Sawstop Rt-tgi User Manual

INDUSTRIAL IN-LINE ROUTER TABLE

OWNER’S MANUAL

MODEL RT-TGI

Copyright SawStop, LLC

All Rights Reserved

1st printing, January 2018

Updates of this manual may be

available at www.sawstop.com

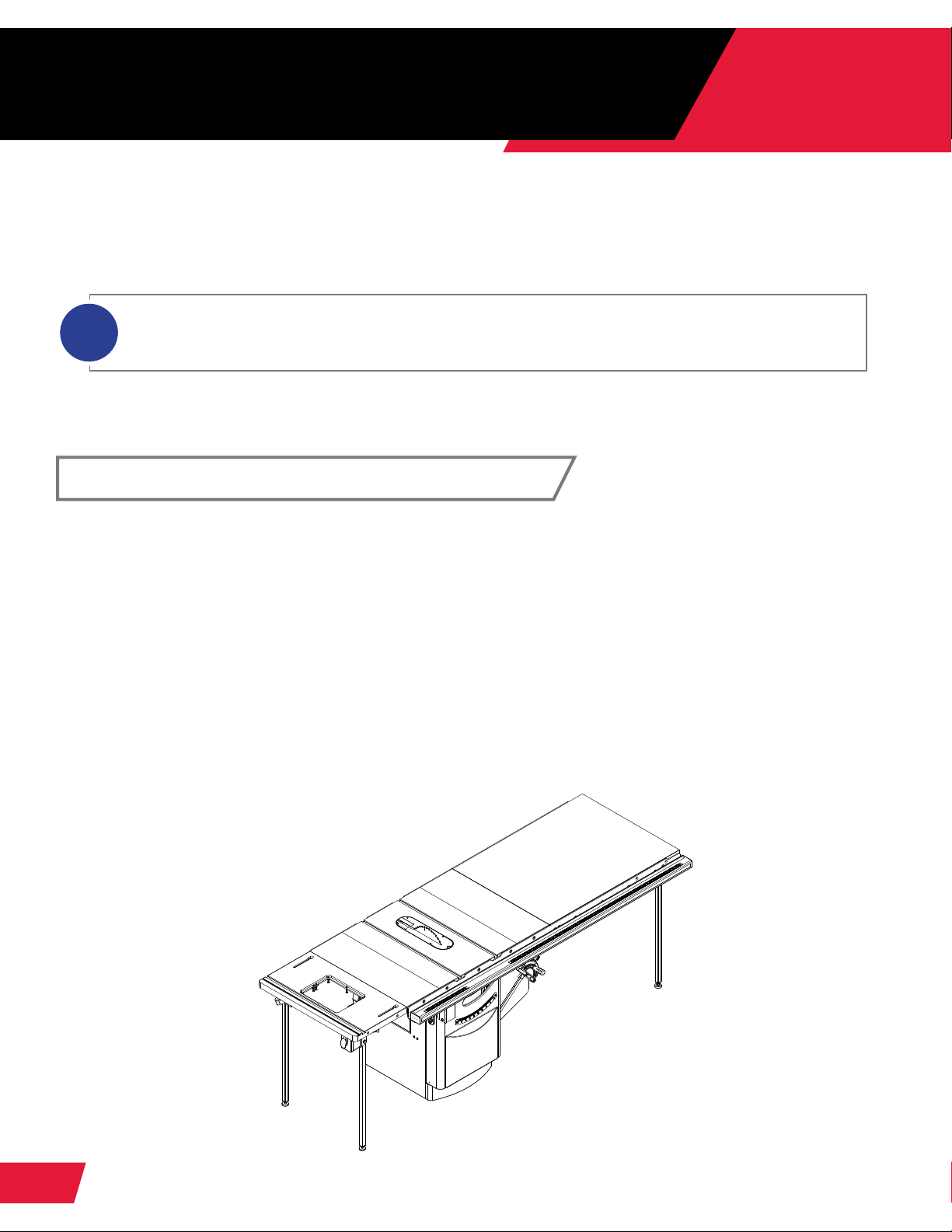

The saw shown on the front cover is the Industrial Cabinet Saw, Model ICS

with Industrial Mobile Base. Your saw may look different.

The ICS In-Line Router Table Assembly shown on the front cover includes the Stock

Guide for Router Table Fence (RT-STP). This is an optional accessory that does not

come included with your ICS In-Line Router Table Assembly. The Four-Post Router Lift

with Lock and Downdraft Dust Collection Box for Router Lift are also shown installed

on the ICS In-Line Router Table Assembly. The Four-Post Router Lift with Lock and

Downdraft Dust Collection Box for Router Lift are not included with your ICS In-Line

Router Table Assembly and your setup may look different.

SawStop, the SawStop blade logo, and the conguration of this product are either

registered trademarks or trademarks of SawStop, LLC. Software copyright by

SawStop, LLC. All rights reserved.

TO OUR CUSTOMERS

Thank you for purchasing the SawStop ICS In-Line Router Table Assembly. We are condent

you will be pleased with the quality and performance.

This manual tells you more about your ICS In-Line Router Table Assembly and how to

operate and maintain it. Please read the manual carefully. The manual also includes our

warranty and important safety information.

If you ever have any questions or comments, feel free to contact us at the address below.

SawStop, LLC

11555 SW Myslony Street | Tualatin, Oregon 97062 USA

Phone: (503) 570-3200

Fax: (503) 570-3303

Email: info@sawstop.com

www.sawstop.com

HOW TO GET HELP

Missing Parts? Have Questions?

Our technical support team is standing by

M-F, 6:30am-5pm PST

to help with whatever you need.

Give us a call at

503.582.9934

Email us at

SERVICE@SAWSTOP.COM

TABLE OF CONTENTS

Assembly Options................................................................................

Before You Begin..................................................................................

Product Specications.........................................................................

Parts Inventory.....................................................................................

Cast Iron Table Parts and Hardware.............................................................................

Support Legs Parts and Hardware...............................................................................

Power Switch Parts and Hardware................................................................................

Fence Assembly Parts and Hardware............................................................................

Assembly & Installation........................................................................

Assembling the Cast Iron Table......................................................................................

Hold-Down Strap Installation........................................................................................

Assembling and Installing the Support Legs and Power Switch...................................

In-Line Installation Left of Left Wing..............................................................................

Rail Requirements: In-Line Right of ICS Right Wing.....................................................

In-Line Installation Right: Between 36” Rails.................................................................

In-Line Installation Right: Between 52” Rails.................................................................

Assembling the Fence Assembly...................................................................................

1

4

5

6

6

7

8

9

11

11

12

16

20

22

23

25

31

Reference............................................................................................

