Sawstop PCS175 User Manual

SawStop ®

10” PROFESSIONAL

CABINET SAW

OWNER’S MANUAL

Model PCS175

Copyright SawStop, LLC

All Rights Reserved.

2nd Printing, November 2012

Updates of this manual may be available at www.sawstop.com.

The saw on the front cover is shown with the optional 36 inch

Professional Series II Fence Assembly. Your saw may look different.

SawStop, the SawStop blade logo, and the configuration of this product are either registered trademarks or trademarks of SawStop, LLC. Software copyright by SawStop, LLC. All rights reserved. Protected by the following U.S. patents: 6857345, 6997090, 7024975, 7055417, 7098800, 7100483, 7197969, 7210383, 7225712, 7228772, 7284467, 7308843, 7350445, 7472634, 7481140, 7525055, 7536238, 7600455, 7610836, 7640835, 7661343, 7681479, 7707918, 7707920, 7788999, 7789002, 7827890, 7832314, 7895927, 7921754, 7958806, 7971613, 7991503, 8006595, 8011279, 8051759, 8061245, 8079292, 8087438, 8122807, 8151675, 8191450, 8196499, 8266997, 8291797, 8371196, 8402869, 8408106, 8438958, 8459157, 8469067, 8489223, 8490527, 8498732, 8505424, 8522655. Also protected by: Australia patents 785422 and 2007201914, Canada patents 2389596 and 2660280, China patent ZL00816099.6, India patent 212026, Japan patent 5043267, Mexico patent 250009 and Taiwan patent 143466. Additional U.S. and foreign patents pending.

To Our Customers

Thank you for purchasing a SawStop® Professional Cabinet Saw! Your saw includes our revolutionary, awardwinning safety system that tells the difference between cutting wood and cutting a person. If you ever accidentally contact the moving blade, the safety system will detect that contact and stop the blade in milliseconds to minimize any injury.

This manual tells you more about your Professional Cabinet Saw and how to operate and maintain it. Please read the manual carefully. The manual also includes our warranty and important safety information.

Again, thanks for purchasing a SawStop® Professional Cabinet Saw. We are confident you will be pleased with its performance. If you ever have any questions or comments, feel free to contact us at the address below.

SawStop, LLC

9564 S.W. Tualatin Road

Tualatin, Oregon 97062 USA

www.sawstop.com

Main Phone - (503) 570-3200

Service - (503) 582-9934

Fax - (503) 570-3303

Email - info@sawstop.com

SawStop 10” Professional Cabinet Saw |

1 |

Table of Contents

Warranty |

5 |

No Warranty of Safety |

5 |

If You Have an Accident |

5 |

Safety and Warnings |

6 |

Warning Labels |

10 |

The SawStop® Safety System |

11 |

Unpacking Your Saw |

14 |

Standing Up Your Saw |

16 |

Assembling Your Saw |

18 |

Installing the Elevation Handwheel |

19 |

Installing the Tilt Handwheel |

20 |

Installing the Dust Port |

21 |

Installing the Motor Cover |

22 |

Mounting the Extension Wings |

23 |

Mounting the Switch Box |

24 |

Mounting the Accessory Holders |

25 |

Get to Know Your Saw |

26 |

Preparing Your Saw for Use |

28 |

Saw Placement |

28 |

Table Insert Removal and Installation |

28 |

Blade or Dado Installation |

29 |

Brake Position Adjustment |

30 |

Blade Guard and Riving Knife Installation |

32 |

Dust Collection |

34 |

Electrical Power Connection |

35 |

Re-Wiring a PCS175 Saw for 208-240V Power |

36 |

Changing the Plug or Power Cord on a 208-240V Saw |

38 |

2 SawStop 10” Professional Cabinet Saw

Table of Contents

Using Your Saw |

42 |

Adjusting the Blade Height |

42 |

Adjusting the Blade Tilt Angle |

42 |

Turning on Main Power and Starting the Motor |

43 |

System Status Codes |

45 |

Using the Blade Guard |

48 |

Using the Riving Knife |

50 |

Using the Miter Gauge |

50 |

Cross-Cutting |

52 |

Using a Fence |

53 |

Rip Cutting |

54 |

Using the Saw in Bypass Mode |

57 |

Using a Mobile Base |

58 |

Using an Out-Feed Table |

59 |

Changing the Brake Cartridge |

60 |

Installing a Brake Cartridge |

63 |

What to do if the SawStop® Safety System Activates |

64 |

Making Adjustments to Your Saw |

65 |

Aligning the Table |

65 |

Aligning the Blade to the Tilt Axis |

69 |

Aligning the Blade Elevation Assembly |

72 |

Adjusting the Elevation Limit Stops |

74 |

Adjusting the Tilt Limit Stops and Tilt Angle Indicator |

75 |

Adjusting the Table Insert |

77 |

Aligning the Riving Knife and Spreader to the Blade |

79 |

Adjusting the Quick-Release Clamp |

82 |

Adjusting the Miter Gauge |

83 |

Adjusting the Motor Belt Tension |

84 |

Adjusting the Tilt Gearing |

84 |

Adjusting the Elevation Gearing |

85 |

SawStop 10” Professional Cabinet Saw |

3 |

Table of Contents

Maintenance |

86 |

SawStop Safety System |

86 |

Brake Cartridge |

86 |

Elevation and Tilt Mechanisms |

86 |

Cabinet |

86 |

Table and Extension Wings |

86 |

Belts |

86 |

Lubrication Points |

87 |

Troubleshooting |

88 |

Professional Cabinet Saw Specifications |

91 |

Professional Cabinet Saw Dimensions |

92 |

Push Stick Construction |

94 |

Auxiliary Fence Construction |

95 |

Push Block Construction |

96 |

Featherboard Construction |

97 |

Drawings and Parts Lists |

98 |

Cabinet and Table Exploded View |

98 |

Cabinet and Table Parts List |

99 |

Internal Assembly Exploded View |

102 |

Internal Assembly Parts List |

103 |

Arbor Assembly Exploded View |

106 |

Arbor Assembly Parts List |

107 |

Blade Guard and Miter Gauge Exploded View |

110 |

Blade Guard and Miter Gauge Parts List |

111 |

Literature, Hardware and Tools Parts List |

112 |

Accessories |

113 |

Index |

114 |

4 SawStop 10” Professional Cabinet Saw

Warranty

SawStop warrants to the original retail purchaser of a new Professional Cabinet Saw accompanying this manual and purchased from an authorized SawStop distributor that the saw and any accessories purchased with the saw will be free from defects in material and workmanship for TWO YEARS from the date of purchase.

SawStop warrants to the original retail purchaser of a refurbished, demonstration or floor model Professional Cabinet Saw from an authorized SawStop distributor that the saw will be free from defects in material and workmanship for ONE YEAR from the date of purchase.

This warranty does not apply to defects arising from misuse, abuse, negligence, accidents, normal wear-and- tear, unauthorized repair or alteration, or lack of maintenance. This warranty is void if the saw or any portion of the saw is modified without the prior written permission of SawStop, LLC, or if the saw is located or has been used outside of the country of residence of the authorized SawStop distributor from whom the saw was purchased.

