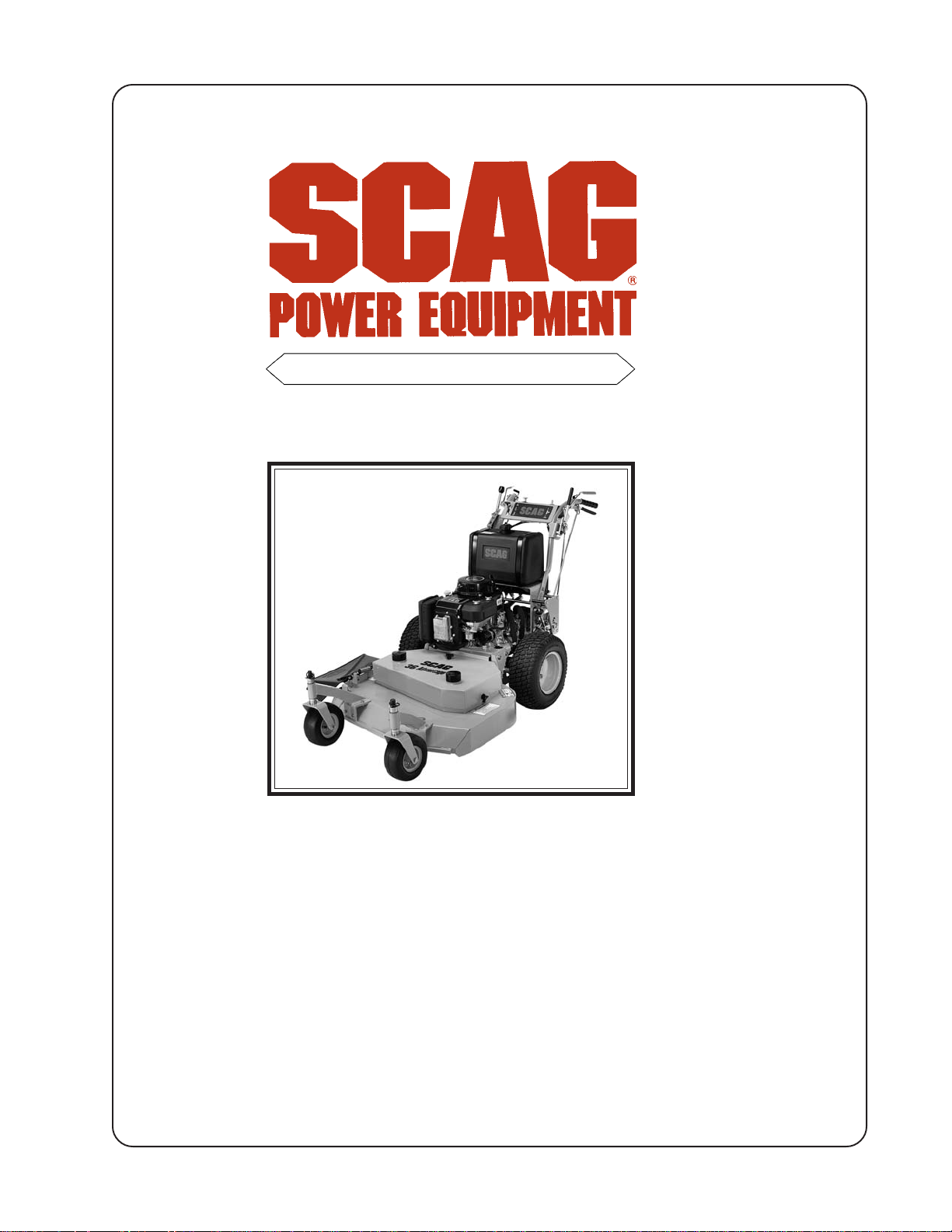

Page 1

MODEL SW

OPERATOR’S MANUAL

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMATION FOR YOUR SCAG MOWER. READING

THIS MANUAL CAN PROVIDE YOU WITH

ASSISTANCE IN MAINTENANCE AND ADJUSTMENT PROCEDURES TO KEEP YOUR

MOWER PERFORMING TO MAXIMUM EFFICIENCY. THE SPECIFIC MODELS THA T THIS

BOOK COVERS ARE CONTAINED ON THE

INSIDE COVER. BEFORE OPERA TING YOUR

MACHINE, PLEASE READ ALL THE INFORMATION ENCLOSED.

© 2004

SCAG POWER EQUIPMENT

DIVISION OF MET ALCRAFT OF MA YVILLE, INC.

P ART NO. 03145

PRINTED 7/04

PRINTED IN USA

Page 2

WARNING:

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all shields in place, especially the grass discharge chute.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wire and ignition key.

* If a mechanism becomes clogged, stop the engine before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as other manuals that came

with your mower.

* Keep others off the tractor (only one person at a time)

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident pre vention are dependent upon the awareness,

concern, prudence, and proper training of the personnel involved in the

operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

SW32-15KA with a serial number of A0100001 to A0199999

SW36A-15KA with a serial number of A0300001 to A0399999

SW36A-15KH with a serial number of A0400001 to A0499999

SW48A-15KA with a serial number of A0500001 to A0599999

SW48A-15KH with a serial number of A0600001 to A0699999

SW48A-17KA with a serial number of A0800001 to A0899999

SW52A-17KA with a serial number of A1000001 to A1099999

SW52A-18HN with a serial number of A1100001 to A1199999

SW52A-18KH with a serial number of A1200001 to A1299999

Always use the entire serial number listed on the serial number

tag when referring to this product.

Page 3

TABLE OF CONTENTS

MODEL SW

SUBJECT PAGE

Introduction.................................................................................................. 1

Direction Reference..................................................................................... 1

Servicing the Engine ................................................................................... 1

Symbols....................................................................................................... 2-3

General Safety Instructions.......................................................................... 4

Signal Words ............................................................................................... 4

Before Operating Considerations ................................................................ 4-6

Operation Considerations............................................................................ 6-7

Maintenance and Storage ........................................................................... 7-8

Initial Run-In Procedures ............................................................................. 8

Mower Operation ......................................................................................... 8-9

Cutter Deck Belt Adjustments...................................................................... 9

Transmission Drive Belt............................................................................... 1 0

Drive Control Adjustments........................................................................... 10

Cutter Deck Adjustments ............................................................................. 10-11

Blade Height Adjustments ........................................................................... 11

Cutter Blades............................................................................................... 11

Custom-Cut Baffle Adjustment..................................................................... 12

Engine Oil Maintenance .............................................................................. 13

Engine Air Cleaner Maintenance ................................................................. 13

Cleaning The Machine ................................................................................ 13

Lubrication and Maintenance Chart ............................................................ 14

Troubleshooting Cutting Conditions ............................................................ 15-17

Technical Specifications .............................................................................. 18-19

WE SUPPORT OPE

TECHNICIAN

CERTIFICATION

I

Page 4

TABLE OF CONTENTS

(CONTINUED)

SUBJECT PAGE

Illustrated Parts List

SWM-32", 36" Cutter Deck .......................................................................... 20-21

SWM-48", 52" Cutter Deck .......................................................................... 22-23

Notes .......................................................................................................... 24

Caster Assembly ......................................................................................... 25

Engine Deck - 15KH, 18KH, 15KA, 17KA, 18HN ........................................ 26-27

Handle Assembly ........................................................................................ 28-29

Instrument Panel.......................................................................................... 30

Peerless Transmission................................................................................. 31

Engine Deck Wire Harness ......................................................................... 32

Handle Wire Harness .................................................................................. 32

Wire Harness Adapter-Honda (18 HP) ........................................................ 33

Wire Harness Adapter-Kawasaki (15 HP & 17 HP)..................................... 33

Replacement Decals ................................................................................... 34-35

Warranty Statement .........................................................................Inside Bac k Cover

II

Page 5

INTRODUCTION

GENERAL INFORMATION

Your mower was built to the highest standards in the

industry . However, the prolonged life and maximum

efficiency of your mower depends on you following the

operating, maintenance and adjustment instructions in this

manual.

If additional information or service is needed, contact

your Scag Power Equipment Dealer.

We encourage you to contact your dealer for repairs. All

Scag dealers are informed of the latest methods to

service this equipment and provide prompt and efficient

service in the field or at their service shop. They carry a

full line of Scag service parts.

USE OF OTHER THAN ORIGINAL SCAG

REPLACEMENT PARTS WILL VOID THE

WARRANTY.

For pictorial clarity , some illustrations and figures in this

manual may show shields, guards or plates open or

removed. Under no circumstances should your mower be

operated without these devices in place.

All information is based upon product information

available at the time of approval for printing. Scag

Power Equipment reserves the right to make

changes at any time without notice and without

incurring any obligation.

USE ONLY SCAG APPROVED ATTACHMENTS

AND ACCESSORIES.

Attachments and accessories manufactured by

companies other than Scag Power Equipment are not

approved for use on this machine. Using unapproved

attachments, (especially "stand-up" riding attachments)

may be hazardous.

SCAG APPROVED ATTACHMENTS AND

ACCESSORIES:

GC-F4 (p/n 9002)

GC-4D (p/n 9001)

Mulch Plate (p/n 9258, 9259, 9260, 9261)

Hurricane Mulch System (p/n 9263, 9264, 9265, 9266)

Cup Holder (p/n 9240)

Hour Meter (p/n 48023)

Turbo Baffle (p/n 423955, 423956, 423957)

Blade Buddy (p/n 9212)

Flat-Free Caster Tires (p/n 9275)

DIRECTION REFERENCE

The “Right” and “Left”, “Front” and “Rear” of the

machine are referenced from the operator’s right and left

when standing in the normal operating position and facing

the forward travel direction.

SERVICING THE ENGINE

WARNING

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

The detailed servicing and repair of the engine is not

covered in this manual; only routine maintenance and

general service instructions are provided. For service of

the engine during the limited warranty period, it is

important to contact your Scag dealer or find a local

authorized servicing agent of the engine manufacturer .

Any unauthorized work done on the engine during the

warranty period may void your warranty .

