Page 1

MODEL STT-31BSD

OPERATOR’S MANUAL

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMATION FOR YOUR SCAG MOWER. READING

THIS MANUAL CAN PROVIDE YOU WITH

ASSISTANCE IN MAINTENANCE AND ADJUSTMENT PROCEDURES TO KEEP YOUR

MOWER PERFORMING TO MAXIMUM EFFICIENCY. THE SPECIFIC MODELS THA T THIS

BOOK COVERS ARE CONTAINED ON THE

INSIDE COVER. BEFORE OPERA TING YOUR

MACHINE, PLEASE READ ALL THE INFORMATION ENCLOSED.

© 2004

SCAG POWER EQUIPMENT

DIVISION OF MET ALCRAFT OF MA YVILLE, INC.

P ART NO. 03153

PRINTED 10/04

PRINTED IN USA

Page 2

WARNING:

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all shields in place, especially the grass discharge chute.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wires and ignition key .

* If a mechanism becomes clogged, stop the engine before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as other manuals that came

with your mower .

* Keep others off the tractor (only one person at a time)

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident pre vention are dependent upon the awareness,

concern, prudence, and proper training of the personnel involved in the

operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

STT-31BSD with a serial number of A7400001 to A7499999

SMST-61A with a serial number of A7500001 to A7599999

SMST-72A with a serial number of A7600001 to A7699999

Always use the entire serial number listed on the serial number

tag when referring to this product.

Page 3

TABLE OF CONTENTS

SUBJECT PAGE

Section 1 - General Information

1.1 Introduction .............................................................................................................................1

1.2 Directional Reference .............................................................................................................1

1.3 Servicing the Engine and Drive Train Components ................................................................1

Section 2 - Safety Information

Symbols ............................................................................................................................... 2-3

2.1 Introduction .............................................................................................................................4

2.2 Signal W ords ...........................................................................................................................4

2.3 Before Operation Considerations ...........................................................................................4

2.4 Operation Considerations ........................................................................................................5

2.5 Roll Over Protection System ..................................................................................................6

2.6 Maintenance Considerations ...................................................................................................8

2.7 Safety and Instructional Decals..............................................................................................9

Section 3 - Specifications ....................................................................................................10-11

Section 4 - Operating Instructions

4.1 Controls and Instrument Identification..................................................................................12

4.2 Safety Interlock System........................................................................................................13

4.3 Initial Run-In Procedures......................................................................................................14

4.4 Starting the Engine................................................................................................................14

4.5 Ground Travel and S teering ..................................................................................................14

4.6 Engaging the Deck Drive .....................................................................................................15

4.7 Hillside Operation .................................................................................................................16

4-8 Parking the Mower ...............................................................................................................16

4.9 After Operation ....................................................................................................................16

4.10 Removing Clogged Material .................................................................................................17

4.1 1 Moving Mower with Engine Stopped ...................................................................................17

4.12 Recommendations for Mowing.............................................................................................17

4.13 Adjusting Cutting Height.......................................................................................................18

Section 5 - T r oubleshooting Cutting Conditions.............................................................. 19-21

I

Page 4

TABLE OF CONTENTS (CONT'D)

SUBJECT PAGE

Section 6 - Adjustments

6.1 Parking Brake Adjustment ....................................................................................................22

6.2 Travel Adjustments ...............................................................................................................22

6.3 Throttle Control and Choke Adjustments..............................................................................24

6.4 Belt Adjustment ....................................................................................................................24

6.5 Belt Alignment ......................................................................................................................24

6.6 Cutter Deck Adjustments .....................................................................................................25

Section 7 - Maintenance

7.1 Maintenance Chart ...............................................................................................................28

7.2 Lubrication Fitting Points ......................................................................................................29

7.3 Hydraulic System..................................................................................................................31

7.4 Engine Oil .............................................................................................................................32

7.5 Engine Fuel System ..............................................................................................................33

7.6 Engine Air Cleaner................................................................................................................33

7.7 Battery ..................................................................................................................................33

7.8 Drive Belts............................................................................................................................35

7.9 Cutter Blades ........................................................................................................................35

7.10 Tires ......................................................................................................................................36

7.11 Cutter Deck Gearbox ...........................................................................................................36

7.12 Cooling System .....................................................................................................................37

7.13 Body , Deck, Hopper and Upholstery ....................................................................................3 8

Section 8 - Illustrated Parts List

Notes ..............................................................................................................................................39

SMST 61"Adv., 72" Adv. Cutter Decks ................................................................................... 40-41

Cutter Deck Controls................................................................................................................ 42-43

Sheet Metal Components.......................................................................................................... 44-45

STT Roll Over Protection......................................................................................................... 46-47

Deck Drive Components .......................................................................................................... 48-49

Radiator, Coolers & Engine Brackets.................................................................................50-51

Brake & Steering Components..........................................................................................52-53

Fuel & Hydraulic System ......................................................................................................... 54-55

Electrical System ...................................................................................................................... 56-57

Hydraulic Pump Assembly - BDP-21L.................................................................................... 58-59

Wire Harness, STT-31BSD ............................................................................................................60

Replacement Decals ................................................................................................................. 61-62

Warranty Statement............................................................................................. Inside Back Cover

II

Page 5

Section 1

GENERAL INFORMATION

1.1 INTRODUCTION

Your mower was built to the highest standards in the

industry . However, the prolonged life and maximum

efficiency of your mower depends on you following the

operating, maintenance and adjustment instructions in this

manual.

If additional information or service is needed, contact

your Scag Power Equipment Dealer.

We encourage you to contact your dealer for repairs. All

Scag dealers are informed of the latest methods to

service this equipment and provide prompt and efficient

service in the field or at their service shop. They carry a

full line of Scag service parts.

USE OF OTHER THAN ORIGINAL SCAG

REPLACEMENT PARTS WILL VOID THE

WARRANTY.

When ordering parts, always give the model and serial

number of your tractor. The serial number plate is

located where shown in Figure 1-1.

SERIAL NUMBER

PLATE LOCATION

E

R

O

M

:

R

TS

O

N

E

E

N

5,832,708

T

O

A

5,865,018

R

P

E

G

D

N

IN

W

U

D

O

G

E

4,991,382

IN

LL

R

D

4,998,948

O

N

TU

F

5,118,617

C

E

5,826,416

PE

H

FA

TS

U

F T

N

N

O

A

M

4,487,006

4,885,903

P

4,920,733

4,967,543

R

TE

A

MODEL

v

i

D

SERIAL

.

c

n

I

,

e

l

l

i

0

v

5

y

g

0

a

n

3

i

M

5

d

f

n

o

n

e

i

t

f

P

s

a

n

r

d

o

c

n

l

c

a

a

s

i

t

d

e

W

e

M

,

u

f

s

e

l

l

o

s

i

I

v

n

s

y

t

o

i

a

n

s

i

e

M

t

a

P

Scag approved attachments and accessories:

GC-STT (p/n 9049, 9039)

GC-STT-CS (p/n 9053, 9041)

Mulch Plate (p/n 9261, 9262)

Hurricane Mulch (p/n 9266, 9267)

Cup Holder (p/n 9240)

STT Hitch (p/n 9242)

STT Bumper (p/n 9256)

STT - Suspension Seat (p/n 9270)

STT - Lights (p/n 9279)

Tiger Striper (p/n 9269)

Blade Buddy (p/n 9212)

WARNING:

For pictorial clarity , some illustrations and figures

in this manual may show shields, guards or plates

open or removed. Under no circumstances should

your mower be operated without these devices in

place.

All information is based upon product information

available at the time of approval for printing. Scag

Power Equipment reserves the right to make

changes at any time without notice and without

incurring any obligation.

1.2 DIRECTION REFERENCE

The “Right” and “Left”, “Front” and “Rear” of the

machine are referenced from the operator’s right and left

when seated in the normal operating position and facing

the forward travel direction.

390S0137A

Figure 1-1 T ractor Serial Number Plate Location

USE ONLY SCAG APPROVED ATTACHMENTS

AND ACCESSORIES.

Attachments and accessories manufactured by companies

other than Scag Power Equipment are not approved for use

on this machine.

1.3 SERVICING THE ENGINE AND DRIVE

TRAIN COMPONENTS

The detail servicing and repair of the engine, hydraulic

pumps and gearboxes are not covered in this manual;

only routine maintenance and general service instructions

are provided. For service of these components during

the limited warranty period, it is important to contact your

Scag dealer or find a local authorized servicing agent of

the component manufacturer. Any unauthorized work

done on these components during the warranty period

may void your warranty .

