Page 1

MODEL STHM

OPERATOR’S MANUAL

THIS MANUAL CONTAINS THE OPERATING

INSTRUCTIONS AND SAFETY INFORMATION FOR YOUR SCAG MOWER. READING

THIS MANUAL CAN PROVIDE YOU WITH

ASSISTANCE IN MAINTENANCE AND ADJUSTMENT PROCEDURES TO KEEP YOUR

MOWER PERFORMING TO MAXIMUM EFFICIENCY. THE SPECIFIC MODELS THA T THIS

BOOK COVERS ARE CONTAINED ON THE

INSIDE COVER. BEFORE OPERA TING YOUR

MACHINE, PLEASE READ ALL THE INFORMATION ENCLOSED.

© 2003

SCAG POWER EQUIPMENT

DIVISION OF MET ALCRAFT OF MA YVILLE, INC.

P ART NO. 03133

PRINTED 7/03

PRINTED IN USA

Page 2

WARNING:

FAILURE TO FOLLOW SAFE OPERATING PRACTICES

MAY RESULT IN SERIOUS INJURY.

* Keep all shields in place, especially the grass discharge chute.

* Before performing any maintenance or service, stop the machine and

remove the spark plug wire and ignition key.

* If a mechanism becomes clogged, stop the engine before cleaning.

* Keep hands, feet and clothing away from power-driven parts.

* Read this manual completely as well as other manuals that came

with your mower.

* Keep others off the tractor (only one person at a time)

REMEMBER - YOUR MOWER IS ONLY AS SAFE AS THE OPERATOR!

Hazard control and accident pre vention are dependent upon the awareness,

concern, prudence, and proper training of the personnel involved in the

operation, transport, maintenance, and storage of the equipment.

This manual covers the operating instructions

and illustrated parts list for:

STHM-23CV with a serial number of 9220001 to 9229999

SM-61A with a serial number of 9230001 to 9239999

SM-72A with a serial number of 9240001 to 9249999

Always use the entire serial number listed on the serial number

tag when referring to this product.

Page 3

TABLE OF CONTENTS

MODEL STHM

SUBJECT PAGE

Introduction.................................................................................................. 1

General Safety Instructions.......................................................................... 1

Signal Words ............................................................................................... 1

Symbols....................................................................................................... 2-3

Before Operating ......................................................................................... 4

While Operating........................................................................................... 4-5

Maintenance and Storage ........................................................................... 5-6

Initial Run-In Procedures ............................................................................. 6

Mower Operation ......................................................................................... 6-7

Parking Brake Adjustments ......................................................................... 8

Neutral Adjustment ...................................................................................... 8-9

Belt Tension ................................................................................................. 9-10

Belt Alignment ............................................................................................. 10

Cutter Deck Adjustments ............................................................................. 10-11

Cutter Blades............................................................................................... 11

Custom-Cut Baffle Adjustment..................................................................... 11-12

Lubrication and Maintenance ...................................................................... 13

Troubleshooting Cutting Conditions ............................................................ 14-16

Technical Specifications .............................................................................. 17-18

Notes .......................................................................................................... 19

WE SUPPORT OPE

TECHNICIAN

CERTIFICATION

Page 4

TABLE OF CONTENTS

(CONTINUED)

SUBJECT PAGE

Illustrated Parts List

SM 61A, 72A Cutter Deck...................................................................... .. 20-21

Engine Deck ..................................................................................... 22-23

Upper Hydraulics.............................................................................. 24-25

Lower Hydraulics........................................................................................ 26-27

Control Linkage.......................................................................................... 28-29

Instrument Panel ............................................................................... 30-31

Rider Frame Assembly ..................................................................... 32-33

Brake Linkage................................................................................... 34-35

Eletrical System................................................................................ 36

Winch Lift System ............................................................................. 37

Replacement Decals ........................................................................

Warranty Statement........................................................ following section 8

Page 5

INTRODUCTION

Your mower was built to the highest standards in the

industry. However, the prolonged life and maximum

efficiency of your mower depends on you following

the operating, maintenance and adjustment instructions in this manual.

We encourage you to contact your dealer for repairs.

All Scag dealers are informed of the latest methods

to service this equipment and provide prompt and

efficient service in the field or at their service shop.

They carry a full line of Scag service parts.

A replacement Operator's Manual is available from

your Scag Servicing Dealer or by contacting Scag

Power Equipment, Service Department at P.O. Box

152, Mayville, WI 53050 or contact us via the Internet

at www.scag.com. Use the contact form to make your

request. Please indicate the complete model and serial

number of your Scag product.

SIGNAL WORDS

This symbol means “Attention! Become Alert!

Your Safety is Involved!". The symbol is used

with the following signal words to attract your

attention to safety messages found on the decals and

throughout this manual. The message that follows

the symbol contains important information about

safety. To avoid injury and possible death, carefully

read the message! Be sure to fully understand the

causes of possible injury or death.

Signal Word:

It is a distinctive word on safety decals and throughout this manual that alerts the viewer to the existence and relative degree of the hazard.

USE OF OTHER THAN ORIGINAL SCAG

REPLACEMENT PARTS WILL VOID THE

WARRANTY.

The “Right” and “Left”, “Front” and “Rear” of the

machine are referenced from the operator’s perspective when in the normal operating position and

facing the forward travel direction.

GENERAL SAFETY INSTRUCTIONS

READ THIS OPERATOR'S MANUAL and all

instructions furnished with attachments.

Perform only those maintenance procedures described in this manual. If major repairs are ever

needed or assistance is desired, contact an Authorized Scag Dealer. To ensure optimum performance

and safety, always purchase genuine SCAG replacement parts and accessories.

Your safety and the safety of others depends significantly upon your knowledge and understanding of

all correct operating practices and procedures of this

machine.

The signal word “DANGER” denotes that an extremely hazardous situation exists on or near the

machine that could result in high probability of

death or irreparable injury if proper precautions are

not taken.

WARNING:

The signal word “WARNING” denotes that a hazard

exists on or near the machine that can result in

injury or death if proper precautions are not taken.

CAUTION:

The signal word “CAUTION” is a reminder of

safety practices on or near the machine that could

result in personal injury if proper precautions are not

taken.

1

Page 6

ISO Symbols

CE Mark

SYMBOL DESCRIPTION

Choke

Parking Brake

On/Start

SYMBOL DESCRIPTION

Transmission

Spinning Blade

48071S

Spring T ension on Idler

Off/Stop

Oil

WARNING

Falling Hazard

FALLING HAZARD

USE ONLY SCAG APPROVED

RIDING ATTACHMENTS

SEE OPERATOR'S MANUAL

481109

2

Page 7

SYMBOL DESCRIPTION SYMBOL DESCRIPTION

481039S

Fast

Continuously Variable - Linear

Pinch Point

Slow

Cutting Element - Basic Symbol

Cutting Element - Engage

Hourmeter/Elapsed Operating Hours

Thown Object Hazard

Keep Bystanders Away

Cutting Element - Disengage

Read Operator's Manual

3

Page 8

BEFORE OPERATING

WHILE OPERATING

1. Know the operating controls and how to stop

quickly.

2. Do not allow children to operate the machine.

Do not allow adults to operate the machine

without proper instruction.

3. Remove all debris or other objects that might be

picked up and thrown by the cutter blades. Keep

all bystanders away from the mowing area.

4. Keep all shields, safety devices, and decals in

place. If a shield, safety device or decal is defective or damaged, repair or replace it before

operating. Also, check all nuts, bolts and screws

for proper tightness, to assure the machine is in

safe operating condition.

5. Do not operate the machine while wearing

sandals, tennis shoes, sneakers or shorts. Also,

do not wear loose fitting clothing which could get

caught in moving parts. Always wear long pants

and substantial shoes. Wearing safety glasses and

safety shoes is advisable and required by some

local ordinances and insurance regulations.

6. Fill the fuel tank with clean, fresh gasoline, with a

minimum octane rating of 87. Avoid spilling

gasoline. Gasoline is highly flammable, handle it

carefully.

A. Use an approved gasoline container.

B. Do not fill the tank while the engine is hot or

running.

C. Do not smoke while handling gasoline.

D. Fill the fuel tank outdoors and up to approxi-

mately 1" (25 mm) below the bottom of the

filler neck.

E. Wipe up any spilled gasoline.

7. Before attempting to start the engine, move the

blade engagement switch to the OFF position and

apply the parking brake.

1. Start the engine when the cutter blades are

disengaged, the parking brake is on and the right

foot pedal is in the neutral position.

2. Do not run the engine in a confined area without

adequate ventilation. Exhaust fumes are hazardous and could possibly be deadly.

3. Using the machine demands attention. To

prevent loss of control:

A. Mow only in daylight or when there is good

artificial light.

B. Watch for holes or other hidden hazards.

C. Do not drive close to a drop-off, ditch, creek

bank, or other hazard.

D. Reduce speed when making sharp turns and

when turning on hillsides.

E. Do not operate where conditions are slippery.

4. The discharge chute must always be installed and

in the down position on the side discharge cutter

deck except when the Scag optional grass

catcher or mulching plate are properly installed.

If the discharge area should plug, shut the engine

off and wait for all movement to stop before

removing the obstruction.

5. Disengage the blades and wait for them to stop

before crossing gravel drives, walks or roads.

6. Shut the engine off and wait until the blades

come to a complete stop before removing the

grass catcher container.

7. Never raise the cutter deck while the blades are

rotating.

8. Always park the mower and/or start the engine

on a level surface. Apply the parking brake to

prevent the mower from moving when you are

not in the operator’s position.

4

Page 9

9. If the cutting blades should strike a solid object

or the equipment should start to vibrate abnormally, stop the engine, disconnect the spark plug

wires, and check immediately for the cause. Vibration is generally a warning of trouble. Check the

machine for damaged or defective parts. Repair any

damage before starting the engine or operating the

cutter deck. Be sure the blades are in good condition and the blade bolts are tight.