Warranty.........................................................................................................................

Safety.............................................................................................................................

Warnings........................................................................................................................

Exploded View 1: Cast Iron Table (RT-C30) ....................................................................

Parts List 1: Cast Iron Table (RT-C30).............................................................................

Exploded View 2: Support Legs (RT-ST2).....................................................................

Parts List 2: Support Legs (RT-ST2)................................................................................

Exploded View 3: Power Switch (RT-PSW)..................................................................

Parts List 3: Power Switch (RT-PSW)...........................................................................

Exploded View 4: 32” Fence Assembly (RT-F32)...........................................................

Parts List 4: 32” Fence Assembly (RT-F32)....................................................................

Available Accessories..........................................................................

36

36

37

37

39

40

41

42

43

44

45

46

47

PAGES:

ASSEMBLY OPTIONS

1-3

The 30” x 16” Cast Iron Router Table with 32" Fence Assembly can be mounted to your

SawStop Industrial Cabinet Saw (ICS) with T-Glide Fence System-Industrial Series II

(TGI2) rails in any of three different congurations depending on your needs.

The between-rail installation of the 30” x 16” router table is only compatible with T-Glide Fence System

i

– Industrial Series II (TGI 2) rails. If you wish to use the T-Glide Fence System – Industrial Series (CBFR)

rails, you will have to modify them signicantly.

In-Line Left of Left Wing

This conguration increases the available table space of your SawStop table saw and

provides the maximum ripping capacity to the left of the saw blade.

Required Components:

• 30” x 16” Cast Iron Router Table (RT-C30)

• Power Switch (RT-PSW)

• Support Legs (RT-ST2)

Compatible With:

• T-Glide Fence System – Industrial Series I or II (CBFR or TGI2) rails

Option 1 of 3

1

RT-TGI OWNER’S MANUAL

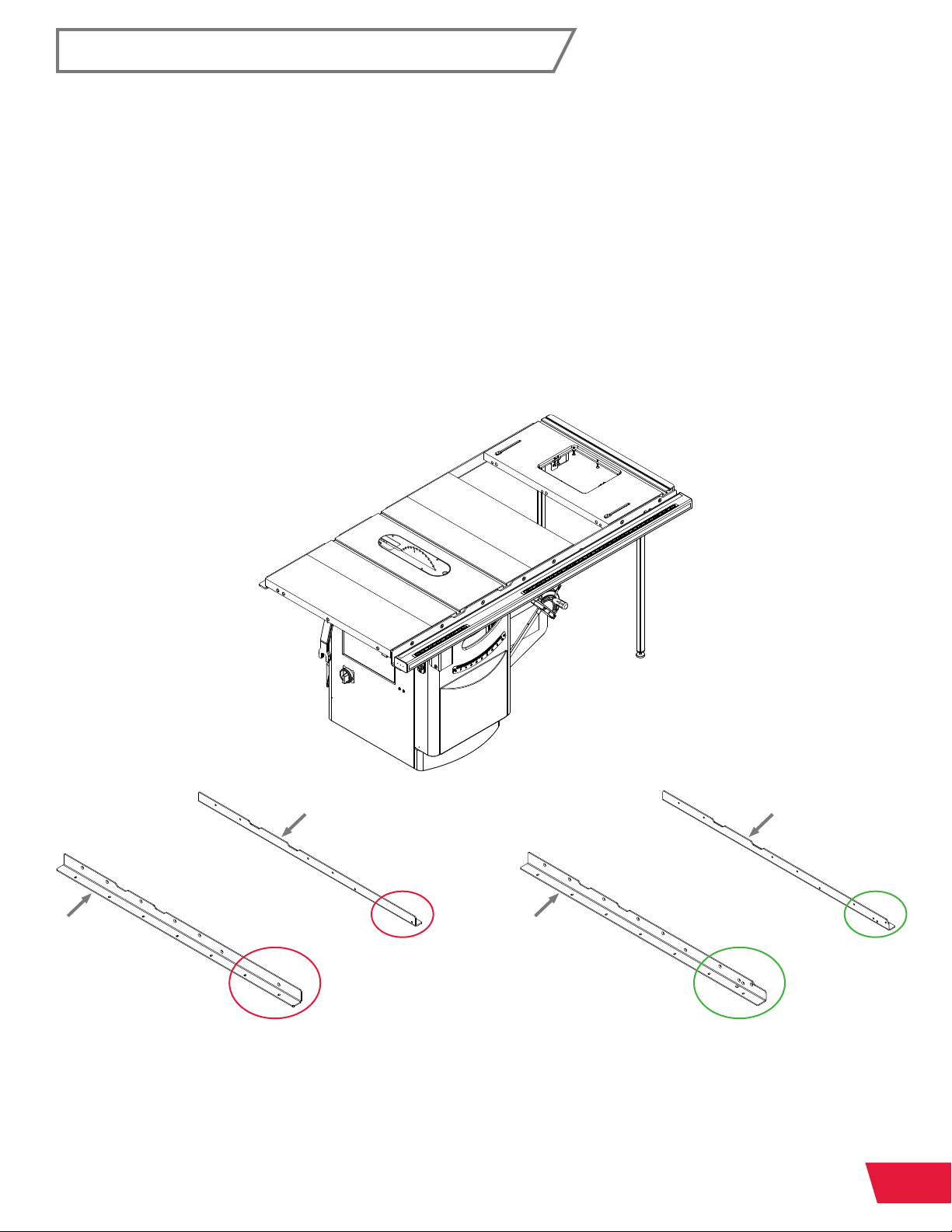

In-Line Right: Between 36” Rails

Option 2 of 3

This conguration minimizes the total footprint of your SawStop table saw and router

table. Users may choose to build an intermediate table to ll the gap between the right

extension wing and the router table (no intermediate table for this conguration is offered

by SawStop). The gap in the table measures 210mm wide.

Required Components:

• 30” x 16” Cast Iron Router Table (RT-C30)

• Power Switch (RT-PSW)

• Support Legs (RT-ST2)

Compatible With:

• T-Glide Fence System – Industrial Series II (TGI2) 36” Rails

REAR RAIL REAR RAIL

FRONT RAIL FRONT RAIL

36” CBFR105 3600 Rails

NOT COMPATIBLE

(Unless user modifies rails)

Refer to page 22 for more information on rail requirements.