1

Page 6

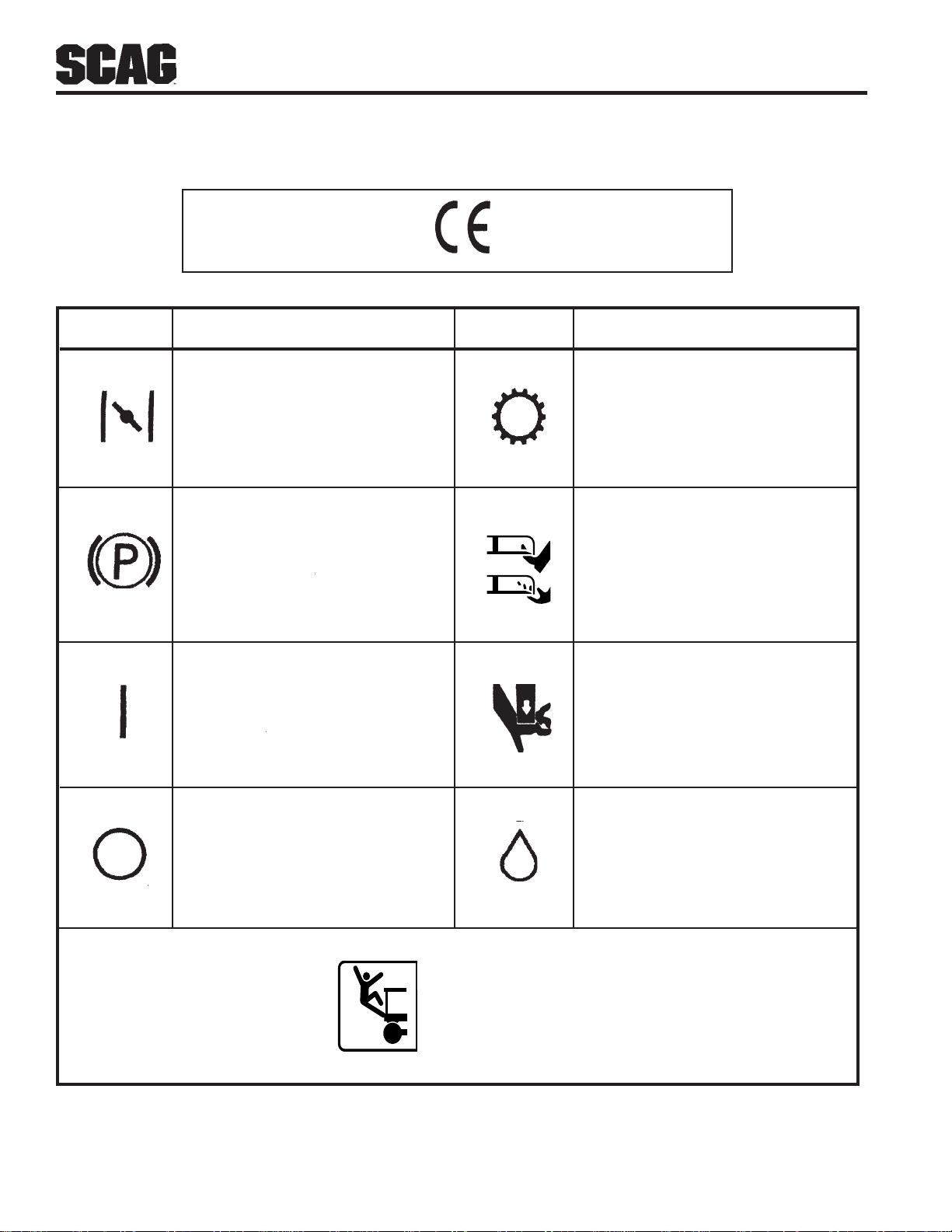

ISO Symbols

CE Mark

SYMBOL DESCRIPTION

Choke

Parking Brake

On/Start

SYMBOL DESCRIPTION

Transmission

Spinning Blade

48071S

Spring T ension on Idler

Off/Stop

Oil

WARNING

Falling Hazard

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

2

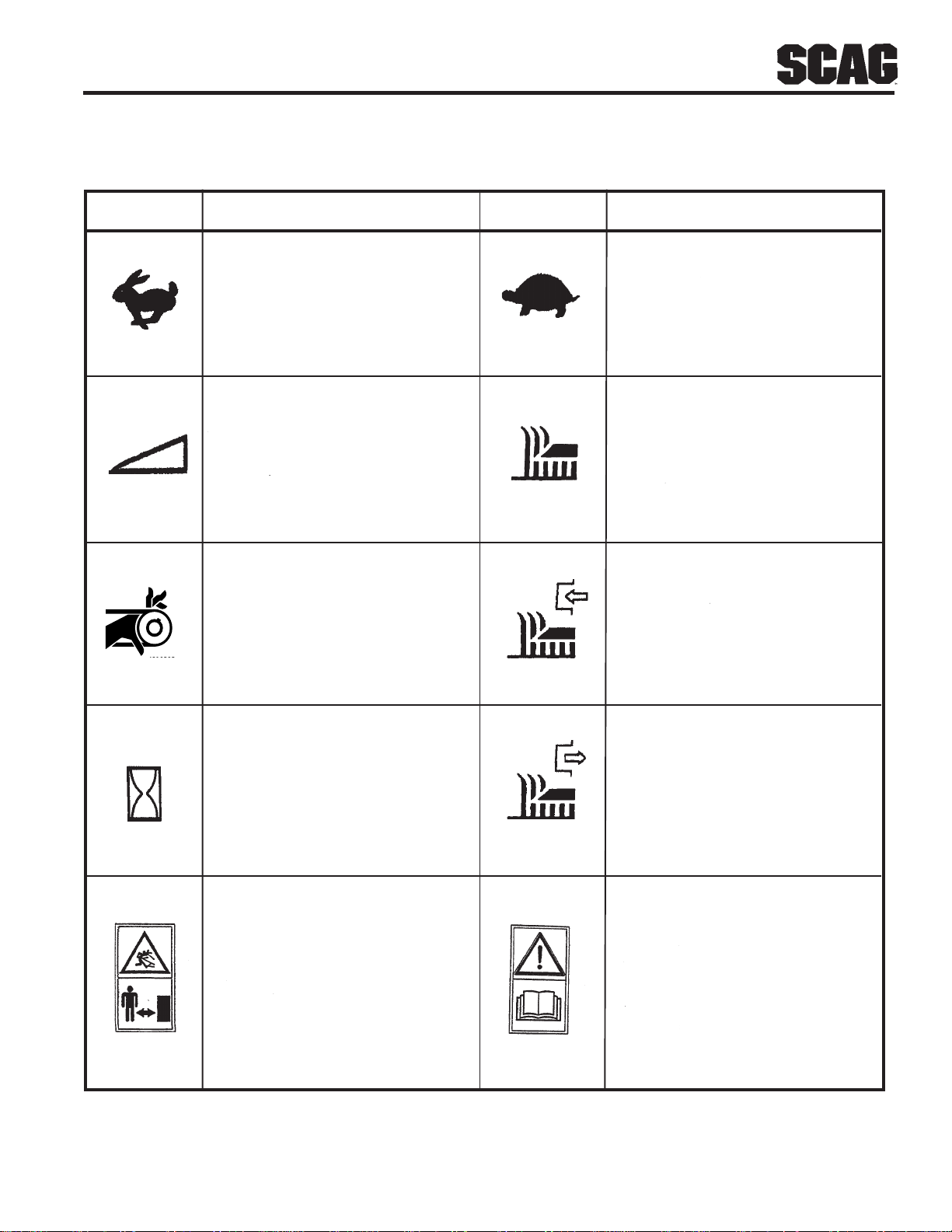

Page 7

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

481039S

Fast

Continuously V ariable - Linear

Pinch Point

Slow

Cutting Element - Basic Symbol

Cutting Element - Engage

Hourmeter/Elapsed Operating Hours

Thown Object Hazard

Keep Bystanders Away

Cutting Element - Disengage

Read Operator's Manual

3

Page 8

SAFETY INFORMATION

2.1 INTRODUCTION

Your mower is only as safe as the operator.

Carelessness or operator error may result in serious

bodily injury or death. Hazard control and accident

prevention are dependent upon the awareness, concern,

prudence, and proper training of the personnel involved in

the operation, transport, maintenance and storage of the

equipment.

and thoroughly familiar with all of the controls before

operating the mower. The owner/user can prevent and is

responsible for accidents or injuries occuring to

themselves, other people or property .

READ THIS OPERATOR’S MANUAL BEFORE

ATTEMPTING TO START YOUR MOWER.

Make sure every operator is properly trained

Section 2

The signal word “DANGER” denotes that an extremely

hazardous situation exists on or near the machine that

could result in high probability of death or irrepairable

injury if proper precautions are not taken.

WARNING:

The signal word “WARNING” denotes that a hazard

exists on or near the machine that can result in injury or

death if proper precautions are not taken.

CAUTION:

A replacement manual is available from your authorized

Scag Service Dealer or by contacting Scag Power

Equipment, Service Department at P.O. Box 152,

Mayville, WI 53050 or via the Internet at

www.scag.com. The manual for your machine can be

downloaded by using the model and serial number or use

the contact form to make your request. Please indicate

the complete model and serial number of your Scag

product when requesting replacement manuals.

2.2 SIGNAL WORDS

This symbol means “Attention! Become Alert! Your

Safety is Involved!" The symbol is used with the

following signal words to attract your attention to safety

messages found on the decals on the machine and

throughout this manual. The message that follows the

symbol contains important information about safety . T o

avoid injury and possible death, carefully read the

message! Be sure to fully understand the causes of

possible injury or death.

Signal Word:

It is a distinctive word found on the safety decals on the

machine and throughout this manual that alerts the

viewer to the existence and relative degree of the

hazard.

The signal word “CAUTION” is a reminder of safety

practices on or near the machine that could result in

personal injury if proper precautions are not taken.

Your safety and the safety of others depends significantly

upon your knowledge and understanding of all correct

operating practices and procedures of this machine.

2.3 BEFORE OPERATION

CONSIDERATIONS

1. NEVER allow children to operate this riding mower.

Do not allow adults to operate this machine without

proper instructions.

2. DO NOT mow when children and/or others are

present. Keep children out of the mowing area and

in the watchful care of a responsible adult other than

the operator. Be alert and turn machine off if a child

enters the area.

3. Clear the area to be mowed of objects that could be

picked up and thrown by the cutter blades.

4. DO NOT carry passengers.

5. DO NOT operate the machine under the influence

of alcohol or drugs.

4

Page 9

Section 2

2.3 BEFORE OPERATION

CONSIDERATIONS (CONT'D)

6. If the operator(s) or mechanic(s) cannot read English

or Spanish, it is the owner's responsibility to explain

this material to them.

7. DO NOT wear loose fitting clothing. Loose

clothing, jewelry or long hair could get tangled in

moving parts. Do not operate the machine wearing

shorts; always wear adequate protective clothing

including long pants. Wearing safety glasses, safety

shoes and a helmet is advisable and is required by

some local ordinances and insurance regulations.

8. Operator hearing protection is recommended,

particularly for continuous operation of the mower.

W ear suitable hearing protection. Prolonged

exposure to loud noise can cause hearing

impairment or loss.

9. Keep the machine and attachments in good operating

condition. Keep all shields and safety devices in

place. If a shield, safety device or decal is defective

or damaged, repair or replace it before operating the

machine.

12. DO NOT add fuel to a running or hot engine. Allow

the engine to cool for several minutes before adding

fuel.

13. Keep flammable objects (cigarettes, matches, etc.),

open flames and sparks away from the fuel tank and

fuel container.

14. Equipment must comply with the latest requirements

per SAE J137 and/or ANSI/ASAE S279 when

driven on public roads.

-NOTE-

If the mower is driven on public roads, it must

comply with state and local ordinances as well as

SAE J137 and/or ANSI / ASAE S279

requirements. Contact your local authorities for

regulations and equipment requirements.

15. DO NOT operate without the side discharge chute

installed and in the down position or with an optional

grass catcher or mulch plate completely installed.

16. Check the blade mounting bolts at frequent intervals

for proper tightness.

WARNING:

This machine is equipped with an interlock system

intended to protect the operator and others from

injury. This is accomplished by preventing the

engine from starting unless the deck drive is

disengaged, the parking brake is on, the steering

control levers are in the neutral position and the

operator is in the seat. The system shuts off the

engine if the operator leaves the seat with the deck

drive engaged and/or the steering control levers are

not in the neutral postion and the parking brake is

not engaged. Never operate equipment with the

interlock system disconnected or malfunctioning.

10. Be sure the interlock switches are functioning

correctly.

1 1. Fuel is flammable; handle it with care. Fill the fuel

tank outdoors. Never fill it indoors. Use a funnel or

spout to prevent spillage. Clean up any spillage

before starting the engine.

17. Make sure all hydraulic fluid connections are tight

and all hydraulic hoses and lines are in good condition

before starting the machine.

2.4 OPERATION CONSIDERATIONS

1. Know the function of all controls and how to stop

quickly.

2. Reduce speed and exercise extreme caution on

slopes and in sharp turns to prevent tipping or loss of

control. Be especially cautious when changing

directions on slopes.

WARNING:

DO NOT operate on steep slopes. T o check a slope,

attempt to back up it (with the cutter deck down). If

the machine can back up the slope without the

wheels slipping, reduce speed and use extreme

caution. ALWAYS FOLLOW OSHA APPROVED

OPERATION.