10. Reduce speed and exercise extreme caution on

slopes and in sharp turns to prevent tipping or

loss of control. Be especially cautious when

changing directions on slopes.

MAINTENANCE AND STORAGE

1. Disconnect the spark plug wire from the spark

plug to prevent accidental starting of the engine

when servicing, adjusting or storing the machine.

2. If the mower must be tipped to perform maintenance or adjustment, remove the battery, drain

the gasoline from the fuel tank and the oil from

the crankcase.

3. To reduce potential fire hazard, keep the engine

free of excessive grease, grass, leaves and accumulations of dirt.

WARNING:

DO NOT operate on steep slopes. To check a

slope, attempt to back up it (with the cutter deck

down). If the machine can back up the slope

without the wheels slipping, reduce speed and

use extreme caution. ALWAYS FOLLOW OSHA

APPROVED OPERATION.

11. Do not touch the engine or muffler while the

engine is running or soon after it is stopped.

These areas could be hot enough to cause a burn.

12. Before leaving the operator’s position or leaving

the mower unattended, move the right foot pedal

into the neutral position, apply the parking brake,

and move the blade engagement switch to OFF.

Shut the engine OFF and remove the key.

13. Do not pass or stand on the grass discharge side of

any mower with the engine running. Stop the cutter

blades when another person approaches.

WARNING:

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after han-

dling.

4. Be sure the machine is in safe operating condition

by keeping nuts, bolts, and screws tight. Check

the blade mounting bolts and nuts frequently to

be sure they are tightened.

5. If the engine must be running to perform a

maintenance adjustment, keep hands, feet, clothing and other parts of the body away from the

cutter deck blades and other moving parts.

6. Do not overspeed the engine by changing governor settings. To be sure of safety and accuracy,

have an authorized dealer check maximum engine

speed with a tachometer.

7. The engine must be shut off before checking the

oil or adding oil to the crankcase.

8. Allow the engine to cool before storing the

mower in any enclosure such as a garage or

storage shed. Make sure the fuel tank is empty if

the machine is to be stored in excess of 30 days.

Do not store the mower near any open flame or

where gasoline fumes may be ignited by a spark.

5

Page 10

9. Always store gasoline in a safety-approved, red

container.

10. Be careful when servicing the battery as it contains acid, which is corrosive and could cause

burns to skin and clothing.

MOWER OPERATION

1. Read and understand the safety instructions

before attempting to operate this machine.

2. Before starting the engine:

11. Batteries release explosive gases when being

charged or discharged. Keep batteries away from

any source of sparks and/or flame.

12. Make sure all hydraulic connections are tight and

all hydraulic hoses and lines are in good condition before starting the machine.

13. Hydraulic fluid is under high pressure. If you

need service on your hydraulic system, please see

your authorized Scag dealer.

INITIAL RUN-IN PROCEDURES

(FIRST DAY OF USE OR APPROXIMATELY 10 HOURS)

1. Check the belts for proper tension at 2, 4 and 8

hours. Adjust as needed. (See Belt Tension,

page 9).

2. Check the neutral adjustment. (See Adjustments, page 8)

* Check the oil level in the engine and the

hydraulic reservoir.

* Fill the fuel tank with clean, fresh, lead-free

gasoline.

* Open the fuel valve on the bottom of the

fuel tank.

-NOTE-

Use gasoline with an octane rating no less than

87.

* The right hand foot pedal must be in the

NEUTRAL position.

* The blade clutch switch must be in the OFF

position.

* The parking brake must be ON.

3. Start the engine:

* Choke as required. If the engine is cold, pull

the choke knob out. When the engine starts,

slowly push the choke in. If the engine stalls,

repeat the above operation. When the engine

is warm, choking may not be necessary.

3. Check the tires for proper pressure.

Caster Wheels 25 psi

Drive Wheels 12 psi

Rear Steering Wheel 15 psi

4. Check for loose hardware. Tighten as needed.

5. Check the safety switches for proper adjustment:

* The engine should crank and start if the

machine is in neutral, the PTO engagement

switch is OFF and the parking brake is ON.

7. Apply lubricant to all the grease fittings. Lubricant

was applied at the factory. This is just a precautionary check to make sure that all the fittings have been

lubricated.

4. Depress the left hand operator presence pedal.

5. Engage the cutter blades by pulling the blade clutch

switch into the ON position. Push the switch to the

OFF position to disengage the cutter blades.

PULL UP TO ENGAGE

PUSH DOWN TO DISENGAGE

390S0138

6

Page 11

-NOTE-

When the PTO is engaged or (possibly) disengaged, a squealing sound from the underside of

the machine is normal. It is caused by the

electric clutch plates meshing as the cutter

blades come up to speed. For best equipment

life, engage the clutch with the engine at 3/4

throttle, not under full load.

WARNING:

If you are not familiar with the operation of the

hydrostatic drive, practice turning and

maneuvering before engaging the cutter blades.

5. Release the parking brake. Depress the right foot

pedal at the toe end to drive forward (See Figure 1)

or depress the pedal at the heel end to drive in

reverse. (See Figure 2)

SGB003

Backward (Reverse) Operation - Depress Heel

End of Pedal

Figure 2

6. When driving over curbs, disengage the cutter blades

and raise the cutter deck to clear the curb. Drive

forward over the curb. After the curb is clear, lower

the cutter deck back to normal operating position.

Be sure to leave slack in the cable after lowering the

cutter deck.

-NOTE-

The left side operator presence pedal must be

depressed for operation.

sgb002

Forward Operation - Depress Toe End of Pedal

Figure 1

7. To "freewheel" or move the machine around without

the engine running, rotate the dump valve lever

located on the left rear of the engine deck to the

freewheel position (See Figure 3). The lever must be

returned to the drive position to operate the machine.

DUMP VALVE

FREE

WHEEL

DRIVE

SGB006

Figure 3. Dump Valve Location

-NOTE-

To prevent damage to the hydraulic system, do not

exceed 1MPH when moving the machine in the

freewheel postion.

7

Page 12

ADJUSTMENTS

PARKING BRAKE

If the drive wheels consistently rotate when foot

pedal control is in neutral, go to step 4.

Minor brake adjustments can be made by loosening

the top nut on both brake cables (see Figure 4).

Back the nuts off approximately 1/4". While pulling

one cable downward, tighten the bottom nut on the

cable until it touches the bottom of the brake cable

mount. Tighten both the top and bottom nuts to

lock the cable in place. Repeat the above steps for

the second brake cable. Make sure that both

cables are adjusted evenly so that the brakes do not

cause the mower to pull to the left or right.

-NOTE-

This is a minor brake adjustment. If the

brakes do not function properly after this

adjustment, see your Scag Service Dealer

before operating your mower.

If the drive wheels inconsistently rotate, i.e. drive

wheels sometimes rotate and sometimes do not

when foot pedal is not depressed, then check

neutral adjustment bolt for "zero free play" in neutral

control spring.

-NOTE-

If there is free play in the foot pedal have your

SCAG servicing dealer inspect the machine and

repair it as needed.

4. If the drive wheels rotate in the forward travel

direction, turn the adjustment bolt clockwise until the

tire rotation stops. If the drive wheels rotate in the

backward travel direction, turn the adjustment bolt

counter-clockwise until the tire rotation stops (See

Figure 5).

Adjust

Nuts

SGB028

Figure 4. Parking Brake Adjustment

NEUTRAL ADJUSTMENT

1. Set the engine deck up on jack stands so the wheels

are free to rotate.

2. Block the caster wheels to prevent an accident

should the machine fall off the jack stands.

3. Start the engine and determine if the drive wheels

rotate.

Neutral Control

Spring

9/16" Socket

SGB029

Figure 5. Neutral Adjustment

8

Page 13

5. Check the adjustment of the right foot control pedal

for full forward speed. The pedal should rest on the

foot plate when the pump is stroked in the full

forward position. To make an adjustment, disconnect the ball joint from the pedal arm and loosen the

jam nut (See Figure 6). Place the foot control pedal

forward against the foot rest and adjust the ball joint

on the rod until the stud aligns with the hole in the

arm. Bolt the ball joint to the arm and tighten the

jam nut.

Jam Nut

Ball Joint

SGB030

2. To adjust cutter deck drive belt: Adjust the nut so

that the belt moves 1/2" with 10 pounds of pressure. (See Figure 7).

End Of L-Shaped

Bracket

Nut

Washer

"J" Bolt

Belt

SGB044

Figure 7. Cutter Deck Drive Belt Tension

3. To adjust blade drive belt: Using a belt tension

gauge, check the belt tension so that the belt moves

1/2" with 10 pounds of pressure. (See Figure 8).

Figure 6. Foot Control Pedal Adjustment

6. Start the engine. The wheels should rotate only

when the foot control pedal is depressed.

BEL T TENSION

CAUTION:

Stop engine and remove the key from the ignition

before making any adjustments. Wait for all

moving parts to come to a complete stop before

beginning work.

-NOTE-

The Hydro Drive Belt is spring-loaded and

does not require adjustment.

To adjust cutter deck drive and blade belts:

1. Remove belt cover.

Use of Tension Gauge

sgb007

Figure 8. Blade Drive Belt Tension Check

9

Page 14

Adjust the tension by tightening or loosening

the nut on the J-bolt.

