of the error and

taking appropriate action to finish the transaction. Responding to a failure

involves identifying the nature of the failure and taking appropriate action to

restore the OV|41 to service. When service cannot be restored, the module

needs to be replaced with an operational one.

To reiterate what is said in the preceding paragraph, a maintenance technician

should troubleshoot OV|41 errors by:

Making sure the OV|41 can power on.

Making sure the correct software versions are on the OV|41.

is in ‘Out of Service’ mode. The device will not read or write to any Farecards.

Figure 4-6 ‘Out of Service’ Screen

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-31

Page 32

When a critical alarm is detected, the OV|41 switches to Out-of-Service mode.

Possible causes include:

Micro SD-card access failure.

Card reader failure.

No currently active business configuration data or other software versions.

The solution is to remove and replace the OV|41. If the failure persists, contacting the Helpdesk is the appropriate action.

4.2 Error Identification

When an error occurs, an indication of the error appears on the LCD. This is the

first place to look for messages such as Already Tapped ( Figure 4-7). Errors

interrupt one type of fare transaction.

4-32

Figure 4-7 Already Tapped

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 33

4.0.1 Cash

Supplement

Required

A cardholder may invoke the screen shown in Figure 4-8 under four sets of cir-

cumstances. These are:

Tapping a Farecard with a Period Pass where Cash Supplement is required,

Tapping an STO card with a valid Period Pass where a Cash Supplement is

required,

Tapping a Farecard with a Transfer Product where Cash Supplement is

required, or

Tapping an STO card with a Transfer Product where Cash Supplement is

required.

Figure 4-8 Cash Supplement

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-33

Page 34

4.0.2 Cash Fare

Required

When a cardholder taps an STO card with an expired Transfer product and no

Period Pass product, the screen in Figure 4-9 appears.

Figure 4-9 Cash Fare Required

4-34

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 35

4.0.3 Not Enough

Funds, Reload

Required

There are three circumstances when a cardholder may invoke the screen shown

in Figure 4-10. These are:

Tapping a registered Farecard with a negative e-Purse,

Tapping an anonymous Farecard with a zero e-Purse,

Tapping an anonymous Farecard with a positive e-Purse that is less than the

fare.

Figure 4-10 Funds Lacking

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-35

Page 36

4.0.4 Card Read

Error

A card read error will cause the screen shown in Figure 4-11 to appear.

Figure 4-11 Farecard Read Error

4-36

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 37

4.1 Failure

Identification

When a failure occurs, an indication of the failure appears on the LCD. This is

the first place to look for messages such as Blocked Card.

4.2.1 Blocked Card A failure occurs when a Farecard tap on fails. The issue may be one of the fol-

lowing:

Blocked Farecard,

A Farecard that has not been activated, or

A card read/write error.

When a cardholder taps a blocked Farecard, a blocked card, a Hotlisted Farecard, or a Hotlisted STO card on the OV|41, the screen in Figure 4-12 appears.

Figure 4-12 Blocked Card

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-37

Page 38

4.1.1 Card Inactive When a cardholder taps a not activated Farecard on the OV|41, the screen

shown in Figure 4-13 appears.

Figure 4-13 Card Inactive

4.2.2 Card Error When a cardholder taps an invalid WMATA Farecard, the screen in Figure 4-14

appears.

Figure 4-14 Card Error

4-38

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 39

4.1.2 Reversal Not

Possible

When a cardholder tries to reverse a fare payment via the OV|41 where fare

reversal is not processed, the screen in Figure 4-15 appears.

Figure 4-15 Reversal Error

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-39

Page 40

4.2 Module

Removal Base Unit

The drawing in Figure 4-16 illustrates how to unlock the OV|41Base Unit and

remove it for field replacement.

STEP 1: Use the key to unlock the device.

STEP 2: Push the Base Unit so fare upward, that the OV|41 can take away from the

mounting unit.

At no time should the service provider open the device to troubleshoot,

repair, or replace OV|41 components in the field.

Mounting Unit

Base Unit

Service

Cover

4-40

Key

Connector

Figure 4-16 Module Removal - Base Unit

NOTE: As a backup to the online data transmission, a second, pre-configured

Micro SD card may be inserted into the OV|41 (different from the backup

module Micro SD-card). This second, pre-configured card may be used if

the OV|41 is not online or cannot connect to the back end. Transaction

data is also stored in the non-volatile system memory (flash memory).