5

Page 10

Section 2

2.4 OPERATION CONSIDERATIONS

(CONT'D)

3. To prevent tipping or loss of control, start and stop

smoothly , avoid unnecessary turns and travel at reduced

speed.

4. When using any attachment, never direct the discharge

of material toward bystanders or allow anyone near

the machine while in operation.

5. Before attempting to start the engine, with the operator

in the seat, disengage power to the cutter deck, place

the steering control levers in the neutral position and

engage the parking brake.

6. If the mower discharge ever plugs, shut off the engine,

remove the ignition key , and wait for all movement to

stop before removing the obstruction.

13. T ake all possible precautions when leaving the machine

unattended, such as disengaging the mower, lowering

the attachments, setting the parking brake, stopping the

engine, and removing the key .

14. Disengage power to the attachments when transporting

or when not in use.

15. The machine and attachments should be stopped and

inspected for damage after striking a foreign object,

and damage should be repaired before restarting and

operating the machine.

CAUTION:

DO NOT touch the engine or the muffler while

the engine is running or immediately after

stopping. These areas may be hot enough to

cause a burn.

WARNING:

DO NOT use your hand to dislodge the clogged

discharge chute. Use a stick or other device to

remove clogged material.

7. Be alert for holes, rocks, roots and other hidden hazards

in the terrain. Keep away from any dropoff. Beware

of overhead obstructions (low limbs, etc.), underground

obstacles (sprinklers, pipes, tree roots, etc.). Cautiously

enter a new area. Be alert for hidden hazards.

8. Disengage power to cutter deck before backing up.

Do not mow in reverse unless absolutely necessary

and then only after observation of the entire area behind

the mower.

9. DO NOT turn sharply. Use care when backing up.

10. Disengage power to cutter deck before crossing roads,

walks or gravel drives.

11 . Mow only in daylight or good artificial light.

WARNING:

DO NOT run the engine inside a building or a

confined area without proper ventilation. Exhaust

fumes are hazardous and could cause death.

16. Keep hands and feet away from cutter blades and

moving parts. Contact can injure.

17. Use care when loading or unloading the machine onto

a trailer or truck.

18. Use care when approaching blind corners, shrubs, trees,

or other objects that may obscure vision.

2.5 ROLL OVER PROTECTION SYSTEM

WARNING:

Seat belt must be securely fastened during

operation. Failure to do so could cause

serious injury or loss of life.

12. NEVER raise the deck with the blades engaged.

6

Page 11

Section 2

This mower has been designed for good traction and

stability under normal mowing conditions. However, caution

must be used when traveling on slopes, especially when

the grass is wet. Do not mow on wet grass. Wet grass

reduces traction and steering control.

Any or all parts of the Roll Over Protection System MUST

NOT be removed. Failure to adhere to this guideline could

result in injury or death.

The potential exposure of this seat belt to severe

enviromental conditions make it crucial to inspect the seat

belt system regularly .

It is recommended that the seat belt be inspected on a

daily basis for signs of damage. Any seat belt system that

shows cuts, fraying, extreme or unusual wear, significant

discoloration due to UV exposure, dirt or stiffness, abrasion

to the seat belt webbing, or damage to the buckle, latch

plate, hardware or any other obvious problem should be

replaced immediately .

INSPECT BUCKLE

& LATCH

INSPECT WEBBING

Figure 2-1 Seat Belt Inspection

WARNING:

Reduce speed when turning, operating on slopes,

slick or wet surfaces. Allow extra distance to stop.

Stay off of slopes too steep for safe operation. To

check a slope, attemp to back up it (with the cutter

deck down). If the machine can not back up the

slope without the wheels slipping, do not operate

the machine on this slope.

WARNING:

Failure to properly inspect and maintain the

seat belt can cause serious injury or loss of

life.

1. Check the full length of the seat belt webbing for cuts,

wear, fraying, dirt and stif fness. See Figure 2-1.

2. Check the seat belt webbing in areas exposed to ultra

violet rays from the sun or extreme dust or dirt. If the

original color of the webbing in these areas is extremely

faded and/or is packed with dirt, the physical strength

of this webbing may have deteriorated. If this condition

exists, replace the seat belt system.

3. Check the buckle and latch for proper operation and

determine if the latch plate is exessively worn,

deformed, or of the buckle is damaged or cracked.

See Figure 2-1.

ALWAYS travel up or down the slope whenever

possible. Never across the slope.

DO NOT mow near drop-offs, ditches or

embankments. The machine could suddenly roll

over if a wheel goes over the edge or if the edge

caves in.

Operate the machine smoothly, no sudden turns,

starts or stops on a slope.

NEVER tow on slopes. The weight of the towed

equipment may cause loss of traction and loss of

control.

DO NOT permit untrained personnel to operate

the machine.

7

Page 12

Section 2

7. Park the machine on level ground and engage the

parking brake.

8. NEVER allow untrained personnel to service the

machine.

9. Use care when checking blades. Wrap the blade(s)

or wear gloves and use caution when servicing

blades. Only replace blades. NEVER straighten or

weld blades.

10. Keep all parts in good working condition. Replace all

worn or damaged decals.

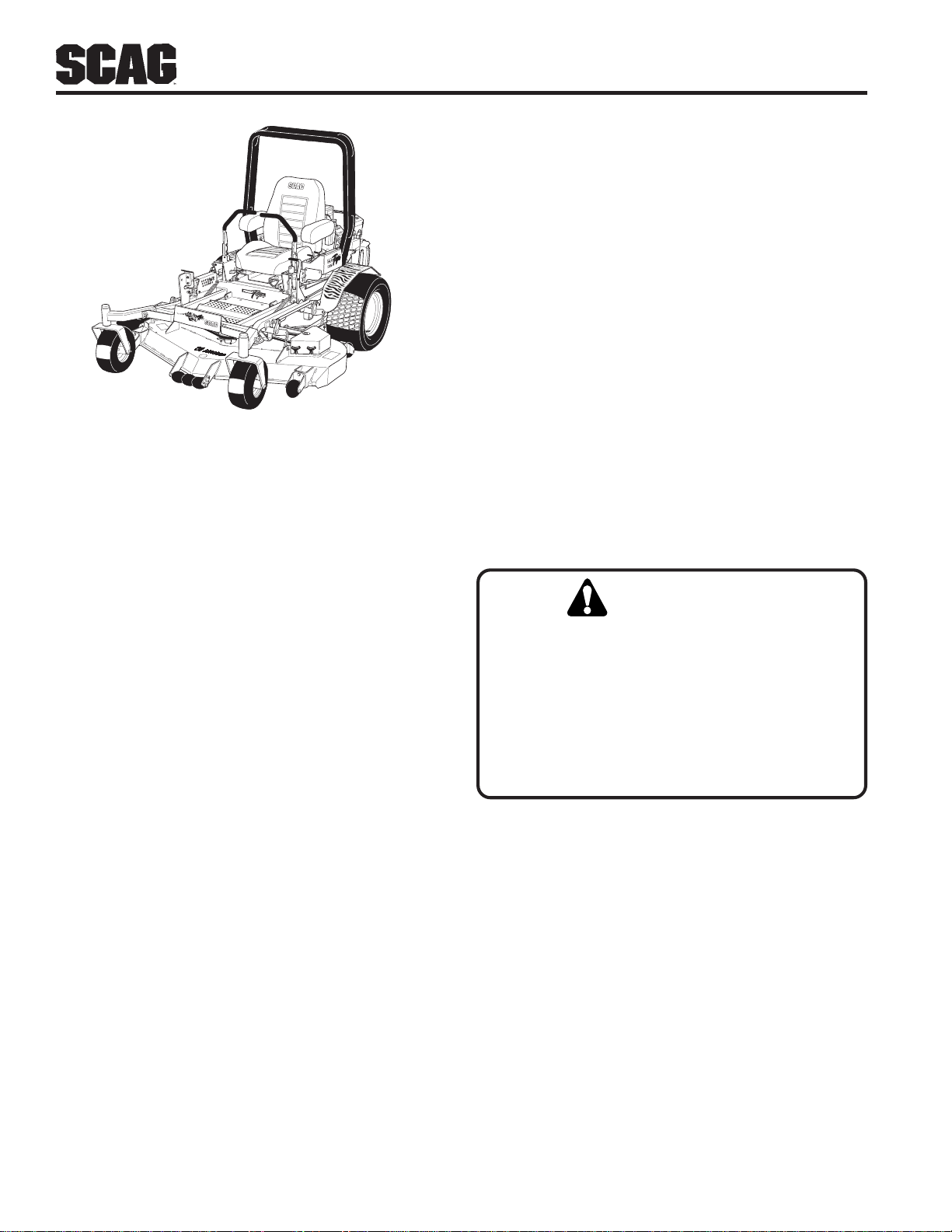

Figure 2-2. STT-BSD With Roll Over

Protection System.

2.6 MAINTENANCE CONSIDERATIONS &

STORAGE

1. Never make adjustments to the machine with the

engine running unless specifically instructed to do so.

If the engine is running, keep hands, feet, and

clothing away from moving parts.

2. Disengage drives, lower implement, set parking

brake, stop engine and remove key or disconnect

spark plug wire to prevent accidental starting of the

engine when servicing or adjusting the machine.

W ait for all movement to stop before adjusting,

cleaning or repairing.

3. Disconnect battery or remove spark plug wire before

making any repairs. Disconnect the negative

terminal first and the positive last. Reconnect the

positive first and the negative last.

11. Use jack stands to support components when

required.

12. Carefully release pressure from components with

stored energy.

WARNING:

Hydraulic fluid is under high pressure. Keep

body and hands away from pinholes or nozzles

that eject hydraulic fluid under high pressure.

If you need service on your hydraulic system,

please see your authorized Scag dealer. If

hydraulic fluid is injected into the skin, it must

be surgically removed within a few hours by a

doctor or gangrene may result.

13. Let the engine cool before storing.

14. DO NOT store the machine near an open flame.

4. Keep all nuts, bolts and screws tight, to ensure the

machine is in safe working condition. Check blade

mounting bolts frequently to be sure they are tight.

5. Do not change the engine governor settings or

overspeed the engine. See the engine operator's

manual for information on engine settings.

6. T o reduce fire hazard, keep the cutting units, drives

muffler and engine free of grass, leaves, excessive

grease, oil and dirt.

15. Shut off fuel while storing or transporting.

16. DO NOT store fuel near flames or drain indoors.

17. Charge batteries in an open well ventilated area,

away from spark and flames. Unplug charger before

connecting or disconnecting from battery . Wear

protective clothing and use insulated tools.