1

Page 6

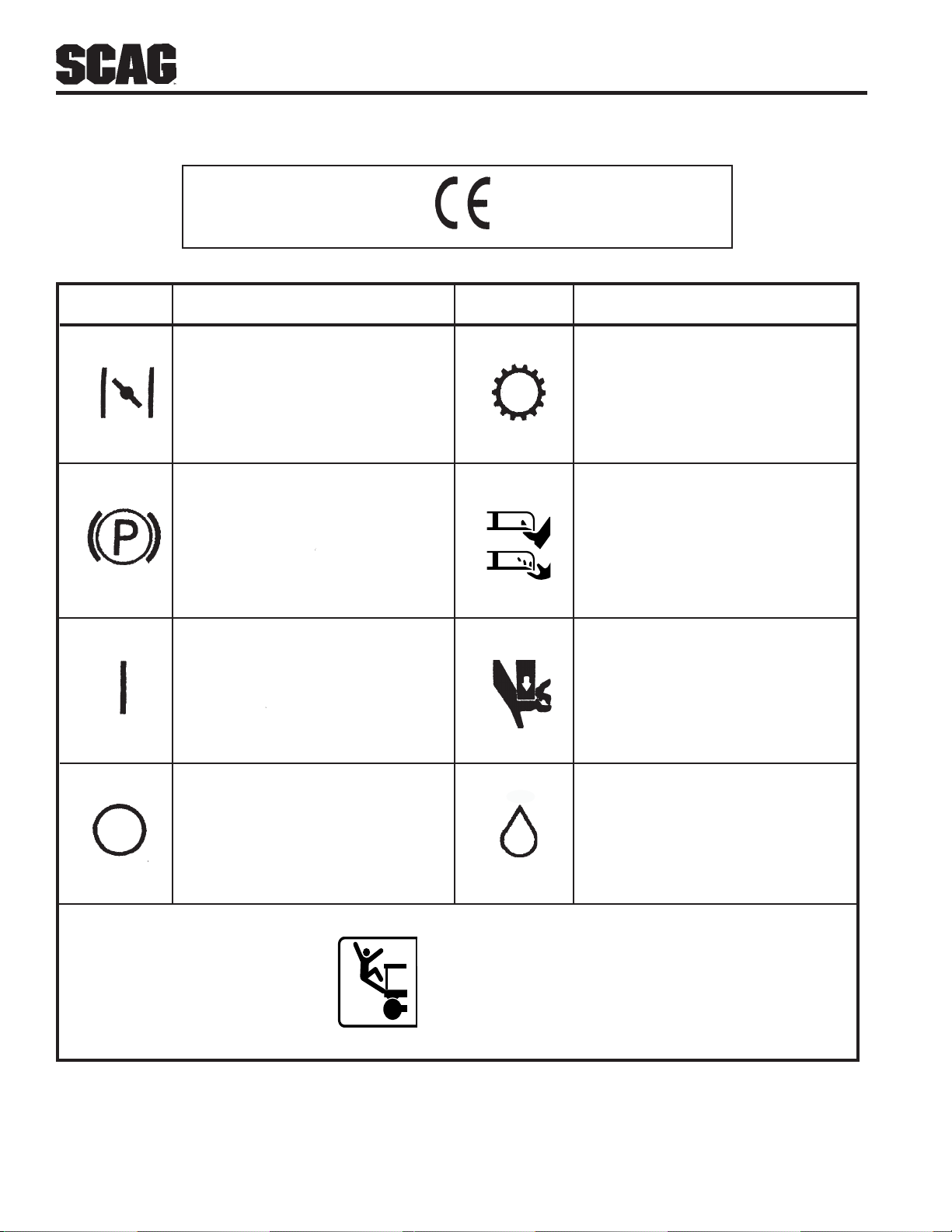

ISO Symbols

CE Mark

SYMBOL DESCRIPTION

Parking Brake

On/Start

SYMBOL DESCRIPTION

TransmissionChoke

Spinning Blade

48071S

Spring T ension on Idler

Off/Stop

Oil

WARNING

Falling Hazard

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

2

Page 7

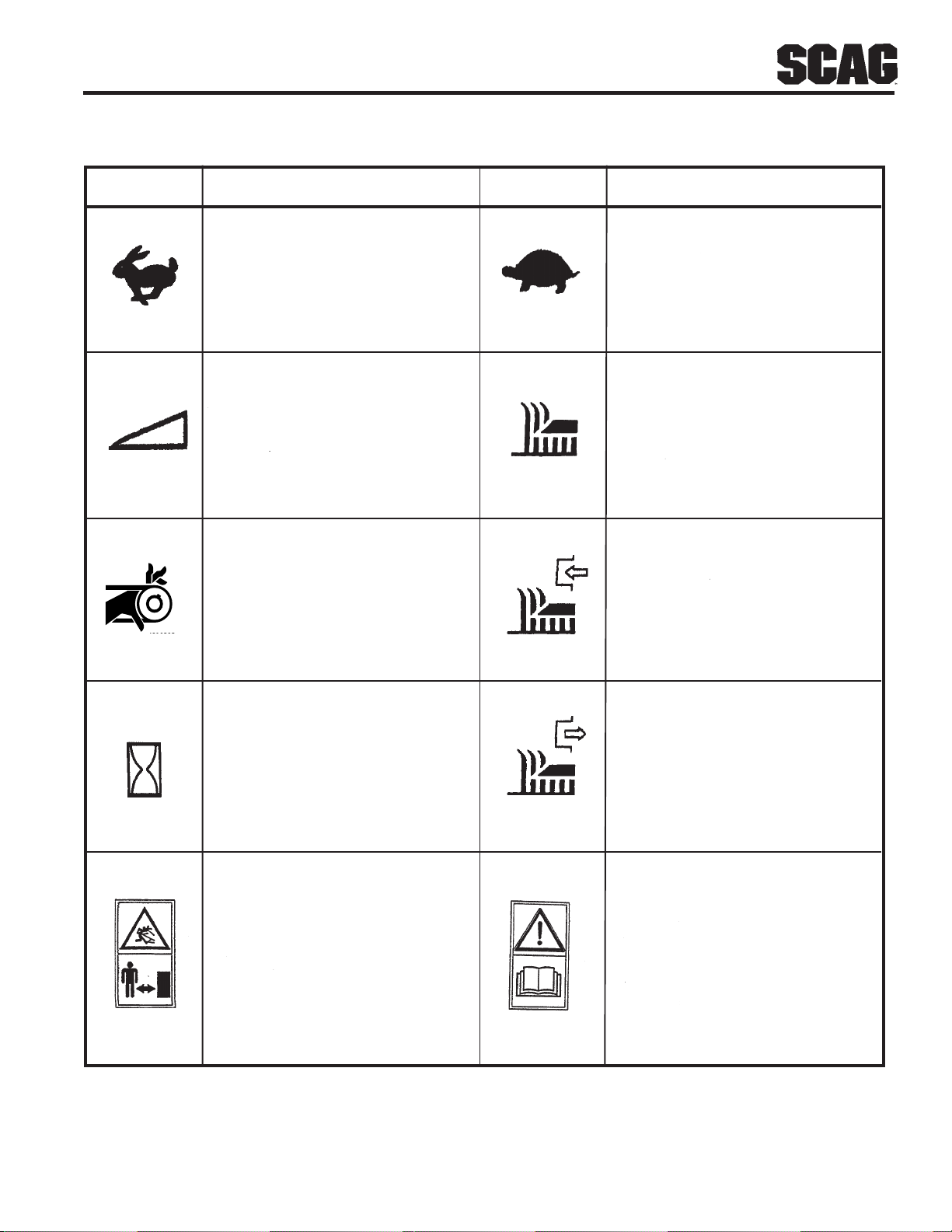

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

481039S

Fast

Continuously V ariable - Linear

Pinch Point

Slow

Cutting Element - Basic Symbol

Cutting Element - Engage

Hourmeter/Elapsed Operating Hours

Thrown Object Hazard

Keep Bystanders Away

Cutting Element - Disengage

Read Operator's Manual

3

Page 8

SAFETY INFORMATION

GENERAL SAFETY INFORMATION

Your mower is only as safe as the operator.

Carelessness or operator error may result in serious

bodily injury or death. Hazard control and accident

prevention are dependent upon the awareness, concern,

prudence, and proper training of the personnel involved in

the operation, transport, maintenance and storage of the

equipment.

and thoroughly familiar with all of the controls before

operating the mower. The owner/user can prevent and is

responsible for accidents or injuries occurring to

themselves, other people or property .

READ THIS OPERATOR’S MANUAL BEFORE

ATTEMPTING TO START YOUR MOWER.

If the operator(s) or mechanic(s) cannot read English or

Spanish, it is the owner's responsibility to explain this

material to them.

A replacement manual is available from your authorized

Scag Service Dealer or by contacting Scag Power

Equipment, Service Department at P.O. Box 152,

Mayville, WI 53050 or contact us via the Internet at

www.scag.com. The manual for your machine can be

downloaded by using the model and serial number or use

the contact form to make your request. Please indicate

the complete model and serial number of your Scag

product when requesting replacement manuals.

Make sure every operator is properly trained

SIGNAL WORDS

Signal Word:

The signal word is a distinctive word found on the safety

decals on the machine and throughout this manual that

alerts the viewer to the existence and relative degree of

the hazard.

The signal word “DANGER” denotes that an extremely

hazardous situation exists on or near the machine that

could result in high probability of death or irreparable

injury if proper precautions are not taken.

WARNING:

The signal word “WARNING” denotes that a hazard

exists on or near the machine that can result in injury or

death if proper precautions are not taken.

CAUTION:

The signal word “CAUTION” is a reminder of safety

practices on or near the machine that could result in

personal injury if proper precautions are not taken.

Your safety and the safety of others depends

significantly upon your knowledge and understanding of

all correct operating practices and procedures of this

machine.

This symbol means “Attention! Become Alert! Your

Safety is Involved!" The symbol is used with the

following signal words to attract your attention to safety

messages found on the decals on the machine and

throughout this manual. The message that follows the

symbol contains important information about safety . T o

avoid injury and possible death, carefully read the

message! Be sure to fully understand the causes of

possible injury or death.

BEFORE OPERATION

CONSIDERATIONS

1. Become familiar with the safe operation of the

equipment, operator controls, and safety signs.

2. NEVER allow children or untrained people to

operate or service this machine.

3. Clear the area to be mowed of objects that could be

picked up and thrown by the cutter blades.

4

Page 9

BEFORE OPERATION CONSIDERATIONS

WARNINGWARNING

DO NOT OPERATE WITHOUT DISCHARGE CHUTE, MULCHING

KIT, OR ENTIRE GRASS CATCHER INSTALLED

(CONT'D)

4. Always wear appropriate clothing, loose fitting

clothing, long hair or jewelry could get tangled in

moving parts. Do not operate the machine wearing

shorts; always wear adequate protective clothing

including long pants. Wearing safety glasses, safety

shoes and a helmet is advisable and is required by

some local ordinances and insurance regulations.

5. Operator hearing protection is recommended,

particularly for continuous operation of the mower.

W ear suitable hearing protection. Prolonged

exposure to loud noise can cause hearing impairment

or hearing loss.

6. Keep the machine and attachments in good operating

condition. Keep all shields and safety devices in

place. If a shield, safety device or decal is defective

or damaged, repair or replace it before operating the

machine.

WARNING:

This machine is equipped with an interlock system

intended to protect the operator and others from

injury. This is accomplished by preventing the

engine from starting unless the deck drive is

disengaged, the transmission is in neutral, and the

neutral latches are in the neutral position. The

system shuts off the engine if the operator releases

the operator presence levers with the deck drive

engaged and/or the transmission not in neutral.

Never operate equipment with the interlock system

disconnected or malfunctioning.

C. Never remove the gas cap or add fuel with the

engine running. Allow the engine to cool before

fueling.

D. Never fuel the machine indoors or in an enclosed

trailer.

E. Never store the machine or fuel container where

there is an open flame, spark or pilot light such as

on a water heater or other appliances.

F. Never fill containers inside a vehicle or on a truck

or trailer bed with a plastic liner. Always place

containers on the ground away from your vehicle

before filling.

G. Remove the machine from the truck or trailer and

fuel on the ground. If this is not possible, then

refuel the machine with a portable container,

rather than from a gasoline dispenser nozzle.

H. Keep the nozzle in contact with the rim of fuel

tank or container opening at all times until fueling

is complete. Do not use a nozzle lock-open device.

I. If fuel is spilled on clothing, change clothing

immediately

J. Replace gas cap and tighten securely.

8. Before attempting to start the engine, shift the

transmission into neutral, move the blade engagement

switch to the OFF position, and move the neutral

latches to neutral.

7. Fill the fuel tank with clean, fresh gasoline, with a

minimum octane rating of 87. To avoid personal

injury or property damage, use extreme care in

handling gasoline. Gasoline is extremely flammable

and the vapors are explosive.

A. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

B. Use only an approved gasoline container.

9. The discharge chute must always be installed and in

the down position on the side discharge cutter deck

except when the Scag optional grass catcher or

mulching plate are properly installed.

5

Page 10

BEFORE OPERATION CONSIDERATIONS

(CONT'D)

6. Using the machine demands attention. To prevent

loss of control:

ROTATING BLADES

NEVER PUT Y OUR HANDS INT O THE DISCHARGE

CHUTE FOR ANY REASON! Shut off the engine and

remove the key and only then use a stick or similar

object to remove material if clogging has occurred.

10. If the mower discharge ever plugs, shut off the

engine, remove the ignition key, and wait for all

movement to stop before removing the obstruction.

Do not use your hand to dislodge the clogged

discharge chute. Use a stick or other device to

remove clogged material.

1 1. Check the blade mounting bolts at frequent intervals

for proper tightness.

OPERATION CONSIDERATIONS

1. Before operating the mower, familiarize yourself

with all mower and engine controls. Knowing the

location, function and operation of these controls is

important for safe and efficient operation of the

mower.

2. Start the engine when the neutral latches are in the

neutral lock position, the cutter blades are disengaged, and the transmission is in neutral.

3. Be sure the interlock switches are functioning

correctly.

A. Mow only in daylight or when there is good

artificial light.

B. Be alert for holes, rocks, roots and other hidden

hazards in the terrain. Keep away from any

dropoff. Beware of overhead obstructions (low

limbs, etc), underground obstacles (sprinklers,

pipes, tree roots, etc.). Cautiously enter a new

area. Be alert for hidden hazards.

C. Do not drive close to a drop-off, ditch, creek

bank, or other hazard.

D. Reduce speed and exercise extreme caution on

slopes and in sharp turns to prevent tipping or

loss of control. Be especially cautious when

changing directions on slopes.

E. Always be sure of your footing. Keep a firm

hold on the handles and walk---never run.

F. Do not operate where conditions are slippery

WARNING:

DO NOT operate on steep slopes. T o check a slope,

attempt to back up it (with the cutter deck down). If

the machine can back up the slope without the

wheels slipping, reduce speed and use extreme

caution. ALWAYS FOLLOW OSHA APPROVED

OPERA TION.

7. Disengage power to the cutter deck before backing

up. Do not mow in reverse unless absolutely

necessary and then only after observation of the

entire area behind the mower.

4. DO NOT mow when children and/or others are

present. Keep children out of the mowing area and in

the watchful care of a responsible adult other than

the operator. Be alert and turn the machine off if a

child enters the area.

5. DO NOT carry passengers.

8. Disengage power to the cutter deck before crossing

roads, walks or gravel drives. Stop blades if not

mowing.

9. Shut the engine off and wait until the blades come to

a complete stop before removing the grass catcher

container.

10. Never raise the cutter deck while the blades are

rotating.

6

Page 11

OPERATION CONSIDERATIONS

(CONT'D)

16. DO NOT operate the machine under the influence

of alcohol or drugs.

ROTATING BLADES

NEVER PUT Y OUR HANDS INT O THE DISCHARGE

CHUTE FOR ANY REASON!

11. Keep hands and feet away from cutter blades and

moving parts. Contact can injure.

12. DO NOT operate without the side discharge chute

installed and in the down position.

13. DO NOT direct the discharge of material toward

bystanders or allow anyone near the machine while

in operation.

14. If the cutting blades should strike a solid object or the

equipment should start to vibrate abnormally, stop the

engine, disconnect the spark plug wire, and check

immediately for the cause. Vibration is generally a

warning of trouble. Check the machine for damaged

or defective parts. Repair any damage before

starting the engine or operating the cutter deck. Be

sure the blades are in good condition and the blade

bolts are tight.