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 41

STEP 3: Open the service cover.

STEP 4: Remove the Backup microSD Card as shown in Figure 4-17.

STEP 5: Insert the MicroSD Card in the replacement OV|41.

STEP 6: Set the base unit on the mounting unit and push it down.

STEP 7: Lock the base unit by turning the key showing in Figure 4-16.

Service Cover

Base Unit

Backup

microSD

Card

CPU module

microSD

Card

Figure 4-17 Service Cover - open

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-41

Page 42

4.3 Module

Removal Mounting Unit

The drawing in Figure 4-18 illustrates how remove the OV|41 mounting unit

from the mounting bar.

STEP 1: Remove the base unit from the mounting unit as shown in Chapter 4.2.

STEP 2: Cut the cable tie and remove the power/network cable as shown in Figure 4-19.

STEP 3: Remove the four screws which fix the mounting plate to the mounting unit front

part and remove the mounting plate.

STEP 4: Remove the four screws which fix the mounting unit rear part to the mounting

unit front part and remove the mounting unit parts from the mounting bar.

Be careful when removing the mounting unit front part. When you push the

Front part up or down you can damage the Power/network cable.

Mounting Unit

Rear Part

10 Nm

Mounting Unit

Front Part

14 Nm

10 Nm

10 Nm

10 Nm

14 Nm

Mounting Plate

10 Nm

10 Nm

10 Nm

10 Nm

Base Unit

4-42

Figure 4-18 Module Removal - Mounting Unit

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 43

Cable Tie

Figure 4-19 Wiring Connections

STEP 5: Place a new OV|41 mounting unit near the proper mounting position and

connect the power/network cable as shown in Figure 4-19.

STEP 6: Secure the plug to the circuit board by a cable tie

STEP 7: Put the OV|41 in the proper mounting position on the mounting post as shown in

Figure 4-20.

Figure 4-20 Wiring Connections

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-43

Page 44

STEP 8: Set the mounting unit rear part on the mounting unit front part and fix it with the

four screws shown in Figure 4-18

STEP 9: Set the mounting plate on the mounting unit front part and fix it with the four

screws shown in Figure 4-18

STEP 10: Install the base unit as shown in Chapter 4.2.

Replacement devices will be pre-initialized. The system provider is not responsible for either initialization or creation of system initialization modules.

NOTE: The back-up module holds the last shift data and the device ID only.

No configuration is needed for creation of the device back-up module. Use an

empty micro SD card, insert in the slot, power on the device. The device will recognize the empty micro SD card and will initialize it automatically. If the device

detects a non-empty micro SD card, the device will reject the micro SD card and

remain out of service. The device initialization through the back-up module will

be completed with a synchronization through IVN. Spare back-up modules

(micro SD cards) will be provided with each spare device. The service provider

is responsible for providing additional spare back-up modules

If the device is faulty, transfer the faulty device’s back-up module to the new

replacement device. There will be no loss of device data. Avoid using an empty

back-up card. Only use an empty card during a device swap if the original back

up module is lost, defective, or the entire device/back-up combination is not

available. Maintenance staff should be careful not to damage or lose back-up

modules when swapping faulty devices, because all backed up data will be lost.

Users may determine if a device back-up module is faulty by checking the Backend system.

4-44

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 45

Figure 4-21 MicroSD Card

Backup

microSD

Card

4.2.3 Recovery Scenarios

4.2.3.1 Recovery

Scenario 1

STEP 1: Remove faulty OV|41 from the bus (unplug data (Cat-6 cable) and power –

STEP 2: Remove the Backup MicroSD card from the malfunctioning OV|41 (spring

STEP 3: Install new OV|41 on the bus (following the standard installation process).

STEP 4: Insert the working MicroSD Backup card (from faulty OV|41) into the new OV|41

STEP 5: Turn on the OV|41 (hook up data and power cables and re-attach to pole).

STEP 6: OV|41 goes through a recovery process (configures IP, data, transactions, etc.).

STEP 7: OV|41 will reboot after the recovery process. At this point the device is identical

If the OV|41 is faulty and the Back-up MicroSD card is still intact, follow Recovery Scenario 1. If the MicroSD card is lost, damaged, or defective but the OV|41

is functional, follow Recovery Scenario 2. If both the OV|41 and the Backup

MicroSD card are damaged (a double failure), follow Recovery Scenario 3.