Nut

Deck

"J" Bolt

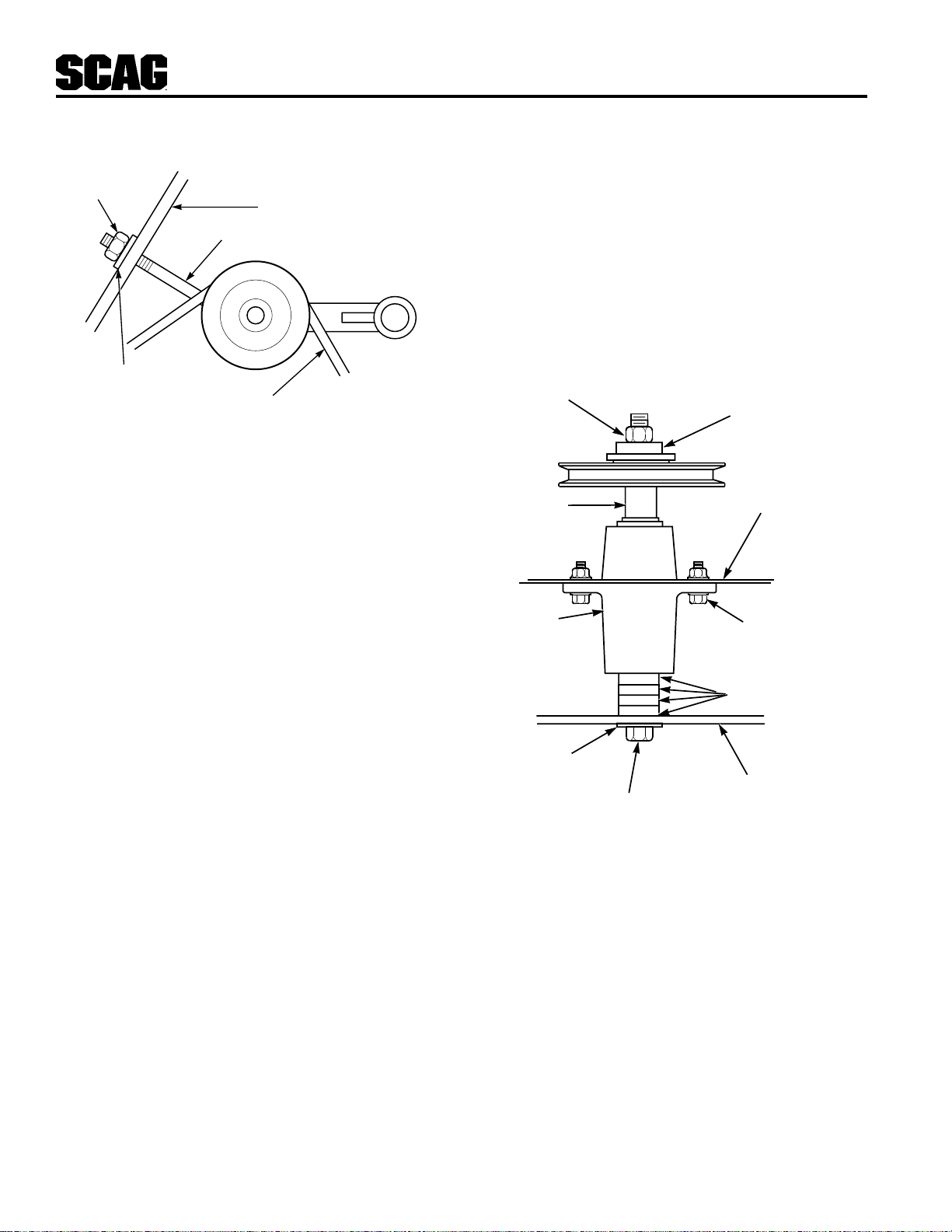

Adjusting the blade height can be done by moving any

number of the five smaller spacers on the blade mounting bolts to the top or to the bottom of the spindle shaft.

All blades should be positioned equally (See Figure 10).

The unit is shipped with one spacer on top of spindle

and four underneath (See Figure 10).

This adjustment does not affect blade pitch.

Washer

Belt

SGB031

Figure 9. Blade Belt Tension Adjustment

4. Replace the belt covers.

BELT ALIGNMENT

Belt alignment is important for proper performance of

your Scag mower. If you experience frequent belt wear

or breakage, see your authorized Scag Service Dealer

for belt adjustment.

CUTTER DECK ADJUSTMENTS

Due to the many conditions that exist, it is difficult to

suggest a setting that will work for every lawn. There

are, however, two adjustments that should be made on

the cutter deck: pitch and height.

Hex Nut-Torque

to 75 Lb-Ft

Spindle

Shaft

Spindle

Assembly

Washer

Hex Head Bolt

Cutter Blade

Spacer 1/4"

Cutter

Deck

Hex Head

Bolt / Nut

Cutter Blade

Spacers1/4"

Cutter Blade

Figure 10. Cutter Blade Adjustment

PITCH is the angle of the blades (comparing front

to rear).

HEIGHT is the nominal distance that the blade is

off the ground. This measurement is made with the

blades pointed side to side and distance is measured

between cutting tip and ground.

-NOTE-

For best results, keep the cutter deck

high in relation to the engine deck and

the blades low in the cutter deck; ie. 4 or

5 spacers below the spindle shaft.

Additional range to the cutting height can be

achieved by repositioning the cutter deck in relationship to the engine deck. This adjustment also affects

the pitch of the deck.

10

Page 15

There are three positions for mounting the cutter deck

(See Figure 11). For cutting in the lowest position,

mount the cutter deck in the top hole (A). For cutting in

the highest position, mount the deck in the lowest hole

(C). Setting the cutter deck height will be determined

by the type of cutting conditions.

CUTTER BLADES

CAUTION:

Blades have a sharp cutting edge. Wear protective

gloves or wrap blades with protective material when

removing, sharpening and installing blades.

A

B

C

SGB032

Figure 11. Cutter Deck Height Adjustment

Caster spacers also can be repositioned to change the

cutting heights and to change the pitch of the deck (See

Figure 12).

To adjust the caster spacers, raise the deck and remove

the pin and caster wheel. Reposition the caster spacers

as needed, then replace the caster, top spacers and pin.

Make the same adjustments on the other caster wheel.

Angle Blade Back

Do Not Cut In

X

X Must NOT Exceed

30

1/3 Blade Width

SGB033

Figure 13. Blade Sharpening

Do not sharpen beyond 1/3 of the width of the blade. (See

Figure 13).

-NOTE-

Dress the blade with a file. Using a wheel grinder may

burn the blade. Check the balance of the blade. If

blades are out of balance, vibration and premature

wear can occur. See your authorized Scag Dealer for

blade balance tools.

CUSTOM-CUT BAFFLE ADJUSTMENT

To adjust the blade height, move any number of the five

1/4" thick spacers on the blade mounting bolts to the

top of the spindle shaft or below the spindle shaft.

Pin

Spacers

2002SGB005

Figure 12. Repositioning Spacers

The Custom-Cut Baffle is designed to deliver optimum

airflow and superior cutting performance in any type of

grass. The Custom-Cut Baffle can be raised or lowered

to precisely tailor the deck's performance for the type of

grass being cut. The baffle can be set in three (3)

different positions for optimum performance.

11

Page 16

A. 3" Position - baffle is installed using the top set of

holes on the front baffle welded inside the cutter

deck. (See Figure 15). The Advantage cutter deck

will deliver the best quality-of-cut in very tall, wiry ,

tough to cut grass.

3. Move the Custom-Cut Baffle to desired position.

(See Figures 15through 17 for position).

4. Reinstall the mounting hardware as shown. (See

Figures 15 though 17). Torque hardware to 39ft.lbs.

B. 3-1/2" Position (factory setting) - baffle is installed

using the middle set of holes on the front baffle

welded inside the cutter deck. (See Figure 16). For

general purpose cutting, place the Custom Cut Baffle

in the 3-1/2" position. This gives the best mix of

cutting performance in all types of grass.

C. 4" Position - baffle is installed using the bottom set of

holes on the front baffle welded inside the cutter

deck . (See Figure 17). Placing the baffle in the 4"

setting will enhance fall cutting (leaf pickup) and

reduce cutter deck "blowout".

T o adjust the Custom-Cut Baffle height:

1. Place the cutter deck in the transport position.

2. Remove the hardware securing the Custom-Cut

Baffle to the cutter deck. (See Figure 14).

-NOTE-

Hardware location used in the illustrations

are for reference only. Location of hardware

may vary depending on cutter deck size.

MOUNTING

HARDWARE

MOUNTING

HARDWARE

TOP SET OF HOLES

FOR 3" SETTING

FLATWASHER

CARRIAGE BOLT

ELASTIC STOP

NUT

Figure 15. 3" Custom-Cut Baffle Position

MIDDLE SET OF HOLES

FOR 3-1/2" SETTING

FLATWASHER

CARRIAGE BOLT

2004 CCB - 3-1/2" Setting

ELASTIC STOP

NUT

Figure 16. 3-1/2" Custom-Cut Baffle Position

BOTTOM SET OF HOLES

FOR 4" SETTING

CARRIAGE BOLT

2004 CCB - 3" Setting

Figure 14. Custom-Cut Baffle

2004 CCB

12

FLATWASHER

ELASTIC STOP

NUT

2004 CCB - 4" Setting

Figure 17. 4" Custom-Cut Baffle Position

Page 17

LUBRICATION & MAINTENANCE

Break-In

(1st 10 Hours)

8 Hours (Daily)

25 Hours

40 Hours (Weekly)

X

X

X

X

X

X

X

X

X

*

X

X

X

100 Hours (Biweekly)

200 Hours (Monthly)

500 Hours or Annually

Check all hardware for proper tightness

Change engine oil and filter at 5 hours

Check hydrostatic oil level

Check belt tension

Fill fuel tank before starting

Check engine oil

Clean blower screen

Remove debris from under belt cover

Sharpen cutter blades

Grease spindle bearings 2 pumps of hand gun

Clean air filter/check for damage or loose parts

Check/clean air intake and cooling areas

Check tire pressure

* Lubrication may be required every 8 to 40 hours, depending on climate and environment.