8

Page 13

Section 2

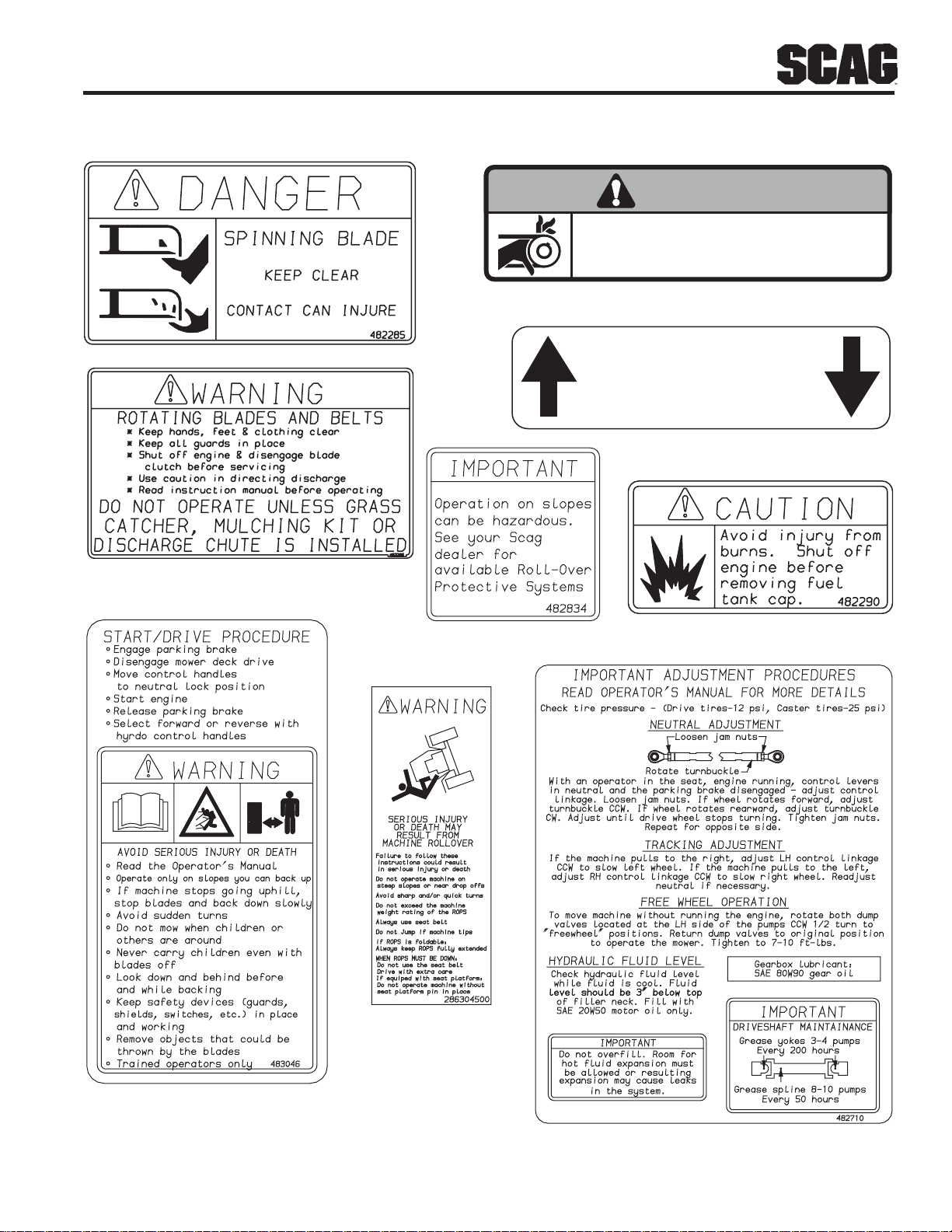

2.7 SAFETY AND INSTRUCTIONAL DECALS

WARNING

INSTALL BELT COVER BEFORE

OPERATING MACHINE

READ OPERATOR'S MANUAL

481039

481039

482285

482286

FORWARD

482834

F

R

REVERSE

481568

482290

483046

482710

390S0150E- Rev 1

9

Page 14

Section 3

SPECIFICATIONS

SCAG “SABRE T OOTH TIGER” ZERO-TURN RIDER

MODEL: STT– 31BSD

ENGINE

General Type: Heavy Duty Industrial/Commercial Turbo Charged Diesel

Brand: Briggs Daihatsu Vanguard Liquid Cooled 31 HP

Model: DM950D

Horsepower: 31 HP @ 3600 RPM

Type: water cooled 4 cycle, overhead valve, 3 cylinder, diesel engine

Displacement: 952cc

Cylinders: 3 inline sleeves

Governor: High-speed flyweight governor, runs faster than engine crankshaft, provides precision

speed governing and a steady low idle, 3600 rpm (±100 rpm), idle set at 1700 rpm

Air Intake Group: Canister type air filter system.

Exhaust Group: Single exhaust canister muffler

Fuel Injection: Distributor injection pump

Oil Pump Group: Positive displacement Gerotor™ oil pump with remote oil filter, capacity 3.2 U.S. quarts

(3.0 ltrs) with oil filter

Valve Group: Overhead

Electrical/Charging System: 12 volt battery with alternator, solid state ignition with key start, 40 amp regulated

charging system, solenoid shift type starter

ENGINE DECK

Fuel Tank: 10 gallon (38.0 litres) seamless polyethylene tank with fuel gauge cap

Drive Wheels/Tires: 24x12-12 four-ply pneumatic tubeless, radius edge, offset rims to improve operator’s view

Parking Brake: Lever operated interlocked parking brake prevents operation with parking brake engaged

Frame: Compact tractor frame with structural steel tubing construction

DRIVE SYSTEM

Type: Hydro drive with two variable displacement pumps and two cast iron motors for

independent control of each drive wheel

Hydro Pumps: Two Hydro-Gear Model BDP 21L pumps with dump valves for movement without running

engine

Drive Wheel Motors: Two 23 cubic inch cast-iron high torque wheel motors

Transmission Belt Idler: Self-adjusting, self-tightening, sealed bearings

Hydro Fluid Cooling Group: 6 qt. capacity nylon fluid reservoir, uses SAE 20W50 fluid and 10 micron filter

Steering/Travel Control: Twin lever fingertip steering control with gas shock dampeners for smooth, responsive

control to each wheel

Axles: 1-1/4" heavy-duty, tapered motor shafts

Wire Harness: 14 gauge wire

Safety Group: Seat actuated engine kill, neutral interlock, mower engagement (BBC) switch, parking

brake

Instrument Panel: Voltmeter, water temperature gauge, oil pressure gauge, key switch, throttle, fuses, BBC

switch (hourmeter located at rear of machine), glow plug indicator, water separator

indicator

Forward Ground Speed Range: 0 to 10.5 mph

Reverse Ground Speed Range: 0 to 5.0 mph

Date of Issue: October, 2004

Specifications Subject To Change Without Notice

-NOTE-

The machine will travel at 10.5 mph for

transport purposes. For best cutting

performance the forward travel speed

should be adjusted depending on the

cutting conditions.

10

Page 15

Section 3

SPECIFICATIONS (CON'T)

SCAG “SABRE T OOTH TIGER” ZERO-TURN RIDER

MODEL: STT– 31BSD

CUTTER DECK

Type: SMST-72A ("Advantage") & SMST-61A ("Advantage") - Floating, adjustable anti-

scalping, hybrid design combines out-front and belly-mount designs. "Advantage" special extended front edge allows Bahia or other tough grasses to enter the deck

standing upright for a clean cutting.

Construction: 10-gauge steel top reinforced with 7 gauge support plate, deck skirt is 7 gauge steel

True Cutting Width: 72" cutter deck = 71.5 inches (181.6 cm); 61" cutter deck = 61.0" (155.0cm)

Cutting Height Adjustment: Foot-operated pedal adjustment from operator’s seat,

1" to 6" in 1/4" increments

Cutter Blades: 72" = Three (3) 24" blades; 61" = Three (3) 21" blades

Cutter Deck Drive: Drive shaft to 90 degree gear box

Blade Engagement: Electric blade engagement clutch with control panel knob

Discharge Opening: Extra wide 11.5" discharge opening with spring loaded discharge chute

Caster Wheels: 13 x 5 x 6 caster wheels with tapered roller bearing pivots

Spindles: Heavy duty 1-1/8" top dimension spindle shaft, cast housing, taper roller bearing, low

maintenance with top access grease fitting and grease overfill relief poppet

Spindle Pulleys: Split Steel with easily removed taper hubs

Cutter Deck Belts: B-section with Kevlar cord

Anti-Scalp Rollers: Two front, two rear 4-1/2" adjustable, two rear 12" fixed

ADDITIONAL SPECIFICATIONS

Seat: Thick padded seat cushions with special springs. Padded arm rests, lever adjustment

forward and back.

APPROXIMATE DIMENSIONS

72" 61"

Length: 92.0" 89.5"

Tracking Width: 56.0” 56.0"

Width: 83.0” 73.0"

Width (with discharge chute up): 73.0” 63.0"

Height: 43.0” 43.0"

Turning Radius: zero radius turning zero radious turning

Weight: 1635 lbs. 1600 lbs.

PRODUCTIVITY

The following chart will aid you in determining how many acres your Scag mower will cut per day .

The chart is an estimate based on 8 hours per day cutting time at 7 MPH with an allowance for overlap and turns calculated in.

Cutting Width: 61" 72"

Acres Per Day: 27 32

Date of Issue: October, 2004

Specifications Subject To Change Without Notice

11

Page 16

OPERATING INSTRUCTIONS

T

CAUTION:

Do not attempt to operate this mower unless you

have read this manual. Learn the location and

purpose of all controls and instruments before you

operate this mower.