36” TGI2 Rails

COMPATIBLE

RT-TGI OWNER’S MANUAL

2

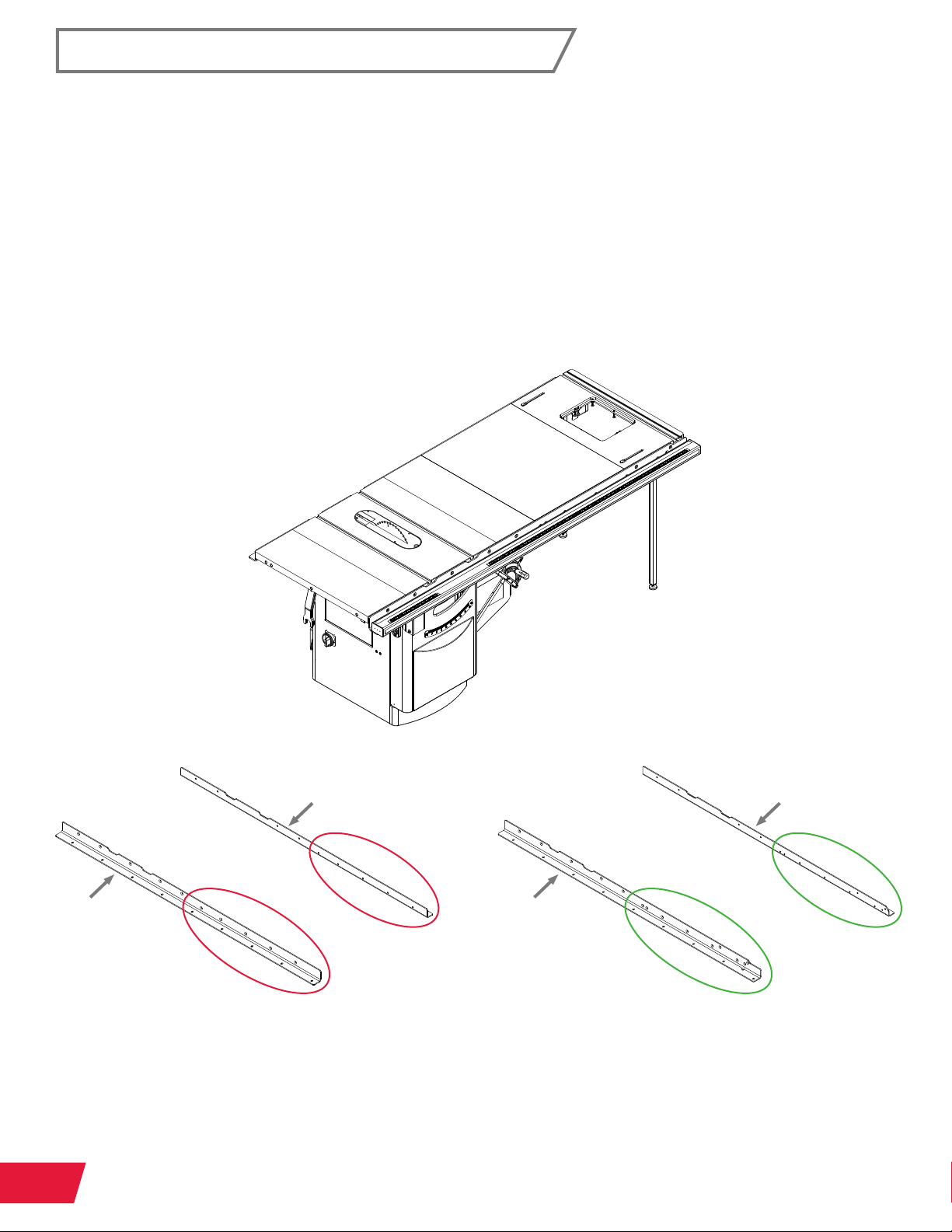

In-Line Right: Between 52” Rails

Option 3 of 3

This conguration maximizes the utility of the existing 52" rip capacity footprint.

Required Components:

• 30” x 16” Cast Iron Router Table (RT-C30)

• Power Switch (RT-PSW)

• Support Legs (RT-ST2) (Also included with 36” Extension Table)

Compatible With:

• T-Glide Fence System – Industrial Series II (TGI2) 52” Rails

• 36” Extension Table (CBFT105 3600) (NOT 52" Extension Table)

REAR RAIL REAR RAIL

FRONT RAIL FRONT RAIL

52” CBFR104 5200 Rails

NOT COMPATIBLE

(Unless user modifies rails)

Refer to page 22 for more information on rail requirements.

3

RT-TGI OWNER’S MANUAL

52” TGI2 Rails

COMPATIBLE

BEFORE YOU BEGIN

Before mounting the Cast Iron Router Table, you may need to replace or modify your rails

or other saw components. See Page 2 for compatibility notes.

Some of the steps involve removing/installing your rails and/or extension wings.

For those steps, please refer to your table saw manual and table saw fence manual.

(Download copies of your manuals at www.sawstop.com.)

DISCONNECT YOUR TABLE SAW FROM ELECTRICAL POWER BEFORE

BEGINNING ANY MODIFICATIONS.

For Unassembled Saws:

If your saw has not yet been assembled, begin by installing and aligning the right and left

extension wings as described in the installation documentation for your table saw. Then,

install the RT-compatible front and rear rails as described in your table saw fence manual,

but do not install the tube or tighten the hardware.