Please contact SawStop to take advantage of this warranty. If SawStop determines the saw or an accessory is defective in material or workmanship, and not due to misuse, abuse, negligence, accidents, normal wear-and- tear, unauthorized repair or alteration, or lack of maintenance, then SawStop will, at its expense and upon proof of purchase, send replacement parts to the original retail purchaser necessary to cure the defect. Alternatively, SawStop will repair the saw or accessory provided the saw or accessory is returned to SawStop, shipping prepaid, with proof of purchase and within the warranty period.

SawStop disclaims any and all other express or implied warranties, including merchantability and fitness for a particular purpose. SawStop shall not be liable for death, injuries to persons or property, or incidental, consequential, contingent or special damages arising from the use of the saw.

This warranty gives you specific legal rights. You may have other rights which vary from state to state.

No Warranty of Safety

It is important to understand that the braking technology in SawStop table saws does not prevent contact with the blade-it minimizes the effect of the contact. If you do contact the blade, the braking technology will stop the blade, and in most cases there will be no injury or only a small nick. However, you may incur a serious injury on a SawStop saw depending on factors such as the speed and direction your hand is moving when it contacts the blade and the type of blade you are using. Also, if you decide to use the saw in Bypass Mode, the safety system will be disabled and will not activate in the event you contact the spinning blade.

If You Have an Accident

We at SawStop hope you never have an accident with your saw, and strongly encourage you to always follow safe practices and to use all the safety equipment provided with this saw. However, if you ever accidentally contact the spinning blade, the safety system will detect that contact and stop the blade within milliseconds to minimize any injury. If this happens, please contact us with information regarding the accident because it is very important to our on-going research and development. The more we know about what happens during an accident, the better we are able to ensure that the safety system will react as quickly as possible in all accident situations. In addition, the brake cartridges store electronic data measured during an accident. If you return the activated cartridge to SawStop, we can retrieve that data to learn how the electronics and software performed. If we confirm that your cartridge activated due to skin contact, we will send you a free replacement cartridge. Thanks for your help.

SawStop 10” Professional Cabinet Saw |

5 |

Safety

A table saw is a dangerous tool and there are hazards inherent with using this saw. Some of these hazards are discussed below. Use common sense when operating the saw and use the saw only as instructed. You are responsible for your own safety!

!WARNINGS

1.Read and understand the instruction manual and all safety warnings before operating this saw. Failure to follow instructions or heed warnings may result in electric shock, fire, serious personal injury or property damage. Save these instructions and refer to them whenever necessary.

2.WARNING: This product contains one or more chemicals known to the State of California to cause cancer and birth defects or other reproductive harm. In addition, some types of dust created by sawing, power sanding, grinding, drilling, and other construction activities also contain chemicals known to cause cancer, birth defects or other reproductive harm. Some examples of these chemicals are lead from lead-based paints, crystalline silica from bricks, cement, and other masonry products, and arsenic and chromium from chemically treated lumber. In addition, wood dust has been listed as a known human carcinogen by the U.S. government. The risk from exposure to these chemicals and to dust varies depending on how often you do this type of work. To reduce your exposure, work in a well ventilated area and work with approved safety equipment including dust masks or respirators designed to filter out such dust and chemicals.

3.THIS SAW MUST BE CONNECTED TO A GROUNDED WIRING SYSTEM or to a system having an equipmentgrounding conductor. In the event of a malfunction or breakdown, grounding provides a path of least resistance for electric current to reduce the risk of electric shock. This saw is equipped with an electric cord having an equipmentgrounding conductor and a grounding plug. The plug must be plugged into a matching outlet that is properly installed and grounded in accordance with all local codes and ordinances. Do not modify the plug provided - if it will not fit the outlet; have the proper outlet installed by a qualified electrician. Improper connection of the equipment-grounding conductor can result in a risk of electric shock and/or malfunction. The conductor with insulation having an outer surface that is green with or without yellow stripes is the equipment-grounding conductor. If repair or replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal.

Check with a qualified electrician or service personnel if the grounding instructions are not completely understood or if in doubt as to whether the saw is properly grounded. Use only 3-wire extension cords that have 3-prong grounding plugs and 3-pole receptacles that accept the saw’s plug. Repair or replace a damaged or worn cord immediately.

4.USE PROPER EXTENSION CORD. Make sure your extension cord is in good condition. When using an extension cord, be sure to use one heavy enough to carry the current your saw will draw. An undersized cord will cause a drop in line voltage resulting in loss of power and overheating. For a cord length of up to 25 feet on 110120V power, use a cord of 12 gauge. For a cord length of 25 to 50 feet on 110-120V power, use a cord of 10 gauge. A cord length over 50 feet is not recommended for 110120V power. If in doubt, use the next heavier gauge. The smaller the gauge number the heavier the cord.

Minimum Extension Cord Gauge

for 110-120V

Length |

Gauge |

0 - 25 Feet |

12 AWG |

25 - 50 Feet |

10 AWG |

over 50 Feet |

Not Recommended |

6 SawStop 10” Professional Cabinet Saw

!WARNINGS

5.Professional Cabinet Saw Model PCS175 in its standard configuration is intended for use on a 110-120V supply circuit that has an outlet that looks like the one illustrated in Sketch A below.

Sketch A

|

cover of grounded |

grounding pin |

outlet box |

A temporary adapter, which looks like the adapter illustrated in Sketch B and C, may be used to connect this plug to a 2 pole receptacle as shown in Sketch B if a properly grounded outlet is not available. The temporary adapter should be used only until a properly grounded outlet can be installed by a qualified electrician. This adapter is not permitted in Canada. The green-colored rigid ear, lug, and the like, extending from the adapter must be connected to a permanent ground such as a properly grounded outlet box.

Sketch B |

Sketch C |

|

|

adapter |

|

|

adapter |

|

metal screw |

|

|

cover of grounded |

grounding |

|

means |

||

outlet box |

||

|

6.Professional Cabinet Saw Model PCS175 re-wired for 208-230V power is intended for use on a circuit that has an outlet that looks like the one illustrated in Sketch D. The saw has a grounding plug that looks like the plug illustrated in Sketch D. Make sure the saw is connected to an outlet having the same configuration as the plug. No adapter is available or should be used with this saw. If the saw must be reconnected for use on a different type of electric circuit, the reconnection should be made by qualified service personnel; and after reconnection, the saw should comply with all local codes and ordinances.

Sketch D

grounding pin

SawStop 10” Professional Cabinet Saw |

7 |

!WARNINGS

7.KEEP CHILDREN AWAY from the saw. All visitors should be kept at a safe distance from the work area. Make the workshop kid-proof with padlocks, master switches, or by removing starter keys.

8.Do not use the saw in dangerous environments. For example, do not use the saw in damp or wet locations or expose it to rain, and keep the work area well lighted.

9.Check to make sure the saw is in proper working order before using the saw. For example, check the alignment of moving parts, look to see whether moving parts are binding or rubbing, check to see whether parts are broken, make sure accessories are properly mounted in the saw, and check any other conditions that may affect the operation of the saw. A guard or other part that is damaged should be properly repaired or replaced.

10.Keep guards in place and in working order. Never operate the saw with the motor cover or access panels open.