+ Compatible Greases: Mobilux #2 found at Mobil Service Stations

Ronex MP found at Exxon Service Stations

Super Lube MEP #2 & Super Stay-M #2 found at Conoco Service Stations

Shell Alvania #2 found at Shell Service Stations

Lidok EP #2 found at industrial shops

PROCEDURE

COMMENTS

Add oil as needed - SAE 10W30

Do not over fill

MORE OFTEN IF NEEDED

US Lithium MP White Grease 2125+

MORE OFTEN IF NEEDED

1

MORE OFTEN IF NEEDED

Add or adjust as required

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

Service precleaner element

Check battery electrolyte level

Grease caster wheel bearings

Grease caster wheel pivots

Grease idler arm pivots

Service air cleaner element

Change engine oil

Check spark plug condition and gap

Clean cooling areas

1

Check all hardware for proper tightness

Change engine oil filter

Check hydro fluid reservoir level

Clean and adjust spark plugs

Grease rider frame pivot

Grease control bell cranks

Grease steering handle bearing

Grease foot pedal bearings

Grease rear wheel pivot (vertical)

Grease rear wheel bearing

X

Drain hydraulic system and replace fluid

X

Change hydrostatic oil filter

1

Distilled water only

Chassis grease

Chassis grease

Chassis grease

1

See engine mfg. information

See engine mfg. information

See engine mfg. information

See engine mfg. information

Chassis Grease

Chassis Grease

Chassis Grease

Chassis Grease

Chassis Grease

US Lithium MP White Grease 2125+

Use SAE 10W30 motor oil

Clean area before removing filter

1. Perform these maintenance procedures more frequently under extreme dusty or dirty conditions.

13

Page 18

TROUBLESHOOTING CUTTING CONDITIONS

CONDITION

CAUSE

CURE

Stringers - Occasional Low engine RPM Run engine at full 3600 RPM

Blades of Uncut

Grass Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Dull blades, incorrect sharpening Sharpen blades

Deck plugged, grass accumulation Clean underside of deck

Width of Deck

SGB020

Belts slipping Adjust belt tensions

Streaking - Strips of Dull, worn blades Sharpen blades

Uncut Grass in Cutting

Path Incorrect blade sharpening Sharpen blades

Low engine RPM Run engine at full 3600 RPM

Belt slipping Adjust belt tension

Deck plugged, grass accumulation Clean underside of deck

Ground speed too fast Slow speed to adjust for conditions

Wet grass Cut grass after it has dried out

Width of Deck

SGB018

Bent blades Replace blades

Streaking - Strips of Not enough overlapping Increase the overlap of each

Uncut Grass Between between rows pass

Cutting Paths

Width

of

Deck

SGB019

Width

of

Deck

14

Page 19

TROUBLESHOOTING

CONDITION

CAUSE

CURE

Uneven Cut on Flat Lift worn off of blade Replace blade

Ground - Wavy

High-Low Blade upside down Mount with cutting edge toward

Appearance, ground

Scalloped Cut, or

Rough Contour Deck plugged, grass accumulation Clean underside of deck

Too much blade angle (deck pitch) Adjust pitch and level

Deck mounted improperly See your authorized SCAG dealer

Bent spindle area See your authorized SCAG dealer

Dull blade Sharpen blade

Width of Deck

SGB020

Uneven Cut on Uneven ground May need to reduce ground speed,

Uneven Ground - raise cutting height, and/or change

Wavy Appearance, direction of cut

High-Low Scalloped

Cut, or Rough Contour

Width of Deck

SGB021

Sloping Ridge Across Tire pressures not equal Check and adjust tire pressure

Width of Cutting Path

Wheels uneven Check and adjust tire pressure

Deck mounted incorrectly See your authorized SCAG dealer

Width of Deck

SGB023

15

Page 20

TROUBLESHOOTING

CONDITION

CAUSE

CURE

Scalping - Blades Low tire pressures Check and adjust pressures

Hitting Dirt or

Cutting Very Close to Ground speed too fast Slow speed to adjust for conditions

the Ground

Cutting too low May need to reduce ground speed,

raise cutting height, change direction

of cut, and/or change pitch and level

Rough terrain May need to reduce ground speed,

raise cutting height, and/or change

direction of cut

Ground speed too fast Slow speed to adjust for conditions

Width of Deck

SGB022

Wet grass Cut grass after it has dried out

Step Cut Blades not mounted evenly Adjust pitch and level

Ridge in Center of

Cutting Path Bent blade Replace blade

Internal spindle failure See your authorized SCAG dealer

Mounting of spindle incorrect See your authorized SCAG dealer

Width of Deck

SGB024

Slope Cut - Sloping Bent spindle mounting area See your authorized SCAG dealer

Ridges Across Width

of Cutting Path Internal spindle failure See your authorized SCAG dealer

Bent deck housing See your authorized SCAG dealer

Width of Deck

SGB025

16

Page 21

TECHNICAL SPECIFICATIONS

ENGINES

General Type: Heavy duty industrial/commercial

Brand: Kohler 23 HP Pro Series (Spec PS-75523)

Models: CV23S

Horsepower: 23HP @ 3600 RPM

Type: 4 cycle gas, twin cylinder, vertical shaft engine

Displacement: 23HP = 674 cc

Cylinders: 2 cast-iron sleeves

Governor: Mechanical type governor with variable speed control set

at 3600 rpm (+50 rpm), idle set at 1900 rpm (+100rpm)

Air Intake Group: Large capacity dual element, chopper-type grass screen

Exhaust Group: Single exhaust canister muffler

Fuel Pump Group: Mechanical fuel pump with inline fuel filter, fixed jet

carburetor with Smart-Choke™ and fuel shutown solenoid

Oil Pump Group: Positive displacement Gerotor™ oil pump.Capacity 2.0 U.S.

Quarts with filter, standard oil cooler.

Valve Group: Hydraulic valve lifters standard

Starter/Electrical: 12 volt battery with alternator, solid state ignition with key

start

Charging System: 15 amp

ENGINE DECK

Fuel Tank: 5 gallon (19.0 litres) seamless polyethylene

Drive Wheels/Tires: 20x10.0-10 four-ply pneumatic tubeless, radius edge

Brakes: Integral braking with drive system

Parking Brake: Drum-type

Frame: Hybrid tractor trailer frame with stabilized pivot

DRIVE SYSTEM

Type: Hydro drive with one variable displacement pump and two

cast-iron high torque motors

Hydro Pump: #15 cast-iron variable displacement pump with remote dump

valve for movement without running engine

Drive Wheel Motors: 12 cu. inch cast-iron high torque motors

Dump Valve: Single lever allows for movement without engine running

Hydro Fluid Cooling Group: Heavy-duty cooling radiator, 13 qt. capacity nylon cooling

reservoir, uses, SAE 10W30 fluid and 10 micron filter

Travel Control: Hydro drive with single foot pedal for forward and reverse

speed control, infinitely variable speeds

Steering: Aircraft-type yoke steering handle with stainless steel cable

Axles: 1-1/4" tapered motor shafts

Safety Group: Foot actuated engine kill, brake interlock, blade/clutch

interlock switch

Instrument Panel: Ammeter, hour meter, key switch, throttle, fuses, manual

choke, blade brake clutch switch

Forward Speed Range: 0 to 6.8 mph

Reverse Speed Range: 0 to 5.4 mph

Date of Issue: August, 2003

Specifications Subject to Change Without Notice

17

Page 22

TECHNICAL SPECIFICATIONS (CON'T)

CUTTER DECKS SM61A, SM 72A

Type: Out-front design with anti-scalp roller and pneumatic shock

absorber for deck flotation

Construction: 10-gauge steel with 7-gauge (3/16") steel skirt

Cutting Width: 61.0 " (155.0 cm), 71.5" (181.6 cm)

Cutting Height Adjustment: Adjustable from 1-3/4" to 5-1/4" in 1/4" increments

Cutter Blades: .197 Thick, Milled Edge, Wear Resistant Marbain™

SM61A:Three (3) 21" blades

SM72A: Three (3) 24" blades

Blade Engagement: Electric blade brake clutch with instrument panel switch

Lift System: Patented manual winch with automatic brake/clutch,

stainless steel cable

Discharge Opening: Extra wide 11.5", 13.75 " discharge opening with hinged

chute

Caster Wheels: 9 x 3.5 smooth tread flotation, inner tubes, split rims, roller

bearings, with quick pin removal

Spindles: Cast housing, taper roller bearing, low maintenance with

top access grease fitting and grease overfill relief poppet

Pulleys: Cast-iron with easily removed taper hubs

Cutter Deck Belts: B-section with Kevlar cord

ADDITIONAL SPECIFICATIONS

Seat: Foam padded, lever adjustment forward and back, with

padded arm rests

OPTIONAL ITEMS/ATTACHMENTS

Grass Catcher: GCV/HD-44/6 Vacuum Grass Catcher with 6 HP engine, 44

gallon capacity, hard plastic cover, mounts on rear bumper

Mulching Kit: Steel plate fits over discharge opening. No blade change

or removal required. Installs and removes in the field.

Electric Deck Lift: Lift mounts to the side of the rider frame assembly to raise

and lower the deck at the flip of a switch.

Cup Holder: 12 Guage Steel with rubber retainer.

APPROXIMATE DIMENSIONS SM61A SM72A

Length: 113.0" 118.0"

Length with Grass Catcher: 137.0" 142.0"

Tracking Width: 50.0" 50.0"

Width: 70.0" 81.0"

Width (with discharge chute up): 63.0" 74.0"

Width with GCV grass catcher: 70.0" 84.0"

Height: 43.0" 43.0"

Height with GCV grass catcher: 51.5" 51.5"

Weight: 950 lbs. 1000 lbs.