RT-TGI OWNER’S MANUAL

4

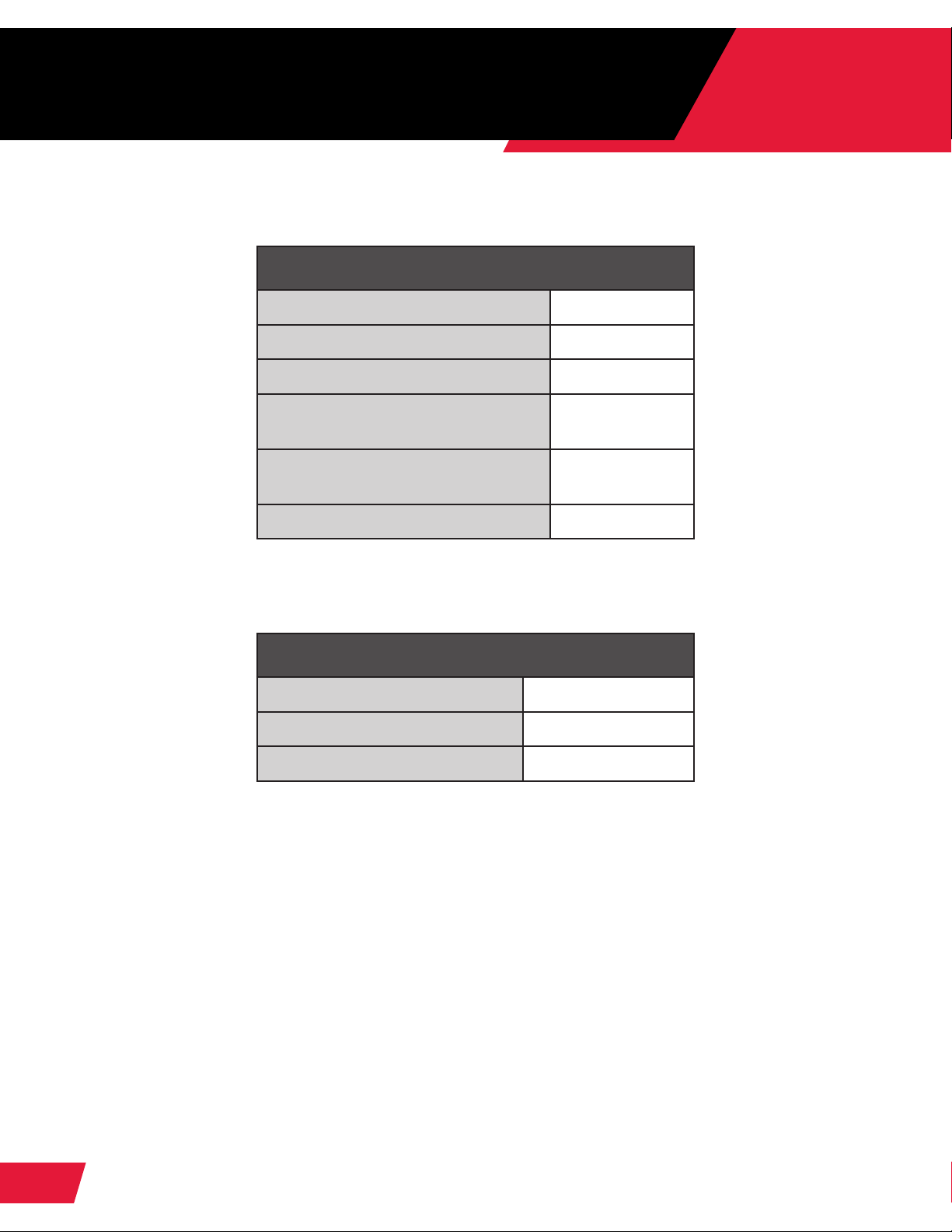

PRODUCT SPECIFICATIONS

30” x 16” Cast Iron Router Table

Cast Iron Table 30” x 16”

Maximum Fence Travel 5 ½”

Front T-slot to Arbor Center 6 ½”

Width of Front T-slot

Width of Rear T-slot

Rear T-slot to Arbor Center 5”

½” at top,

3

⁄8" at bottom

1” at top,

¾" at bottom

32” Fence Assembly for Router Tables

Length 56 ½”

Height 3 ½”

Depth 4”

5

RT-TGI OWNER’S MANUAL

PARTS INVENTORY

Please unpack the parts carefully and conrm you have received each item on

the list below.

IF YOU CANNOT FIND AN ITEM ON THIS LIST, CHECK THE MOUNTING

LOCATIONS OR EXAMINE THE PACKAGING MATERIALS VERY CAREFULLY.

CERTAIN COMPONENTS MAY HAVE BEEN PRE-INSTALLED FOR

SHIPPING PURPOSES.

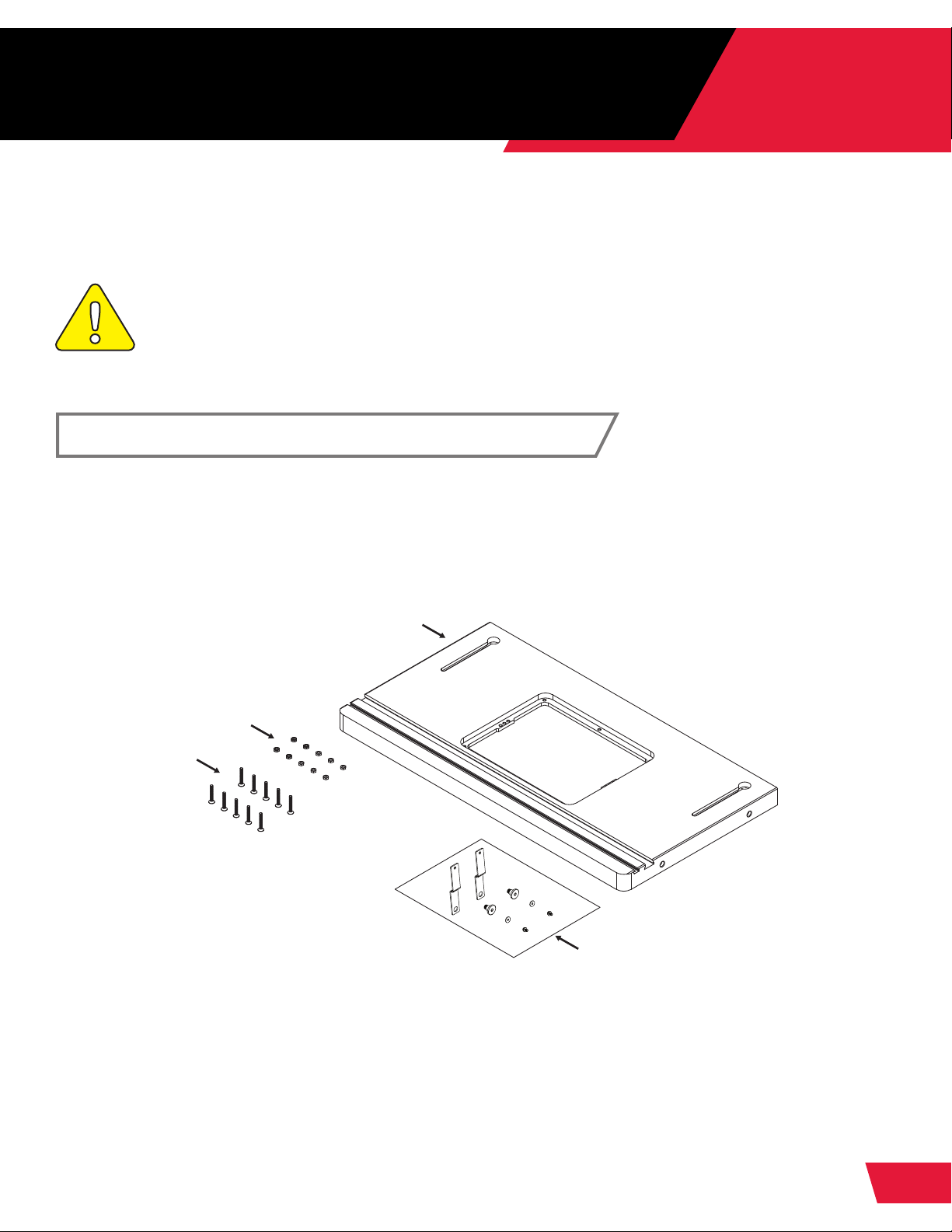

30” x 16” Cast Iron Router Table (RT-C30)

A.