11.Wear eye protection. Always wear safety glasses when using the saw. Everyday eyeglasses are not safety glasses. Also use a face or dust mask if the cutting operation is dusty.

12.Wear proper apparel when using the saw. Do not wear loose clothing, gloves, neckties, rings, bracelets, or other jewelry which may get caught in moving parts. Non-slip footwear is recommended. Wear a protective hair covering to contain long hair.

13.You must install a rip fence before using this saw. Attempting to use the saw for rip cutting without the rip fence could result in serious personal injury.

14.REDUCE THE RISK OF UNINTENTIONAL STARTING. Make sure the power switch is in the OFF position before plugging in the saw. Also, remove adjusting keys and wrenches from the saw before turning it on.

15.Keep hands out of the line of the saw blade. Never reach around or over the saw. Do not overreach or stretch to get something when using the saw. Keep proper footing and balance at all times.

16.Never stand on the saw. Serious injury could occur if the saw is tipped or if the cutting tool is unintentionally contacted.

17.Feed work into the blade against the direction of rotation of the blade only. Feeding the work in the direction of rotation may cause the work to be thrown by the blade and could result in serious personal injury.

18.Do not perform any operation freehand. Freehand means not using a fence (for rip cuts) or a miter gauge (for cross-cuts) to guide the work piece as it is being cut. Always maintain firm control over the material being cut.

19.Use a blade guard and spreader for every operation for which it can be used, including all through sawing. Use a push stick when required.

20.Secure your work. Use clamps or a vise to hold work when practical. It’s safer than using your hand and it frees both hands to operate tool.

21.Pay particular attention to instructions on reducing the risk of kickback. Kickback occurs when a work piece contacts the downstream edge of the blade as it is being cut and is propelled back towards the user at high velocity.

22.DON’T FORCE THE TOOL. It will do the job better and safer at the rate for which it was designed. For example, do not try to cut wood faster than the motor can handle.

8 SawStop 10” Professional Cabinet Saw

!WARNINGS

23.USE THE RIGHT TOOL. Do not try to force the saw to do something it was not designed to do. Don’t force a tool or attachment to do a job for which it was not designed. Use the right blade for the job.

24.Never leave the saw running unattended. Wait until the blade comes to a complete stop and then turn the main power switch to OFF and unplug the power cord when you are finished using the saw.

25.Turn the main power switch to OFF and unplug the power cord before servicing the saw and when changing components or accessories such as blades, brake cartridges, and the like.

26.MAINTAIN TOOLS WITH CARE. Maintain the saw as specified in this manual. Keep tools sharp and clean for best and safest performance. Follow instructions for lubrication and changing accessories.

27.Use only recommended accessories with the saw. Consult this manual for recommended accessories. The use of improper accessories may cause risk of injury. When servicing, use only identical replacement parts.

28.Keep the top of the saw clean and free from clutter. Cluttered areas invite accidents.

SawStop 10” Professional Cabinet Saw |

9 |

Warning Labels

Warning labels are mounted on the right and back sides of the saw, on the table insert, on the switch box, and on the motor cover. Some of the warnings on those labels may be additional to the warnings listed above. Be sure to read the warning labels before using the saw. Copies of the English text of the warning labels are reproduced below:

! WARNING

To avoid loss of SawStop protection during coast down, do not turn off Main Power until blade has stopped spinning.

! WARNING

Do not operate with door open. The blade can retract and cause

a severe injury if you touch it inside the cabinet. Also, moving parts can cut, pinch or crush.

! WARNING

Moving gears and parts can pinch, cut or crush.

Do not operate with door open.

Thank you for purchasing this SawStop® table saw.

This saw is equipped with the SawStop® safety system, designed to reduce the potential for a serious injury in the event of accidental contact with the saw blade.

This saw operates differently than ordinary table saws. Each operator must read and understand the Owner’s Manual before operating this saw.

!

WARNING

For your own safety, read the instruction manual before operating this saw.

1.Wear eye protection.

2.Use the blade guard and spreader for every operation for which it can be used, including all through sawing.

3.Keep hands out of the line of the saw blade.

4.Use a push-stick when required.

5.Know how to reduce the risk of kickback.

6.Do not perform any operation freehand.

7.Never reach around or over the saw blade.

8.Never try to test fire the brake system.

9.Never adjust the position of the brake cartridge while the blade is spinning.

10.Do not try to disable the brake system.

11.Unplug the saw before changing the blade, changing the brake cartridge or servicing.

12.Do not connect the motor directly to a power supply.

13.Use the bypass switch only when necessary.

14.Do not expose to rain or use in damp locations.

15.Do not put your hands inside or underneath the cabinet while the blade is spinning.

16.Do not unplug or disconnect the saw from electrical power before the blade has stopped spinning.

17.If connected to a circuit protected by fuses, use time delay fuse marked D.

! WARNING

Moving belts and parts can pinch, cut or crush.

Do not operate with door open.

10 SawStop 10” Professional Cabinet Saw

The SawStop® Safety System

This Professional Cabinet Saw is equipped with the SawStop® safety system. This revolutionary technology was developed to reduce the potential for a serious injury in the event of accidental contact with the saw blade. SawStop® saws are the only saws smart enough to know the difference between you and the wood you are cutting.

The SawStop® safety system includes two components, an electronic detection unit and a fast-acting brake. The electronic detection unit detects when a person contacts the blade. A small electrical signal is induced onto the blade by electrodes placed around the arbor. Although

this low voltage, high frequency signal is too small to feel, it can be measured by the detection system. When human skin comes into contact with the blade (or arbor), a portion of the signal is absorbed by the body due to the inherent electrical capacitance of the human body. As a result, the signal on the blade gets smaller and the detection unit recognizes this as contact.

Wood and other non-conductive materials such as plastic, foam, cardboard, Corian®, melamine, etc., do not cause a drop in the signal because those materials do not absorb the signal on the blade. Conductive materials such as aluminum and other metals, carbon fiber materials, mirrored acrylic, carbon-filled materials, etc., will typically cause the brake to activate. If you need to cut these conductive materials, the safety system can

be placed in “Bypass Mode” to temporarily disable the Brake Cartridge brake. (The Bypass Mode is discussed on page 57.)

The fast-acting brake includes a small fuse that holds a strong spring in compression. If the electronic detection unit detects contact while the blade is spinning (including during coast down), the fuse is burned by a surge of electric current. The spring then pushes an aluminum pawl into the teeth of the spinning blade. The teeth cut into the pawl, stopping the blade. The total time between the detection of contact and stopping the blade is just a few milliseconds. If the brake is activated while the blade is at or near full speed, the blade will also quickly retract below the table. The system will not activate the brake when the blade is stopped–even if you spin the blade by hand. This allows you to touch or change the blade when the motor is off just as with ordinary table saws. However, for safety, always turn the main power switch to OFF and unplug the power cord when changing the blade.

The SawStop® safety system is active whenever the main power is on. The safety system continuously performs many different self-checks to ensure that the components of the system are operating properly. If any problems are detected, the safety system will disable the motor and display a system status code to identify the problem (see page 45 for a description of the system status codes and the corrective action). If the problem is detected while the motor is spinning, the motor will be shut off. The safety system will not allow the motor to start, even in Bypass Mode, as long as a problem is detected.