15. T ake all possible precautions when leaving the

machine unattended, such as disengaging the mower,

stopping the engine, and removing the key .

17. Use care when loading or unloading the machine

onto a truck or trailer.

18. Use care when approaching blind corners, shrubs,

trees, or other objects that may obscure vision.

19. Do not change the engine governor settings or

overspeed the engine. See the engine operator's

manual for information on engine settings.

MAINTENANCE AND STORAGE

1. Allow only trained personnel to service the machine.

2. Park the machine on level ground.

3. Never make adjustments to the machine with the

engine running unless specifically instructed to do so.

If the engine is running, keep hands, feet, and

clothing away from moving parts.

4. Disengage drives, lower implement, stop engine and

remove key or disconnect spark plug wire(s) to

prevent accidental starting of the engine when

servicing or adjusting the machine. W ait for all

movement to stop before adjusting, cleaning or

repairing.

5. If the mower must be tipped to perform maintenance

or adjustment, remove the battery, drain the gasoline

from the fuel tank and the oil from the crankcase.

CAUTION:

DO NOT touch the engine or the m uffler while

the engine is running or immediately after

stopping. These areas may be hot enough to

cause a burn.

WARNING:

DO NOT run the engine inside a building or a

confined area without proper ventilation. Exhaust

fumes are hazardous and could cause death.

6. Keep all nuts, bolts and screws tight, to ensure the

machine is in safe working condition. Check the

blade mounting bolts frequently to be sure they are

tight. Replace all worn or damaged decals.

7. Clean grass and debris from cutting units, drives,

mufflers, and engine to help prevent fires. Clean up

oil or fuel spillage.

8. The engine must be shut off before checking the oil

or adding oil to the crankcase.

7

Page 12

MAINTENANCE AND STORAGE (CONT'D)

9. Let the engine cool before storing.

10. DO NOT store the machine near an open flame.

11. Shut off fuel while storing or transporting.

12. Always store gasoline in a safety-approved, red

container.

13. Use jack stands to support components when

required.

14. Carefully release pressure from components with

stored energy.

15. Use care when checking blades. Wrap the blade(s)

or wear gloves and use caution when servicing

blades. Only replace blades. NEVER straighten or

weld blades.

INITIAL RUN-IN PROCEDURES

(FIRST DAY OF USE OR APPROXIMATELY 10 HOURS)

1. Check the belts for proper tension at 2, 4 and 8

hours. Adjust as needed.

6. Apply lubricant to all the grease fittings.

Lubricant was applied at the factory. This is just a

precautionary check to make sure that all the

fittings have been lubricated.

MOWER OPERATION

1. Read and understand the safety instructions before

attempting to operate this machine.

2. Before starting the engine:

* Check the oil level in the engine.

* Fill the fuel tank with clean, fresh, lead-free

gasoline.

* Open the fuel valve on the bottom of the fuel

tank.

-NOTE-

Use gasoline with an octane rating no less than

87.

* The transmission must be in NEUTRAL.

* The blade clutch switch must be in the OFF

position.

* The operator's presence levers must be released.

2. Check the steering control rods for neutral adjust

ment (See Adjustments, page 10).

3. Check the tires for proper pressure.

Caster Wheels 25 psi.

Drive Wheels 12 psi.

4. Check for loose hardware. Tighten as needed.

5. Check the safety switches for proper adjustment:

* The engine will not start if the PTO switch is on.

* The engine will not start if the machine is not in

neutral.

* The engine should start if the machine is in neutral

and the PTO engagement switch is off.

* The neutral latches must be in the neutral lock

position

* The key switch must be on.

3. Start the engine:

* Choke as required. If the engine is cold, pull the

choke knob out. When the engine starts, slowly

push the choke in. If the engine stalls, repeat the

above operation. When the engine is warm,

choking may not be necessary.

4. Engage the cutter blades by depressing the operator

presence levers and pulling the blade clutch switch

into the ON position. Push the switch to the OFF

position to disengage the cutter blades.

8

Page 13

MOWER OPERATION (CONT'D)

WASHER

NUT

SC401G

BELT

PULL UP TO ENGAGE

PUSH DOWN TO DISENGAGE

390S0138

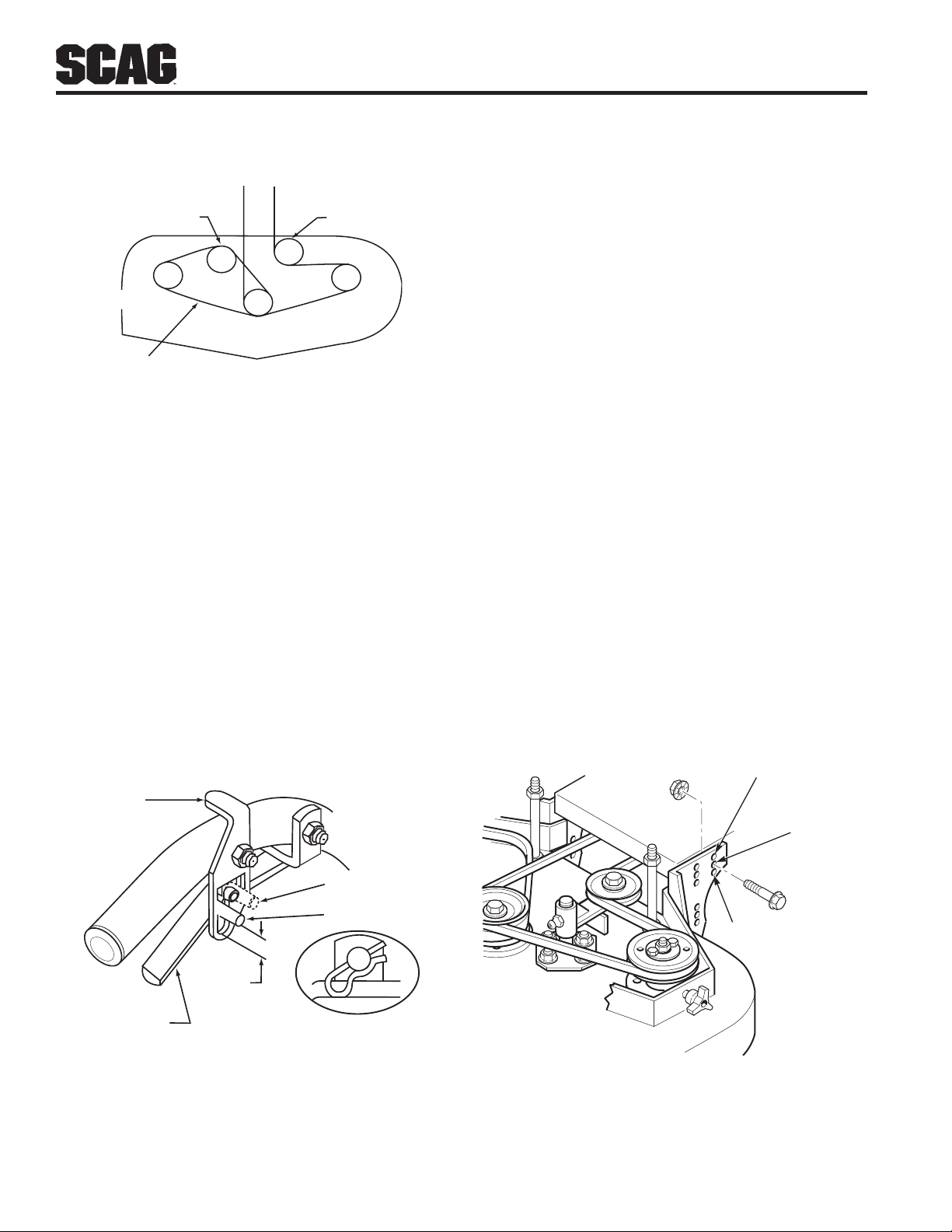

CUTTER DECK BELT ADJUSTMENTS

CAUTION:

Stop engine and remove the key from the ignition

before making any adjustments. Wait for all moving

parts to come to a complete stop before beginning

work.

-NOTE-

When PTO is engaged or (possibly) disengaged,

a squealing sound from the underside of the

machine is normal. It is caused by the electric

clutch plates meshing as the mower comes up to

speed. For best equipment life, engage the

clutch with the engine at 3/4 throttle, not under

full load.

WARNING:

To avoid serious bodily injury and damage to the

transmission, the machine must be at a full stop

before shifting between gears or shifting between

forward and reverse.

5. Shift the transmission into gear for the desired

mowing speed.

-NOTE-

Top speed is suggested only for transport!

6. While squeezing the steering brake levers with both

hands, release both neutral latches.

1. Remove the belt cover.

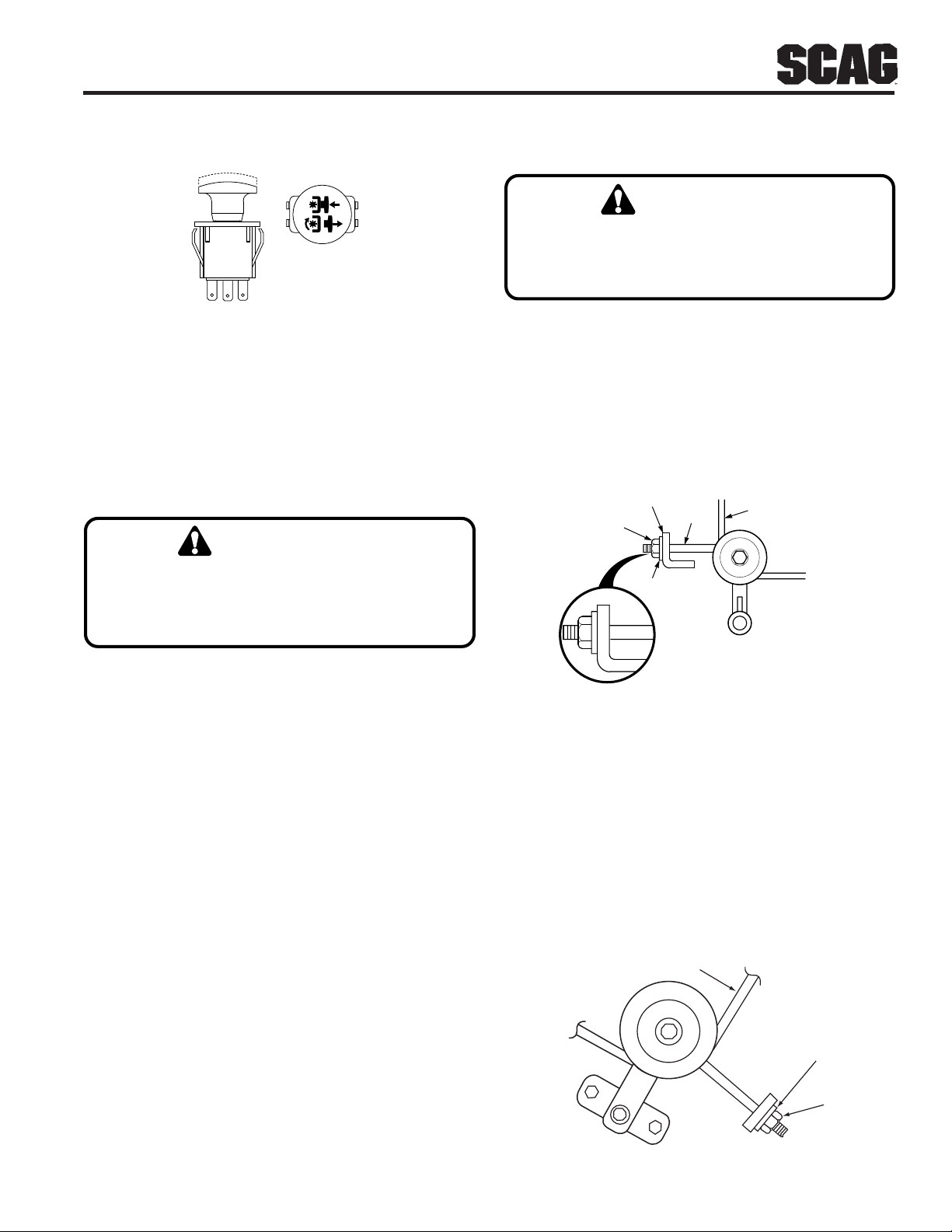

2. Adjust the cutter deck drive belt using a belt tension

gauge. Adjust the belt so that the belt moves 1/2"

with 10 pounds of pressure. Adjust the tension by

tightening or loosening the J-bolt nut. ( See figure 1).

END OF L-SHAPED

BRACKET

NUT

CUTTER DECK DRIVE BELT TENSION

"J" BOLT

WASHER

ALIGNMENT IDLER - L.H.

BELT

SC400G

Figure 1. Deck Drive Belt Adjustment

-NOTE-

Due to initial belt stretch and to prevent the belt

from slipping, check this adjustment after the

first 2 hours, 4 hours and 8 hours of operation.

7. When the steering brake levers are released, the

machine will travel straight. To make a right turn,

squeeze the RH lever. To turn left, squeeze the LH

lever.