30” x 16” Cast Iron Router Table (1)

B.

M6 x 1.0 Hex Nut (10)

PAGES:

6-10

C.

M6 x 1.0 x 40 Flat Head Phillips Screw (10)

D.

Mobile Base Cabinet Hold-Down Kit for Router Tables (1)

A

B

C

You will also need the following tools:

D

• Phillips Head Screwdriver

See Exploded View #1 on page 39 for more information.

RT-TGI OWNER’S MANUAL

6

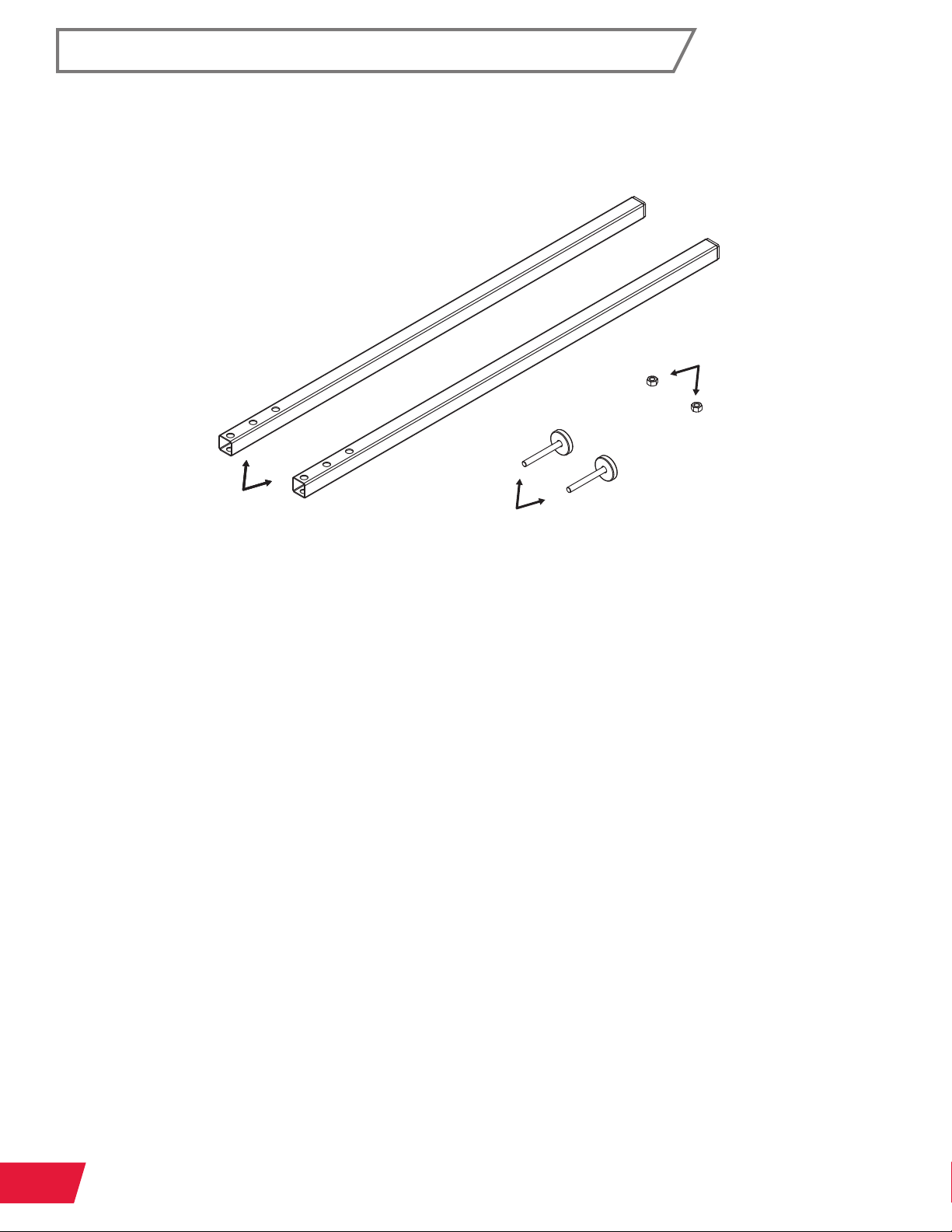

Support Legs for In-Line Router Tables (RT-ST2)

A.

Support Leg (2)

B.

M8 x 1.25 Hex Nut (2)

C.

Foot (2)

AAA

C

B

You will also need the following tools to complete the Support Legs:

• 13mm Wrench

See Exploded View #2 on page 41 for more information.