The electronic detection unit and fast-acting brake are contained in the “brake cartridge,” which is positioned under the table and just behind the blade, as shown above. The brake cartridge must be correctly installed before the motor can be started (see page 61 for instructions on removing and installing the brake cartridge). In the event that the brake is activated, a new brake cartridge must be installed before the saw can be used again.

SawStop 10” Professional Cabinet Saw |

11 |

The SawStop® Safety System

The SawStop® safety system does not interfere with your use of the saw. You can still make all the cuts that you can with ordinary saws including 0° to 45° bevels, non-through cuts, and dado cuts (with the optional dado brake cartridge and the optional dado table insert).

Your SawStop® saw operates differently than ordinary table saws, and there are a few important points to keep in mind as you use the saw.

1.Do not rely on the SawStop® safety system to protect against unsafe operation. Although the system is

designed to react and stop the blade very quickly in the event of accidental contact, it cannot react until contact is detected. This means that you may receive at least a minor injury even with the SawStop® safety system.

Therefore, always use safe operating practices, and use the blade guard, push stick and other safety devices whenever possible. The SawStop® safety system, like the airbag in a car, should be considered as a last measure to minimize injury when all other safety practices and devices have failed to prevent an accident.

2.In the event of contact, the blade will be stopped in about 3–5 milliseconds (coarse toothed blades stop more quickly than fine-toothed blades such as plywood blades). Therefore, the seriousness of the injury incurred will

depend on the speed at which a person’s hand or other body part is moving toward the blade. For example, if a person’s hand is moving toward the blade at 1 ft.⁄sec., then the depth of the cut will be approximately 1⁄16 inch (1 ft.⁄sec.* 0.005 sec. = 0.005 ft. or 1⁄16 inch). At faster speeds, the cut will be proportionally deeper. Therefore, it is possible to be seriously injured even with the SawStop® safety system.

3.Do not operate the saw in Bypass Mode unless you are cutting electrically conductive material. When Bypass Mode is engaged, the SawStop® safety system will not activate the brake if contact is detected and a serious injury could result if you contact the blade.

4.The motor cannot be started without a blade installed. Since the safety system disables the motor if the blade is spaced too far from the brake, a missing blade will be detected as a blade-to-brake spacing error and the motor will be disabled.

5.Blades

You can use any standard 10 inch saw blade or 8 inch dado set with your SawStop® saw, although the following precautions should be observed:

i.Never attempt to use a blade other than a single 10 inch blade with the standard SawStop® brake cartridge. Never attempt to use a dado set or blade other than an 8 inch dado set with the SawStop® dado cartridge. The use of smaller diameter blades with a brake cartridge designed for larger blades could result in a serious injury because the brake cannot be positioned correctly to stop the smaller blades.

ii.Never stack dado blades thicker than 13⁄16 inch. The 8 inch dado brake cartridge is not designed to stop dado stacks thicker than 13⁄16 inch.

iii.Do not use molding heads. The use of molding heads could result in a serious injury because neither the standard brake cartridge nor the dado brake cartridge is designed to stop a molding head.

iv.Never use a blade with damaged or missing teeth as this can result in a more serious injury or a false activation of the brake. Blades with variable spacing between teeth are compatible with the SawStop® safety system, however you must ensure the brake is positioned correctly by rotating the blade at least one full revolution to be certain that none of the teeth touch the brake (see page 30 for more information on setting the brake position).

v.Never install the blade backwards. The brake might not stop a blade that is installed backwards.

vi.Do not use saw blades or dado sets that have a lacquer or other coating on the teeth. These coatings are non-conductive and therefore can reduce the speed at which the system detects contact. In other words, a coated tooth must cut slightly deeper into the skin for contact to be detected, resulting in a somewhat more serious injury. Used blades that originally had a coating are OK to use since the coating is worn away within a few uses. However, SawStop recommends that you examine each tooth on such blades to confirm that no coating remains.

12 SawStop 10” Professional Cabinet Saw

The SawStop® Safety System

vii.Blades with depth-limiting shoulders may take longer to stop in the event of an accident than standard blades, and you could receive a more serious injury. Therefore, SawStop recommends using blades without depth-limiting shoulders.

viii.The SawStop safety system is designed for use with standard 10 inch blades with kerfs from 3⁄32 inch to 3⁄16 inch. Blades with kerfs much thinner than 3⁄32 inch should not be used because those blades might not be strong enough to withstand the force applied by the brake when it activates. As a result, those blades

might deform and stop more slowly in the event of an accident, resulting in a more serious injury. Blades with kerfs much thicker than 3⁄16 inch are heavier than standard 1⁄8 inch kerf blades, and should not be used because they may stop more slowly than standard blades in the event of an accident, resulting in a more serious injury. Similarly, stacks of two or more 10 inch blades should never be used on your SawStop saw

as the combined weight of the blades may be too heavy to stop quickly. If you need to use a blade with a kerf thicker than 3⁄16 inch, use an 8 inch dado set with the optional Sawstop 8 inch dado brake cartridge.

ix.Do not use non-conductive blades, including abrasive blades, blades with plastic hubs, or blades that have non-conductive teeth. The safety system cannot induce the electrical signal onto a non-conductive blade, and blades with non-conductive teeth may prevent the system from detecting contact. Only standard steel blades with either steel or carbide teeth should be used.

6.Do not use table inserts, guards, fences or other devices which have metal parts that may come into contact with the blade. Any metal part that contacts the blade may cause the brake to activate. All SawStop® accessories are specifically designed to prevent metal contact with the blade.

7.Wet, pressure-treated wood may cause the brake to activate. The chemicals used to pressure treat wood often contain large amounts of copper, which is conductive. When pressure-treated wood is wet, the combination of copper and water substantially increases the conductivity of the wood. Therefore, allow wet pressure-treated wood to fully dry before cutting. Typically, the wood will be sufficiently dry if left unstacked in a dry location for 24 hours. If you must cut wet pressure-treated wood, you can make several cuts in the wettest piece(s) using the Bypass Mode to test whether the wood is too wet. See page 57 for instructions on using Bypass Mode and page 47 for information on testing the conductivity of a material. If the test indicates the wood is too wet to cut with the safety system active, you must either allow the wood to dry or make the remaining cuts in Bypass Mode.

8.Do not replace the arbor belt with a non-SawStop® belt. The SawStop® arbor belt is custom designed to dissipate static electricity that may build up on the spinning blade which could cause a false activation of the brake.

9.Never touch the arbor, arbor pulley, arbor nut or arbor washer when the blade is spinning because you may receive a serious injury. These parts are all electrically coupled to the blade and the brake will activate if contact with these parts is detected.

10.Never reach under the blade while it is spinning. In the event the brake is activated, the retraction of the blade may cause a serious injury if you contact the bottom of the blade.

11.Do not remove the dust shroud because a large portion of the blade will be exposed. If you contact the blade under the table, the blade may retract toward you and cause a severe injury.

12.Do not unplug or disconnect the saw from electrical power before the blade has stopped spinning. If the power is interrupted while the blade is moving, the safety system will not be active and therefore the brake will not activate in the event of accidental contact. You may receive a serious injury if you contact the spinning blade while the electrical power has been interrupted.