8. TO STOP, squeeze both levers, lock the neutral

latches, and shift the transmission into neutral.

3. Adjust the RH blade drive belt using a belt tension

gauge. Adjust the belt so that the belt moves 1/2"

with 10 pounds of pressure. Adjust the tension by

tightening or loosening the J-bolt nut. (See Figure 2

& 3).

Figure 2. Cutter Deck Belt Adjustment R.H.

9

Page 14

CUTTER DECK BELT ADJUSTMENTS

5

(CONT'D)

BELT TENSION

ADJUSTMENT IDLER

DISCHARGE

AREA

CHECK BLADE DRIVE

BELT TENSION HERE

CUTTER DECK

ADJUSTMENT

IDLER

SC402G

Figure 3. Cutter Deck Belt

4. Replace the belt cover.

TRANSMISSION DRIVE BELT

Adjust the transmission drive belt so that there is about a

3/16" deflection with 10 lbs. of pressure. Adjust by

loosening idler pulley mounting bolt and sliding the idler

left or right to change belt tension.

DRIVE CONTROL ADJUSTMENTS

1. Adjust the steering control rods so that there is

approximately 3/4" clearance from the bottom of the

rod to the bottom of the neutral latch slot when in the

drive position. (See Figure 4)

Neutral

Latch

2. Adjust the steering brake rods so that the brakes do

not apply until the steering levers are pulled tight to

the handles. When the steering levers are locked in

the neutral position the machine should move freely.

CUTTER DECK ADJUSTMENTS

Due to the many cutting conditions that exist, it is difficult

to suggest a cutter deck setting that will work for every

lawn. There are two adjustments that can be made on

these decks, pitch and height.

PITCH is the angle of the blades (comparing front to

rear). A 1/4" downward pitch (front of deck down) is

recommended for best cutting performance.

HEIGHT is the nominal distance the blade is off of the

ground. This measurement is made with the blades

pointed side to side and distance is measured between

cutting tip and ground. (Also see Blade Height Adjustment, next page).

Changes to the cutting height can be achieved by repositioning the cutter deck. (This adjustment will also effect

the pitch of the deck). There are three available positions

(See Figure 5).

LOW CUT (1 3/4" to 3")

Neutral Lock

Position

Drive Position

3/4"

Steering

Brake Lever

SC404GB0

-NOTE-

Operator presence lever removed for clarity.

Never operate equipment with the interlock system

disconnected.

Figure 4. Steering Control Rod Adjustment

MID RANGE

(2 1/2" to 3 3/4")

HIGH CUT

(3 1/4" to 4 1/2")

SC405G-2

Figure 5. Cutting Height Adjustment

10

Page 15

CUTTER DECK ADJUSTMENTS

(CONT'D)

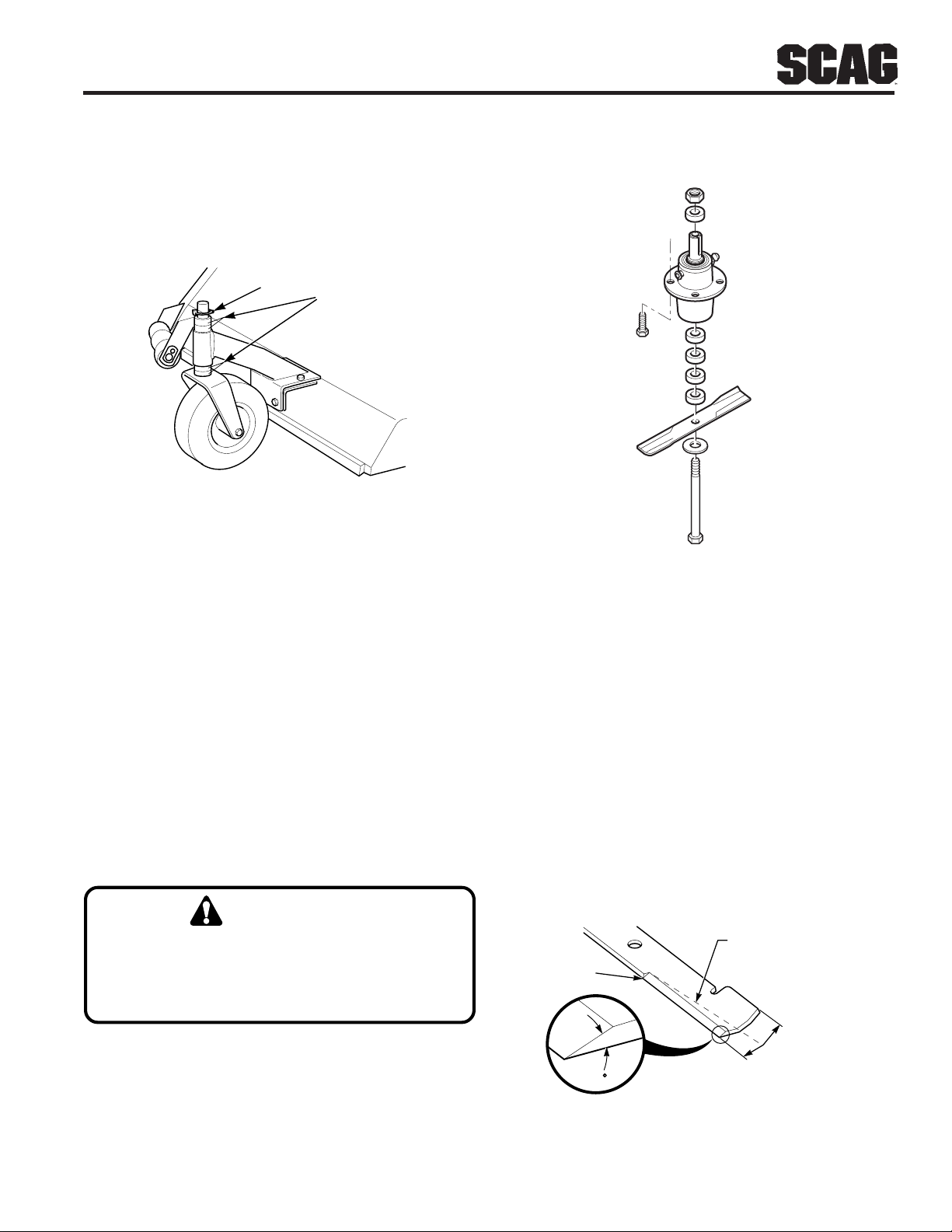

Caster spacers also can be repositioned to change cutting

heights and to change the pitch of the deck. (See Fig

ure

6).

Pin

Spacers

2002SGB005

Figure 6. Caster Wheel Spacers

BLADE HEIGHT ADJUSTMENT

2002 SC407G

Figure 7. Blade Spacers

Adjusting the blade height can be done by moving any

number of the five smaller 1/4" spacers on the blade

mounting bolts to the top of the spindle shaft or below the

spindle shaft.

-NOTE-

All blades should be positioned equally.

For best cut and discharge, a minimum of three spacers

should be installed between the blade and the spindle

(See Figure 7).

WARNING:

Blades have a sharp cutting edge. Wear proper

eye protection and protective gloves or wrap

blades with protective material when removing,

sharpening and installing blades.

CUTTER BLADES

Do not sharpen beyond 1/3 of the width of the blade.

(See Figure 8).

-NOTE-

Dress the blade with a file. Using a wheel

grinder may burn the blade. Check the balance

of the blade. If blades are out of balance, vibration and premature wear of spindle assembly can

occur. See your authorized Scag dealer for

blade balancing or special tools, if you choose to

balance your own blades.

Angle Blade Back

Do Not Cut In

X

X Must NOT Exceed

30

1/3 Blade Width

SGB033

11

Figure 8. Blade Sharpening

Page 16

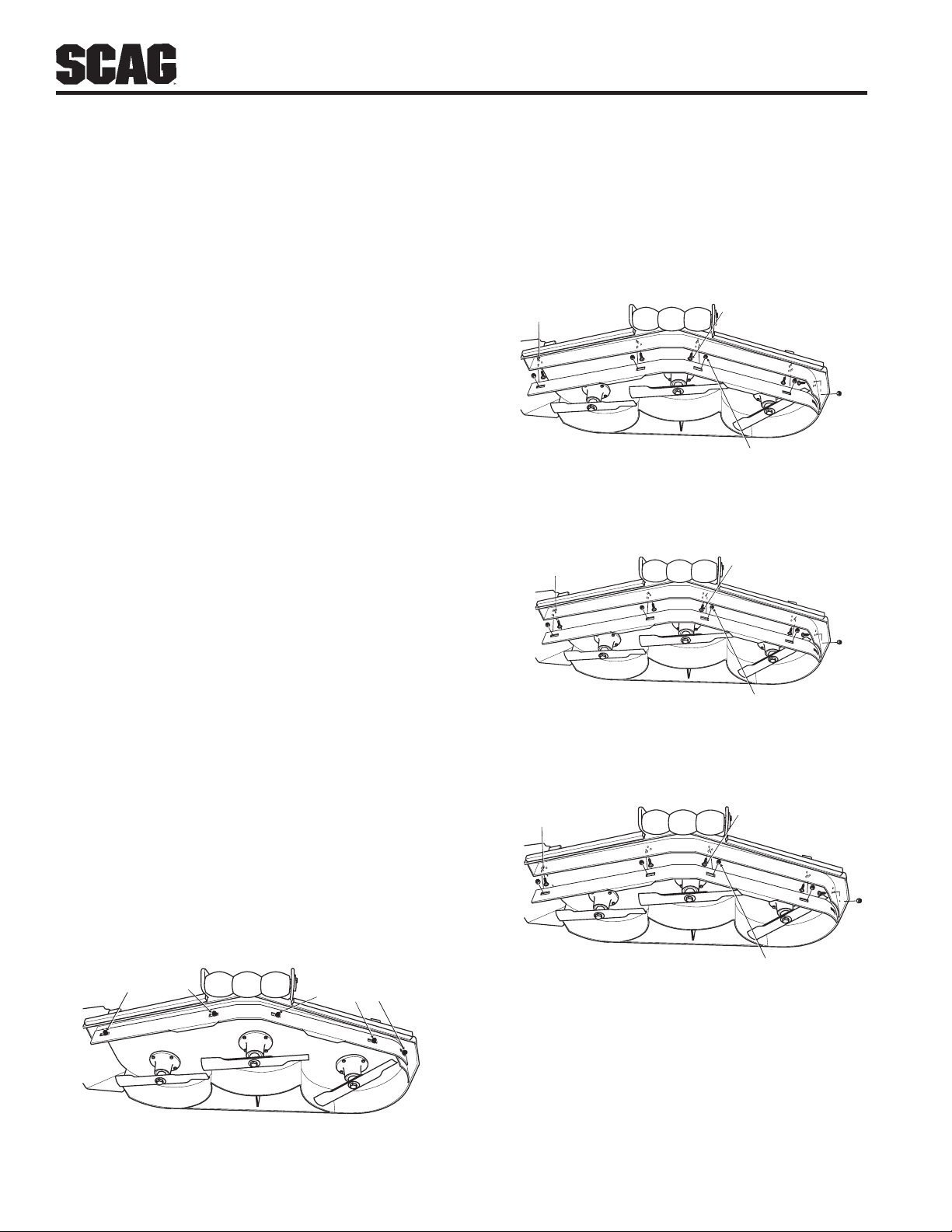

CUSTOM-CUT BAFFLE ADJUSTMENT

The Custom-Cut Baffle is designed to deliver optimum

airflow and superior cutting performance in any type of

grass. The Custom-Cut Baffle can be raised or lowered

to precisely tailor the deck's performance for the type of

grass being cut. The baffle can be set in three (3)

different positions for optimum performance.

A. 3" Position - baffle is installed using the top set of

holes on the front baffle welded inside the cutter

deck. (See Figure 10). The Advantage cutter deck

will deliver the best quality-of-cut in very tall, wiry ,

tough to cut grass.

B. 3-1/2" Position (factory setting) - baffle is installed

using the middle set of holes on the front baffle

welded inside the cutter deck. (See Figure 11). For

general purpose cutting, place the Custom Cut Baffle

in the 3-1/2" position. This gives the best mix of

cutting performance in all types of grass.

C. 4" Position - baffle is installed using the bottom set

of holes on the front baffle welded inside the cutter

deck. (See Figure 12). Placing the baffle in the 4"

setting will enhance fall cutting (leaf pickup) and

reduce cutter deck "blowout".

TO ADJUST THE CUSTOM-CUT BAFFLE

HEIGHT:

2. Move the Custom-Cut Baffle to desired position. (See

Figures 10 through 12 for position)

3. Reinstall the mounting hardware as shown. (See Figures

10 though 12). Torque hardware to 39ft.lbs.

TOP SET OF HOLES

FOR 3" SETTING

CARRIAGE BOLT

2004 CCB - 3" Setting

ELASTIC STOP

NUT

Figure 10. 3" Custom-Cut Baffle Position

MIDDLE SET OF HOLES

FOR 3-1/2" SETTING

CARRIAGE BOLT

2004 CCB - 3-1/2" Setting

ELASTIC STOP

NUT

Figure 11. 3-1/2" Custom-Cut Baffle Position

1. Remove the hardware securing the Custom-Cut Baffle

to the cutter deck (See Figure 9).