Weight with GCV grass catcher: 1250 lbs. 1300 lbs.

Date of Issue: August, 2003

Specifications Subject To Change Without Notice

18

Page 23

NOTES

19

Page 24

SM-61A & SM-72A CUTTER DECK

41

37

43

30

47

40

39

37

38

29

44

30

20

33

50

51

49

32

29

43

29

107

11

21

27 28

89

90

30

31

34

33

32

35

36

46

29

30

38

47

48

5

57

6

5

2

52

4

4

7

8

9

26

12

5

24

3

25

8

15

16

17

10 7

19

18

10

9

13

21

14

8

9

20

22

23

25

72

80

69

85

86

38

86

85

84

82

73

75

76

45

21

77

74

83

81

71

29

88

79

75

17

70

3

42

67

65

1

87

68

56

8

8

58

61

53

66

63

54

55

38

59

60

56

62

78

20

STHM2004CD

64

Page 25

SM-61A & SM-72A CUTTER DECK

Ref. Part

No. No. Description 61 72

1 461655 Cutter Deck, Advantage (Incl. decals) x

1 461658 Cutter Deck, Advantage (Incl. decals) x

2 461296 Discharge Chute, Advantage x x

3 04001-09 Bolt, 5/16-18 x 1" Hex Head x x

4 04021-10 Nut, 5/16-18 Elastic Stop x x

5 04029-03 Wing Nut, 3/8-16 x x

6 461583 Belt Cover (Incl. Decals) x

6 46848 Belt Cover (Incl. Decals x

7 04020-09 Nut, 5/8-11 Hex Head x x

8 43592 Spacer, Cutter Blade x x

9 48926 Tapered Hub, 1.125 Bore x x

10 04001-172 Bolt, 1/4-20 x 1" Hex Head Grade 8 x x

11 482745 Pulley, 6.35 O.D. x

482747 Pulley, 6.95 O.D. x

12 48940 Pulley, Double Groove, 6.35/5.75 O.D. x

48966 Pulley, Double Groove, 6.95/5.75 O.D. x

13 48265 Belt, R.H. Blade Drive x

48295 Belt, R.H. Blade Drive x

14 48912 Belt, Deck Drive x

481001 Belt, Deck Drive x

15 04021-05 Lock Nut,3/8-16 Hex Head x x

16 04004-14 Stud, 3/8-16 x 6-3/4" x x

17 04019-04 Nut, 3/8-16 Serr. Flange x x

18 04001-46 Bolt, 3/8-16 x 2-1/4" x x

19 04041-07 Flatwasher, 3/8 (.391 x .938 x .105) x x

20 482416 Pulley, Belt Guide x x

21 04017-16 Capscrew, 5/16-18 x 3/4 Ser. Flg. HH x x

22 04021-09 Nut, 3/8-16 Elastic Stop x x

23 421355 Idler Pulley Support x x

24 04001-108 Bolt, Hex Head 5/16-18 x 4-1/4" x x

25 04019-03 Nut, 5/16-18 Ser. Flg. Hex Hd. x x

26 482744 Pulley, 5.75 x x

27 04019-06 Nut, 1/2-13 Ser. Flg. Hex Hd. x x

28 04017-37 Capscrew, 1/2-13 x 1-1/4 Ser. Flg. x x

29 04021-09 Nut, 3/8-16 Elastic Stop x x

30 04041-07 Flatwasher, 3/8 (.391 x .938 x .105) x x

31 48181 Pulley x x

32 04041-12 Flatwasher, 3/8 (.375 x 1.50 x .060) x x

33 43077 Spacer x x

34 46081 Idler Arm (Incl. 37 & 38) x x

35 04001-46 Bolt, 3/8-16 x 2-1/4" x x

36 45037 Idler Pivot x x

37 48100-05 Bushing, Bronze Oilite-3/4 ID x x

38 48114-04 Grease Fitting, Str. 1/4-28 Self Tap. x x

39 04041-08 Flatwasher, 3/4 ( .776 x 1.25 x .059) x x

04041-08S Flatwasher, 3/4 ( .776 x 1.25 x .035) x x

40 04050-02 Retaining Ring, .75 EXT 'E' x x

41 43028 J-Rod Idler Pulley x

44078 J-Rod Idler Pulley x

42 04001-175 Bolt, 5/16-18 x 1-1/2" Hex Head Gr 8 x x

Ref. Part

No. No.Description 61 72

43 04019-03 Nut, 5/16-18 Ser. Flange x x

44 04001-77 Bolt, 3/8-16 x 3-1/2" Hex Head x x

45 46082 Support Assembly x x

46 04050-05 Retaining Ring, 1-1/8 EXT 'E' x x

47 48100-02 Bushing, Bronze Oilite- 1-1/8 ID x x

48 45329 Idler Pivot Support x x

49 43277 Spacer x x

50 46748 Idler Arm (Incl. 38 & 47) x x

51 44078 J-Rod, Drive Idler x x

52 482245 Spring, Chute Return x x

53 461663 Spindle Assembly x x

54 43589 Shaft, Cutter Spindle x x

55 481024 Seal, 2.00 O.D. x 1.50 Bore x x

56 481022 Bearing Assembly x x

57 48098 Shield, Spindle x x

58 48677 Relief Fitting, Cutter Spindle x x

59 43664 Spindle Housing x x

60 43312 Spacer, Outside x x

61 43296 Spacer, Inside x x

62 481025 Seal, 2.00 O.D. x 1-5/8 Bore x x

63 43297 Spindle Bushing Bottom x x

64 481035 Nut, 1-1/16-18 UNEF-2B x x

65 04001-41 Bolt, 5/8-11 x 9-1/2" x x

66 04040-10 Flatwasher, 5/8 (.688 x 1.75 x .134) x x

67 482879 Cutter Blade, 21" Standard x

482880 Cutter Blade, 24" Standard x

68 04063-08 Key, 1/4 x 1/4 x 2" x x

69 04066-01 Quick Pin x x

70 45944 Shaft, Roller x x

71 482295 Guide, Roller x x

72 48307 Wheel Assy., Caster x x

73 481774 Tire Only, Caster Wheel x x

481773 Inner Tube Only, Caster Wheel x x

74 481772 Rim Pair, Caster Wheel x x

75 481770 Retainer, Caster Wheel x x

76 48114-03 Grease Fitting, 45 Deg. 1/4-28 x x

77 481768 Hub Assy. W/Bolts, Caster Wheel x x

78 481771 Tapered Hex Nut, 5/16-18 x x

79 481769 Roller Bearing, Caster Wheel x x

80 46079 Caster Wheel Assembly x x

81 04001-37 Bolt, 1/2-13 x 5-1/2" Hex Head x x

82 04021-07 Nut, 1/2-13 Elastic Stop x x

83 43022 Sleeve, Caster Wheel Bearing x x

84 45006 Caster Yoke x x

85 43037-01 Spacer, Caster Yoke 1/2" x x

86 48100-01 Bushing, 7/8 x 1" Flanged x x

87 423792 Baffle, Custom Cut 61A x

423795 Baffle, Custom Cut 72A x

88 04003-23 Bolt, Carriage 3/8-16 x 1” x x

89 04021-22 Nut, Elastic Stop 5/16-18 Grade 8 x x

90 04030-03 Lock Washer, 5/16" x x

21

Page 26

2

99

ENGINE DECK

18

90

39

6

13

14

8

77

101

9

15

10

12

17

19

15

94

19

11

93

18

100

64

22

101

19

20

21

19

23

5

4

1

16

3

96

19

16 16

16

89

74

92

83

80

82

81

19

16

38

79

63

66

53

55

67

65

76

76

77

78

75

62

27

103

61

70

19

22

102

54

56

26

61

34

24

33

35

58

59

60

37

22

57

25

38

43

61

26

16

44

40

28

42

36

38

41

39

50

46

28

29

32

45

48

31

49

30

51

29

31

47

84

52

SGB010B

98

19

95

1697

85

88

87

86

68

69

71

72

69

73

19

91

19

83

26

83

16

22

Page 27

ENGINE DECK

Ref. Part

No. Number Description

1 04003-01 Carriage Bolt, 1/4-20 x 6"

2 423308 Battery Box

3 04029-01 Nut, Wing 1/4-20

4 48015 Battery

5 42392 Battery Cover

6 48099 Insulation, Battery Cover

7 48292 Pad, Fuel Tank Strap

8 481556 Cap, Fuel Tank

9 46846 Fuel Tank Assy. (Includes items 10 - 11)

10 48309 Bushing, Fuel Tank Valve

11 48308 Fuel Shut Off Valve

12 421239 Strap, Fuel Tank

13 04010-10 Phil RDHD Machine Screw 1/4-20 x 2"

14 04020-02 Hex Nut, 1/4-20

15 48205 Pad, Fuel Tank Support

16 04003-12 Carriage Bolt, 5/16-18 x 3/4"

17 42377 Support, Fuel Tank

18 421522 Bracket, Fuel Tank Support

19 04019-03 Serr. Fl. Hex Nut 5/16-18

20 04031-09 Lockwasher, 5/16 Int. Tooth

21 481776 Engine, 23 HP Kohler CV, (Spec PS-75523)

22 04001-12 Hex Head CPSCR, 5/16-18 x 1-3/4"

23 482352 Oil Drain Extension

24 422534 Plate, Backing

25 45586 Engine Deck

26 48030-09 Wire Loom, .50 I.D.