13.Never attempt to disable the SawStop® safety system or modify the electrical wiring of the saw in any way. Any change or modification or disablement of the safety system or other wiring could result in a serious injury and will void all warranties.

14.Never attempt to repair, adjust, modify or otherwise service a brake cartridge. There are no user-servicable parts inside the brake cartridge. The brake cartridge is permanently sealed against dust and other contaminants. Destruction, removal, or alteration of this seal voids all warranties.

SawStop 10” Professional Cabinet Saw |

13 |

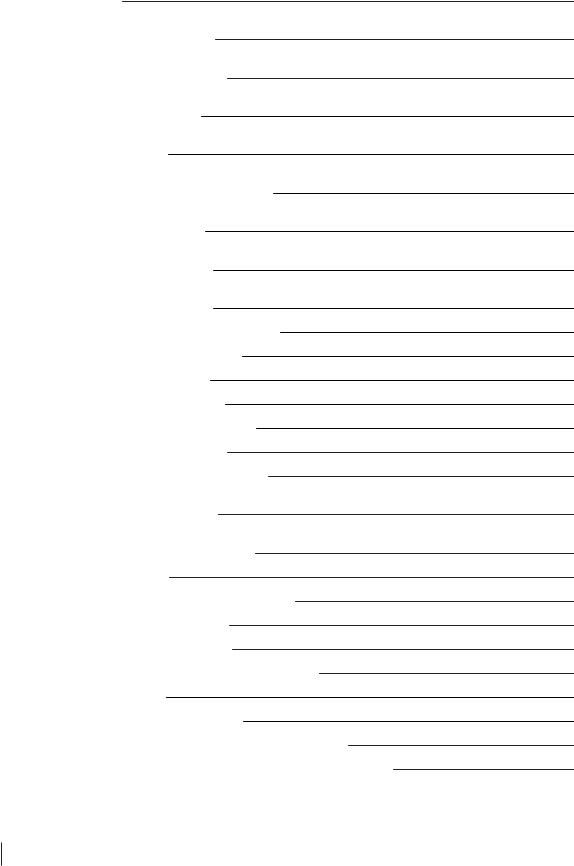

Unpacking Your Saw

Remove all packing materials and accessories before removing the saw from the shipping pallet. While unpacking your saw verify that all the components shown on this page and the following page are included. Use care when unpacking your saw to prevent damage to any of the saw components or accessories. If the saw or the accessories have been damaged during shipping, report the damage to your shipper before proceeding with unpacking. Read and understand this manual fully before assembling and operating your saw.

blade guard assembly |

accessory tool holder |

handwheel package |

|

|

(two) |

riving knife |

blade wrenches |

lock knobs |

(installed in saw) |

(two) |

(two) |

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

||||||

|

|

Hardware for Steps 2-3 |

Hardware for Step 4 |

|

the |

|

||

|

|

|

|

|

|

|

|

|

|

1 |

Keys, |

2 Set Screws, |

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

||||

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

|

|

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

||

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

Mounting the Switch Box |

|

Holder |

|

|

||

|

|

|

13 |

|

|

|||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

14 Lock |

15 Button Head |

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

|

|

|

|

10 M6 (2) |

|

Switch Box |

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

|

|

|

Adjustment Gauge (1) |

|

|

|

|

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|||

|

|

|

Tools |

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

SawStop ®

10” PROFESSIONAL

CABINET SAW

OWNER’S MANUAL

table saw hardware pack |

owner’s manual |

miter gauge |

push stick |

WARNING! The saw weighs approximately 247 pounds without the extension wings and 317 pounds with the extension wings. Be careful in handling the saw to avoid injury.

14 SawStop 10” Professional Cabinet Saw

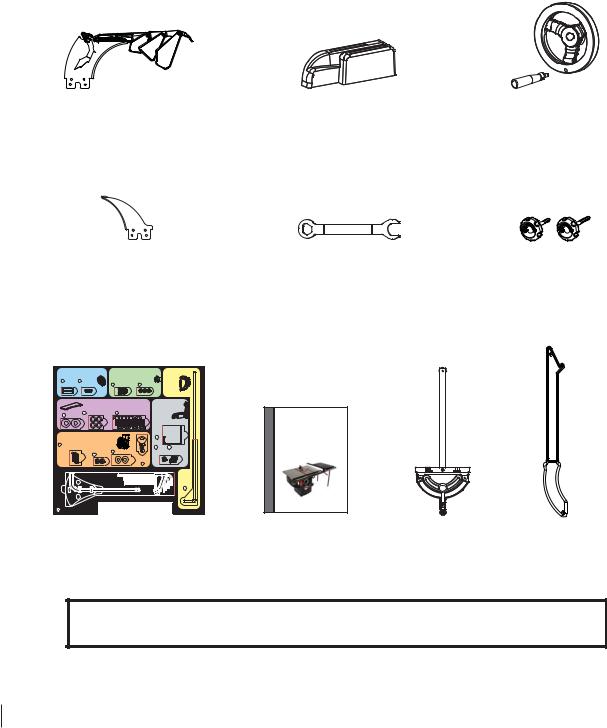

Unpacking Your Saw

dust port

(attached to the end of the flexible hose inside of the saw)

switch box assembly

(connected to the saw by electrical cables)

! |

WARNING |

motor cover

extension wings

(two)

10” blade

table saw

(with pre-installed zero-clearance table insert, brake cartridge, and brake cartridge key)

SawStop 10” Professional Cabinet Saw |

15 |

Standing Up Your Saw

1.Your saw is shipped horizontal to protect it from tipping during transit. To stand up your saw, first remove all packing materials and accessories from the shipping pallet (see Fig. 1). There is a poster that ships with the saw that shows where all of the accessories are located in the packaging.

Fig. 1

2.Take the top piece of Styrofoam and place one of its short sides next to the pallet by the back of the saw, as shown in Fig 2a. Place the Styrofoam so that the top edge of the table and the bottom edge of the saw both overhang the edges of the Styrofoam (see Fig. 2b).

top piece of Styrofoam

the bottom edge of the saw should overhang the edge of the Styrofoam

Fig. 2a

! WARNING

the edge of the table should overhang the edge of the Styrofoam

Fig. 2b

16 SawStop 10” Professional Cabinet Saw

Standing Up Your Saw

3.With the help of another person, carefully roll the saw

off the pallet and onto the top piece of Styrofoam, as shown in Fig. 3. You can use the cast iron table and the elevation control shaft as lifting points to help you roll the saw. Wear safety gloves and be careful to use proper lifting technique to avoid injury.

use the table and the elevation control shaft as lifting points to help roll the saw

Fig. 3

If you have a Professional Cabinet Saw Mobile Base ...

install it now while the saw is on its side. Refer to the manual that comes with your Professional Cabinet Saw Mobile Base for instructions. Once the mobile base is installed, continue with step 4 to stand up your saw.