-NOTE-

Hardware location used in the illustrations are for

reference only. Location of hardware may vary

depending on the cutter deck size.

MOUNTING

HARDWARE

MOUNTING

HARDWARE

2004 CCB

Figure 9. Custom-Cut Baffle

BOTTOM SET OF HOLES

FOR 4" SETTING

CARRIAGE BOLT

Figure 12. 4" Custom-Cut Baffle Position

12

2004 CCB - 4" Setting

ELASTIC STOP

NUT

Page 17

CHECKING ENGINE CRANKCASE OIL LEVEL

The engine oil level should be checked after every 8

hours of operation or daily as instructed in the Engine

Operator’s Manual furnished with this mower .

CHANGING ENGINE CRANKCASE OIL

After the first 5 hours of operation, change the engine

crankcase oil and replace the oil filter. Thereafter,

change the engine crankcase oil after every 100 hours of

operation or bi-weekly, whichever occurs first. Refer to

the Engine Operator’s Manual furnished with this mower

for instructions.

CHANGING ENGINE OIL FILTER

After the first 5 hours of operation, replace the engine oil

filter. Thereafter, replace the oil filter every 200 hours of

operation or every month, whichever occurs first. Refer

to Engine Operator’s Manual for instructions.

ENGINE AIR CLEANER

3. Repair damaged metal surfaces using Scag touch-up

paint (P/N 48521) available from your authorized

Scag dealer. Wax the mower with an automotive

paint wax for maximum paint protection.

For any air cleaner, the operating environment dictates

how often the air cleaner should be serviced. Refer to

the Engine Operator’s Manual furnished with this mower

for instructions.

-NOTE-

In extremely dusty conditions it may be necessary

to service the air cleaner daily to prevent engine

damage.

CLEANING THE MACHINE

CAUTION:

Do not wash any portion of the equipment while it

is hot. Do not wash the engine; use compressed

air.

1. After each use, wash the mower and cutter deck.

Use cold water and automotive cleaners. Do not use

pressure cleaners.

2. Do not spray electrical components.

13

Page 18

LUBRICATION & MAINTENANCE

BREAK-IN

8 HOURS (DAILY)

40 HOURS (WEEKLY)

+ Grease spindle until grease comes out the relief valve.

Compatible Greases: Lidok EP #2 (found at industrial shops)

Ronex MP (Exxon service stations)

Shell Alvania (Shell service stations)

100 HOURS (BIWEEKLY)

Mobilux #2 (Mobil service stations)

Super Lub M EP #2 (Conoco service stations)

500 HRS OR ANNUALLY

PROCEDURE

X

X

X Check engine oil Do not over fill

X Remove debris from under belt cover More often if needed

X Sharpen cutter blades More often if needed

X Grease spindle bearings + US Lithium MP White Grease 2125

X Clean air filter More often if needed

X Check belt tension

X Check tire pressure Add or adjust as required

X Change engine oil See engine mfg. information

X Replace air filter More often if needed

X Grease caster wheel bearings Chassis grease

X Grease caster wheel pivot shafts Chassis grease

X Grease idler pulley bracket on cutter deck Chassis grease

X Grease drive wheel bearings Chassis grease

X Grease transmission couplers Chassis grease

X Grease idler bracket LH & RH Chassis grease

X Check all hardware for proper tightness More often if needed

Check all hardware for proper tightness

Change engine oil and filter at 5 hours

X Adjust air gap on electric clutch Contact your Scag dealer for information about

making this adjustment

COMMENTS

14

Page 19

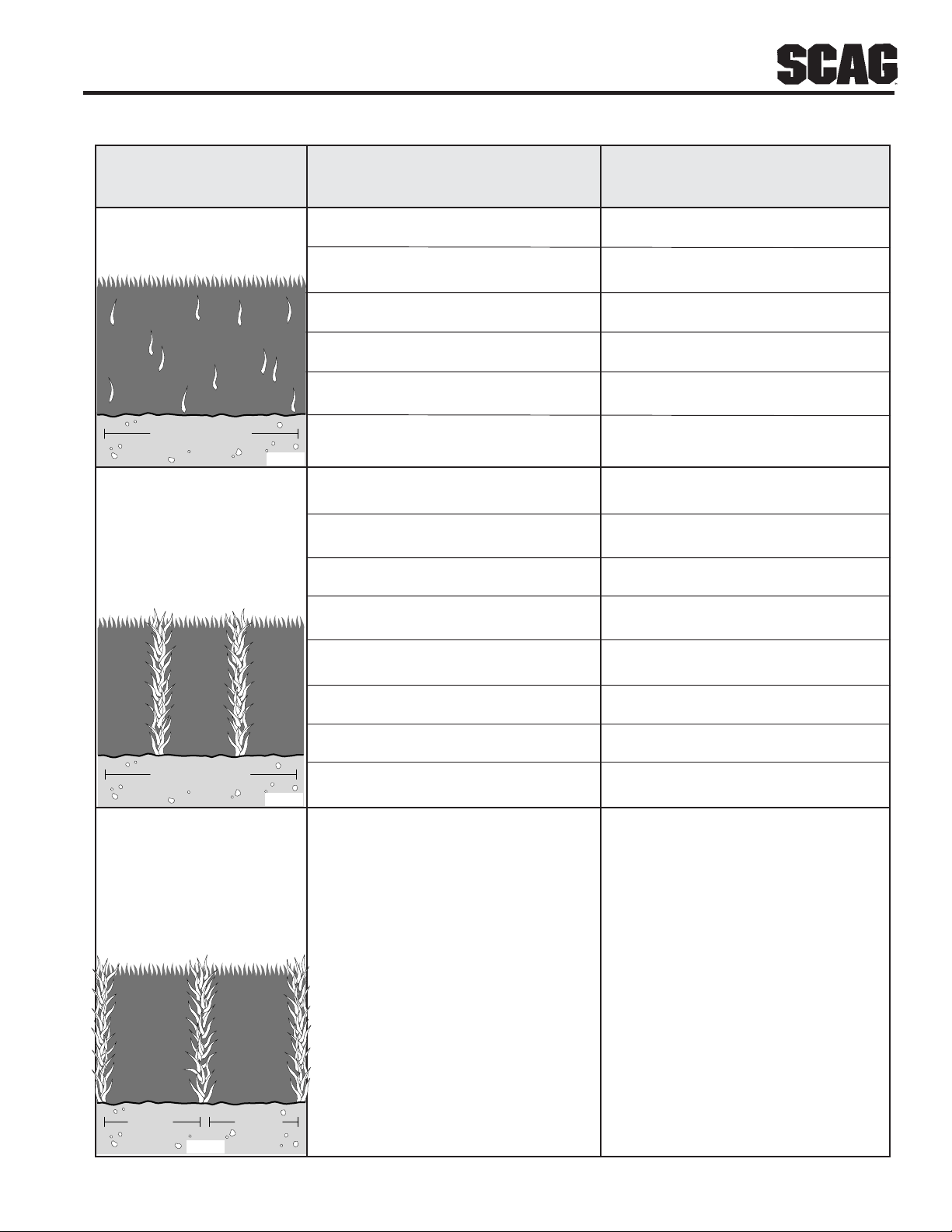

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Stringers - Occasional Low engine RPM Run engine at full 3600 RPM

Blades of Uncut

Grass Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Dull blades, incorrect sharpening Sharpen blades

Deck plugged, grass accumulation Clean underside of deck

Width of Deck

SGB020

Belts slipping Adjust belt tensions

Streaking - Strips of Dull, worn blades Sharpen blades

Uncut Grass in Cutting

Path Incorrect blade sharpening Sharpen blades

Low engine RPM Run engine at full 3600 RPM

Belt slipping Adjust belt tension

Deck plugged, grass accumulation Clean underside of deck

Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Width of Deck

SGB018

Bent blades Replace blades

Streaking - Strips of Not enough overlapping Increase the overlap of each

Uncut Grass Between between rows pass

Cutting Paths

Width

of

Deck

SGB019

Width

of

Deck

15

Page 20

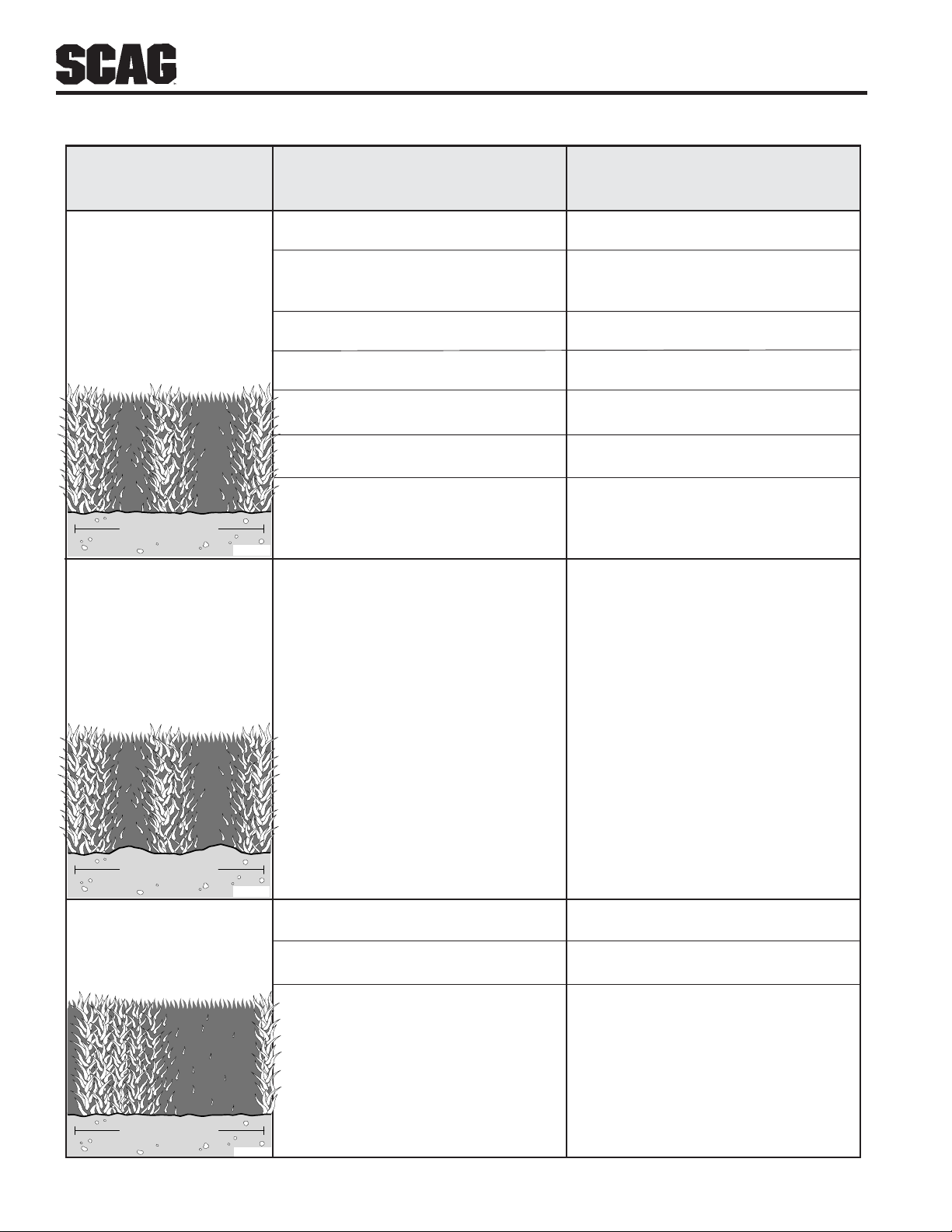

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Uneven Cut on Flat Lift worn off of blade Replace blade

Ground - Wavy

High-Low Blade upside down Mount with cutting edge toward

Appearance, ground

Scalloped Cut, or

Rough Contour Deck plugged, grass accumulation Clean underside of deck

Too much blade angle (deck pitch) Adjust pitch and level

Deck mounted improperly See your authorized SCAG dealer

Bent spindle area See your authorized SCAG dealer

Dull blade Sharpen blade

Width of Deck

SGB020

Uneven Cut on Uneven ground May need to reduce ground speed,

Uneven Ground - raise cutting height, and/or change

Wavy Appearance, direction of cut

High-Low Scalloped

Cut, or Rough Contour

Width of Deck

SGB021

Sloping Ridge Across Tire pressures not equal Check and adjust tire pressure

Width of Cutting Path

Wheels uneven Check and adjust tire pressure

Deck mounted incorrectly See your authorized SCAG dealer

Width of Deck

SGB023

16

Page 21

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Scalping - Blades Low tire pressures Check and adjust pressures

Hitting Dirt or

Cutting Very Close to Ground speed too fast Slow speed to adjust for conditions

the Ground

Cutting too low May need to reduce ground speed,

raise cutting height, change direction

of cut, and/or change pitch and level

Rough terrain May need to reduce ground speed,

raise cutting height, and/or change

direction of cut

Ground speed too fast Slow speed to adjust for conditions

Width of Deck

SGB022

Wet grass Cut grass after it has dried out

Step Cut Blades not mounted evenly Adjust pitch and level

Ridge in Center of

Cutting Path Bent blade Replace blade

Internal spindle failure See your authorized SCAG dealer

Mounting of spindle incorrect See your authorized SCAG dealer

Width of Deck

SGB024

Slope Cut - Sloping Bent spindle mounting area See your authorized SCAG dealer

Ridges Across Width

of Cutting Path Internal spindle failure See your authorized SCAG dealer

Bent deck housing See your authorized SCAG dealer

Width of Deck

SGB025

17

Page 22

TECHNICAL SPECIFICATIONS

MODELS SW32-15KA, SW36A-15KA, SW36A-15KH, SW48A-15KA,

SW48A-15KH, SW48A-17KA, SW52A-17KA, SW52A-18KH,

SW52A-18HN,

ENGINE

General Type: Heavy duty industrial/commercial

Brand / Model: Kawasaki FH451V & FH500V

Kohler CV15T & CV493T

Honda GXV610QAF

Horsepower: Kawasaki FH451V=15HP, FH500V=17HP

Kohler CV15T=15 HP, CV493T=18HP

Honda GXV610QAF=18HP

Type: Kawasaki 15 HP & 17 HP 4 cycle, air cooled, V twin cylinder,

vertical shaft engine.