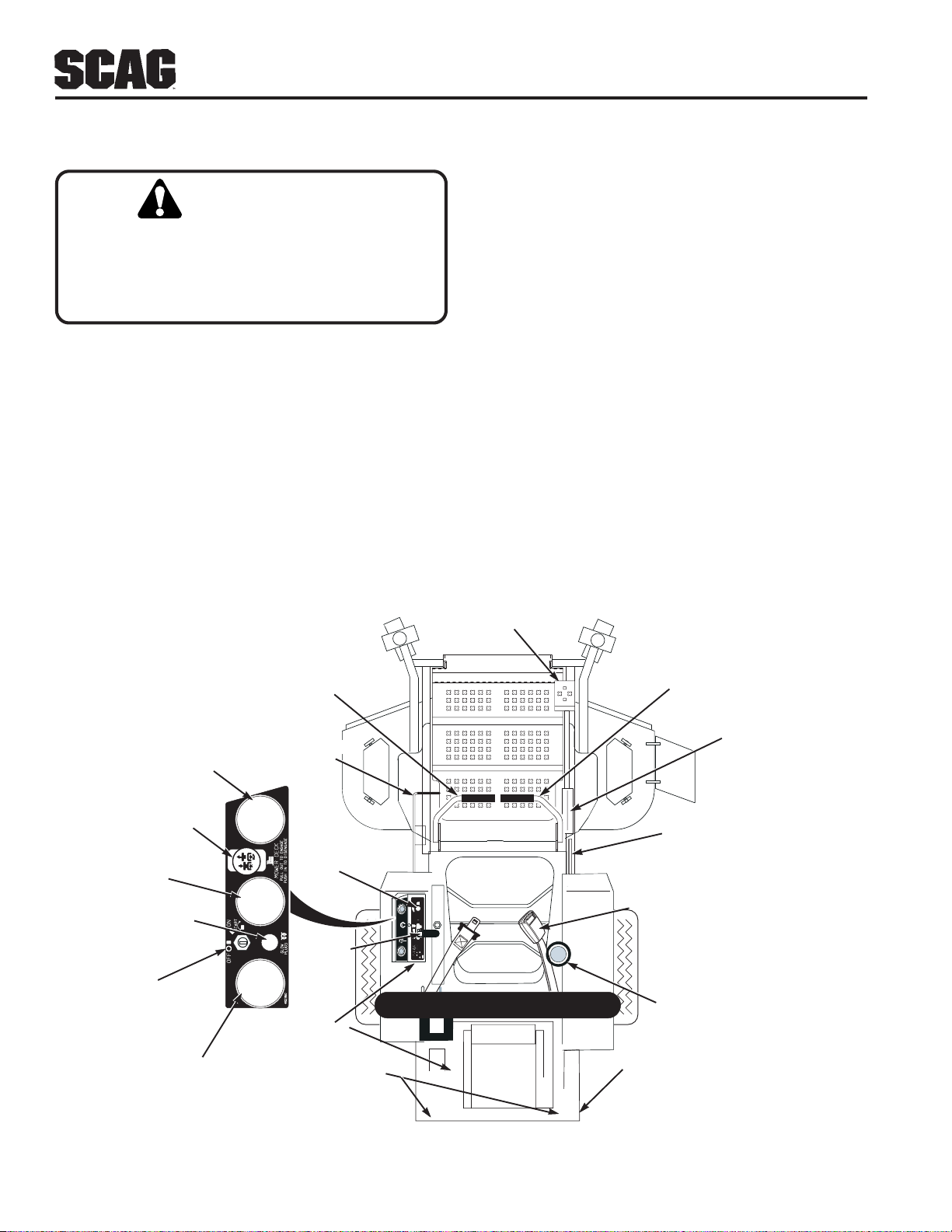

4.1 CONTROLS AND INSTRUMENT

IDENTIFICATION

Before operating the mower, familiarize yourself with all

mower and engine controls. Knowing the location,

function and operation of these controls is important for

safe and efficient operation of the mower .

1 . Ignition Switch (Figure 4-1). The ignition switch

is used to start the engine and has three positions;

OFF, ON, and START.

Section 4

2 . Water Seperator Indicator (Figure 4-1). Amber

indicator turns on when the Water Seperator is full

and needs to be cleaned out.

3 . Mower Deck Switch (Figure 4-1). Used to

engage and disengage the mower drive system.

Pulling up on the switch will engage the deck drive.

Pushing down on the switch will disengage the deck

drive.

4 . Glow Plug Indicator (Figure 4-1). Yellow

indicator turns off when the glow plugs have been

properly heated after the ignition switch is turned on.

5 . Engine Throttle Control (Figure 4-1). Used to

control the engine speed. Pushing the lever forward

increases engine speed. Pulling the lever back

decreases engine speed. Full back position is the

IDLE position. Full forward is the cutting position.

WATER TEMPERATURE

MOWER DECK SWITCH

OIL PRESSURE

GLOW PLUG INDICATOR

IGNITION SWITCH

VOLTMETER

LEFT STEERING

CONTROL

PARKING BRAKE

CONTROL

WATER SEPARATOR

INDICATOR

ENGINE

THROTTLE

CONTROL

FUSES

DUMP VALVE

DECK LIFT

RIGHT STEERING

CONTROL

CUTTING HEIGH

ADJUSTMENT

DECK RELEASE

irjf;o3rf

irjf;o3rf

irjf;o3rf

aljalefja

sorgf

aljalefja

aljalefja

afkrjf ;w

H

C

OFF

OFF

OFF

SEAT BELT

FUEL GAUGE

HOURMETER

Figure 4-1 Controls and Instruments

12

BSD2005CONTROLS

Page 17

Section 4

6 . Voltmeter (Figure 4-1). Indicates the condition of

the charging system. When the engine is running, in

normal operating conditions, the needle should be in

the 12 to 14 volt range.

7 . Oil Pressure (Figure 4-1). Indicates engine oil

pressure. Reference the engine operator's manual

for further information.

8 . Hourmeter (Figure 4-1). Indicates the number of

hours the engine has been operated. It operates

whenever the engine is running. It can be used to

keep track of maintenance intervals and the amount

of time required to perform various tasks.

9 . Fuse Holders (Figure 4-1). There are two 20-

amp fuses and one 40-amp fuse that protect the

mower’s electrical system. To replace fuses, pull

fuse out of the socket and install a new fuse.

10 . Left Steering Control (Figure 4-1). Used to

control the mower's left wheel when traveling

forward or reverse.

DUMP VALVE

CONTROL

390S0141BSG

Figure 4-2 Dump V alve Control

16 . Cutting Height Adjustment (Figure 4-1). Used

to set the cutter deck at the desired cutting height.

17. Deck Release Lever (Figure 4-1). Used to lock

the cutter deck in the transport position. Push the

foot pedal forward and lift up on the release lever to

release the cutter deck for normal mowing.

18 . Temperature Gauge (Figure 4-1). Indicates the

operating temperature of the engine.

11. Right Steering Control (Figure 4-1). Used to

control the mower's right wheel when traveling

forward or reverse.

12 . Parking Brake Control (Figure 4-1). Used to

engage and disengage the parking brakes. Pull the

lever back to engage the parking brakes. Push the

lever forward to disengage the parking brakes.

13 . Fuel Tank Gauge (Figure 4-1). Indicates the

amount of fuel in the fuel tank.

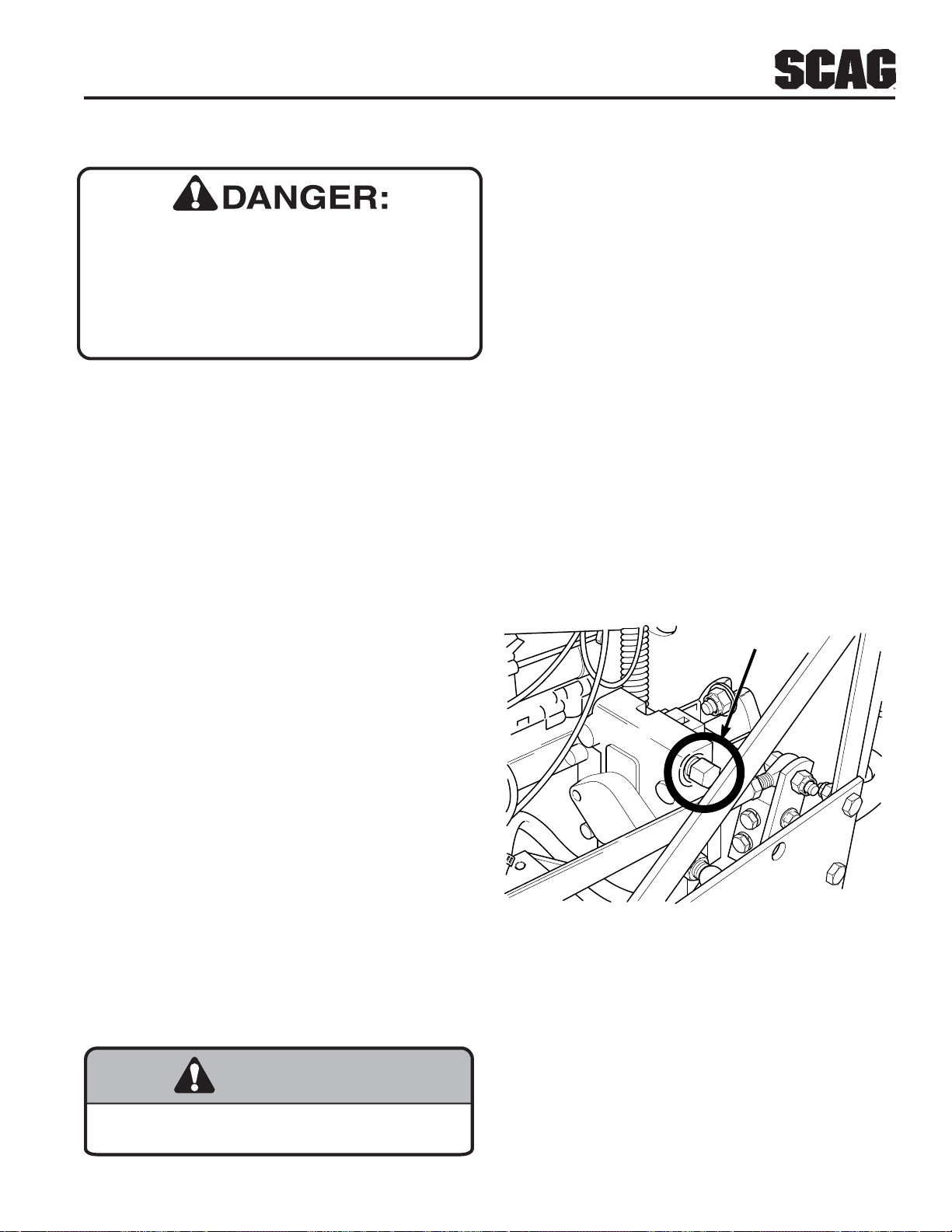

14 . Dump Valve Control Levers (Figure 4-2).

Located on the hydraulic pumps, used to “freewheel” the mower. Rotating the levers clockwise

until they stop allows the unit to move under

hydraulic power. The levers must be in this position

and torqued to 10ft/lbs during operation of the

mower. Rotating the levers counter-clockwise

allows the mower to be moved by hand (freewheeling).

15. Deck Lift Foot Lever (Figure 4-1). Used to raise

and lower the cutter deck.

19 . Seat Belt (Figure 4-1). Used to secure the

operator. Seat belt must be worn at all times during

operation.

4.2 SAFETY INTERLOCK SYSTEM

The mower is equipped with a safety interlock system

that prevents the engine from starting unless the deck

drive is disengaged, the parking brake is engaged, the

steering control levers are in the neutral position and the

operator is in the seat. The interlock system shuts off

the engine if the operator leaves the seat with the

steering control levers not in the neutral position and/or

the cutter blades engaged and the parking brake not

engaged.

WARNING:

Never operate the mower with the interlock

system disconnected or malfunctioning. Do

not disengage or bypass any switch; injury to

yourself and others or property damage could

result.

13

Page 18

Section 4

4.3 INITIAL RUN-IN PROCEDURES (First

Day of Use or Approximately 10 Hours)

1. Check all belts for proper alignment and wear at 2, 4

and 8 hours.

2. Change the engine oil and oil filter after the first 5

hours of operation. (See Section 7.4.)

3. Check hydraulic oil level in reservoir. (See Section

7.3.)

4. Check for loose hardware. Tighten as needed.

5. Check interlock system for proper operation. (See

Section 4.2.)

6. Check tire pressure. Adjust pressure if necessary.

(See Section 7.10)

4.4 STARTING THE ENGINE

CAUTION:

DO NOT USE STARTING FLUIDS. Use of starting

fluids in the air intake system may be potentially

explosive or cause a “runaway” engine condition

that could result in engine damage and/or personal

injury .

6. Move the engine throttle control to about half engine

speed.