4.With the help of another person, carefully tip the saw to the upright position by lifting under the rear edge of the cast iron table (see Fig. 4). Lift the saw slowly so that it slides off the Styrofoam and onto the floor without damaging the cabinet.

lift under the rear edge of the table

Fig. 4

SawStop 10” Professional Cabinet Saw |

17 |

Assembling Your Saw

The instructions to assemble your Professional Cabinet Saw are listed below. In addition to the tools included with the Table Saw Hardware Pack (shown in Fig. 5 below) you will also need the following tools to complete the assembly:

•a Phillips screwdriver

•a 13 mm wrench

•a 14 mm wrench

•a level or straight edge

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

|

|

|

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

||

|

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

Mounting the Switch Box |

|

Holder |

|

|

|||

|

|

|

13 |

|

|

||||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

14 Lock |

15 Button Head |

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

||

|

|

|

10 |

M6 (2) |

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

Switch Box |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|||

|

|

|

Tools |

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

Fig. 5

1.Once the saw is in the upright position, remove the plastic covering from the cast iron table top and remove the yellow label from the top of the table insert. Wipe the oil off the table top with a soft, clean cloth (see Fig. 6). Do the same for the extension wings. The table top and extension wings are shipped with a coating of oil to prevent the cast iron from rusting.

NOTE: Before assembling the saw, make sure that all packaging has been removed and all parts unpacked.

In particular, DO NOT PROCEED with the assembly of the saw until the switch box has been moved to the outside of the cabinet. (See unpacking poster). When unpacking the switch box assembly, be careful not to damage the power cord or the cords attached to the switch box when cutting the cable ties. Be sure to remove all cardboard pieces from the inside of the cabinet.

wipe the table top with a soft, clean cloth

!

WARNING

Fig. 6

18 SawStop 10” Professional Cabinet Saw

Assembling Your Saw

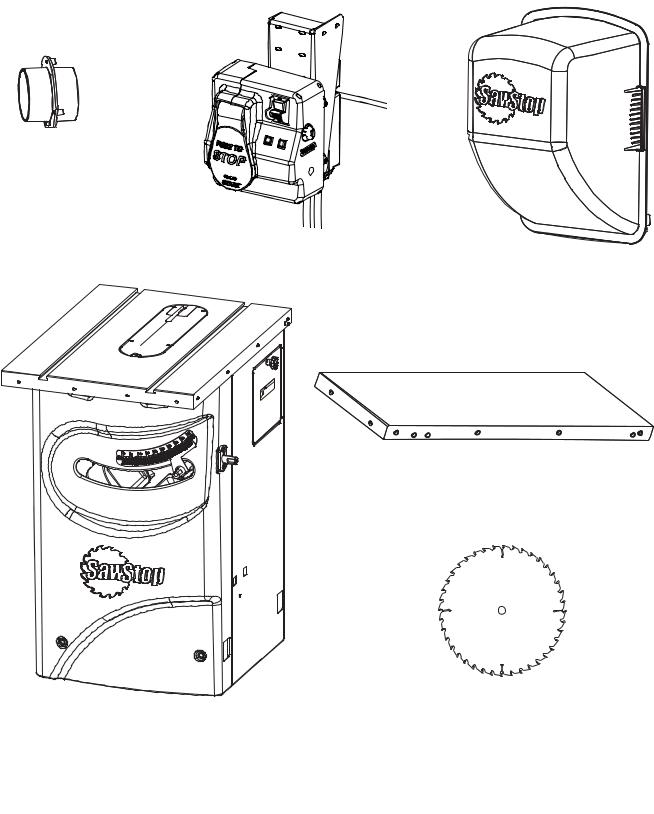

Installing the Elevation Handwheel

2.Open one of the handwheel packages included with your saw and screw the handle into the handwheel (see Fig. 7). Tighten the handle with a 14 mm wrench. The hardware required to install the elevation handwheel is located in the area with the blue background on the Table Saw Hardware Pack. Remove a key from the Table Saw Hardware Pack and insert it into the slot at the end of the elevation control shaft (see Fig. 8). Slide the handwheel onto the end of the elevation control shaft (see Fig. 9) until the face of the handwheel is flush with the end of the shaft. Remove a set screw from the Table Saw Hardware Pack and insert it into the small hole located on the side of the handwheel (see Fig. 10). Use a 3 mm hex key to fully tighten the set screw. Locate the lock knob with the longer shaft. Screw the lock knob into the end of the elevation control shaft (see Fig. 11), but don’t tighten it completely. The lock knob is used to prevent the handwheel from turning after the blade has been set to a new elevation.