27 04040-14 Washer, 1/4 (.312 x .750 x .065)

28 04001-72 Bolt, Hex Head 1/2-13 x 2"

29 43041 Sleeve, Shock Absorber Mount

30 48516 Shock Absorber

31 04021-07 Hex Locknut, Elastic Stop 1/2-13

32 04017-42 Serr. Fl. Hex Head CPSCR, 7/16-14 x 1"

33 04019-05 Serr. Fl. Hex Nut, 7/16-14

34 48769 Motor - White (Includes item 52)

35 04030-06 Lockwasher, 1/2"

35A 04020-07 Nut, 1/2-13

36 421289 Anchor, Brake

37 04001-59 Bolt, Hex Head 1/4-20 x 1-1/4"

38 04019-02 Serr. Fl. Hex Nut, 1/4-20

39 04017-16 Serr. Fl. Hex Head CPSCR, 5/16-18 x .75"

40 48461 Parking Brake Assembly (Incl. 41-44)

41 48461-02 Brake Pads- Pair

42 48461-03 Springs - Pair

43 48461-04 Actuating Arm, Incl. Pin & Clip)

44 48461-05 Clip

45 46929 Hub Assembly (Includes item 50)

46 48513 Brake Drum

47 48933 Rim and Tire Assembly (Includes items 48, 49)

48 48933-02 Tire 20 x 10 x 10, 4 Ply

49 48416-04 Rim Only

50 04008-03 Bolt, Hub

51 04028-01 Wheel Nut

52 48680 Castle Nut, 1.0-20 UNEF

53 43261 Spacer, Clutch

Ref. Part

No. Number Description

54 04063-08 Key, 1/4 x 1/4 x 2"

55 04012-04 Hex Socket Set Screw, 5/16-18 x 3/8"

56 48792 Pulley, Engine Pump Drive (Incl. 55)

57 461397 Clutch, Electric (Ogura)

58 04041-28 Flatwasher, 7/16 (.469 x 1.75 x .25)

59 04030-05 Lockwasher, 7/16"

60 04102-05 Bolt, Hex Head 7/16-20 x 2.75"

61 04021-10 Hex Locknut, Elastic Stop 5/16-18

62 422533 Backing Plate, Clutch Stop

63 481716 Rubber Pad, Clutch Stop

64 481641 Heatshield, Muffler

65 04001-12 Bolt, Hex Head 5/16-18 x 1-3/4"

66 04063-12 Key, Woodruff 3/16 x 5/8"

67 48581 Pulley, Pump Input

68 43117 Sleeve, Idler

69 04050-06 Ring, Retaining, 1-9/16 Internal

70 48854 Belt, Pump Drive

71 46370 Pulley, Idler-Traction Drive (Incl. 68,69,72)

72 48102 Bearing, Idler Pulley

73 43063 Spacer, Idler

74 46327 Pump Idler Arm (includes items 76, 79)

75 45037 Idler Pivot Base

76 48100-05 Bushing, Oillube

77 04041-08S Flatwasher, 3/4"

78 04050-02 Ring, Retaining, 3/4" Ext. "E"

79 48114-04 Grease Fitting

80 04020-12 Hex Nut, Jam 3/8-16

81 04001-62 Bolt, Hex Head 3/8-16 x 3-1/4"

82 48929 Spring, Pump Drive Idler

83 04019-04 Serr. Fl. Hex Nut, 3/8-16

84 04061-04 Cotter Pin, 5/32 x 1.50"

85 04001-47 Bolt, Hex Head 3/8-16 x 5"

86 04015-03 Socket Head CPSCR, 1/2-13 x 1-1/4"

87 04030-06 Lockwasher, 1/2"

88 04041-04 Flatwasher, 1/2 (.516 x .938 x .105)

89 481100 Pump, Sundstrand

90 421520 Bracket, Oil Tank Support

91 04001-21 Bolt, Hex Head 3/8-16 x 1-3/4"

92 04041-10 Washer 2" OD, 3/8 ID, 16 Ga.

93 04003-02 Carriage Bolt, 1/4-20 x 3/4"

94 421523 Guard, Pulley

95 421521 Gusset, Battery Box

96 421705 Support, Battery Box

97 04003-04 Carrage Bolt, 5/16-18 x 1"

98 48030-10 Wire Loom, .75" I.D.

99 48661 Rubber Pad

100 48058 Fuel Hose, Order by the inch

101 48059-01 Clamp, Fuel Hose

102 04001-52 Bolt, 1/2-13 x 2.50"

103 04021-08 Nut, 1/4-20 Elastic Stop

23

Page 28

UPPER HYDRAULICS

12

7

6

5

4

2

20

5

13

11

3

9

12

8

9

10

A

1

5

14

23

14

16

24

14

9

19

18

21

17

22

14

15

A

9

3

14

24

SGB027

Page 29

UPPER HYDRAULICS

Ref. Part

No. Number Description

1 48711 Tank, Hydraulic

2 481164 Cap, Hydraulic Tank

3 48634 Hose, Pump to Oil Cooler

4 48942 Hose, Oil Cooler to Tank

5 48136-04 Clamp, Hose

6 48936-01 Coupling, Flare Swivel

7 48572-05 Tube, Union

8 48645 Oil Cooler Assembly

9 04003-12 Carriage Bolt, 5/16-18 x 3/4"

10 421279 Bracket, Oil Cooler

11 48350-05 Elbow, 90 Degrees

12 48603-02 O-Ring

13 48936-02 Coupling Flare Swivel

14 04019-03 Serr. Fl. Hex Head Nut, 5/16-18

15 421280 Brace, L.H. Cooler Support

16 421281 Brace, R.H. Cooler Support

17 04021-08 Elastic Stop Nut, 1/4-20

18 04017-05 Serr. Fl. Hex Head CPSCR, 1/4-20 x 3/4"

19 421288 Strap, Oil Tank

20 481507 Filler Neck Insert

21 48482 Hose, 1/4" Pushlock, Order by the inch

22 48059-01 Clamp

23 48309 Bushing

24 48939 90 Degree Elbow

25

Page 30

LOWER HYDRAULICS

LOWER HYDRAULICS

21

27

13

13

11

1

20

A

B

28

28

6

C

31

9

15

30

29

10

H

21

A

20

25

23

10

22

26

G

H

2

F

26

E

4

28

13

17

18

C

15

3

J

2624

13

14

32

13

26

25

26

19

5

19

B

F

J

26

26

E

17

33

12

G

5

28

27

9

6

7

11

D

D

8

I

I

32

16

4

18

20

26

Page 31

LOWER HYDRAULICS

Ref. Part

No. Number Description

1 04017-04 Capscrew, 1/4-20 x1/2 Serr. Fl. Hex Head

2 48462-02 Filter Head

3 48758 Filter, Spin-On Lube

4 48991 Hose Assembly

5 48688 Hose Assembly

6 48350-03 Elbow, 90 Degrees

7 04062-01 Hairpin Cotter

8 44088 Lever, Dump Valve

9 48353-02 Connector, Flare Swivel with Hose Barb

10 48136-04 Hose Clamp

11 48482 Hose, 1/4 Pushlock, Order by the inch

12 48482 Hose, 1/4 Pushlock, Order by the inch

13 48059-01 Hose Clamp

14 48935-01 Tee Union, Pushlock Hose

15 48482 Hose, 1/4 Pushlock, Order by the inch

16 48853 Hose, Dump Valve

17 48350-05 Elbow, 90 Deg.

18 48856 Inlet Hose, 3/4" ID

19 48937-01 Tee, 1/2" Run

20 48905 Motor Hose

21 48634 Hose, Pump To Oil Cooler

22 48936-01 Coupling, Flare Swivel

23 48936-02 Coupling, Flare Swivel With Barb

24 48572-06 Tube Union

25 48938-01 O-Ring Bushing

26 48603-02 O-Ring

27 48603-03 O-Ring

28 48603-04 O-Ring

29 48571-03 Cap

30 48810-02 Tee, JIC to O-Ring

31 48602 Hose, Order by the inch

32 48911-01 Compression Fitting

33 48350-12 Elbow, 90 Deg.

27

Page 32

CONTROL LINKAGE

CONTROL LINKAGE

30

27

10

11

14

15

17

18

17

31

4

5

4

5

6

31

1

6

26

2

7

13

5

8

25

12

14

19

11

9

5

8

21

3

12

13

16

20

28

11

29

14

10

15

24

23

sgb011

28

Page 33

CONTROL LINKAGE

Ref. Part

No. Number Description

1 46328 Control Linkage, Bellcrank (Includes 30, 31)

2 04040-15 Flatwasher, 5/16 (.375 x .875 x .083)

3 04001-13 Bolt, Hex Head 5/16-18 x 2-3/4"

4 04001-19 Bolt, Hex Head 3/8-16 x 1"

5 04040-05 Flatwasher, 3/8 (.406 x .812 x .065)

6 43212 Sleeve, Pump Control Link

7 42658 Link, Speed Control

8 04021-05 Hex Locknut, 3/8-16

9 45485 Control Arm, Pump

10 04003-05 Carrage Bolt,RH SH SQNK 3/8-16 x 1-1/2"

11 04041-07 Flatwasher, 3/8 (.391 x .938 x .105)

12 48464 Rod End, RH Female THD 3/8-24

13 04021-09 Hex Locknut, Elastic Stop 3/8-16

14 04020-14 Hex Nut, 3/8-24

15 44044 Control Rod

16 48512 Bolt Hex Head, 3/8-24 x 6-3/4"

17 43257 Bushing, Spring Keeper

18 48463 Spring, Neutral Return

19 421148 Retainer, Neutral Spring

20 04003-04 Carrage Bolt, 5/16-18 x 1"

21 04019-03 Serr. Fl. Hex Nut 5/16-18

22 ** Number Not Used

23 04001-59 Bolt, Hex Head 1/4-20 x 1-1/4"

24 04021-08 Hex Locknut, Elastic Stop 1/4-20

25 04021-10 Hex Locknut, Elastic Stop 5/16-18

26 43110 Sleeve, Control Arm

27 04061-02 Cotter Pin, 3/32 x .75"

28 48343-04 Clevis, Pump Control

29 04064-02 Pin, Clevis 3/8"

30 48114-05 Greese Fitting, 1/4-28 Self Tap

31 48100-04 Bushing, Bronze

29

Page 34

INSTRUMENT PANEL AND ELECTRICAL COMPONENTS

INSTRUMENT PANEL AND ELECTRICAL COMPONENTS

21

9

A

B

C

7

2

8

19

10

10

3

25

21

1

15

D

E

9

PTO Switch

Connector

12

34

11

F

18

17

16

18

17

20

35

21

4

6

9

13

14

5

13

15

21

23

33

32

22

31

28

33

24

30

26

27

25

29

31

32

STHM99IP&E

30

Page 35

INSTRUMENT PANEL AND ELECTRICAL COMPONENTS

Ref. Part

No. Number Description

1 461360 Instrument Panel (includes Decal)

2 48298 Blade Fuse, 20 amp.