Kohler 15 HP & 18 HP = 4 cycle gasoline engine, air cooled, single

cylinder, vertical shaft engine.

Honda 18HP = 4 cycle gasoline engine, air cooled, V twin cylinder,

vertical shaft engine.

Displacement: Kawasaki 15 HP=494cc: 17HP=494cc:

Kohler 15 HP=426cc: 18 HP=490cc

Honda 18 HP=615cc

Gove rno r: Mechanical type governor with variable speed control. Settings:

Kawasaki 15 HP = 3600 rpm (+/- 75 rpm), idle set at 1200 rpm

(+/- 75rpm), 17HP = 3600 rpm (+/- 75 rpm), idle set at 1550 rpm

(+/- 75 rpm)

Kohler 15 HP = 3600 rpm (+/- 50 rpm), idle set at 1200 rpm (+/ - 75 rpm),

18HP = 3600 rpm (+/- 50 rpm), idle set at 1500 rpm (+/- 75 rpm)

Honda 18 HP = 3600 rpm (+/- 150 rpm), idle set at 1700 rpm

(+/- 150 rpm)

Air Cleaner: Large capacity duel element with cyclonic-type air filter.

Exhaust: Single & dual exhaust canister muffler.

Starter/Electrical: Electronic ignition with recoil starter.

Fuel Pump Group: Varied - See manufacturer's specification.

Oil Pump Group: Varied - See manufacturer's specification.

Valve Group: Varied - See manufacturer's specification.

ENGINE DECK

Thickness: 7 gauge steel.

Fuel Tank: 6 gallon (19.0 liters) seamless polyethylene with integral cup holder.

Drive Wheels/Tires: 13.0 x 6.50-6 two-ply pneumatic tubeless.

Handle Bars: 1-1/4" diameter.

Date of Issue: July, 2004

Specifications Subject to Change Without Notice

18

Page 23

Section 3

TECHNICAL SPECIFICATIONS (CON'T)

CUTTER DECKS SWM 36 Advantage, SWM 48 Advantage, SWM 52 Advantage,

SWM 61 Advantage.

Type: Out-front design with anti-scalp rollers

Construction: SWM36A, 48A: 7-gauge steel with 7-gauge (3/16") steel skirt

SWM52A, 61A:10-gauge steel with 7-gauge (3/16") steel skirt

Cutting Width: 35.5" (90.2 cm), 48.0 (122.0 cm), 52.0 " (132.0 cm),

61.0 " (155.0 cm).

Cutting Height Adjustment: Adjustable from 1-3/4" to 4-1/4" in 1/4" increments

Cutter Blades: Marbain

SWM 36: Two (2) 18"; SWM 48: Three (3) 16.5"

SWM 52: Three (3) 18"; SWM 61: Three (3) 21"

Blade Engagement: Electric blade brake clutch with instrument panel switch

Discharge Opening: Extra wide 11.5", 13.75 " discharge opening with hinged

chute

Caster Wheels: 9.4 x 3.5 smooth tread flotation, inner tubes, split rims, roller

bearings, with quick pin removal

Spindles: Cast housing, taper roller bearing, low maintenance with

top access grease fitting and grease overfill relief poppet

Spindle Pulleys: Split steel with easily removed taper hubs

Idler Pulley: 5" diameter pulley, welded and riveted construction,

1-3/8" O.D. Bearings

Idler Arm: Heavy duty idler arm of 1/4" channel steel

Cutter Deck Belts: B-section with Kevlar cord

TM

, .197 thickness

ADDITIONAL SPECIFICATIONS

OPTIONAL ITEMS/ATTACHMENTS

Fabric Grass Catcher: GC-F4 Grass Catcher with 4 cubic ft. capacity

Metal Grass Catcher: GC-4D Grass Catcher with 4 cubic ft. capacity and rope pull

dump or pick-up and dump

Turbo-Baffle High velocity discharge baffle. Improves quality-of-cut, and

discharge disbursement.

Hurricane Mulch Kit: The unique Hurricane Mulch System employs "eye of the

hurricane" mulching plates combined with bolt-in v-baffles,

flow directors, Eliminator blades, and a side discharge close-off

plate.

Cup Holder: Enable operator to safely and conveniently carry a beverage with

them.

APPROXIMATE DIMENSIONS SWM36A SWM48A SWM52A SWM61A

Length: 74.0" 76" 78" 76.0"

Length with Grass Catcher: 74.0" 76" 78" 76.0"

Tracking Width: 37.0" 42.0" 42.0" 42.0"

Width: 54.5" 59.0" 62" 70.0"

Width (with discharge chute up): 37.5" 49.0" 52" 63.0"

Width with grass catcher: 55.0" 65.0" 78" 80.0"

Height: 43" 43" 43" 43"

Height with grass catcher: 43" 43" 43" 43"

Weight 515 lbs. 555 lbs 560 lbs 565 lbs.

Weight with grass catcher: 555 lbs. 595 lbs 600 lbs. 605 lbs.

Turning Radius: Zero Zero Zero Zero

Date of Issue: July, 2004

Specifications Subject to Change Without Notice

19

Page 24

32" & 36A" CUTTER DECKS

53

20

20A

18

52

23

23A

52

19

13

21

21

25

25

29

11

27

26

39

29

33

26

28

27

30

30A

32

34

33

43

42

54

42

14

36

35

28

11

7

22

A

31

24

56

9

A

40

24

45

41

37

44

38

39

2

55

14

57

58

19

12

11

17

1

1A

10

11

15

15A

16

SW-SWZ04CD36A

50

48

47

8

46

5

54

6

3

5

51

49

20

Page 25

32" & 36A" CUTTER DECKS

Ref. Part

No. Number Description 32 36A

1 461708 Cutter Deck (Includes Decals) x

1A 461634 Cutter Deck (Includes Decals) x

2 461663 Cutter Spindle Assy. x x

3 43312 Spacer, Outside x x

5 481022 Tapered Bearing (Two) x x

6 43644 Spindle Housing x x

7 04001-154 Bolt, 5/16-18 x 4-3/4" Hex Head x x

8 43589 Spindle Shaft x x

9 04001-77 Bolt, 3/8-16 x 3-1/2" Hex Head x x

10 04063-08 Key, 1/4 x 1/4 x 2" x x

11 43592 Spacer, Cutter Blade - Small x x

12 04001-175 Bolt, 5/16-18 x 1-1/2" Hex Head Grade 8 x x

13 482245 Spring, Chute Return x x

14 04019-03 Nut 5/16-18 Serrated Flange x x

15 481706 Cutter Blade, 16-1/2" Marbain x

15 481707 Cutter Blade, 18" Marbain x

15A 481710 Cutter Blade 16-1/2 Hi Lift Marbain x

15A 481711 Cutter Blade, 18 Hi Lift Marbain x

16 04043-06 Flatwasher, 5/8 W x x

17 04001-41 Hex Hd. Bolt, 5/8-11 x 9-1/2" x x

18 46079 Caster Assembly x x

19 04017-16 Cpscrw,5/16-18 x 3/4" Ser.Flg. Hex Head x x

20 461291 Discharge Chute x

20A 461295 Discharge Chute x

21 04021-10 Hex Nut, 5/16-18 Elastic Stop x x

22 04001-09 Hex Hd Bolt, 5/16-18 x 1" x x

23 461709 Belt Cover Assy (Includes Decal) x

23A 461413 Belt Cover Assy (Includes Decal) x

24 04043-04 Flat Washer, 3/8" Special x x

25 04029-03 Wing Nut, 3/8-16 x x

26 482744 Pulley x x

27 48926 Tapered Hub x x

28 04001-172 Hex Hd. Bolt, 1/4-20 x 1" x x

29 04020-09 Hex Nut, 5/8-11 x x

30 48278 Belt, Blade Drive x

30A 48204 Belt, Blade Drive x

31 04021-22 Elastic Stop Nut, 5/16-18 Grade 8 x x

32 04021-05 Hex Nut, 3/8-16 Center Locknut x x

33 04019-04 Nut, 3/8-16 Serrated Flange x x

34 04004-02 Support, Belt Cover x x

35 04017-36 Cpscrw, 1/2-13 x 1"Ser.Flg. HH x x

36 04112-05 Nut, 1/2-13 Spiralock x x

37 43277 Spacer, J-Hook x x

38 04041-12 Washer, 3/8 x 1-1/2 x 16 GA x x

39 04021-09 Elastic Stop Nut, 3/8-16 x x

40 45423 Idler Pivot x x

41 46748 Idler Arm Assy. (Inc. 42 & 54) x x

Ref. Part

No . Number Description 32 36A

42 48100-02 Bronze Bearing x x

43 04050-05 Retaining Ring, 1-1/8" Ext. ”E” x x

44 44078 J-Hook x x

45 482416 Idler Pulley, Belt Clutch x x

46 481024 Seal, Cutter Spindle x x

47 43297 Spindle Bushing x x

48 43296 Spacer, Inside x x

49 481035 Nut,1.06-18 x x

50 48677 Relief Fitting, Cutter Spindle x x

51 481025 Seal, Cutter Spindle x x

52 48098 Spindle Shield x x

53 04029-04 Wing Nut, 3/8-16 (Small) RH side x x

54 48114-04 Grease Fitting x x

55 04021-09 Nut, Hex Elastic Stop 3/8-16 x x

56 04030-03 Lock Washer, 5/16" x x

57 04003-23 Bolt, Carriage 3/8-16 x 1" x x

58 423783 Baffle Weldment x

21

Page 26

48A, 52A" CUTTER DECKS

26

19

24

21

18

20

67

22

22

14

26

70

64

28

30

11

4

26

14

31

13

23

23A

65

11

20

35

34

37

35

29

30

38

32

29

28

11

36

A

33

28

20

25

30

27

40

29

50

25

43

45

48

49

36

9

63

62

7

39

72

73

2

1

10

A

62

14

60

5

54

47

46

14

44

41, 41A

46

7

36

25

59

25

61

52

42

42A

53

49

36

8

51

7

69

71

68

68A

22

12

11

17

11

15

15A

16

SW-SWZ05CD48, 52"