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

handwheel |

1 |

key |

||||||

|

|

Hardware for Steps 2-3 |

Hardware for Step 4 |

|

the |

|

|

||||

|

1 |

Keys, |

2 Set Screws, |

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

||

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|

|

|

|||

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|

|

|

||||

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|

|

|

||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

|

|

|

||

|

|

|

|

|

|

Blade |

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

Wrench |

|

|

handle |

|

|

||

|

|

Mounting the Switch Box |

|

Holder |

|

|

|

|

|

||

|

|

|

13 |

|

|

|

|

|

|||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

|

elevation |

|

|

|

10 M6 (2) |

|

Switch Box |

14 Lock |

15 Button Head |

|

|

||

|

|

M6 x 20 (2) |

|

|

|

|

|

||||

|

|

|

Lock Washers, 11 Washers, M6 (2) |

|

Washers, |

Screws, |

|

|

|

||

|

|

|

|

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

control shaft |

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

5 |

Fig. 7 |

|

Fig. 8 |

|

|

|

Adjustment Gauge (1) |

|

|

|

|

Motor |

|

|

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|

|

|

|||

|

|

|

Tools |

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

handwheel |

elevation control shaft

Fig. 9

! |

WARNING |

2

set screw

set screw

elevation control shaft

handwheel

handwheel

handwheel |

Fig. 10 |

elevation |

handwheel |

lock knob |

|

|

elevation |

|

lock knob |

Assembling Your Saw

Fig. 12 |

Fig. 11 |

|

|

SawStop 10” Professional Cabinet Saw |

19 |

Assembling Your Saw

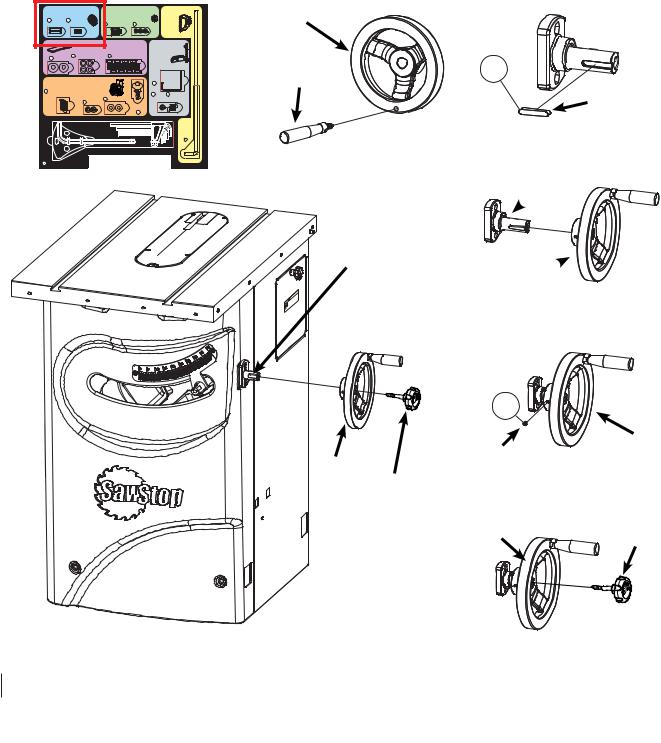

Installing the Tilt Handwheel

3.Open the other handwheel package and screw the handle into the handwheel (see Fig. 13). Tighten the handle with a 14 mm wrench. The hardware required to install the tilt handwheel is located in the area with the blue background on the Table Saw Hardware Pack. Remove a key from the Table Saw Hardware Pack and insert it into the slot at the end of the tilt control shaft (see Fig. 14). Slide the handwheel onto the end of the tilt control shaft (see Fig. 15) until the face of the handwheel is flush with the end of the tilt control shaft. Remove a set screw from the Table Saw Hardware Pack and insert it into the small hole located on the side of the handwheel (see Fig. 16). Use a 3 mm hex key to fully tighten the set screw. Locate the lock knob with the shorter shaft. Screw the lock knob into the end of the tilt control shaft (see Fig. 17), but don’t tighten it completely. The lock knob is used to prevent the handwheel from turning after the blade has been set to a new tilt angle.

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

the |

|

handwheel |

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

|

|

|

||

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

Motor |

|

||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

|

||

|

|

|

Hardware for Step 7 |

|

|

Blade |

|

|

handle |

|

|

|

|

|

|

Wrench |

|

|

|||

|

|

Mounting the Switch Box |

|

Holder |

|

|

|

|||

|

|

|

13 |

|

|

|

||||

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

14 Lock |

15 Button Head |

|

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

|

||

|

|

|

10 |

M6 (2) |

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

|

Switch Box |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

Fig. 13 |

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|

|||

|

|

|

Tools |

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

tilt control shaft

! |

WARNING |

handwheel

tilt lock knob

tilt control  shaft

shaft

1

key

Fig. 14

tilt control  shaft

shaft

handwheel

Fig. 15

2

set screw |

handwheel |

|

|

|

Fig. 16 |

handwheel |

tilt lock |

|

knob |

Fig. 18 |

Fig. 17 |

20 SawStop 10” Professional Cabinet Saw

Assembling Your Saw

Installing the Dust Port

4.The dust port comes attached to the end of a flexible hose residing within the cabinet. Notice that there is a small semicircle on the dust port flange (see Fig. 19). The dust port must be inserted into the four inch diameter hole at the back of the cabinet from the inside of the cabinet as shown in Fig. 20. The semicircle acts as a key to correctly orient the dust port. The hardware required to install the dust port is located in the area with the green background on the Table Saw Hardware Pack. Remove the three dust port screws and lock washers from the Table Saw Hardware Pack and place a lock washer on each screw. Keep the screws nearby.

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

|

|

|

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

||

|

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

Mounting the Switch Box |

|

Holder |

|

|

|||

|

|

|

13 |

|

|

||||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

14 Lock |

15 Button Head |

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

||

|

|

|

10 |

M6 (2) |

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

Switch Box |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

5 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|||

|

|

|

Tools |

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

dust  port

port

flange

semicircle

Fig. 19

dust |

Fig. 20 |

port |

Holding the dust port in your hand, reach inside the cabinet through the opening on the side of the cabinet through which the motor protrudes and fit the dust port in the hole so that the semicircle fits in the cabinet and the flange around the dust port lies flat against the inside of the cabinet. When correctly installed, the three holes in the cabinet surrounding the dust port will line up with the three bosses in the dust port.

While holding the dust port firmly in |

|

|

|

place on the inside of the cabinet, |

|

|

|

insert each of the three screws into |

3 |

4 |

|

the holes surrounding the dust port |

! WARNING |

|

|

on the outside of the cabinet, as |

|

|

|

shown in Fig. 21. Using a Phillips |

|

|

|

screwdriver, tighten each screw |

|

|

|

a little bit at a time until all three |

|

|

|

screws are securely in place. |

|

|

|

|

|

Fig. 21 |

|

|

|

SawStop 10” Professional Cabinet Saw |

21 |

Assembling Your Saw

Assembling Your Saw

Installing the Motor Cover

5.Locate the motor cover and remove the motor cover rod from the area with the yellow background on the Table Saw Hardware Pack. Hold the motor cover against the side of the saw over the motor such that the two arrows on the side of the cover point to the two metal tubes on the side of the cabinet (see Fig. 22).

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

||

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

||

|

|

|

|

|

|

|

|

|

! |

|

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

Mounting the Switch Box |

|

Holder |

|

|

|||

|

|

|

13 |

|

|

||||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

14 Lock |

15 Button Head |

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

||

|

|

|

10 |

M6 (2) |

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

Switch Box |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|||

|

|

|

Tools |

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

upper tube |

arrow on |

|

motor cover |

||

on cabinet |

||

|

Fig. 22

WARNING

Slip the straight end of the motor cover rod up through the bottom tube then through the row of halfcylinders along the edge of the motor cover and finally through the upper tube (see Fig. 23). Rotate the motor cover rod so that the bent end of the rod fits into the hook on the motor cover just below the bottom metal tube (see Fig. 24).

! |

WARNING |

rod

5

5

Fig. 23

To open the motor cover press on the ribbed section on the front of the motor cover until it unlatches and swing the cover away from the cabinet. Reverse the process to close the cover (see Fig. 25).

lower tube |

on cabinet |

rod |

hook on |

motor |

|

Fig. 24 |

cover |

Fig. 25

22 SawStop 10” Professional Cabinet Saw

Assembling Your Saw

Mounting the Extension Wings

6.The hardware required to mount the cast iron extension wings to the cast iron table top is located in the area with the purple background on the Table Saw Hardware Pack. Position one of the extension wings next to the left side of the cast iron table with the chamfer toward the front and align the holes in the side of the wing with the four threaded holes on the side of the table (see Fig. 26). Mount the left extension wing with four M8 washers, four M8 lock washers and four M8 x 20 hex bolts, but do not tighten. Repeat the same procedure to mount the other extension wing to the right side of the table.

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

8 |

||||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

7 |

|||

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|||

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 |

M5 (3) |

|

||||

|

|

|

|

|

|

|

|

|

Cover |

||

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

|

Mounting the Extension Wings |

|

Mounting the |

6 |

|||||

|

|

|

|

Hardware for Step 6 |

|

|

Wrench & Tool |

||||

|

6 |

M8 (8) |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||||

|

|

Washers, |

|

|

|

|

|||||

|

|

|

|

|

|

|

|

Hardware for Step 8 |

|

||

|

|

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

|

Mounting the Switch Box |

|

|

Holder |

|

|

|

|||

|

|

|

|

13 |

|

|

|

||||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

|

14 Lock |

15 Button Head |

|

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

|

Washers, |

Screws, |

|

||

|

|

|

10 |

M6 (2) |

|

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

|

Switch Box |

|

|

|

|

|||

|

|

|

|

|

|

|

|

|

|

||

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

|

Motor |

|

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

Hex Key, M8 (1) |

|

|

|

|

Rod |

|

|

|

|

|

|

|

|

|

|

5 |

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|

||||

|

|

|

Tools |

|

|

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

|

|

Fig. 26

Use a straight-edge to level the extension wings with the cast iron table top and tighten all of the M8 x 20 hex bolts with a 13 mm wrench (see Fig. 27).