7

RT-TGI OWNER’S MANUAL

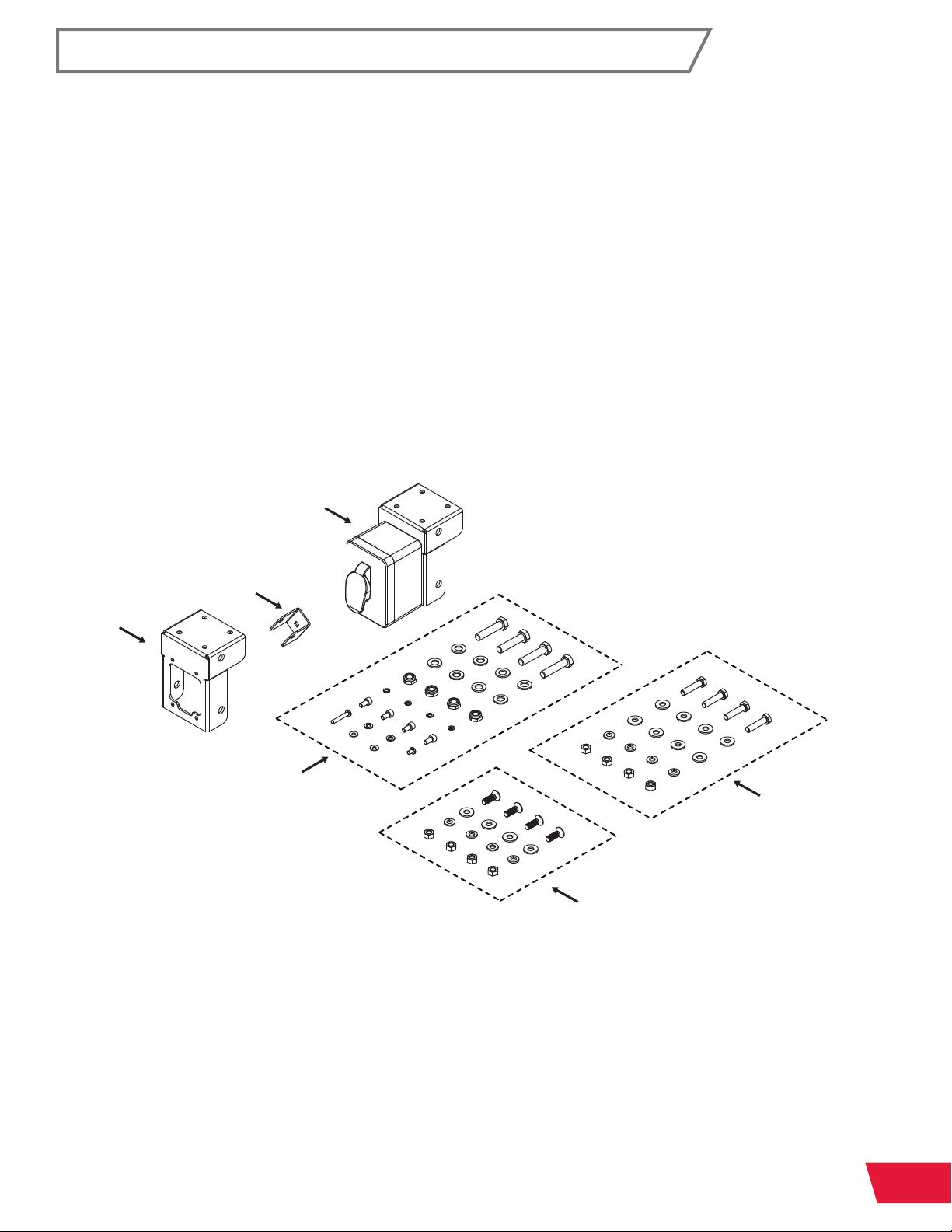

Power Switch for In-Line Router Tables (RT-PSW)

A.

In-Line Switch Box Mounting Bracket

Assembly (1)

B.

Handle Mounting Bracket (1)

C.

Leg Mounting Bracket (1)

D.

Leg Mounting Hardware Pack (1)

• M10 x 1.5 x 45 Hex Head Bolt (4)

• M10 x 19 x 2 Washer (8)

• M10 x 1.5 Lock Nut (4)

• M6 Lock Washer (4)

• M6 x 1.0 x 12 Socket Head Cap Screw (4)

• M5 x 0.8 x 30 Pan Head Phillips Screw (1)

• M5 Lock Washer (2)

• M5 x 12 x 1 Washer (2)

• M5 x 0.8 x 8 Pan Head Phillips Screw (1)

A

E.

Wing Mounting Hardware Pack (1)

• M8 x 1.25 x 45 Hex Head Bolt (4)

• M8 x 19 x 2 Washer (8)

• M8 Lock Washer (4)

• M8 x 1.25 x 12 Hex Nut (4)

Rail Mounting Hardware Pack (1)

F.

• M8 x 1.25 x 25 Flat Head Socket

Screw (4)

• M8 x 19 x 2 Washer (4)

• M8 Lock Washer (4)

• M8 x 1.25 x 12 Hex Nut (4)

B

C

D

F

You will also need the following tools to complete the Power Switch:

• Phillips Head Screwdriver

• 5mm Hex Wrench

• 16mm Wrench (x2)

• Level or Straight Edge

• 13mm Wrench (x2)

E

See Exploded View #3 on page 43 for more information.

RT-TGI OWNER’S MANUAL

8

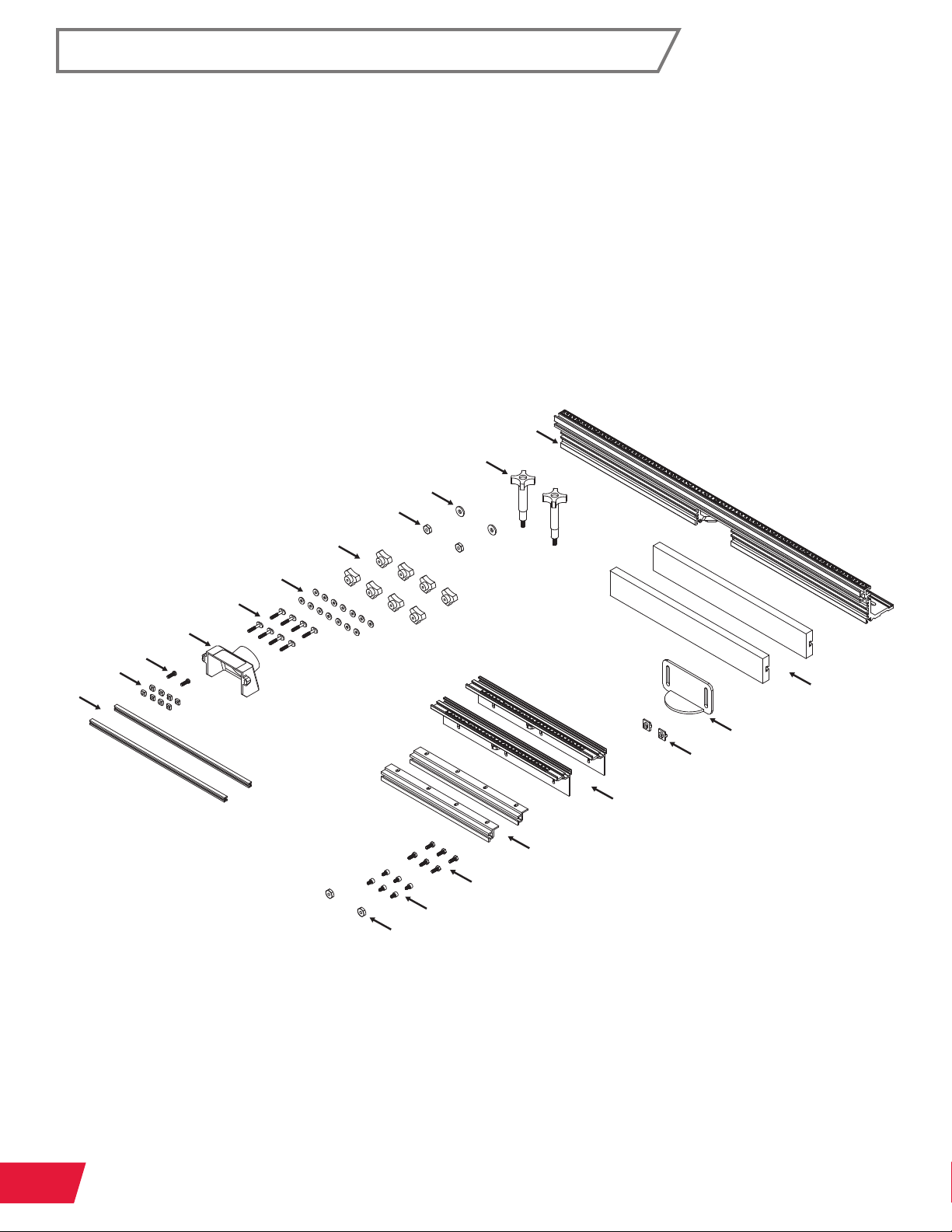

32” Fence Assembly for Router Tables (RT-F32)

A.