56

6

55

3

5

66

57

Page 27

48A, 52A" CUTTER DECKS

Ref. Part

No. No. Description 48A 52A

1 461636 Cutter Deck (Includes decals) x

461643 Cutter Deck (Includes decals) x

2 461663 Spindle Assembly x x

3 43296 Spacer, Inside x x

4 482744 Pulley x x

5 481022 Tapered Bearing (Two) x x

6 43644 Spindle Housing x x

7 48114-04 Grease Fitting Str. 5/16" x x

8 43589 Spindle Shaft, Tapered Brng x x

9 45037 Idler Pivot x x

10 04063-08 Key, 1/4 x 1/4 x 2" x x

11 43592 Spacer, Cutter Blade - Small x x

12 04001-175 Bolt, 5/16-18 x 1-1/2" Hex Head GR-8 x x

13 04001-154 Bolt, 5/16-18 x 4-3/4" Hex Head x x

14 04019-03 Serrated Flange Nut, 5/16-18 x x

15 481706 Cutter Blade 16-1/2" Marbain x

15 481707 Cutter Blade 18" Marbain x

15A 481710 Cutter Blade 16-1/2 High Lift Marbain x

15A 481711 Cutter Blade 18 High Lift Marbain x

16 04043-06 Flatwasher,5/8" (.688 x 1.75 x .134) x x

17 04001-41 Hex Head Bolt, 5/8-11 x 9-1/2" x x

18 46079 Caster Assembly x x

19 48098 Spindle Shield x x

20 04017-16 Capscrew, 5/16-18 x 3/4" x x

21 461295 Discharge Chute x x

22 04021-10 Nut, 5/16-18 Elastic Elastic Stop x x

23 04001-11 Bolt, 5/16-18 x 1-1/2" Hex Head (Front) x x

23A 04001-12 Bolt, 5/16-18 x 1-3/4" Hex Head (Rear) x x

24 461095 Belt Cover (Includes decals) x

46804 Belt Cover (Includes decals) x

25 04043-04 Flat Washer, 3/8" Special x x

26 04029-03 Wing Nut, 3/8-16 (Large) x x

27 482744 Pulley x x

28 48926 Tapered Hub x x

29 04001-172 Bolt, 1/4-20 x 1" Hex Head Grade 8 x x

30 04020-09 Nut, 5/8-11 Hex x x

31 482748 Pulley, Double x x

32 48087 Belt, RH Blade Drive x

48285 Belt, RH Blade Drive x

33 48089 Belt, Blade Drive x

48286 Belt, Blade Drive x

34 04021-05 Nut, 3/8-16, Nut Centerlock x x

35 04019-04 Nut, 3/8-16, Serrated Flange x x

36 04021-09 Nut, 3/8-16 Elastic Stop x x

37 04004-02 Support, Belt Cover x x

38 04001-09 Bolt, 5/16-18 x 1" Hex Head x x

39 04017-36 Cpscrw, 1/2-13 x 1" Ser.Flg. HH x x

Ref. Part

No. No. Description 48A 52A

40 04112-05 Nut, 1/2-13 Spiralock x x

41 04041-08 Flat Washer 3/4" Special x x

41A 04041-08S Flat Washer 3/4" Special x x

42 44078 J-Hook x

42A 43028 J-Hook x

43 48181 Idler Pulley, “V” Groove x x

44 04050-02 Retaining Ring, 3/4" Ext.”E” x x

45 46081 Idler Arm Assy. (Incl. 7 & 46) x x

46 48100-05 Bronze Bearing x x

47 43028 J-Rod, Idler Pulley x x

48 43077 Spacer, J-Rod x x

49 04041-12 Washer, 3/8 x 1-1/2 x 16 ga. x x

50 04001-46 Bolt, 3/8-16 x 2-1/4" Hex Head x x

51 481024 Seal, Cutter Spindle x x

52 46748 Idler Arm Assy (Includes 7 & 62) x x

53 43277 Spacer, J-Rod x x

54 48677 Reiief Fitting, Cutter Spindle x x

55 43312 Spacer, Outside, Cutter Spindle x x

56 43297 Spindle Bushing x x

57 481035 Nut, Cutter Spindle x x

58 04029-04 Wing Nut, 3/8-16

59 04001-77 Bolt, 3/8-16 x 3-1/2" Hex Head x x

60 45329 Idler Pivot x x

61 482416 Idler Pulley, Belt Clutch x x

62 48100-02 Bronze Bearing x x

63 04050-05 Retaining Ring x x

64 482295 Guide Roller x x

65 45944 Roller Shaft x x

66 481025 Seal, Cutter Spindle x x

67 482245 Spring, Chute Return x x

68 423786 Baffle Weldment 48A x

68A 423803 Baffle Weldment 52A x

69 04021-09 Nut, Hex Elastic Stop 3/8-16 x x

70 04003-23 Bolt, Carriage 3/8-16 x 1" x x

71 423972 Heatshield x x

72 04021-22 Nut, Hex Lock 5/16-18 x x

73 04030-03 Lock Washer 5/16 x x

23

Page 28

NOTES

24

Page 29

2

3

4

3

CASTER ASSEMBLY

1

2

6

5

8

7

9

10

11

13

12

17

16

14

15

16

SW-SWZ2003CSTR

Ref. Part 32 36A

No. No. Description 48A 52 A

1 04066-01 Quick Pin x x

2 43037-01 Spacer, Caster Yoke, 1/2" Long x x

3 48100-01 Bronze Bearing x x

4 48114-04 Grease Fitting x x

5 46082 Support Assembly (Includes Items (3 & 4) x x

6 45006 Caster Yoke x x

7 04021-07 Elastic Stop Nut, 1/2-13 x x

8 43022 Sleeve, Caster Wheel Bearing x x

9 04001-37 Hex Hd. Bolt, 1/3-13 x 5-1/2" x x

10 48307 Wheel Assy. (Includes Items 11-17) x x

11 481774 Tire Only, Caster Wheel x x

481773 Inner Tube Only (Not Shown) x x

12 481768 Hub Assembly x x

13 48114-03 Grease Fitting, 45 Degree 1/4-28 x x

14 481771 Tapered Nut, 5/16-24 x x

15 481772 Rim Pair, Caster Wheel x x

16 481770 Retainer, Bearing, Caster Wheel x x

17 481769 Roller Bearing, Caster Wheel x x

25

Page 30

ENGINE DECK

56

12

43

15 KA

17 KA

ONLY

55

42

45

49

44

18

34

57

1

18

40

46

11

14

48

18

52

52

4

5

3

10

(3)

13

(1 loc.)

5A

7

8

6

60

53

9

18 HN

ONLY

39

41

40, 40A

38

38A

38B

38C

38D

39

29

28

A

15

37

27

24

26

22

35

47

17

16

23

25

2

58

20

A

51

54

33

59

61

2

47

50

21

30

31

32A

32B

SW2005ED

26

Page 31

ENGINE DECK

Ref. Part 15KH 15KA 18HN

No. No. Description 18KH 17KA

1 482853 Engine,15HP Kohler x

(CV 15T, Spec PS-41621)

482854 Engine, 18HP Kohler x

(CV493T, Spec PS-27526)

482804 Engine, 15HP Kawasaki x

(Spec FH451V-AS19)

482805 Engine, 17HP Kawasaki x

(Spec FH500V-AS42)

482705 Engine, 18HP Honda x

(Spec GXV610QAF)

2 48030-09 Cable Clamp x x x

3 481580 Transmission, 5-speed x x x

(Peerless 700-070, 9 tooth spline)

4 48231 Neutral Safety Switch x x x

5 48122-01 Fibre Washer, thin x x x

5A 48122-02 Fibre Washer, thick x x x

6 481581 Coupler, Jackshaft x x x

7 48114-05 Grease Fitting, straight 1/4-28 x x x

8 481582 Jackshaft (fits SW32,36,48 & 52) x x x

9 04063-09 Key, Hi-Pro #9 x x x

10 04017-16 Bolt, 5/16-18 X 3/4" Hex Head x x x

11 43085** Wheel Axle (SW36,48 & 52) x x x

43104** Wheel Axle (SW 32) x

12 Muffler (Purchase from Kawasaki) x

13 04001-08 Bolt, 5/16-18 X 3/4" Hex Head x x x

14 04040-14 Flat Washer 1/4" (.312 X .75 X .065) x x x

15 04030-03 Lock Wshr. 5/16" x x x

16 04019-04 Nut, 3/8-16 Serrated Flange x x x

17 461741 Engine Deck (fits SW32) x x

461743 Engine Deck (fits SW36,48 & 52) x x x

18 04021-08 Nut, 1/4-20 Elastic Stop x x

19 04019-03 Nut, 5/16-18 Serrated Flange

20 04001-51 Bolt, 3/8-16 x 3-3/4" Hex Head x x x

21 461397 Electric Clutch (Ogura) x x x

22 04041-07 Washer, 3/8" (.391 x .938 x .105) x x x

23 48197 Pulley, Transmission Input x x x

24 04063-07 Key, Woodruff #9 x x x

25 04050-09 Retaining Ring, 5/8" Ext, Basic x x x

26 48203 Belt, Transmission Drive x x x

27 481048 Idler Pulley, Transmission x x x

28 481666 Pulley, Traction Drive x x x

29 04063-19 Key, 1/4 x 1/4 x 3/4" x x x

30 04041-28 Flat Washer, 7/16" Special x x x

Ref. Part 15KH 15KA 18HN

No. No. Description 18KH 17KA

31 04030-05 Lock Washer, 7/16" x x x

32A 04102-04 Bolt, 7/16-20 x2-1/2" Hex Head x x

32B 04103-03 Cpsrw, M10-1.5 x55 Metric Hex Hd x

33 04001-12 Bolt, 5/16-18 x 1-3/4" Hex Head x x x

34 04002-07 Bolt, M8-1.25 x 1.0 x

35 04021-09 Nut, 3/8-16 Elastic Stop x x x

36 04040-15 Flat Washer, 5/16" x x x

37 04018-01 Bolt, M8-1.25 x M25 Metric Hex Hd x

38 48192 Wheel Assembly (incl. 38A-38B) x x x

38 48253 Wheel Assembly x x

38A 481860 Tire, 13 x 6.50-6, 2-ply x x x

38B 481859 Rim & Bearing Assembly (incl. 39) x x x

38C 481861 Tire, 13 x 5.00-6 2-ply (SW32 only) x x

38D 481862 Rim Assembly (incl. 39) (SW32 only)

39 481858 Wheel Bearing (OD 2.000 - 2.005) x x x

40 04042-05 Washer, 1-1/16 x 1-3/4 x 12 ga x x x

40A 04041-14 Washer, 1-1/16 x 1-1/2 x 18 ga x x x

41 04050-08 Retaining Ring, 1" Ext.- "E" x x x

42 48200 Pulley, Wheel Drive x x x

43 43088 Spacer, Wheel Pulley x x x

44 48209 Brake Drum x x x

45 04017-19 Bolt, 5/16-18 x 1-1/2" Serrated flange x x x

46 04003-03 Bolt, 3/8-16 x 2" Carriage x x x

47 04021-10 Nut, 5/16-18 Elastic Stop x x x

48 *** Rectifier (Purchase from Honda) x

49 423943 Mounting Bracket, Rectifier x

50 482902 Manifold, Exhaust x

51 481716 Rubber Pad, Clutch Stop x x x

52 04003-02 Bolt, 1/4-20 x 3/4" Carriage x

53 482903 Clamp, Muffler x

54 422533 Backing Plate x x x

55 04003-06 Bolt, 1/4-20 x 1" Carriage x

56 481717 Wire Harness Adapter (15KA, 17KA) x

57 04031-09 Lock Washer Internal Tooth x x

58 421370 Anti Rotation Bracket x x

59 04003-04 Bolt, 5/16-18 x 1" Carriage x x

60 482901 Muffler x

61 422534 Plate, Backing x x x

(fits SW36,48,52)

(incl. 38C-38D) (SW32)

(fits SW36,48,52)

(fits SW36,48 & 52)

x x

** = Requires welding onto chassis.

*** = Honda part number 31750-769-751

27

Page 32

63

64

HANDLE ASSEMBLY

30

7

26

66

25

69

65

69

70

8

27

28

72

8

29

71

1

61

45

44

62

59

47

46

60

57

9

23

48

49 51

20

58

58A

58B

9

12

50

55

67

68

56

52

35

34

19

38

13

31

20

19

14

53

17

19

32

37

14

39

19

15

15A

33

40

16

2245

36

18

54

27

41

43

8

3

24

11

14

13

22

5

4

19

6

5

43A

10

19

2

21

19

SW 2005 HA

28

Page 33

HANDLE ASSEMBLY

Ref. Part 15KH 15KA 18HN

No. N o . Description 18KH 17KA

1 461780 Handle Assembly x x x

2 421360 Belt Guard x x x

3 04017-27 Capscrw, 3/8-16 x 1" Serr. Flg. x x x

4 04041-07 Washer, 3/8" (.391 x .938 x .105) x x x

5 04021-09 Nut, 3/8-16 Elastic Stop x x x

6 48755 Spring, Idler x x x

7 04001-10 Bolt, 5/16-18 x 1-1/4" Hex Head x x x

8 04021-10 Nut, 5/16-18 Elastic Stop x x x

9 04017-05 Capscrew, 1/4-20 x 3/4" Hex Head x x x

10 44140 Control Rod, Steering x x x

11 04062-02 Hair Pin, Small x x x

12 04001-23 Bolt, 3/8-16 x 4-1/2" Hex Head x x x

13 43032 Swivel Joint x x x

14 04062-01 Hair Pin, Large .094 Diameter x x x

15 45847 Idler Bracket, RH x x x

15A 45846 Idler Bracket, LH x x x

16 43092 Idler Sleeve x x x

17 04001-62 Bolt, 3/8-16 x 3/4" Hex Head x x x

18 04004-17 Support Belt Guard x x x

19 04019-04 Nut, 3/8-16 Serrated Flange x x x

20 04019-03 Nut, 5/16-18 Serrated Flange x x x

21 04017-28 Cpscrw, 3/16-18 x 1-1/4" Serr. Flg. x x x

22 43286 Spacer x x x

23 48309 Bushing x x x

24 483042 Steering Lever x x x

25 04017-17 Capscrew, 5/16-18 x 1" Serr. Flg. x x x

26 48312 Bushing x x x

27 04040-15 Washer, 5/16 (.375 x .875 x .083) x x x

28 483040 Spring, Operator Presence x x x

29 451689 Operator Presence Lever, LH x x x

30 451691 Operator Presence Lever, RH x x x

31 44005 Brake Rod x x x

32 45092 Brake Lever x x x

33 45093 Brake Link x x x

34 42254 Brake Link Plate x x x

35 04024-01 Nut, 3/8 Push-on x x x

36 48114-05 Grease Fitting, Straight 1/4-28 x x x

37 04050-01 Retaining Ring, 5/8 Ext. "E" x x x

38 48210 Brake Band x x x

39 04001-45 Bolt, 3/8-16 x 2" Hex Head x x x

40 04031-08 1/4" Internal Tooth Lockwasher x x x

41 04032-01 Curved Spring Washer x x x

42 04015-13 Socket Head Capscrew #8-32 x 1/2" xxx

43 461242 Neutral Latch, RH x x x

43A 461241 Neutral Latch, LH x x x

44 48202A Belt, Wheel Drive x x x

45 48198 Idler Pulley, Wheel Drive x x x

46 482645 Pulley, Jackshaft (Inc. 50) x x x

47 04012-04 Setscrew, Hex Socket Knurl x x x

Cup Pt. 5/16-18 (nylock)

48 43098 Spacer, Jackshaft Pulley x x x

49 48223 Flange, Jackshaft Bearing x x x

50 48224 Bearing, Jackshaft x x x

51 04050-09 Retaining Ring, 5/8 Ext. Basic x x x

52 04030-03 Lock Washer 5/16" x x x

53 04017-16 Capscrew, 5/16-18 x 3/4" Serr. Flg. x x x

Ref. Part 15KH 15KA 18HN

No. N o . Description 18KH 17KA

54 04001-17 Bolt, 5/16-18 x 2" Hex Head

55 04019-02 Nut, 1/4-20 Serrated Flange

56 04040-15 Flatwasher, 5/16 (.375 x .875 x .083)

57 424113 Bracket, Choke Mt.