3 482289 Decal, Instrument Panel

4 48023 Hour Meter (includes Bracket and Hardware A, B, C)

A * Hour Meter Bracket

B * Lockwasher, #10 Ext. Tooth

C * Hex Nut, 10-24

5 481755 Ammeter (includes Bracket and Hardware D, E, F)

D * Ammeter Bracket

E * Lockwasher, #10 Int. Tooth

F * Hex Nut, #10-32

6 04010-11 Phillips Rd. Head Screw, #10-32 x 1-1/2"

7 42413 Bracket, Fuse Holder

8 04021-01 Elastic Stop Nut, #10-32

9 04003-12 Carriage Bolt, 5/16-18 x 3/4"

10 04010-01 Phillips Washer Head Screw, #10-32 x .50"

11 48798 Keyswitch

12 * Lockwasher, 5/8 Int. Tooth

13 * Nut, Special 5/8-32

14 48017-02 Ignition Key and Ring Assy.

15 482315 Choke Control

16 48879 Throttle Control

17 04031-01 Lockwasher, #10 Ext. Tooth

18 04020-01 Hex Nut, #10-32

19 481687 Switch, PTO

20 481275 Wire Harness With Relay

21 04019-03 Serr. Fl. HH Nut, 5/16-18

22 482700 Battery (Not sold through Scag)

23 04001-44 Bolt, Hex head 1/4-20 x 1/2"

24 04020-02 Hex Nut 1/4-20

25 481683 Wire Harness, STHM

26 04031-09 Lockwasher 5/16 Int. Tooth

27 481776 Engine, 23 HP Kohler CV(Spec PS-75523)

28 481474 Switch, Parking Brake

29 481476 Switch, Foot Safety

30 461397 Clutch, Electric

31 04003-12 Carriage Bolt, 5/16-18 x 3/4"

32 48030-09 Wireloom

33 04021-10 Locknut, Elastic Stop 5/16-18

34 48029-15 Battery Cable, 36" Black

35 48029-13 Battery Cable, 25" Red

31

Page 36

RIDER FRAME ASSEMBLY

RIDER FRAME ASSEMBLY

15

51

67,68

61

10

11

12

13

54

9

6

5

4

3

2

1

42

64

62

63

65

7

45

5

42

14

8

43

18

21 20

46

41

44

16

22

23

24

42

40

26

31

17

14

19

24

25

27

28

29

55

52

57

58

60

59

47

66

42

45

55

58

5256

53

52

55

2

51

49

50

STHM99RFA

48

19

39

38

37

37 A

30

36

32333435

32

Page 37

RIDER FRAME ASSEMBLY

Ref. Part

No. Number Description

1 46715 Steering Frame (includes Bshgs and Fittings)

2 48100-01 Bronze Bushing, 7/8 ID x 1.0 Flanged

3 04050-03 Retaining Ring, 7/8 external

4 04021-10 Hex Nut, Elastic Stop 5/16-18

5 04040-15 Flat Washer, 5/16 (3/8 x 7/8 x 13 ga.)

6 46029 Steering Handle (includes item 7)

7 48159 Grip

8 04001-12 Bolt, Hex Hd., 5/16-18 x 1-3/4"

9 482119 Seat Assy. (includes items 10 thru 13,54)

10 482111 Cushion Assembly

11 482108 Arm Pad - R.H.

12 482105 Seat Back Cushion

13 482107 Arm Pad - L.H.

14 04019-03 Serr. Fl. HH. Nut, 5/16-18

15 46570 Seat Adjuster Track

16 04003-05 Bolt, RDHD Carr. 3/8-16 x 1-1/2 (52" & 61")

04003-03 Bolt, RDHD Carr. 3/8-16 x 2.0" (72")

17 421342 Seat Plate

18 42482 Ballast, Seat Mount (72" cutter deck only)

19 04019-04 Serr Fl. Hex Nut, 3/8-16

20 42026 Seat Spring

21 04001-83 Bolt, Hex Hd., 7-16-14 x 3-1/2"

22 42366 Reinforcement, Seat Spring

23‘ 04050-05 Retaining Ring, 1-1/8" external

24 48100-02 Bushing, Oilite - 1-1/8 ID x 1.0 Flanged

25 45008 Rear Wheel Pivot

26 04001-32 Bolt, Hex Hd., 3/8-16 x 1-1/4"

27 * Hex Jam Nut, 3/8-24

28 * Lock Washer, 3/8 Internal Tooth

29 45035 Rear Wheel Yoke

30 04021-13 Hex Elastic Stop Nut, 5/8-11

31 04001-40 Bolt, Hex Hd. 5/8-11 x 9"

32 43020-01 Spacer, Rear Wheel, short

33 481897 Seal, Grease

34 481896 Bearing Cone

35 481895 Bearing Cup

Ref. Part

No. Number Description

36 481894 Rim Only

37 48005 Rear Wheel Assy. (includes items 33-36, 37A)

37A 481893 Tire Only

38 43021 Sleeve, Rear Wheel

39 43020-02 Spacer, Rear Wheel

40 48828 Cable, Steering (includes Hardware)

41 45606 Pedal, Foot Safety Switch

42 48114-04 Grease Fitting

43 04021-11 Hex Elastic Stop Nut, 7/16-14

44 04010-17 Screw, Phillips flat hd #10-32 x 3/4"

45 04019-02 Serr. Fl. Hex Nut, 1/4-20

46 481056 Spring, Foot Safety Switch

47 04021-08 Hex Nut, Elastic Stop Lock, 1/4-20

48 481476 Switch, Foot Safety

49 04001-02 Bolt, Hex Hd., 1/4-20 x 1-3/4"

50 45009 Steering Shaft

51 04050-02 Retaining Ring 3/4 Ext. “E”

52 48100-06 Bushing, Oilite - 3/4 ID x 1.0

53 45502 Foot Pedal

54 04010-22 Screw w/washer, 1/4-20 x .75"

55 04041-08 Flat Washer, 3/4 x 1-1/4 x 16 Ga.

56 45506 Foot Pedal Arm

57 04065-01 Pin, Drive Lock 3/16 x 1-1/4"

58 48100-03 Bushing, Oilite - 3/4 x .50 Flanged

59 45488 Sulky Mtg. Brkt. L.H.

60 45256 Sulky Mtg. Brkt. R.H.

61 04001-37 Bolt, Hex Hd., 1/2-13 x 5-1/2"

62 48208 Pulley, Winch Cable

63 48100-04 Bushing, Oillube - 1/2 ID x .56

64 04040-13 Flat Washer, 1/2 (.562 x 1.375 x .109)

65 44028 Retainer, Winch Cable

66 04021-07 Hex Elastic Stop Nut, 1/2-13

67 482109 Arm Rest Bracket, Left Hand

68 482110 Arm Rest Bracket, Right Hand

33

Page 38

Deck Weldment

BRAKE LINKAGE

4

1

3

2

8

5

10

6

22

24

23

11

12

10

14

6

15

5

12

5

6

6

11

6

11

6

13

10

7

10

11

9

11

11

21

20

19

34

18

4

16

17

SGB050

Page 39

BRAKE LINKAGE

Ref. Part

No. Number Description

1 04019-04 Serr. Fl. HH Nut, 3/8-16

2 04021-05 Hex Locknut, 3/8-16

3 43032 Swivel

4 04062-01 Hairpin Cotter (.094 x 1.62)

5 04001-32 Hex Head Bolt, 3/8-16 x 1-1/4"

6 43212 Sleeve, Hydro Linkage

7 421338 Link, Cam

8 48342 Grip, Parking Brake

9 45504 Handle, Parking Brake

10 04041-07 Flat Washer, 3/8 (.391 x .938 x .105)

11 04021-09 Hex Nut, Elastic Stop 3/8-16

12 04003-11 Carriage Bolt, 3/8-16 x 1-1/4"

13 04001-21 Hex Head Bolt, 3/8-16 x 1-3/4"

14 421339 Lever, Brake

15 04020-12 Hex Jam Nut, 3/8-16

16 43260 Washer, Neutral Lock

17 04017-27 Serr. Fl. HH CPSCR, 3/8-16 x 1"

18 45647 Bracket, Neutral Lock

19 44085 Rod, Neutral Lock

20 48881 Cable Assembly, Parking Brake R.H.

21 48880 Cable Assembly, Parking Brake L.H.

22 48045 Cable Winch

23 04070-03 Eye Bolt, 3/8-16 R.H.