When the OV|41 is faulty and the Backup MicroSD Card is still intact, follow

these steps.

remove from the pole).

loaded, pressing it down will pop it up for removal). It is a small module; be

careful handling it.

(left slot).

to the failed one.

STEP 8: Turn on the device and sync to Backend system (to receive updated lists /

version data) – confirm that the OV|41 is operational and communicating online.

STEP 9: DATA STATUS: NO data loss.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-45

Page 46

4.2.3.2 Recovery Scenario 2

STEP 1: Open the OV|41 cover. If necessary, remove the faulty backup module.

STEP 2: Insert a formatted new MicroSD-Card. The device auto recovery function will

STEP 3: DATA STATUS: NO data loss - All transaction data will be retrieved from the

STEP 1: Create a Service Modul to execute the Service Command automatically on the

If the MicroSD card is lost, damaged, or defective but the OV|41 is functional, follow these steps.

copy the correct Backupmodul.ini file onto the new card (ini file is now also

saved on device internal hard disk) and backup the data.

working OV|41 and uploaded to the Backend system.

If Manual Data Recovery must be attempted, follow these steps.

Device. This may be created on Backend system in Offline Modul processing.

Figure 4-22 Initialize Offline Data Carrier

STEP 2: The Procedure on the Device is the same as in Recovery Scenario 1.

4-46

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 47

4.3.0.1 Recovery

Scenario 3

STEP 1: Remove the damaged OV|41 from the bus; it needs to be replaced.

STEP 2: Send OV|41 (along with its MicroSD backup module) to Central Repair Depot to

STEP 3: Install a new OV|41 on the bus.

STEP 4: Insert new Backup SD card which has the file Backupmodule.ini with the correct

STEP 5: DATA STATUS: Possible Loss. The transaction data generated since the last

If both the OV|41 and the Backup MicroSD Card are damaged (a double failure),

follow these steps.

attempt retrieval of the shift files (data recovery may not be possible depending

on the extent of the damage).

ID setting (this number will be the same as the one on the original backup

module, and can also be seen under Extended Parameters in Device

Maintenance). The OV|41 will configure itself and use the SD card as the backup

module when it is powered on.

IVN sync is at risk of being permanently lost in the case of the dual failures of

both the OV|41 and Backup module. If the main logic board of the OV|41 is

intact, or if the SD card can still be read, then data recovery at the Central Repair

Depot may be possible.

Please note: The format for the ID number in the Backupmodule.INI file is as follows:

AABBBBBBCC, where AA is the provider number (12 for WMATA), BBBBBB is

the 6 digit device ID (such as 020001), and CC is the position in the bus of the

OV|41 (02, 03, or 04). Thus, an example number would be 1202000103. This

information is also available by opening the INI file in notepad, and is easily set.

4.3 Verifying

Software

Versions

4.4 Tools and

Consumables

Here is an example:

Backupmodul.ini Identifier=129999902

Operator ID 12

Busnumber 999999

OV|41 1.

As a troubleshooting step, a maintenance technician may verify the device software versions with the expected version. If the versions are different, the technician should request that the Backend system Operator confirm that the new

software versions are linked to the device. If so, attempt the device software

download through the Backend system maintenance of jobs.

There are no consumables for this device. The only tool is a unique key used to

open and close the device.

Name Part Number

OV|41 Base Unit 00 XXXXX

03 XXXXX

03 XXXXX

Table 4-3 Part Numbers

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

4-47

Page 48

4-48

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 49

Chapter 5 Preventive Maintenance

5.1 General

Maintenance

and Cleaning

The following general preventive maintenance procedures are for the overall

maintenance and cleaning of the OV|41. This includes testing and validating the

equipment to ensure proper operation. During this Preventive Maintenance process, notify the Network Control Administrator that alarms may be triggered.

Unless otherwise specified, the power must be turned “Off” prior to

performing maintenance procedures.

Status LED

Open

Payment

Status LED

LCD/Touch Screen

Mounting Unit

(Bracket for Pole)

Base Unit

Figure 5-23 OV|41

Smart Card Area

Barcode Reader

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

5-49

Page 50

5.2 Preventive Maintenance Schedule Summary

The following table is a single source that summarizes all of the preventative

maintenance procedures mentioned in this chapter. Use this table to determine

what procedures that need to be accomplished, and when they should be

scheduled.

When the recommended preventive maintenance intervals have both a

time period and a receipt usage maximum, then preventive maintenance

must take place when either the time or the usage maximum is reached.