58 48058 Fuel Hose,1/4"ID, 10" (KH Only)

58A 48058 Fuel Hose,1/4"ID, 23" (KA Only)

58B 48058 Fuel Hose,1/4"ID, 26" (Honda Only)

59 48059-01 Clamp, Fuel Hose

60 482314 Choke Control

61 483041 Plug, Handlebar

62 48308 Valve, Fuel Shut Off

63 461729 Fuel Tank Assy.(Incl. Bush. & Val.)

64 482547 Fuel Tank Cap

65 422279 Shift Lever

66 461163 Shift Lever Extention (incl. 72)

67 04001-09 Capscrew, 5/16-18 x 1" Hex Head

68 04041-07 Washer, 3/8 (.391x .938 x .105)

69 04020-14 Nut, 3/8-24 UNF

70 48028-05 Cable Tie

71 04001-53 Bolt, 5/16-18 x 2-1/2"

72 481839 Grip, Shift Handle

xxx

xxx

xxx

xx

x

x

xxx

xx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

xxx

x

29

Page 34

INSTRUMENT PANEL

3

7

2A

2B

6

5

4

1

8

SW99IP

Ref. Part 15K H 15KA 1 8HN

No. No. Description 18KH 17KA

1 48717 Switch, Neutral Interlock

2A 482814 Throttle Control

2B 48946 Throttle Control

3 481687 Engagement Switch, Electric Clutch

4 48609 Key Switch (Includes hardware)

5 48023 Hour Meter (dealer installed)

6 * Screw, #10-32 x .50 Phillips Washer Head

7 04019-01 Nut, #10-32 Serrated Flange Hex Head

8 482711 Handle Wire Harness, Manual Start

NS 48030-09 Clamp, Wire Harness

x x x

x

x x

x x x

x x x

x x x

x x x

x x x

x x x

x x x

* Common hardware which should be purchased locally. All bolts grade 5 plated, all other fasteners zinc plated.

30

Page 35

PEERLESS 700-070

FOR REFERENCE

ONLY

ORDER PARTS FROM

PEERLESS / TECUMSEH

Ref. Part

No. No. Description

1 772083A Case, Transmisson

2 780086A Needle Bearing Grease Spec

2A 780142 Needle Bearing

3 770061A Case, Transmission

8 792089A Shift Key

9 784266 Shift Collar

10 784376 Shift Rod & Fork

11 778154 Bevel Gear (42 teeth)

12 778176 Bevel Pinion (14 teeth-steel)

20 792077 Steel Ball, 5/16" dia.

21 792078 Set Screw, 3/8-16 x 3/8"

22 792079 Spring

24 780071 Thrust Bearing

25 792073 Screw, 1/4-20 x 1-1/4" (6)

27 792035 Retaining Ring

28 788040 Retaining Ring

29 780072 Washer (6)

30 780108 Washer (5)

32 792001 "O" Ring

34 780105A Flanged Bushing

49 778146A Spur Gear (37 teeth)

REF. PART

NO. NO. DESCRIPTION

50 778125 Spur Rear (35 teeth)

51 778239A Spur Gear (32 teeth-steel)

52 778124A Spur Gear (30 teeth)

53 778123A Spur Gear (25 teeth)

56 778145 Spur Gear (12 teeth-steel)

57 778151 Spur Gear (15 teeth)

58 778240 Spur Gear (18 teeth-steel)

59 778126A Spur Gear (20 teeth)

60 778127A Spur Gear (25 teeth)

65 780139 Washer

66 776135 Input Shaft (3-11/16" long)

67 776402 Shifter & Brake Shaft

71 788069 Square Cut Ring

72 792074 Threaded Plug (Shipping only, not used)

81 786081 Roller Chain (No. 41 chain, 24 links)

82 786082 Sprocket (9 teeth)

83 786083 Sprocket (18 teeth)

90 788067B Grease (32 oz. bottle Bentonite grease)

150 510334 Gasket Eliminator (Loctite #515)

178 * Coupling (See page 24-25 for part number)

179 * Connector Shaft (See page 24-25 for part number)

31

Page 36

BLADE

CLUTCH

ENGINE DECK

WIRE HARNESS

EA

FB

GC

HD

INSTRUMENT

PANEL HARNESS

BLACK

BLUE

WHITE

WHITE

YELLOW

NEUTRAL

INTERLOCK

BLACK W/RED STRIPE

WHITE

BLACK W/RED STRIPE

BLACK

GROUND

KOHLER (15 HP & 18 HP)

KAWASAKI (15 HP & 17 HP)

HONDA (18 HP)

PART NO. 483075

WIRE HARNESS

ADAPTER - ENGINE

SW04WH483075

HANDLE WIRE HARNESS

MANUAL START

PART NO. 482711

BLACK

BLK W/RED STRIPE

TO

OPERATOR

PRESENCE

SWITCH

YELLOW

POS

HOURMETER

KEY

SWITCH

WHITE

BLACK

NEG

HOURMETER

32

MOWER

ENGAGE

SWITCH

BLK W/RED STRIPE

BLACK

BLUE

WHITE

YELLOW

AE

BF

CG

DH

TO ENGINE

DECK WIRE

HARNESS

SW2003WH482711

Page 37

GROUND

WIRE HARNESS

ADAPTER

TO

RECTIFIER

TO

ENGINE

STATOR

HONDA (18 HP)

PART NO. 482848

BLACK

RED

RED

BLACK

YELLOW

YELLOW

YELLOW

MAIN WIRE

HARNESS

WHITE

TO

CAPACITOR

TO

MAGNETO

SW04WH482848

WIRE HARNESS ADAPTER

KAWASAKI (15 HP & 17 HP)

PART NO. 481717

SW2003WH481717

33

Page 38

CHOKE

FAST

SLOW

48314

)

48404

BEFORE OPERATING

Read operator's manual

Make sure guards, shields

& safety devices are in

place & working

Clear area of children,

bystanders & debris

Trained operators only

482284

R

481122

482816

TOP

MIDDLE

MIDDLE

BOTTOM

BOTTOM

BOTTOM

482286

CUTTING HEIGHT ADJUSTMENT

DECK MOUNTING HOLE POSITION

NUMBER OF CASTER SPACERS (BELOW SUPPORT

NUMBER OF SPACERS ABOVE CUTTER BLADES

0 1 2 3 4 5

-

0

-

0

-

1

-

2

-

3

4-3/8

4

-

-

-

4

4-1/8

2-3/8

2-5/8

2-3/4

3-3/4

3-7/8

2-1/8

2-3/8

2-1/2

3-1/2

3-5/8

1-7/8

2-1/8

2-1/4

2-7/8

3-1/4

3-3/8

482816

1-5/8

1-7/8

2

2-5/8

3

3-1/8

32" - 48315

36" - 482297

48" - 481953

52" - 481954

48404

RN 1 2 3 4 5

48332

48332

34

Page 39

FAST

SLOW

PARKING

BRAKE

OFF

ON

481483

WARNING

482285

WARNING

INSTALL BELT COVER BEFORE

OPERATING MACHINE

READ OPERATOR'S MANUAL

481039

481039

Hea

vy-

Co mmerc

MANUFACTURED UNDER ONE OR MORE

OF THE FOLLOWING PATENTS:

4,487,006 4,885,903 4,920,733 4,967,543

4,991,382 4,998,948 5,042,239 5,118,617

5,133,176 5,826,416 5,832,708 5,865,018

6,192,666

Duty

ial

481971

481971

PATENTS PENDING

483044

WARNING

WARNING

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

481109

DO NOT OPERATE WITHOUT DISCHARGE CHUTE, MULCH

MASTER, MULCH PLATE, OR ENTIRE GRASS CATCHER

INSTALLED

482165

35

Page 40

LIMITED WARRANTY - COMMERCIAL EQUIPMENT

Any part of the Scag commercial mower manufactured by Scag Power Equipment and found, in the reasonable judgment

of Scag, to be defective in materials or workmanship, will be repaired or replaced by an Authorized Scag Service Dealer

without charge for parts and labor . This warranty is limited to the original purchaser and is not transferable. Proof of

purchase will be required by the dealer to substantiate any warranty claims. All warranty work must be performed by an

Authorized Scag Service Dealer.

This warranty is limited to the following specified periods from the date of the original retail purchase for defects in

materials or workmanship:

* Wear items including drive belts, blades, hydraulic hoses and tires are warranted for ninety (90) days.

* Batteries are covered for ninety (90) days.

* Frame and structural components including oil reservoir, fittings, and oil coolers are warranted for 2 years

(Parts and labor 1st year; Parts only 2nd year).

* Cutter decks are warranted against cracking for a period of three (3) years. (Parts and labor 1st year; Parts

only 2nd and 3rd year) The repair or replacement of the cutter deck will be at the option of Scag Power

Equipment. We reserve the right to request components for evaluation. This warranty does not cover any

mower that has been subject to misuse, neglect, negligence, or accident, or that has been operated in any way

contrary to the operating instructions as specified in the Operator’s Manual.

* Engines and electric starters are covered by the engine manufacturer’s warranty period.

* Major drive system components are warranted for two (2) years by Scag Power Equipment. (Parts and labor 1st

year; Parts only 2nd year) (T wo year warranty exclude fittings, hoses, drive belts). The repair or replacement of

the hydraulic pump or hydraulic motor will be at the option of Scag Power Equipment. This warranty does not

cover any mower that has been subject to misuse, neglect, negligence, or accident, or that has been operated in

any way contrary to the operating instructions as specified in the Operator’s Manual.

* Electric clutches have a Limited Warranty for 2 year (Parts and labor 1st year; Parts only 2nd year).

* Cutter Spindle Assemblies 461663 have a Limited Warranty for three years (Parts and labor 1st year; Parts

only 2nd and 3rd year).

* Any Scag product used for rental purposes is covered by a 90 day warranty.

The Scag mower, including any defective part must be returned to an Authorized Scag Service Dealer within the warranty

period. The expense of delivering the mower to the dealer for warranty work and the expense of returning it to the owner

after repair will be paid for by the owner. Scag’ s responsibility is limited to making the required repairs and no claim of

breach of warranty shall be cause for cancellation or rescission of the contract of sale of any Scag mower.

This warranty does not cover any mower that has been subject to misuse, neglect, negligence, or accident, or that has

been operated in any way contrary to the operating instructions as specified in the Operator’s Manual. The warranty

does not apply to any damage to the mower that is the result of improper maintenance, or to any mower or parts that have

not been assembled or installed as specified in the Operator’s Manual and Assembly Manual. The warranty does not

cover any mower that has been altered or modified, changing performance or durability. In addition, the warranty does not

extend to repairs made necessary by normal wear, or by the use of parts or accessories which, in the reasonable judgment

of Scag, are either incompatible with the Scag mower or adversely affect its operation, performance or durability .

Scag Power Equipment reserves the right to change or improve the design of any mower without assuming any obligation to modify any mower previously manufactured. All other implied warranties are limited in duration to the two (2) year

warranty period or ninety (90) days for mowers used for rental purpose. Accordingly, any such implied warranties

including merchantability, fitness for a particular purpose, or otherwise, are disclaimed in their entirety after the expiration

of the appropriate two year or ninety day warranty period. Scag’s obligation under this warranty is strictly and exclusively

limited to the repair or replacement of defective parts and Scag does not assume or authorize anyone to assume for them

any other obligation. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you.

Scag assumes no responsibility for incidental, consequential or other damages including, but not limited to, expense for

gasoline, expense of delivering the mower to an Authorized Scag Service Dealer and expense of returning it to the owner ,

mechanic’s travel time, telephone or telegram char ges, rental of a like product during the time warranty repairs are being

performed, travel, loss or damage to personal property, loss of revenue, loss of use of the mower, loss of time or inconvenience. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Page 41

GARANTÍA LIMITADA - EQUIPO COMERCIAL

T oda pieza del cortacésped comercial Scag fabricada por Scag Power Equipment que, según criterio razonable de Scag, presente

materiales o mano de obra defectuosos será reparada o reemplazada por un distribuidor autorizado Scag sin cargo por las piezas ni