7. Turn the ignition key to the on position until the

yellow indicator for the glow plugs goes out. Then

turn the ignition key to the ST AR T position and

release the key as soon as the engine starts. Do not

hold the key in the ST ART position for more than 15

seconds at a time. Allow at least 60 seconds

between each cranking attempt to prevent

overheating of the starter motor. Prolonged cranking

can damage the starter motor and shorten battery

life.

8. Allow engine to warm before operating the mower.

4.5 GROUND TRAVEL AND STEERING

-IMPORTANT-

If you are not familiar with the operation of a

machine with lever steering and/or hydrostatic

transmissions, the steering and ground speed

operations should be learned and practiced in

an open area, away from buildings, fences, or

obstructions. Practice until you are comfortable

with the handling of the machine before

attempting to mow. Learn the operation on flat

ground before operating on slopes.

-IMPORTANT-

Start practicing with a slow engine speed and

slow forward travel.

1. Before initial start or after running out of fuel, you

must prime the fuel pump located on the right side of

the engine. Pump the primer pump until it can no

longer be depressed.

2. Be sure the fuel shutoff valve, located behind the

operator's seat, is completely open. (See Section 7.5

Page 30)

3. Sit in the operator’s seat, fasten seat belt and place

the steering control levers in the neutral position.

4. Engage the parking brake.

5. Place the PTO switch in the disengaged position.

Learn to feather the steering controls to obtain

a smooth operating action.

Practice operating the mower until you are

comfortable with the controls before proceeding

to mow.

Forward T ravel

T o travel forward with the mower , disengage the parking

brake and slowly push the steering control levers forward

an equal distance. The further the steering control levers

are pushed forward, the greater the forward speed will

be. To increase the speed, push the steering control

levers further forward and to decrease the speed, pull the

steering control levers back.

14

Page 19

Section 4

T o stop the forward travel, pull the steering control levers

back to the neutral position.

T o steer the mower left while traveling forward, pull the

left steering lever back. The further the lever is pulled

back, the quicker the mower will turn left.

T o steer the mower right while traveling forward, pull the

right steering control lever back. The further the lever is

pulled back, the quicker the mower will turn right.

-NOTE-

Smooth operation of the steering levers will

produce smooth mower operation. While

learning the operation of the steering controls,

keep the travel speed low.

-IMPORTANT-

Do not travel forward over a curb. The mower

will hang up on the curb. Raise the deck and

travel backwards over the curb at a 45 degree

angle. (see section 4.13 on Page 16 for cutter

deck raising instructions)

Reverse Travel

-NOTE-

The mower may not travel straight in reverse.

Slight adjustments may need to be made using

the steering controls.

T o steer left while traveling in reverse, allow the left

steering control lever to move forward. The further the

control is allowed to move forward, the quicker the

mower will turn left.

T o steer right while traveling in reverse, allow the right

steering control lever to move forward. The further the

control is allowed to move forward, the quicker the

mower will turn right.

T o stop the reverse travel, allow the steering control

levers to return to the neutral position. If the mower is to

be parked, engage the parking brake.

4.6 ENGAGING THE DECK DRIVE (CUTTER

BLADES)

1. Set the throttle at about 3/4 speed. Do not attempt to

engage the deck drive at high speed as this shortens

the electric clutch life — use only moderate engine

speed when engaging the deck drive.

CAUTION:

Disengage power to the mower before backing up.

Do not mow in reverse unless absolutely necessary

and then only after observation of the entire area

behind the mower .

CAUTION:

Before backing up, observe the rear for persons and

obstructions. Clear the area before backing up.

Possible injury or property damage could occur .

T o travel in reverse, pull both handles back. Keep the

travel speed low while traveling in reverse.

2. Engage the deck drive by pulling out on the yellow

switch, located on the instrument panel, (Figure 4-3)

to the engage position.

PULL UP TO ENGAGE

PUSH DOWN TO DISENGAGE

STT99CES

Figure 4-3 Cutter Engage Switch

-NOTE-

A squealing noise may be heard when

engaging or disengaging the deck drive. It is

caused by the electric clutch plates meshing

as the mower comes up to speed.

15

Page 20

Section 4

3. T o disengage the deck drive, push the switch in to

the disengage position.

4. Always operate the engine at full throttle to properly

maintain cutting speed. If the engine starts to lug

down, reduce the forward speed and allow the

engine to operate at maximum RPM.

5. To properly burnish the electric PTO clutch brake,

follow the following steps.

A. Start and run the engine at approximately 3/4

throttle.

B. Engage and disengage the PTO

approximately 25 times, waiting for 10

seconds between each on/off cycle.

-NOTE-

Burnishing the electric clutch improves

longevity and performance and should be done

on every new machine and after a clutch

replacement. The burnishing procedure should

not be performed while cutting grass.

3. Keep tires properly inflated.

4.8 PARKING THE MOWER

1. Stop on level ground and place the steering control

levers in the neutral position.

2. Disengage the cutter blades

3. Slow the engine to idle speed.

4. Engage the parking brake.

5. Turn the ignition key to the OFF position and remove

the key.

4.9 AFTER OPERATION

1. Wash the entire mower after each use. Do not use

high pressure spray or direct the spray onto electrical

components.

4.7 HILLSIDE OPERATION

WARNING:

DO NOT operate on steep slopes. T o check a slope,

attempt to back up it (with the cutter deck down).

If the machine can back up the slope without the

wheels slipping, reduce speed and use extreme

caution. ALWAYS FOLLOW OSHA APPROVED

OPERATION.

1. The mower has been designed for good traction and

stability under normal mowing conditions. However,

caution must be used when traveling on slopes,

especially when the grass is wet. Wet grass reduces

traction and steering control. The Roll Over

Protection System is standard equipment for this

machine. See section 2.5, page 6 of this manual for

further details.

-IMPORTANT-

Do not wash a hot or running engine. Cold

water will damage the engine. Use compressed

air to clean the engine if it is hot.

2. Keep the entire mower clean to inhibit serious heat

damage to the engine or hydraulic oil circuit.

3. Check the drive belts for proper alignment and any

signs of wear. Correct and adjust if necessary.

T o a v oid injury fr om burns, allow the mower to cool

before removing the fuel tank cap and refueling.

4. After the mower has cooled down, fill the fuel tank

with fresh, clean fuel with a minimum cetane rating

of 40 at the end of every day of operation.

2. T o prevent tipping or loss of control, start and stop

smoothly , avoid unnecessary turns and travel at

reduced speed.

5. Check the tire pressure. Adjust pressure if

necessary.

16

Page 21

Section 4

WARNING

4.10 REMOVING CLOGGED MATERIAL

ROTATING BLADES

NEVER PUT Y OUR HANDS INTO THE DISCHARGE

CHUTE FOR ANY REASON! Shut off the engine

and remove the key and only then use a stick or

similar object to remove material if clogging has

occurred.

1. If the discharge chute becomes clogged, shut off the

engine and remove the ignition key . Using a stick or

similar item, dislodge the clogged material. Then

resume normal mowing.

4.11 MOVING MOWER WITH ENGINE

STOPPED

T o “free-wheel” or move the mower around without the

engine running, place the dump valve levers in the FREEWHEEL position (Figure 4-2). Disengage the parking

brake and move the mower by hand. The dump valve

levers must be returned to the DRIVE position and

torqued to 10ft/lbs to drive the mower.

3. Cut grass when it is dry and not too tall. Do not cut

grass too short (cut off 1/3 or less of existing grass

for best appearance). Mow frequently .

4. Keep mower and discharge chute clean.

5. When mowing wet or tall grass, mow the grass twice.

Raise the mower to the highest setting for the first

pass and then make a second pass to the desired

height.

6. Use a slow travel speed for trimming purposes.

7. Operate the engine at full throttle for best cutting.

Mowing with a lower RPM causes the mower to tear

the grass. The engine is designed to be operated at

full speed.

8. Use the alternate stripe pattern for best lawn

appearance. Vary the direction of the stripe each

time the grass is mowed to avoid wear patterns in the

grass.

DUMP VALVE

CONTROL

4.12 RECOMMENDATIONS FOR MOWING

1. Do not mow with dull blades. A dull blade will tear

grass, resulting in poor lawn appearance and reduced

mowing power.

2. The discharge chute must not be removed and must

be kept in the lowest position to deflect grass

clippings and thrown objects downward. Direct the

side discharge away from sidewalks or streets to

minimize cleanup of clippings. When mowing close

to obstacles, direct the discharge away from the

obstacles to reduce the chance of property damage by

thrown objects.

WARNING

DO NOT OPERATE WITHOUT DISCHARGE CHUTE, MULCHING

KIT, OR ENTIRE GRASS CATCHER INSTALLED

390S0141BSG

Figure 4-2 Dump V alve Control

17

Page 22

Section 4

4.13 ADJUSTING CUTTING HEIGHT

The mower deck can be adjusted from a height of 1-inch

to 6 inches at 1/4-inch intervals. T o adjust the cutting

height:

1. Push the cutting height adjustment foot pedal all the

way forward using your right foot until it locks in

place. (Figure 4-6).

2. Insert the lanyard pin into the cutting height index at

the desired cutting height. Push forward on the deck

lift foot lever, hold in place and lift up on the deck

release lever, (Figure 4-7). Slowly release the foot

pedal. A deck height decal is located on the cutting

height index as an aid in adjusting the deck to the

desired height. (Figure 4-6).

LANYARD

PIN

481543

1

1.5

2

2.5

3

3.5

4

4.5

5

5.5

T

6

H

G

G

N

I

I

T

E

T

H

U

C

DECK RELEASE

LEVER

Figure 4-7 Deck Release Lever

CU

HE

TTING

IGH

6

5.5

T

5

4.5

4

3.5

3

2.5

2

1.5

1

48

1

54

3

390S0151-1

HEIGHT ADJUSTMENT PEDAL

Figure 4-6 Adjusting Cutting Height

390S0140-1

18

Page 23

Section 5

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Stringers - Occasional Low engine RPM Run engine at full RPM

Blades of Uncut

Grass Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Dull blades, incorrect sharpening Sharpen blades

Deck plugged, grass accumulation Clean underside of deck

Width of Deck

SGB020

Belts slipping Adjust belt tension

Streaking - Strips of Dull, worn blades Sharpen blades

Uncut Grass in Cutting

Path Incorrect blade sharpening Sharpen blades

Low engine RPM Run engine at full RPM

Belt slipping Adjust belt tension

Deck plugged, grass accumulation Clean underside of deck

Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Width of Deck

SGB018

Bent blades Replace blades

Streaking - Strips of Not enough overlapping Increase the overlap of each

Uncut Grass Between between rows pass

Cutting Paths

Width

of

Deck

SGB019

Width

of

Deck

19

Page 24

TROUBLESHOOTING (CONT'D)