These are maximum maintenance intervals, which may have to be

reduced, and they assume average usage in a moderate environment. If

certain devices are heavily used or exposed to atypical environmental

conditions, such as extreme temperature fluctuations or nearby construction work, then preventive maintenance must be undertaken more frequently in order to reduce the amount and frequency of field

maintenance. Operation and maintenance histories should be consulted

and preventive maintenance procedures undertaken for those devices

and locations where experience shows more frequent preventive maintenance will reduce field maintenance.

Table 5-4 Recommended Preventive Maintenance Schedule/Frequency

5.3 Materials and Replacement Parts

FREQUENCY DESCRIPTION

Every Month Cleaning and Visual

Inspection of the Exterior

Screen Preventive Maintenance

Smart Card Antenna

Lock Preventive Maintenance

Every Three Months Cleaning and Visual

Inspection of the Interior

Table 13-2 provides a complete list of the materials and replacement parts

needed to perform corrective maintenance on the OV|41.

ITEM PART NUMBER WHERE USED

Canned Air General Use

Alcohol Isopropyl, (70% min.) General Use

Lexan Cleaner Windex (or other mild) Customer Display

Heavy Duty Shop

Cloths

Lint-free, soft Miscellaneous Use

5-50

Table 5-5 Materials and Replacement Parts

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 51

Chapter 6 OV|41 Installation

6.1 Overview The OV|41 installation instructions described in the this chapter explain how to

install the devices, but do not prepare the devices for operation. Once installation is complete, the installer should follow the OV|41 Initialization instructions.

The following information and instructions are provided for the installer of a

OV|41.

To avoid damage, deliver OV|41 equipment to the installation location in the

original packaging and Scheidt & Bachmann wrapping.

The OV|41 device is installed inside bus vehicles and provides Farecard

validation.

The OV|41 equipment is fragile. Handle with extreme care. Do not drop!

6.2 Hardware The OV|41 assembly is composed of two main parts:

The OV|41 Base Unit

The Mounting Unit

6.3 Dimension and Weight

6.4 Power Requirement s

The Mounting Unit is mechanically fixed onto a pole internally on the bus. The

Mounting Unit supports the OV|41. The OV|41 base unit is securely fixed to the

Mounting Unit.

The internal components of the device are covered by the front and the rear covers which protect them against vandalism and water. Both covers are screwed

together so that unauthorized access to inner components from outside is not

possible.

The dimensions of the OV|41 are in Table 6-6.

Height Width Depth

Base Unit 295 mm 155 mm 56 mm

Base Unit incl. Mounting

Unit

Table 6-6Dimensions

The weight of the OV|41 is approximately 4 kg.

The power/network connector of the OV|41 is located in the mounting unit and

has a full operating range from 20 VDC to 40 VDC.

Use only S&B EPF systems as power source and CAT6 SFTP cable as wiring.

295 mm 155 mm 148 mm

In standby mode, the OV|41 uses 8 W. In operational mode, the OV|41 uses 12

W.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-51

Page 52

The safety labels shown in the section “Device Safety Labels” must be

followed. Review them carefully before proceeding.

Mode Power Consumption

Standby OV|41 ready to accept Smart Card 8 W

Operational Farecard processing and audio 12 W

NOTE: Use only S&B EPF systems as power source and CAT6 SFTP

cable as wiring

Table 6-7 Power Consumption

Power supply

Article No. Description

0377252 OV41 Power Box cpl. without CPD

Table 6-8 Power Supply

(

6-52

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 53

6.4 Network

Requirements

A NRTL listed, flexible Cat 6 cable will provide data communication and power

supply. The cable complies with NFPA70 and NEC including Chapter 800. The

Ethernet Connector is a standard RJ45.

Figure 6-24 Block Diagram OV|41

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-53

Page 54

6.5 Operating Features

OV|41 operating characteristics are shown in Table 6-9.

Characteristic Specification

Operating Humidity 10% to 95%, non-condensing

Operating Temperature -30 °C to +50 °C

Power Supply Nominal 24VDC (20VDC to 40VDC)

Power Consumption 12 Watts maximum, 8 Watts standby

Use CAT6 SFTP cable as wiring.

Table 6-9 Operating Characteristics

6.5.1 OV|41 Mounting

and

Environmental

Considerations

During transportation and when OV|41 equipment is installed but not operational, the environmental and storage conditions of Table 6-10 must be met. The

requirements for OV|41 equipment mounting must also be met. Observing these

requirements is the responsibility of the Transit Authority, its architect, and

installers. Minimum clearances, minimum distances from obstructions, placement in a convenient location, and the comfort of the operator are all considerations that should be foremost in the minds of those planning the installation.