24 04020-04 Hex Nut, 3/8-16

35

Page 40

FUSES

NEGATIVE

HOURMETER

ELECTRICAL WIRING HARNESS

481683

POSITIVE

HOURMETER

ENGINE GND

RED

BLACK

BLACK

MOWER

CLUTCH

BLACK

BRAKE

INTERLOCK

BLUE

RED

BLACK

YELLOW W/RED STRIPE

GREEN

BLACK W/RED STRIPE

YELLOW

RED

BLACK W/RED STRIPE

NEGATIVE

AMMETER

POSITIVE

AMMETER

WHITE

GREEN

WHITE

MOWER ENGAGEMENT

PTO SWITCH CONNECTOR

WIRE HARNESS WITH RELAY

PART NO. 481275

RELAY

BLACK

BLUE

RED

SC481275

GREEN

KEY

SWITCH

TO ENGINE

To Engine

Ground

FOOT PEDAL

INTERLOCK

YELLOW

GREEN

WHITE

481683

STARTER

SOLENOID

To Starter

To Blue Wire

From Engine

36

To Starter

Red Battery

Cable Post

Page 41

WINCH LIFT SYSTEM

21

22

23

4

3

24

8

11 9

5

6

7

10

2

14

1

12

13

25

Steering

Frame

20

19

18

Ref. Part

No. Number Description

1 48043 Winch Assembly (Incl. 1-7, 11-13, 15-23)

2 204803 Locknut, 7/16-14

3 404409 Ratchet Pawl

4 205167 Ratchet Bolt

5 205055 Flatwasher

6 404166 Ratchet Spacer

7 204363 Ratchet Spring

8 42127 Cable Guide

9 48045 Winch Cable Assembly

10 04021-03 Hex Locknut, 1/4-28

11 304753 Winch Reel

12 203161 Reel Shaft

13 204803 Hex Locknut, 3/8-16

17

16

sgb008

Ref. Part

No. Number Description

14 48044 Winch Handle

15 205015 Handle Nut

16 204364 Handle Spring

17 208328 Shaft Bushing

18 404163 Pressure Washer

19 404164 Ratchet Wheel

20 204362 Pressure Plate

21 204012 Shaft Bushing

22 205116 E-Ring

23 304758 Drive Shaft

24 04017-27 Serr. Flg. HH Capscrew, 3/8-16 x 1"

25 04019-04 Serr. Flg. HH Nut, 3/8-16

37

15

Page 42

REPLACEMENT DECALS & INFORMATION

Hea

vy-

Duty

Co mmerc

1 2, 2a, 2b

3 4

5

ial

481971

7

9 10, 11 12

Ref. Part

No. Number Description

1 481971 Decal, Heavy Duty Commercial

2 48314 Decal, Scag Logo ( Cutter Deck)

2a 48968 Decal, Scag Logo (Battery Box Front)

2b 48825 Decal, Scag Logo Seat Back

3 482285 Decal, Danger-Spinning Blades

4 482286 Decal, Warning-Rotating Blades

5 48656 Decal, Patent

6

8

Ref. Part

No. Number Description

6 482289 Decal, Instrument Panel

7 481039 Decal, Warning-Belt Cover

8 48993 Decal, Dump Valve

9 48404 Decal, Metalcraft-Made In USA

10 481955 Decal, 61 Advantage

11 481956 Decal, 72 Advantage

12 482817 Decal, Height of Cut

38

Page 43

LIMITED WARRANTY - COMMERCIAL EQUIPMENT

Any part of the Scag commercial mower manufactured by Scag Power Equipment and found, in the reasonable judgment

of Scag, to be defective in materials or workmanship, will be repaired or replaced by an Authorized Scag Service Dealer

without charge for parts and labor . This warranty is limited to the original purchaser and is not transferable. Proof of

purchase will be required by the dealer to substantiate any warranty claims. All warranty work must be performed by an

Authorized Scag Service Dealer.

This warranty is limited to the following specified periods from the date of the original retail purchase for defects in

materials or workmanship:

* Wear items including drive belts, blades, hydraulic hoses and tires are warranted for ninety (90) days.

* Batteries are covered for ninety (90) days.

* Frame and structural components including oil reservoir, fittings, and oil coolers are warranted for 2 years

(Parts and labor 1st year; Parts only 2nd year).

* Cutter decks are warranted against cracking for a period of three (3) years. (Parts and labor 1st year; Parts

only 2nd and 3rd year) The repair or replacement of the cutter deck will be at the option of Scag Power

Equipment. We reserve the right to request components for evaluation. This warranty does not cover any

mower that has been subject to misuse, neglect, negligence, or accident, or that has been operated in any way

contrary to the operating instructions as specified in the Operator’s Manual.

* Engines and electric starters are covered by the engine manufacturer’s warranty period.

* Major drive system components are warranted for two (2) years by Scag Power Equipment. (Parts and labor 1st

year; Parts only 2nd year) (T wo year warranty exclude fittings, hoses, drive belts). The repair or replacement of

the hydraulic pump or hydraulic motor will be at the option of Scag Power Equipment. This warranty does not

cover any mower that has been subject to misuse, neglect, negligence, or accident, or that has been operated in

any way contrary to the operating instructions as specified in the Operator’s Manual.

* Electric clutches have a Limited Warranty for 2 year (Parts and labor 1st year; Parts only 2nd year).

* Cutter Spindle Assemblies 46631 have a Limited Warranty for three years (Parts and labor 1st year; Parts

only 2nd and 3rd year).

* Any Scag product used for rental purposes is covered by a 90 day warranty.

The Scag mower, including any defective part must be returned to an Authorized Scag Service Dealer within the warranty

period. The expense of delivering the mower to the dealer for warranty work and the expense of returning it to the owner

after repair will be paid for by the owner. Scag’ s responsibility is limited to making the required repairs and no claim of

breach of warranty shall be cause for cancellation or rescission of the contract of sale of any Scag mower.

This warranty does not cover any mower that has been subject to misuse, neglect, negligence, or accident, or that has

been operated in any way contrary to the operating instructions as specified in the Operator’s Manual. The warranty

does not apply to any damage to the mower that is the result of improper maintenance, or to any mower or parts that have

not been assembled or installed as specified in the Operator’s Manual and Assembly Manual. The warranty does not

cover any mower that has been altered or modified, changing performance or durability. In addition, the warranty does not

extend to repairs made necessary by normal wear, or by the use of parts or accessories which, in the reasonable judgment

of Scag, are either incompatible with the Scag mower or adversely affect its operation, performance or durability .

Scag Power Equipment reserves the right to change or improve the design of any mower without assuming any obligation to modify any mower previously manufactured. All other implied warranties are limited in duration to the two (2) year

warranty period or ninety (90) days for mowers used for rental purpose. Accordingly, any such implied warranties

including merchantability, fitness for a particular purpose, or otherwise, are disclaimed in their entirety after the expiration

of the appropriate two year or ninety day warranty period. Scag’s obligation under this warranty is strictly and exclusively

limited to the repair or replacement of defective parts and Scag does not assume or authorize anyone to assume for them

any other obligation. Some states do not allow limitations on how long an implied warranty lasts, so the above limitation

may not apply to you.

Scag assumes no responsibility for incidental, consequential or other damages including, but not limited to, expense for

gasoline, expense of delivering the mower to an Authorized Scag Service Dealer and expense of returning it to the owner ,

mechanic’s travel time, telephone or telegram char ges, rental of a like product during the time warranty repairs are being

performed, travel, loss or damage to personal property, loss of revenue, loss of use of the mower, loss of time or inconvenience. Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you. This warranty gives you specific legal rights, and you may also have other rights

which vary from state to state.

Page 44

GARANTÍA LIMITADA - EQUIPO COMERCIAL

T oda pieza del cortacésped comercial Scag fabricada por Scag Power Equipment que, según criterio razonable de Scag,

presente materiales o mano de obra defectuosos será reparada o reemplazada por un distribuidor autorizado Scag sin

cargo por las piezas ni mano de obra. Esta garantía se limita al comprador original y no es transferible. Para acceder a

cualquier reclamo de garantía, el distribuidor requerirá el comprobante de compra. T odo trabajo bajo garantía debe

realizarlo un distribuidor autorizado Scag.

Con respecto a materiales o mano de obra defectuosos, esta garantía se limita a los siguientes períodos especificados a

partir de la fecha de compra original:

* Los artículos desgastables, incluyendo correas de transmisión, cuchillas, mangueras hidráulicas y llantas, están

garantizados por noventa (90) días.

* Las baterías están garantizadas por noventa (90) días.

* El bastidor y los componentes estructurales, incluyendo el depósito de aceite, las conexiones y los enfriadores de

aceite, tienen una garantía de 2 años (piezas y mano de obra, primer año; piezas solamente, segundo año)

* Las plataformas de corte están garantizadas contra grietas por un período de tres (3) años. (Piezas y mano de obra,

primer año; piezas solamente, segundo y tercer año) La reparación o el reemplazo de la plataforma de corte estarán

sujetos a discreción de Scag Power Equipment. Nos reservamos el derecho de solicitar componentes para su

evaluación. Esta garantía no cubre ningún cortacésped que haya sido sometido a uso indebido, descuido,

negligencia o accidente, o que se haya operado de manera distinta a la especificada en el manual del operador.

* Los motores eléctricos y los arrancadores están cubiertos por el período de garantía del fabricante del motor.

* Los componentes principales del sistema de transmisión están garantizados por Scag Power Equipment por dos (2)

años. (Piezas y mano de obra, primer año; piezas solamente, segundo año) (La garantía de dos años no incluye las

conexiones, las mangueras, ni las correas de transmisión) La reparación o el reemplazo de la bomba hidráulica o el

motor hidráulico estarán sujetos a discreción de Scag Power Equipment. Esta garantía no cubre ningún cortacésped

que haya sido sometido a uso indebido, descuido, negligencia o accidente, o que se haya operado de manera

distinta a la especificada en el manual del operador.

* Los embragues eléctricos tienen una Garantía limitada de 2 años (Piezas y mano de obra, primer año; piezas

solamente, segundo año)