Section 5

CONDITION

CAUSE

CURE

Uneven Cut on Flat Lift worn from blade Replace blade

Ground - Wavy

High-Low Blade upside down Mount with cutting edge toward

Appearance, ground

Scalloped Cut, or

Rough Contour Deck plugged, grass accumulation Clean underside of deck

Too much blade angle (deck pitch) Adjust pitch and level

Deck mounted improperly See your authorized SCAG dealer

Bent spindle area See your authorized SCAG dealer

Dull blade Sharpen blade

Width of Deck

SGB020

Uneven Cut on Uneven ground May need to reduce ground speed,

Uneven Ground - raise cutting height, and/or change

Wavy Appearance, direction of cut

High-Low Scalloped

Cut, or Rough Contour

Width of Deck

SGB021

Sloping Ridge Across Tire pressures not equal Check and adjust tire pressure

Width of Cutting Path

Wheels uneven Check and adjust tire pressure

Deck mounted incorrectly See your authorized SCAG dealer

Deck not level side-to side Check for level and correct

Width of Deck

SGB023

20

Page 25

Section 5

TROUBLESHOOTING (CONT'D)

CONDITION

CAUSE

CURE

Scalping - Blades Low tire pressures Check and adjust pressures

Hitting Dirt or

Cutting Very Close to Ground speed too fast Slow speed to adjust for conditions

the Ground

Cutting too low May need to reduce ground speed,

raise cutting height, change direction

of cut, and/or change pitch and level

Rough terrain May need to reduce ground speed,

raise cutting height, and/or change

direction of cut

Ground speed too fast Slow speed to adjust for conditions

Width of Deck

SGB022

Step Cut -Ridge Blades not mounted evenly Adjust pitch and level

in Center of

Cutting path Bent blade Replace blade

Wet grass Cut grass after it has dried out

Internal spindle failure See your authorized SCAG dealer

Mounting of spindle incorrect See your authorized SCAG dealer

Width of Deck

SGB024

Slope Cut - Sloping Bent spindle mounting area See your authorized SCAG dealer

Ridges Across Width

of Cutting Path Internal spindle failure See your authorized SCAG dealer

Bent deck housing See your authorized SCAG dealer

Width of Deck

SGB025

21

Page 26

Section 6

ADJUSTMENTS

6.1 PARKING BRAKE ADJUSTMENT

WARNING:

Do not operate the mower if the parking brake is

not operable. Possible severe injury could

result.

The parking brake linkage should be adjusted whenever

the parking brake lever is placed in the “ENGAGE”

position and the parking brake will not prevent the mower

from moving. If the following procedures do not allow

you to engage the parking brake properly , contact your

Scag dealer for further brake adjustments.

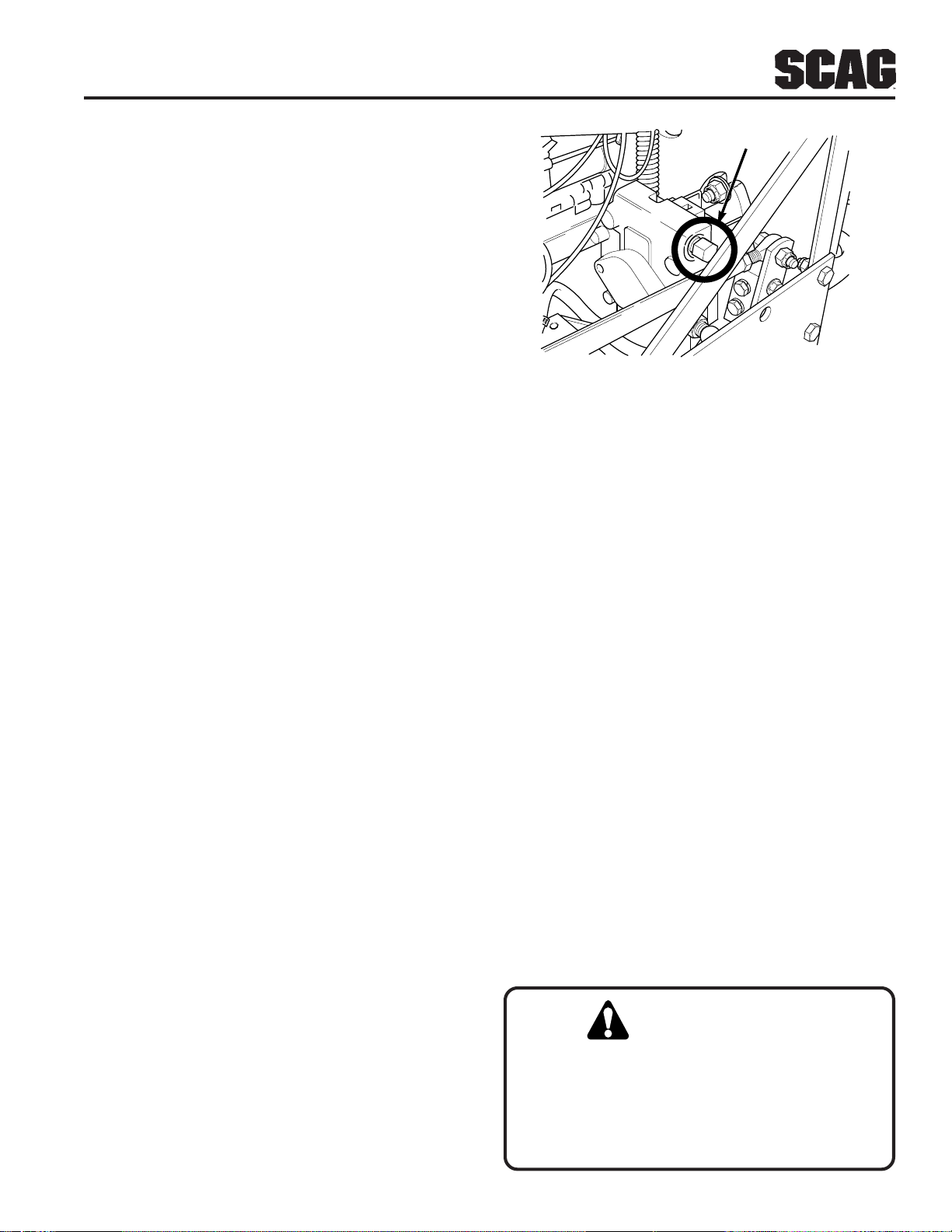

1. Position a floor jack under the rear of the machine.

Raise the machine and support it to prevent it from

falling. Block the caster wheels to prevent the

machine from moving. Remove the drive wheels.

7. Repeat steps 4-6 on the RH side of the machine.

8. Replace the drive wheels and test the brake.

-NOTE-

If this procedure does not achieve proper brake

adjustment, please contact your authorized Scag

dealer.

LOOSEN HERE

2" to 2-1/4" Clearance

390S0152-1

2. With the brake lever in the disengaged position, check

the distance between the top of the frame tube and

the bottom of the brake handle. The distance should

be 2" to 2-1/4" (See Figure 6-1).

3. If the distance is not at the specified measurement,

adjust by loosening the jam nuts at both ends of the

brake control rod and turning the rod until the proper

distance is achieved. (See Figure 6-1). Tighten the

jam nuts.

4. With the brake in the engaged position, check the

distance between the lower nut on the brake actuator

rod and the brake actuator lever on the LH side of the

machine. The distance should be 1/8" (See Figure 6-

2).

5. If the distance is not at the specified measurement,

loosen the jam nut at the clevis on the top of the

brake actuator rod (See Figure 6-2).

Figure 6-1. Brake Adjustment

LOOSEN

HERE

1/8"

390S0153-1

Figure 6-2. Brake Rod Adjustment

6.2 TRAVEL ADJUSTMENTS

Neutral or tracking adjustments will need to be made if:

6. Turn the bolt at the bottom of the brake actuator lever

until the 1/8" measurement is achieved and tighten the

jam nut at the clevis on the brake actuator rod. (See

Figure 6-2).

A. The steering control levers are in the neutral

position and the machine creeps forward or

backward. (Neutral Adjustment, See Page 21).

22

Page 27

Section 6

B. The steering control levers are in the full forward

position and the mower pulls to one side or the

other when traveling in a forward direction.

(Tracking Adjustment, See Page 23).

Neutral Adjustment

1. Be sure the dump valve levers are in the run position

and the steering control levers are in the neutral lock

position.

2. With an operator in the seat, start the engine and

disengage the parking brake.

3. Run the

machine creeps forward or backwards.

engine at full operating speed and check if the

CONTROL

ROD

4. Adjust the RH wheel by loosening the jam nuts on

the steering control rod and turning the rod until the

drive wheel turns in the forward direction. Turn the

rod back until the drive wheel stops moving. Turn

the rod an additional 1/2 turn. (See Figure 6-3).

5. Tighten the jam nuts and repeat for the LH wheel.

(See Figure 6-4).

6. Actuate the steering control levers forward and

reverse several times and return them to the neutral

position.

7. Check that the drive wheels remained in neutral and

readjust if necessary .

8. Check that the steering control levers hit the stop

before the pumps reach full stroke. Adjust as needed.

LOOSEN

HERE

LOOSEN HERE

390S0149-1

LOOSEN

HERE

390S0147-1

LOOSEN HERE

ADJUST HERE

2KBSGRHCRA

Figure 6-3. RH Steering Control Rod Adjustment

23

ADJUST HERE

2KBSGLHCRA

Figure 6-4. LH Steering Control Rod Adjustment

Page 28

Section 6

Tracking Adjustment

CAUTION:

Stop the engine and remove the key from the

ignition before making any adjustments. W ait for

all moving parts to come to a complete stop

before beginning work.

CAUTION:

The engine and drive unit can get hot during

operation causing burn injuries. Allow engine

and drive components to cool before making any

adjustments.

-NOTE-

Before proceeding with this adjustment, be sure

that the caster wheels turn freely and that the tire

pressure in the drive wheels is correct. If the tire

pressure is not correct, the machine will pull to

the side with the lower pressure.

A. Stop the machine and place the steering control

levers in the neutral position. Loosen the lock

nuts securing the ball joints at each end of the

RH steering control rod. Rotate the control rod

to lengthen the rod and tighten the lock nuts.

This will cause the control rod to stroke the RH

pump less, slowing down the RH wheel. (See

Figure 6-3)

-NOTE-

If after making the adjustment as outlined in step

2A, the machine creeps forward or backward, the

neutral adjustment must be made as described on

page 21.

6.3 THRO TTLE CONTROL

These adjustments must be performed by your Scag

dealer to ensure proper and efficient running of the

engine. Should either need adjustment, contact your

authorized Scag service center.

6.4 BELT ADJUSTMENT

1. If at full speed the mower pulls right, it is an

indication that the left wheel is turning faster than the

right wheel. T o adjust this condition, proceed as

follows:

A. Stop the machine and place the steering control

levers in the neutral position. Loosen the lock

nuts securing the ball joints at each end of the

LH steering control rod. Rotate the control rod

to lengthen the rod and tighten the lock nuts.

This will cause the control rod to stroke the LH

pump less, slowing down the LH wheel. (See

Figure 6-4)

-NOTE-

If after making the adjustment as outlined in step

1A, the machine creeps forward or backward, the

neutral adjustment must be made as described on

page 21.

2. If at full speed the mower pulls left, it is an indication

that the right wheel is turning faster than the left

wheel. T o adjust this condition, proceed as follows:

WARNING:

Before removing any guards, shut the

engine off and remove the ignition key.