The OV|41 should be operated only when “office environmental conditions” exist

in the workplace.

Environmental Condition Acceptable Range

Temperature Range -40 °C to +70 °C

Humidity 10% to 95%, non-condensing

Table 6-10 Non-Operational Environmental Conditions

Non-operational environmental and storage conditions must be observed!

Non-operational environmental and storage conditions apply when the

OV|41 is installed but not operational. During operation “Office

Environmental Conditions” must be provided.

6-54

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 55

6.6 Installation

Requirement

The following materials, standard tools, and preconditions are required for

OV|41 installation.

s

6.6.1 Materials At a minimum, the following materials will be included in the OV|41 package:

1 x Fully Assembled Functional OV|41 unit

6.6.2 Standard Tools Below is a list of required tools and materials:

Small wrench with bit holder

Cable Cutter

Drill

Spiral Drills

Edge Trim for the cable opening

Measuring Tape, minimum 2 meter length

6.6.3 Special Tools Drilling Aid

6.7 Needs and Requirement s for OV|41 Installation

The following preconditions must be met by installer before installing the OV|41

(OV|41). The installer must check the following items:

Is there enough space available for the OV|41?

Are all installation components present?

Is a regular metric tool set available? A 174 piece SAE/Metric tool set with

4 drive tools, 10 wrenches, and 121 additional tools, similar to the Alltrade

320329 Tool Set with Tool Box, should have all the necessary tools to

make any adjustments, connections, or installations required.

Is an Ethernet/Power cable with an RJ 45 plug available?

Are a pencil and pad of paper available for note taking, such as noting IP

addresses, and check list verification?

Is the unique key available?

Ensure there is no other cabling in the bus framework that may be

damaged by the installation.

Before starting installation, ensure there is no power on any cable,

breakers are shut off, and all data cabling is disconnected.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-55

Page 56

Mounting Unit

Rear Part

Figure 6-25 OV|41 Mounting Unit

Mounting Unit

Front Part

Mounting Plate

6.8 Installation This section gives details related to the mechanical mounting of the OV|41. A

Mounting Unit will be attached to the bus framework. The chosen location is to

be agreed upon between the installation subcontractor and the customer.

The mounting unit of the OV|41 consists of two parts that are mounted together

with four screws ( Figure 6-25). The base unit covers all the electrical components. Two fix studs in the front part of the mounting unit will avoid twisting the

OV|41 around the pole. The OV|41 base unit will be secured by a lock under the

mounting unit.

6-56

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 57

Follow these steps to attach a OV|41.

STEP 1: Mark the upper edge of the OV|41 on the pole. (See Figure 6-26)

Upper OV|41 Position

Figure 6-26 Marking Upper OV|41 Position

STEP 2: Clamp the drilling aid on the pole. The top hole of the drilling aid is located 97

mm from the upper edge of the validator.

Upper OV|41 Position

97mm

Drilling Aid

Figure 6-27 Marking Upper OV|41 Position

STEP 3: Drill the 5 mm holes for the studs and the cut out for the cable into the pole

(see Figure 6-27 and Figure 6-28).

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-57

Page 58

STEP 4: Expand the 5 mm hole for the cable opening (middle hole) as needed for the

existing cable with a appropriated drill.

STEP 5: De-burr all boreholes.

Wear safety glasses when drilling for eye protection!

Grip the drill firmly. If it sticks, it can twist in your hands and cause serious

injury!

STEP 6: Use a trim along the sharp edges of the cable cut out to protect the wiring. This

edge trim must comply with TÜV-SÜD-NRTL R/C QMFZ2 Plastics with a

minimum Flame class HB.

Use edge Trim

Cable Opening

(predrilled 5 mm)

Figure 6-28OV|41 Mounting Openings

STEP 7: Run the Power/Network cable through the pole and pull it out through the cable

opening.

STEP 8: First plug in the cables to the OV|41 mounting part ( Figure 6-29)

STEP 9: Secure the plug to the circuit board by a cable tie see ( Figure 6-29).

STEP 10: and then place the OV|41 onto the pole by inserting the studs in the designated

holes. The studs prevent the OV|41 from twisting on the pole ( Figure 6-30).