32” Router Table Fence (1)

B.

Fence Lock Knob (2)

C.

M8 x 23 x 2 Washer (2)

D.

23mm Lock Knob Nut (2)

E.

Fence Face Plate Lock Knob (8)

F.

M6 x 16 x 2 Washer (14)

G.

M6 x 1.0 x 35 T-Bolt (8)

H.

2 ½” Dust Port (1)

I.

¼”-20 x ¾” Pan Head Phillips Screw (2)

J.

¼”-20 Square Nut (8)

E

K.

Face Plate Space Bar (2)

L.

Router Fence Face Plate (2)

M.

Router Fence Guard (1)

N.

Router Fence Guard Spacer (2)

O.

32” Table Rail with Ruler and Lock Knob (2)

P.

Rail Mounting Bracket (2)

Q.

¼”-20 x 5⁄8” Hex Head Bolt (6)

R.

M6 x 1.0 x 12 Socket Head Cap Screw (8)

S.

19mm Lock Knob Nut (2)

A

B

C

D

F

G

H

I

J

K

N

O

P

Q

R

S

You will also need the following tools to complete the 32” Fence Assembly:

L

M

• Phillips Head Screwdriver

See Exploded View #4 on page 45 for more information.

9

RT-TGI OWNER’S MANUAL

i

Throughout the manual, the exploded views are referenced to clarify the location and

name of each part. There are multiple exploded views in this manual, so a

decimal point system is used. The number before the decimal point refers to the

exploded view number (in this case, 1 through 4). The number after the decimal point

refers to the part number (as indicated by the number in the balloon in the exploded

view). For example, a part referenced as “1.1” would be the part labeled with a “1”

balloon in the exploded view #1.

• Exploded View #1: 30” x 16” Cast Iron Router Table – See page 39

• Exploded View #2: Support Legs for In-Line Router Tables – See page 41

• Exploded View #3: Power Switch for In-Line Router Tables – See page 43

• Exploded View #4: 32” Fence Assembly for Router Tables – See page 45

Important Part Identification Note:

RT-TGI OWNER’S MANUAL

10

ASSEMBLY AND INSTALLATION

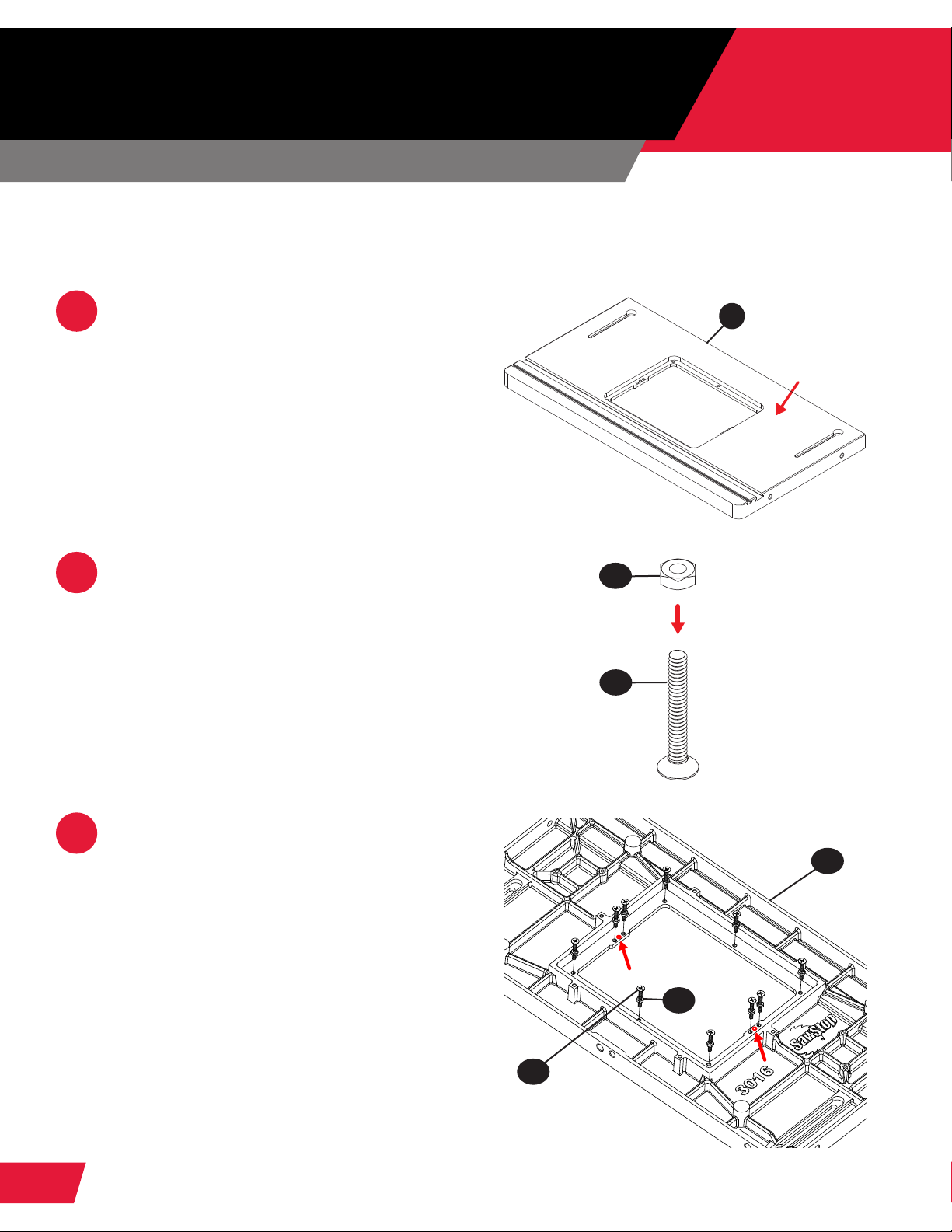

Assembling the 30” x 16” Cast Iron Router Table

Requires: 30” x 16” Cast Iron Router Table Hardware

Phillips Head Screwdriver

Remove the protective covering from

1

the table (1.1) and wipe off the oil with a

soft, clean cloth.