All drive belts and cutter deck belts are spring-loaded

and self-tensioning. The belts should be checked

periodically for proper alignment and wear.

6.5 BELT ALIGNMENT

Belt alignment is important for proper performance of

your Scag mower. If you experience frequent belt wear

or breakage, see your authorized Scag service center for

belt adjustment.

24

Page 29

Section 6

6.6 CUTTER DECK ADJUSTMENTS

Cutter deck level, pitch and height are set at the factory.

However, if these adjustments should ever need to be

made, the following procedures will aid in obtaining the

proper cutter deck adjustment.

-NOTE-

Before proceeding with the cutter deck

adjustments, be sure that all tires are properly

inflated.

Cutter Deck Level

The cutter deck should be level from side-to-side for

proper cutting performance. To check for level, be sure

that the mower is on a flat, level surface, the tires are

properly inflated and the cutter deck is set at the most

common cutting height that you will use. On the RH side

of the machine, check the distance from the bottom of

the cutter deck to the floor. Next check the distance

from the bottom of the cutter deck to the floor on the LH

side of the machine. Both measurements should be the

same. If the two measurements are different, the cutter

deck level must be adjusted as follows:

1. On the front LH side of the cutter deck locate the

cutter deck adjusting bolt. (See Figure 6-5)

JAM NUT

ADJUST HERE

3. Tighten the elastic stop nut to secure the cutter deck

in the proper position.

Cutter Deck Pitch

The pitch of the cutter deck should be equal between the

front and rear of the cutter deck for proper cutting

performance. To check for proper deck pitch, be sure

that the mower is on a flat, level surface and the tires are

properly inflated. Use the following procedures,

however, measure from the top of the cutter deck rather

than the bottom edge. Lay a straight edged object on the

top of the Advantage cutter deck, protruding towards the

front of the machine, when measuring the front height.

Check the distance from the top of the cutter deck to the

floor at the rear RH side of the cutter deck directly

behind the cutter deck hanging chains. Next check the

distance from the top of the cutter deck to the floor at

the front RH side of the cutter deck directly in front of

the cutter deck hanging chains. The measurement at the

front of the cutter deck should be equal to the

measurement at the rear of the deck. Make these

measurements at the LH side of the cutter deck also. If

the measurement at the front of the deck is not equal to

the rear, the cutter deck pitch must be adjusted as

follows:

1. Loosen the jam nuts on both adjusting rods.

(See Figure 6-5)

2. Using a wrench on the spring compression nut (See

Figure 6-5) turn the adjusting rods until the 1/4"

forward pitch is obtained on both the RH and the LH

side of the cutter deck. Tighten both jam nuts.

390S0174-1

Figure 6-5. Cutter Deck Adjustment

2. Loosen the elastic stop nut and move the bolt up or

down in the slot to adjust the cutter deck until the

distance from the bottom of the cutter deck to the

floor is the same as the measurement on the RH side

of the machine.

-NOTE-

To prevent the cutter deck from teetering, all four

cutter deck hanging chains must have tension on

them. If all four chains do not have tension on

them and the deck teeters, you must readjust the

cutter deck as outlined in the procedures above.

25

Page 30

Section 6

Cutter Deck Height

The cutter deck height adjustment is made to ensure that

the cutter deck is cutting at the height indicated on the

cutting height index gauge. To check for proper deck

height, be sure that the mower is on a flat, level surface

and the tires are properly inflated.

1. Place the cutter deck in the transport position.

Loosen the jam nuts on both ends of the deck height

control rod. (See Figure 6-6)

LANYARD PIN

CONTROL ROD

HEIGHT ADJUSTMENT PEDAL

LOOSEN

HERE

5

5.5

T

6

H

G

N

I

IG

T

E

T

H

U

C

Figure 6-6. Cutter Deck Height Adjustment

3

4

5

1

8

4

1

1.5

2

2.5

3

3.5

4

4.5

390S014A

3. Check the cutter deck cutting height by placing the

lanyard pin in the 3" position on the cutting height

index. Release the deck from the transport positon

and allow the deck to move to the 3" cutting height

position.

4. Check the measurement from the floor to the cutter

blade tip. If the measurement is not at 3", an

adjustment can be made using the deck height

control rod. (See Figure 6-6)

-NOTE-

If an adjustment has to be made, be sure that the

cutter deck can easily be locked into the

transport position.

Custom-Cut Baffle Adjustment

The Custom-Cut Baffle is designed to deliver optimum

airflow and superior cutting performance in any type of

grass. The Custom-Cut Baffle can be raised or lowered

to precisely tailor the deck's performance for the type of

grass being cut. The baffle can be set in three (3)

different positions for optimum performance.

2. Turn the control rod (See Figure 6-6) until there is a

1/4" space between the rear deck stop and the top of

the cutter deck. (See Figure 6-7). Tighten the jam

nuts on the control rod.

DECK

STOP

1/4"

390S0175-1

Figure 6-7. Cutter Deck Stop

A. 3" Position - baffle is installed using the top set of

holes on the front baffle welded inside the cutter

deck. (See Figure 6-9). The Advantage cutter deck

will deliver the best quality-of-cut in very tall, wiry ,

tough to cut grass.

B. 3-1/2" Position (factory setting) - baffle is installed

using the middle set of holes on the front baffle

welded inside the cutter deck. (See Figure 6-10). For

general purpose cutting, place the Custom Cut Baffle

in the 3-1/2" position. This gives the best mix of

cutting performance in all types of grass.

C. 4" Position - baffle is installed using the bottom set of

holes on the front baffle welded inside the cutter

deck . (See Figure 6-11). Placing the baffle in the 4"

setting will enhance fall cutting (leaf pickup) and

reduce cutter deck "blowout".

26

Page 31

Section 6

T o adjust the Custom-Cut Baffle height:

1. Place the cutter deck in the transport position.

2. Remove the hardware securing the Custom-Cut

Baffle to the cutter deck. (See Figure 6-8).

-NOTE-

Hardware location used in the illustrations are

for reference only. Location of hardware may

vary depending on cutter deck size.

MOUNTING

HARDWARE

MOUNTING

HARDWARE

Figure 6-8. Custom-Cut Baffle

2004 CCB

MIDDLE SET OF HOLES

FOR 3-1/2" SETTING

FLATWASHER

CARRIAGE BOLT

2004 CCB - 3-1/2" Setting

ELASTIC STOP

NUT

Figure 6-10. 3-1/2" Custom-Cut Baffle Position

BOTTOM SET OF HOLES

FOR 4" SETTING

FLATWASHER

CARRIAGE BOLT

2004 CCB - 4" Setting

ELASTIC STOP

NUT

Figure 6-11. 4" Custom-Cut Baffle Position

3. Move the Custom-Cut Baffle to desired position.

(See Figures 6-9 through 6-11 for position).

4. Reinstall the mounting hardware as shown. (See

Figures 6-10 though 6-11). Torque hardware to

39ft.lbs.

TOP SET OF HOLES

FOR 3" SETTING

FLATWASHER

CARRIAGE BOLT

2004 CCB - 3" Setting

ELASTIC STOP

NUT

Figure 6-9. 3" Custom-Cut Baffle Position

27

Page 32

MAINTENANCE

7.1 MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS

HOURS

Break-In 8 40 100 2 0 0 500 Procedure Comments

(First 10)

X Check all hardware for tightness

X Check hydraulic oil level See paragraph 7.3

X Check all belts for proper alignment See paragraph 7.8

X Change engine oil and filter See paragraph 7.4

(First 5)

X Check hydraulic hoses for leaks Use extreme caution when

checking the hydraulic hoses

See paragraph 2.5

Section 7

X Check coolant level See paragraph 7.12

X Check engine oil level See paragraph 7.4

X *Clean mower See paragraph 7.14

X Check condition of blades See paragraph 7.9

X Apply grease to fittings See paragraph 7.2

X Check tire pressure See paragraph 7.10

X Check coolant level See paragraph 7.12

X Check battery electrolyte level, See paragraph 7.7

clean battery posts and cables

X Check belts for proper alignment See paragraph 7.8

X Apply grease to fittings See paragraph 7.2

X Change engine oil See paragraph 7.4

X *Clean air cleaner element See paragraph 7.6

X Check lubricant in cutter deck gearbox See paragraph 7.11

* Perform these maintenance procedures more frequently under extreme dusty or dirty conditions

28

Page 33

Section 7

MAINTENANCE CHART - RECOMMENDED SERVICE INTERVALS (CONT'D)

HOURS

Break-In 8 40 100 200 500 Procedure Comments

(First 10)

X Apply grease to fittings See paragraph 7.2

X Check hardware for tightness

X Change engine oil filter See paragraph 7.4

X Check hydraulic oil level See paragraph 7.3

X Replace engine fuel filter See paragraph 7.5

X Drain hydraulic system and See paragraph 7.3

replace hydraulic oil Use SAE 20W50

Motor Oil

X Replace hydraulic oil filter See paragraph 7.3

X Replace cutter deck gearbox lubricant See paragraph 7.1

X Change coolant See paragraph 7.12

7.2 LUBRICATION

GREASE FITTING LUBRICATION CHART

(SEE FIGURE 7-1)

LUBRICATION NO. OF

LOCATION INTERVAL LUBRICANT PLACE S

1 Caster Wheel Pivot 500 Hours/Yearly Chassis Grease 2

2 Caster Wheel Bearings 100 Hours/Bi-Weekly Chassis Grease 2

3 Brake Actuator 200 Hours/Monthly Chassis Grease 2

4 Cutter Deck Bellcranks 40 Hours/Weekly Chassis Grease 4

5 Cutter Deck Pusharms 100 Hours/Bi-Weekly Chassis Grease 2

6 PTO Spindle 40 Hours/W eekly +Lithium MP White Grease 2125 1

7 Cutter Deck Spindle 40 Hours/W eekly +Lithium MP White Grease 2125 3

8 Brake Handle 200 Hours/Monthly Chassis Grease 1

9 Cutter Deck Drive Shaft 40 Hours/Weekly Chassis Grease 3

+ Compatible Greases: Mobilix #2 found at Mobil Service Stations

Ronex MP found at Exxon Service Stations

Super Lube MEP #2 & Super Stay-M #2 found at Conoco Stations

Shell Alvania #2 found at Shell Service Stations

Lidok EP #2 found at industrial shops

29

Page 34

Section 7

10

GREASE FITTING LUBRICATION

LUBRICANT / INTERVAL

LITHIUM MP WHITE GREASE 2125

( 40 HOURS / WEEKLY )

CHASSIS GREASE

( 100 HOURS / BI-MONTHLY )

CHASSIS GREASE

( 200 HOURS / MONTHLY )

CHASSIS GREASE

4

( 500 HOURS / YEARLY )

1

6

3

5

7

2

8

1

9

2

4 3

5

9

10

390S0145-2

Figure 7.1 Lubrication Fitting Points

30

Page 35

Section 7

7.3 HYDRAULIC SYSTEM

A. Checking Hydraulic Oil Level

The hydraulic oil level should be checked after the first

10 hours of operation. Thereafter, check the oil after