Assembling Your Saw

Fig. 27 |

|

SawStop 10” Professional Cabinet Saw |

23 |

Assembling Your Saw

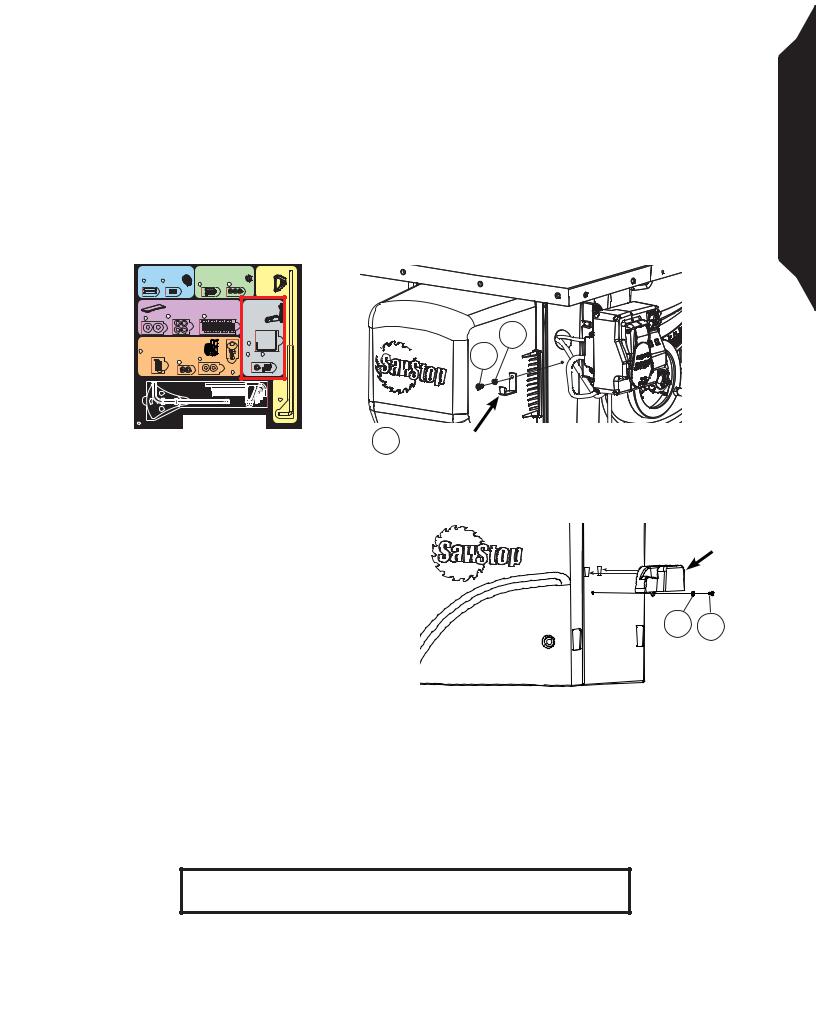

Mounting the Switch Box

7.The hardware required to mount the switch box is located in the area with the orange background on the Table Saw Hardware Pack. Remove two M6 x 20 button head socket screws, two M6 lock washers and two M6 washers and place a lock washer followed by a washer on the end of each screw. Mount the switch box under the left extension wing by inserting the screws into the two holes at the upper end of the switch box mounting bracket (see Fig. 28) and threading them into the holes towards the front of the left extension wing (see Fig. 29). Tighten the screws with a 4 mm hex key.

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

|

|

|

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hardware for Step 8 |

||

|

|

|

|

|

|

|

Blade |

|

|

|

|

|

|

|

|

|

Wrench |

|

|

|

|

Mounting the Switch Box |

|

Holder |

|

|

|||

|

|

|

13 |

|

|

||||

|

|

|

Hardware for Step 7 |

|

|

|

|

|

|

9 |

Button Head Socket Screws, |

|

|

|

|

|

|

||

|

|

M6 x 20 (2) |

|

|

|

14 Lock |

15 Button Head |

||

|

|

|

Lock Washers, |

11 Washers, M6 (2) |

|

Washers, |

Screws, |

||

|

|

|

10 |

M6 (2) |

|

|

M6 (2) |

|

M6 x 12 (2) |

|

|

|

|

Switch Box |

|

|

|

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Keys (2) |

|

|

|

|

|

|

|

|

|

12 |

|

|

|

|

|

|

Blade Spacing |

|

|

|

|

Motor |

|

|

|

|

Adjustment Gauge (1) |

|

|

|

|

||

|

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

Hex Key, M8 (1) |

|

|

|

Rod |

|

|

|

|

|

|

|

|

5 |

||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Hex Keys: M3 (1), M4 (1), M5 (1), M6 (1) |

|

|||

|

|

|

Tools |

|

|

|

|

|

|

F |

|

|

|

|

|

|

|

|

|

switch box mounting bracket

mounting holes

Fig. 28

10 9

11

|

SawStop |

System Status Codes |

|

Grn |

Red Status |

Fig. 29

24 SawStop 10” Professional Cabinet Saw

Assembling Your Saw

Mounting the Accessory Holders

8.Your saw comes with two tool holders to store saw accessories. The blade wrench holder provides a place to hang the wrenches that came with your saw. The accessory tool holder provides a place to store your riving knife, miter gauge and blade guard. The hardware required to mount the two accessory holders is located in the area with the gray background on the Table Saw Hardware Pack. To mount the blade wrench holder, remove the blade wrench holder, one M6 x 12 button head screw and one M6 lock washer from the Table Saw Hardware Pack. Place the lock washer on the screw, insert the screw through the hole in the blade wrench holder and then thread the screw into the hole on the left side of the cabinet behind the switch box (see Fig. 30) Tighten the screw with a 4mm hex key.

Installing the Handwheels |

Mounting the Dust Port |

Mounting |

|||||||

|

|

Hardware for Steps 2-3 |

|

Hardware for Step 4 |

|

the |

|

||

|

|

|

|

|

|

|

|

|

|

|

1 |

Keys, |

2 Set Screws, |

|

Button Head Screws, |

Lock Washers, |

|

Motor |

|

|

5 x 5 x 25 (2) |

M6 x 8 (2) |

|

3 M5 x 3 x 15 (3) |

4 M5 (3) |

|

|||

|

|

|

|

|

|

|

|

Cover |

|

|

|

|

|

|

|

|

|

Hardware for Step 5 |

|

|

|

|

Mounting the Extension Wings |

Mounting the |

|||||

|

|

|

|

Hardware for Step 6 |

|

Wrench & Tool |

|||

|

|

|

|

|

|

|

|||

|

6 |

Washers, |

7 Lock Washers, M8 (8) |

8 Hex Bolts, M8 x 16 (8) |

Holders |

|

|||

|

M8 (8) |

|

|

|

|

|

|

|

|

|

|

|

|

|