Holes for Studs (5 mm)

Cable Opening

(expanded to 18 mm)

6-58

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 59

Cable Tie

Figure 6-29Wiring Connection

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-59

Page 60

NOTE: The cable, must be attached to the back of the OV|41 mounting unit.

Figure 6-30Pole Installation

STEP 11: Put the rear part of the mounting unit on the front part of the mounting unit

around the pole and fix it with four screws. (see Figure 6-31).

14 Nm

10 Nm

10 Nm

10 Nm

10 Nm

10 Nm

14 Nm

10 Nm

10 Nm

10 Nm

6-60

Mounting Unit

Rear Part

Mounting Unit

Front Part

Mounting Plate

Figure 6-31Mount the Mounting Unit

STEP 12: Put the mounting plate on the mounting unit front part and fix it with four screws.

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 61

STEP 13: Put the base unit on the mounting unit.

STEP 14: Lock the device as shown in Figure 6-32.

Mounting Unit

Base Unit

Lock

Figure 6-32Lock

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

6-61

Page 62

6.9 PostInstallation

Checklist

The installer must use the following checklist to verify proper installation of the

OV|41 and associated equipment.

Ensure the stability of the OV|41 on the Pole.

Verify any attached cables are secure.

Ensure there is adequate power and network.

6.10 Disassembly and Removal

STEP 1: Turn off Main Circuit Breaker.

STEP 2: Disassemble the OV|41in reverse order .

STEP 3: After removing the OV|41, the remaining cables and conduits must be removed

Should it become necessary to remove the complete OV|41 (mounting unit and

base unit) from its permanent location, the following procedure must be followed.

Ensure power to all cables is shut off before starting the removal. Breakers

must be shut off and all data cables should be disconnected. Electrical

power must be turned off at the source.

by an authorized worker.

Any questions please contact the Environment Agency on 0XXXX XXX XXX.

Registration Number XXXXXXXX

6-62

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 63

Chapter 7 OV|41 Initialization

7.1 Initialization This chapter explains how to initialize the OV|41.

7.1.1 Initialize OV|41 With New System Software

STEP 1: Take the base unit from the mounting unit.

STEP 2: Remove the service cover.

STEP 3: Insert the micro SD card containing the new system software into the

To perform a base initialization of a OV|41, follow these steps.

For these procedure the OV|41 must have a connection to the software

server.

"System microSD card" slot (see Figure 7-33).

Refer to Figure 7-33 for the location of the micro SD slot that may be used.

Backup

microSD

Card

(optional)

System

microSD

Service Cover

Figure 7-33 Micro SD Card Location

STEP 4: Put the base unit on the mounting unit.

STEP 5: The OV|41 will run through the boot process.

STEP 6: When the device starts up, the SysInit will be downloaded from the software

server.

STEP 7: When the device is starting up, the following screen will be shown:

Card

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

7-63

Page 64

Figure 7-34 SysInit "IDLE" screen

STEP 8: Choose "online SysinitDataCarrier" to download the latest successful build or

latest pinned build.

7-64

Figure 7-35 SysInit "download" screen

Edit: Stevens Art.#.: 86 -----, Ver. 1.06 Datum:13.12.2017

Page 65

STEP 9: When the SysInit Data Carrier was successfully downloaded, press "run sysinit".

Figure 7-36 SysInit "run SysInit" screen

STEP 10: After a minute the device will reboot. Now you see the processes starting:

sbuser@Trizeps7:~$ psiinfo -l

PSI - Process List

Process-ID Status (Name)

0x00000020 running (PSI Timer Process)

0x00000021 running (Config Process)

0x00000023 running (Powerfail Process)

0x00000027 running (Tcp32 Process)

0x00000031 running (Crypto Process)

0x00001081 running (Version Control [135_1551])

0x00001088 running (Transaction Recorder [177_1349])

0x00001100 running (DeviceControl [169_1481])

0x00001413 running (Event-/Status-Handler)

0x00002100 running (Service Process [127_1352])

0x00003405 running (Production Process)

0x0000340C running (Smart Card Process Version 16.9.26,o,r)

0x00003800 running (Payment)

0x00003806 running (LogicalIO [211_1673:16/11/16_0949])

0x00003C50 running (Filetransfer)

0x00003C51 running (OnlineControl)

0x00004C01 running (PxUSB S&B Smartcard Reader)

0xFFFFFFFC running

0xFFFFFFFE running (Rousnp Process)