PAGES:

11-35

1.1

Thread ten M6 hex nuts (1.2) partway

2

onto ten M6 at head Phillips screws

(1.3).

Place the router table (1.1) upside down

3

on a at surface and thread the

M6 at head Phillips screws (1.3) with

prethreaded nuts into the threaded

holes around the insert opening in the

table until they extend about ¼” below

the table’s top surface. These screws

will support and level the router lift

relative to the table top. The 2 holes in

the center of the opening (shown in red)

do not receive leveling screws; they will

be used later to attach the router lift to

the router table.

1.2

x10

1.3

1.1

1.2

1.3

11

RT-TGI OWNER’S MANUAL

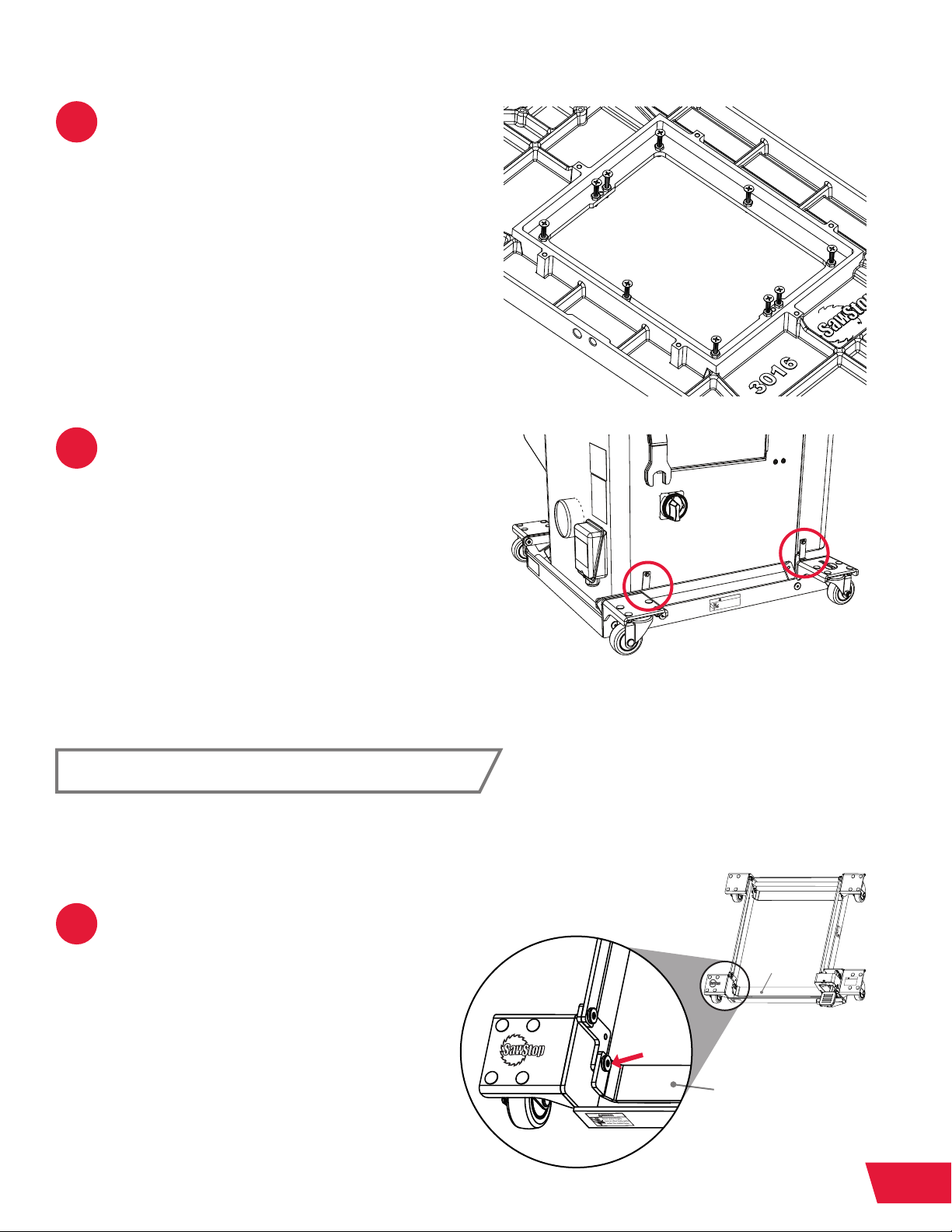

Finger tighten the hex nuts up against

Never place fingers,

toes or other body parts

under the mobile base.

!

WARNING

1. Never place fingers, toes or other

body parts under the mobile base.

2. Always use the saw and the mobile

base on a level surface.

3. Do not continue to step on the foot

pedal once the upper limit is reached.

4. Lower the saw before use. Never use

the saw when it is raised off the floor.

!

WARNING

Low

Raise

Never place fingers,

toes or other body parts

under the mobile base.

!

WARNING

4

the bottom of the table. You will adjust

the screws and fully tighten the hex nuts

later, after you install your router lift.

Your router table includes a Mobile Base

5

Hold-Down Kit (1.5). These should be

attached to your Industrial Mobile Base

now to ensure stability. If your mobile

base already has hold-down straps, the

ones included with your router table

can be discarded. Otherwise, please

complete the following steps to install

the hold-down straps. If the hold-

down straps are already installed,

or you do not have a mobile base,

proceed to page 16.

WARNING

!

Never place fingers,

toes or other body parts

under the mobile base.

Hold-Down Strap Installation

If your saw already has the Industrial Mobile Base installed without the

hold-down straps, you will need to remove the saw from the mobile base

to install the hold-down straps before proceeding.

Unscrew the M8 x 1.25 x 18 shoulder

1

socket screw at the front-left of the

mobile base in the front support strap,

as shown by the red arrow in the gure.

FRONT

SUPPORT

STRAP

WARNING

!

Never place fingers,

toes or other body parts

under the mobile base.

FRONT SUPPORT STRAP

RT-TGI OWNER’S MANUAL

WARNING

!

Never place fingers,

toes or other body parts

under the mobile base.

WARNING

!

1. Never place fingers, toes or other

body parts under the mobile base.

2. Always use the saw and the mobile

base on a level surface.

3. Do not continue to step on the foot

pedal once the upper limit is reached.

4. Lower the saw before use. Never use

Raise

the saw when it is raised off the floor.

Low

12

Loading...

Loading...